Page 1

zJli;tx>.

lili

]~

J:JJ

INSTRUCTION

iJi

EJij

MANkJAL

•i~-=¥-M

1fitl'

PARTS

BOOK

Page 2

§I

~

1JE:

Jf1

i5t

~Jj

CONTENT

Operation Instruction

1,

.:E~t!=*;E_.W,;ft

2,.

~f!=§tr1tf£$::I~m:

3,

5te~~$

4.,

ii~Jj~

Oiling

.:rh·~·ll·~~·r<:<t=.-:a

5

..,

l!rl

~fl·J

i~

d~

6

...

Ml~~jfi17~a·'~1;~~

7

...

1til*a9iJ~ftt

8.,.

:iElt81!]~fJl.ilf.I'criodical

9.~

~~!Ji$.'jgifl

"' 0 .,

i~

~

·Rotating thread · · · · · · · · • · · · · · · · · · · · · · ·

1

i,

7}':2-~~fLti-

12.,

:§.f

[§1

~

i

3..,

i~:PttgE~Q'fi!j~

",1-'

••

;~?S!?1r.~flJL-r-,

'"t

_

',%or:;J

xili~

·j

5,.

im~B-h::'h

16,

J~~~~1J

17

...

iJ~~~;fji

i

8,

tt:f.&~.§_

i 9

...

i]j

20-.

~~~:f'Li&:f.&atliJ!Jf.l

21,.

~'E~1!f:lf1£~

14=1¥-J~~

JJ

tf.J~~J:i~1~

SPECIFICATIONS········· ..

BEFORE OPERArlON····································o····o·······.,···· .. ·····

Installation for

•........

'T}-,,

1.11..

.,;t··

.1

.1

....

S1

Oil purnp supply adjustment

belt

································································o···········2

o

••••••••••••••••••••••••••.••••••••••••••••••••••

t'

Ua

To

;:·,,·1·

10D

01

vl

111g

adjust the oil feed to rotating hook ··············································3

r.:::Jeaning

Fixing belt

InstaUingtheneedle

cover···"·········

............

Itiding the need thread · · · ·

Adjusting the stitch length

A.rt'

JIA.J

,~

To

Adjust

3f{&m-m

. h h d .

...... Jusnng t c t

adjust

need.1e

bobbin thread

Adjusting feed dog

Fixing the throat

Operating and fixing

rea

thread tension

tension·····

Using the waste materia1

Changing

other

• • • • • •

·················

••

•• • ••

•.

•.

...............

••

• • • • • • • • • • • • • • ·-• • • • • • • • • • • • • • • • • • • • • • • • • • • •

o · · ·. · · · · ... · · ·. · · · · ·. o · · ...... , .. " ......

o.

..............

·····································································3

•o

••

• • •

••

•••

••

• •

••• • •••• • •••

··

· · · · · · · · · · · · · · · · · · · · · · · · , · · · · · · · · • · · · · • · · · · · · · · · · · · · · · · · o • • •

,.

....

,,

......................................................

·"

· · · · · ·

··

· · · · · · · · · • · · · · · · · · · · · · ·

and

control11ng

tension······························································

...•..........•....

...

·•·•••·••···•·

slope······················

plate······························································

of

trimmer

guide····

parts································································

the

··.··········•·····························

..

·••·••••···••···•

··

· ·

···

· · · ·

........... : .........

o

•••••••••••••••••••••••••••••••••••••

oo

......................

• •

••••

• •

•••••

• •

•• • •••••

"·

· · · · · · · · · · · · · · · · · · · · · · · · · · ·

reverse

..

··················

·-~

sewing··················

......

·

··

··

··

·· · ·· ·· ··

•·••••··••••···••

..

· · · ·

···········•o··········· 7

•••••••

o••····3

•••••• • ••

~

· ·

.,

···············

··

···

··

· · · · · · · 6

•

·4

· · · · 4

·j

·i

2

3

4.

4

5

5

5

5

5

6

7

~1t:f:*$*

Parts

1

..

2..

3

..

4"'

5,

6,

7..

8,

Book

*Jt~=giH*A.rm

...t~~t*'f~~~$14=

f~3F~~H}~~f4=

ttHE!iJI.IT.i"~~14:

ffiJWJ~iH!f:

i;JJJJ1~$1J$14Knife

jj!j~$itf:

iftt&

...

llft1!.f:

bed

components······························································B-9

Arm shaft vertical shaft needle bar and thread take-up······

Needle bar and thread tension components

Stitch length regulating mechanism

Presser foot

p<rrts

.................................................................

controlmechanism··················································18-19

Lubrication

mechanism·························································

Oil reservoir and accessories

...........................

................................

................................................

·1

0-11

12-13

~···14-

i 5

·16-17

·20-21

22-23

Page 3

jt.

~t~f~*t:!t~

SPECIFICATIONS

t:W.t~

~*4

ji~~it(rpm)

jtjcft~(mm)

$tff1i-*~(mrn)

til$+

Biiflil!i'tJt

~

~

~JJt

~1-~*~

~·:bJE~

I

'Fl£(mm)l

!

"'l£

;~:l!"(

I ii!JlffAA

....

m

!

I

t

I

I

f N ffile

Specification

Application

Max

sewing speed

Max stitch length

Needle bar

ting height

oresser foot

Lubricating system

Rotating hook

Lubfieation

Motor power

mm~

-

jomney

I

I

I

'

'I

Hand lifter

Knee lifter

~~

ri*4.3IJ:fl~*l

4500

5

31.8

DPx1 9#-14#

4

10

§~

m

~ilfJ~tnte~

~~~WI

0.37::P"M: (

~~JJ1JL={f)fj$..1JL)

Parameter

For light materials and medium heavy materials

4500spin

Smm

31.

Bmm

DPxl

Automatic hook lubrication

Automatic lubrication

9#~14#

4mm

lOmm

Auto

0.37KW

t

r

t

I

j2.

~ftffut.ti\$JY!

BEFORE OPERATION

- 1 -

I.

Caution

l)Keep

2)Please

3)Please

4)To

S)Do

6)Do

your

hand

of

tlie

noodle

the

machine

).Vorking P.lace ot-when

IS

machine

adjust

head

wheel,

is

of

thread

machine

installed

hand

turn

unattenaed.

tum

head

or

avoid

personal

and

other

V

in

belt

operation.

not

put

the

needfe,

take

is

not

start

housing

away

and

is runmng.

off

power

off

install

remove

objects away:

and

_your

the.

