Page 1

TABLE

BLIND

STITCH

MACHINE

~

PARTS

1i

PARTS

.

llJ

1!1

ZOJE

1*

ffl

•

llJ

Jl.tt m

SEWING

-=¥-

BOOK

tji

BOOK

mt

PJ.I

iliilll211:1 § HIH.H5J

MACHINE

CO

..

LTD

Page 2

~

~

........................................................................................................................

1'

1Jlmi1\llit···············································································································2

1

2, 'E'!l'liDi'W!l!!····························,············································································2

3, IJ!Hil'l'ii'!lt'lllli'f'Flft;'lr·····························································································3

1'

!llmiil'l'ii'!lt························································ ·················································3

( 1 ) Ill

Y<

il'l

Jjj(

ill· ........................................................................................................ 3

(2)tn.~ag~~---······································································································4

3)1Jl#.o

il'l'ii'!lt

( 4

)l'El&!ll

........................................................................................................

f'fil'l'li'!lt

..................................................................................................

·4

·5

2, !l'f'Flitril'lllilr··············································· ····················································6

( 1

)lliUit!Jl%.!

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·6

(2)1Jlw~"'············································································································6

.

(3lfllHil'lii1Jill··

4, lllmiil'llt!!l·· .......................................................................................................... 7

1'

'Eiiltil'lltrlil'!llltlB!···································""""""""""""""""""""""""""""""""""""""""""""""""'"··7

2,

!Jlttill;l'l'···· ..................................................................................................... 7

3, !il!>-'llllttoci't·· .............................................................................................. a

4, Ill Hillli<f:lnt · ·

5,

ll'!>J\"i!··· .. ···············,································"·"""""""""""""""""""""••··················· ..

6'

!ilii'!il'l

7,

.l'iittil<'li···························· ............................................................................

8,

j!J¥43f~Jlt~lJ*:i':····-

5,

IJ!Hil'Jil!l!i!··

1 ,

!>ilH<O

2,

lflt~j¥ff[agira]1)

3'

!hii'!l&!h:tJ

4,

Ill

tt

-'lHl&fii:'liiJlll'i

{1

)!W"J§ti:ii·

.. · ··

· ······ ···

··

!h}..jllljj(

··

· · · · ·

· · · · · · · · · · · · · ·

..

ill· ............................................................................................

..................................................................................... 10

···

·· · ·· · ··

· · ···· · ··· ····· · ··· · · · · · · ........ ·

ll!

il'liJlll'i

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

.....

-·

................................................... ---.-----

iJlll'i

...............................................................................................

· ·

···

· · · ···

.... --............................

··

...

···

·· · ..

· ........ ·

· · · · · · · · · · · · · · · · · · · · · · · · · · · · . · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

··

· ..... · · · · · · ·

-·

............................................ --.....................

··

·· · ..

··· · ··

...

·· .. ··

· · · · ···

· · ·

···

·· · .. · ···

··

..

· · · ·

......

· · · ·

..

·· · ..

··

......... · ..... · ........ ·

··

· ·

··

····· · ······

· · · · · · · · · · · · · · · ·

· · · · ····· ·

..

.......................... ·-·12

···

·· · ·· · ·· · ·· · ···

...

··

· · · · ····· · ··· ····· · ·

· · · · · · · · · · · · · · · · · · · · · · · · ·

..

.. · ··

· · · · · ···· · ·

· · · · · · · · · ·

· · · ·

··

···

..

· 7

.. · ·a

···9

·9

10

··

·11

·11

·12

·· · ·13

·13

(2)li'ifJ.tf;i:'li

(3)1Jl

tt-'"

........................................................................................................

:li'llHRf;i:'li

..

· · · · ·

..

· ·

.. · ..

· ·

..

· · · · · · · · · · ·

..

· · · · · · · · · · · ·

..

· · · · · · · · · ·

..

· · · · · · · · ·

..

· · ·

..

· · · · · · · · · · · · · · · · ·

·13

·14

Page 3

(4)j}!Jtjj!jji:

5,

<!/~)Z,.j}!Jtf!Iiifl'JiJll1'i

(1

J<~~~&>'<fl'lliPI<

(2)

IIlli

...................................................................................................... ·····15

..... ····· ...................................................................... ····15

mil·... . . . . . . . . . . . . . . . . . .......................................................................... 1 5

;z

fl'J:ti":t>lll":ii

................................................................................................ 1 6

(3)<1//&J<fl'J

( 4 )lllii>Z

6,

l~if!l$1\,..

(1

)ti":t>I!I:ii·

~flii!I:ii·

fl'llltr

F.ii!I:ii

ffiif!)l&fl'Jf;)-iiiJOJ1'i

............................................................................................... 1 7

................................................................................................ 1 8

.................................................................................

............. ····· .........................................................................................

18

18

(2)WiF.ifll":l!············································································································20

(3)

lllif!l>l\fl'JI!i'il<

7'

ffilll!Jffi:IJ

8,

m!~~*:IJ

6,

f!\$":1;>\;

..............................••.........................•...........•..........

.....................................................................................................

fl'JiJll1'i·

fl'JiJll1'i

...................................................................... ····· ................ ····20

........................................................ ····· ..................................

··•·· .......•...•. ·····•··· ····22

·20

·21

7, jJ!,jUifi'F····································································································· ·········:22

8, l!l!!ilJIIIi'F···································· ··········································································22

9,

r.§llJiH>~'·

10,

'!l'i'FfPI<··

1'

2,

3'

4,

5,

..............................................................................................................

..........................................................................................................

.f:JL~;flliiilffl'ffi14=······················-··························-··············································24

:Eilill!!i'F···

i!Sif!l

)f:W>tlllll!!

lll!&>Zllli'e·····

itl&l!!J'F

......................................................................................................

....................................................................................................

............................................................................................................

'

f!F·

..............................................................................................

23

23

26

·28

30

32

6,

l~if!I$1\:WIIlffill!Jl!!i'F··

7'

lllif!l>l\J-.il!J.!!.hltitl!!f'F··

8,

lll1mEEillll&.II:illlm#··

9,

ll<!&ii:l.!!.!!ii!J;l!!j'f'

10,

ltl&l!!f'F

........................................................................................................

...........................................................................................

........................................................................................

...........................................................................................

................................................................................................

34

36

39

40

42

Page 4

TABLE OF CONTENTS

ForeWord····································

1.

Brief lntroducion to The MOd8J·· ····· · ··· ·· · ····· · ·· · ··· ··· ·· · ·•••· · ···•· · ··· ··· ·••·· · ····· · ·•••·· ····· · · ·· ··••· · · 2

2.

Main

TeChnical

3.

Mdachine Installation and Operation Preparation···················· ...

1.

Machine

(1)Unpacklng machine

(2)Fitting machine

(3)Fitting

(4)Fitting

2.

(1)Cieaning·······································

(2)lnspection····················································· ..

{3)Lubrication··············

4. Opeation the

1.

2. Needle

machine

Work

Operation preparation

Rotating direction and sewing speed

Specifications···················································································· 2

installation·································································································3

head·······················································································

franme·····························································································4

head·························································································

plate components

.............................................................................................

............ , .................................................................................

Machine--· ....... · ..... · ........ · ........ · ........ ···· ..... · ..... · .. · ..... · ..... · ..... · .. · ............ · 7

selection--.. · .. ·

..

..

···············································································1

·····································

.................................................................................

........................................................................

··································"··········

of

main

shaft···--···

· .. · .. · ..... ·· .... · ..... · ........... · ........... · .. ·--· ..... ·

..............................................

..

··----·

..

·· .... · ..... ···· ·8

.. ·· 5

..

·····

3

4

6

6

6

6

7

7

3.

Specifications--..... · ..... · .. · ........ · ..... · ..... · ...

4. Needle

5.

Threading········ ......

6. Feeding and

7.

Skip

8. Regulating feed dogs height·· ..... ·

5. Adjustment

1. Regulation

2. Adjust men

3.

Regulation

4. Position regulation

(1)The front and the rear

(2)The positioning

(3)The

replacemet--..... · .. · ..... · .. ·

·································

pulling

stitch device·· ........ · ........ ·· .... · ..... ····

of

the Machine··

of

stitch length··--

of

blindstitch sewing penetration--

of

the pressure

left

limit

position

out

of

..

of

needle and needle plate

of

position··---

of

location·····--·--··--......................................................................

of

the needle

··

... · .. · ..... · ..... ·--· ........ · ........... · ........... · ... · 8

..

· ........... · ..... · ........ · ..... ·

... ········· ... ··············· ......

sewn materials

....

· .. · .. · ..... · ..... ·

................................................................................

of

material retainer· ........... ·

...........................................................................

..................................................................

..

· ..... · ..... · .. · ..... ·· ....... ·· .... · ..... ····

· ..... · ........ · .. · ............ · .. · .. · ..... · ..... · ..... · ...... · · · ... ·

..

···· ........ ·· ....... · ..... · .. · .. · ........... · ..... · ..... · ... ·

.............................................................

........................................................

......................................................................

....................

..........................................

· ........... · .. ·

························

..

· ........ ··

----8

·9

g

10

10

11

11

12

--12

:--·13

13

14

14

Page 5

(4)The limit of needle throw··············

5.

Regulating position of needle and thread hook··

(1

)Basic position of thread hook·· ........ · ........ · ..... · ..... · .. · ..... · ........ · ........ ·.·· ..... · ................... 15

.........................................................................

.............................................................

15

15

(2)Positioning of location for pronged thread

(3)Adjustment

(4)Positioning Of lOcation of thread hook

6.

Regulating position of ridge forming disc and material retainer·--·· ........... · ........ · ..... · .. · ...... · 18

(1)The left and right position.................................................................................... 19

{2)Regulating of the front and the back posution......................................................... 20

(3)Disassembling and fixing ridge forming disc·--......................................................... 20

7.

Regulating presser pressure ....... · · · · ..... · ..... · ........ · ..... · ..... · .. ·

8.

Regutating thread tension

6.

Mode of Sale·· .. · .. · ....

7.

Machine Head Accessories

B.

Machine Frame Accessories··---............................................................................... 22

9.

Warranty Period·--·· .................... ·

10.

Parts Book

1.

2. Main shaft components··"··

of

the position of the

·•

..... · ..... · ..... ·· .... · .....

............................................................................................................

Machine casing and lubrication components··"·"

th'

....................................................................................

..................................................................

.................................................................................

hook--

............................................................

'3ad

hook

..................................................................

.....................................................................

..

· ..... · .. · ..... · ..... · .. · ... · 2 1

··

.... · .. · .. · ..... · ..... · ..... · ..... · ..... · .. · ..... · .. · .....

, .................... 22

............................................................................

.....................................................

·•

·16

17

18

21

22

23

23

24

26

3.

