Page 1

HIGH-SPEED LOCKSTITCH SEWING

MACHINE

if

•

INSTRUCTION

PARTS

m

ill:

iJt

~

a.JJ

BJJ

MANUAL

BOOK

Ill

~·Ill

ZOJE

II

SEWING

fil

~!II

iliR

MACHINE

R2

ffl

Jij

DR~

CO., L TO.

61

Page 2

-'hf:tffEJJ~1iffif~JtJ

fr£f=8

~~Ji~fFtffi

1

~

fC:

i{~

f&~

2,

:1ilii:%.f!Jf~-U~BJj,

3,

~m*m$,

4~

f~ffi

~~+JlWIJ.eX:f5i!Jil~Jfl.Rt,

~~;:.

~:t;:

~;--

)/cf.:

-'tff

/L

-"'--

_-L

5,

6~

7

~

~

.::r-'-----'=3--·F".l

t*fl=

A

}:j

·r

ffi~fj~J

F9U'fHI~£-F,

7-1

HL'f-l·~g)tfwt~f~;G'o

7-2

1':

7-3

itt

*tJl,

liJtJi~1~F1J

·f5J

BJ

{1£

;ffi

xt*ifJlB~*ti=fJ}J~~JE5J'-

i5tBJl

-~o

~frJ:ffi-~1$tl~*WHw1tk:Mf~ffl

.ffl

?t(

f}t,

~!JI

-J

~~

~

#·f¥ff~f-f~Jtl

iR.BJJ

~~~M~*m~~~~~~,

?JT-:f=f~~*j[£,~9!Wc*1f3to

]"$

Jlf·

-!:._!\-;\fir:

--

r--17f'..

..

ui

~~·3Vf

;\.

:tif<:

tJLtt,

frtt

fl$st

';-h

---x<

1,

f?:i:tiEl

-~r~

~::,

i~1~ll1

lHf-P,

o

4.-r-..

r:A::

'I

J L

~

8.~f-1§iJfl

'it1f1,~

l:§j1Jfff*E&:wtf~~1~Hu~,

H

-1

tr

~r·ro

1'&,

o

~

*

8~ ~ ~

~t=so

__

*'1-

;t,

T~lf,

~rVf,

ftO-*~~'

~1£~-~t:~fFo

'EJJ%

{B

/G

i~M!Bt~l5iJo

~$~~~~*~~~fflo

J

1!f

f4

\f-1'&

~

o

,

lfs:ifJL

~~

ifJL~:JE$~Bt,

i~f¥1¥ftfi£

r T

~~J

4¥-IY!

o

'_,_

1-H

ff

fiT

7-4

t4~f1::

iK±~xJ\Bt

8.

tE1JL

~#iJrJ

iffiiliJi·~-

MD

' + ''.£:

"""J=l'

'J::

•-J-r

---717

f~

[:(

i {frl

iJ

9,

;7[.

10,

tJl1?-~B~Jg1lf1$,

11...

12,.

~£\

Eti.

**

f~:[)

13

,

f~

·,ut""'t++n

f

14...

i.:.

1

L

fX

{'

f---1

.1<<

riP

_}L

Lf::

~1l

if. i§:

${?

~1

EFJ

1;(

lt-~iJ!I

;gf

1±

c~

.ill'.

r:'@.

f-ct: ·---

~

t:z

lW.

JfJ

:Itg

IBJ

~

51i

~"t{

1~~

rr=

·+\.'I~LBJ,

2~jnfPi~~~I

J"'

i# J\

Jtjj

o

B't,

if/f~

-Po -f--

rz;:::

E')<.

~, F ~

!itt~

1

1(?--•-f:'"-

-:=t~

lZi

IJJG

r}2.-

tn

)i!fr-msts"Jgtfft:fP

.ln.

liJG

~

,

\,,

~ P 1~

~~

00

ftu

m:

.r'//"h'~+/.--'::P-'·-~t:+--

~--'

;y~

:tit

lj\;L'it~EIHiilE~U

:zi:·•

El"'

0

%L

iJJ

!ffl

~

f'F~16,;_W

~

1x

*A

1!:.

fJL

i~

~'tc

ifJL

~ o

1--r~;~,:r?;:-(~,

§~~~..

4=

irr

f!:f::

rPJ1t~ttlf:A!JJ.ilifr

t~~~I

JJ1

8~

tiE%

Hili$~

If11::::rT-kil:'--;:;":rr-;:t2nP~'~

. rPi'.l-Jt.JTG

$:~~PgjrifJl¥Eln~JUliJ¥f¥El3,

f P

Y!c

~?&Ji

o

o

f'Fo

F itt

1-J

lf

:k

~

~--g:r

o

~

J~l-l*si);r-,

14

8~

ME

1~,

-frn~lf:--r-cl:J

){H

~

tjJi!

~

Page 3

16,

rrt1ID

tc~B"J

76$~~fcmEJG~icit!:*~JL

f1J~/G~11i~{f

o

t!=*ffl~~)(i=1Jfr8"J~:£:t~7liiio

*0n.Ixtffi

17, *

18,

ifJl

R:@:

Jil~~f~

Mf*~-B-t£/J\f-4

A

~~Jl~3J

1*f'F-ABtEJG§lf~A91.t~t±~

a

A

1,

:7g~~A~1JJ~,

3fZ9JiffLHo

2,

:7g~l=iJ§~~~;fJlH~$~~hX:8"JA53-11J~,

Jft~_t$t,

!f.\'JJUB::f:$Ji)j

~wtu

o

f$i)J}trff1~,

Et!~Jlo

~.Litz!J~,

1?-¥~EJG12~~IBt,

-¥1~,

_t$£,

~wtu

.

iw/G~

~#~tP;&~~M

lt!.JJLJWJmi/G

~

nJ:.lf.

ff

fey

~m

Jl~

o

3,

~~~A~m~,

~~rrH~m**~~~mu~,

nfltf;flllft--r:n o

4,

:7g~~A5tf%~,

5,

JJ~t&~~:iE~Bt,

i~

*f~~Jl

6,

~~~§~~:92.A~fJ)~,

~Jl

~

7,

~~~~~~m*~~~m~~~~~-~,

HLw~tPitwBt,

8,

~Q51~:ftrzs"JifJL~

~:92.mu~~~m~~~~~$M,

9,

~~:92.~!RJ:fl,

1o,

7g~

i~

:k

~

Et!

I*J

:g:~

0

eyf:l~~~fHmr:§.Wtt:E!~gil

14!

Et!

¥W-

3f:ko

~JlH~~Bt,

tJJPJ~~-¥7J)cA.fJEg~~P'lo

PJ~~¥1~1J_)[t£J]JEif:~~#:lf.fo

¥J3f*o

~m1~I!Jt1~3tifJl~Bt,

iw*1¥ifJL~s"Jit!.¥W-o

wem

f\§j

~~

lt!.ifJL,

f$iJJ

Et!¥J±ttL~Bt,

ifJL$*~$~Bt,

iNWitifJlU:IE~o

f!:f:~tffiL

~~~¥

5J17~,

~*~m~~lt!.~3f*o

:tEtmJ:.~W:rtru:*.-

~t~{.~Bt,

W~¥1§'1JkA

ffl~m~EJG~~

lt!.ifJLxllt-s o

:7g

zoo,

-

ii-

Page 4

+""

f:~c-u...,'

:r*

r

~B=rrm

111J

1..±.~,

tn

2

'll'l..tu:tiJ~~*·······················

~

y,

.......................................................................................

nh

r+-t

~±

............................................................. 1

1

-==-

...

ll9...

E..

/'\...

-t...

!\....

.11...

+...

+

~

+ =

-tJl~s~n£Jif

b"JE

*~

iEH

tJlrrs~~~

f~Jl.."B~~~

00~8~~¥i;;

rr.fi!E.s~ifiliJ-=p-

~~~-tfj]

f;!Eg~~s'ti.)i!ij~

.ff

J¥.q1

:t&

...

&JJtP

&.:fJ

...

*t4f§{fl.8"t-Uijj-=TJ.

.................................................................................... 2

:;1:

ifi!J-=TJ

.....................................................

....................................................................................

.................................................................................... 3

.................................................................................... 4

...........................................................................•........ 4

....................................................................................... 5

.................................................................... 0

f.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

s-t

i)ijj

-=p-.

. . . . . • • . . . . . . . . . . . • . . . . . . . . . . . . . . . . . • . . . . . • . . . . . • . . . . . . . . . • . . . . • . . . . . . . . . . . . . 6

··o······

......

....

o .

........................................................

~

. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

••••••••••••

3

5

6

~-

1

-=-

+ll9

+n

+

/\...

+-t

+ !\.