-

up

running.

the

machine

the

belt

or

protect

the

power

motor

hand

lever

from

driving

the

the

machine.

injury

into

driving

cover

the

lower

wheel

when

the

while

the

leaving_

working

when

tilting

wheel

belt

,keep

you

from

the

the

whe~

cover

unless

and

P,rotect the

eye housing.

wnen

place

and

fingers,

the

machine

ltwer

and

when

it

has

part

the

the

fiand

part

the

the

been

Page 4

2.

rlff.@t~n:

l)~*MM~~~~~-~-~,·~·

fFtJl~o

2)~*mu£•~mm,~~m•~~•

~1JL~o

s)~-~•wm~~~~~·••~~~

~~~~0

;t

tf~

~

4)~~~~ffi(·~~~~~~~~~

~~:affi~o

3.

~ft~{lf-::

l)

~ffc.1:E~~lE~

-r~mm~,

2 )

)~£:96

1£:9(~£If~

!3.

~~~BiiW

1 )

1JIJf.H:~£JJ

2)W·~-~h,~~~~~bW~-~

*~~~tJtMi~,

JfF¥lliT,

(~~~~~~~tl*,

fOJ

7J

~

81

$t:lf

(OJ

0 )

)

fig/lEA

(

35t~J!~)

.-:emtlm~~ili~wJto

r

1Y!

ffl

fJL~

(

001)

tJU~o~~

Ltwlol

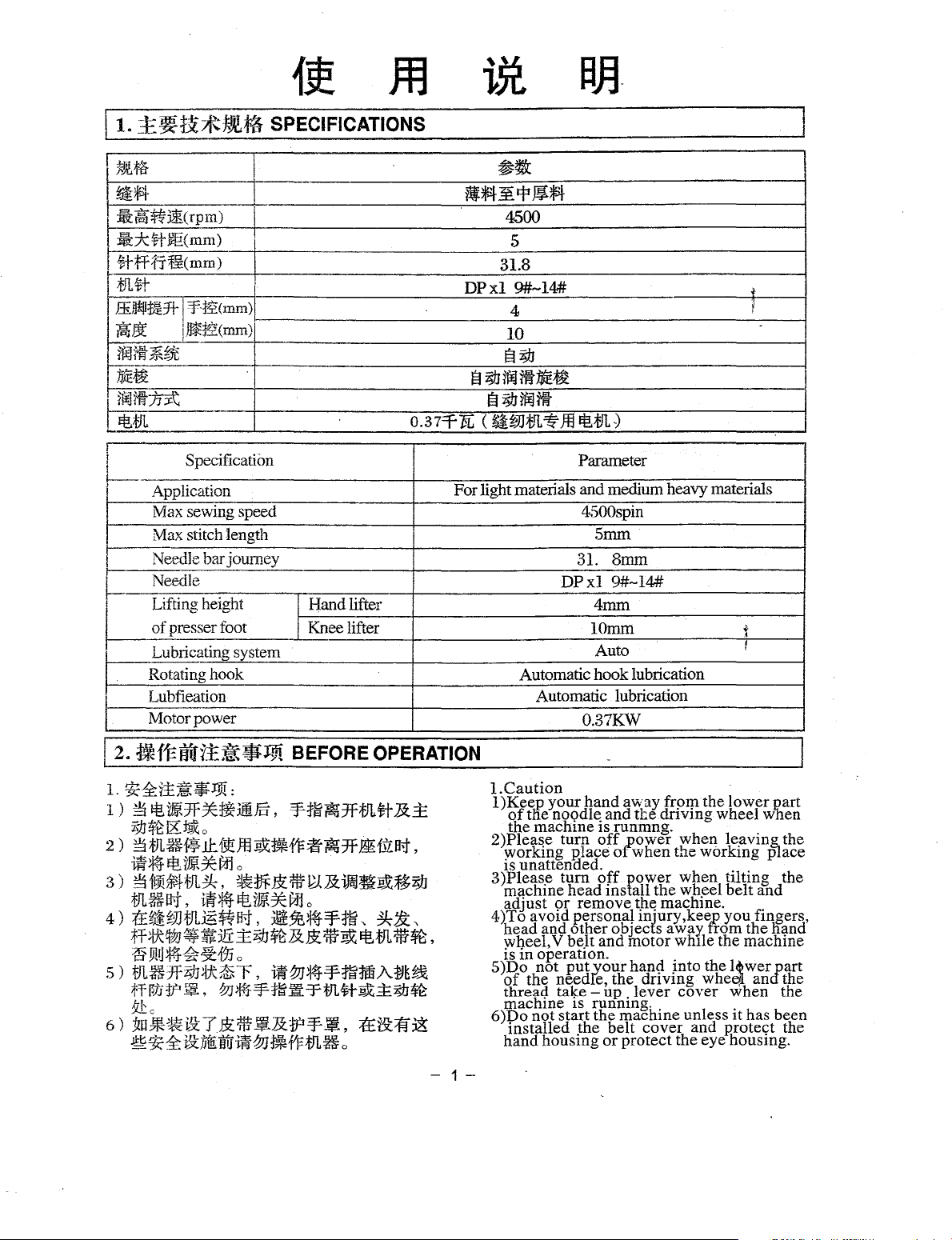

INSTALLATION

o

fr.~w;trcoot=flJL\1ili

~rr~;it!lomm-l5mm

~

!tiC~

o

FOR

&PUfo

1)

Use

the

belt

2)

Regulate

high

to

of

with

sewing

of

electr01neter

adjust

deflection

the

the

finger.

the

tension,

in

machine

belt

tension;

through

there

the

belt

special 0 type

change

turn

the

IS 1

0-l

when

it

is

pressed

the

nut

5tnln

2.Noted

l)Must

2)If

on

not

reservoir,

your

use

start

the

machine

machine

is

all

operate the machine before

3)\Vhen

4)Confirm

3.Pre-start

l)Never

abnormally

higher)

trouble.

2)The

BELT(FIG

running

counterclockwise

fight

side

start

the

reverse

correctly

plug

power

environment

clockwise

has

supply.

operate

otherwise

machine

the

of

the

machine

that

set.

confurm

been

properly

checks

your

high

has

that

1)

balance

rotation

balalice

when

direction.

the

vdtage

machine

te:mperature (

the

machine

to

be

is

from

ifno

oil

in

oiling)

lubricateo

·wheel :must

wheel)J~/hwt

balante

that

connected

operated

dust.

