Page 1

INSTRUCTION MANUAL

To

get the most out

to use this machine correctly.

of

the many functions of this machine and operate

Z:J

8

tCO

it

in safety,

it

is necess

ary

Please read this Instruction Manual carefully before

your machi

Please remember to keep this manual

1 Observe the basic safety measures, including, but

2. Read

3.

4. All safety devices must

5. This machine

6.

7.

ne

for

a long time.

In

a safe place.

you

use the machine.

all the mstructions, •ncluding, but not limited to this Instruction Manual before you

use the

anytime when necessary

Use the machine after

valid

The operation without the specified safety deVices is

For your personal protection, we recommend that you

For the following, tum

the receptacle.

machine , In addition, keep this Instruction Manual

it

has been ascertained that it confonns with safety rules/standar

in

your country.

be

In

position when the machine Is

shall

be

operated

off

by

appropriately-trained operators.

the power switch

of

disconnect the power plug

7·1 For threading needle(s) and replacing bobbin.

7-2 For replacing part(s)

7-3

For repair work.

7-4 When

8.

If

you should allow

w

1th

contacted areas and consult a medical doctor.

leaving the workJng place

your

eyes

or

of

needle. presser foot, throat plate, feed

of

when the work

oil

, grease, etc. used with the machine and devices to come m contact

skin

or

swallow any

of

such liquid

use

. Whe hope you wi!l enjoy t

not

limited to the following ones, whenever

so

ready

not

allowed.

wear

safety glasses.

dog

1ng

place is unattended.

by

mistake, immediately wash the

that you

for work

, cloth gUide

may

re::~d

or

in operation.

of

the machine from

etc

he

.

use

it

at

of

ds

9. Tampering with the live parts

is prohibited

10. Repainng, remodeling and adjustment works must only

technicians

11

. Gener

12

. Repair and maintenance works

electric technicians

Whenever you find a failure

13

. Periodically clean the machine throughout the

or

specially skilled personnel.

al

maintenance and mspection works have to

or

under the audit and guidance

of

and

devices. regardless

of

electrical components shall be conducted

any

of

electrical components, Immediately stop the machine.

-

11

be

period

-

of

wllether the machi

be

done

done

by

appropriately trained personr.el.

of

specially skilled personnel.

of

use.

by

appropriate

ne

Is powered,

ly

by

qualified

trai

ned

Page 2

14. Grounding

machine

as high-frequency welde

15.

An

appropriate

plug

has

16

. The machine is only allowed to

17. Remodel

all the effective safety measures. We assumes no responsibility for damage caused

remodeling

the

machine is always necessa

has

to be operated in an enviorment that Is free from strong noi

r.

power

to be connected to a grounded receptacle.

or

modify_

or

modification

plug has to

the machine in accordance with the safety rules/standards while taking

of

be

attached

be

used for the purpose Intended. Other used are not allowed.

the machine.

ry

fot the nonnal operation

to

the machine

of

the machine. The

se

sources such

oy

electric technicians , Power

by

18. Waming hints

~

&

are

marlled with the two shown symbols.

Danger

Items requiring special attention

of

injury to operator

or

service staff

- 12 -

Page 3

FOR

1.

To

avoid electncal shock hazards, neither open the cover

SAFE

OPERATION

of

the electncal box

for the motor nor touch the components mounted inside the electrical

1.

To

avoid personal

cover, finger guard

2.

To

prevent possible personal Injuries caused by being caught in the machine. keep

your fingers, head and

while the machine

id

3.To avo

"ON"the

4.To avoid personal

while

he

5.T

possible •njury to

the hook dunng opera

machine when replacing the bobbin.

6.

To

avoid possib

machon

To

avoid possible aCCidents because

7

the power to the machine when tilting the machine head or removing the belt

cover and the V belt.

8.

11

your machine is equ ipped with a servo-motor,the motor does

no1se

personal injury, never put your hand under the needle when you turn

power switch

the machine is in operation.

hook rotates

e when !Jiing/raising the machine head.

while the machine is

onjury,

of

is

1njury,

at

a high speed while the machine is

hands, be sure to keep your ha

le

personal Injuries,

never operate the machine with a

safety davices removed.

clothes away from the handwheel. V belt and the motor

operation. In addition, place nothing around them.

or

operate the machine.

never put

!Jon

. In

at

your

additoon

be

rest.

To

fingers into

, be sure to tum OFF the power

careful

of

abrupt start

avoid possible accidents

the

in

nds

away from the

not

to allow

of

thread

operation.

your

the machine, tum OFF

ny

box.

of

the belt

ta~e-up

fingers

due

To

vicon,ty

not

produce

to abrupt

cover

preve

to

in

nt

of

the

the

start

of

the machine, be sure to turn

9.

To

avoid electncal shock hazards, never operate the sewing machine vlith

the ground

1 0

To

preve

component(s),turn

on

of

j

wore

for the power supply removed.

nt

poss1ble

OFF the power switch in prior to the connectrion/dlsconnecti

the power plug.

accidents because

OFF

the power to the machine

of

electric shock

-13-

or

damaged electrical

Page 4

CONTENTS

BEFORE

1. INSTALLATION························

2.

LUBRICATION ...

3.

ADJUSTING THE AMOUNT OF OIL (OIL SPRASHES)

4.

ATTACHING THE NEEDLE·······

5.

SETTING THE BOBBIN INTO THE BOBBIN CASE

THREADING THE MACHINE HEAD

6.

7. ADJUSTING THE STITCH LENGTH

8.

THREAD THENSION ... ··· ............ .

9.THREAD TAKE-UP SPRING···

HAND LIFTER···

10.

OPERATION·····························································

·········•··

......

··· ... ···

···········

... ··· ...

···

.........

.....

···· ..

......................................................

......................................................

.......................

.........

...... ························

···········································

················

·····

· ... ···· .... ·· ··· .. ······ ...

··········•····

... ··· ... ·•········•····•··· ·· ··· ... 20

·· ...

·····················

IN

THE HOOK ..

...............

··· ···

............

... ··· ...

··•·•·············

···

·····

····

.. •······· ·18

...

...............

······ ··· ·· ·20

····15

···15

... 16

-·

.. 16

18

,g

19

···21

11.

PRESSER FOOT PRESSURE·········

12. ADJUSTING THE FEED TIMING··· ...

13. HEIGHT

14. NEEDLE-TO-HOOK RELATIONSHIP···

ADJUSTING THE HEIGHT

15.

ADJUSTING THE THREAD TAKE-UP STROKE···

16.

17.

INSTALLING THE BELT COVER AND THE BOBBIN WINDER ... ···

ADJUSTING THE HEIGHT

18.

SPECIFICATIONS

19.

OF

THE FEED DOG ...

..................

OF

THE PRESSER FOOT··· .....

OF

THE KNEE LIFTER ...... ···

............ ············

········•············•··

·········

···

... ···

............

..................

......

·····

......

·········

···

···

······

.....................

...........

...............

..............

···· ...............

··· ......

···•··

....

....

...

······

......

··• ...... 22

······ ......

.........

.............

··· ... 23

.........

··· ... 24

·•· ···22

...

21

21

23

23

25

-14-

Page 5

I Attention required before operation

Attention:

To

avoid

1.before

the

2.make

connected.

3.if

do

4

..

make

S.during

speed

machine damaging

dust

the

not

using

sure

voltage

use

sure the

the first

or lower

the

and

make sufficient lubrication.

that

in

it

month

or

some accident,

machine for the first time,please

the

voltage

your

country

running

speed.

is

direction

when

right

,and that plug

is

different from

of

the

using

this

the

motor wheel

machine,

please

clean

and

voltage

you

do remember:

it

thorough

power

is

should

of

right.

source

this

machine,please

run

it

in

ly,

are

the

get

nd

of

all

correctly

normal

I Fixing

of

the machine

"'

~·~==

'"""''

====

2

-----,~~~~

~1

Fig.1

a A -

Fip.::!

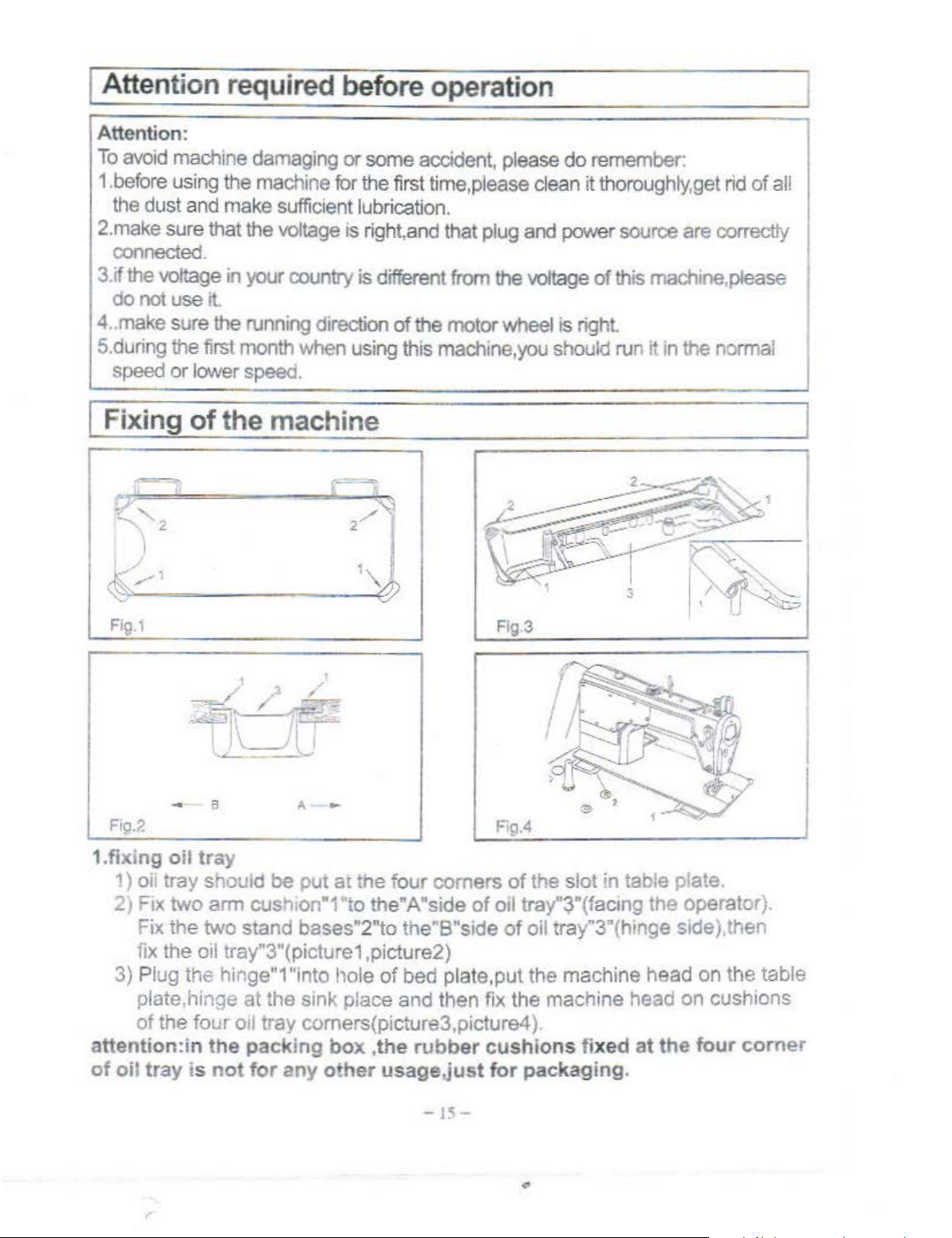

1.fixing

1)

2)

3) Plug the hinge"1 "into hole

attention:in

of

oil

-

oil

tray

oil tray should be

Ftx

two arm cus

Fix

the two stand bases"2"to the"B"side

fi

x the oil tray"3"(picture1,picture2)

plate,hinge

of the four

tray

is

at

oil tray comers(picture3,picture4

the

packing

not

for

put

h1on"1

the sink place and then fix the machine head

any

,~

\

~

2/

1

~

at the four comers

'to the"A"side

of

bed

box ,the

other

rubber

usage.just

of

plate,put the machine head

F!g.4

of

the slot in table plate.

oil tray"3"(factng the operator).

of

oil tray"3"(hinge side),then

on

the table

on

cushions

).

cushions fixed at

for

packaging.