+JL,

~~~~~~

...

JZS:

IJ'~

./J IJ

~

rSJ

Jx

......

0

••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••••

...

:tJl:ft

~1ifff~8"-l*-*

...

ffiJJtP~ocs"JiJi!U::p-

fJEgxtffJ~~_m.s~iPUlt

...

&wafQ~~-ws-t~~

...

~*1~~&8-ti~~··················································~····························

.:F~tt#1;!!;!.*~·················································································10

........................................................................... 7

......................... _ ............................................. · ........ 8

........................................................................ 8

.....................................................................

-iii-

7

9

9

Page 5

it":

~•~m•~~~~~-~,m~~~:

·~-~~~m*m~,•m~m~,

·~~~ffi~Ntt~,M~~~~~~~~~~o

·~~~oo*~~ffi~*m~~~~ffi~~~,~m~m*mo

•

1iiO

iA It!

tJL

~

~

191

1J

rfiJ

J! N lE

.~m*m~~-~~,mBM~k~~~r~~~~~~~o

liftL

~*~•~-~~~$~~,

*~~~~~mo

---

B

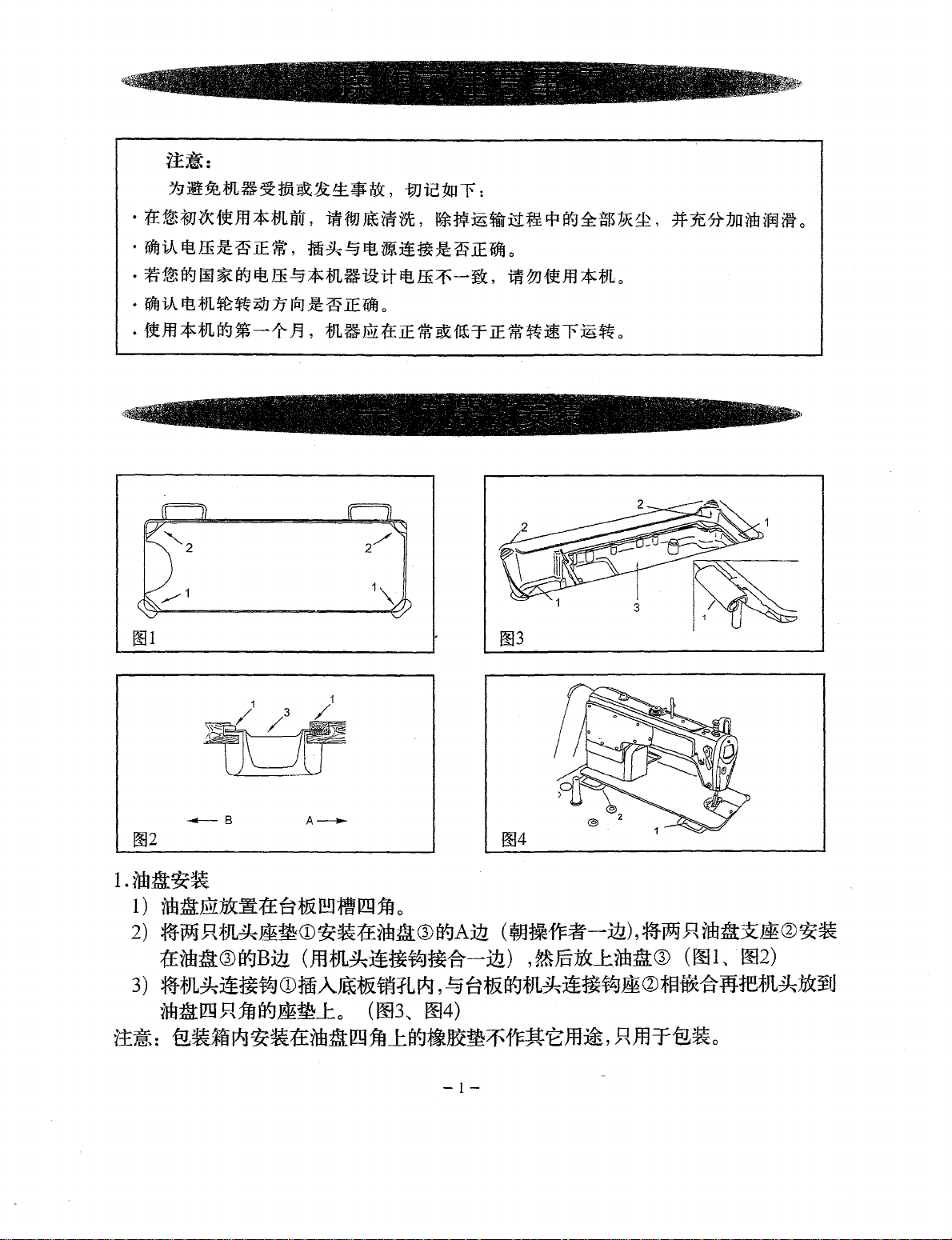

I.nail~?&

1 )

nailM»t~

2)

~imf{fJLih~mCD~~1±irllll®I¥-JAjft

1£nbil®~B:itl

3)

~fJL~~~t7JCDfmA~tit~:fLI*J,

naillmftjfjf8~~J:o

A~

r±

at&[!!}

111m

1ft

0

(~1*1'F~-Jll.),~Wj~iffiil~~Q)~~

(fflfJL~~~t~~-€1-:lll.)

,~J§iOCJ::ifbtl®

!:§~~l]gfJL~:i!~f~~<J)t§W(-€1flf.1~fJL~~¥U

(~3,

~4)

~~=~~~I*J~~~na~~~J::ag~~~~~~Em~,~mrg~o

-1-

(001,

002)

Page 6

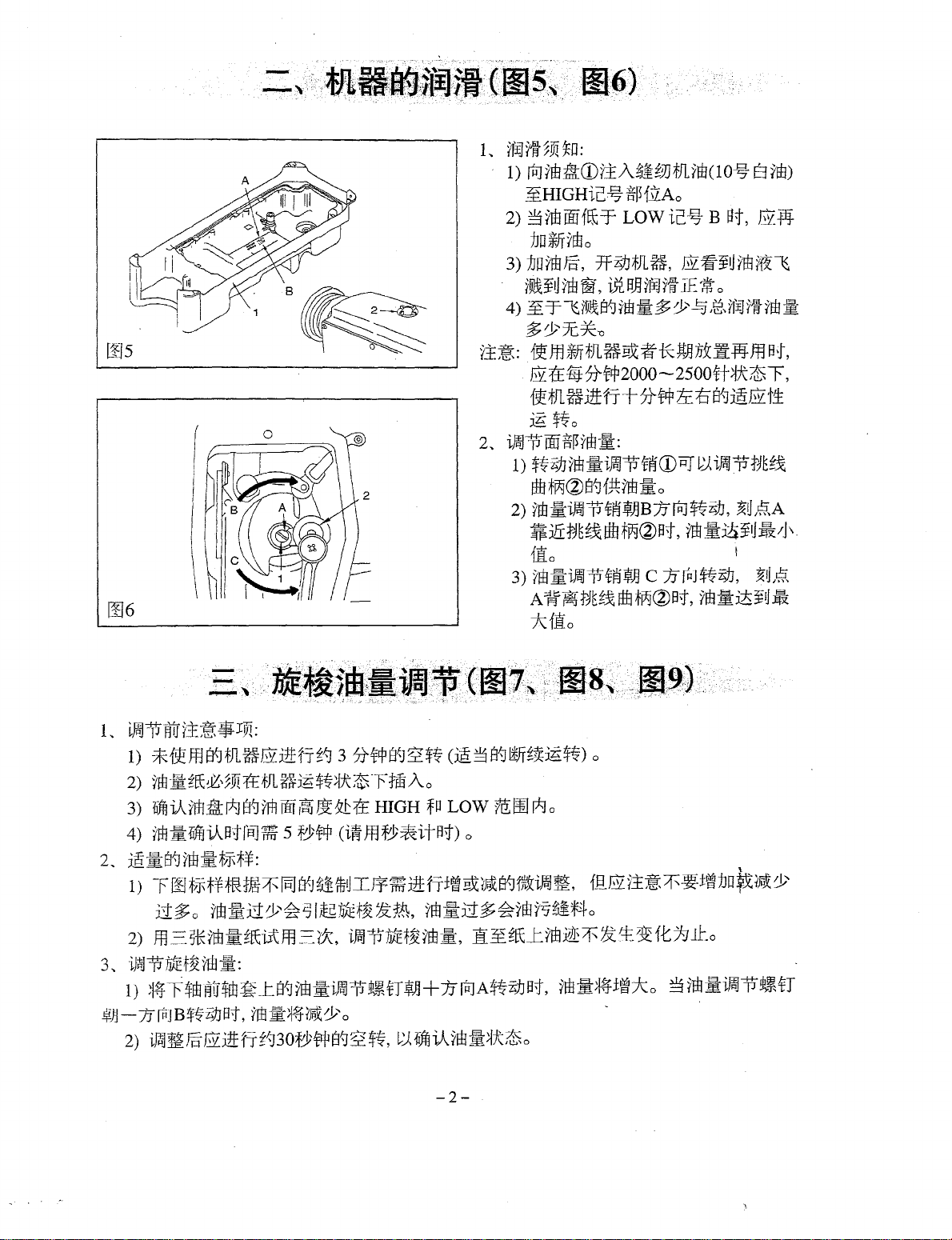

~5

B~

~2.

0~

1..

~JiJ

¥1f

1ffJ

~IJ:

1)

!PJ

¥IE

.ftCDi±AgJig3J

~HIGHic%f§~fj[Ao

2)

~~ruoofE\:~

1JowJTrm

3)

1Jo?ruFo,

i!ilit¥1J

~W

4)

~ r ~iV&B"J1mm$Y~

Low

o

1f~JJ;tJl~,

iJ,

i)lB~

tJUliJ

ic-'% B at,

l2~¥u?mH~~

~IfJ

¥f

1E

$0?7C:k-o

a:~:

2..

~

m

wJT

tfl

~

Et

w-K

~y§

f\Z

B:

fi¥

57\.T$

2ooo--

~*fl

~itt

fr

+

~

t~o

iml

-:p

00

-15~

i!E

_,;_:

1)

$~~}]¥IE;.

aH

t~~

2)

?ru;i~l1tf:f~JjB1JIPJ~~}J,

~JlifJE~aHt~~Bt,

i~-='P

!'l~

1ftna

2500rr

77\.f*

ti

tf:f

CD

PI

_m

o

¥ru.mJ4¥rJ:W£!J\.

fHo

3)

?m.m

i~l1ff:f~JJ

A

1r~fJE~Iffit~~Bt,

c

1JrPJt7~JJ,

*fHo

(1

O%

B

il±I)

fi\lfl}

1ft

o

,g-¥1£1/tim•

11tli-¥}

tJs'-1

l2A

ma-t,

~:k~

T,

~m

·ti

i~

:11

fJE~

~U,~A

l

~u}~

im;.:ii5iiJ.

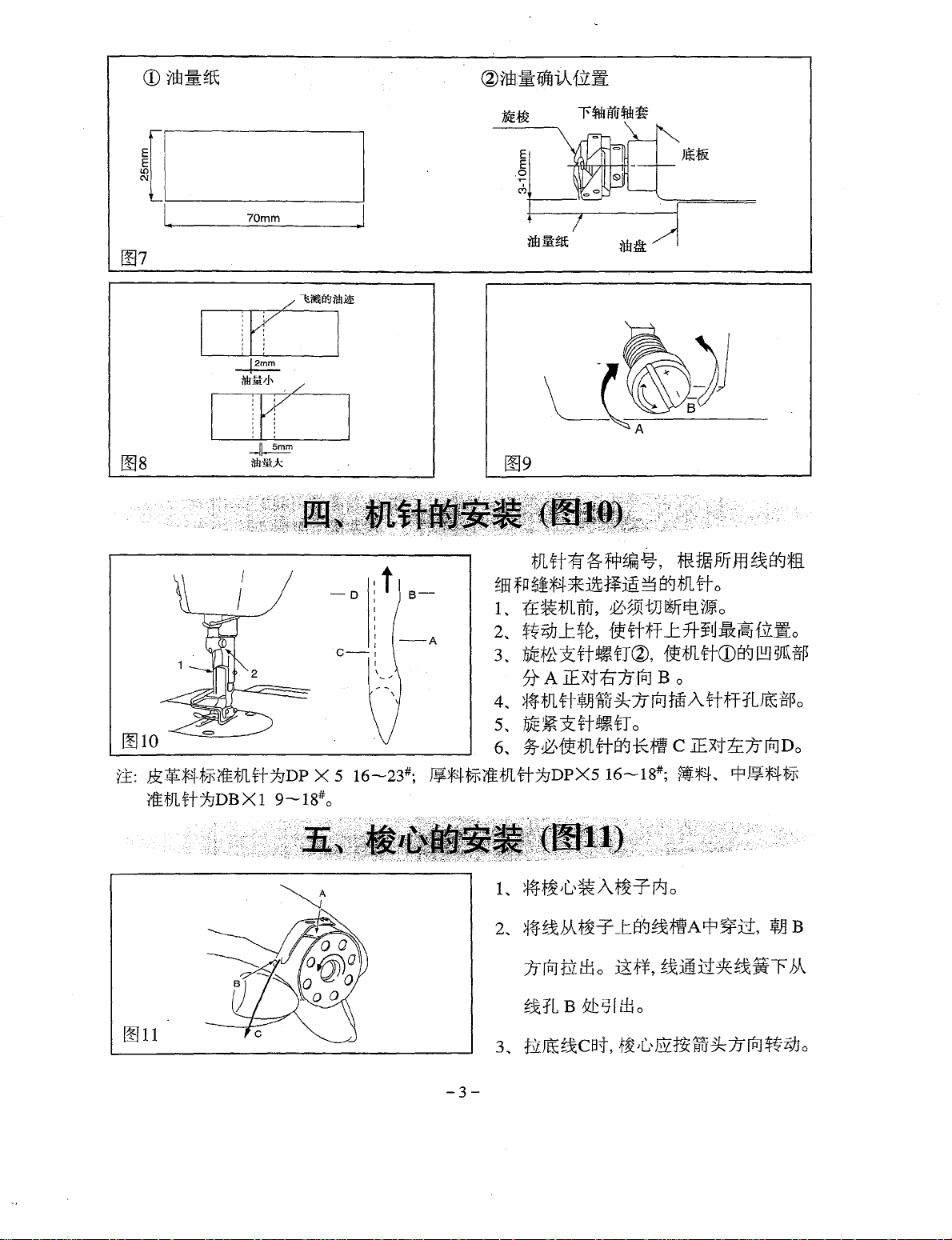

1..

ijtijl)mJ~i~*rw:

1)

*1~fflE!"JtJl-Hf\Z:ittf-rg"J

2)

1mi!}E1:

3)

uflhA

4)

iffi_m1iJ:liABtlflJ~

2,

~_ms"J~m~tffit¥:

1) T !!I

i1$

2)

JtL=J-lE

3

..

i}t]

-=p

1)

~~~

¥Jj-7J(n:JB~#E}JBt,

2)

iJiiJ~Jl5DZJt!:fri"J30f:!/¥/JE!"J~$~,

~,

39!

a

;tJL

iEH

Jl

r-*J

8'-J

iW

t~~t*t~

0

:fj]E

f~

T

$ffi

t~

/G

/Iii

:I:

J1

:J.~

¥li1

_;_g~irt

1ff!Ji:

~IJ$ffi

~

_t

B"J

iEB::I=~~i~j,~o

~~:IE$~

!if

5

1PJ

~

ffl

3

71T$EI"J2:$~

~;It:$

1ti'J

OC

91:

tE

f')9;r:p

(iff

fflf:!;~itB'f)

B~

€JH!iiJ

Iff:~

iJ

r

~:JJ~t~

--=-

iJ\,

i~

1J:JJ!El&

~'ffl

~t~l1

t~

Tfill

HIGH

C~~E!"J®f!~~t~)

Ao

fP

LOW

m

fiJ

pg

o

o

o

:ittfri~

£J~,

TT~J.J

~~1ii§iA~Eit!l~:k0o

§X:iJ8tEI"J

rati:J1$

?m

:i.,

][~

+

1J

rPJ

A!ft~JJ

-2-

~i~

~,

~ir±J

¥5gJit4o

g~_t

rm~

/G

Bt,

1m;_~

fElfY

~3:~

6t±

~

±~*o

/G*i~1JIJ

ft:Jg

Jt.o

~

?m

'-

~{~

0?

_;_

i~-='P

t~

fJ

Page 7

(1~1

1!110

I.