(view

\Vheei

has

the

under

35 c or

will

do

not

from

.not

been.

power

to

the

the

be

in

an

I 1

in

in

in

1

L~

10-15mm

(!;-t/1

Kg1J)

10-lSmm

About

force

~~

lkg

14~

~¥Jtft

(

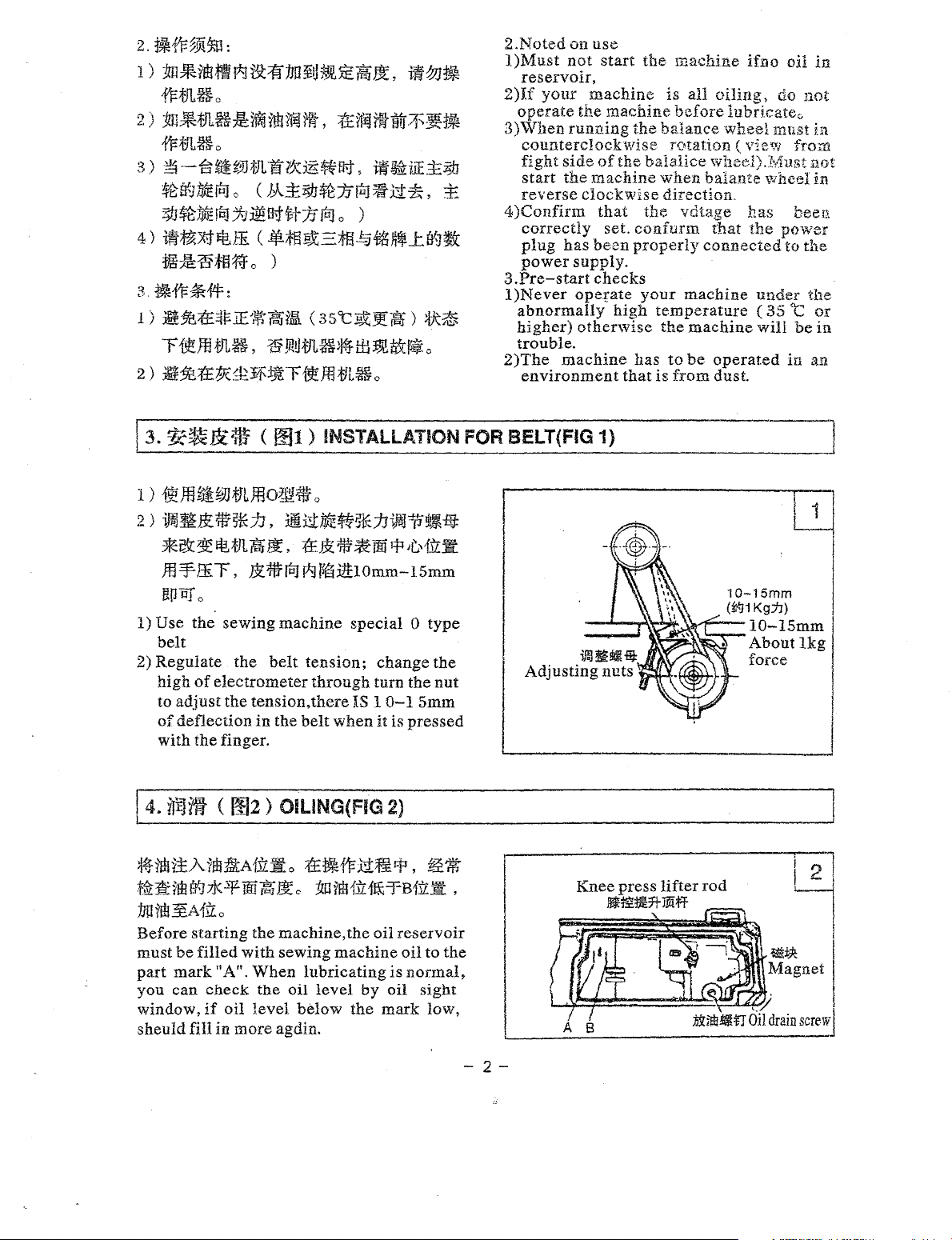

002)

OILING(FI.G

2)

'--------------

~~1mi1A.tffifi!A1ilito

~~~~*·W~~c

1111

rffi

~A

1ft

o

Before

must

part

you

window,

sheuld

starting

be

filled

mark

can

fill

"A".

check

if

oil

in

more

the

with

When

level

:fr~f'F~fir-p,

~~~~~Bili.,

machine,

sewing

the

oil

agdin.

below

the

oil

machine

lubricating

level

by

the

reservoir

oil

is

nonnal,

oil

sight

mark

§.£m

to

the

low,

-2-

A B

]tfB:!!JifJ

_j

I l

1

21

I

~±~

Magnet

. I

'-~

Oil

drain

screw

l

J

Page 5

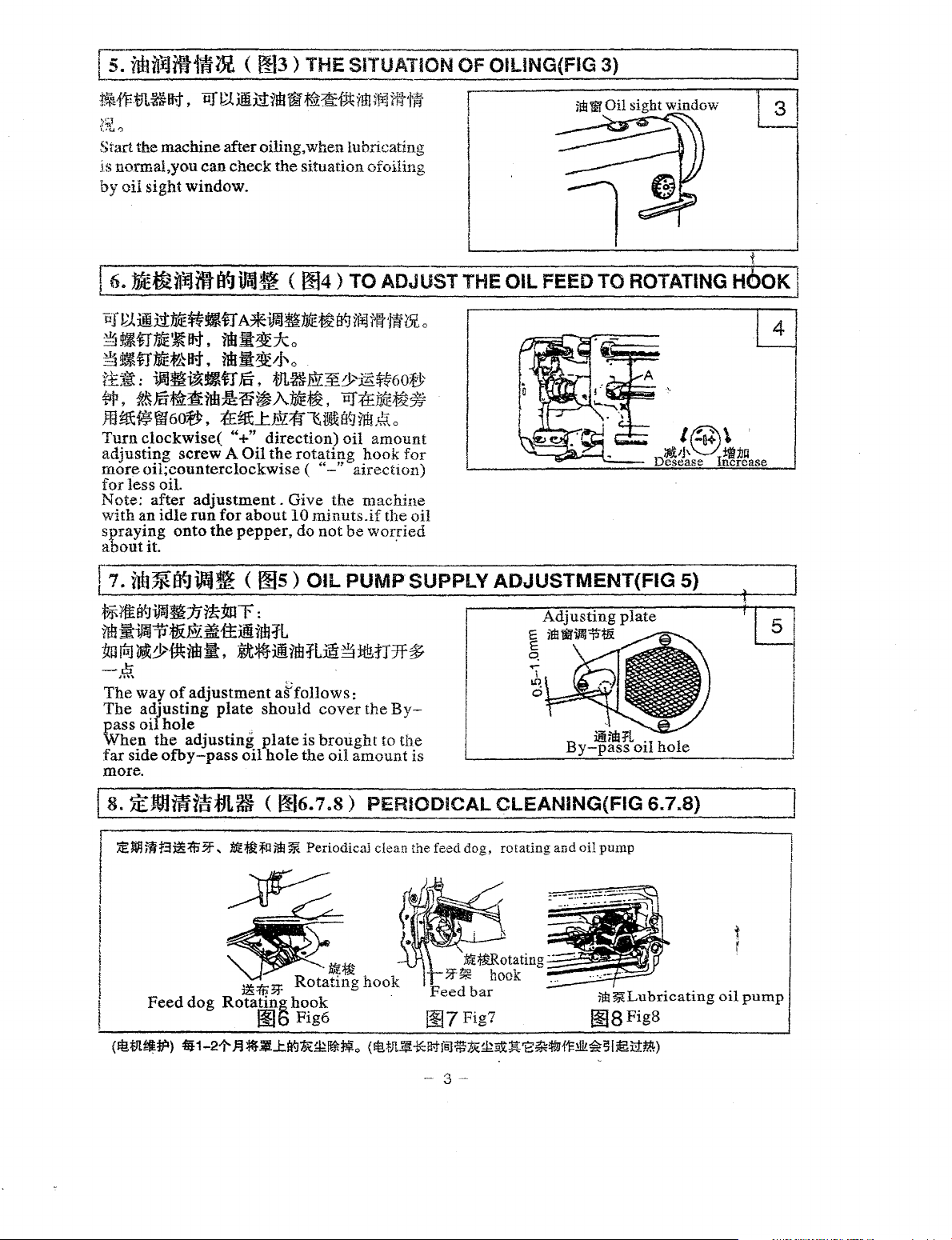

I 5.