the

four

comer

-

IS-

Page 6

j

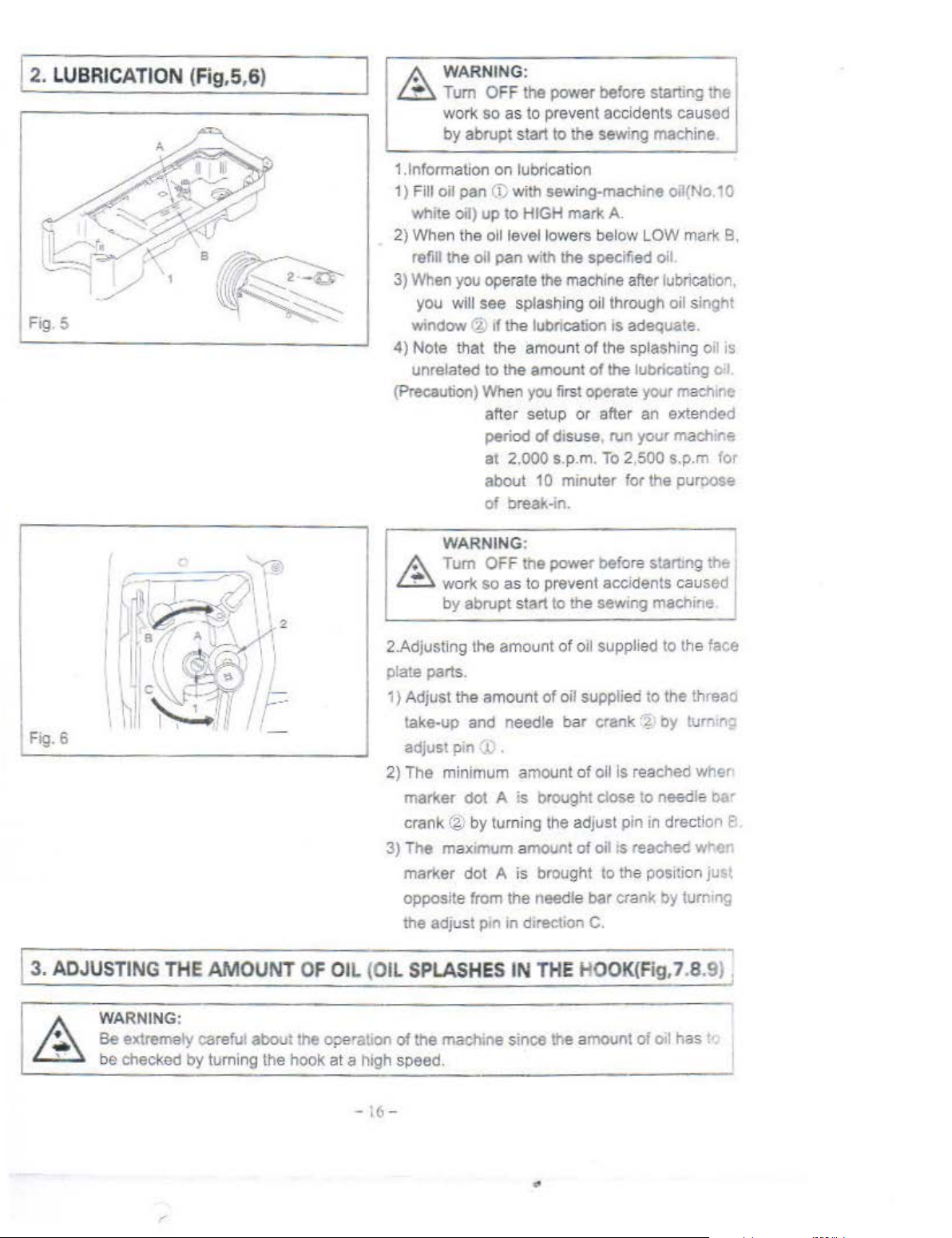

2.

LUBRICATION (Fig

Fig.5

,5,6)

A

WARN

L.t:::l.

Turn O

work

by

1.1nf

orm

1)

Fill oil pan (i:; with sewing-machine oii(No

whit

e Oil)

2) When the oil level lowers below L

refill the oil pan with the

3)

When you operate the mach

you

window(~

4)

Note

unrelated to the amount

(Precaution) When you first operate your ma

ING:

FF

the

power

befo

re starting the

so

as

to prevent accidents csused

abrupt

ation on lubrication

will

that

start

to

the

sew

ing

machine

up

to

HIGH mark

see splashing oil through oil singht

rf

the

lubncation

the

amount

after setup

period

at

about 10 minuter for the purpose

of

of disuse

2.000 s.p.m. To 2,500 s.p.m

break-in.

A.

OW

spec

ifi

ed

oil

me

after fubrica!to

rs

adequate.

of

the splashing oil is

of the lubricating o I

or

after an

run

ext

your

mark B,

machtr.e

10

n,

ch1ne

ended

for

Fig. 6

1

3.

ADJUSTING

THE

AMOUNT OF

2.Adjusting

plate parts.

1)

2)

3) The max tmum amount

OIL (OIL

WARNING

A

Tum

L.t:::l.

work

by abrupt

the

Adjust

take-up and needle

adjust pin J.; .

The

marker

crank @ by turning the adjus

marker

opposite from

the adjust ptn

the

minimum

dot

dot A is

SPLASHES

:

OFF

the

pow

er before stanmg

so

as

to prevent

start to the sewing machine

amount

amount

A is brought close

the

tn

of

oil supplied

of oil

supp

b

sr

amount

dtrection C.

IN

of oil is reached wher·

of

brought to

needle

THE HOOK(Fig

accidents

to

lied to the threao

crank'?

oil;s

bar

to

t p

in

in drection e

reacred

the

posttion

crank

by

needle

by

,7.8

the

caus

ed I

the face

turn:!"<;

b"'

vmer

jus~

turntng

.91;

WARNING :

Be extremely carefut

be checked by turning the

about

hook

the operation

at

a high spee d.

-16

of

the

mach~ne

s

ince

the amount

-

..

of

oil h

as

Page 7

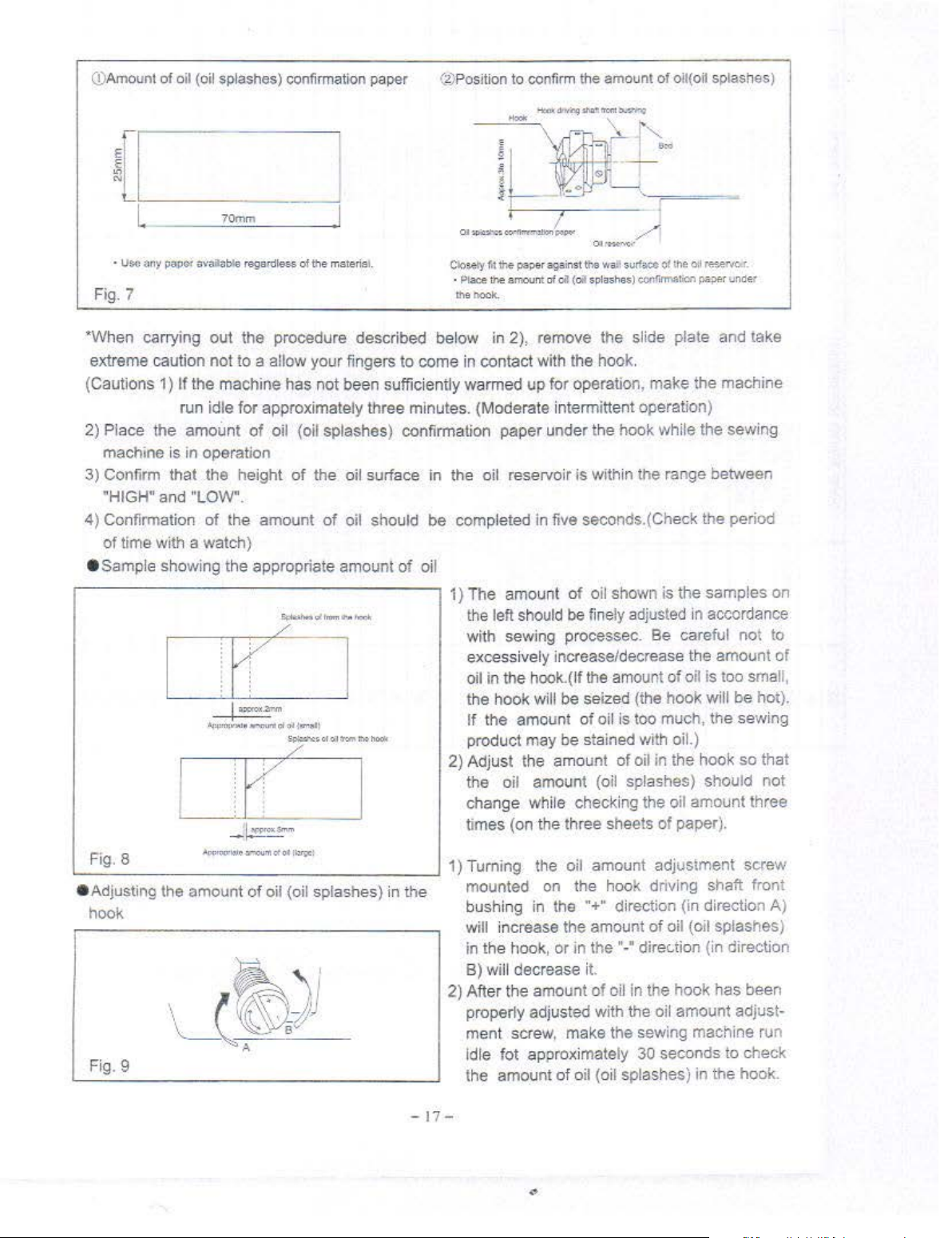

(!)

Amount

of

oil (oil splashes) confirmation paper (?)Position

to

ccnfirm the amount

of

oll(oil splashes)

~[I

·f-L

---

• U$0

.:.ny

papG-r

Fig. 7

*When carrying out the procedure described below in 2), remove the slide plate and take

extreme caution not to a allow your fingers to come in contact with the hook.

(Cautions 1)

2) Place the amount

machine is in operation

3) Confirm that the height

"HIGH" and "LOW".

4)

Confirmation

of

time with a watch)

• Sample showing the appropriate amount

r-

----

-

70mm

availatt.e

If

the machine has not been sufficiently warmed

run idle for approximately three minutes. (Moderate intermittent operation)

of

the amount

------

.-.!i~"fll

1 :

- I

-~

regardleu

of

["

l

li:ccw:b'.m

....

.....,.,.

r(J

;'«""

of the msterisl.

up

for operation, make the machine

oil (oil splashes) confirmation paper under the hook while the sewing

of

the oil surface

of

oil should

-----

~u'"-'mtmm,.

ol ~ ..... ,.,

S~$(ll~l

,.,,.

...

~~llooll

l'll:d!

of

in

the oil reservoir

be

completed in five seconds.(Check the period

oil

--,

1) The

2) Adjust the amount

amouflt

the left should be

with sewing processec. Be careful not to

excessively increase/decrease the amou

oil in the hook .(

the hook will be seized (the hook will

If

the amount of oil is

product may be stained with oil.)

the oil amount (oil splashes) should not

change while checking the oil amount three

lim

es (on the three sheets

is

within the range between

of

oil shown is the samples on

fine

ly adjust

lf

the amount

of

ed

of

oil is too small,

too

much, the sewing

oil in the hook so that

of

paper).

in accordance

be

nt

of

hot).

'-F_i_g_. _a

e Adjusting the amount

____

hook bushing in the

Fig. 9

...,.,

_~_

....

_~_-_"_"_'

of

____ '

oil (oil splashes) in

_____

__J

t'le

1)

Turning the o

mounted on the hook dnvlng shaft front

will increase the amount

in the hook,

B) will decrease i

2)

After the amount

properly adjusted with the oil amount adjustment screw, make the sewing machine run

Idle

lot

the amount

or

approximately 30 seconds to check

of

il

in the •-• dir

oil {oil splashes) in the hook.

