Page 1

HIGH-SPEED

OVERLOCK

SEWING

MACHINE

11

•

OPERATION MANUAL

PARTS

m

itt:

m

Iii·

ZOJE

ijt

a}j

=F

BOOK

=K

•

m Jllill!ll

SEWING

MACHINE

mn

n~

tR

J5i

ae~

C::O..

LTD

61

.

Page 2

INTRODUCTION

Thank you very much for purchasing 700 Series machine.

This instruction manual describes daily routine maintenace and safety precautions to keep the

machine in the best possible conditions.

Please study this manual very carefully before operating the machine.

~

.J"t.il~JJ~L*

e

tr:mwr.

-

~~JJ~L{t:f!l!

etr

:~·Ua~

fati

J~LWHll£.

CHUTION

OBSERVE

Though Pegasus lakes

e

To

e

Do

e Before maintenance,adjusting,cieaning, threading

Check that the machine will not operate when the pedal

~

&*ftl•

£1n,

~

ffJ

Jri~)-~

·

.J!t~·i::;((.Jti1-:tl:

r

:

hf~

i

tl:

ti1:J!Ji

~.$tn

(f.J

:Y~

n~fi:((.Jtl'ii.R.

Jilll

·t,

i.'t-'f~~ft~~

J~L.i.!l:ti

THESE SAFETY

prevent accidents,do not temove safety devices or parts whi

not leave tools or other unnecessary objects on

f¢.~.

iJ.Hi.

!iltJ

J~L

I!H

~fl.tiJJLJli.

PRECAUTIONS

the

utmost care to producesafe sewing machi

il:

.\1.

-------

l:l!lllltf<l'st'~Uifr.JtmN.

Iii

v.l

tel

tt

fj;lll'~

ttt~

iJJ!l!W

liU11

Ali

{I}~

*"

a>

.

J

~L

fi

1:/tcnl:J~&!at~JIIot

j,'HI.

~~t~.

lli.i.!J:~

r •

.x:«t•

!Itt

~

if

fQ •

~aw

111.

~~

~

-F

f!l!JIJ

~H':fli

i~ft.

the

machine table while operating t

or

replacing the needle,and to prevent accidents,be sure the power is turned

is

pressed.

l!~

a>

.iA:IIHIH~

i;.IJ

t1

•. a

.

l,'J~lKtJt.*!~f10it1;.

,

Jl:

U:'ftlfi!:I~((.J.

-'f~~·~«-J4mM,

t:f1;n.t,

fiJ~Ji

ti:~

1:·J~/&. I.'I~H~·I1Jmill!

nes

and devices,operators should follow these basic safe

le

operating

the

machine.

Note

In

case a crutch

keep

on

rotating

off

power

suppluy

C) is

stepped

because

the

keep

on stepping

the

machine

power

supply

il'it&M

.

hemachine.

-------

type

by

inertia

<D

on I

nadvertently,

mach

ine

on the

comes

(j) .

.

to

1i1.:Jt!!.iJH i 1J1

.-f~ ~l1FWit

mo

If

teh

will

a st

tor

is

used

after

machine

it is

move

machine

op

after

tuming

unexpectedly

Ji11!1!111

pedal

;.

.

i)i\,

-.....

, it

will

pedal

danger

ous

<'-)

unlil

turning

(r:~OiAI!II{!l!~

.

off

F

ty

rules

.

off.

--

e

(r:~Jf!il~JJfiu.t,

e W

II!II

·tt!!.i.'l*£·X:!l~

e

.:.<J

(0:1.:.

uf:fiky((.J,

1.'

1 HJ.ii:

h'l*~·:X:f'~l

I

I!OO

.

~~~L:t~f((.JmtJHJ

,Q:

.

---

e

Tum

e

e

the

In

the

Check

l!

i)J\

.

L

,

II

'ii\'.o.'HCtJ.l:~'

- 1 -

power

event

that

off

before

of a power

the

machine

leaving

the

failure, be

is

securely

machine

sure

to turn

grounded

table

.

the

.

machine

off

.

Page 3

~

CONTENTS

•

?fiJ!ffl

0

~t&1.mii!l

0

tl~!JJ*JL~j(~1Jj~

0

~~!JJ*JL~Mi~JJicl&~~

0

i:JtiEb

Z.lru"

3

4

5

6

•

BEFORE

0

Schematic

0

Installing

0

The

machine

0

Lubricaion

~

OPERATING

dia~ram

of

the

the

machine

speed

head

and

machine

the

tumin9

table

direction

3

4

5

6

0

-=ffd.J~iEb

0

~*

H R

~mi:JtfEb

0