nbi!¥Jift1Rf?Jt

L--~~~~----~--------------------------~--~--------------~

Start the machine after oiling, when lubricating

is normal,you

by

oil

sight

window.

can

(

003

check

) THE SITUATION OF OILING(FIG 3)

the

situation ofoiling

t

160

~~jf£jlftfi{JJM~

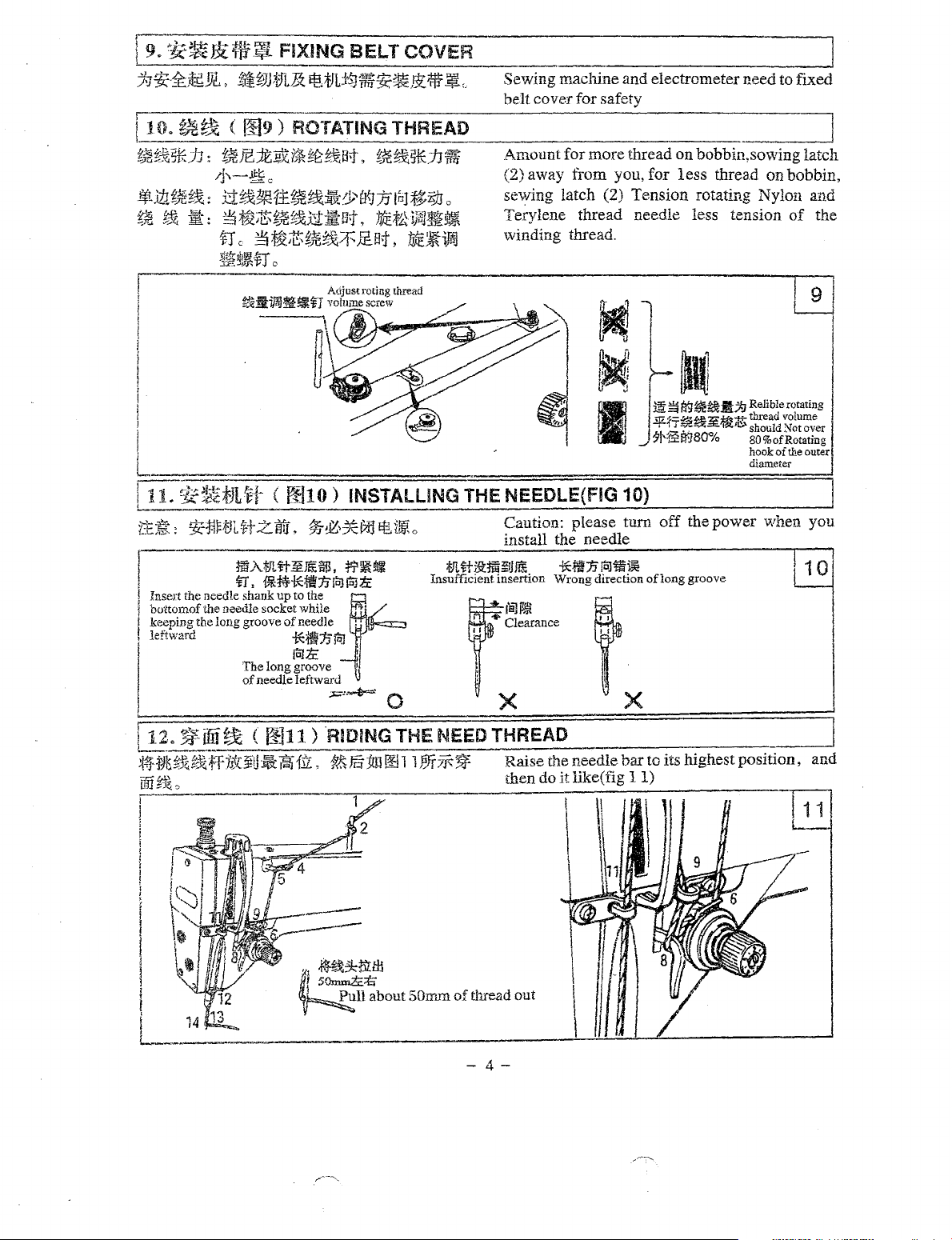

( 004)