Feed dog and needle shan componentg

4.

Thread hook components

5.

Needleplale components··

6.

Ridge fanning disc and lifting presser

7.

Disc oscillating and skip stitch components-

8.

Disc locking mechanism and

9.

Thread tension and nipper parts components··

10.

Work plale components

..................................... ; ..............................................

..................................................................................

componenls·--··--·"''''"'"'"'"'"'"'"''""'""'"·

knee

lifting presser shaft parts···

....................................................................................

..................................................................

·· 34

...........................................................

....................................

.....................................................

•·

28

ao

32

36

38

40

42

Page 6

li'!Oh~tJLUJttftiH<ili\ifi

J:k:lll P

®--1'-l'ii

Jl.#.

:;jqltllf

Ill r

9'

WEll..

J>r.J!<.

il>'fa'Jllt-~.

Ill

f'

fl!HI!Wilril<il2fs:t1J.a'Ji<l!lll;f!!l/.\lllt1J·i!;,

tL

r~llif~II1".

@EI"®Illlf'lxifmlJL#WJlll.

¥Iiili

~

((

i<l!lll

i<l!lll.

if'!§>>

!l~~'i'l-:!Jil!i'ltt-llJ\'-1-'.

,

M~Ji\Hl'.

%.

4'11L*fflttffiit~.

lliflit<{Jt.

f!l.

Xif'i'l-51>'1'/ill~lll'®li!i'l.

'1'/illifiJJl;a'JIM'll'.

tJL~®i<l!lll~.

#iirlf&JI!ii&:IJ.

i\Jl~:klll?9.

'JCA9\fllliA;Ii;lllJi#4=i.li'l§'j;,

jg,lfp~Jl.%-.

Jt;;iJ~tl/1iJ!i10.

ltli!O!i/UJ.

H@!i,llJMEi:'!"f'f

'l'~~~r~~~.ffi~ti'B~fti,llli<l!lll;f!l!l~WW~'le.

~?.f-2fs:t1J.!J\f!;;f!!i,llllit:tfll<.

m-l!!UM-'f!!~Jfnll;

~Hll'.

llfili!l*lll'.

(frnmtt.

~.7fi>li/!Ul.l!lffltf8JJI!ilt~i,llllli!!

lii#~~J

~(Jt6t:li:J¥tfLD1l!l.

Foreword

Y.llil'l!ll

!li~;f!l'l'l'Jli!Alil

1031!'1-"P-~lii'i\':~j!J;,

;f!!i,llll'1J'l<11Lf!l.

~~l:kllll"~

litti'B!Ii'.@

~

M

£!ifii!!Y.7U!lta'J

blindstitch sewing machine, another

conglomerate is

of

either Chinese-style

literature covering maintenance, operation, and principles, has been available on domestic

market.

To help customers have a good mastery

"OPERATION MANUAL"

ministrative.

The model adopts needle bar thread take up and swing thread hook system

needle and a thread hook may form stitch

equipped with a regulating device for presser pressure, thread tension, stitch length, blindstitch

penetration, height

needle, ridge forming disc are changed and particular mechanism regulated

now

dedicated

or

of

feed dogs and blindtitch space etc. Only when appropriate parts such

to

customers. This

Western-style clothes such as garments, skirts.

of

is

specially written for reference

tYPe

Model

the essence

103

chainstitch

product

is

widely applied

of

operation and adjustment

of

service men, operators and ad-

and

newly developed

to

blindstitching

Up

to now, fewer

so

straight blindstitch .

C3J.1

the Model meet

by

of

it, an

that an arc

It

is

also

as

. 1 .

Page 7

the needs

by numerous customers.

ated

1.

1.

of

sewing various sewn materials

on

It's lifetime depends

or

repaired regularly.

Read instructions carefully before operating the machine.

not only manufacturing

of

different thickness. Thus it has been well received

quality

*)l.gjiifiji)-

Brief

Introduction to The Model

but also whether it is properly

operk

ZJBOO

~~~m.~~mr~~~~~~~~AA~~~~I~.~~~o

>l<Jit!!IIJ

Ai!!ii~WJI!>I~~

*ilt!lif!Jlti!l'.

~~~.;~;,~~~~~~~ilt~z-.~~~~.

materials such as trouser

clothes etc.

The model

mance, smoother running,, precision fit, longer lifetime, aesthetic stitching, easier operation. It

is one

of

indispensable pieces

Welcome to patronage.

1.

:±:~tt*ni'.m

ll'JHlfliHil;l;,-#$1Jl\<f*'iillJI!!J1'.f

,

lllfii/J~¥;10;)~,

Jf>Jl!i;

103ll'J$~~

.k~Tm~~<~

<

~fl<tL

iJtltil"'<ll.

ZJ600

has

blindstitch sewing machine is ideal for blindstitching medium weight

leg seam, lower hem

fullowing features: Advanced construction, unique design, excellent perfor-

r)

~~!t"JJ.

1illllttR.

of

sewing equipment.

"'~'f~

..

of

garment,

!lf,!'l!i!],,

~~11\'.

and the fronl

~i':.

of

~;!Etle*·

West-ern-style

:10!

1.

Main Technical Specifications

2500

(I)

Ji1<""~~JJJ!!>:~

(2)

lllf!E~WM

1t /7)-

2000<f

. 2 .

/7)-

Page 8

< 3

>>JOiiH<Il

W~lilliJIEtt

3-8

1:1

il!:J!t

2:1

<s

> Billlli'l\IE

< 6 >

JlUIHII.fr

m

JIUilli!

(

8)

1!!11L:W

< 9 l

1IL

(JO)til~ll>:!li:

(l)Maximum

(2)Normal

(3)Stitch

(4)Blindstitch

(S)Lift

(6)Needle:

(7)Thread~

Ill!

>I!

JUt-!!>

sewing

length:

clearance

sewing

speed:

space

of

speed;

ratios:

presser

foot:

7il!;jf(

GLXI

14.

270W

SlOX

2500s. p. m

2000s.

'!)!

NM75-!00(LWX6T#3-#4l

5-7.

Stex

360X245(

24.5~Jf

p.

m

3-Bmm

1:1 2:1

7mm

NM75-100

14.

S-7.

Stex

.:t!D!iG~

of Modle

cotton

¥:X

14.8-7.

jt

X~)

GLX

thread

4tex

ICLWX6T3#

or

~1\11~

14.

8-7.

-4#)

4tex

polyester

(8)Eiectric

(9)0verail

(10)Net

3.

;f!L~rt;J'ti;~:fDi~f'F;ft~

3.

Machine

1.

Machine

o

>til

M~~~~~ti!JI,~.T-~m$ti!AL~~B'J~$~.m~~~.ull!l~~.tr~~m~$~

flli\'H'f

Fo,

motur

power;

dimension:

weight

installation

Jl,

B'J

1±19:~1f!ili

of

machine

Installation

l!H!:

fflxt~~

head:

and

1\iil'ii;

270W

SlOX

24. SKg

Operation

T-ll!*l'r:iffil

cotton

360X

thread

245(LXBXH)

Preparation

i'!~tft'~,

1!.1

!Mi

!1:~1'1',

il~

'EF

•

3 .

Page 9

(1

)Unpacking

machine head

Unpacking

macnine head

nent

parts

li.!.t

to

avoid losing

( 2

)Vi.!!!!

CD

"11

machine head from its packing box. Be

such

as

and

accessories,

l¥J

,_.,ill;

Jt

m111

thread tension

parts

and impairing production.

~

ffl

fi!IIH!l111!

don't

assembly

throw

111-"i

li' :t;

any packing material

;tJ

and

tiuead

~:it~

.

l'i'

* l'ii ill

sure

not

guide etc.

about

Ill

fll ill

to

damage projecting

After

unpacking all compo-

without

il!i

fll

checking

It

jji

il!i

if.!;;

parts

of

the

packing

l'iH!l1illffi

:it

Ill.

®'ilffjl.ijl)Vi.-"iaill:it!ll.

ailllUJ!Il!!!!J:

®'ilf

Ill;;;

•

@'ilf

1:

•

l'

Iii

lf

EJi'i,'ilf/i1illllJ~,:j{fj;ijq'jj1;!1,1lJJi;,~/i1J&Ji;{i'l.

(2)Fitting

(j)

machine frame

Frist

connect

?l-MU

-"i

rear

iii

.

.p

II!

VI.

.!Uilill tr 1-f:it

stand

lliJ!Ill1ll

side

fl

a

ill

support

'II!

~Jr.lHf

It

,

and

ttl'

treadle

Fo

Ill

1: lli

l1ll

fl

aill*l$!>Ifll m ll'ilf a ill

lf

It

!k •

ill~

If

li1illl¥J

shaft

beam with side frame

li'

:t;

-'i!lli!!!

fl!il011f

(left

Ill

and

right),

ers,

ter

to locate the treadle.

1:. Jf

l::t<Al~ll>"l",

~t'f\jjllJ)i;<IIJ

and then link up

®Mount

@Put

the

and fix

@U;>nnect

regulating

c 3 l Ill!!<

W!.:

<D'ilf

!ii;llt l'li

li£11l!

fli'LFo

@:j{f

If

Jll!!l

@!ll;J: -.

treadle

the

motor

table

the

table and machine frame with washers

upper

position

ill;

li

:j{ffJl!

Jfill~&O<~I1l!Ql!(fl>,

ff"

2).

!li

* "N.. •

onto

onto

and lower

of

treadle

'fi!"D",

Q'J•i<

K ".!l.l'

li'

with

the

machine

pull

(left

Vi.

ill

Jii;llt "C", !llill

ill

~lt"F"

f\jj

"L

"-"i

:t;

fl'""

treadle

table.

frame,

rod with motor and treadle

and

lio

il!i

l!!lil.

w.'ll.

shaft beam by treadle

partition

right,

h\l:l'IJ

:j{flll!l,lll;i;l'Ei/W:l:CI!I

Ji!ilii!

:it

~t

the

and

high and

l'lilifll

Hl!

!l1;

II!

"B". l'li!i'fi!"E".

A

l't.

,

If

Ill

m

lil~t

table

at

wood screws.

low),

9'.

II<

lk

!!l

lf

1J!

lf

-"ill!

!k"'

shaft

and treadle

the

centre with four table

lever.

put

on pull rod

fix the treadle.and pull rod joint

Ill

!k "A"fl<

l'l:

l'li¥4'11!

"G".

!).

ll\i

i/ill

"J"Ji!ilii!

m

x<

II£Fo

*

I!!

lX.ll!:l'IJ a ill

'l"fll"H"

Be;<\\

mm;;;

shaft

joint.

Y'i

I

tEa

base.

wash-

Fo!t

)f

!I'll>/

illl'

Af-

•

lll'P

II!

m,..

ill:i!l'/l.