~~~1Jj~·

•

litti

0

ffi$11

ffi:tJ

~

lfaj

iJ

0

~

7d.J

~t

~

lJ!J

iJ

0

}t$P*Jl~lJ!Jil

0

~~~~lJ!Jil

•

iiffl

o

~~!l.lm~r~E

0

~lt

0

~if*Jljfb

~1¥11*~

~fill\

7

0

8

0

9

0

•

1 0 0

11

0

1 2 0

13

0

14

15

16

Manuallunrication

Filling

the

HR

device

Threading

TEST

SEWING

Adjusting

Adjusting

Adjusting

Adjusting

•

0

0

0

the

presser

the

diff.

feed

the

stitch

length

the

thread

MAINTENANCE

Cleaning

Replacing

Checking

the

machine

the

needle

the

oil

circulation

with

silicon

foot

pressure

retio

tension

DURING

oil

USE

7

8

9

10

11

12

13

14

15

16

0

~*Jljffi

0

l'JJJ:t~£~

0

ifal~~li~~~

0

*JL}t~Xt

•

~it!=¥-M

}t-i}x>J"mi~

17

18

19

.

19

20

-

Replacing

0

Replacing

0

Adjustment

OStandard

.PARTS

2-

the

oil

the

lower

dimentions

needle

BOOK

0

-

knife

Comparison

table

of

equivalent

sizes

17

18

19

19

20

Page 4

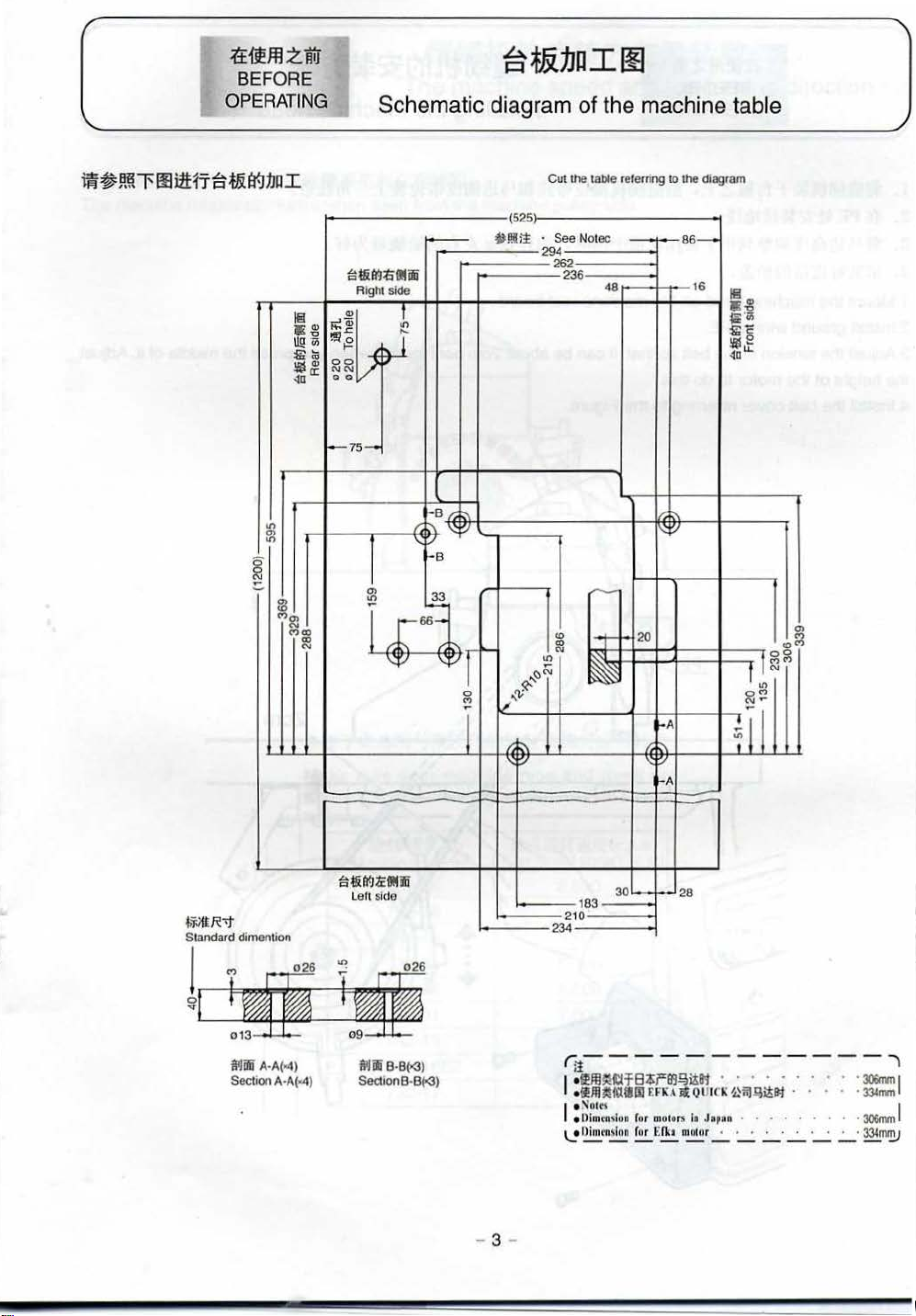

1£-f!JfJZ.iitr

BEFORE

OP

ERATING

Sc

hematic dia