70mm

.I

~Jl

ft

ff

~

f!fl~%,

~m

fP~*4*:i?t1-¥m~

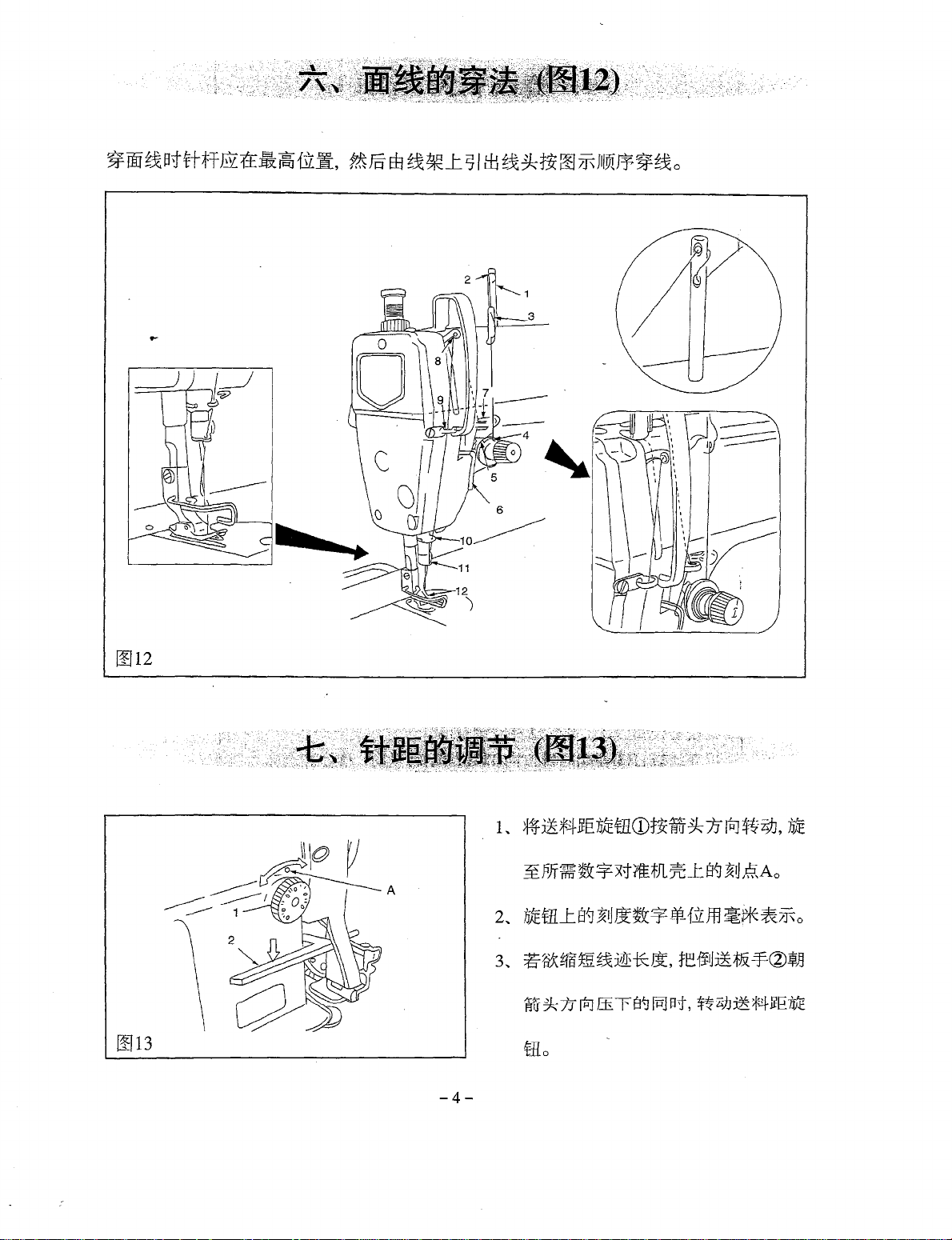

1..

t£

?&~Jl!W,

2,

~i}J_t$~,

3,

~~~rr•rr~,~mrroo~~~~

)J\.

A

4..

*t~Jl

tt

s..

~~xftt~fr

6

..

95-~,f_t~JL#B"J-Kift

~,~Ji

'itff~f

IExtt:J1J(P]

WJiu

~

*

1E

?JT

m

~

tt-J

*ll

s"J~Jl

rr o

t)J

l!ff

~

M o

L:3T~U:&l~EJ{.fl~o

B o

7I

~1m

A.

rrfffL~

o

C

lExtt:c7IIrDDo

ff~o

i.£:

$:1fi;f4~1.FiiE1Jltf:lgDP

X 5 16---23#;

l¥*411.Ff'f:EtJlrr:/9DPX5

iltJltt:/9DB X 1 9---18# o

L

~A

*tt~JL'~At~-Tr*Jo

2

..

~~~~r_t~~~A~~li,~B

1JrtJtlllio

~fL B 5zt~l

1!111

-3-

16--18#;

J!~~,

fif*4

~:imu~~:ii~

t:Bo

..

i=fJ!J*4tl.F

~

Page 8

0012

1..

~i!*-41F§)iJEfH

CDttiti

* 1f

!PJ

$t#JJ,

1JJE

~?JTMi~*

2

..

~m~~~~ft*~ffim~**~o

3

..

*~~~.ffi{~-Koc,

~v

*

1r

!!I

13

-4-

fllo

x1fitJL%1:8"J

rtiJ

ff

T

skJ

1UJ

~~

,8Ao

1Efitl:i!t&-¥~~JJ

s-t,

~~

Li}J

~

;f4

N~

iff:E

Page 9

1!114

tiE!x

jim·~}]~

~-Z91

~~It,

1,

2,

~Ji

fjE~:ifmiJJ~8"JiJfiJlt:

1)

1JJE*'t~

2)

tl::

3)

tl::

fjE!x~5iEf78"Ji)ijj1J:

)']

8-1

o~

*·

~Ji!3J

fiju

JJ8'-J~Ji*~

f.fi!t~tJ~o

*!X !ItT

~~jx

t~

D!U

& z o

®¥JJ

}I[Vi

Bt

<ft

tT®~JJ

i2!

Rt

ft

}I

1i

it

rPJ

rtJ

(

(

8~

fii

*-~t-

t!PA1J

t!fJ

B

1J

1..

2_

-.

C

f]Jt

rPJ

)$#i)J B

rtJ

)${r}J Dt,

00

~~

5~

7J

8"Jif~

T.J:

1)

tR

f'*

~

[PJ

B~

~i

ft·IJ

*

f4'

-H}*ifr1J~tm~~5tE1J

2)

~tl::t~-BJ.CD

rP:l)

*~

~)]

'

fi.+-

-:+t-o

rPJ)

-t;;rvJ

rn:

0=:

2~)!

~,\.!:-.X..

J

~-~

J

1)

~*1-~~~~~tJ~fii

1J

rP

j)

2)

~~~~~!il~t1C2J:f:tz]~Bti:t7f

7J

In:!)

$~r)]

lfi=!),

Vl!J

~

;J,

1:3t~~ji

:f?JE~~

t£7J!NH•J:f-!-)i

B•J,

IId

j

--,--

1-l'.'

Uil

a'

{r

i

~1-;+.

:;

v,P.J

lJ

$-~:i)J

Bt,

s~·,

iJ£

~~

:tJt!&

fl'~

*

BJ

::;

g,~

~K

fJ

;j~

±~

1 : •

;1

1/

f •

9,

.

~~

Jt\:

.

HFJ1B't:f-t·:i:i

~(

~:~

Jfff.:~

~:

i~

rJJ

ii

~

:?;)J

;_

jo

7J

~j+j-;ls!(

g-K

)J

1~

5tE

)J

;;Rx

[f~

5-K

::iJ.

~14

±~

j(

;j-ff

1~

j;'

(

~!JAJ-J

Jc::

I

1

.;

\:;

rtJ

(

~rc

1

}::_

c

rPl(~PD

-'J

\c

f P

3~

Jf

o

o

1)

iifE;f!~

JE

fiL!l~

tJ~,

2)

1ifEif'~JE1il!R~<fT@,

3)

1~*

g~!l~

tT®~A

4)

1~1f::

gx9t~

fT@¥JJ

~~,mu~mr~,

B•J,

~Tm~£fJf:i!tfri~~o

~5U±E#j~

#$~i}J1f::!xt~<fT®o

Jllft1Bt

rr1J

i2!

Bt

ft1J

m~•~B~B~*o

1!115

(

g_fiflf

rtJ

(

t!PA1J

rRJ

( epB 1J

)@ o

rRJ

)$~i}J

rPJ

)$!?~}]

I

/·

I

I

'-5-

Bt,

tiE

st(if

8~

51(

iJ

~if±~}(

BJ,

l~t

~K

~

Bl5tz

:h

~4

g~~~m%~~~M~~~~~~

o

;J~

Yo

Page 10

L

f~;fJL~lliE*Pt&-f-

f~

ff

Jjtp

:t~tf

2~

ff)jtps'-J:ttlt.s:S:g"J/95.5~*0

3

~

3

ffijtp

:tJi

~CD:MB

0

CD~

A 7JfR]${i}J,

1J

rPJ

*~i}J

Bt,

lliijtp

1!116

~7Ji@]

4~

x1E*t!ffJj!p,

7ctir~~g'-]7g13~*0

L

2~

3

~

4..

~*fj[~o

1~~£g'-]1]lO~*·

7J~f'tiMJff.t~-BJ:(Z)Jli91Btrr

$~iJJ

fEJ!p

iffiJ

-=p

t~

lfJ,

~Btft(~PB:lJ

fT,

ffJJ~4i~~~o

iffil

·=p

)f§-

J]JE

xt

---

f.N

1!J

;fJF{fE~

~/933-36~*(5kg)o

rPJ)t#i}J

~

i,ffl]

ff

~-t

rm ~ ,

.t~

ff

(~~AlJrPJ)

ff

n

~

ff)jtpiffiJl1

-B}

0

JP

iftH

-=p

~

±~B!a

o

t~

t~

fi

s"J

~18

~

mrflf'.

-6-

L

71JEt~*r4fi{.-$t:CDI.s~5Ef.flt~fT(Z)fiJ

@,

**41i

f~

f6

rr

2~

;fffiilt§fJ[:

j~)fE4

~

JL"

~;t

f3lt"

3~*4~

_tizf/lj,

8

$tCDi.fflJ¥Vm

fJ~

fiJ

®o

b\rrf&OO~~~Bt,

rr

iLJ:ftfM-

fll

ftt&__I:

3

8~

1.fr.Ii,

ftfM-

W

x'.!Jfo

3

~

~~~f4fA~H~."