-17-

amount adjustment screw

"+"

direction (in direction

of

oil (oil splashes)

ec.t

ion (in direction

t.

of

oil in the hook has been

A)

Page 8

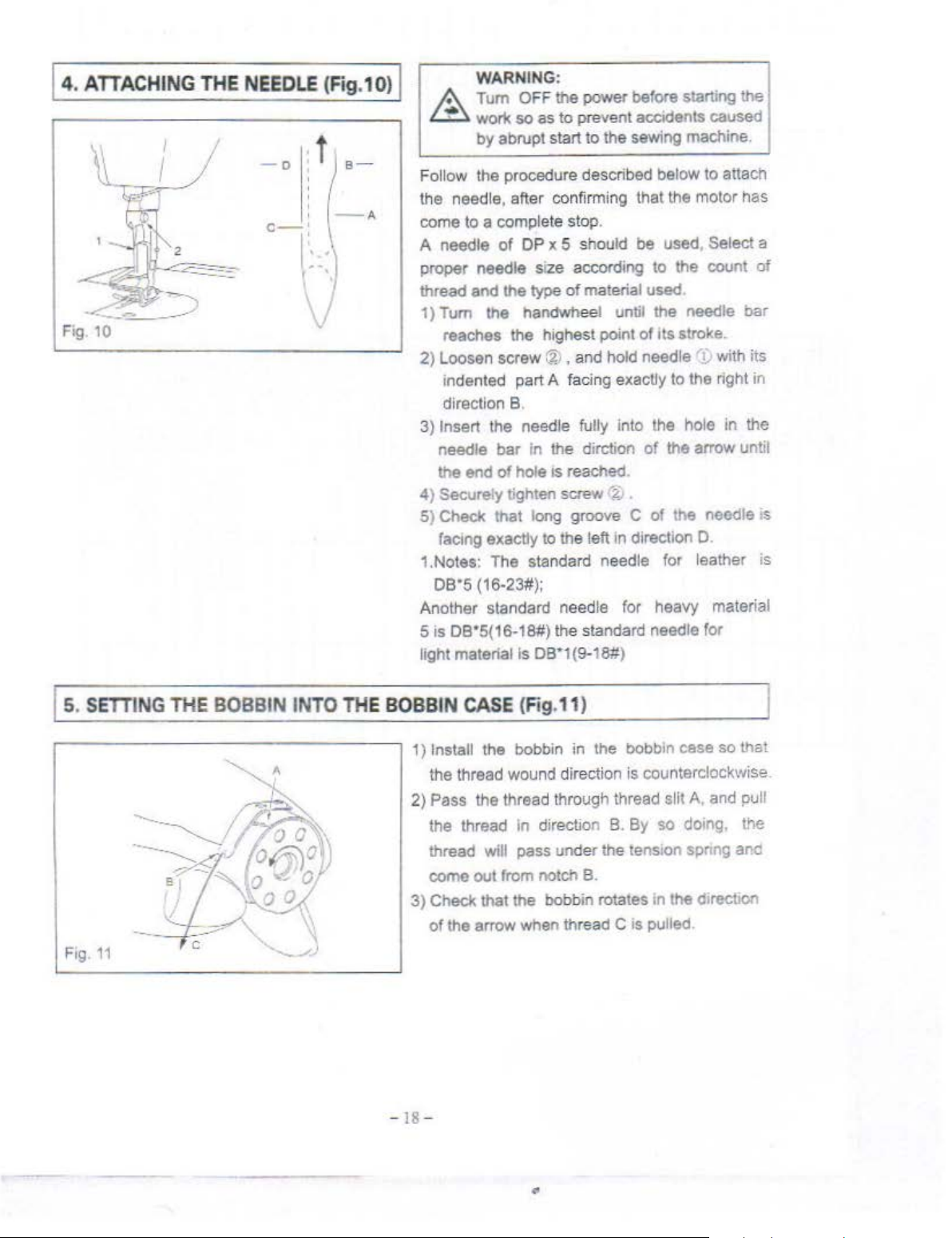

14.

ATTACHING

THE

NEEDLE (Fig

- o

C- '

.10) I

·f

s -

•

'

' - A

•

v

WARNIN

G:

A Tum OFF the power before starting the

l..:tf::.

wor1<

so

as

to prevent accodents caused

by

abrupt start to the sewing machine.

Follow

the needle, after confirming that the motor has

come to a complete stop.

A needle

proper needle

thread

1)

2)

3)

4)

5)

1.Notes: The standard needle for leather is

Another standard needle for heavy material

5 is

light

the procedure described below to attach

of

OP

x 5 should be used, Select a

s•ze according to the count

and

the

type

of

material used

Tum the handwheel until the needle

reaches the highest poi

Loosen screw

indented part

direction B.

Insert t

needle

the end

Secureiy tighten screw

Check that long groove C

facong

oB·s

he

bar

of

exactly to the left in direction 0

{16·23#);

oa•S(16-18#) the standard needle for

material Is

(%)

, and hold needle

A facing exactly to the right

needle fully into the hole in the

in

the dirction

hole Is reached.

oa•1

(9-18#)

nt

of

~:

.

its

stroke.

'!

• with its

of

the arrow until

of

the needle

of

bar

in

oS

Is.

SETTING

Fog

11

THE

BOBBIN INTO

THE

BOBBIN

1) Install the bobbin in the bobbin cese

" '

2) Pass the thread through thread slit A, and pull

3)

-18-

CASE

the thread wound direction is counterclockwise.

the thread

thread

come out from notch B.

Check that the bobbin rotates

of

the arrow when thread C

(Fig, 11

in

will pass under the

)

direction B. By

so

tens1on

in

the d•rection

os

pulled.

so

that

doing. the

spnng and

Page 9

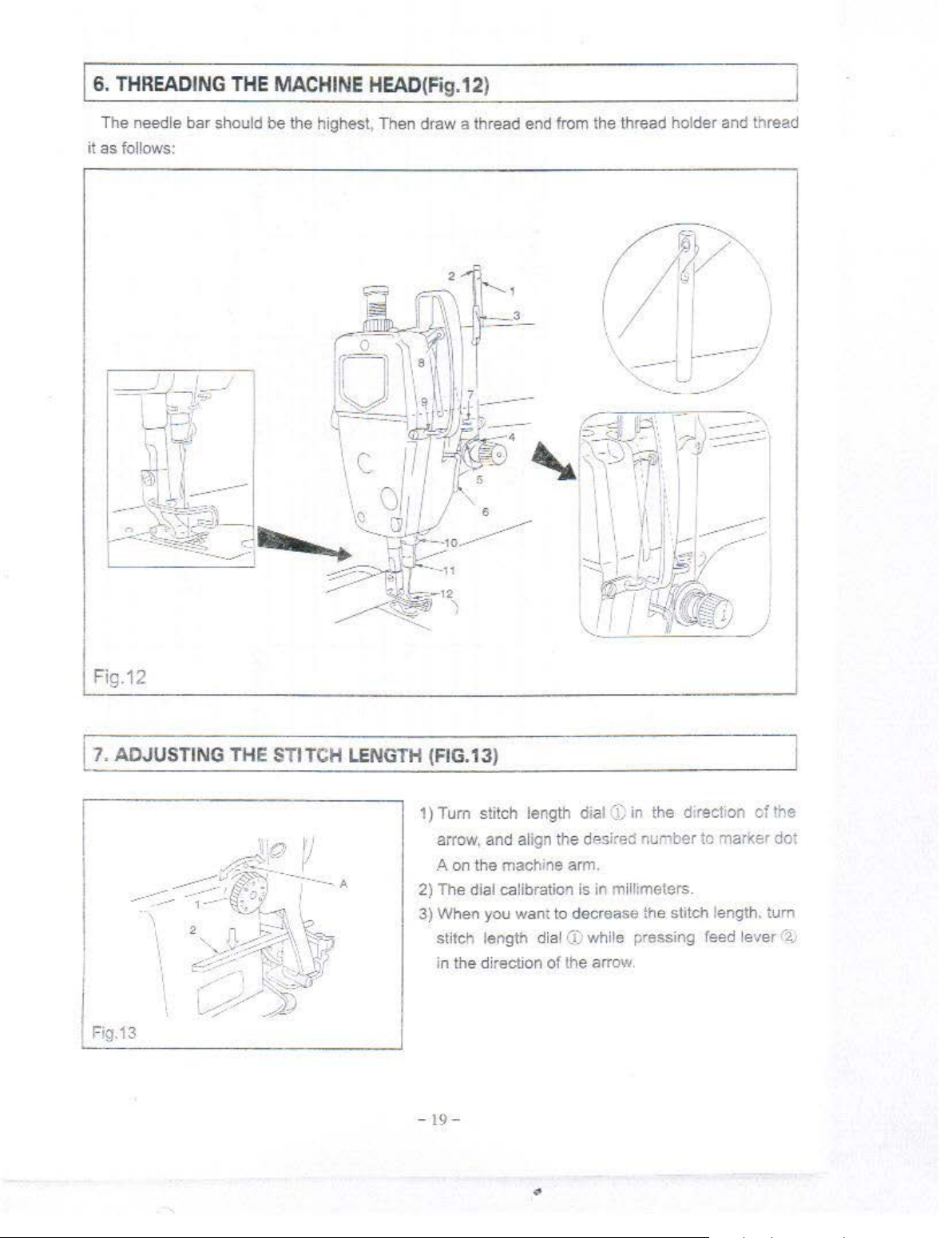

I

s.

THREAD

ING

THE

MACHINE H

EAD(Fig.12

)

The needle bar should

it as follows:

be

the highest, Then draw a thread end fr

om

the thread holder and thread

Fig.12

1

1.

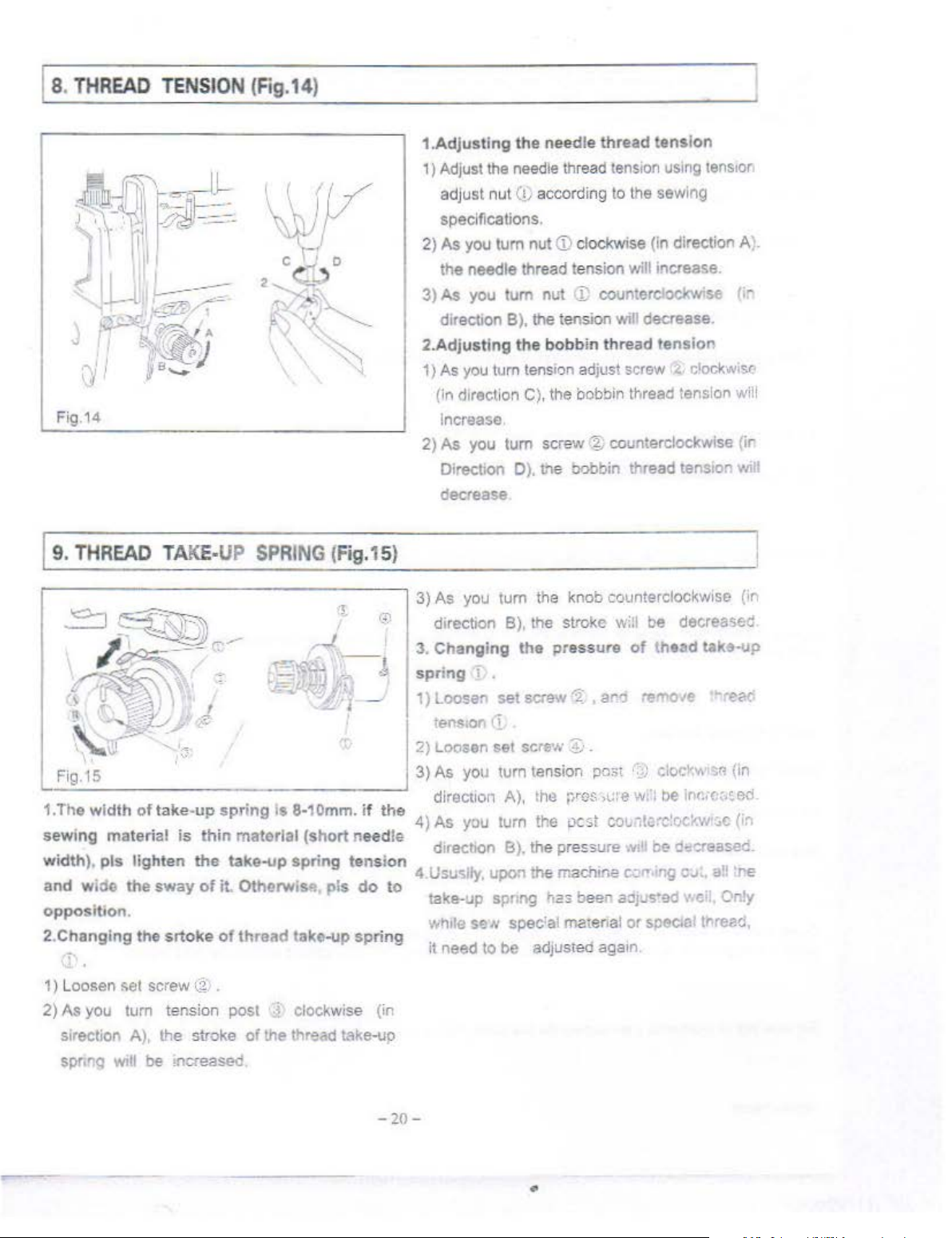

ADJ

Fig.13

USTING THE STITCH LENGTH (FIG.13)

1)

Tum

stitc h length dial

arrow,

and

A on the machine arm.