gram

of the machine ta

Cut the table refernng to the diagram

ble

-

~!!«it

.--

---~

o See Notec

""

--

86

-

~~iitR"<t

Standard

dimen11011

I

..,

•!

~~

~

01

~

ft!Jilii

AoA(><4)

Sec!IOn

A·A("")

t3~1't-Jli:lll!ilii

Le

ft

sldo

026

:2

~~

0:

6o6('<3)

Mili

Section

026

6o6(<3)

~

--~2118_3

J----234-

30

"--:-28

__

-i

--

-1

rll---

·

l!lll~tt=f8<f;F£5~i381

I

•lflll!l!fllfiiJl

01" I

•

I

enimtn,fon (or

l!

l~e•!2! ~ E~ o~

-

EF

KA

mOIOI"S

- 3

-

---

0 0 0 0 0 0 0 0 0 0

)£QUICK

01il!\i!lll o o o o o

In

Jap•

n 0 °

r

_:_

:.....:..

-

0 0 0 0

0

:._

---

....:_

o

~

0 0 0

;_

-,

306nvn

3341Ml

306mm

o

~m

I

~

Page 5

1£-ftmzm

BEFORE

OPERATING

1.

:¥.f!I:!~JJ-t~L

2. tl: PE

3.

~~!.

4.

il'l~~JIJc:~IHf.r

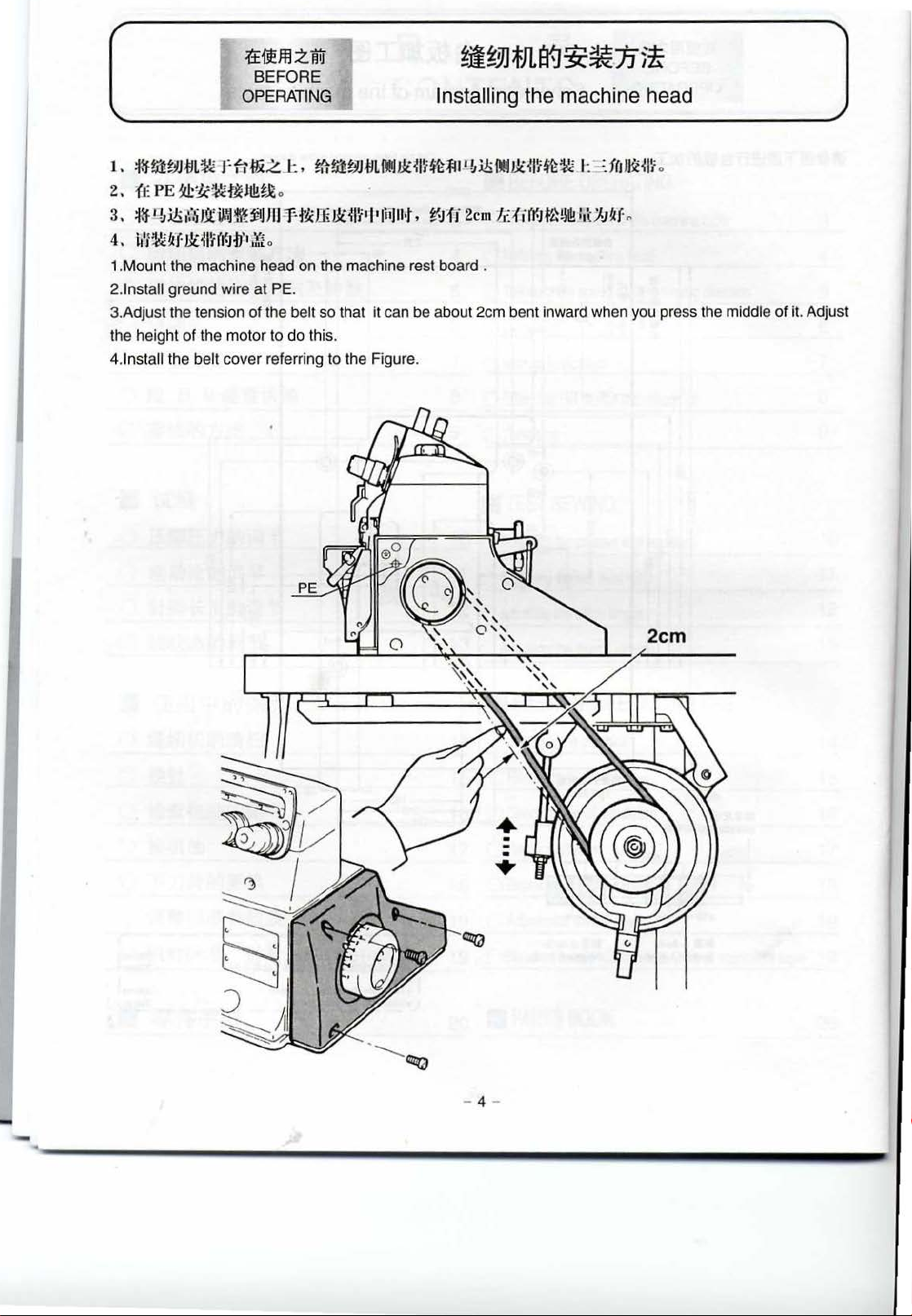

1.Mount the machine head on the machine rest board .

2.1nstall greund wire at PE.

3.Adjust the tension

the height of the

4.

1nst

all the belt cover referring to the Figure.

~

ft.-.f&.ZJ:,