~t

&:

**

~

!1£

T'ili'ii:

:~~:

;5

•

•

.:!-

•

Page 10

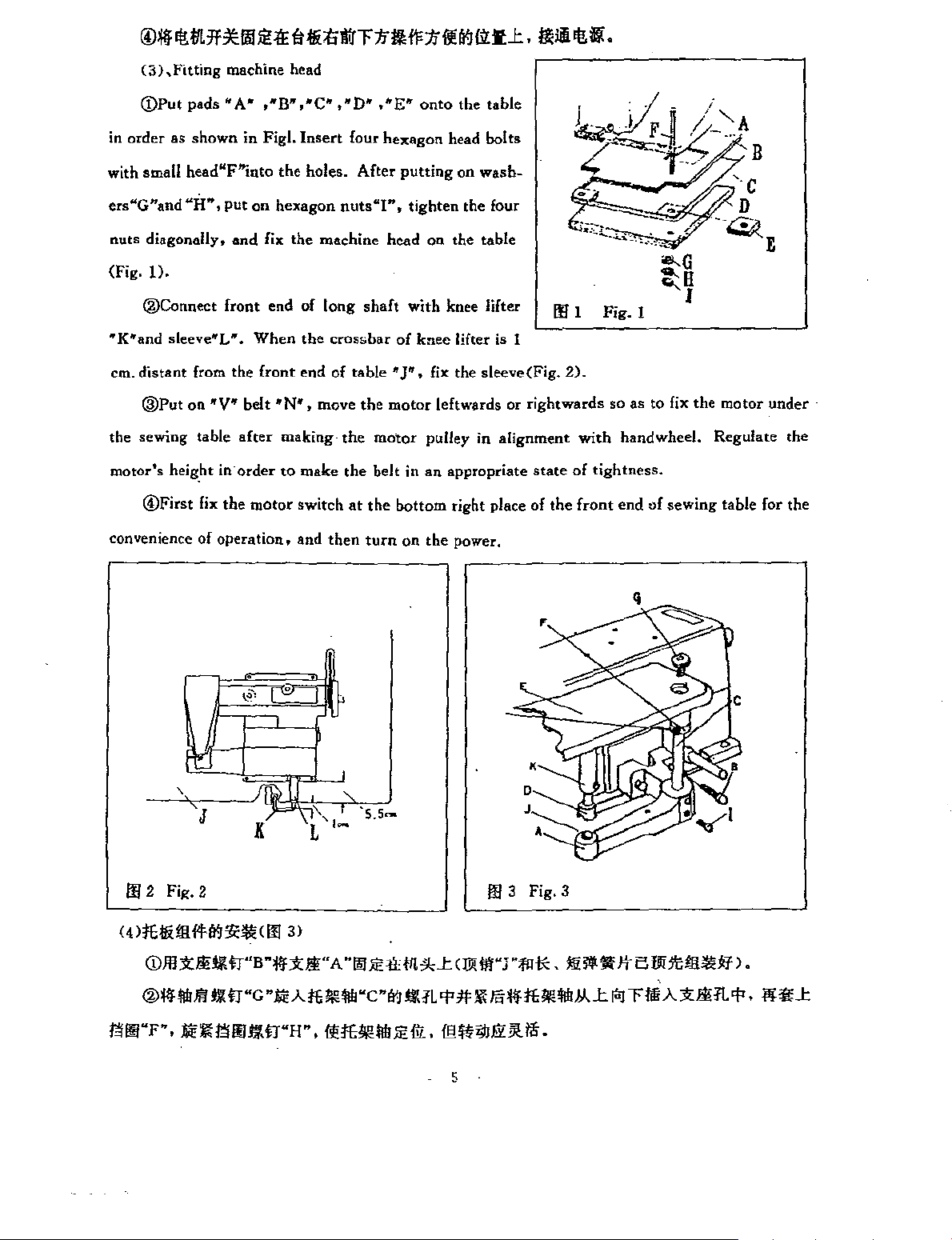

(3),Fitting

machine head

(!)Put pads

in

order

as

with small head"F"i.nto

ers"G"and

nuts diagonally,

(fig.

1).

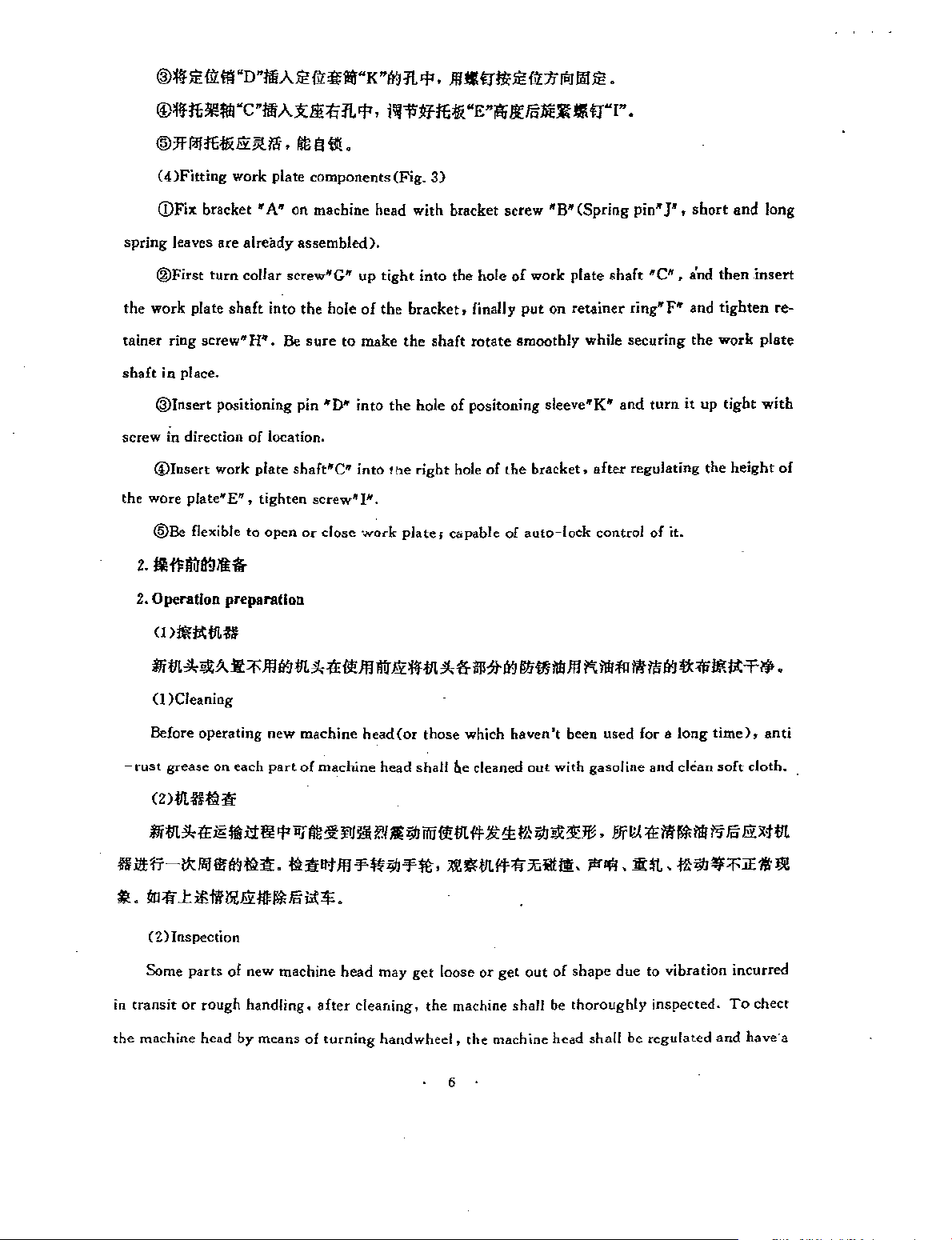

®Connect

"K"and

em.

the sewing table

motor's

convenience

sleeve"L".

distant

@Put

heig.ht in-order

@First

"A

shown

"H",

put

front end of

from the

on

"V"

fix

the

of

operation,

• ,

in

Figl.

on

and

When

front

belt "N", move

after

motor

"B"

,"C" , "0" • "E"

Insert

the

holes.

hexagon

fix

the

machine head

long

the

crossbar

end

of

making-

to

make

switch

and

then

four

hexagon

After

nuts"l",

shaft

table

the

the

motor

the

belt in

at

the

turn

onto

the

head

bolts

putting

tighten

with

of

"J", fix the

motor

bottom

on

on

wash-

the four

on

the table

knee lifter

knee

lifter is 1

sleeve(Fig.

leftwards

pulley in alignment

an

appropriate

right place

the

power.

table

or

llfl

2).

rightwards

with

state

of

tightness.

of

the

front

""G

~H

of

sewing

I

motor

table for the

Fig.l

so as to fix the

hand wheel. Regulate the

end

under

0

t..51

,..

I

'

'J

I!!

2 Fig. 2 m 3 Fig. a

w

;'tj!i

!II ffW!i'

CDJll

x!IH.Ofi""B"¥fx).;f[" A

®¥flil!ii"l

111

1!1l"F" • .oi'

:i1t

ffl!ill_

,/=''\::'•,_

K

ll<

<IE

!¥

fl"G ".oi'A!t

ffllil.\7.

WH"

3 l

L

lil!lll!

,

ll!lt!¥1

"

·s.s-

"lilllE

"C";<j

1t llleU:

ll\IL

lll!

lE

ffi •

<ll!

lii"J "f!! * . llHI"'f

'I'

it:!(

l!ll'i

'lllbie

5

§*f;'tlll!lii!M.J:

!l!Jii •

It

Bffiltli!ll<!lf

i"J

Tlili A

xJ.;ffl1.

l.

'I' •

l'l''l!'l:

Page 11

@jlfjl;

Ill:

Ill

"D"Ii!lAJE

(l):il!'ii!"K

"ii'J'/1.'1',

!llll!tr!JilE

fll::IJ(oj

JIIJE

•

@jlfjU!!lll

"C

"!ill

®'lf/l!Jlijj(fi!i<lli.

(4)Fitting

CDFix

spring

tainer ring screw"H"".

shaft

screw

the

leaves are already assembled).

®First

the

work plate

in place.

@Insert

in direction

@Insert

wore

@Be

work plate components(Fig.

bracket"

turn

collar screw"G" up

shaft

positioning

of

work

plate

plate"'E".

flexible

tighten

to

Ax81:ti

11.

'I',

l~ll'flJlijli_

"E"i!li

!l'Fo.o;;Jt

f!lllllll!.