2) The dial calibration is in millimeters.

3) When you wam to decrease the stitch length. tum

stitch length dial

In the direction

-19-

(i;

align the desired

CC

while pressing feed lever

of

the arrow.

in

the d:rect,on

nunber

of

the

to marker dot

(2J

Page 10

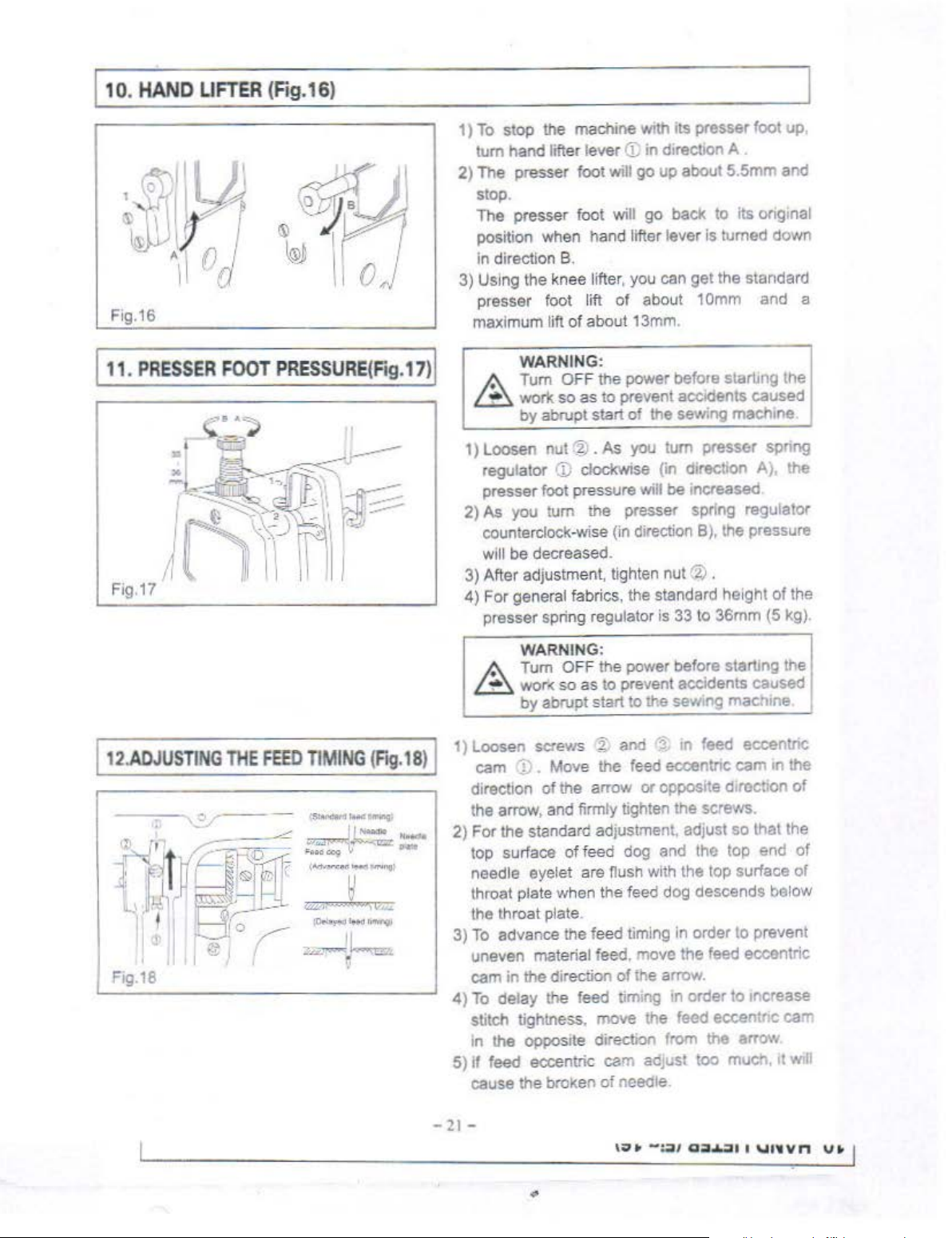

Is.

THREAD

TENSION

(Fig.14)

Fig.14

,

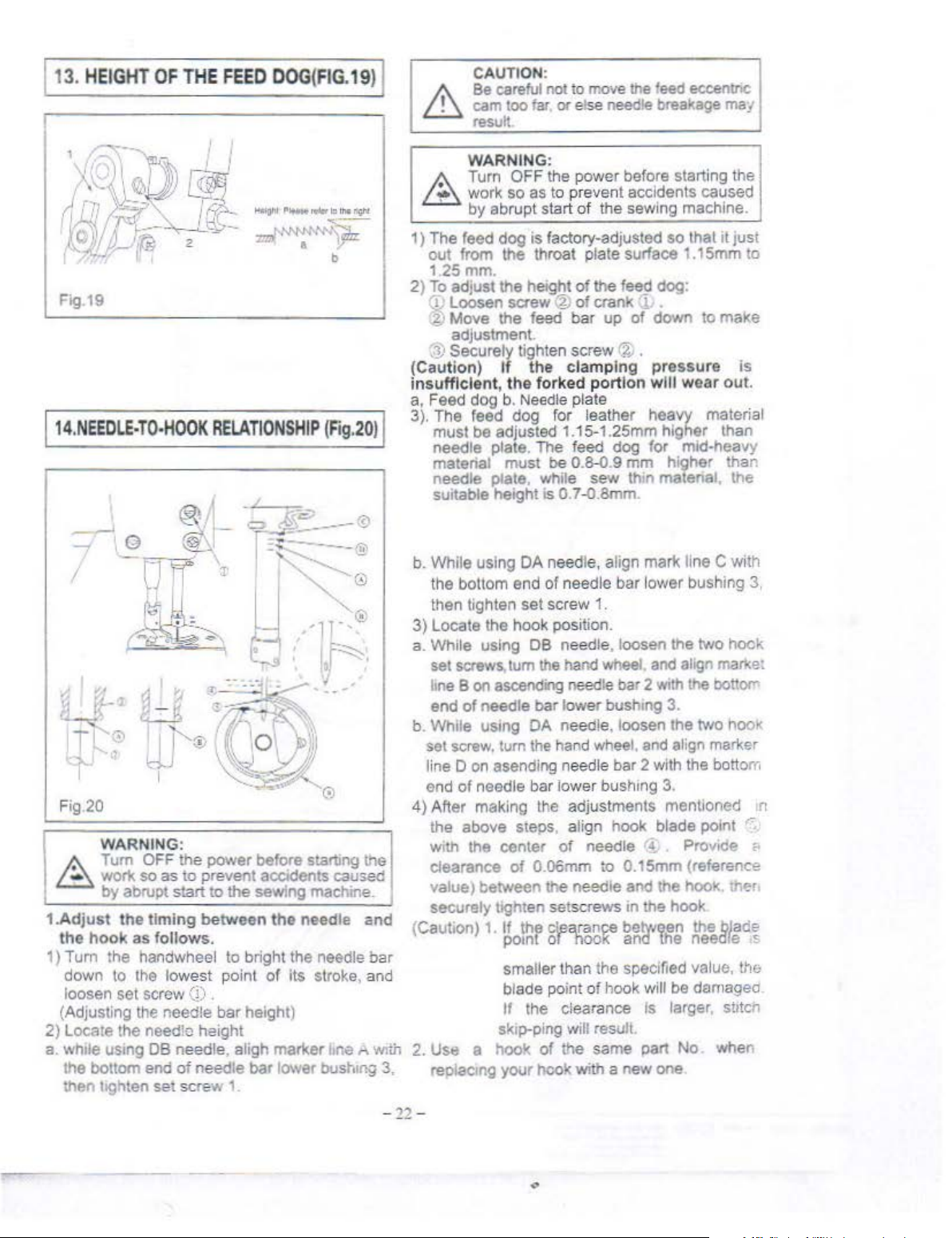

9.

THREAD

TAKE-UP SPRING (Fig.15)

~~~l\ ,'

~

I

...>-..:::!}) ~ / r

.,.

~--

/'~

~~

~~·

-

f-

~¢.

~~~-!t,}.l

1.Adjustlng

1) Adjust the needle thread

adjust

specifications.

2)

As

you

the needle thread t

3)

As

you

directiOn

2.Adj

ustlng

1)

As

you tum

(in direction C), the bobbin thread tension will

increase

2)

As

you

Direction

decrease

3)