~~~!&!1!!~x

~i!;,\1J1£U.1!(f~JJIJ

f

f•lti

of

the belt so that it can be about 2cm bent inward when you press the middle of it. Adjust

motor

Ut!i':!tJ

JfJL

~IJc:{

o

T-tl<ffiiJc:~

o

to do this.

W•I•J

r• JII•t

In

stalling the machine head

l~

~:fH '~i!i

,

¥

-J1i

2c

OOJJ.U~

I

H~~

t:

:==

.foJ~~~

m

b:;(

i((oJt~!}l!!

IJt;,(JM

~;

o

..

- 4 -

Page 6

:r±iimzmr

BEFORE

OPERATING

fatJ

J:#Lff.J

1Jf~1i

The

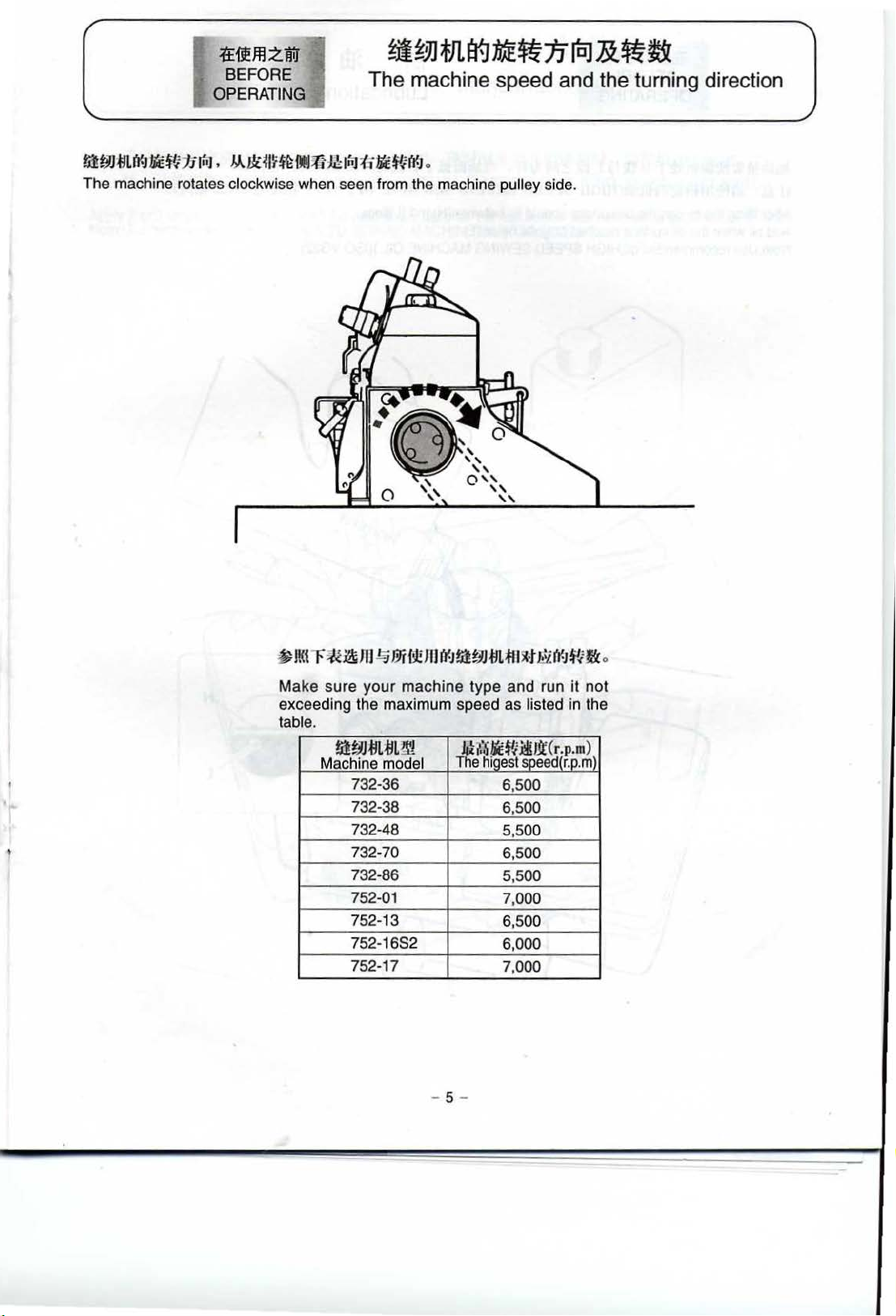

machine rotates clockwise when seen from the machine pulley side.

(liJ

,

.lA

J1r:

{I~$~

fll~

Jl:

~~lJ]

*Jt

tr.J

!Jfl~

The machine speed and the turning direction

IPJ

1i

1X

~

1'1'1

o

1J

icJ

bt

~~

Make

sure

your

machine

exceeding the maximum speed

table.

!iltJJ.tfUJ

Machine model

732-

36

732-

38

732-48

732-70

732-86

01

752752-13

752-1

752-17

L

~

6$2

type

~?.'6Ji~

The

higest

- 5 -

and

run it

as

listed in the

~J.O:

(

speed(r.p.m)

6,500

6,500

5,500

6,500

5,500

7,000

6,500

6,000

7,000

not

r.p.m

)

Page 7

iffimzntr

BEFORE

OPERATING

1~

5m

Lubrication

JJitilltl,t~N!ilhffll~r

if:~:

i#N!JIIftiJk((.J.t1Lnh(HlGH

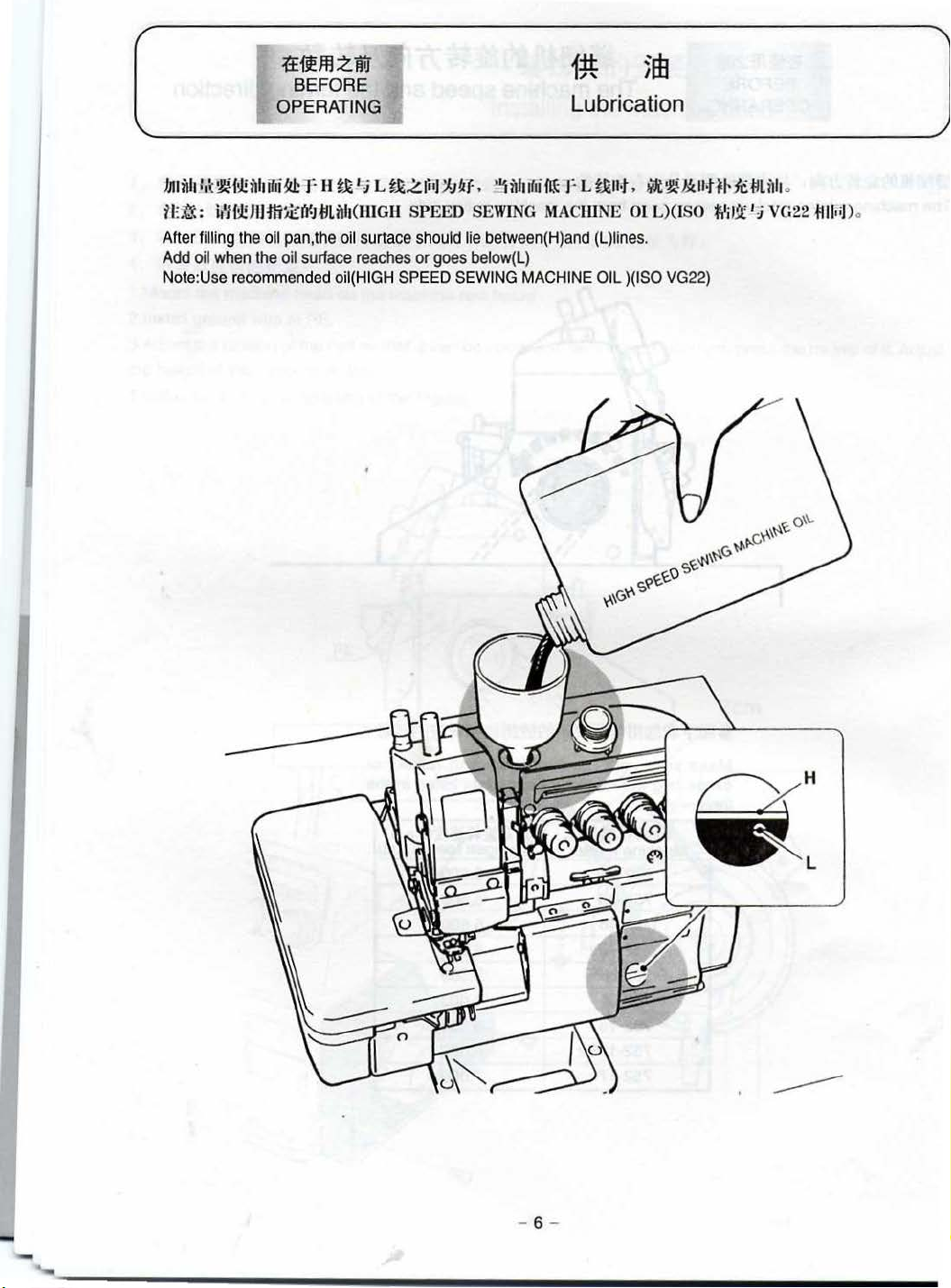

After

filling

the

oil

Add

oil

when

the

Note: Use

recommended

pan,

oil

surface

H

~~.Lj

the

oil

oii(HIGH

L~~.Zih)~JU,

SPEED

surtace

reaches

should

or

goes

SPEED

SEWING

~ill11fri~

SEWING

lie

between(H)and

below(L)

F

Lt~ll·t,

MACffiNE

MACHINE

~~}Jdfit~~feflll)h

01 L)(ISO

(L)Iines.