3)

A" on machine head with bracket screw

tight

into

the

hole

Be

sure

to make

pin

"D*

into

location.

shaft~~"C"

open

oc

into

screw"

dose

of

the

IN.

work

into the hole

bracket,

the

shaft

the

hole

!he

right

plate;

of

hole

cbpable

of

work plate

finally

rotate

positoning

put

smoothly while

of

lhe

of

auto-lock

1.!\

~~'B"

(Spring

on

retainer

sleeve"K"

bracket.

<!"I".

shaft

and

after

control

pin"JW

• short and long

"C",

ring"F"

securing

turn

it

regulating

of

it.

a'nd

and

the

up

the

then

insert

tighten

work

tight

height

re-

plate

with

of

2. Operation preparaUon

(1

>ll!litll!ff

mm*~~•~m~m*~~ffl$fijlflll**$*~~~Mm~M~~$~~~ll!lit~~.

0 )Cleaning

Before

-rust

grease on each

operating

new

part

machine

of

machine

head(or

head

those

shall

which

1\e

cleaned

haven't

out

been used for a

with

gasoline

and

long

dean

time),

soft

anti

doth.

<Z>ll!fftHf

mm*~"'lll;;:

Ba~-~~@~~~-~~~ffl¥~;;tJ¥~.~~ll!#~~~m.~~.I~.W;;tJ~~~~~

~

• m

~

J:

i£iiii>Lfi

(Z)lnspection

Some

parts

in

the

transit

or

rough

machine head

m

.p

11'111<

Fo

of

new machine

handling.

by

means

BJii!l1!:

iit * .

after

of

turning

l'J

ll!l!!i

head

cleaning,

At""

may

hand

w

!>!

get

loose

the

wheel,

m #

:~t

or

machine

the

machine

1o

get

t<

""~

out

shall

'l!'ll' •

of

shape

be

thoroughly

head

shall

Elfl'l<E~I*

due

be

M t5

to

vibration

inspected.

regulated

Fo

fi>tll!

incurred

To

and

have·a

chect

6

Page 12

test in case

some

( 3

I!Lfl'~E~~ff~*tt$K~~A~~~WIJL

$

<1!1

ol

abnormal phenomena

parts

etc.

)IJLfl'

if<

1ft

4)

,l!lllHiEIIL#ill:!iJl!li!01li!!Ui

such

1i

as

running difficult of machine

!lJ

if<

lit.

head,

getting

loose

of

~11<!!

~~-~~~~~~«.~$~~11Lfl'~~E~

n:St#~~~*li!!*~~*~~~w.

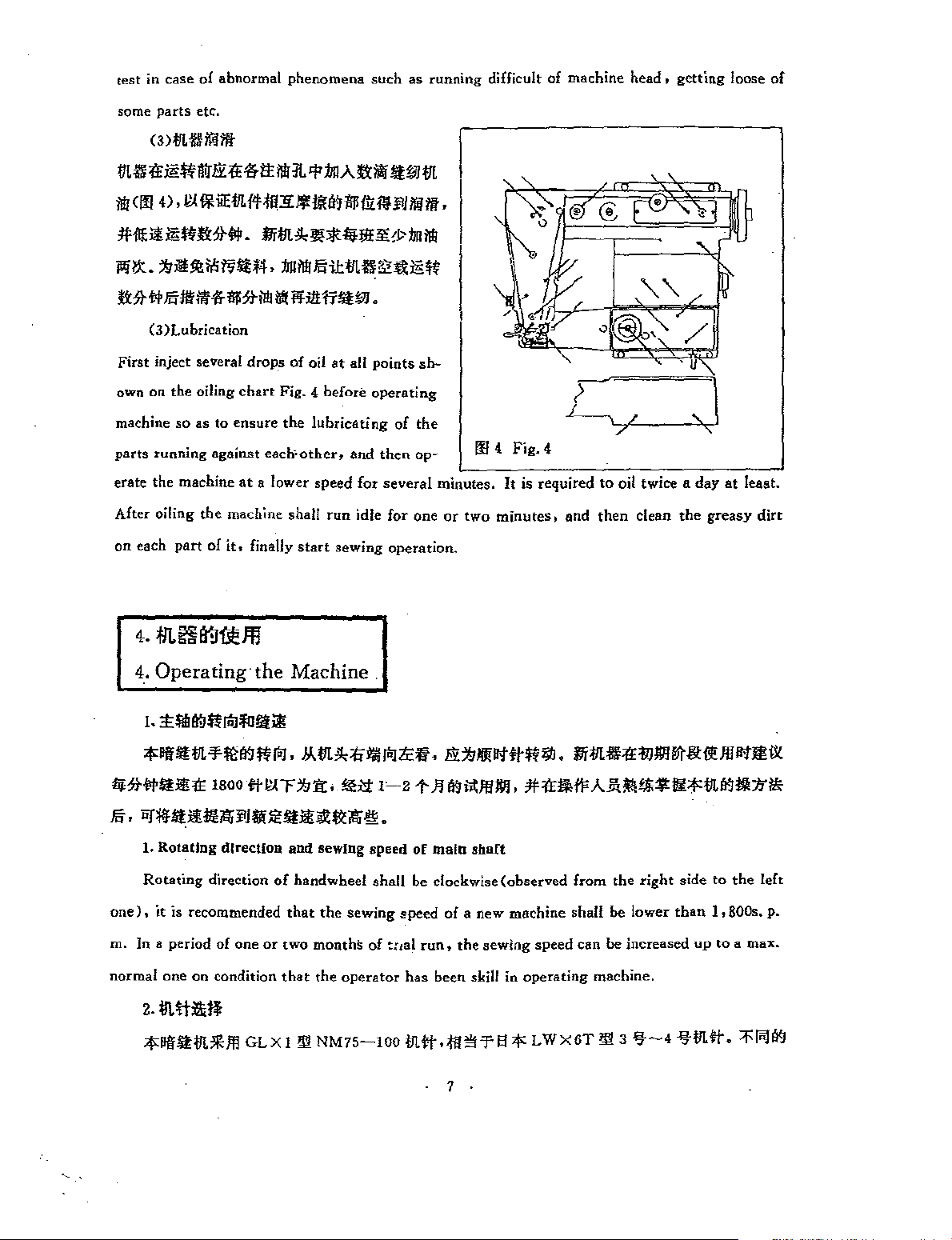

First inject several

own on the oiling

machine

parts

erate the machine

After oiling the machine shall

on

iE

~lt:St#.

(3)Lubrication

so

as

running against each>other, and

each

part

of

4.-

Operating·the

drops

chart

to

ensure

at

a lower speed

it.

finally

flii!L

!1,

J!>lt

of

oil

Fig.

the

start

Machine.

4-

before

lubricAting

run

l;j;!lf.¥

at

sewing operation.

all

points

operating

then

for

several

idle

for

ol>

of

bn

sh-

the

op-

one

$

minutes.

or

m

two

4.

minutes,

Fig.

4

It

is required

and

to

oil twice a

then

clean

the

day

greasy

at

least.

dirt

].

"'lilf.l~

;f>:~~IIL~m~~M.~IJLJI,~~M~~.ff~~~#~~.flii!Lfl'~Wlll~&~m~m~

li>:SJ-#*1:!!~

E·~~*ii!~~~~~*l:i!~~~®.

1.

Rotating

Rotating

one),

it

is

m. In a period of one

normal one

2-

jlt~>lill'

;tlllf*I:IJLJlO!l

loJ

'ID!iiii

1soo

fti!CF~'ii:.

direction

direction

recommended

or

on

condition

GLX

and

sewing

of

handwheel

that

two

monthS

that

the

!l!l

NM75-100

!\!>'t

the

sewing

operator

1~21-

speed

of

shall

be

speed

of

~:1al

run,

has

lil.#.il!!'!'f S

. 1 .

Jl

~~mill.

main

shaft

dockwise(observed

of

a new machine shall

the

been skill in

#~!;.ii'AJJ;~t,O:!tlll!;f>:IJL~lll:lfl*

sewing speed can

operating

;f>:

LWX6T

from

be

machine,

l!13

the

right

be

lower

increased

't-4

side

than

up

'tilL

to

the

left

],

BOOs.

p.

to a max.

!'I'·

'l'i"J~

Page 13

2.

Needle selection

The

Model

3ft:-

4

f:t:

priate

size.

3.

f;t!£-'Oi!.ttr.!~

~Loom~s~~~~~~@~m~~~m~m~.~w~~~*~~~T~~~~~~m

ftf!l

!tl!l<

il.tt.!lf!la-'O!i*'lr.!~

selects

of

model L WX 6T. A

~

11

IJi

•

needle

NM75-

certain

100

kind

of

of

modle

sewing

GL X 1,

material

on

equivalent

shall

select

of

Japan

a needle

-made

of

an

needle

appro-

Select

4.