1JoH~~*4tEI{~,

4~

~4~;f4fiJL"u~~JJf.i~&7JrPJiffiJ~,

~~~*#~~'

r.±~:

~**41ffia{,,.*:iJ~~tt~,

8

$~.!f!Jlfri

~

1J

rPJ

iffiJ

~,

~

~JJJ.C~r41¥Jti~o

·

m*~~~~~~o

mu~i71,g

®fffo

Page 11

1!119

1.

~-#.

if&~

7fEtttrrif&~tB

~*4B;f,

2.

~I:J*:i!*4

~~ifc~*4~~0

3,

b

iJ~j"=p~~+7f~Jto

1)

t~f'£tit

2)

L.

3)

]"JE~ffEfP§!t~'fJ@o

~#*#~~~-~~*

tB

1.15-1.25 mmo

0.8-0.9

;lt~tfj~jJ0.7-0.8mmo

7fjj:5J\.8

7f

)l3f~

B±l

~f$E}J3f~m1-T~-='fi

~J¥*4-~*4

mm,

rmgil

ttl,

1£ti¥f*4Bt,

til§

CD

8'-J

~liD\~

tT~

o

o

8:~:

*r±Bt~~~lfJ~~ffi}J:*;J\

1)

${E}J_t$~,

2)

1iJH~rrift~oc=

a,

~

ttXE:1ilt~fTCDo

b,

f!i!fflDAftBt,

tt~

3)

1i~iE:h"JEt.&filii:

a.

{~Jt!DB<ftBt,

ffT$ffi~@B"J~tz#&o

b,

ftfflDAttBt,

1tTtfffil-T:S:fE£i~C

fflDB

ftBt' 1t trff@

~Ttiff@_ts{]~Jj~Cxtitftiffr$~@1¥JTftfffi,

f1rt"

TJCD

o

JJJEt'£-=Q:h"JEt.&~fil!t"fJ,

__

t

I¥J

JJJEta=_RhfEt.&/E11r\"<fJ,

~~ti:J?tJZJf~r±Bt~~mo

WnJEf'£TtiffJ!~tt/Efilt"<fTCDo

~tl

~Axt

it

rrff

T$E8~@1¥J

fr~E}J_t~,

#-$tE}J_L$£,

Tftfffi'

~ftiff@_t1¥J~tl~Bxtii<ft

{~Jtff@_tB"J~tl~Dxtfiftiff

?.t

1§-:h"JE~

f.~J§":h"}E~ftiffi!~

rriff~~

T$ffi~@B"JT~o

4)

t£_t:i£~7t

r.t

!§"

1±~:

a.7Efi'SJ

b.JJJEt.&JJR*m

1$

T,

1tJJJE1.&

rr

~tJEt~

~

!);'itf~;J\,

8'~

i9

~

~ID

t~

fT

o

~~19H.&~;

ft~W.-¥5-,

i~1~€,

~®

xt

7Efi'SJ

t''l

tJl

tt@

I¥J

~,

L.

~

!);~x*,

i~1tm

~51~1f3~ft

}Jjl*s'-1~%

-7-

Jt

_!:;]

o

o

JJJEt~

8"J

I'SJ

WJ.:

~o.

04-o .1

mm,

Page 12

0020 j

[!121

1.

~*ffi~~~~~•noo~~ffiff

~

oc

ctr

I±JJtP

.r.

rt-:&i

~at

rr~&

rnr

13

ffil1tP

ffi:

00

lEP-

~

5.5

~*)

o

2.

iJJ-='P€,

1.

~1ffuJI~t¥4Bt,

fr~~~t~iTCDo

~~tl~iiJCD¥Jt6:7JrtJ

Af_~i}],

2.

~Ji

1tU

¥i

~4

Bf$i')J,

3.

:tl~itJ(D_t~~tl~!3t~iT*'L.'-i~

Bt

1J

1/F

~22

-8-

~jf~jc~~~:;:o

Bt,

B~DI-ft

tl

~

ft)00¥)j

~t'~IJ\ME~£o

f~

fJLAo

:tl1J

rPJ

Page 13

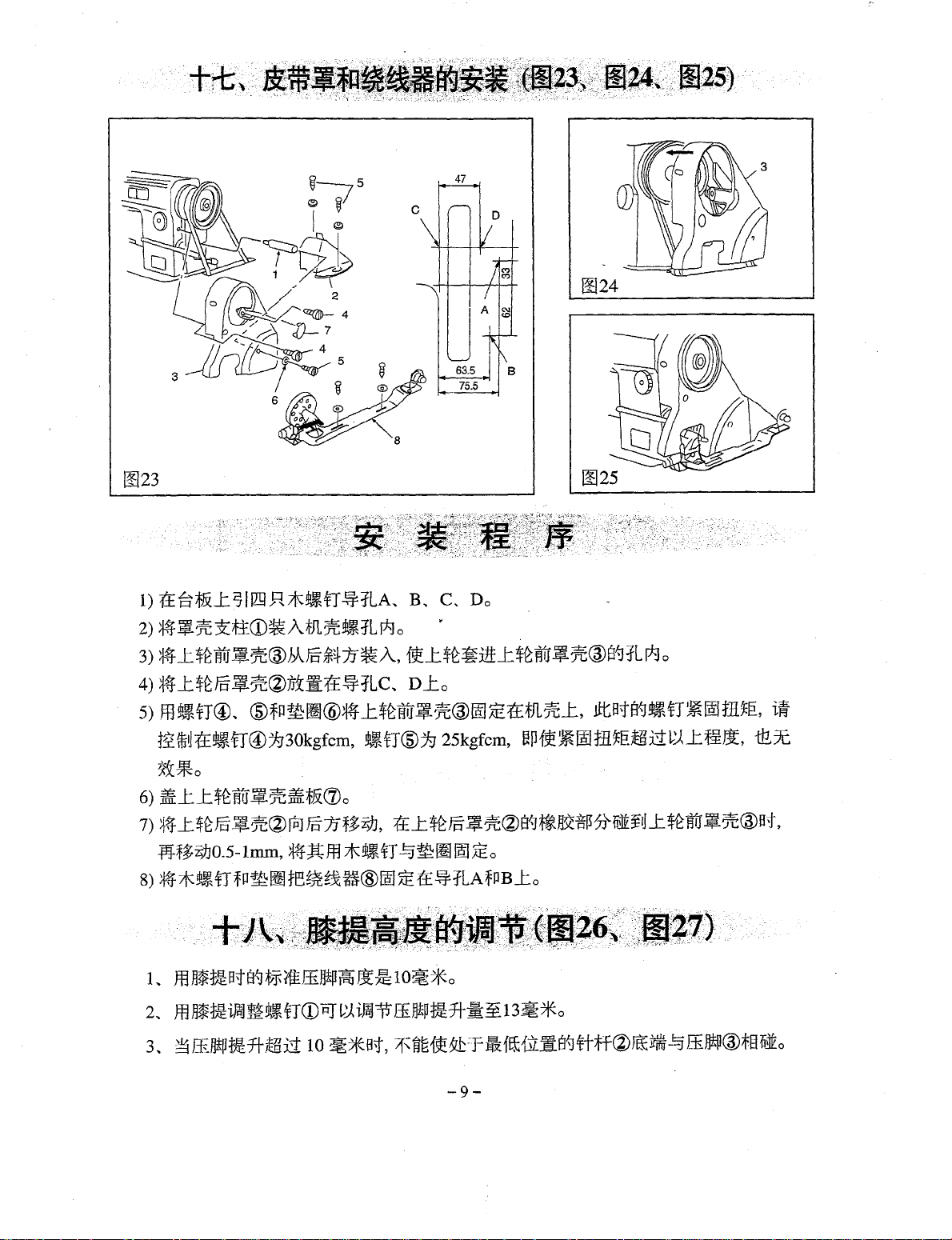

47

63.5 8

75.5

1!]23

1)

T±Ei't&.L

2)

~1J%3Et±CD~AtJL%t~iLI*Jo

3)

~

_t$~1W~'ie@JAJ§-~~1J~A,

J71!21LR*!l!Jt~fT~1LA

..

B

.. C ..

Do

{9!_t$~~:ttt_t~fltr1l%@s~fLr*Jo

0024

4)

~

_t~J§-

5)

mt~fT®

1~*u1±t~fT@~30kgfcm,

~'if:@J]~ifif~tLC..

..

@fQf11:~@~~

.L$£1frJ.$7C®IAI1Eif~JL%_t,

n_to

t~aT@)g

25kgfcm,

~Pf~~riDt.H~f:i:~tLi:i~.Lf.¥&,

~~*0

6)

~_t_t~WJ~'ie~f,&(1)o

7)

~if

_t$~!§-~~~~

1Pf~E}J0.5-1mm,

8)

~*t~fTfPf11:~t~~~t3%H®m!~

1..

ffl

n*ti:Bt8~f~ilffil3!P

2..

ffl

n*mi~~t~fTCDPJ

3..

~

ffijj!p~ff-!11Li:iiO

f6"1Jf~E)J,

*tJtffl*t~fT~m!m!ID~o

tf_t_$£J§"~'ie®B"J~~{f~]J\.i~ftl_tJ~§tr~'iC@Bt,

tE.!$fLAfPBl:o

tsJ

J.lJ'f!::

10~*o

~~

ifflJ-='P

ffi,ljtPt~ff-

~*Bt,

7f~fi~{t~~-f!lf~{Jiit8~rrff@J"€fitffit!3

_;_E~J3~*o

-9-

ttats~t~fT~Iillt.H~EI,

i~

i:E.x

ffiJ]tl1@1§1i]to

Page 14

~i*4

~f-~L

~~*4

[!!27

~

*~

..

~1¥*4

~r~g]i)f

~*f·t-IEE

ffi]tPi=Jt

fh~

oc < -¥m)

CH*t~)

-tfltt

~1fJ¥f.tnb

~AJlr}J~~

i±:

L

~f4~~JJBtfm~t~ll]tP,

2..

ff.IJ*P1Ji~$~83Jjipm~:r±~ru!-~

5500~tJ)J\.

5rnm

6mm(il*)

13mm(il*)

DBXl

9#--18#

lftif&,

I

z;f47f#-f'Fm~B~iml~o

51JORo

3ooo~t-!-ln\.

8mm

6mm(~:k)

13mm(il*)

DPX5

16#--18#

-

3000!tti)J\.

8mm

8mm(il:k)

13mm(~*)

DPXS

1o%a¥m

370W

20#--23#

~fi~~-~~-~~~-~~~~m•~~m•••,

~~~l=~fr~~*ilffl

i}ta~

~

I*J~~I!ii~

F

~£trrrmmJ2Z~S£o

-10-

Page 15

INSTRUCTION MANUAL

To

get the most out

to use this machine correctly.

Please read this Instruction Manual carefully before use. Whe hope you wi!l enjoy the use

your machine for a long time.

Please remember to keep this manual

1.

Observe the basic safety measures, including, but not limited to the following ones, whenever

you use the machine.

2.

Read all the instructions, including, but not limited to this Instruction Manual before you

use the machine ,

anytime when necessary.

3.

Use the machine after it has been ascertained that it conforms with safety rules/standards

in

valid

4.

All safety devices must be

The operation without the specified safety devices is not allowed.

5.

This machine shall be operated by appropriately-trained operators.

6.

For your personal protection, we recommend that you wear safety glasses.

7.

For the following, turn off the power switch

the receptacle.

7-1

7-2 For replacing part(s)

7-3 For repair work,

7-4 When leaving the working place

8.

If you should allow oil, grease,

with your eyes or skin or swallow any

contacted areas and consult a medical doctor.

your country.

For threading needle(s) and replacing bobbin.

of

the many functions

In

addition, keep this Instruction Manual so that you may read it at

in

position when the machine is ready for work or

of

needle, presser foot, throat plate, feed dog, cloth guide etc.

of

this machine and operate it

in

a safe place.

of

disconnect the power plug

of

when the working place

etG.

used with the machine and devices to come

of

such liquid by mistake, immediately wash the

is

in

unattended.

safety, it is necessary

of

the machine from

in

operation.

in

contact

of

9.

Tampering with the live parts and devices. regardless

is prohibited.

10.

Repairing, remodeling and adjustment works must only be done by appropriately trained

technicians or specially skilled personnel.

11.

General maintenance

12.

Repair and maintenance works

electric technicians or under the audit and guidance

Whenever you find a failure

13.

Periodically clean the machine throughout the period

and

inspection works

of

any

have

to

of

electrical components shall be conducted by qualified

of

electrical components, immediately stop the machine.

of

whether the machine

be

done by appropriately trained personnel.

of

specially skilled personnel.

of

use.

-11-

is

powered,

Page 16

14.

Grounding

machine has to be operated

as high-frequency welder.

15.

An appropriate power plug has to be attached to the machine

plug has to be connected to a grounded receptacle.

16.

The machine is only allowed to be used for the purpose intended. Other used are not allowed.

17.

Remodel or modify the machine

all the effective safety measures. We assumes no responsibility for damage caused by

remodeling

18.

Warning hints are marked with the two shown symbols.

the.

machine is always necessary

in

an enviorment that is free from strong noise sources such

in

or

modification

of

the machine.

of

Danger

Items requiring special attention

injury to operator or service staff

tot

the normaloperation

bY

electric technicians, Power

accordance with the safety rules/standards while taking

of

the machine. The

-12-

Page 17

FOR

1.

To

avoid electrical shock hazards, neither open the cover

for the motor nor touch the components mounted inside the electrical box.

1.To avoid personal injury, never operate the machine ·with any

cover, finger guard

2.To prevent possible personal injuries caused by being caught

your fingers, head and clothes away from the handwheel, V belt and the motor

while the machine is operation.

3.To avoid personal injury, never put your hand under the needle when you turn

"ON"the power switch or operate the machine.

4.To avoid personal injury, never put your fingers into the thread take-up cover

while the machine is

5.The hook rotates at a high speed while the machine is in operation.

possible injury to hands, be sure to keep your hands away from the vicinity

the hook during operation.

machine when replacing the bobbin.

6.

To

avoid possible personal injuries, be careful not

machine when tiling/raising the machine head.

7.

To

avoid possible accidents because of abrupt start

the power to the machine when tilting the machine head

cover and the V belt.

8.1f

your machine

while the machine is at rest.

noise

of

start

9.To

the machine, be sure

avoid electrical shock hazards, never operate the sewing machine with

SAFE.

of

safety davices removed.

in

operation.

is

equipped with a servo-motor,the motor does not produce

OPERATION

of

the electrical box

of

in

the machine.

In

addition, place nothing around them.

To

In

addition, be sure to turn OFF the power to the

to

allow your fingers

of

the machine, turn OFF

or

removing the belt

To

avoid possible accidents due to abrupt

to

turn OFF the power to the machine.

the belt

keep

prevent

of

in

the

the ground wire for the power supply removed.

10.To prevent possible accidents because

component(s),turn

on

of

the power plug.

OFF the power switch

of

electric shock or damaged electrical

in

prior-to the connectrion/disconnecti

-13-

Page 18

CONTENTS

BEFORE

1.

INSTALLATION·················································································15

2.

LUBRICATION··················································· ...

3.

ADJUSTING

4.

ATTACHING

5.

SETTING

6.

THREADING

7.

AqJUSTING

8.

THREAD

9.THREAD

10.

HAND

OPERATION·····································································

-.

..

·····················

THE

AMOUNT

THE

NEEDLE·······························································

THE

BOBBIN

THE

MACHINE

THE

STITCH LENGTH······································· ···············1 9

THENSION··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ··· ···20

TAKE-UP

LIFTER···········································································

SPRING·····························································

OF

OIL

COIL

SPRASHES)

INTO

THE

BOBBIN

HEAD···················································

CASE······························

IN

THE

HOOK······16

····15

···16

···18

···18

···1 9

···20

···21

11.

PRESSER FOOT

12. ADJUSTING THE FEED

13.

HEIGHT

14. NEEDLE-TO-HOOK

15. ADJUSTING

16. ADJUSTING

17.

INSTALLING

18. ADJUSTING

SPECIFICATIONS·····························································~·······

19.

OF

PRESSURE······················································

TIMING···················································

THE

THE

THE

THE

THE

FEED

HEIGHT

THREAD

BELT

HEIGHT

DOG·······················································

RELATIONSHIP·············································

OF

THE

TAKE-UP

COVER

OF

THE

PRESSER

STROKE······························

AND

THE

KNEE

FOOT·····················

BOBBIN

LIFTER· ..

WINDER············ ···23

························

···21

···21

···22

···22

···23

···23

... 24

···25

-14-

Page 19

I Attention required before operation

Attention:

To

avoid machine damaging

1.before using the machine for the first time,

the dust and make sufficient lubrication.

2.make sure that the voltage is right,and that plug and power source are correctly

connected.

3.if the voltage in your country

do not use

4

..

make sure the running direction

5.during the first month when using this machine, you

speed

it.

or

lower speed.

or

some accident, please do remember:

please clean it thoroughly, get

is

different from the voltage

of

the motor ,wheel is right.

of

this machine,please

should run it

rid

in

the normal

of

all

Fixing

Fig.1

Fig.2

1.fixing

1) oil tray should be put

2) Fix two arm cushion"1 "to the"A"side

Fix the

fix the

3)

Plug the hinge"1 "into hole

plate,

of

attention:in

of

oil

---

oil

the

tray

of

the machine

B

A~

tray

at

the

four

two

stand bases"2"to the"B"side

oil tray"3''(picture1 ,picture2)

of

bed plate,put the machine head on the table

hinge

four

is

at

the sink place and then fix the machine head on cushions

oil tray corners(picture3,picture4

the

packing

not

for

any

box

other

,the

usage,just

corners

of

rubber

Fig.3

Fig.4

~~--------------------~

of

the slot in table plate.

oil

tray"~"(facing

of

oil tray"3"(hinge side ),then

).

cushions

for

packaging.

fixed

the operator).

at

the

four

corner

-15-

Page 20

12.

LUBRICATION

(Fig,5,6)

A WARNING:

~

Turn OFF the power before

work so as to prevent accidents caused

by abrupt start to the sewing machine.