OIL

)(ISO

VG22)

f.

1

il.!l:

1

J

o

VG22

f'tlf.iJ)

o

- 6 -

H

L

-----

Page 8

ifi!Jflziitr

BEFORE

OPERATING

Ma

nual lubrication

T·#J~illl:le'l't~~J

il::

it'H£11Hti)f:((-J~Lil

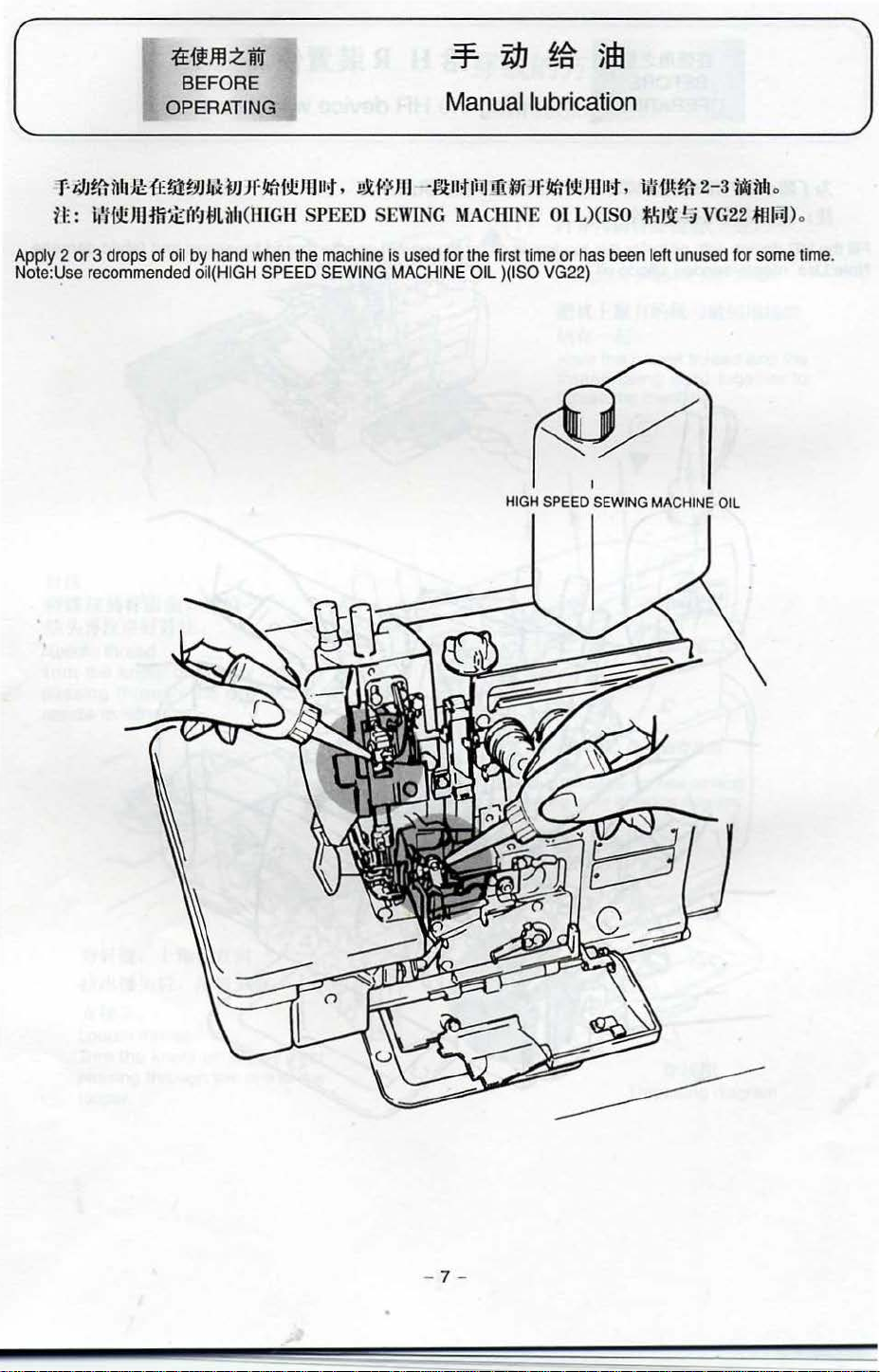

Apply

2 or 3

Not

e:~se

drops

recommended

of

oil

Jl!HJJJI

by

oii{HIGH

:!z&

h(HIGB

hand

when

SPEED

f

!l.:Jf:JII•t,

the

.!l.Xn

JIJ

SP

EED SEWING

machine

SEWING

is

MACHINE

FJ;IIofJiUruifr

MACillNE

used

for

the

OIL

first

){ISO

JFJifjfJI!JfJU•t,

Ol

L)(ISO

time

or

has

VG22)

I

HIGH

SPEED

SEWING

ilHJ~~

1

f.li

J!t

been

left

unused

MACHINE

2-3

~

VG22

~nbo

.#llfiJ)

for

some

OIL

o

time.