~>

tr"B",

J:ll

tr"B

W'3

75

90

100

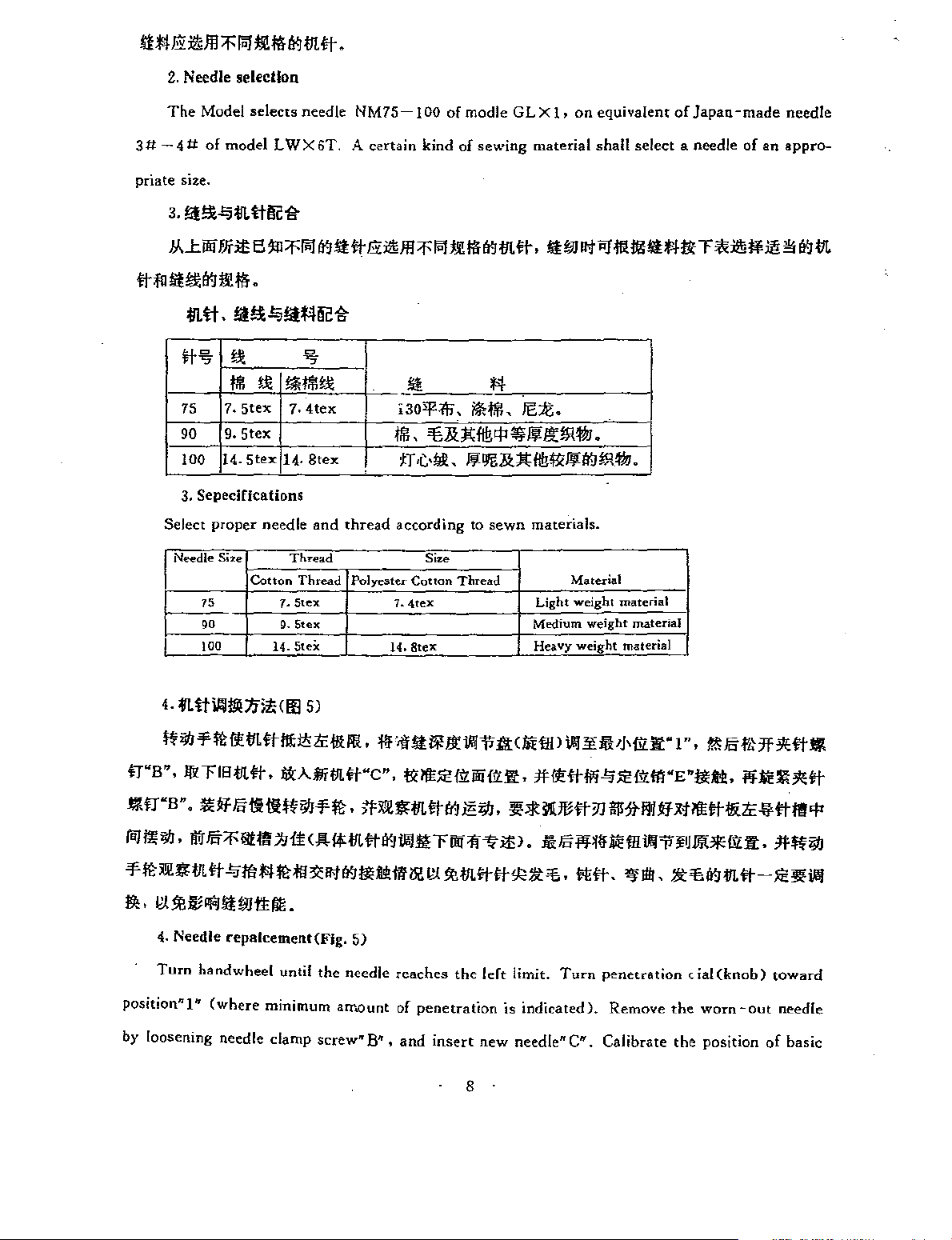

3. Sepecifications

Needle

7.

9.

14.

proper

Size

75

'"

!00

!!!

!Nit!!

5tex

5tex

5tex

needle

Cotton

~!Nit!!

7.

}4.

Thread

7.

!).

14. SteX

il.ttWl!O:IJi'IHtll

iJIJ-¥

mit

m

tt

l!l:i!i

l!<

TIS

m

ft

,

lli:AIJT

".

!lUf Folt ll!

I>

~

"5

4tex

8tex

and

Thread

Stex

Stex

SJ

ti

iJIJ-¥

thread

Polyester

liHI<

IJ!

WC",

IB

,

~

_!t

i30'l':ffi".

*if

i*lli!.

JEt.

lli!.'B.&l';fl!l<P'I>Jll!itlll#J.

IT

according

1.

1<1.

•

'ilf

01

l'l!

~m

•C•!ll..

Cotton

4tex

8tex

!t

!l<

~IJil.&J!:fl!ll!IJll!(t,J!)l#J

to

sewn

materials.

Size

Thread

Light

Mfflium

Heavy

lJi!

~r

!1!11'

:lll:

< liun )

I!EJE

{!1.

iili

fii.ft •

#I!

tt

It!;!;

iJIJ

,

J!:;Jt

Material

weight

weight

ll!"'

ttli'i

1/IU!Ht

•

material

weight

material

material

>~VHJz.r

-'0

lE

j1J

'ill:St~l

1 • •

fii.

ill

"E

~Xi'

~For&

"lUi •

I!E

~l!tti

7f

;~~ott

•

jlj'

i1;

:I!;/<~

-ll'

~lll

'I'

(i!J

1!

iJIJ

•

Jitr

Fo

~II!

If

1.1

it

<,!;,

U:m

tt

~

illl!iH

oo

1f

~

ltl

.

.ll:

Fo

i'i'1~

-¥m~~m~~m~~m~~~~~~~~~m~~~£~.~~.~®.£~~mtt-JEJ!~

p,.

~~llill'J~Wttlll<.

4.

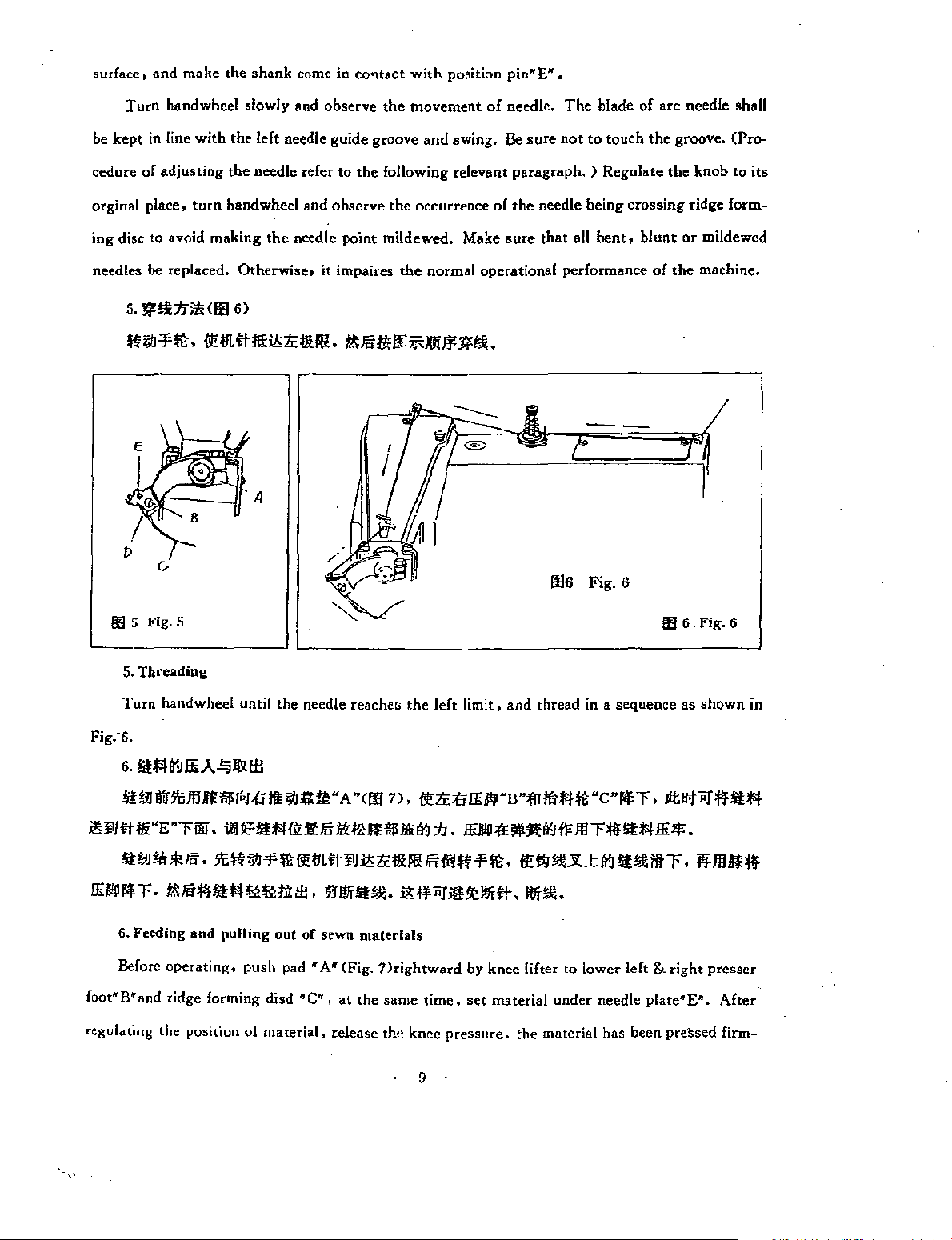

Needle

Turn

position" 1"

by loosening

repalcement(Fig.

handwheel

(where

needle

minimum

clamp

until

5)

the

needle

arnount

screw"

B",

reaches

of

penetration

and

insert

the

left

new

limit.

is

indicated).

needle

Turn

C"'. Calibrate

8 .

M'

Ill

il'li\'JIJJ!OIE

penetration

Remove

cial(knob)

the

worn-

the

position

fii.ft • JHt

toward

out

needle

of

basic

iJIJ

Page 14

surface,

Turn

be

kept

and

make

the

shank

come in

handwheel slowly and observe

in line

with

the left needle guide groove

CO'ltaCt

the

with

po~ition

movement

and

swing.

pin"E".

of

needle.

Be

sure

The

not

blade

to

touch

of

arc needle shall

the

groove.

(Procedure

orginal place,

ing

needles

of

adjusting

disc to avoid

be

replaced.

5.

!i'!l:IJ>ll<lfl

«~f~.~m~m~£~m.~s*oc~~~~!l.

the

turn

handwheel and

making

Otherwise,

6)

needle refer

the

needle

it

to

the

observe

point

impaires

following relevant

the

occurrence

mildewed. Make

the

normal operational performance

-7~£----,t~~.,r

r

0':15 Fig. 5

paragraph. ) Regulate

of

the

needle being

sure

that

all

bent,

lll6 Fig. 6

the

crossing

blunt

of

the

IE 6 Fig.6

knob

to

its

ridge

form-

or

mildewed

machine.

~~

5.