1.1nformation on lubrication

1)

Fill oil pan

white oil) up to HIGH mark A.

2)

When the oil level lowers below LOW mark

refill the oil pan with the specified oil.

3)

When

you

window®

4) Note that the amount

unrelated to the amount

(Precaution) When

WARNING:

CD

with sewing-machine oii(No.1 0

you

operate the machine after lubrication,

will see splashing oil through oil singht

if the lubrication is adequate.

of

of

you

first operate your machine

or

after setup

period

at

about

of

of

2,000 s.p.m.

10 minuter for the purpose

break-in.

after an extended

disuse, run yout machine

st~rting

the splashing oil is

the lubricating oil.

To

2,500 s.p.m for

A Turn OFF tne power before starting the

~

work so as to prevent accidents caused

by abrupt start to the sewing machine.

the

B,

Fig. 6

13.

ADJUSTING

. 2.Adjusting the amount

plate parts.

1) Adjust the amount

take-up and needle bar crank

adjust pin

2) The minimum amount

marker dot A is brought close to needle bar

crank®

3) The maximum amount

marker dot A is brought to the position just

opposite from the needle bar crank by turning

the adjust pin

THE

AMOUNT

WARNING:

Be extremely careful about the operation of the machine since the amount

be checked by turning the hook at a high speed.

OF

OIL

(OIL

-16-

SPLASHES

CD

.

by turning the adjust pin

in

of

oil supplied to the face

of

oil supplied to the thread

of

oil is

of

oil is reached when

direction

IN

THE

C.

HOOK(Fig,7.8.9) I

® by turning

reac~ed

of

when

in

drection

oil has to

B.

Page 21

(,'

I '

~·'\..,

r-

...

..

'

u

(!)Amount

Fig. 7

*When carrying out the procedure described below

extreme caution not to a allow your fingers to come

(Cautions

2) Place the amount

machine is in operation

3) Confirm that the height

"HIGH" and "LOW".

4) Confirmation

of

esample

of

oil {oil splashes) confirmation paper

tl

1!-----------.1

70mm

• Use any paper available regardless

1)

If

the machine has not been sufficiently warmed up for operation, make the machine

run idle for approximately three minutes. (Moderate intermittent operation)

of

oil (oil splashes) confirmation paper under the hook while the sewing

of

the amount

time with a watch)

showing the appropriate amount

I

.I

of

the material.

of

the oil surface

of

oil should

Splashes of from the hook

[/

I approx.2mm

Appropriate amount of

I 1[/

--JI

F"

1

L...-_

_9_·

8-----------------~

eAdjusting

hook bushing

Fig. 9

Appropriate amount of oil (large)

the amount

oil (srnall)

Splashes

of

oil from the hook

:pprox.Smm

of

oil (oil splashes) in the mounted on the hook driving shaft front

®Position to confirm the amount

_

Oil splashes confimrmation paper

Closely

• Place the amount

the hook.

in

contact with the hook.

in

the oil reservoir

be

completed in five seconds.(Check the period

of

oil

1) The amount

the left should

with sewing processec. Be careful not to

excessiveiy increase/decrease the amount

oil

the hook will be seized (the hook will be hot).

If

product may be stained with

2) Adjust the amount

the

change while checking the oil amount three

times

1) Turning the oil amount adjustment screw

will increase the amount

in

B)

2) After the amount

properly adjusted with the oil amount adjustment screw, make the sewing machine run

idle fot approximately

the amount

of

oil( oil splashes)

Hook driving shaft front bushing

___..:.H::.:OO;:_k

--..

Oil reservoir

fit

the paper against the wall surface

of

oil (oil splashes) confirmation paper under

in

2), remove the slide plate and take

i~

within the range between

of

oil shown is the samples on

be

finely adjusted

in

the hook.(lf the amount

the amount

oil amount (oil splashes) should not

(on the three sheets

the hook,

will decrease it.

of

oil is too much, the sewing

in

the "+" direction (in direction A)

or

in

the"-"

of

oil in the hook has been

of

oil (oil splashes) in the hook.

of

the oil reservoir.

in

accordance

of

oil is too small,

oil.)

of

oil

in

the hook so that

of

paper).

of

oil (oil splashes)

direction (in direction

30 seconds to check

of

-17-

Page 22

14.

ATTACHING

Fig. 10

THE

NEEDLE

-o

c-Q:

(Fig.1

-A

\

\

0)

I

Follow the procedure described below to attach

the needle, after confirming that the motor has

come to a complete stop.

A needle

proper needle size according to the count

thread and the type

1) Turn the handwheel until the needle bar

2) Loosen screw ® , and hold needle

3) Insert the needle fully into the hole in the

4) Securely tighten

5) Check that long groove C

1.Notes: The standard needle for leather is

Another standard needle for heavy material

5

light material is

WARNING:

A Turn OFF the power before starting the

~

work so as to prevent accidents caused

by abrupt start to the

of

DP x 5 should be used, Select a

of

reaches the highest point

indented part A facing exactly to the right in

direction

needle bar

the end

facing exactly to

08*5

is

DB*5(16-18#}the

B.

in

of

hole is reached.

(16-23#);

08*1

the dirction

screw®.

the

standard needle for

(9-18#)

sewinQ machine.

material used.

of

its stroke.

of

the arrow until

of

tHe

left in direction

CD

with its

needle is

D.

of

is.

SETTING

Fig.

11

THE

BOBBIN

A

INTO

THE

BOBBIN

1) Install the bobbin

2) Pass the thread through thread slit A, and pull

3) Check that the bobbin rotates

-18-

CASE

the thread wound direction is counterclockwise.

the thread

thread

come out from notch

of

the arrow when thread

(Fig.11}

in

the bobbin case so that

in

direction

will pass under the tension

B.

By so qoing, the

B.

in

Cis

pulled.

the direction

~pring

and

Page 23

js.

THREADING

THE

MACHINE

HEAD(Fig.12)

-

The needle bar should be the highest, Then draw a thread end from the thread holder and thread

follows:

it as

Fig.12

j1.

ADJUSTING

Fig.13

THE

STITCH

LENGTH

-19-

(FIG.13)

1) Turn stitch

arrow, and

A on the machine arm.

2) The

3) When you want to decrease the stitch length, turn

dial calibration is in millimeters.

stitch length dial

in

the direction

length dial

align the desired number to marker dot

of

CD

in

the direction

CD

while pressing feed lever ®

the arrow.

of

the

Page 24

Is.

THREAD

Fig.14

19.

THREAD

TENSION

TAKE-UP.

(Fig.14)

SPRING

(Fig.15)

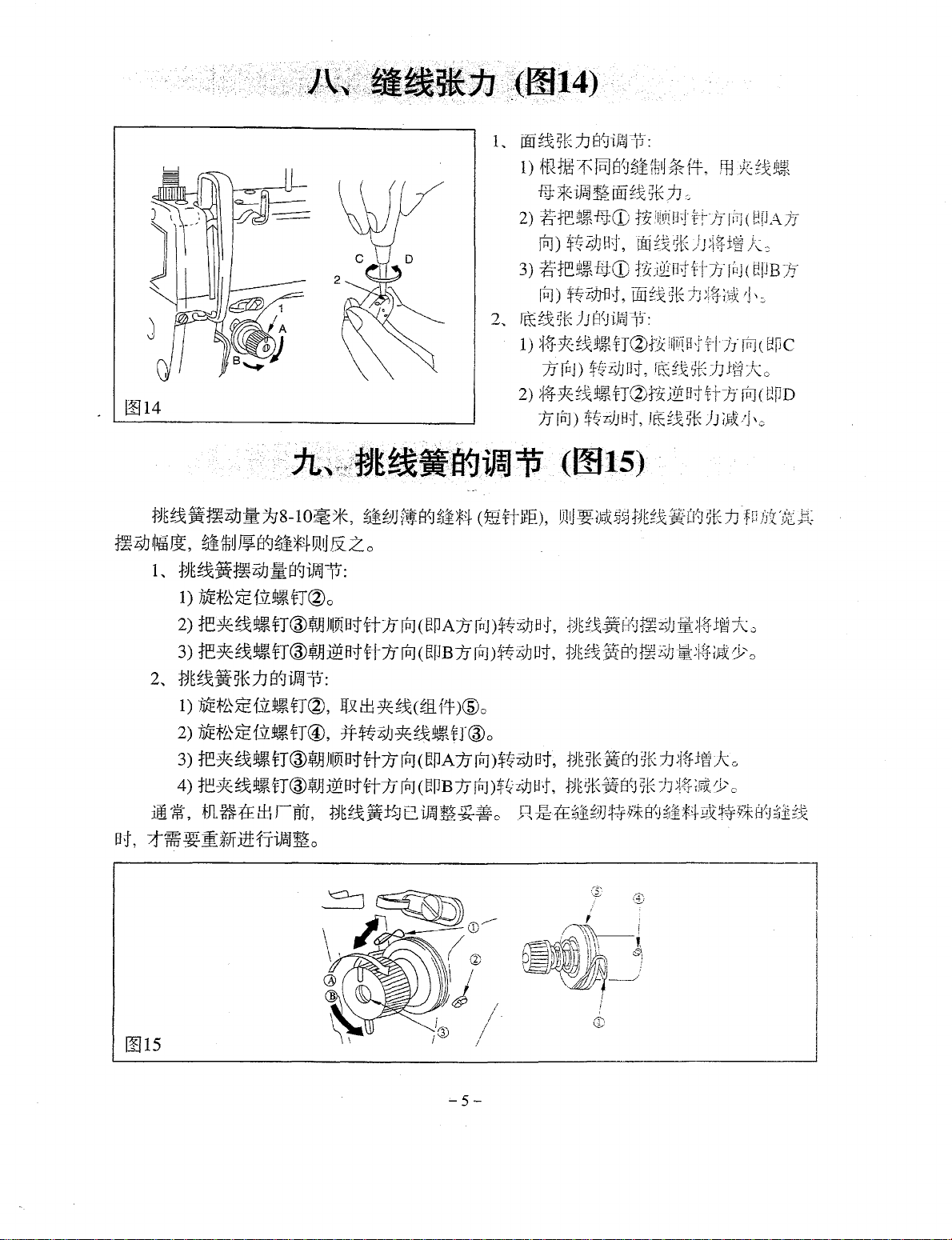

1.Adjusting the needle thread tension

1)

Adjust

the

needle thread tension using tension

adjust nut

specifications.

2) As you turn nut

the needle thread tension

3) As you turn nut

direction B), the tension will decrease.

2.Adjusting the bobbin thread tension

1)

As

you

(in

direction C), the bobbin thread tension will

increase.

2) As you turn

Direction

decrease.

CD

according to the sewing

CD

clockwise (in direction A).

will increase.

CD

counterclockwise

turn tension adjust screw ® clockwise

screw®

D),

the bobbin thread tension will

counterclockwise (in

(in

® direction B), the stroke will be decreased.

I

I

CD

Fig.15

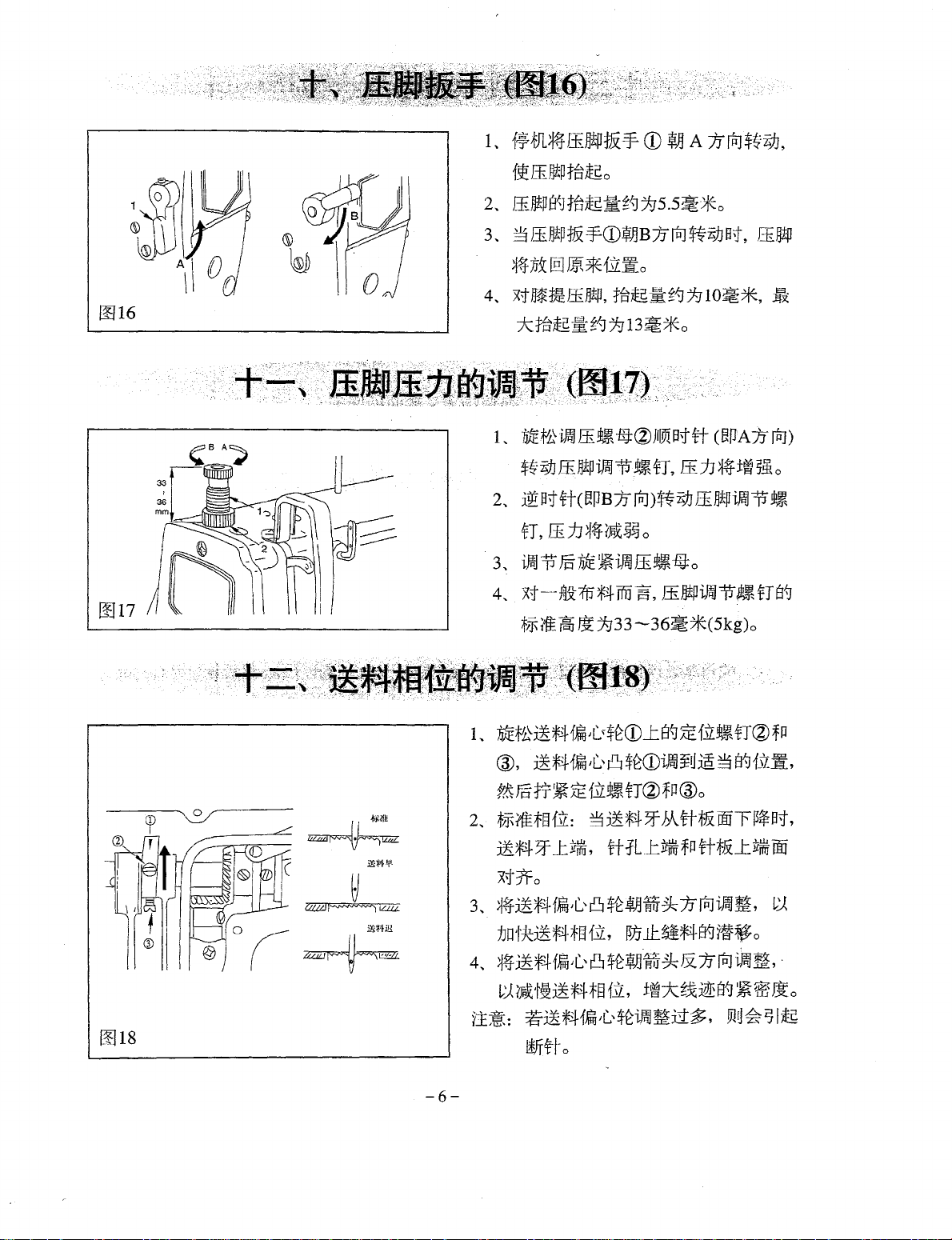

1.