- 7 -

Page 9

i±ilmziltr

BEFORE

OPERATING

JoJ

71W

Jl:

;{fi

~Hft!lJG~~

it:

fliil

hit'f~JTJ.Jti

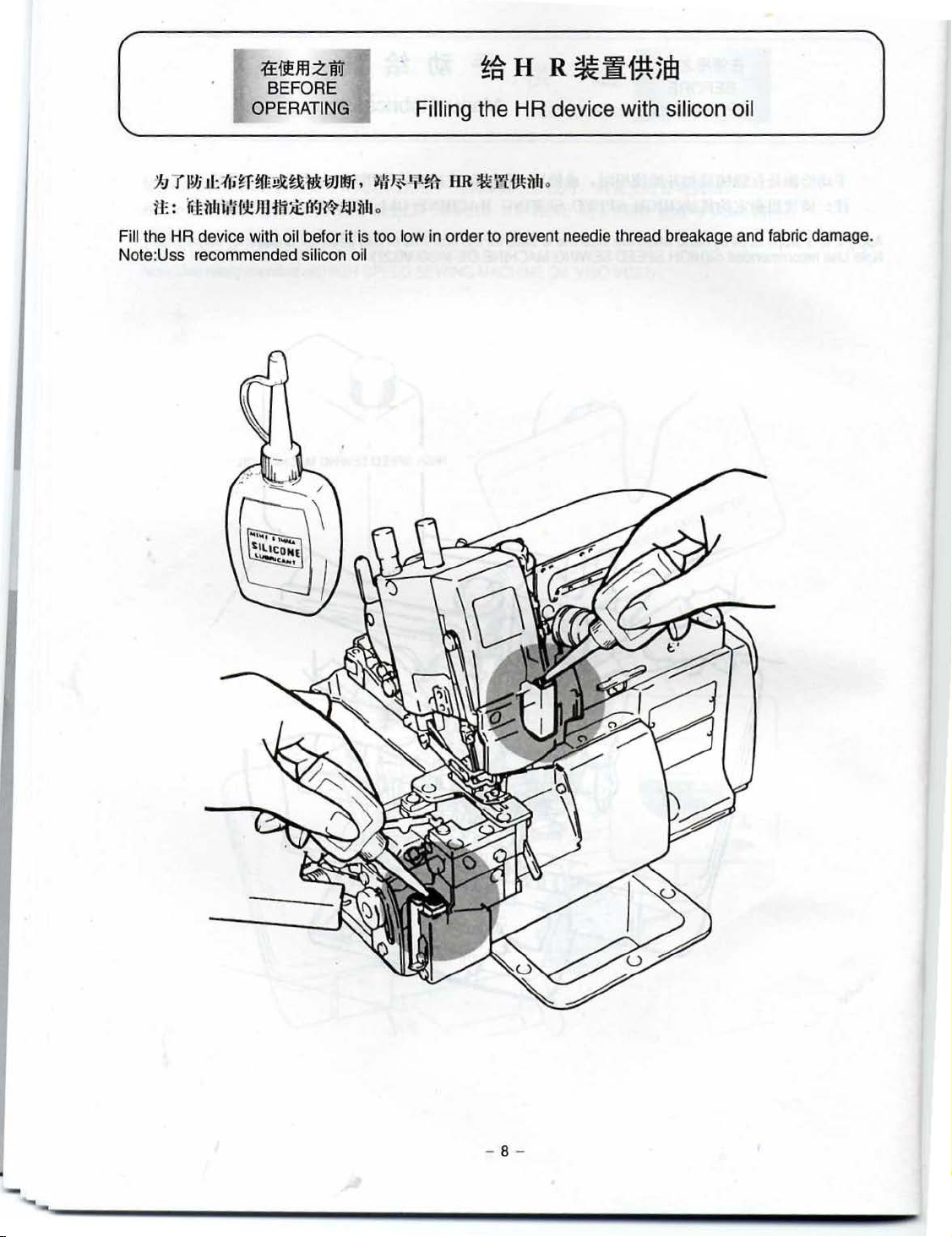

Fi

ll

the HR device with oil befor it is too

Note:Uss recommended

·11J

}E(I'oJ~

silicon oil

1m

,

};jJi!b

g*H

R~~~jfh

Filling the HR device with silicon oil

~·t

~!Jl-~

o

low

HR

in order

~

i!'HJ~

ilh

o

to

prevent needie thread breakage and fabric damage.

- 8 -

Page 10

ifilmzntr

BEFORE

OPERATING

H~x

:#f

~JC;

J,f.i~

l 'tl

·lll~

1iii

•

9H

:t

~.'i!).;

llj.(.k~~~f'il-~~

Needle thread

Trim the knots

passing through the eye of .the

needle to rethread.

0

off

neatly before

Threading

H

JfffiJII.PHlU~L.Xi(

Open three covers.

Swing the presser foot aside.

re.f:lu

~.'l{t:-~

Knot the preset thread and the

thread being used together to

thread the machine.

:

)JjH

ut..,~~

-=

~)

'J~~JJIJ

~xtJtl

f,f.I

I

H~.:J,Jii,

:f

H~

J. o

Looper thread

Trim the knots

passing through the eye of the

looper.

JIJ~VJ

J

9'1

oH

neatly after

- 9 -

Page 11

ffi

Jl!ll

ff1

Jli

1J

1>1

Tum

adjusting screw

obtain the

TEST

SEWING

Jli

1J

IY1

~1

\'f

iiJ1tE~-i~Wl:ilH'T

M o

to

adjust the presser foot·pressure.lt should

pr

oper stitch formation.

~~

light

Adjusting the presser foot pressure

i11

\J

o

tt:l~

.fri:tRi~H~

k f

Jt-

~IN

1!~.ti

be

as light

J 1-J

tt

JI.IIIIY~

as

possible,yet be sufficient to

rli

FIJI

R ,

~Iii

tm

lll!Jll

~

ijs]

- 10 -

Page 12

~

fdJ

tt

~i)!]

TEST

SEWING

~rJ

Jltfi''JU.~~jJJ:f'Mf~L*

Loosen the nut and move the lever up and down to obtain the correct differential feed ratio.

Tighten the nut after positioning the

m,

trli?JJ-*illfiU.,'W,

lever as desired.

Adjusting the diff.feed ratio

~11:;cm,

:m~J:ttr~

il

o

-

11

-

Page 13

lit.~

TEST SEWING

tt&P¥:Jla9~iJ

Adjusting the stitch length

1.