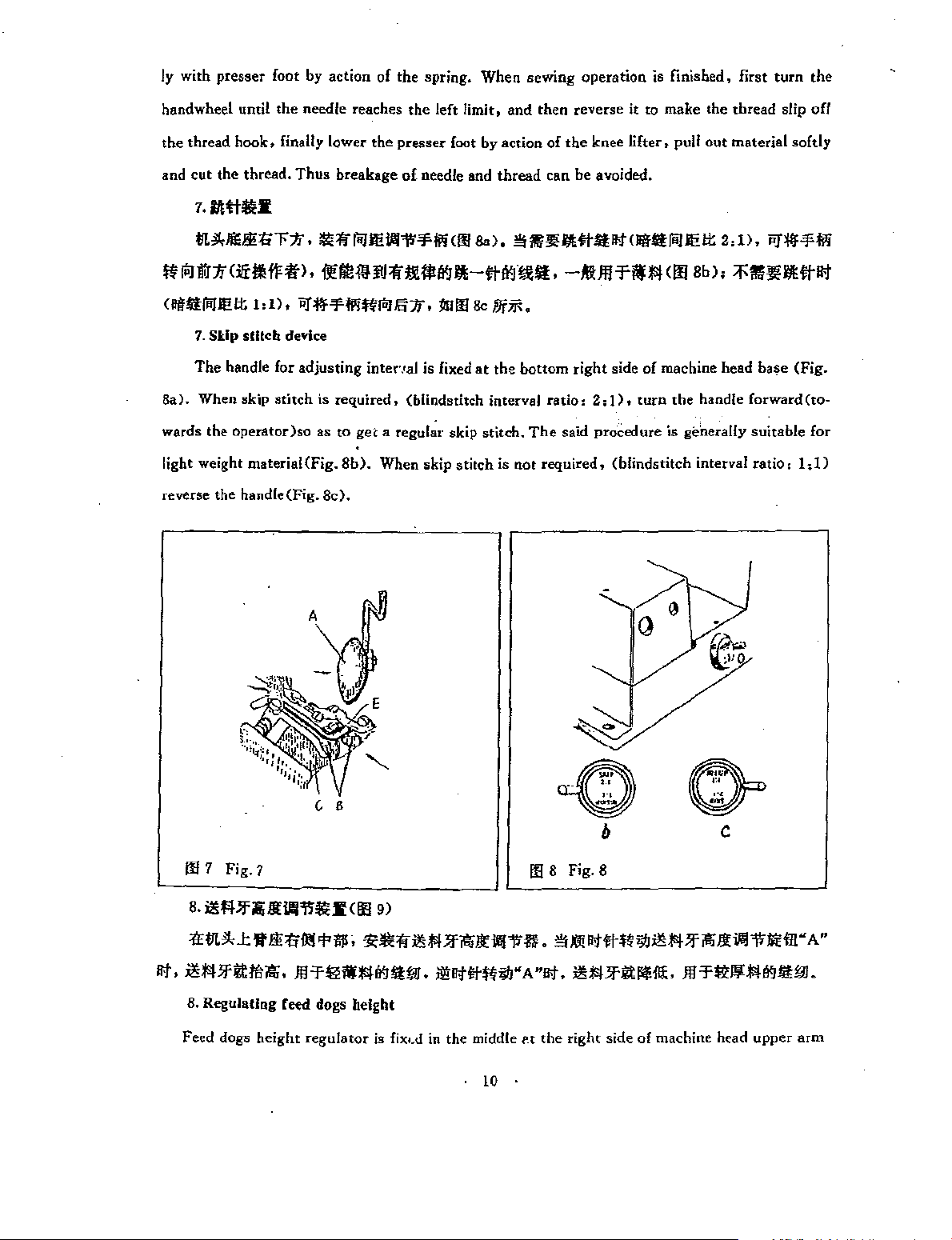

Threading

Turn handwheel until the needle reacher;

Fig.·6.

6.

Ill

l'l

!9

IliA

_,.lilt

1fl

l'f

w ll"lltJ!l

il'tj!Jft

l&

"E

!li:W!Ii

IEIIII!fol;T.~s'ifltl'l~~m~.~~lt!al.~~iiJ~~~~.~!l.

6. Feeding

Before

foot"B"illld ridge forming disd

regulating the position

If

lil!"'

""Filii • il!

*"'

.

5t

and

pulling

operating,

:fi

111

~am·

Jfl'fl'li.\1:1!';.6

~>

""f

~

!l! m

~"J

out

or

sewn materials

push

pad

"A"

~c~~,

of

material,

release th,, knee

A·

1!:

l!HUI!Ill'

(Fig.

at

the

the

<00

' > •

i'l'£:fi

(!<)

~

tcl!U!lsiflt>

?)rightward

same

time,

9

left

limit,

and thread in a sequence as

!EI'I"B

:h

•

IEIIII'!'E

by knee lifter to lower left &

set

pressuce.

·m

!I'

jil'(l<)

¥IE • "'"'

material

~he

m u

~

11'

J!l

!l!.l':

J:(l<)

under

material has been preSsed firm-

•

cnlfol;

r •

lit

n;-

r'IHtl'IIE lf: •

ltiai

11t

r • N

right

needle plate"E"'.

shown

iiJ

'if

!Ill*

presser

After

in

nu

'If

Page 15

ly

with

presser

foot

by

action

of

the

spring.

When

sewing

operation

is

finished,

first

turn

the

handwheel until

the

thread

and

cut

the

7.1/ttt~I

IlL

!I, JlliEIHir:lf •

ff

ill!lU:If<lfr!IHI'if>,

( i!lfftfoill!!

7.

Skip

The

handle for

8a).

When

wards the

light weight material<Fig.

reverse the

the

hook,

finally

thread.

!t

siUc:h device

11kip

operator)so

handle(Fig.

Thus

I •

1)

, PJ:jlf-J'jjljffilJ Iii

adjusting

stitch

needle reaches

!10

~M!11!JIJ:ffi!U!VJI!t-ttl¥.il'.llllt,

is

as

8c).

lower

the

breakage

=If

foil

11!

intenal

required,

to

get a regular

8b).

When skip

the

left

limit,

presser

foot

by

of needle and

IIIli'

-J'jjlj

(

00

& > ,

:If , 11100

is fixed

(blindstitch interval

Be

skip

stitch

at

stitch.

and

action

thread

!1!

/)fjj; ,

the

bottom

is

not

then

reverse

of

the

knee

can be avoided.

II

'lif

/llitt!t

-AlJI!

right

ratio:

2:}),

The

said

procedure

required,

it

to

make

lifter • pull

I>H

II§

lit

foil

'fMJS!

side

(blindstitch

<ill

of

machine head

turn

the

is

the

thread

out

material

11!

!t

2 , D , PJ'ili-l'lili

Bb),

~\lliJ!IIIittlit

handle

forward(to-

geD.erally

interval ratio 1

suitable

base

slip

softly

(Fig.

l;D

off

for

C B

IE

7

Fig.

1

B.

~fil)fji;!f{l/llii'~Jf(lf!9)

lit •

'iffiLJI,

i!JS!

B.

Feed

J: 'It

!l!t;

Jfttltl~

Regulating reed dogs height

dogs

•

height

fll!

<I'

lill•

'!<~'If

Ill

'fi£iW#I¥.it!liiJ,

regulator

is fix..d in the middle

i!S

lSI

)f~

Ji'

J!!litttffijlj" A "lit,

. 10 .

lll'll'

III B Fig. 8

fi

. l1j

X!!

-'!#

f'_t

the

right

b

lit ttff;;!) i!S#

Jftti'l'il<,

side of machine head

)f

Ill

'ft!(JJJS!il'lilflil!.

c

~

Ji'llll\'li<fll"

upper

A"

arm

Page 16

base.

Turn

the

controller-

knob

11

A"

clockw-

ise to raise

bt weight

"A,.

counter

5.

5.

Ill

fi'.J

-ll!JeAI.;!~~~EY'!I!Illlitt*m.w~~!l!ll~~~~.:;;:?£~~~t!l~'lt'>'"Jll;~~li1l!l"

ttiti

T , B

JUXI!~tt~~~~.

the

feed

dog

for

the

material;

clockwise

turn

the

to

lower the feed

sewing

controller-

of

lig.

knob

dog.

~~rtil'OOI!

1119

Adjustment of the Machine

!.

!£jj;i<tll:®il1lil<lfl

~~~~~~~~~~.~~~m~L~~5Ln~ll~*OCil1l~*mlliT.§!l~*oc~

T

l;l

lti(A!l~*tll:il1l~Jii<.•i;li'll'!lli!

L~li!J

!lX<tlf!i,

lit

A

!l~

*til:

'llf~~t!l~

l!:'¥l1iii<

10)

<Flit

;li-~>'1

'It'

.ll

~!fi:fitH~-F~~,

ll'fl\"111

&z.

•N!;~

R~llill:*!tJt;l;:,

¥-I!!IIJI:

i)I.P~

<P

, i!!

HIOiiE*!l:WlNtJ!!Wo,

Fig.9

"'If·~

i"

'If.

~

lit~~

'l<!ll1:tEJ!U4110•t·llti;'!t.<l'~l!l1!1:1£l'l'Jf~f1illl

iJ.

:h

\1'1

~>'Hl'l

•

:II'

'!lf

m•1i:!lift'll<;ll;*!t·

l!!

fill

!fiji;

JIJ

~Ill

liT

It

if<:

I!:

'>'~!lill:

*!till'J' ,

*i!!!!Wm!lill:*lt~

l!l~~m:ha-s•*z~fi'.J!li~~n~ttm.lll?~~-•fl~I~'llf*.~~·~~!lill:*

!f.

1.

Regulation

Depress

srm

base by left

end of

can be

the indicated

of

to a certain

in

quired

mean

length 'according

the

felt

the

machine base.

stitch

length is

turn

Number

stitch

controller-plug

by

recess

the

itself.

o£

stltcb

lengtb(Ffg. HI)

controller-

hand

left hand. Keep depressing

number

of

required,

hand

on

the

The

to

button

while

turnirtg

is

inserted

on

the left is in line

The

steel ball in

the

controller

turn

wheel

counter

left of

the

adjustmer.t

sewn

materials

located

handwheel

eccentric sleeve

the

clockwise.

pulley indicates

ran:~e

and

on

the

into

a recess

the

botton

with

the

the

hole

of

handwheel

the

of

stitch

processing

upper end

by

right

of

and

graduation

feed eccentric sliding sleeve has been

by

clockwisef

changing

lengt~

requirement.

of

the

hand. Click

the

eccentric sleeve.

turning

action of

is

the

on

the

if

an

of

stitch

{rom 3

rear

of

can

be heard

handwheel

right

of

spring.

increase

length,

to

8mm. Select

the

machine head

The

falling of

by

the

front

In

short,

in

stitch

the

numbers

upper

when

the

the

right

hand

oblique plane

inserted

if

a decrease

length

doesn't

the

ideal

stitch

lower

plug

untii

in-

is re-

.

11

.

Page 17

2.

Bll~;ltllll:

l'ET

'If

•c

"!'Jiili

ll!I<Ji! T Ill iii

~~ii~~.l!lJI!ii~~~N!l'~ffii!J"P,~~~~~Aft~~.

~il!l'\5

Ji(I'J

'I'll!!

'0:!1<

(I'J

=lflt!

*'f

lt

ft!!l' , ilii

iili

II!

!l'

il!l"P

til ,

1'::!'1

'I' f'l JHo!l! • A",

it

(I'J

ll!!l'<iH~llllJI!

lii*'f

(I'J

JJ

!l'

"'t-It

Moi!IJ<;I:l

ilii "'tit •

m

JI!I"B".

1.!1

Jlt

It! *'flt

l'E!Uillltr

S:

Jl!!l!f~~~llf!l!.

~llf~~~llf!l!,lt!*'flt*~·~*ffliift!Jl,

llim

II!"B

".1:0<!

z,

Adjustment

Regulator

which knob"

tration depends on

ing of thickness for

shall

be

made.

it in

an

ideal

tion1

turn

Graduation

tion

of

the

for ridge forming disc height is fixed in

A"

Regulate

state.

the

knob

knob(Fig.ll)

lt!*'fltl'ffif

~ll.

o!

bllndstllcb

is located

the

height

sewn

Turn

counter

on

the

indicating ring

••

,J,II!iift!ll'

Ill

jj\

T

II!

It

lll!l

(I'J

sewing

and

out

of ridge forming disc NC",

materials. Before

penetration

the

knob

clockwise to

penetration

of

which indicating

accordingly

clockwise

raise

..

B"

indicates

n

~».&>Ill~

operation,

with

to

lower ridge forming disc for a

ridge forny.ing disc for

the

~(I'J:If

the

middle

11

ring"B

the

changing

is located. Blindstitch

but

penetration

a trial sewing

degree

of

of

1'1

<III

of

the

exposure

an

penetration

I1J

•

lower

changes

runing

of

for

decrease

increase of

and

arm

with

several

Stitching

rotative

base,

within

sewing

penetration.

the

stitches

to

of

penetra-

pene-

chang-

make

direc-

/'

~~~raduation

Ill

10

Fig. 10

3.