As

you

directoon B), the stroke will be decrease1

_J

l,--,

~~~~

-

~

3.

Cha

nging

sp

ring

1)

~::::

the

needle

nut

(!)

according to the sewing

tum

nut

tum

nut

B). the tension will decrease.

the

bobb

tens1on

tum

screw@

D)

. tne bobbin thread tension

tum

the knob counterclockwise (

the

pressure

'

~

~~screw

thread

<D

clockwise (in direction A).

ens

ion will increase.

J;

countorclockwse (ir

in

thread

adjust screw

<2

•

aro

tension

tens1on

counterclockwise (ir.

tension

of

thaad

remove

using

·.

c'ockwosc

iens1or

take-up

vli

ll

ir

''"r

e~

c

-- .

· J

'.

_Fig

.

IS

Tl

1

.

sewmg

wt • p s

an

opposltoon.

2

.Ch

1)

2) As you

I f k

1e w dth o ta e-up

. .

materoat

'dth)

d

WI

anging

')'•

Loosen

sirection A),

spr.ng

1 1

·d h

e t e

$&1

tum

Wlll

.

19

the

screw

be

",'

J

spring

is

h h . d•rection B). the pressu. re

thin

te

n t e

.

sway

the stroke

1

o 1t.

srtoke

tension post ~ clockwise (in

of

(i

..

mcreased.

Is 8·1

material

take-

up

Ot 4.Ususlly. u

herwis"

thread

of

the thread take-up

,...,

Omm.

if

the

(short

sprtng tension

take-up

pis

need

le

do

to

spring

-20-

2)

Loosen

3)As

1

direction A), the

4)

As

take-up spr.

while seN

il

need to be adjusted

set

you turn tension

you turn the pest

po

spec

screw

:1

J .

pco~t

ves·,c:

co~ n

n the machme c;.,..-•

ng

t.::s

beer

'al matenal or

aga1n

..

·;,; clocl'v.

:e w; 1 be

t.:rc:

w~l

oe

.n

ao;us·ed v.cil, Only

specoa

.

~~(in

ln

<"•C::,~

en

oc:-:w•:.

g

c

(in

d~o:reased.

c;.~t.

a

!! •re

l tnreed,

Page 11

I 10.

Fig.16

HAND

LIFTER (Fig

. 1 6)

1)

To

stop

the

machine with its presser foot up.

tum

hand

lifter lever

2)

The

presser foot will

stop.

The presser foot

position when hand lifter lever

in

direction B.

3)

Using the knee lifter, you can

presser foot lift

lift

maximum

of

<B

in

go

will

go

of

about 1

about13mm

direction A

up about

back

to

is

turned down

get

the standard

Omm

.

5.5mm

and

its onginal

and

a

I 1 1.

PRESSER

I

12

.ADJUST

FOOT

ING THE

PRESSURE(Fig

FEE

D T

IMI

NG

(Fig.

. 1 7) I

18)

I

WARNING:

A

Tum

OFF the power before starling the

L.:f:'::l.

work

so

as

to

prevent

by

abrupt start

1)

loosen

regulator

presser foot pressure

2)

As you

counterclock-wise (in direction

Will

3) After adjustment, tighten

4)

For general fabrics, the standard height

presser spring regulator

nut

'?.)

())

tum

be

decreased.

WARNING:

of

•

As

clockwise (in direction

the presser spring regulator

arodents

the sewing machine

you

tum

presser spnng

will be increased

8),

the pressure

nut

~

.

is

33 to 36mm (5 kg).

caused

A),

A Tum OFF the power before startmg the

L.:f:'::l.

wor~

so

as

to

prevent accidents caused

by

abrupt start

loosen

1)

cam

direction

the arrow, and firmly tighten the screws.

2) For

top surface

needle eyelet are nush with the top surface or

throat pla te when the feed dog descends below

the throat plate

3)

To

uneven material feed. move the feed eccentric

cam

4)

To

stitch tightness,

in

5)

if

cause the broKen

screws % and

:]'

. Move the feed eccentnc

of

the arrow or opposite d,roction

the standard adjustment, adjust

of

advance the feed timing in order to prevent

in

the direction

delay the feed timing in order

the

opposite direction from

feed eccentric earn

to

the sew,ng maeh,ne.

'i

1n

feed eccentnc

cam

so

that the

feed dog and the top end

of

the arrow.

to

mcrease

move

the feed eccentnc cam

the

of

needle.

adJUSt

too much.

arrow

of

in

11

the

the

the

of

of

will

-

2t-

\

;:> • -:;,

,

a:~

...

.,,

1

'·

"~

v n

V > I

Page 12

113.

HEIGHT

Fig.

19

114.

NEEDLE-TO·HOOK

OF

THE FEED

DOG(FIG.19

RELATIONSHIP

/

(

Fig.20

) I

6

~

1)

2) To adjust

(Caution)

insufficient, the

a, Feed dog b. Needle plate

3). T

)1

CAUTION :

Be careful not to move the feed eccantne

cam too far. or else needle breakage

result

WARNING:

Turn

OFF the

work

'

The feed

out

from the throat plate surface 1.15mm

1

25mm.

·:r

Loosen screw ®

1J

Move

adjustment.

::p

Securely tighten

he

must be adjusted 1.15-1.25

needle

material

n

eedle

suitable height

so

by

abrupt start

dog

the

the feed

If

feed dog for lea ther

plate. The feed

must

plate. while

power before starting t

as to

prevent accidents caused

of the sewing machine.

is

factory-adjusted so that it

height

the

forked

be

is

0.

of

the

feed dog:

of

crank 1 .

bar

up

screw ~ .

clamping

portion

dog

0.~.9

7 -{).8mm.

mm

sew

thin matenal.

of

down

pressure

will

heavy

mm

higher

for

higher

mat

he

just

to

to

make

is

wear

out.

material

than

mld·heavy

than

the

_j

\ G

7

I

-~n

(--(£iii!~

~

~

!Jf-~

[rp

>-

" id.J

I I

Fig.20

WARNING:

&

1.Adjust the ti

1)

2) Locate the needle height

a.

Tum

work

by

abrupt

the hook

Turn

the

down

to

loosen

(Adjusting the needle bar height)

wh1le

the bottom end

then

set

usmg DB needle, aligh marker .ne "

lighten

~-

~

-~:=?----0

· . :

\

~-

~

~

~

1

h

OFF the

so

as

to

start

ming

as

follows.

handwheel to bright the needle

the lowest

screw (j) .

of

needle

set

scre

M

' t

-..;;, '

~ik~----··

1\)~:

~

-

"'""

-~~

power

prevent accidents caused

between the

before starting the

to

the

sewing machine.

point of Its stroke, and

bar

w 1.

:r

---

,

~

.·jl>

'

[f~

,

I_

·

~

'®

needle

lower

bust.mg 3,

-'"'

;

·-

,'

and

bar

Wlth

b.

While

using

DA

needle, align mark li

the bottom e

then tighten

3)

locate

a.

While

screws,lum

set

hne B on ascend"'9 needle bar 2

end

of

b.

While

sel screw,

line D on asending needle bar 2 with the boll

end

of

4) After making the adjustments mentioned

the above steps, align hook blade point

with

the center

clearance

value) between

securely

(C

aut

ion)

2.

Use a hook

reo1acmg

nd

of

needle bar l

set

screw 1.

the hook position.

using

needle

usmg OA needle,

needle bar lower bush•ng

DB

needle

the

bar

turn the hand wheel. and align marker

of

of

O.!l6mm

the

light

en setscrews m

1.

if

the

c~

pomt or nooK and

smaller than the specified value,

blade point

If

the clearance

sk1p-ping will result.

of

the same part No. when

yo<Jr

hook with a

, loosen

hand wheel. and align marke:

low

er bush1ng 3.

loos

needle

needle and the hook. tr;er.

arance

of hook will be damaged

r!

to

0.15mm (reference

the

between

new

ower

the

Wtth

en the

3.

hook

the

is

larger,

one

ne

C with

bushmg 3,

two

hook

the botiOffi

two

hook

Provide

the

blade

needle

s!Jtcn

om

'"

r-

<·

.s

the

-12-

Page 13

l

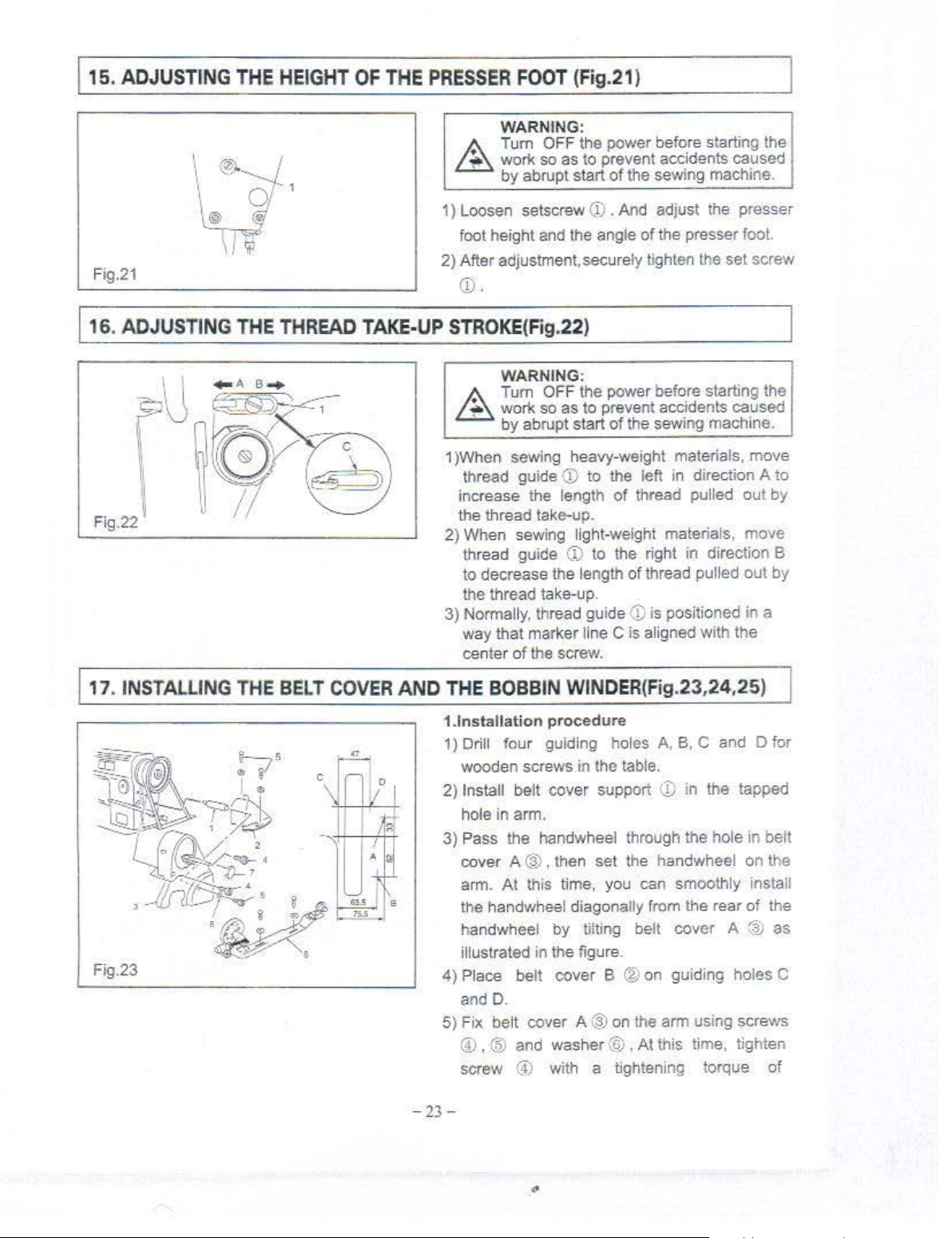

1s.

ADJUSTING

THE

HEIGHT

OF

THE

PRESSER

FOOT

WA

RNING:

(Fig.21

)

A Tum OFF the power before starting the

t..:Z:::.

worl<

so

as to prevent accidents caused

·

by

abrupt start

of

the sewing machine.

Fig.2

1

11

6.

ADJUSTING

THE

THREAD

TAKE-UP

1) Loosen setscrew

foot height and the angle

2) After adjustment, securely tighten the set screw

(j),

STROKE

(Fig.22)

WARNING:

(j) . And adjust

of

the presser foot.

the

presser

A Tum OFF the power before starting the

/..:!::::;.

worl<

so

as

to prevent accidents caused

·

by

abrupt start

1 )When sewing heavy-weight materials, move

thread guide

increase the length

the thread take-up.

2) When sewing light-weight materials, move

thread guide

to decrease the length

the thread take-up.

3)

Normally, thread gui

way that marker line

center

of

CD

the screw.

of

the sewing machine.

to the left in directi

of

thread pulled out

(1)

to the right in direction B

of

thread pulled out

de

(j)

is positioned in a

C is aligned with the

on

A to

by

by

!

11

.

INSTALLING

Fig.23

THE

BELT COVER

AND

THE

1.1nstallation

1)

Drill four guiding holes

wooden screws

2)

Install belt cover support

hole in arm.

3}

Pass the handwheel through the hole

cover A @ , then set the handwheel on the

arm.

the handwheel diagonally from the rear

han

illustrated in the figure.

4)

Place belt cover B ® on guiding holes C

and D.

5) Fix belt cover

@ , @ and washer @ ,

screw

-23-

BOBBIN

At

dw

heel by tilti

(,4)

WINDER(Fig.23

procedure

in

the table.

this time, you can smoothly install

ng

belt cover A

A @ on the arm using screws

At

with a tightening torque

,24,25)

A,

B, C and D for

<.])

in the tapped

this time, tighten

in beft

of

the

(~

as

of

"

Page 14

Flg.24

Fig.25

l

1s

.

ADJUSTING

THE

HEIGHT

OF

of

30

kgf/cm and screw ® with a tightening

torque

screws, the securing state

not

6) F

7) Move belt cov

8)

War

THE

KNEE LIFTER (Fig.26

of

change.

it

cat (f) to the belt cove A .

rubber secticn of

ac

cont

move the

by

0.5 to 1 mm.

in position using wooden screw

Fix bobbin winder ® 1n

and

B using wooden screws

nings

25

kgl/cm.

t with belt cover A (

belt cover 8 in the same direction

: 1) F

2) The

If

you tighten further these

of

the belt cover

er

B @ backward E until the

belt cover B @ comes in

3)

• Then, further

Now

,

fix

the belt cover 8

and

gu1d1ng

or salty

should be installed

bobbin winder should be para

to the plate belt holes.

's needs, belt cover

left and right parts

and

holes A

washers.

,27)

will

washer.

of

the

II

Fig.26

WARNING:

A Turn OFF the power before starting the

t.::::;:,.

work so

by

1)

The standard height

using the knee lifter is 1

2)

You can adjust the presser foot

13mm using knee lifter adjust screw

3)

When you have adjusted the presser foot lift

to over 1

of needle bar@ in its lowest

not hit presser

Fig.27

as to prevent accidents caused

abrupt start of the sewing machine.

of

the presser foot lifted

Omm.

loft

up

i"

•

Omm,

be sure that the bottom

foot@) .

~

~

C

l'e"

-

3----~

I

- - 2

-,..J

r

·~

---<

poslt1on

does

to

end

-

24-

Page 15

119.

SPECIFICATIONS

Application

Max

Sewing

Speed

Max Stit

ch

Length

1-

L•fting

height

of

presser Knee

foot

Hand

lifter

lifter

-

Needle DBX1

Lubrication oil

Moto• oower

1.

11'./hile

Sewing Light materials. the machine need

do

dog and

2. Machine with "R" added

some adjustment.

For Light mediumheavy ma!erials

RPM

5500

Sm

m

6mm(MAX.) 6mm(MAX.)

13mm(MAX.)

9~-18

I

Is

using roller presser foot.

11

For heavy materials

3000

13mm(MAX.)

DPXS

White

to

change the presser foot. needle

RPM

8mm

16H

od

No.10

370'N

- 18

11

For Leather

materials

3000 RPM

Smm

8mm(MAX

13mm(MAX.)

DPXS

20#-23#

bar

.)

·-

and feed

To

order

or

for furt

her

information, please contact:

• Please

when necessary.

•

The

the commodity without notice

do

not

hesitate to contact

description covered

in

our

dis:ributors

th1s

mstruction manual

or

agents in your areas for further

1S

subject to change for Improvement

1nforma~on

of

-

25-

.,

Page 16

~

14:

-=¥

mt

PART

It was a new-revised endition in December, 2001.

The machme with 'A" added

Please conftrm the relative applications Ref. No, part no

S

BOOK

is

ustng roller presser foot.

When buying the parts.

-26

-

Page 17

§

CONTENTS

1,

fJl~~ffi#

2,

.:%:$!1lliU~k~ff~ffii*

3.

~tff.

Machine

YUtl!&&t~~iJJ$!1l~ffi#

Frame

Main

& Miscellaneous Cover Components ...............

Shaft & Thread Take-up Lever Components

Needle Bar, Upright Shaft & Hook

~

........

28

31

Drivmg

4,

U~ffi#

5,

~*4~tffif*

6,

)iillf~ffi#

7,

illi&~ffif*

8, It:;g:,.,

Stand Components ......................................................................... .45

9,

~~R~~M~ffl1*Modei'R"

10,

ll#i*

Shaft Components .............................................. , ...................

Presser Foot Components ................................................... 36

Feed

Oil Lubrication Components ................ ,

Oil Reservoir Components

~~~.!:3i:!J~~~ffi#

Accessories .................