!\lHHl<~l.

2 .

.i!ll·t.iUMfJ:rl<l/l

lf1U!Ji~·~rl

<D

While

handwheel to seek the position at which the push

button goes further into the depth.

® Then,keeping the push button pressed , '

turn the handwheel and,set the desired )

scale to the aligning mark. v 7

tl::

HIJ!.IJ

Note:Stitch length adjustment must only be made

after the differential feed ratio has been changed.

li*7T--~.

f1

~Jf.c

fl'i

.

pressing

t\:J.O:iJ.~J

\'i

j}·e·i,'I(J:u.'J

ti<fU~~'ii!l:.\.l!t;,Htc

,

lll*~rJ

J

""f~,

Ul!.f

the

push

button,turn

\

'iX

~

iJJLt.Zii1.ilH1

.

.:c!lft~;

iCJ·};(.f Aligning

~j)Jj/;J

t!il~

iC

Mark

~,

~

the

Ej,.._

~

~

' -

.

~

~

~

~

1

3£tj\

Fif1.,!

~

~

~

\

~...;

: Q

._

~

~

....._~

7

~*

Coarse

\

C

~

-=¥~

-12-

Page 14

itt~

TEST

SEWING

~

~ICJJ~~t

Make tension adjustments with the needle thread knob

knob

m~r\'i,

<»

.

it'IJJJ

~g!~'31

'j~ti

1<D. 1:~'~1-!l·~n)~tl'la>.

Adjusting the thread tension

<D

~'J'~H~~~

.

the

upper looper knob

,

W**ttff

<»~IH!Hl'~~~

Q>

. and the lower looper

'j

o

\ I

~·

••

• • l'i':i

t'LHf

To

loosen

)

To

tighten

- 13 -

Page 15

!Q!~J

fJL(~

ftlf

Ma

inly the slots

{!J:iji:ptr.Ji*~

MAINTENACE

DURING

H ,

ld.

'fl·

of

the needle plate and the feed rows should be cleaned.

USE

.f&Wfl?d~,/tl

}f

~'d [J~

~J±

o

Cleaning the machine

- 14 -

Page 16

flffli:fltr..Ji*~

MAINTENACE

DURING USE

Replacing the needle

R®m~~OOMfi,

H~*h';I

((.Jfrftf!H

LIY-J~

e Check the needle carefully

e Insert

Be

the

needle

ti-ifld

~JIJ

((.J~~JJH,

sure

to

use

standard

to

the proper depth,and fasten securely.

il'1~

needle.Refer

~-fi~~~fi~,

~~~

o

to

see

that t

J!Q.~*IlH1:ff(.J

to

ADJU

~ft~-~

he

scart

is turned

"v-~!f:~R3l<"

STMENT

DIM

ENSIONS

~illfi~~

to

the

;

rear of the machine.

on

the

end

OK!

of instructions.

NO!

l

J

-

15

-

[

)tJ!

)

ilif\~il££!01'*

[

Note) Do

not

remove

the

·

screw

.

Page 17

ilJfl~~i*~

MAINTENACE

DURING USE

*~

1tt

*JL

5m

~

~m

J~

Checking the oil circulation

- 16 -

Page 18

illfllfll¥-1~~

MAINTENACE

DURING

USE

Replacin g the oil

fJLnhff.J!li¥~.

Replace the oil one month after the first use and every six months thereafter.(See P7.)

it'Ht:

i~ffl:lf~li'-JJJII~l~

fJ~nhi,'t~mm

1

!A

o

(X,

?i.\ffi,

1!i61'-JJ~~

(X

o

-17-

Page 19

'(iJij

MAINTENACE

DURING USE

i!P"FFJJft

To

remove the lower knife

l~

F n

{.f

HflHi•J

Ji

.Ill

,

Jll

ti~

~

<D

t1f

IH

lli1l£

o

Temporaily screw (1)

sliding the lower

after

knife holder to the left.

cp~

i*~

Replacing the low

er

knife

1'

JJ

lt

Correct

lower kni

732

lB.Yft

angles

fe

~ilf

.II

1fJ

to

resharpen

Jl

the

~~l'JJJt

To replace the lower knife

.t~Jf-

*'R~t~,

!JIIJii

•J

.(

i

Loosening the screw

makes

holder slide to the right.

-r

J

J

~ - _ Turn the handwheel

.ftz;/

J o as the drawing on the

~

the l

ower knife -

~~i;IJ:f~:r.f

~IF{ il~ll

__

right figure.

~.~.t;

m~~''..tf

1r "J

~ f,'l i~l

:U:

1

-r;

J J'·

1' 1

~~

Insert the

(See the nght frgure)

!owe~

I~JJ.ftQJ)(

~~~

o

FJPJ

Cutting edge of

the

B

f

~H.fli.U

~JifiJJk

Levelof(A)=Levelof(B)

•

kmfe.

~~f"

Chek cutting actro

~

J B

lower knife

nm~

rfli

•Jq,[

f JJ J'·Jii·

1

.-f:

""}~~

A

!;j"f

'.vl

o

.i!Hi

11

.

n of knrves.