TO

ADJUST

THE

OIL

FEED

TO

ROTATING HOOK I

!lJ~iln1itf~!fi$J

~~~ff:JifE~ft1'

~~tJJi[E*'~IJ1'

it:~=

~,~$~~~~~~A~~.~ft~~~

ffl~~\W60;f'P,

Turn

adjusting

rnore

for

Note;

with

sprayi~g

about

ti~i'rtB'-liJJ~:JJt!

nti:i:iJ.f:Plli~m1±ii

~~-~~~•,•••~~m~~n*~

-.5

The

The

pass

When

far

more.

l}.ij~~•tr

clockwise(

screw

oil;counterclockwise ( "-"

less

oil.

after

an

idle

onto

1t.

JH'

way

of

adjusting

oil

side

adjustment

hole

the

adjusting

ofby-pass

A*OO~J1Ji~Et-1?1~11J'·t~t5lo

llB:i?~::ko

nBil1f/J'\o

Jl§",

m~~~Y.i5~6o~

:tf~_t~:fl~lt8f.Jtf!LSZo

"+"

A

Oil

adjustment.

run

for

about

the

pepper,

~lrF

=

rm~L

plate

should

..

plate

oil

direction)

the

Give

l 0

aifollows:

hole

oil

rotating

the

minuts

do

not

cover

is

brought

the

oil

amount

hook

airection)

machine

.if

the

be

wor_ried

the

By-

to

the

amount

for

oil

is

imftfHL

By-pass

.

oll

hole

js.

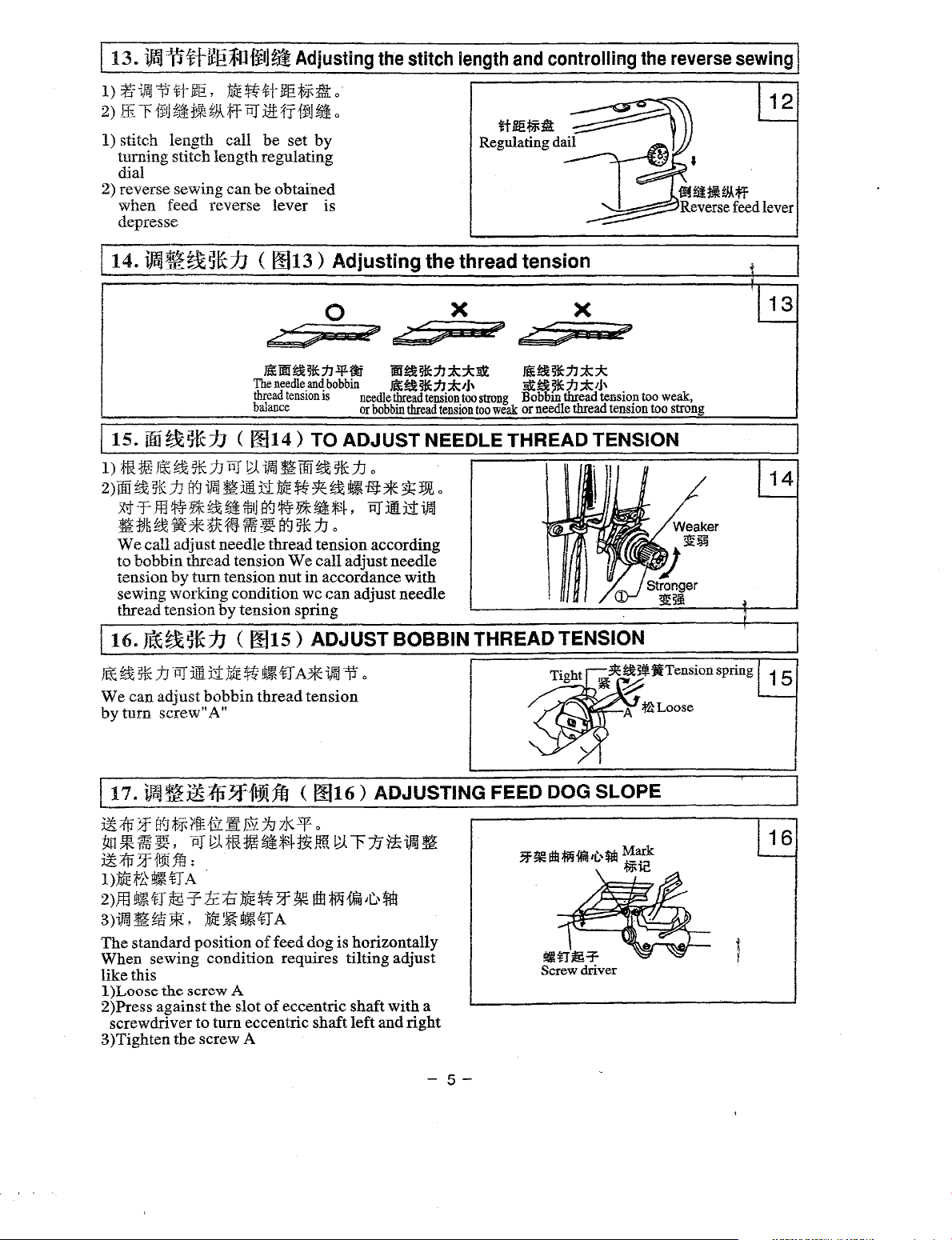

Ji::Miffiam~

( 006.7 o8)

PERIODICAL

-3-

CLEANING(FIG

6.7.8)

t

Page 6

I • -

!

9~

:~~t&:ftt-~-

~--------------------------------------------

FIXING

BELT

COVER

Sewing machine and electrometer need to fixed

belt cover for safety

Amount for more thread

(2) away from

se\ying latch (2) Tension rotating Nylon and

Terylene thread needle less tension

winding thread.

~~ZiiJ~.§:.I

J..t-:

..

.,.j.'IJ1'.:VJ

o

~----·

1 '

I

!

l I

--.-_

--:,.rljustrotingthread

Q!)

-~

-

-:-,.

l

L---~.

! 11.

r-·

!

! Insert the needle shank

j

! keeping the long groove

I left"'ard .IL·l;l!;--t:-f.::'!

.

~

f (tiJ;£' • I

L

l12c

L-·-----··-

~~·iJfi~~~:%tfht{JU~~if}Z:,

Im

~~

l

~

i

--=-=···=====================================================ru=·~=e=te=r==~

~:?~tllt1~

bo'ttomofthe

.~

.....

vv

~-ffif~x

§'t~

0

..

--------

-~

0010)

~A.tJut~~w,

t.r

' 1*f?f*;{f1J

up

needl.'

The

of

to the

e socke.t while

of

needle .

~11=!f.,l.J

long

groove '

needle leftward

(

~]11)

INSTAlLING

#~911

toJ

ltiJ

ii.

Insufficient insertion

t=

3~§

~:-~

.RIDING

rAfriJm~

0

THE

NEED

llJ~fr~*3¥

;fj1ttJ!ittflatlJi

THE NEEDLE{FIG 10)

Caution: please

install the needle

*~:ntoJ~~

Wrong

.;fBJ~

Clearance

X

THREAD

Raise the needle

then do

----------------..----,

it

you, for

kfJ

ti

~

~

direction

like( fig

on

bobbin,sowing latch

less

thread on bobbin,

of

the

J I

~

I

flll11!

91

II

>--~

'"'

j~~fl9~£ftit59

..m."'-

~..e.c-~:

•

2:~~:-'f~JC>.shouldNotover

9~1.:z:.a980

tum

off

the power when

ofiong

groove

X

barto

its highest position, and

11)

Relib1erotating I

Z>:"i:ft-H- thread volume

Yo

80%ofRotatino

hook

of

the

out~r

you

l

I

I

!

I

.f1f~:!ldliili

50mm..lc-::ti

(!

~11

about

50rrLffi

of

thread out

I

i

L-~

-4-

Page 7

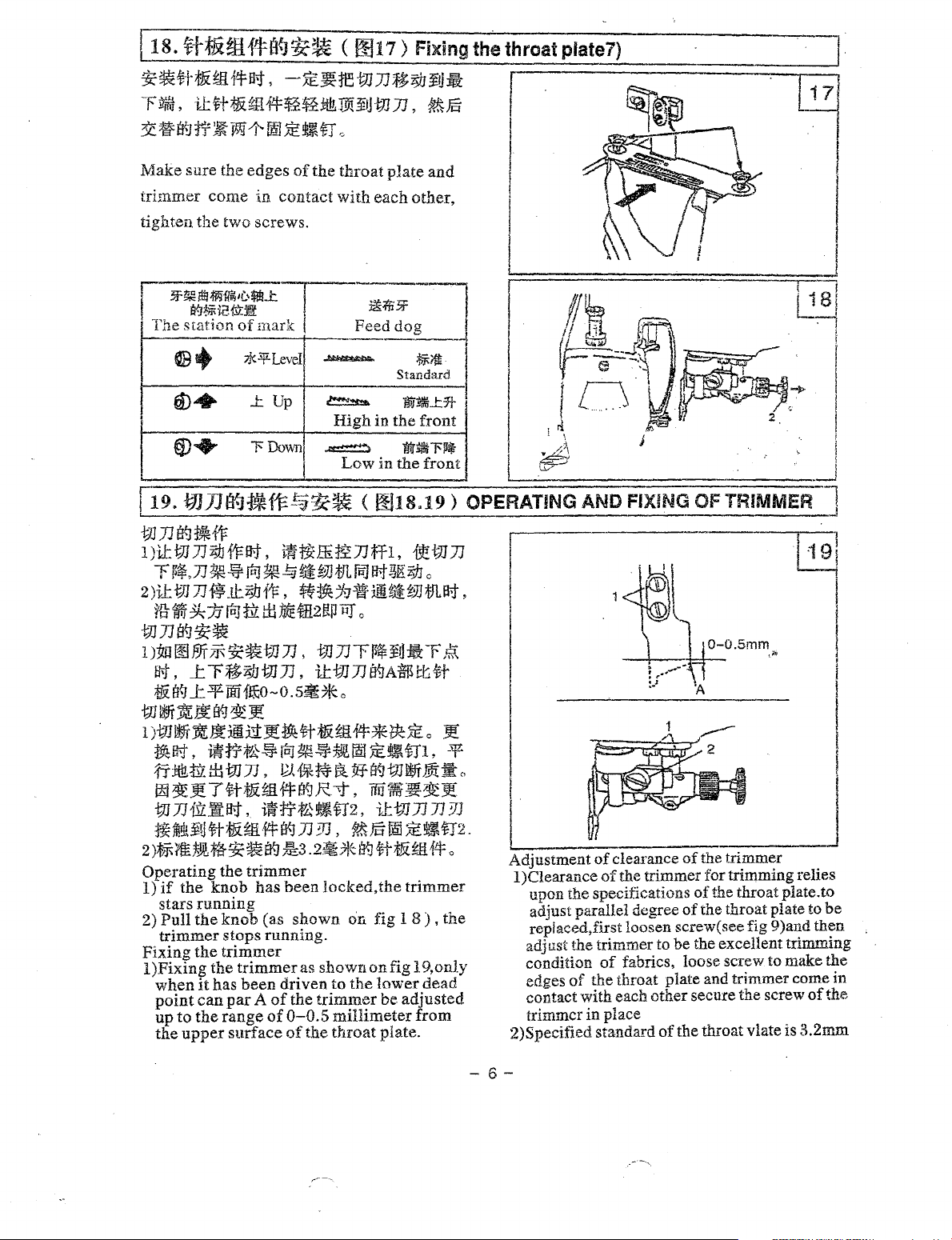

j13.

iJtilnft~efLHJIJ~

l)

~

iJJ

t.r

tt

~f_L

JjfE

W

2)

H5.

~

1~u

ri

1*

;A

HPJ*

l)

stitch length call

turning stitch length regulating

dial

2)

reverse sewing can

when feed reverse lever is

depresse

14.

iJJl!~s-t(n

tt

N§

1r

be

be

obtained

Adjusting

;f;ft

~

fitl

¥i

set

by

the

stitch length

o

0

( 0013) Adjusting the thread tension

and

controlling

the

reverse

sewing j