Mechanism Components ............................................. 38

.............................

......

....

.......................................

Belt Cover, Bobbin Winder & Thread

Presser Rollar Special Accessory ...............

.....................................

................ ......

33

.41

43

48

50

..

Page 18

Machine fram .

& miscellaneous cover components

e

-28-

..

Page 19

N~::

'j_PAR

l

.!'~:..

__

I

GR5!\1·~

1

GRSX2-~

1

GS15CI-k

4

GRt-~1)

S

GRSX~-R

6 GR5ll4·R I \

., GS31lO·" J

R GR578-X

9

GR571l-R

I 0 GR"i86-&

II

jGR5~7-H

12

GR611-~

GR800·X

11

GR60'-l-

I

14

IGQ200·R

15

GS310-X ;i

1

l(l

GS310

17

•GRt'<l?

18

IGS31

19

:o

IGL:t\7-~

11

'GR6()<).~

2:!

~GWJ

Ci\v:o2.-k

23

GR60S-

241GR.607-8

2S

GS314-X

'h

Ghl~J-8 1 M.,.~i"i

,.

GR60(·-H

28

IGS315-~

'~

GS11'

'0

GX~IIO-&

31

GM161>·H

GMl"

.~2

GS33~-S

3~

GR604-R

34

!GS~I3 R .i.:!J:llJ~li!TllM'

35

G;uR3:

36 'GS:Joo

~7

I~MW4-RI·firt~~mae,hlid~ASM

38

(rVIIoS-)( lU}'(

39

GW I

IIDJ!x

'-S

I

J jJf';.

1

-~

·S

I {jtt\l>

~-R

I

1

84-~

~

1

I ·U·

.,.l<>

l''f•

R : f h \;<calc

·~

-.<

1

90-X

---

H~

fJ''t"Pl•te \SM.

1

Face

1

~.~l!llf'i!\.'RL~\11/8

f.!

...

~,;·,jg~

~JF.'t'~H:'l~/

1{'

t!ii

I?J~#:fl'~

~f;

<-~~.r:·s~H

Pof,

I><

S1d~

.1,:;

i;;l

~'

<i:

Ga,~et

1!.

tfl~''

.,,

ilHLI

'~"l:r

{L~

It

'<eedl~

i:trt

i r

Needle

.fl:tl.

Th'l.-.!·~oe

Hi.!:H~;f;f,'!'

1

tt•fiJ'•J;!JI}!].TSM3116"X2X

-.r::~t!-J!.'\"TS\13,16

Arr.:

t,ff.\l,,Ji-l'JS:\1111~4')!44)

-kit

·::~?f,

f'l·

~t~r:

hl

Tcn<1nn

+.

t'(

IJ,f,>'( T

:kf~J,

Tenswn

·!:..

~1

1./.

Ten~i-m

f'l!fS.

"'.{

Tonsiot.

;.{14,~;

J~t\~n

!'>!:.ft.;,.~-;

lc'l."''<"'"··· _.. •

~c:!

H~JJi.-1

t.=t~r

'HjJ'i

;JiJ!'(JHr:<flr.

!''

Ten>ion

Screw

Toke-up-nring

~.if

t r l

,,

...

4

•.•

tJ _.,,;,,

, ,

~e~!

:-.edlepl~o~

I

•.

o,RJI.lthre"d

lfl

'>~il

Shdopiur~

f"<

V.:

<;>rir•f

iJ

I::'~CRI"TION

pl.ou

ga,kcl

X+l

L:.:

SeT<"

I/8"X4<1 [.>.!

AR.\.1

"'

hicod

AS\1

..