The width of take-up spring is

sewing material

width),

and wide the sway of

opposition.

2.Changing the srtoke

pis lighten the take-up spring tension . .

.

is

thin material (short needle .

it. Otherwise, pis do to :

of

thread take-up spring

8-1

Omm.

if the

CD.

1 ) Loosen set screw ® .

2) As you turn tension post @ clockwise (in

of

sirection A), the stroke

spring

will

be

increased.

the thread take-up

3) As you turn the knob counterclockwise

3.

Changing the pressure of thead take-up

spring

1) Loosen set screw ® , and remove thread

2) Loosen set

3)

4) As you turn the post counterc ockwise

4.Ususlly, upon the machme commg

CD.

tension

As

direction A), the pressure will

direction B), the pressure WI e decreased.

take-up spring has been adjusted

while sew special material or special thread,

it need to

CD.

screw@.

you turn tension post @ clockwise

be

increased.

1

b

11

~t.

well, Only

be

adjusted again.

(in

(in

(

in

all the

-20-

Page 25

11

0.

HAND

Fig.16

LIFTER

(Fig.16)

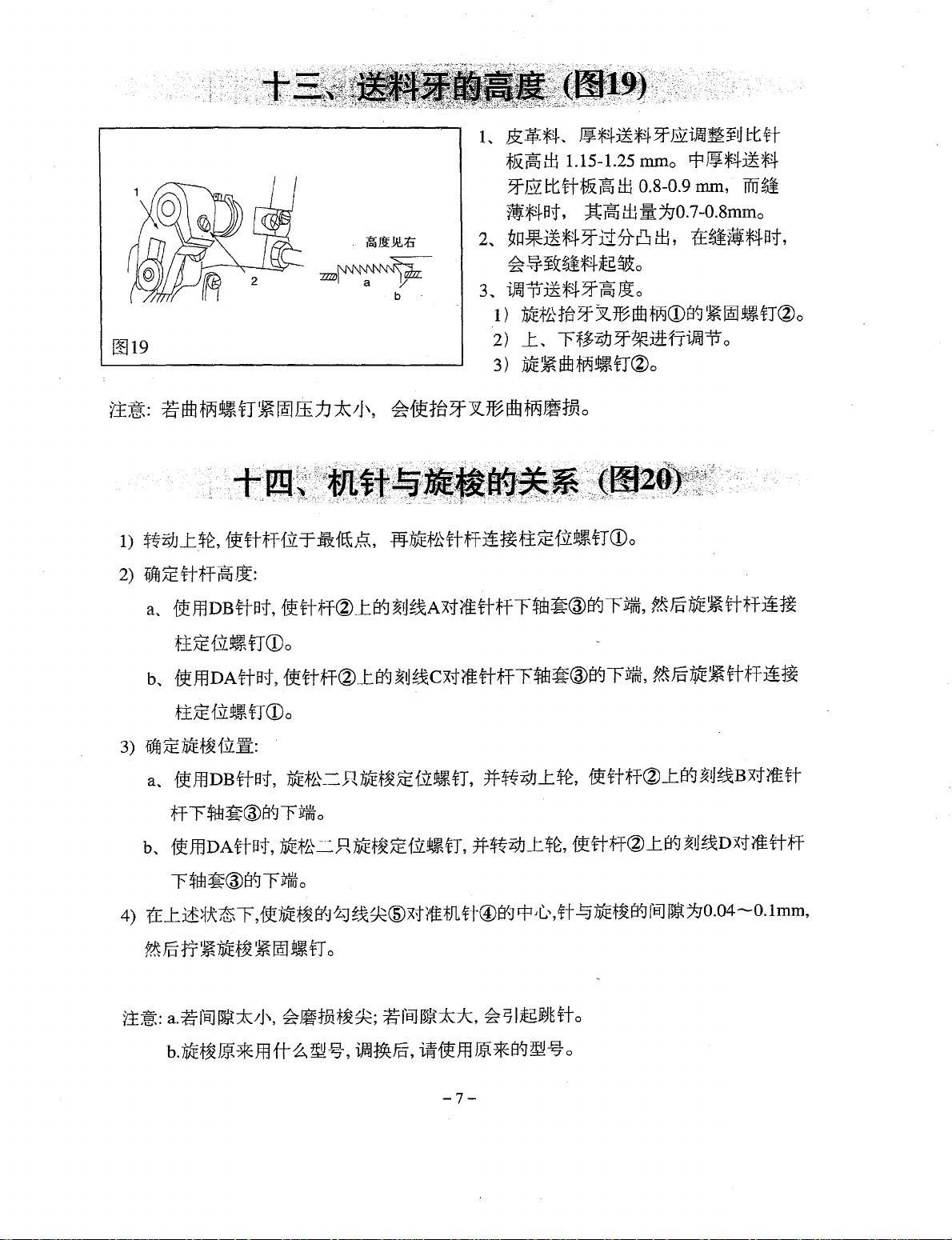

1)

To

stop the machine with its presser foot up,

turn hand lifter lever

2) The presser foot will go up about 5.5mm and

stop.

The presser foot will go back to its original

position when hand lifter lever is turned down

in

direction

3) Using the knee lifter, you can get the standard

presser foot lift

maximum lift

B.

of

CD

in

direction A .

of

about 1

about 13mm.

Omm

and a

111.

PRESSER

FOOT

PRESSURE(Fig.17)

I

A Turn OFF the power before starting the

~

1) Loosen nut

regulator

presser foot pressure will be increased.

2) As you turn the presser spring regulator

counterclock-wise

will be decreased.

3) After adjustment, tighten

4) For general fabrics, the standard height

presser spring regulator is 33 to

A Turn OFF the power before starting the

~work

12.ADJUSTING

. . cam

1

Fig.18

THE

FEED

TIMING

(Standard feed timing)

_ J [ Needle Needle

~plate

( (Advanced feed timing)

?222ai""""""""4

(Fig.1S)

~

I222Z

I 1) Loosen

2) For the standard adjustment, adjust so that the

3)

@or=+::

4)

5)

direction

the arrow, and firmly tighten the screws.

top surface

needle eyelet are flush with the top surface

throat plate when the feed dog descends below

the throat plate.

To

uneven material feed, move the feed eccentric

cam

To

stitch tightness, move the feed eccentric cam

in

the opposite direction from the arrow.

if

feed eccentric cam adjust too much, it will

cause the broken

WARNING:

work so as to prevent accidents caused

by abrupt start

® . As you turn presser spring

CD

WARNING:

so as to prevent accidents· caused

by abrupt start to the sewing machine.

screws_

CD

. Move the feed eccentric cam

of

the arrow or opposite direction

of

advance the feed timing

in

the direction

delay the feed timing

of

the sewing machine.

clockwise (in direction A), the

(in

direction B), the pressure

nut®.

36mm

® and ®

feed dog and the top end

of

of

needle.

in

in

order to prevent

the arrow.

in

order to increase

feed eccentric

(5

of

in

the

kg).

the

of

of

of

-21-

Page 26

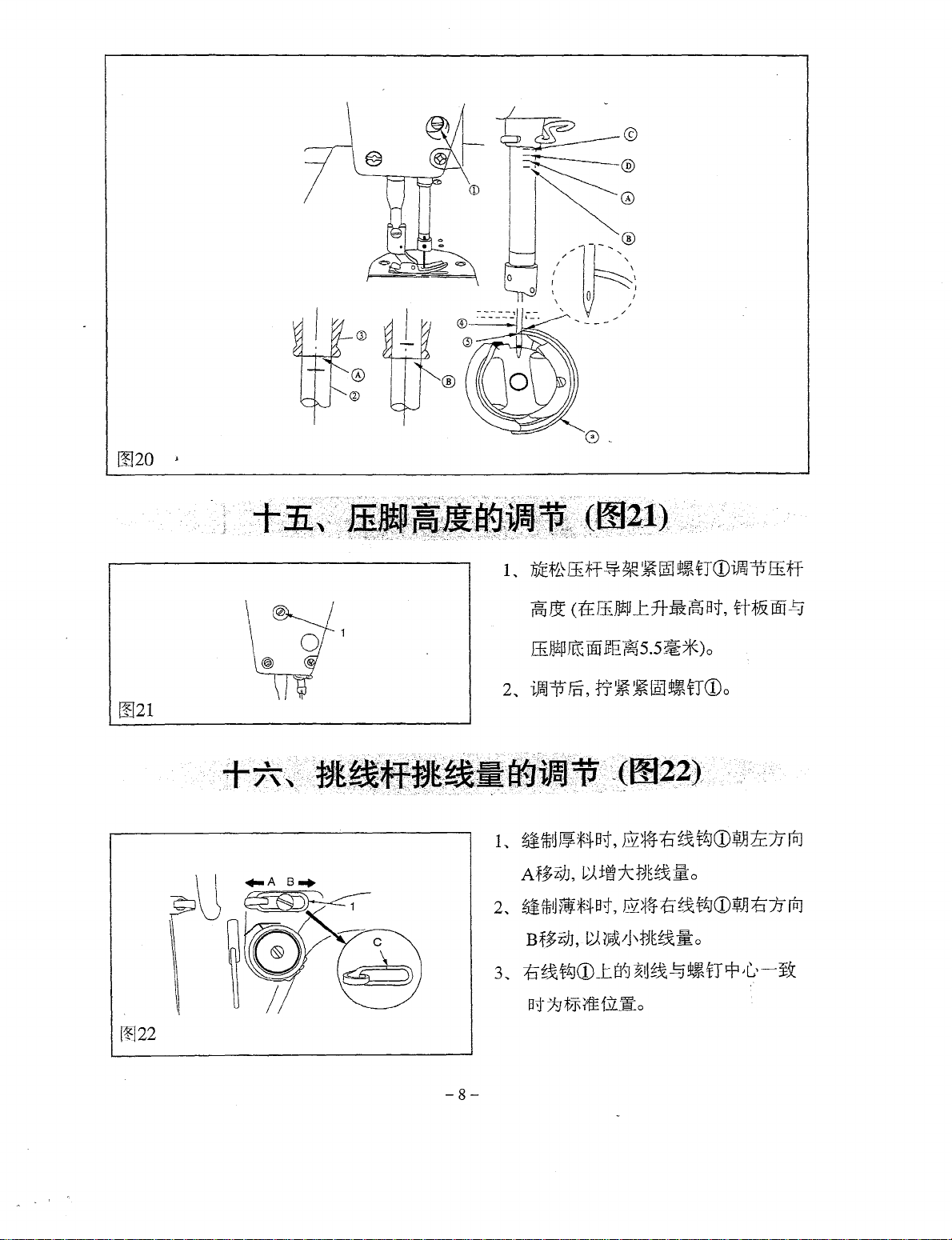

113.

HEIGHT

OF

THE

FEED

DOG(FIG.19)

Height: Please refer to the right

I

CAUTION:

Be

careful not

cam

too

result.

WARNING:

to

move

the

far,

or else needle breakage

feed

eccentric

A Turn OFF the power before starting the

~

work so as to prevent accidents caused

by abrupt start of the sewing machine.

may

Ym~

b

Fig.19

114.NEEDLE-TO-HOOK

WARNING:

A Turn OFF the power before starting the

~

work so as to prevent accidents caused

by abrupt start to the sewing machine.

1.Adjust

the

1) Turn the handwheel to bright the needle bar

down to the lowest point

loosen set screw

(Adjusting the needle bar height)

2) Locate the needle height

a. while using

the bottom end

then

the

timing

hook

as

follows.

DB

tig~!en

set screw 1 .

RELATIONSHIP

between

CD

.

needle, aligh marker line A with

of

needle bar lower bushing

the

of

{Fig.20)

needle and

its stroke, and

I

3,

1) The feed dog is factory-adjusted so that it just

out from the throat plate surface 1.15mm to

1.25 mm.

To

adjust the height

2)

CD

Loosen screw ®

® Move the feed bar up

adjustment.

@ Securely tighten screw ® .

(Caution)

insufficient,

a,

Feed dog

3). The feed dog for leather heavy material

must be adjusted 1.15-1.25mm higher than

needle plate. The feed dog for mid-heavy

material must be

needle plate, while sew thin material, the

suitable height is

b.

While using DA needle, align mark lfhe C with

the bottom end

then tighten set screw

3) Locate the hook position.

a.

While using DB needle, loosen the two hook

set

line B

end

b.