~~~~n¥~

Theneedle.anqbobbin

thread

tensiOn

balance

[ 15.

ffiitXsiC:h

1)

:m

~

Jf£

M * fJ

2~~*j;~~•mrt~~~~-~*~~o

( 0014) TO ADJUST NEEDLE THREAD TENSION

PJ

lj,

iffi.1

ts

~Tiff~*

~~ffl~-~-~~~a-~,

~t}fi~~*9tf#1rtf~

We

call adjust needle thread tension according

to

bobbin thread tension

turn

tension by

sewing working condition we can adjust needle

thread tension

l16e

Jtt:tx~lt:}J

~

M *

fJ

·ey

We

can

adjust bobbin

by

turn screw" A"

jt7.

l;a]~J2${fi3f-f@tff.J

:IS

/fJi

*

(ttl

~iF

~*-~'

~

;trJ

:f

1®!

i¥J

l)Ji/Et~~~JA

2)f§

~~iT~

3)~~~3R,

The standard position

When sewing condition requires tilting adjust

like this

l

)Loose

2)Press against the slot

screwdriver to turn eccentric shaft

3)Tighten the screw A

the

tension nut in accordance with

by

JI!i

it

JJJE

rft

ffL

:ie

mN~M·~~ft~~~~-·

:

.

-T

1i.

ti

JifE~!l~!fTA

screw

A

l¥J*j; 0

We

call adjust needle

tension spring

(

0015)

~

~~

thread

m

:7v

Jifi

~

of

ADJUST BOBBIN THREAD TENSION

~J

A*~

tension

(

~16)

Jk

3fl 0

3.f

~

liB

1W

feed dog is horizontally

of

eccentric shaft with a

~~~~~*~

~~51t~~'J'

needle

thread

tension

thread

fJ

or

bobbin

o

too

tension

~~~~~*

~~?*~~'J'

strong

Bobbm thread

too

weak

or needle

PJB~W

l:l

o

ADJUSTING FEED DOG SLOPE

iU

Jt\

~

left

and right

.

tensiOn

thre·ad

tension too strong

too

weak,

t

f

-

5-

Page 8

I'":

1:::8=:.

l::-::t:=-tli=~-=fi-:-{*:-A_{]_t;;~~~(-=[if=-1

~~<fi·;fi~li14Bt,

-r

~

, il:

$tt&£JJ.14=~~ttl!.

~if

i¥!1

rr

~

M"

~1£~1EtJJJJ~i9J!tl:&i

1'-!fTI

5E

i~

$I~

m

ftJ

__

-m

7_:_)_F

__

ix-=-in~g--=th.:..::~..::t~h:.:.:.r..::.:oa=t~pl=at=e.:.!.7)~

_______

_jl:

l

n ,

~

J§

1

L_l·

7 ·

I

Make

sure

the

edges

of

the

throat

plate

trimmer

tighten

come

the

two screws.

in

contact

with

each

and

other,

1.

I

~========~====~=J

~Bl

2.

·.

7

'

-:--"j

_J

l

I

l

l

I

I

!

I.

1

he

sratwn

of

rnark

Feed

dog

I

--I

~+

®+

tD+

ll9.

WJJA\Jfift!~:ti~

7.k-¥Level

Up

.l:

l'Downl

~

~

High

~

Low

(

~ft.