Hif'!lli:!!i:IJillli5<111

J~.;lft

!11H11.1!l1l'o:Jt<!'J~~.~~~

*'f~"A

llffl":lfl'l~~illl"Pl!!WB",

"(I'J

Hi:IJill'rri!I"P.

3. Regulatfon

of

12)

nlltl~~.

\f!lli"(I'J:Ifl!<~.

HiiJIII:'J'.

the p.-essure

o£

mate..J~tl

ep

JJ*'f, l\\l*'fli'J!l • fli w l!f

Pli!l!f~~~\f!l"Pli!!WB".

il[Jil'f!tl\\ll!L

refalner(Fig.

.

12

m

11

Fig. u

12).

.

~·

m il!lll!t.!lfJJ!l •

Bi:h~*,

il[Jil

'fiHh

~"Hi

il!

Page 18

The

needle

plate

of

this

Model

is

a

unive;-s~l

one,

and

suitable

for both light

weight

and

heavy weight

pressure

sewn materials.

Regulating

A.

B.

4. Position regulaUon of needle

<

1l

Ei:lll11:

l!HI!:illUT"

!i'i'il'

ill :llll! n

(l)The

The

C

...

(Fig.

Turn

Turn

!Ill

front

I3a).

sewn

of

material

procedure

screw"B"

screw"B"

ii'ii!L

~

1>1'

lll •

front

and

If

materials.

clockwise

counter

VI.

WB

A"

,

litr

and

the; rear

rear

positions

the

needle

retainer

is

as

clockwise

"litr

J1i

fHiJit

of

is

shall

be

regulated accordingly

foHows:

to

increase

and

Fo

i!L

.it

;/<

"D"

position.

oC

needle" B" shall pass

deviated from

pressure

to

decrease

needle plate.

It

if

It

<00

!3b

t1i

ti: ~ It

l.ffl

the

centre.

with

for heavy

pressure

J!i

~n'lt

weight

for

light

"C"

•N-

1ill

!'J

i!L.W:

the

eentre

loosen lock screw" A

the

changing

materials.

weight

l!Ht<

00

,

lt

IJJ.

of

left needle guide grooVe "

materials.

!3a

l •

#!Ill

FoVl.fl

...

of

thickness for

llll

Ji1,

i!L.W:

l'tft

, move needle

liifJ;

Jf

ll<

clamp

...

D"(Fig.l3b)backward

said positions complies

with

and

forward in a frame

the

requirements.

8

tighten

of

reference

the

lock

to

screw.

the

needle

shaft.

After

A

III

12>

Fig. 12

Q)IJJ.It"flttliti:%1tJ!i"C"Iltlliiie~:fj;:'f

@IJJ.

#

"!

IJ\

It

!P

t&

"1"

El:

~II!

!Ut

,

@t!l.lt"f#tli:ti~ltlfiltllii

<K

L

!!illiil~IJ!tfjUJ<.

!!I

13a

0.

3

~lit'

Fig.

I3a

00

13b

Fig.

13b

the

ill!

.tl£

VI

fl:

:f

.iE

liUt

,g,

%1<

Wilt,

WI

!ilL

IJt

lt~la~

.

13

•

.

Page 19

i'i

J1

il!ll":lfll<,

Jl:ll!

il!ll"llHJ"I",

JtlitLt

'It

It

!ftl!tril'i

ttfi:it

1J!Jttfix'l!!<Plll!ft'JWi

!E

..t

1'

Ill!$.

1Llltt

>1

Jt'l!!!it m ltm·w. l'i'!liiJIJttfi..tlllft'J

& -':;lit

fti>'J

;lli ilfllll'U;f

{';

_tjj;

:!iPltllt , l'i'l<

!itftj&xll!'itllllUJ

(2)The

There are three locations between

(i)The

shall

be

®Be

@ Make

right

needle guidle groove.

Incorrect positioning

The

Loosen two

die plate movable. When

the

requirement,

positioning

space between

less than

sure

following is

,

0,

3mm.

to

make needle

the

tip

bracket

tighten

It

ff-j&

of

of

the

will

the

procedure

set

the

bracket

location

the

Jill

)E '!t.iUli>'J

the

needle

needle

resul~-

screws

relative location

and

come

slightly

cott.o!

ir. breakag-e 'Jf needle and thread

of

regulation~

"H".

set

screws

lll.II;J:

needle and the needle

the

right

and

<Ill

15)

o

bottom surface

into contact with needle

into

the

bottom

turn

two

bracket

of

the needle and needle plate is in accordance

of

needle

plate

in

plate(Fig.

of

the

left

guard

surface

etc.

regulating

place(Fig.

14)

~

needle guide groove"C•

"J".

<KL

arc

screws

15).

surface)

"I"

to

make nee-

of

with

the

c

m 14 Fig.

""'..,>rill

\I'!

'I!!

!3b)

I<

t~

(3)

LeftJimit

point

shall

16).

The

14

ft'1

:n

11!

oo"F"'f

1f

II<

,

I>

iiiJ

,

'il'ft

!<Sf!!

The

left limit position

shall be

be

flush with

regulating procedure

K l

*"'lit

'¥It lt!Jl

XH'#tiiH'I'

ff-

taken

the

m

tt-1>'1

w.

>'1

it;£

l!!llll.

!>;I) ,

of

the

needle

as a frame

right

side

is

as follows:

H

15

Fig.l5

I!Eililf£

fiZJ!l,

{j;:

#

1<-'Hf-j&;£

of

reference.

"F"

'

r

H

I

I

&I< m 15

I!!

'I'

of

the

left needle guide groove

1-ff!;

-0'

ff-lll

When

> 0

..t

the

iBPlt.

ft'J

ti

1l!

needle is

\

•

)

..

m 16 Fig. 16

PT~ft

iii

;l<!l!'iUUJ

'f:J\'HP

at

the

of

iiT

o

left

needle

"A"

limit,

needle

plate(Fig.

<m

14 .

Page 20

Turn

said

req,urernt:m,

han!lwneel until needle

loosen needle

reaches

earner

the

screw"

lelt

lim1t

A",

posifion.

turn

the

If

needle

needie

carrier-on

doesn't

accord

needle

with

shaft

the

until

needle

l3b).

W

#iii

:fj

l!Ll:i£

ll'l

'f

ff

(4JThe

The

the

right

plate

right

die

throw

earner

l!lfrll'!

{JJJ

iJii

ilZJit

!'I'

:If

iiiJ

l!H

right

limit,

(Fig.

needle

snaU

1!1

il'J

Iii

'!'

1E

I* , ill

·.fjt$

limit

limit

the

17).

guide

shall be

be flUsh

lll

II!

1J 2 l'i

Iii

,

<l·

JJi

l!ld: fl'

ill"

F"

, II!

oi

needle

of

needle

neeote-poim

At

this

groove(Fig.

regulated.

with

tr

(I<)

I!

Jf(;£:fj

ll'lliHIL

.o'

iL •

l'll'H

fflllll!

throw

depends

moment,

17).

the

right

Ill~

li'

T

(Jij

l7J

,

#

n!

l!l.

hU:

iJIJ

ftt

!1!'£

(,n

shall

be in

the

needle

If

the

side

of

the

til

ff

:Ei

IIH!l

Jlt

llttf;li

Wm

lll

>!!!

'£'l<lt.

the

limit

about

2mm

point

positioning

left

needle

il'J

ilZ

ill' •

JPl<

~1>1'

!l!

li

Ill

'HL

• H"

<I'

!i. ilii

It

11!

ft'

of

the

needle

distance

is

right

put

of

location

guide

11!

:Ei

'l'

{1!<

A .

I!

Iii!

throw.

from

out

is

incorrect,

groove

ff

#Ill

ft

iii

>'1

the

of

E

;tJ

itl :Eil!Ullllt •

il'J

l!Hll..!l;

tf!!lfl\

'!if

>Jt

<Ill 18 > •

When

right

the

limit

the

of

needle

plate(Fig.

"E

"<Ill 17 > •

lf.fT"G" • l'i'

the

needle

side

of

the

point

"E"

limit

of

tj-;1:;

Jll

reaches

needle

of

the

the

nee-

>JJ

Jtl

ilil

The

Remove

on .the

throw.

top

Turn

Thus

s.

W!J<JZ!;;~tttr:ii~l'i

5.

Regulating

(ll

!'>

lltG.l'fi!l!ti'i

(!)Basic

Basic position

shaft

"B" ·

shaft,

fix

the

regulating

the

upper

of

the

upper

the

eccentric ball

make

!i!!JI.

il'J

1i!i

1:

B'J

Ill!.\\\

position

of

When

tne

crank

procedure

arm

arm.

the

limit

position

:.f>:

lli

il

" • "

of

the

thread

mark

of

thead

is

as

follows:

cover,

shaft

of

of

W.

thread

hook is decided by

"."

hook

loosen lock

pin

"F"

the

needli:

needle

!'>

and

!11!

J1.

thread

il'J

1i!i

icM If£± lii.J:

hook

on

the

crank

in place

with

screw

screwdriver

throw

hook

'I'{;):

1!1

(l'J

"V"

positions

coincides

(Fig.

1.9).

"G"

comply

EIJI'l

!1\!JI.

lfil!l

with

with

</'

·C.·Of,

of

with

screwdriver

to

change

ill

ti'i

the

the

requirements

"A

"Ej ± lll!" B

l'!l'l~JI.

crank:

"A"

the

centu

of

of

through

angle

ill

ti'i

thread

"V"

o(

"il'J

!>Ill,'

groove

the

(Fig.

UZJ'

<00

hook

the

hole

needle

18).

~

lio'

I;

l ,

and

on

the

shaft

•

x!l>

main

main

"H"'

IS ·

Page 21

I

]t.-;,

'

E

,

'

ji

,H

\

~==~

'""

\-lcf

·n

f

\ '

Jg;

------

£j;h

l!!

_.,.

""ll

•

-~y

!'§'-

'J

A

J

f\

)'i

•.•

;~

"0~,

~

fl~~

/

';:/

J

""

::..sr

___,

0017

Bill'

Fig.l7

(

2)

Ill lilt\!.