While using DA needle, loosen the two hook

set

screw,

line D

end of needle bar lower bushing

4) After making the adjustments mentioned in

the above steps, align hook blade point

with the center

clearance

value) between the needle and the hook, then

securely tighten setscrews

(Caution)

2.

Use a hook

replacing your hook with a new one.

-22-

If

the

b.

Needle plate

screws,

turn

on

ascending needle bar 2

of

needle bar lower bushing 3.

turn

on

asending needle bar 2 with the bottom

of

1.

If the clearance

pornt

smaller than the specified value, the

blade point

If

the clearance is larger, stitch

skip-ping will result.

of

the feed dog:

of

crank

CD

.

of

down to make

the

clamping

forked

the

the

0.06mm to 0.15mm (reference

portion

0.8-0.9 mm higher than

0.7-0.Bmm.

of

needle bar lower bushing

1.

hand

wheel,

hand

wheel,

of

needle @ . Provide a

or

hooK

of

of

the same part No. when

pressure

will

wear

and

align market

with

the

and

align marker

3.

in

the hoqk.

betwe@n

and

hook will be damaged.

t11e

the

needfe

is

out.

3,

bottom

@

blad.e

1s

Page 27

l1s.

ADJUSTING

Fig.21

116.

ADJUSTING

THE

THE

HEIGHT

THREAD

OF

THE

TAKE-UP

PRESSER

FOOT

WARNING:

(Fig.21)

A Turn OFF the power before starting the

~

work so as to prevent accidents caused

of

by abrupt start

1) Loosen setscrew

foot height and the angle

2) After adjustment, securely tighten the set screw

the sewing machine.

CD

. And adjust the presser

of

the presser foot.

CD.

STROKE(Fig.2~}

WARNING:

A Turn OFF the power before starting the

~

work so as to prevent accidents caused

' by abrupt start

1 )When sewing heavy-weight materials, move

thread guide

increase the length

the thread take-up.

2) When sewing light-weight materials, move

thread guide

to decrease the length

the thread take-up.

Normally, thread guide

3)

way

that marker line C is aligned with the

center

of

the screw.

of

the sewing machine.

CD

to the left in direction A to

of

thread pulled out by

CD

to the right

of

CD

in

direction B

thread pulled out by

is positioned

in

a

117.

INSTALLING

Fig.23

THE

BELT

COVER

47

AND

THE

BOBBIN

1.1nstallation

1) Drill four guiding holes

wooden screws in the table.

Install. belt cover support

2)

hole in arm.

3) Pass the handwheel through the hole

cover

arm. At this time, you can

the handwheel diagonally from the rear

handwheel by tilting belt cover A

illustrated in the figure.

4) Place belt cover B ® on guiding holes C

and

5)

@ , @ and washer ® ,

screw

-23-

A ® , then set the handwheel on the

D.

Fix

belt

@ with a tightening torque

WINDER(Fig.23,24,25)

procedure

A,

CD

smo~thly

cover

-A @ on

the

arm

At

this time, tighten

B,

in the tapped

C and D for

in

belt

install

of

the

® as

using

screws

of

Page 28

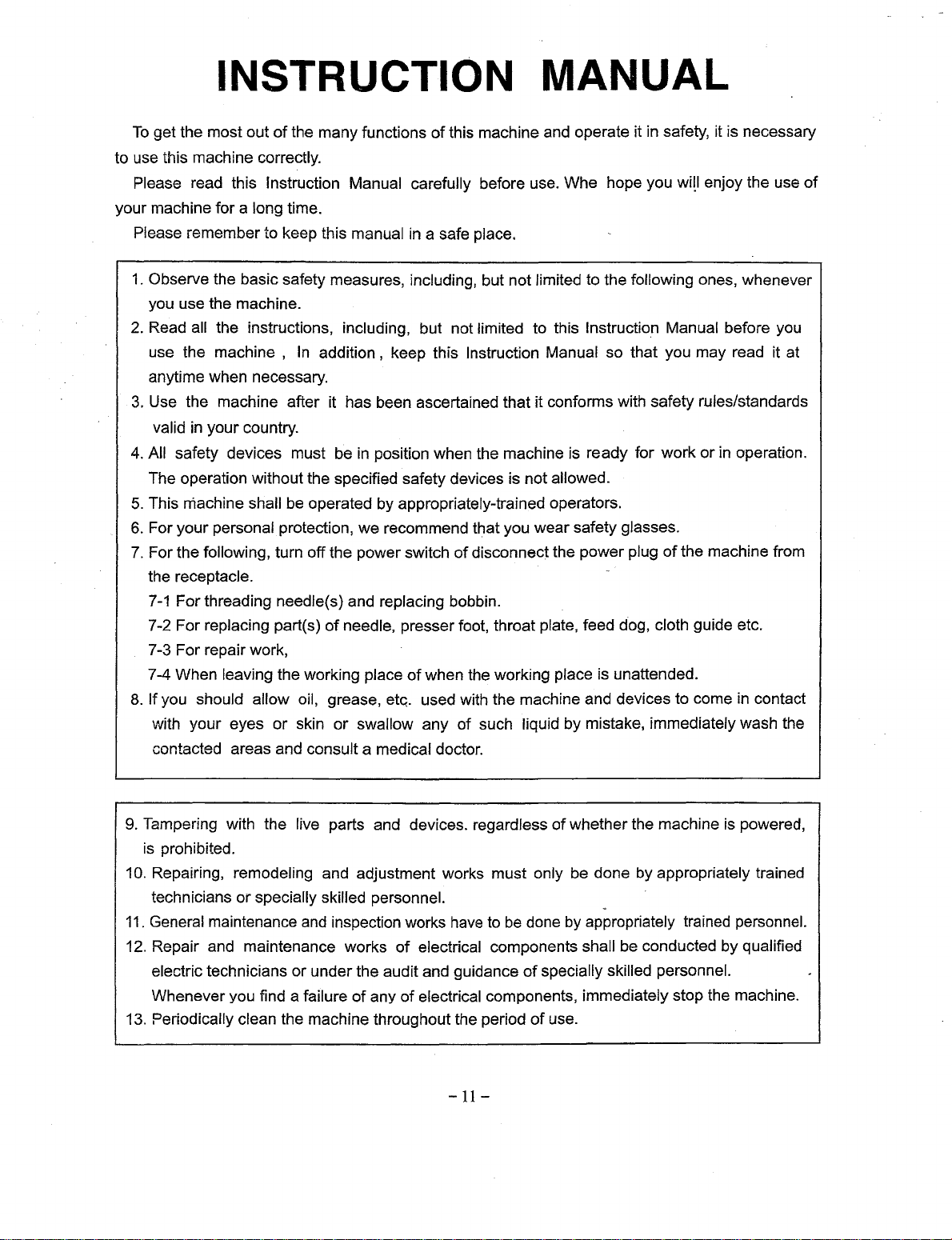

Fig.24

Fig.25

l1s.

ADJUSTING

Fig.26

THE

HEIGHT

OF

THE

of

30 kgf/cm and screw @ with a tightening

torque of 25 kgf/cm.

screws, the securing state

not change.

6) Fit cat

7) Move belt cover B ® backward E until the

8) Fix bobbin winder

Warnings: 1) For safty's needs, belt cover

KNEE

(J)

to the belt cove

rubber section

contact with belt cover

move the belt cover B in the

by

0.5 to 1 mm. Now, fix the belt cover B

in

position using wooden screw and washer.

and B using wooden screws and washers.

2) The left and right parts

LIFTER

WARNING:

(Fig.26,27)

If you tighten further these

of

the belt cover will

A.

of

belt cover B ® comes

A®.

Then, further

sam~

® in guiding holes A

should be installed.

bobbin winder should be

to the plate belt holes.

A Turn OFF the power before starting the

~

work so as to prevent accidents caused

' by abrupt start

1) The standard height

using the knee lifter is 1

2)

You

can adjust the presser foot lift up to

13mm using knee lifter adjust screw

3) When you

to over 1

of

needle bar ®

not hit presser foot

have-

Omm,

of

the sewing machine.

of

the presser foot lifted

Omm.

adjusted the presser foot lift

be sure tl)at the bottom end

in

its lowest position does

r

® .

in

direction

of

the

parall

CD

.

Fig.27

-24-

Page 29

119.

SPECIFICATIONS

I .

DPX5

For Leather

materials

3000 RPM

Smm

8mm(MAX.)

20#-23#

Application

Max Sewing

Speed

Max Stitch

Length

Lifting

height

of presser

foot

Hand

Lifter

Knee

Lifter

Needle

For Light mediumheavy materials

5500 RPM

5mm

6mm(MAX.)

13mm(MAX.)

DBX1

g#-18#

For heavy materials

3000 RPM

8mm

6mm(MAX~)

13mm(MAX.) 13mm(MAX.)

DPXS

~

16#-18#

f

()il

Lubrication oil

Motor power

1.

While Sewing Light materials, the machine need to change the presser foot, needle bar and feed

dog and do some adjustment.

2.

Machine with "R" added

is

using roller presser foot.

White

No.1 0

370W

l

To

order or for further information, please contact:

* Please do not hesitate to contact our distributors

when necessary.

* The description covered

the commodity without notice. ·

in

this instruction manual is subject to change for improvement

or

agents

in

your areas for further information

of

-25-

Page 30

~··

1!J:

-¥

Jill

PARTS

It was a new-revised endition

The machine with

Please confirm the relative applications Ref. No,

..

R"

added is using roller presser foot.

BOOK

in

December, 2001.

partno.

When buying the parts.

-26-

Page 31

~

CONTENTS

1

..

~Jl.~~ffiftF

2

..

:E*fbbzJ~E~ff?tffi14=

3

..

ttff..

Machine Frame & Miscellaneous Cover Components

Main Shaft & Thread Take-up Lever Components

~~&~~~~i9.1tlb~ftlf-l:

Needle Bar, Upright Shaft & Hook

.~

...............

.........

28

31

Driving

4..

lliH!P?tftlftf:

5..

~*4~g.EHtf:

6..

7fiJ)ft~ffiftf:

7

..

j(:Q1l[?tffiftf:

8

..

Ji:ffl~

Stand Components

9..

~~R7~*~lliH!P.:tf

1

0..

B1tf4:

Shaft Components

Presser Foot Components

Feed Mechanism Components

Oil Lubrication Components

Oil

Reser-Voir

..

~~~

Accessories

~i1~~~ftlf!f

...........................................................................

Jf.Jftf:Modei

..............................................................................

...............................................

...................................................

.............................................

................................................

Components

Belt Cover

.. R ..

Presser Rollar Special Accessory

·····················~·····························43

..

Bobbin Winder & Thread

~

..................

...............

33

36

38

41

45

48

50

-27-

Page 32

1

..

fJtft*'t.D.f-f:

Machine frame & miscellaneous cover components

8

4

~

37

. !

_j

I

I

~-----------..

I . I

I<)>''

las~~

l39

I j I

I 40

---------

L

_________

11

I

~

~41

-28-

Page 33

1..

tln7t~.H.

{4. Machine frame & miscellaneous cover components

J¥-'%

14

REF.

No.

PART No.

1 GR581-8

GR582-8

2

GS159-8

3

4 GR679/2-8

5 GR585-8

GR584-8

6

GS300-8

7

GR578-8

8

GR579-8

9

10

GR586-8

GR587-8

11

GR611-8

12

GR800-8

GR602-8

13

GQ200-8

14

GS310-8

15

GS310-8

16

GR603-8

17

GS313-8

18

19

GL167-8

20

GR609-8

21

GW184-8

22

GW202-8

23

GR608-8

24 GR607-8

GS314-8

25

GW183-8

26

GR606-8

27

28

GS315-8

GS316-8

29

30 GX200-8

GM166-8

31

GM173-8

GS338-8

32

GR604-8

33

34 GS313-8

GR583-8

35

GS300-8

36

37

GM167/4-8

GM168-8

38

GW190-8

39

%1

lifi~Ji

Face plate

trot&~

Face plate gasket

lij;iB3t&9\.~tTSMl/8"X44

!MtJiiSJJiilit&if~14

t11:~jtffff~~1l~

'ftff[ti:Jtp;j~.fl~

f§"iftJi!ll.'-iTSM3116"

fE

M

t&

Side

J~Wt&~

)!*4

iJWW

T

$1[3l~

JitX

ff

Needle

:ii~tt

~

1~~1~~

13E~tf1J~JJ!l\.~fTSM3116"X28

=-ft~t~T:iJt~iTSM3/16"X28

f:J-fXT:iJ

t"~f±J!I\.~fJSMll/64"X40

*~liS:gli

~~t~-BJ

~~fl]Iji}J*Ji

~tit)!

~tx:ii

f'~tltt&

~tit*&

xtlt~iT

~Etltif

tiE~:iH~~~

3<:tltt~T:J~~9\.~T:TSM9/64"

3<:~~!1\.'-iT

f!ttX

itif& Needle plate

itt&

rrt&9l.~T:T11164"

ft.~i'AJ

ti:~~Jt~fT11164

ilff;f&ifi1t'Pl~fl~

OO*&~T:T3116"X28

}i;j:&{f!)f!j: Bed slide

:flt& Slide plate

HH&i{

Needle thread guide pin 1

§~~#J

Ann thread guide-Right

Tension spring

Tension spring 1

Tension Disc holder

Tension Disc

Take-up spring

iT Thread release

Needle plate

ARM thread guide-left

Spring of slide plate

~

DESCRIPTION

ASM.

L=4

ARM

oil shield

Rubber plug

Rubber plug

X28L= 9

plate

Gasket 1

Wfl~

~

14

Rubber plug 1

Rubber

plug

thread

guide

Three-hole thread eyelet

Earthing indication plate 1

Thread tension

Tension nut

Tension

Screw

Screw

Disc

stopper

Tesion post socket 1

pin

X40L=8.5 Screw

11

X40L=

Rubber

plug

L=9

ASM.

~$

Scr~w

ASM.

Screw

pin

L=6.Screw

L=6

Screw

L=6

Screw

ASM.

Screw

9/64"

11/64"

Screw

6

Screw

3/16

l/8"X44

3/16"X28

3/16"X28

3/16"X28

11/64"X40

X40

L=8.5

11164" X 40

11

X

28

L=9

L=4

L=9

L=6

L=6

L=6

L=6

I~~~

I~'

I

QTY

~

1 .

1

1

1

2

1

8

1

~~?st¥4\

For

L!ght

medium-heavy

materials I matenals

*

*

*

* *

* * *

* *

*

*

*

1

1

-1

1

1

1

1

1

1

~

1

1

1

2

1

1

~

1

1

1

1

1

2

1

1

-

2

3

1

I

1

I

I

1

I

* *

*

*

* * *

*

*

*

*

*

*

*

*

*

*

* * *

*

* *

*

*

* * *

*

*

*

*

* * *

* * *

*

*

I

*

)I~C¥4

I

he_avy

tiqiN

For

lcath.er

matenals

1 ·

For

* *

* *

* *

*

*

*

*

*

*

!

*

*

*

* *

* *

*

*

* *

*

*

*

*

*

*

i;t

*

*

*

*

*

*

*

*

*

*

*

*

* *

*

*

*

it

*

* *

*

*

*

*

*

_,

*

t

*

*

*

*

I

*

I

-29-

Page 34

l,

tl7C5t~iftf:

Machine frame & miscellaneous cover components.

J:f%

14

REF.

PART

No.

40 GS339-8

41

GS299-8

GR724-8

42

43 GS373-8

44 GQ195-8

GQ218-8

45

GX196-8

GK153-5

46

GK162-8

GQ196-8

47

GR1428-8

48

-%

No.

tf:U&.iiiJ~-~fT3/32"X56

f~t&

Ji:tt Bed screw STUD

~~fJit?M

Jl

~~fj[f'~

Jl

~%~Model

ru!%

#$

Model plate

ru%

#'

Model plate

~%~~PfT