Standard

fru~...tJ"t

in

the

tru~l'~

in

the

0018~19)

I

front

front

OPERATING AND FIXING

I

I

II

~-i~

I 0

~

l ··'

J j '

~

I

J11

[rrf; .

e.~~

~

' -

~

..

OFTRIMfv1ER

'a

,-

tJJ

JJ

8"1

1*ft

l)ittJJJJZ#Jf'Fat'

~

~~,n

~~

2hlWn~~~~,~•**••wm~,

m-wr

~7iro1illili~m2r:tPur

tiJ]]Ettl*~

1

)ten

oo

wr

~

~~

~,k~8~WJJ,ftfflJJ~A8~*

i1:Ji

891:

.If

00

-ttiWT1EJl:IE~J!

~~~-~mttM•*fim#*~~o£

~EM·,

fi~illmmn,

~~~7*•m~ooR~,w•~~~

wn~w~,·~~•n2,~Wnn~

•M~*~m#~nm,~~~~•n2.

2

);{:~

Operating

l)

stars

2)

trimmer

Fixing

l)Fixing

when

point

up

the

iNt?f'l~lo1~~~11Ultt~$Jl~

~~t~»L

**~

the

running

the

the

it

can

to

the

upper

the

knob

knob

stops

trimmer

the

has

par A of

range

surface

if

Pull

i1ii:t:ffit~JJ;ffl,

fO:I

~_Eq!Ji~JJtJt

tJJ

n ,

{ij;O-

0.

5~

tlJ

* o

~

0

n

T-!Wf.

19!"WJJ

B1~fiZ5JJ

Jtl

~

o

-r

~~

-¥

w.~~~~~~~~•o

!¥-]

~3 . 2~

trimmer

has

been

(as

running.

trimmer

been

driven

of

0-0.5

of

the

locked,

shown

as

shown

trimmer

the

71~

~~

$t

;ff{

the

o'n

fig I 8),

on

fig

to

the

lower

be

millimeter

throat

plate.

g_fi

1!f

0

trimmer

the

19,on1y

dead

adjusted

from

..___.,

____

Adjustment

l)Clearance

upon the specifications

adjust parallel degree

replaced,first

adjust the trimmer to

condition

edges

contact

trimmer

2)Specified standard

of

cleaTance

of

the trimmer for trimming relies

loosen

of

fabrics, loose screw to make the

of

the throat plate and trimmer come

with

each

in

place

of

of

screw( see fig 9)and then

be

other

secure

of

the throat vlate

j

the trimmer

of

the throat plate.

the throat plate to

the excellent trimming

the

screw

of

is

3.2mm

to

be

in

the

-6-

Page 9

j20.

ft~WJfLf&~~Atlf:t!Jfl

1

)1'~m

~JBffi[)f.t

J:,

2)1-i~~~LlJii&i:Hi$~

~iim~f9!ffl

l)When

cover

2)After

sew only

7fli1:JJ

n

B1,

i~%~1-1~

~I¥-J1-tFN:ifL~*iif£!U14~wg

ii~AtmL.1itli:r

o

not

using

the

onto

the

opening A of

putting

on

the

o

B{J~lf

cutting

cover,the

(

0020)

~~*&ifF

lEi,

~OJ

knife.

the

chip

machine can

-F

3-~t&

fF.-:h

place

funnel

USING

,

the

THE

r

I

WASTE

MATERIAL

GUIDE

j

*mrei-tr.J~~t&~1:!:.lt~I/8"(3.2mm)c

m•mPW*,am~~*re•7~~~

~*'~~£~,~~~~*~#£~~

Specified

(3.2mm).

please

standard

read

If

you

this

of

want

list

'J£*.o

l

I

~~~4

I

I

1/8"

1/4"

3/8"

i

1118"~

~

•••

3/32"(2.4}

1/811(3.2)

5i32f44.0)

3/16"(4.8)

1/411(5.4)

3/8"(9.5)

I

3/32"(2.4)

ttf&~-f!f

3/32"

1/8"

5/32"

3/16"

1/4A

3/8"

Throat plate

"3

3/32~'

Feed

dog

3/32''

~;fp~

3i32"

1/8"

1/4"

3/8"

I

I

I

I

I

I

I

I

ffill!IJ

-

1/8"

1/4"

3/8"

Presser

foot

1/8''

the

to

change

throat

plate

some

I

I

;(j)Jilf~t&

1/8"

I

1/4;'

3/8n

I 1/8''

is

parts,

..

~

I

l/8"

I

1/8"(3.2)

5132"(

4.0)

3/16"(4.8)

l/4"(6.4)

3/8~'(9.5)

1/8~,

5132"

I

3/16"

114"

3/8"

1/8,,

1/8"

114~~

3/8~~

~...-.

I

I

·-

7-

I

1/8~~

I/4"

3/8~~

I

I

t

f

I

1/8'~

114~~

~

3/8''

I

Page 10

-.

*Jl~~B14=

Arm

Bed

Components

28

~

g-9

~29

54l:l~

53

'

58

-8-

Page 11

I

1¥~

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

21

19

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

.!i5-

00

Part

number

20-01-001

20-01-002

20-01-003

20-01-004

20-01-005

20-01-006

20-01-007

20-01-008

20-01-009

20-01-010

20-01-011

20-01-012

20-01-013

20-01-014

20-01-015

20-01-016

20-01-017

20-01-018

20-01-019

20-01-020

20-01-021

20-01-022

20-01-023

20-01-024

20-01-025

20-01-026

20:..-01-027

20-01-028

20-01-029

20-01-030

20-01-031

20-01-032

20-01-033

20-01-034

20-01-035

20-01-036

20-01-037

20-01-038

20-01-039

20-01-040

20-01-041

20-01-042

20-01-043

20-01-044

20-01-045

20-01-046

20-01-047

20-01-048

20-01-049

20-01-050

20-01-051

20-01-052

20-01-053

20-01-054

20-01-055

20-01-056

20-01-057

20-01-058

20-01-059

20-01-060

20-01-061

20-01-062

20-01-063

~

16

Name

iiit&.Face

iii*ffi.~Gasket

plate

"OO*ffi.!lllflScrew

iiit&.~Bt~Rubber

iii*Ji~1\1Thread

~~!lllflScrew

~t*f

fi±l

MH~m31-ifiiff(E:)!lll=f

..t.~mim=FL~Rubber

.

;fjJ:j!\lJ=fL~hole

=

~tt~~Thread-hole

.=:.~N~~!lllflScrew

f:Jt~iff~J'j~.f~Thread

f:Jk~ifT~J'j~.f~!lltTScrew

;E~~Frame

i1~iffNeedle

l'~tiiJFrame

l'~tiiJ!lllflScrew

~~~Bobbin

~~~~~!lllt"TScrew

-tJJ~JJKnife

~f-1-*~!llJ-H;Nuts

r:pJ:1~*.&~1!fMiddle

*~!llJ-H;Thread

~~tiThread

Jj\~~*.&Disc

-tJJ~JJ