J.~

Ruhbt:r

Rubber

6 X

pl•tc 1

Kuhlx"T

Ruh!Xr

lhr~ad

thread gutde

bnhing

li',re:.v

ru;de·R•th•

l'hrcad

wn-.itlll

""'

~~~

mn

,,pring

~:"ring

•>•·c

Di~c

1

T,·

.ioJ

•'•I

';

(''SM9/64'

rdct<e

o1ale

lib-!"

X.:OL=~.S

X4(lL:6

'·

Ruhber

X~~

of

ild~

plu~

r1ug

plate

Screw

5CI'I:W

9/0:.

1116--1

:Vl~

1

1i6'Xl5

:\/WX28 L:6

1•'t:")!~~

]I/6,''X!O

X.iQ

L=~

:X~O

X28

..

2M.~

9 Sere"

piug

piu~

guoJe

p1n

ron

thrc:.·' "!tc·

mdicallun

l.=(o

)<.'~L~~St·r,"

1.=:6

A.~M

Dis<

,tnr~r

ilol<kr

f'<'•\1

x-~e:

;,.-rew

p1n

Sc:e"· lllf>-

gwd"·l~fl

~crc·v

piu

L=9

S.·rew

plate

L--9

1.=6

L-~

5

l."o

~•

1

~

' I

.,

.•

.r

J

..

..

'Cr

-tr

*

-t.r

*'

-;..-

.

'·

-29-

r

Page 20

~if{tfUI

LJ

If!'}

R

No

-;;.

~

,

.

~

339-8

Q21

196-8

!!-

8-8

-8

-8

r}

8

It-

£1'.

PART};o. DESCRIPTION

.

40

GS

41

GS299-8

42 GR724-8

GS373-8

GQ195-8

44

GQ11

IG

45

GX

46 GKI53-5

GK162

47

GQI96

48 GRI428-8 0

Machin e frame f miscellaneous co

Ma

ffi!

j!i

ii/~

rt~~Jt~1

1

l'il

:itflt

l:fH~J'iJl

'I'

!i

!'!'

j!

~ .

'R

;t!<;

· ~ '.l

lt'!~tGl!eH

#t

f!i~Hi

JJt~

ff~

'l<:1:

fli

11!!"<1

ve

r corr:g?nents

chine frame miscellaneous cover com onents

I

jj:

~

i4

' ; 1

'4

1

~

t)'3/32"X56

B

ed 'crew

Rul

er

~H

Ruler

M

odel

pla

M

odel

plate

odel

plate

P

ole

iJ

PiR

Thread

fjjt~

,J;t~

Rubber

Thread

Safety-indicating

ring

L=L9 Screw3/32"X56 L=L9

STUD

plate

plate

sere"

te

tak

e-up lever

take-up lever

~

plate

cove

cov

er

f«

QTY

2

4

I

2

I

I

I

2

r

1

I

L;,&h•.

med.iurn

ln.llet

*

*

*

* *

*

*

*

i

I

*

J!j.

~

llt.ll'l)

FPr

al~

~a:em.ls

1

*

.

~

.

ilf.l

t

hel'''f

*

*

* * 43

*

ur

1e<e'oct

rrattr-.z.l!

-

*

*

~

*

·

t:

*

* I *

'"f:?

*

* *

I

l

I

I

I

I

I

I

I

I

!

-3

0-

"

Page 21

2.

±

$tk.&m!xff~~Jlf-1:

Main shaft & th

read

ta

ke-up lever

component

~

Q-1~

~·4

27

-31-

..

Page 22

2.

1J1b.&bHi:fH)'g

·;: f}

l1=

.ft.{~

Main shaft & thread take-up lever components

REF

1\o. J

PART

:-lo.

DESCRIPTION

J I OX

~

:t

4 GH212-8

5

6

,

8

9 GS309-8

I 0

I I

12

13

14

15 01'156 -8

16

17

I R GR588·8

I

'I

:!0

~1

22

~3

24

25

26

27 GP147-8

28 1GS:I04-8

29

30

31

31

33

199~8

01{59~:2

05308·8

GRS95-8

I

l!lf,-k/t

-8 IJErx;~

1*-fXli~l.~~t:l51~X28v!05

~1!tHH:Jitl1¥

li!fblH

GH358-8

GH~

I 014-8

GH350'4-R t!tl_.itf'rdl:!

G0~65-8

GH21)8/2

Gl-1352

GH:I3-8

GS307-S

(iH.>4~-8

Gico--s

ORI1>7-~

GR592-8

OS371-8

GTIS9-S

GS~3~-S

G0256-ll

GR65(l·/!

GR5R9-~

GS.l0~-8

007.59-~

GX

198-R

Go:!~!<-8

GS306-S

GRI>3R

GR808-g

GPI5--R

\GZ22q.g

GR590-S

G0261-8

GRS91-8

IGS311-8

Ji~i1.ii

tlE#x:!

!Jl~>.l";f(\t~

-RI

!J~ttrtlliPilim

2-

81li!t\lllll;.ijiij>i'j

t•fl:.f"-

F:r\

I

trftr.b!i'i);tW~tr913lX~&

tiHUII!fli

H•Tiiill'~

!4lfl.III!J9i·<E~~t'Tl/~OX.!OL=6

~{,itffJ0'\',]1

~11fdfltf!j~I~~.!T9/32X28

:i!'f'lill.J::i~

j~

*l!l.J·(:!~

Ji..flfl,;.(.·f~~t:

l~tlili'i~ut:

.~~Ji!11H

i*:!iitHt:tlldl"'-~

r

~i'illc

!

.!:1ll

.U:Iililit.!l-t

HI!

l1~i1h

_!:.tiJ!il1;a

-~<1•!:;

-8

i!A

.ili:f1l~k·~~f.f:W

I

r

l~

l

~ ~

r-

~t.

I

1·

~

Bh

"!liiiJ

..!:f,-;;lh-!itiioli)fll1l:

lfuhi;m

1

'0-U~ii*(~:-ff9/64X40

•

~t~,

tV>f'f

Thread

~'"FH

liP

I-t

Thread

Oil

Thread

mke-up

F

Thread

H

':till

f't

Tiu-tad

1

-t

Thread

1-;

!\~edle

Needle

Needle

:'\eedle bar<nnl

,

"'\C.:.j(~~:9;o-IX;j()l=4_8

Counter

Counterw

Rubberring

Feed

F~d

II-IX40

Matn~h;aft

Oil

~eal

Tnnm

4

il"-

~t-1140"X40

:,J:~iHl'J

f:

f~l

•r;

..

,.(:li~'ifl!i

Hand

Han<h

tr

Sere~

\1am

l,i;~l~

ilii

co!ler

Main

Oil

lntcrmC<!late

&rew

Thru<t

wheel

hcd

shaft

itill!s

Roller

ll!l\0"'-'t" 0 -ring

take-

up

crank

take-up

resistant

ta~e-up

take-up

lake-up

bearing

bar

bar

weight

eight

dnve

eccentric

dnve

eccentric

L=ll

rcarb

Soapriog

L=6

~h:lf't

from

amount

bushing

collec

Th1u~1

coller

felt

Sleeve

crank shaft

Smw

co'cr

bar

bar

lever

lever

crank

crank

rod

End

;crt"

v l6

Screw

Screw

L=

Screw

cam

cam

Screw

u<hlllg

sere,,

bu<hing

adju~ting

nf

oil

amount

l=6

Sere"

shaft

15i~X28vi0S

ASM

ASM

](ft9164X4nt_.:!~

9/32X28

1/.!0X.!O

9/32X28

lf..!X40

1/40'

X40 Le6

pin

adjusting

9164X40

v16

L:o6

L=

L=ll

pin

L-~

! I

l

2

2

1

I

I

2

1

I

J

I

I

I

I

I

I

I

I

I

i

2

A.

..

,

t.:

*lu

~

I*

*

~

*

*

- .n -

..

I

Page 23

3,

lttf,

~ttk.&btd~!l~ttk5ttll.f4

Needle

bar,

uprigbt

shaft & hook

driving

shaft

components

,___

2

I

---8

'

ta-,3

~"

~~

~·

13--{p

15~

~-16

®--13

1.

17

19

24

~

-1

20

___-

21

22

- 33 -

32

Page 24

3.

ltff

.

If,~

fif

REF.

No. PART

I GRS99·8

2

G0266-8

3

GZ~30-8

GZ251·8

4 GR598-8

5 GS311·8

6

GU152-S

7

GR600-8

GR801-8

8

jG0:67-8

G02S9-g

1

9 GS312·8

10 GR601·8

GRS02-8

I

li

GV132-S

GVI~4-1<

1~

C.ClS~-S

13

·as319-s

14

GC156-8

15

GC15S-R

16

GC154-8

I'

GZ234-8

GZ255-8

18

Gl\

GN566-g

19

00272-8

20 GS403-8

c I

G02~1-8

22

c.o2~o-s

23

Gl\137-l<

24 GR636·S

~5

!GS331-8

26

GR631-l!

GR818-R

27

GS328-8

2R

('.0269-8

00291-8

29

G$316-S

GS414-~

30 GR63.J-8

31

GS330-8

!

tir&iH

.!o}

1\o.

n•r

HtT

~r

H

~i>

ft>i+j1;fiH*

It~'·

rrtE£~if:llf~

iTH

\t:ff fllil

rHT-!fh

ir••"Ftdl

I

.:iH!!!Itfi;SX.14~.5

~;

*=HH~

rr•tt'i

liLt- IDDXIl

tJU'

J

-~~N)~

*t1-;~~~fJii4X40L:S

~$3k~

~~i!I

F$ffi<'):{~,

'l$.

~ t:prighr

-~

...

139-8

Hi

·L:

iJl-C:

'~:llllJ.mJ~

!li'ffi '::tl

~~•.?•

'

;;-jllJJii$-l!t'

~!l~

~t~

"F:tsl'

"F!;bf"":!"'tTli/64X40L=4.~

X'-t~t~til

~~2

~~Hi;~{\1t~.!Jf!tT1

FtlllniJ~-#

-·lll!u

T~u.>:tt:

-t"

r-

.-:Jii· . .oa:J.:;.

Tt!il'i

Hllif'ii•l!I~U't:f.1ll/64X-IOL=3.5

i4!

~5ttllff:

Needle bar. upright shaft & hook

DESCRTJ>TIOl'

t:t,

fN~~

l:~

•fi:

NCC\llc

I

Needle

i!

~

~f.t"'

F

!rt

i.'tH~

!)tH~J

f::

f:

~~

iDBX5

f~·1~

-

F1i>J;q4t

~~

l'pright shaft

Bllbbin

Bobbin

l;~U3116X28L--9

;:-

Hook

Hook

ll1l

ThMt

li1

t'q

i!lu-S:;:

-~

..

,.,.,

;r.t~

Cap

Nee

dle bar

upper

bu.~hing

bar

bar

'ieedlc bar

H9/64

Needle

:-;eedle

Needle bar

Need

le bar thr

•*-1

!']•'

t*i

( N

>haft

Uppe

t:png,htsluft

Rc<~r

P~iooning

Posiuomng

i/64X40L=9.S

Frunt

Front

;-y

T •

!'

Thrust

connecting-rod

X40L=6

Slide

black

Needle

~eedleDBXl

N~eDBX5

collar

'>crew

!)crew

~ar

thread

Needle

r

bushtng

hu•hmg

bar

lhread

bar

lower

bushing

bar

lower

bushmg

Sctew 1/SX44L=4.5

thread

guide

ead gui

Gearofmannhaft(big)

Screw

Gearofuprightsi1aft(~mall)

Gearofupnght shaft

Gear

of

hook

bushing

Screw

lower

·

screw

finger

finger

bushing

c:>ilar

Screw

de

J/4X.iQL=8

bu.•hing

Screw

Cr

9164 X 401..=6

guid

e

guid

e

(big)

drivingshafl(small)

3/16X28L=9

111MX40L=4.R

ll/64X40L=9.5

ew

ll/64X401.:3.5

dri,ing shaft

I

1 *

l

1

l

l

g

I

1

l

I

I

I

J

I

1

1

I

1

I

I

2

I

l

I

1

1

1

1

~

I

"'(<

*

*

-·~

...

components

-::

*I~

* tr

I*

*

*

-34

-

..

Page 25

3,

tt

.ff

,

~tM.l~!

'-f-'j

l<t

REF.

I

1\o. l'ART No.

,,

~.,

...

GR133-S

GIU52-~ F ~at

"

G"l

138

~.>

34

GR633-S

,.

_,::-

GS3~<1-X

36

OS-W2

-8

-8

liHi

iJ$ib~tllf!l:

l:i

-

'Ftla

Hook

drh·mg

He>ot;

dri"in~

tli

:lc

Rnhbm

1

llbi:

Fli:~l1lJ.t:

Hl!l

Ill!

'Fll!:'ii~

c3~

Bobbm

c3~

01l

illJ

J::i

I,

S<'"'w

~Clin116X28L=12

N~dle

t;

DF.SCRlPT!ON

•haft

shaft

wick

ba

r,

uprig

ht s

'.~

\

f''

Screw

3116X28L=I2 I

haft & hook

~.$:

IQTY

I

I

I

I

I

I

driving

i11},

'ti'HI

For

Li~t.1

oed:IJ'n-beav\

tiliictiaJ-.

*

1:!

"{:;:

* *

*

shaft

components

l!t~l

•

r(.:!

beb~y

z:urcnU

·

-tr

*

><'

*

I

I

l

~lf-•1

For

IC?·

Ib.~t

m.tterul~

'

*

*

-::r

?

*

I

I

-35-

..

I

I

I

Page 26

4,

Jf

lJI,IJ~tlH'f:

Presser foot components

2

6-------

\

..

• c

/

/

/

/

/

1S

- 36-

Page 27

4,

Ai

iJ1JI*tli.f-f

Pr

esser

foo

t components

.,

T

ft:

RJ:F

~l

PART

I GRnl'l-8

2 GS322-8

3

GR611-~

4

GR620'~-8

s GR6133-8

I

CoR625-8 < Uf

6

7

<iS3:!3-8

R

Gl\1164

GR803t5-R i3

9 GR61S-8

10

GR622-R

12

OS326-8

I.'\

GS3.:!5-H

I-I

GR6~0-8

GR630.8

16

GR62&

17

GR615-S

IR

GW189-8

19

GW185-8

20

GX201-S

21

GR627-8

GR314-S

"

,,

GS3 IS-S

-·'

1-1

GLlf>S-8

25

IGR613-8

26

GW253-8

27 GRiil4·8

(iZ231-8

28

29

GR615-8

30 GS319-S

31

GS320-ll

32

G0:!6b-8

G0:90

33

GS321-S

:!&~

QTY

0.5

cam

lever

link

vertical

rerum

ase

pin

release

bracke

guide

Screw

Sere"

bushing

bushing.

Scre

#;:

ring

rod

opring

spring

pin

'haft

t

I/4X40L=g

Y164X40L=8.5

w

9164

X

401.=

I

~

"<o.

tF-Iil~tli

'Ldt-~lH+.'!\"T

f.tlj!H~

Jiii!P~

1~Giti!IPHPI11•!4

tit:

5-~

;;!li~tr.:!t

!l,il\;x

!li~•1l·llfi:~

71-~H~~tt.:

Jfii:.

r,:·wH:LtL!!i.tr

llf;U:.~~

ti:'±~-lfl!H

1;5fl'J)1iti.'f

-8

~iXJfi'i{·Ot\.::.l

¥tHU~~t

<..Hii:t'Ri'HHi'

f!~tt:).J!H

>'.tt};rn~

1

•t:f'.UI!~~r.l:if

~f:F~

t~!li~i';

~tt~H

iiii!Ifi

m

!.iiH

I

.z

"''"llll~i~

=z.::t:o.·

£:1

f~f{i.141ifill!n'916-:X40L=8.5

H=:i"'~R

-8

lli~:lff;

i fi

f

f.~l

.f-8 ~

}1-

1.1

F!:!r.:li'l

r.gtp;:;~fi

i'iHH

.

.ji;.hf!-~.tr

t:

Presser<pnng

Bi:l*

Pre"cr

'ifJi.:

H

Pr

esser

" •

'T-'RJ!lrJ

·;;ij1jl~~

~

DESClUPTJON

H"nd

lifter I

S<.·rew

0'\'ll>"l

rJ

1'1

'f''i

rr

·I~

f~?ilcnsion

Ten;ion

Tension

Pn:'-.er

l'\ut

J>re,...:r

rre~ser

Pn:Nr

Pn:•~r

t19/64 X40L=I

Rubber ring

Jl'

f I

Hand

lifter

Hand

lifter link 1

Snap

nn~

Link

<haft

Presserfoot

Prc':-cr

IICI

l.ilii

ng

n

-1"1'!1

Lifton~

Connecting

Ltfung

Tcn'lon rele

,

~pnng

bar

Prc''~r

I/40X40L=8

AS~

foot

ASM

Snap

nng

lever

Lifting

Hmge

screw

Hinge

<ercw

level

rod

Jc,d

connecting

Snap

ring

release

relca.~

supporting

release

plate

Tension

spnng

regulation

guide

bar I

bar

j:Uide

bar

thre3d

bar

lower

barlo"

cr

0.5

~

..

:h~t!

fullcllt

mtdium·Scary

m.a.t~:"IUis

-{:(

I

l

I

*

*

fnr

* * *

I

2

l

1

3

I

I

I

I

I

I

I

2

1

I

l

I

I

l

I

I

I

I

I

I

I

2

l

I

I

* * *

* *

*

*

* *

*

* *

* *

*

*

*

*

*

* *

*

* * *

* *

*

*

* *

*

* GW203-8

*

* * *

*

*

*

*

*

~·C!;n

nn

oa:cnals:

!'<.·~

F:.ill

~)tro-y

;~t~r

m•:ernl!1

*

k

*

*

*

*

*

*

*

*

*

*

*

* I 1 GR626-8

*

*

* *

*

* *

*

* ,:,

*

* *

*

*

*

*

* *

*

*

I

*

*

*

*

*

* *

*

* *

*

* *

* *

*

*

- 37 -

..

Page 28

5, ~

*

'-

Ht~Jf.flf:

Feed mechanism c

omponents

10

21

69

15

65

14

13

38

~37

61

-

3R-

Page 29

5,

J!*'~1f~JH4

if'.}

14

REF.

'<o.

PART

-¥}

}\o.

Feed mechani sm components

DESCRJPTION

I GH341-8

GH355-8 fl4iHiiit1

2 GX111-8

GX123-8 fiiliHM:

3

GR654-R

GR814-8 i!ifhlll

4

Gm7+8

5

GS3·lH

6 GW 19

7 GX111-8

8 GR652-8

GR

813·8

9 GS34 2-8

10

GH214-8

GH353-8 l!*l.iiiT

11

GX204-8

12

GS333-8

13

GH218-8

14

GR653·8

15 GW192-8

GW204-8

16

GR625·8

17 GH344

GI-1357

IS

GS346-8

GS407-8

19

GRn15-R

10 GS.,li-S

11

GX20~-8

~:

GR63Q·l'

23 GR6-IO-S

~4

GR6-II 2-8

GR~II

:'5

GX:07-X

26

GS~-<

·-

GS3:>3-!\

2&

GX22~-S • ~q

~Q

j GR643-8

30

Gi\.ll6'-8

GM

174-11

31 \l1>.L

32

GRil-l~ j :.t~•il;t:t

GR~

W

~i!t~a~l

ll4i!Hi!H\1i

15Hii!I1T<il

FccdadJu.\lrod

Feed

f%-tl'l

Fttd

1\

ilS

F«d

Feed

Feed

i!f'lilt!Tl!Sfdl'f feed

iHii11viltt

1-

8 .i!fl.l'l!mfr K

~nt'IHC!N

iEt~#liiaitfl!

nll~~fl!

iH'illil>'itH~·J

.iU.

I.iti·

i!HiiiHI'I

iUHHfii'•~H9i64X40L=6

tk!fiHf

.il;~l·ii'J

W!llt.~O'I'Iim

filli!'ifltltJ.\

fiiJJ!f.H>H~

~l!tlii!M!illE

&iliUiil!Jli'liilWt

Screw

Spnng

Pin

Feed

Feed

Connecting

Connecting

Pin

Connecting

Spring

Spring

!PliH41ffl!Piil1114

1r1Jitfi1!1Jiiljlll(lf

!:.1i.:d1il:t1•~!1lH

f)'Ji!JHiH

i~i•\1-

!\!!};r..'JT·

i~tlk..

iiifH"~:J.l~

iiill

l -8

'ifu

::t

f"'!T:-J)(iffi1.._

T J

nh-\.~tT9164X40L.-ii

;;s::

;;,.

f 1

J!

f,

i-~

J!>.

i 1 .

f'.!

1 ......

J"li4X40

_j.:\n

{

Lmlo:(long)

Link

t

l!

.;!JIll

1'!\

..

f

!!~:;!'(

!'$Ll516-1X18L=-Screwl5/64

~61-

~

.,.

VI

>!;.Jill

tiM

~(cd

bar<hafl

>r.r

fiJI

l·~~d

dog

F~te!

do$

t Jl/8

X-14L=6

reed

~ar

f~ed

bar

adJU~I

rod

rcgula10rpin

regulator

regulator

re&ulator

re$ulatorbusbing

dial

dial

Screw

rod

rod

rod

Rubber

Snap

RevCT"<C

Reverse

Screw

Sere"

Snap

L=6

Pin

l'hort)

,:It

r<'Cd

Feed

Ad\1.\ling

RcUtninJ:

AS\1

AS\1

ptn

ring

ring

feed

arm

feed

ann

ring

Scrcw9/64X40L--6

adu.<hng

adw.ong

link

Scrct>W6J

ring

Screw

Screw

9/64X40L=6

ASM

ASM

ASM

ASM

~aft

X28L=7

X40L=6

1/8X44L=6

I I

I I

I

I

I

I

I

I

1

1

I

I

I

I

I

I

1

1

1

1

1

I

1

I

I

I

I

2

2

2

2

I

1

1

1

I

I

2

l

1 I

*

* *

* *

* *

* *

*

*

* *

*

* *

* *

* *

* *

*

* *

*

* *

* *

* *

* *

* *

* *

* *

1:!

u *

*

*

*

*

- 39 -

Page 30

5,

~

W~ffi{4

Feed

machanism components

f'-{t

T·'

H

REF.

PART

No.

33

GR657-8

GR816·8

GZ235-8

34

GX208-8

35

GS333-8

36

GLI42-8

37

GH354-8

OS334-8

39

40 GH217-8

41

GS334-8

GS341-8

42

43

GZ236·8

44 OR589-8 i!f.Hl

45 OSI67

00273

46

47 GS344-8

GSOSI

48 GS336-8

49 OR634

50

OR807-8

51

GSJ42

52

GR658

,,

_,

GH216·8

54

OS340·8

00273-8

55

56

GR5S9·8 til

57 GSI67

GR424-8

58

02237

59

GZ253-8

00275-8

60

61

GR656·8

GS319-8

62

GS319-S

63

64 GZ254-8

GWJ93-8

65

GW205-8

GS40tl-8

66

67 GR817·8

68

GR~05-S

GS347

69

J

'"'

No.

tH'i~~

H~f.\¥l;il:!i&

i!H~I

ifittllllmt~

llllmtrl~f19/64X40L=6

tl.l?fiHl'$!l!ri~lJ9/32X28

ili~

i!fl.!I

\li:fifillllili~l'

tftjfJ

tf1

!tl'fl!ii:ff41h!1:~U

fg.

illf!:1il

-8

iH

i.M·li!

f!:lJiH~~~~n

4l¥!W!~U11164X40

ffr'f~~lllll'li!ll

;:f·~~

:{~fi!i.~U3116X28L=I4

&:

til'l'

ltl:t)(~~illi!l'l~fflli64

l

fl3f4li

lfr'f~kJ"l~~Ul/4X

~.i!:i<i-1\l!O~!lll

-8

lfllillfil.:!!ll

fjljii;'

f¥!Jm

~Jiilsf!t&T

~Ji~f!l&

'i'lm.f4l&-f5E-lli~ul/4X40L=8

ili:H~W~~

il!iiiJt'.i.,l!ll.;\I

l:!'!SJJ~!i'l[

JE14).liJi'H1HilliliHT

:i!Ni.l'J

liiJillfHiltt,l;~!m

~-!it'.i.!i.~n

:t

DESCRIPTION

t&

Feed

spring

hook

Feed spring

I

Feed

rO<:ker

Pin

4d!HJll

Feed

rocker

MJfl

Feed

rocker

f3116X28L=15.S

~

fliljpj

Lifting

;f

~!Hlt~9i.ltf3116X28L=I5.5

jf~

Feed

driving

lij;!i

fiij

Thrust collar

l~~

l!HTI/4X40L=6