l

:nJ

Upper knife

I

Top

the

;·

't

f'.f

~~<

surface of

needle

rM

A

~~~

JH

J B

jC

f

~Y~.

~

f

fJ

iA!)IH1J~iJl

•

o

- 18 -

Page 20

732

Adjustment

dimentions

(mm)

732732-38

732-48

732732-86

752

752-01

752-13

752-1682

752-

.

732

36

70

17

~

10.6

10.6

10.1 3.9 3.3

10

.6

12.0

_l.l

10.1

10.1 4.6

10

10.1 4.2 3.3

tf-/l{tffl

~

3.9

3.9

3.9 3.3

3.4 3.3

t !l

Adjustment

~~0

4.2

.1

tf.J~~ll.l~t

4.2

Standard

~

3.3

3.3

0.9-1.1

0.9-1.1 5.5

0.9-

1.1

0

.9-

1.1 5.5 1.5

0.9-

1.1

dimentions

tl~

3.3

4.0

3.3

needle

752

~

5.5

5.5

5.5

~

0.9-1.1

0.9-

1.1

0.9-1.1

0.9-1.

'lo

1.5

1.5

1.5

1.5

~

5.5

5.5

6.0

1

5.5

tf-/l{tffl

(mm)

tf.Jiil~ll.l~

Standard

needle

I

n ~

Organ

DCX27

732-36

732-38 14

732-48 14

732-70 14 752-17

732-86

732

. 752

B*it~

Japanese size (Organ)

*OOt+~

Chinese size (Organ)

(Organ)

11

21

tt~X1lffi*

Comparison

#

Nm 1

9

65

table

of

equiva

11

75

752-01

752-13

752-1682

lent

sixes

14

90

~t

~

Organ

DCX27

9

9

11

9

16 18

100 110

21

30

- 19 -

Page 21

HIGH-SPEED

OVERLOCK

SEWING

MACHINE

PARTS

BOOK

Page 22

1

~

.

~;:·

"

/j

•

-24033t

•

732

fj

e

m..a£n~

m.a_

--.;_

20957

..

,

..

81

II

0

Page 23

iU~~Uif.llt'Bl!l=ft

m

P

lease confirm

the

correct

part

by

the

gauge

parts

lists

.

.

752•

752·13~

...

.

752

·-

-

:109662-92

11#!~\Ui"f.l:~

m

P

lease

confi

rm

the

13

lLt~

_

.,3

correct

part

by

the gauge

parts lists.

n m

--

iW.~

Pl

..

Uif.l!ttBf-1:~

ease

confirm

the

correct

part

by

tho

gauge

parts

hsts

.

.:.

...

m

il'l~l¥iHif.)(£~f.l:~

Please

coofirm

tho

corrCC1

part

by

tho

gauge

pans

liSts.

Page 24

-

:s

lists.

011546·92

m

il~~U!r.~'lf-1:~

\::11

Please

confirm

the

correct

part

by

the

gauge

parts

lists.

m

il~~.,T-~'If-1:~

\::11

Please

confirm

the

correct

732

209542

732

007021

e732

209667

;{if~

\j

.752

209666 •

"

part

by

the

gauge

parts

~00~7019

.=51

752

§\

"007020

lists.

•

m

i.l~llr;it-!f.~'~f-1:~

\::11

Please

confirm

the

correct

part

by

the

gauge

parts

m

lists.

m

\::11

• 732-36,-38,-48,-70

005328~

20891~ [ 208532

005409

e1s2

208525-928 005328

l.i~llr;it-!ii~'~f-1:~

Please

confirm

the

correct

part

by

the

gauge

parts

• 732-86

.

~·~5

·36,-70

r.·~~~-

208531

eM732-4B

..,-I

l #?

I

~208528-8

a~

208958-B

~·

{~

•

-Q1

210585"~-

''*

·-01

210584

• 13,-1652,-17

211600

1=~~:

"" , '~I

4

005030

'r-L

~

fo

~~

loot

fi"9m

i'

.

~~-::.""'::.-----,..,

~-~

ft1UI1¥ll!f

~-rPresserfootassembly

208958-B~

r~

1

~~202875

005328

V]

'

?;,/

208956-8

• -1652,-17

~--:

i"!ll¥1!1'1'

P;-esse,f001assemb"'

1231

2o12~5a{

.....

~.

~

lists

.

005157

~4683

Page 25

UJ

m m

~!~~~~~correct

part

by

the

gauge

parts

lists

.

~~~1

07011~

732-70,llll

(N05om>

l

2Cl96ID

oonue

~1021 .&'

Page 26

m

.

73:2

\

w

:

r..

il!t.'!lli

~

H~lt~f-1:~

P

lease

confinn

lhe

correct

21

0529-9U

pall

by

lhe

gauge

IISIS

parts ·

.

732

Page 27

11

11l

...... _ 1

.

752:.0

1

210891

~~-----------2/·~-------

2

1

~2<a15

21

2.&38

215515 20104.5

775521

:r

\

m m

i!t$ff;U~Uf.!:N

Please

0004$3

confirm

the

corred

pa

rt

by

lhe

gauge

parts

lists.

Page 28

732

f;T-11£~14=*

732 GAUGE PARTS LI ST

~

~}

~

I.IACiirlETYPE

tSI'EC

732·36

732-38

732-48

732·70

732·86

~

~

~'SW

-~

752

*Fit~1**

-~

I . -· . •- I I . I . . - I . .. -- I . I

-~~

.

l!!.i!lM

it

GAUGE

NE£ru

PlAJE

3

204367

4

204367 210505

3

4

3

204940

4

5

a:>mll\

5

204529 210509

5 6

~

~

~~~~

!'(

ti:tH;

~i!lllflft

fe!ll.E

IJ.AlNFEED

ANGER

DOG

PlAJE

210505

208065

208066

210505 208074

210506 208063

208064

\ {

\

~

~r&

l:u!Hf

IJ.WIFEED

ASS.

DOG DOG

I

12043951

L!204396)

{204931)

I

~

204394112080591

~

lfli!IUf

AUX

FEED

I

1204425

{20Eni0)

{2al061)

I

1201:!0591

~

~

w~

~.ihi11lf

DIFF.FEEO

208218

208219

204420

208215

208217 208955 204703

DOG

fU!f!llt

PR£SS

FOOT

208501

208501

208508

208502

\ \

ER

ASS.

~

1:~\t

U

PPER

LOOPER

204062

204702

204702

204702

\

@~@

~

...

~~

... I ..

I

...

~

-

F~H

LO',.iER

LOOPER

204072 209685

204072 209685

204072

i!U'IUfi!

~

.t>

...

I I -

~·

C

IUt~it

~

LOOPER

209685

209685

~

~

I ..

§-~\(~

§ '

\'

nf

...

..

~·--

~ ~

1

~

\!~·

1

~

~

•I!~!

~

'

• f

~ § ~

~71~

~

~

~

•

II>

liO

- \

/

1/ u .

;..

I

~

~~~r

i l8 -

'=

li

~

:?

~

\

~

~

\

{

Loading...

Loading...