~~~ff~JJt?

~E~tf~JJt?

1(:@:i=!Ir~~

Oru!

Ill Rubber ring

~

DESCRIPTION

L=l.9 Screw 3/32"X56 L=l.9

Ruler plate

!!!,.~

fJ

Ruler plate screw

plate 1

Pole

.!l Thread take-up lever cover

~Ii\

a Thread take-up lever cover

Safety-indicating plate

~-

QTY

2

4

1

2

1

1

2

1

1

1

1

...

9=IJJ*4

For

Light

medium-heavy

materials

*

JJ;f4

For

heavy

materials

* *

* * *

*

*

* *

*

* GQ228-8

*

* * *

*

*

*

*

* *

*

1tifi*4

For

leather

materials

*

*

*

*

-30-

-

Page 35

2,

3:tdl.&~~ff~i.D.f-l:

Main

shaft & thread

take-up lever components

18

17

6--13

@--14

27

-31-

Page 36

2

..

±!fdl.&mt~ff:5jr~_[f~

J:f-%

REF.

No.

14

-5

PART No.

Main shaft & thread take-up lever components

36

I)ESCRIPTION

~

...

r:p

For

~·

QTY

Light

medium-heavy

materials

Jf;f-1-

Jf~4

For

materials

Jt~t+

For

heavy

leather

materials

GX199-8

1

GR596/2-8

GS308-8

2

GR595-8

3

GH212-8

4

;GH358-8

5

IGH210/4-8

.GH350/4-8

6

IG0265-8

'7

GH208/2-8

I

GH352/2-8

GH213-8

8

GS309-8

9

GS307-8

10

'GH349-8

11

GH207-8

GR167-8

12

GR592-8

13

GS371-8

14

GT156-8

15

GT159-8

GS332-8

16

G0256-8

17

GR588-8

18

GR650-8

19

GR589-8

20

2I

GS305-8

G0259-8

22

GX198-8

23

24

00258-8

GS306-8

25

GR638-8

26

GR808-8

27 GP147-8

GP157-8

GS304-8

28

GZ229-8

29

GR590-8

30

G0261-8

31

GR591-8

32

GS311-8

33

1jE~J!ff1rf~~f4

1~E~J!;fH~if~14

iiE~J!tt1~!1\.'-'fT15/64X28L=105

~E~ff~~nll~

~E~J!H·

1jEgxJiff Thread take-up bar

~li~x:iiff)J\.~11.

tJHxJ!tf)J\.gJ:i

tJE~ffi~f-Hmi¥\

t:IE~ffBt~~~ftj:

~E~Iitlt~-~~14

~tfFJ!tf

#Eg~fiM~ft:J)JE~;tT9/64X40L=4.8

#ffilllm~1111-t'-n9t32X2s

#ff

liB

t~

'fttf

liB

t~

tlE~Iitltp;j~f.flt~'fTli40X40

J;EfJr.t~aro~[IJ

'ft·fflitltfl-J5Ef.fl.t~'fT9/32X28

:i!f4fffi!H

:i!f4fffiJH..'$~

)!f4f~{.'~{:~ltT114X40

..t$!§"$~

..t

tf:!5f)!{f$r!!JtH~~

..t!fr!Jffl~

1:$rtl~fl.t~'fTll40"

..t!fr!lmT!fr!l~

ffE

l-.!fr!IJ:f!fr!l~

.lJm~!fr!J~.t~iJ

:ib:f4fffiiH:.'$~~t&

:T!f4f,lffi-l.-$t~t&

..t$~

_L$~

..t~.t~'fT

_t

liB

fflltr;jirtJ"I:iftiJ$i~~

ffll:tiJ;J¥8ti'iftiJ$

1~'L'$~Iffi:f&~tT9/64X40

..

'$~

!fr!li!B

i-t

fi};jlffi]i:iJt!Jltfff

Hand wheel

Hand wheel

$!H

Main

fp;j

i!B

It~~

Thread take-up crank shaft

Thread take-up crank shaft

Screw

15/64X28L=105

Oil resistant cover

Thread take-up bar

14

Thread take-up lever

14

Thread take-up lever

Needle bearing

Needle bar crank

Needle bar crank

Needle bar crank rod

End

L=16

Counter weight

Counter weight

L=6

Rubber ring

L=

Feed drive eccentric

Feed drive eccentric

L=11

Main shaft rear bushing

Oil

seal

Snap

ring

Thrust coller

X40

L=6

Main shaft front bushing

Oil amount adjusting pin 1

Intennediate bushing 1

Screw

Thrust caller

Thrust coller 1

Screw 1

shaft

tM

{8.

Roller felt

Sleeve of oil

1

~~0~[fl

0-ring 1

L=6

screw

Screw

Screw

Screw

cam

cam

Screw

Screw

amount

Screw

ASM

ASM

left

9/64X40L=4.8

9/32X28

l/40X40

9/32X28

114X40

1/40"

adjusting pin 1

9/64X40

X40

L=16

L=ll

L=6

L=6

J

1

1

I

1

2

L=6

L=

1

I

1

1

1

1

1

1

1

1

2

-

1

1

1

1

2

1

1

1

1

2

1

2

1

-1

1

1

1

2

*

*

*

*

*

*

*

*

*

* *

*

*

*

* *

*

*

*

*

* *

*

*

*

* *

*

*

*

*

* *

*

* * *

*

*

* *

*

*

*'

*

*

*

*

*

*

*

*

*

*

*

*

*

* *

*

*

*

*

*

*

*

*

*

*

* *

* *

*

*

* *

*

*

*

*

*

*

*

*

* *

*

*

*

*

*

*

*

* *

*

*

*

-32-

Page 37

3,

itff,

~WJ&1i:m!JI!~$dl5tftl.f-l:

Needle

bar,

upright

shaft & hook

driving

shaft

components

L1s

17

~12

2

,.

13

~14

~

15

13--ift

.

19

21

~

~16

®--13

22

18

36

30

23

28

-33-

Page 38

3,

~%

REF.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

ltff,

{t:j:

PART

GR599-8

G0266-8

GZ230-8

GZ251-8

GR598-8

GS311-8

GU152-8

GR600-8

GR801-8

G0267-8

G0289-8

GS312-8

GR601-8

GR802-8

GV132-8

GV134-8

GC157-8

·as319-8

GC156-8

GC155-8

GC154-8

GZ234-8

GZ255-8

GN139-8

GN566-8

G0272-8

GS403-8

G0271-8

G0270-8

GN137-8

GR636-8

GS331-8

GR631-8

GR818-8

GS328-8

G0269-8

G0291-8

GS316-8

GS414-8

GR634-8

GS330-8

g£!ftk_&1i~!l~!ftk5ttiUtf:

%

No.

~i·ff

J:.$W~1L~

ftff

_l_$83~

fttf

ftff

ftff:i!~ff

ttiff:ii~ff!l~fJ9/64X40L=6

ttff:i!~tt¥f*

ittFf$W~~~tj

fttFf$8~~~

fttfT$8~

ftffT$83~

~

rrt~iT1/8

ftff~ii;J

ftff~it.J

tJlft

tJli·r

Ltm~fu~

~-&~!l'-iT114X40L=8

1£$rf!_l_~-&~

Q£$rf!T~&$t

T$W~w~

Q£$83

.Y£$83

t~{.'

t~JL'

~~$81:$8~

~$81:$1I*~fi3/16X28L=9

~$!IT$*

T$ffiffi$8~

~fEti

Hook

JJJEt~

Hook

T$~

T$8~~!l'-iT11164X40L=4.8

fiJEt~

JE

J1JEt~JE

JJJEt~

~fir

T$11tr$W~

~-!fr±nw$83~

T$rll~u$W~!l~lfT

Tttenw!fill~~~h

T$W1~na~

-F$81SiEB~t~iT11164X40L=3.5

Needle bar upper bushing

Needle bar

Needle

X44L=4.5

Needle bar thread guide 1

Needle bar thread guide

(DBX1)

(DBX5)

Upright shaft

Upright shaft 1

Bobbin

Bobbin

~

Thrust collar

1.fl

ftJ

Positioning finger

1.fl

~

Positioning finger

fi;J

~"'IT

Front bushing

Front bushing

Thrust collar 1

Needle

;g

DESCRIPTION

Cap 1

bar

Needle bar connecting-rod

Slide black

Needle bar thread guide 1

Needle

Needle bar lower bushing

Needle bar lower bushing 1

NeedleDBX1

NeedleDBX5

Gear

(

*)

(;J\) Gear

(*)

Gear

( !J\)

Upper bushing 1

Upright shaft lower bushing 1

Rear bushing 1

11/64 X 40L=9

bar,

upright

f*

Screw 9/64X40L=6

bar

thread guide

Screw 118X44L=4.5

of

main shaft (big) 1

Screw 1/4X40L=8

of

upright shaft (small)

Gear

of

upright shaft (big) 1

of

hook driving shaft (small)

Screw 3116X28L=9

·screw 11164X40L=4.8

Screw

.5

shaft & hook

11164

X 40L=9

~·

QTY

.5

I

Screw

Screw

Crew 11/64X40L=3.5

driving

...

medium-heavy

J

1

1

1

1

1

1

1

1.

1

1

1

8

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

r:p

For

materials

*

*

*

*

*

*

*

*

*

*

*

*

*

* *

*

* * *

*·

*

*

*

*

*

*

* *

* *

*

*

*

*

*

*

shaft

JJf-+

Light

components

ff*il-

For

materials

ltlt~

heavy

leather

materials

*

*

*

For

*

*

*

* *

* *

* *

*

*

*

*

*

*

*

*

*

*"

*

*

*

*

*

*

*

* *

*

*

*

*

*

*

*

*

*

*

*

*

*

*

I

*

*

*

I

I

I

* *

I

*

{~

I

!

*

*

*

*

*

-34-

Page 39

3~

ltff

~

f:f%

14

REF.

PART

No.

32

GR233-8

GR252-8

33

GN138-8

34 GR633-8

35

GS329-8

36

GS402-8

~fdl.&tlf~!J!~$dt5tffi.ftJ:

%

No.

r$13

Hook

driving

rttffi

Hook

driving

t~%

Bobbin

~%

Bobbin

r~~~nE~

r$H~~rffi~.YT

r!ffBJ§"!fffi~~fJ3116X28L=l2

case

case

Oil

Needle

~

DESCRIPTION

shaft

shaft

wick

Screw

bar~

upright

~

Screw

3116X28L=12

shaft & hook

~__§.

_m.

-

QTY

1

1

1

1

1

1

1

driving

shaft

ft.,~

~t-t

For

Light

medium-heavy

materials

*

* *

* *

*

JI1:f4

For

materials

·*

* *

.,

-

I

I

components

)f:;*4

For

heavy

leather

materials

*

*

*

*

*

*

I

-35-

I

I

I

I

I

Page 40

4,

ffMJft~D.f4

Presser

foot components

I

)

./

/~

/

19

-36-

Page 41

4..

ffiJW5tiJ)Jtf:

Presser foot components

J¥%

14

REF.

PART

No.

I

GR6I9-8

2

GS322-8

3

GR621-8

4

GR620/2-8

5

GR623/3-8

6 GR625-8

7 G8323-8