~~~iPHl

f1t'.i.

'f1llltil~

iFft

Feed

lfi'l'lm

~llliffi~tr

Feed

bar

driving

Washer

X.IB

ilil

fR

Lifting

!Wl

~h'f

Feed

Thrust collar I

Rubber

Reverse

*'

Hill

Reverse

#illi$!J;g

Bushing

Reverse

.f~fTJ/4X40L=&

Feed

tLP.

NJ~

\l'~~f£lii!

St-rew

hook

shaft

Screw9/64X40L=6

rocker

Screw

shaft

rocker

Screw

Screw

3/16"X28L=7

L=7

Retaining

crank

forlc

X40L=10.5

rocker

40L=6

ring 1

feed

shaft

feed

shaft

feed

controllever

adjusting

Reverse

Reverse

Washer

feed

feed

Screw

Washer

¥>

Nut

Screw3116''

Screw3/16X28L=I5.5

Screwi/4X40L=6

shaft

bushing

II/64"X40L=7 I

Screw

3/16"

ring

Screw

3f!6"X28L=!4

Scrtw

shaft

bushing

Screwi/4"X40L=6

Screw1f4"X40L=R

Screwi/4"X40L=8

shaft

spring

spring

X28L=15.S

X28L=7

I

I/64"X40

L=I0.5

f<i!:

QTY

1

I

1

1

1

1

2

I

I

2

1

I

I

1

1

l

I

I

I

I

I

I

2

~~.

For

meilit::m-he3vy

materials

I

I

I

I

I

I

I

I

I

I

l

I

I

I

I

I

Ligbl

)!j:*'f

for

mmrials

cp~U

~

*

*

*

*

lll.$*1

f(l.:

heavy

lcatt::r

muerials

*

*

*

* *

*

*

*

*

* 38 GH215·8

*

*

* *

*

* *

*

*

*

*

*

*

*

* *

*

*

* *

* *

* *

*

* * *

*

*

*

*

*

*

*

* *

* *

*

*

*

*

* *

*

*

1-r

*

* *

* *

*

*

*

*

*

* *

*

*

*

* *

* *

*

* *

*

* *

*

* *

1r

*

*

*

*

*

*

* *

*

*

*

-40

-

Page 31

6.

lfiJ~5tffi.f-l:

Oil lubrication components

/

8

-

41-

Page 32

6,

llif11HttJl

f-f

Oil lubrication components

J~~

12

·

• J

{'t.

REF.

PART

No.

GR672-8 imw

I

GR673-8

2

3

GR6~9-8

GS351-8

4

GS353-8

s

GS310-8

6

GR678-8

7

8

GR675-8

9

10 GR644-8

GR670-8

II

GR671-8

12

GS353-8

13

14

GWI95-8

GS352-8

15

GR659119-8

16

17

GR660

18

GS348-8

GR662-8

19

GR663-8

20

GS349-8

21

GR665-8

22

GR664-8

23

24

GR666-8

GWI94-8

25

26

GS350-8

GR667-8

27

GS328-8

28

29

GR668-8

~

No.

Oil

ilil'fi.l'O~FJJ

J·.

i1lJ1Mtll"B'

illl~~t!Z~ft

ilk~H~H'JI5/64X28L=9

@li!Mf1l:l!JilH3116X28L=6

l!:!ll'l!!

lli

1l:

fDii1llirtiH4

IE!

illlft~

iHH1lli1ll~

ii'tW1Jl<i1ll'i;f

\li~f!!:illl~

ffi~~Hl5/64X40L=9.5

l

tiJ~

i!1tiiel1\'ji.

~W

il!l~il!Jil~H

ilil*

tli{4

i~i*"ii:it-1&

-8

iill~

:

i<:~~i!tfTh13X8

im;.JH$

iill.flillt~

ilil*~'~HT

ilil

illl~n

l!:li1ll

tt~N

H:

·Hlll!~i

~H.ll*9iiltTI

fMillti'~~

Oil

iii

ilii

Oil

t

!iiotf

ti:~

Plunger

~t!!!U

ill

.:!?.

sight

window

Rubber

Main

Oil

Oil

felt

Oil

rerum

Holder

Oil

wick

Oil

rube

ffi

~ Tube

Oil

pump

Oil

pump

pump

Oil

pump

Screw

pump

;:l

l.(

Oil

Plunger

spring

Plunger

-E'

Hook

l/64X40

Oil

tube

DESCRIPTION

ring

shaft

oil

rube

pump

support

Screw15/64X28L=9

presser

tube

ASM

holder

Screw15/64X40L--9.5

Spring

Oil

adjusting

ASM

installing b

Scr,ew

impeller

cover 1

pump

impeller

'c-rew

driving

shaft

L=9.5

joint I

~

Scrcw3116X28L=6

lower

screw

ase

M3X8 3

cover 1

oil

tube

Scre

wll/64X40L=9.5 I

'l&:i:

QTY

iiJ,

mediUm·

I

I

1

1

I

I

I

I

I

I

I

1

I

I

I

I

I

I

I

3

I

I

I

I

nea

...

"{::(

*

y

matenal

Uf.l

i

<P~t~

ForLi~

ma1erials

~*'-1-

for

vy

materials

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

* *

*

"{::(

*

* *

* *

* * *

*

*

*

*

*

*

*

*

*

* *

* *

*

* *

*

*

* *

*

* *

* *

* *

*

*

*

* *

*

*

*

For

e~thct

s

*

*

*

*

*

*

*

*

*

*

*

*

*

1-r

*

*

*

*

*

*

-42-

Page 33

7.

h

btl~ffi~

~--25

Oil reservoir components

~

.__-26

~

- -

----

I

I

I

I

I

I

I

I

I

I

I

I

L _____ _ _

----

18

I

·

I

23

--------'

11

13

I

I

I

I_

---

-----

I

I

I

I

I

I

I

I

--

-- -- --

~

-

43-

Page 34

7,

idJ~Jjo&JHt-

Oil reservoir components

rr:

-1:}

f4

REF.

PART

~0.

1

GR6roi25·8

2 GR681-8

GH344-R

3

•

~

GR682·8

GR683-8

5

GS355-8 tfi!HllffT

6

7

GR684-8

8 GH345-8

9 GWI96-8

10

GR688-8

GR689-8

11

GS358-8

12

13

GLJ70-R

14

GS357·8

•JS356-8

15

GZ238-8

16

17

GR69016·8

18 GR693-8

19

GR691-R

20

GR694·8

GR692-8

21

22

GR695-8

23

GS359-&

24

GR686·B

GR687-8

25

26

Gl::!Xl41-8

-13-

No.

jW,

1>:¥-*'~

t,

DF.SCRIPTIOX

i'1B

fl

ffH1=

Oil

reservoir

iefl:

Oil

re<CTVOIT

tfllli!llffl'

ili!ii

!.ll:!k''iif/1.

llilllitlJfTOJI;fl:

{ltf:Uil~l~ldltli'i

U:tuiiii!Mtll~

tfl:£W$!!!1Fnt5(1.

tflli~lf!i!I.H

l~t\\Wi7!k!IHT9132X20L=20

<.:r.Jill!~!ii!!Hl'li.l11l'!l~15164X28

~l~l.ltli!iRlflij!

IG(oolilbli'it'IH

tfl/EP,'~~7f

~t\HH~I'f

l~t!l..fl;(tk'l~

1\ki!i.

t.iltiA

~tiA

I'Mi'H

115'<l\i!tTI5/64X28L=15

ii!!Atl!l!!ti

jJll~.'!

imfH<it

~

Oil

ff

Hfl!:

~

j)):

PI{

1'1'1

Top

reser.·oir

Head

Screw

Twisting

i\;it.

f>!llifi5164X2S

Screw

CJ

t'llil

Knee

Knee

Knee

pre~smg

Knee

Knee