Ill !3\Jl

II!!

fi'J

ii'l'i

:!1 2 lifli'li'l'i

fi'J

ii'ti

fiL

W:l!t

l!t

•

~Ill

(

[!l

20

!3\

).

llllll1flli '

Q)I;HH\ li'llHI:"£", ti';t!J;i;tJllH·

21).

®fl';;iJ'fl\l,

&:·

jjllifill·i.· 'tjji;

@lll!D'

i!'.lf

~!Ill.

iT

llllll! •

:t

(2)

Positioning

When

lill

the

~ ~ ~~

..

(o;]

ii'

tFl\'1

ill;!\

Jl

ilb

li'i

J:

iii

I'A

llllll!lll !&Xii'Jii':ti

it

<'I

lil.J!

:fit~

of

location for

pronged

threaC:

tlt.ll "F"iii;;IJ<'Illl

!llllll

fi'J

I!!!.

a"

•

hook

00

Jl

D'

18

fi'J

•

• "j.j;

W:l!t.

Fig.l8

ll<

Jl

'*'

~iii;

ttli'ti"K

iG

-'i

&:·

pronged

intersects

00

!9

"i

111.

rr

9'

·i.·

!&lll

5I!

at ,

'f:"D", itl"IJ:l!O!i<,;Jtllt,

"fi'J

Jil:ili,a

"G

_±

1lil

"V"

1fi

l\!1

fi'J

lim

W:l!t

Jlll!!l!!

thread

the

J>i*

hook

central

fll'l5t.

line

l'EJ:l£

of

the

Fig.l9

ll<

Jl

'*'

9'

-1.·

£H\

"atJHilllll!

<

[!l

19 > Wll

=!}

W <Pff!!Bi;J;lHil

needle,

the

<'1

lilt!-

J'f

!&

11.

ii'ill

~

li'll!\~"E"

<

[!l

22 > •

!&

X

fi'J

centre

of

<ID

lllHIH!!III

ii'

;t

fiL

'il'

!U!i!!

pronged

thread

and tighten the

G" ( 1 needle guard

eccentric supporting sleeve shaH be made.

groove on the main

micro-adjustment

hook

is

deviated

Regulating

(!)Loosen

@Turn

@Adjustment

procedure:

set

set

handwheel to make

bolt

"E" • move

bolt

"K"(Fig.

of

location of

shaft

of

the

from

the

left

side

the

"E"

(Fig. 21).

the

pronged thread

22).

if

"F"

the

r..ark "

(Fig.

19)

impairs the positioning

position for thread

eccentric

of

the

needle eye

supporting

comes into

·"

on tl:e

ho~k

shall

l6

in

2mm

distance

sleeve

"D*

hook

"F"

move towards

contact

with

"G",

crank

of thread hook in relation

of

the

location

be made accordingly.

(Fig.

20).

Tightward

fine-adjustment

of

the

and

the

nearest

thread hook.

An

ideal condition

leftward,

point"

of the

to

"V"

Thus

Page 22

of

operation

the

from

=4

00

20

three

l

Fig.

can

be a¢quired

said

20

only

procedures.

'-----=

E

III

21

Fig.

when

careful selection

-

D

\

21

and

repeated

00

adjustment

22

Fig.

22

have been made

F

ll\lli!:IIIIi

(j)

®

<I'

~1

"'lll

(3)

Make

not

come into

tban

0. 05mm.

Regulating

®Loosen

the

thread

®When

ment.

the

die

can also pass

Iii'

WI~

1!111!

il'

i:

i£

!Ill

It

!ll11!:r

Adjustment

the

prong

contact

procedure

set

hook

is

the

needle

~

"E" C 00

2ll ,

ll! Iii. ;HJllU'IIl

<I'

fi'l

ffi:l!Viit ,

of

the

position

of

screw

at

thread

point

the

thread

with

'"'E"

the

"H"

thread

the

1

right

hook

shall

hook

needle.

(Fig.

end

locates

be

hook

1'1

r'JlHiJ

!!<X

!liJ

1Hl!

of

intersect

21}

may

in

at

a location lower a bit

1£

li' Jlj

Ill!

the

The

and

comply

at

the

the

lii·C.·

J\:il<

COO

,

~·

iJl

thread

the

interval

turn

the

with

left end

middle

2 3 l

f1i

hook

needle

between

of

~"D"

llt

,

lJI.

.ffi

8:

i!lll! • iii

(Fig.

eccentric

the

above-

(Fig.

the

prong

,

I>!

Ill

!.I!

!t"

H"D'J

'ill

20)

the

prong

supporting

said

23)

after

of

the

than

the

X 1£:/illllltiii'ill

It

~8:

;(£Ill!.!! X "C"

2'i'

:ti

lfflffi.

on

condition

and

sleeve

require-ments.

completing

thread

middle.

the

that

needle

"D"

the

hook

Micro-

i:

i£

prong

sball

so

tbat

said

"C".

adjustment

:!:f

(r'J

be less

adjust-

The

>11.

X

iJ

shall

when

nee-

can be

made

if

the

needle

point

comes

into

contact

17

with

the

thread

hook.

Page 23

(4)

l'l

l!t~

fl)

lltr

Fo

l!I'it

-

Jj1j

1'1

IE

i!llli!nll;

<DiE

®

, (!!

®!Hi£

!X:ilt

illl

;;iJ')U\

litr

Iii ill !l:i!ll lit

l'l

!<X

i!llli! ,

iOl

it

'Ill

r,

i!llli! lii'J: i!lli!l'l !;\X

Mi

zi"''E

iii'

it

'*'·

(4)positioning of location

Regulating proo;cdme:

@Adjustment

thread hook and

®The

Loosen

threak hook bar

"V"

front

and

regulating

one

<!!I

24l

liE

lltr

liinrt'l fli

Jli!

Iii

ill

it

i!l

ik

i1i

•

llt:~

of

of

timing

groove

back position of

circle

nut

relation

on

"F"

so

that

and

t<l'l !;\X

ill

*

itWI/i!.it

i!lll'i

>t

thread

by

the

main

thread

two

the

ii!Jffl

ff''I

!tJIEit

to:

l'llil! X

hook

regulating

shaft

screws

thread

1:/lll.'-\"

"Iii

WJJ:lBIPlt

;1;

If

(Fig.

hook

~H"

hook brings about· displacement forward

• "lf.ico!!!>H

Ill!

i!li1H~

WF"f!l

•

,

1if

lit

l'l:

i4

!!I\

X

lltr

Ill !llf-';; i4

the

19).

(Fig.

at

lil!

position

24)

the

back

J!'l

:1\

IIi!

!1\

X ll!t'il

of

the

of

thread

±:lill"V"

!UlW

iJ"K",

"C

"z

1"1 1"1

mark

" • "

hook

%1!!!iL'i1 < 00

"H" •

l't;;iJ

!!tit~

!II:'!'

on

bar

f#J\4

xr

the

"I".

and

i4

iOl

!10:

o.

crank

turn

!9

l •

X 1f

ti'J

5

1il

of

the

back-

@When

tion,

loosen

ward. Interval between

O.Smm.

rn

23 Fig. 23

6.

Regulating

mli':fi

*'ij&

"D"fl) V !Ull'i'l'

the

the

&.It

position

thread

position

adjusted

book

the

from

or

lf!tl

fii"C

·G&:'!r-'"lf!t'~lt"C"'l'

set

screw"K",

the

ridge

"(t';

dol">

end

of

forming

4'

.C.-&'!t!i'

not

comply

and

move

thread hook

Fig. 24

disc

'Htj&"

bKlillti:-

with

slightly

bar

and

A"

<!!I

the

r~qui~ement

the

thread

and

shaft

shouder

material

J:B'J

retaine;

JE-i'IJii.ll'i

26).

after

completing

hook

forward

"C" shall be less

'l'·C'IlZlliJii:i:-

regula~

and

back-

than

([!)

25

l'

1E

. 18 .

Page 24

i'l!l!:l;-li<l!l

(!)o

%Iii!!} ll:

m~.

t~tll''ilf:itl<li!n"c"IIE:t.

27)

lE

l1!

WC",

*'i

~

JJl

9<iUJ"B"

, fl!

j(j

t41tlill'fi

lf"

A"

;JG$

1oJ

li! ~ , i!!.lUiOt IIi

®lie!!}-\'

'f

#li!WL:Ii

.!;li.,

Jli!!jllfi]f :fill Ill.

®lil~lli1'Hiili\WA",

<Ill

Z6li!1,

(1)

The

on

needle

centre

of

Regulating

CD

regulating

II!

"D"

B'J

<00

25>1lt¥fill:it

iU\lli:Mllilf.tr.

The

left

and

centre

of

the

pl3.te

"A"(Fig.

ridge

forming

procedure1

Loosen

lever"

set

screw

A"

swings

ilt:llli!

right

ridge

25);

disc"O"

"C"

fJ" E

"li

ilil

!UJ"E"

li

"G"I>i'

t£:fi!J;i;I)Jlit!lli:"D"<00

position.

forming

nimbly

the

(Fig.

and

disc

centre

26).

turn

anJ

c•.

®After

ridge forming disc

25),

tighten

from

having

loosening

lock

screw

axial

play

lock

leftward

"E"

and

screw

or

rightward

and

swing

"E~

"G".

nimbly.

Make

Ill"

F"lfJII!:it

:II, noli

"C"

coincides

of

"V"groove

pointed_

IS

of

to

The

screw

kept

from

collar

"0"

set

the

sure

ridge forming disc

11\n"G

W.!~Ult;\$3i;$(o]

12l!l;llit41&

having

and lock

ridge

that

"ll'

'ilf

Ul

V llilll<1'·t·-'5Ult41t <\'•t·lt{f

with

the

centre

of

material

"'B"

forming disc in a

the

ridge

to

axial

screw

retainer

secure

play.

forming

shaft

t4$t£;(j

!11

i;IJ,

of

material

"D"

that

the

and

"G"

of

position

disc

shall

not

!j;

i;IJ

@li!i!itt'illli;IJ,

coincides

ridge

tighten

crank

shaft

come

, fl!

Ul

retainer

forming

set

"f",

move

required

shall

into

t!

li;

groove

with

the

disc

screw"

the

<Fig.

be

keft

contact

*

1l_

with

either

the

left

®Loosen

rightward

the

ridge

material

to

make

froming

A 6 <

~\~

III

25

Fig.

25

IE 26

Fig.

26

presser

the

disc

retainer

centre

(fig.

foot

26).

or

the

right

one.

screw"

of

~

V"

groove

Tighten

A",

move

material

on

material

material

retainer

retainer

retainer

screw

.-------------------------,

M