~~~~Hm!mThread

im

~fj~Wa.J-=¥.i

~~ml'~t!=FL~Rubber

~Jt.~Rubber

tfff.:~Warning

~~~Model

!llJ~TScrew

$Oil

s~ht

=FL~Rubber

WPflScrew

l'~ar~:rL~Rubber

~t&J~ifTArm

*~Hffi.

*~!111-H;Thread

~~!l!Jta:Jtzro*.&Tread

~~~$tliThread

f~~;f.&Tension

~~*&Thread

~~!ili~TScrew

=EIK~iiTake-up

~~Wa.Jlt~Thread

*~Wa.IT.i

o~~mo

f~~~TTension

~~~

1!fThread

~!llJ~TScrew

ring

~~!lllt"JScrew

J§_&if.&Side

gUidon

thread

thread

thread

winder

tension

tension

for

window

plug

plate

plate

bed

tension

tension

release

tension

spring

release

plate

plug

plate

flug

~hole

plug

guid

take-up

guid

right

guid pin

guid

lower

base

components

thread

nut

spring

pre-tension

tension

plug

plug

plug

assy

tension

asm.

nut

disc

rotation

spring

disc

disc

tension

post

pin

plug

lever

guid

cover

plate

asm.

stopper

socket

asm.

-

J§_&if.&!§Gasket

l§

.&

if.&!lll·fl

lt*.&Threat

~tif.&!ll't"JScrew

3tif.&Siide

3tt:&tiSiide

3tif.&ti

~ m ~*.&Chip

~ ~ ~if.&!I!Jnscrew

~~~

4if.&Chip

~~~

4if.&!l!J:ITScrew

~H~

4Chip

~~~4!l!I:ITScrew

ffi.

1!fSc rew· as m.

plate

plate

plate

!ilJUScrew

funnelcover

funnel

funnel

·

spring

plate

-

9-

-

~m.

Qt.

I

1

3

2

I

2

I

2

2

I

1

1

1

1

1

1

1

3

1

1

1

1

1

1

. 1

1

1

1

1

1

1

2

1

3

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

8

1

2

1

1

2

1

2

1

1

1

2

2

ji_

if

Remark

t

r

t

l

t

f

t

I

Page 12

=·

L.$m~tiff~K~~B14=Arm

Shaft, Vertical Shaft

And

Thread Take

-up

Mechanism

..

~.---41

40~

421

-

10-

Page 13

~-'%

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

I

38

39

40

41

42

43

44

I

45

46

47

48

49

t::l

-r;;

IE

Part

number

20-02-001

20-02-002

20-02-003

20-02-004

20-02-005

20-02-006

20-02-007

20-02-008

20-02-009

20-02-010

20-02-011

20-02-012

20-02-013

20-02-014

20-02-015

20-02-016

20-02-017

20-02-018

20-02-019

20-02-020

20-02-021

20-02-022

20-02-023

20-02-024

20-02-025

20-02-026

20-02-027

20-02-028

20-02-029

20-02-030

20-02-031

20-02-032

20-02-033

20-02-034

20-02-035.

20-02-036

20-02-037

20-02-038

20-02-039

20-02-040

20-02-041

20-02-042

20-02-043

20-02-044

20-02-045

20-02-046

20-02-047

20-02-048

20-02-049

~

~

Name

.:E.Zd.J$iBalance

±W,J*i!it,tTSet

...t~~}!ffij!l!JflScrew

...t~mb~(ti)flil

J:$1Emb~(ti)

**-!.!-CJ$tFeed

*~CJ$t!il,flScrew

3=€:13fj!fFConnecting rod

~

*-!.!-

Cl

$i

1s

**-!.!-CI$~13

*~:i!*f.Connecting

~;fJ!.CI~t3~Retaining

...t$!E$:w$~Bevel

$:w$~!l!lflScrew

...t~~~Collar

...t$1E

}ill

!l!ltJScrew

...t$IE~~($)

...t$rh$1E~($)!l!l~TScrew

...t$!EArm

...t$!E$!E~(;tc:)

~tH:

~tiff

~tiff

~t~

~t~

fill;f:p;jilfl§ifc.!-:pt~Oil

~tff:i!ff~t~ff::k£.13.14:Thread

~t~H:~3Z:~~Hinge

~t~*f~~~$lil

~t*fii~Needle

~tfftl~!l!ltJScrew

~t*fii~ffl±}<:Need

~tfftl~~1f±)<:.@~Guide

j~±Jc.@

~t*f

~t*f$1E~(...t)q§iQ:Felt

~t*t$!E~(...t)

~tiff-Needle

~+*t$1E~Cl')

~t

*f. i1

~~t!l!ltJScrew

fll~tNeedle

!¥1:$1E$:w$~(...t)

~$1B$1E~(...t)

!¥i:~!EVertical

!¥i:~IE$1E~Cf')Vertical

~$!E$:-&$~Cf)

""F~m¢~~tbevel

fill m :i!ff!l!ltJScrew

shaft

fill

;WiCrank

fill

;J.W

XE:fli!l!I~TScrew

fill

;@J!l!JtJScrew

!ibm!l!Jnscrew

fill*p;j!l!J~TScrew

$11.

!l!J

...t~~~&:~Rubber

~

Iil\b us hi n g

wheel

screw

i10il

seal

Arm

shaft

and

feed

J:t

Washer

J:t!l!ltJScrew

rod

gear

for

arm

Arm

shaft

Arm

shaft

amount

pin

!l!l

tiS

crew

bar

link

bar

ns

crew

plug

Needle

bar

Needle

Vertical

shaft

Bevel

Bevel

gear

bar

bar

gear

shaft

shaft

gear

bushing(right)

lifting

eccentric

for

feeding

for

feed

lifting

ring

for

arm

shaft

shaft

bushing(middle)

bushing(left)

adjusting

take-up

guide

slide

biock

for

slide

block

plug

bushing(

bushing(lower)

bushing

bushing

assy

upper)

pin

asm

~;_

Qt.

1

1

3

2

1

2

1

'

2

2

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

3

1

1

1

1

1

2

1

1

1

..

1

1

1

1

1

5.t

Remark

*

l

r

t

'

-

11

-

Page 14

=.

j:~

31-~*~~~14:

Needle

Bar

And

Thread

Tension

Components

o--3

16

14

s::;

s~

,_,~

9

10

31

7

30

32

8

18

~

21

23

-

12-

Page 15

ff~

Part

1::1

~

""?

number

~

~

Name

~;

Qt.

ltr

~r~

Rem~-

k No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

20-03-001

20-03-002

20-03-003

20-03-004

20-03-005

20-03-006

20-03-007

20-03-008

20-03-009

20-03-010

20-03-011

20-03-012

20-03-013

20-03-014

20-03-015

20-03-016

20-03-017

20-03-018

20-03-019

20-03-020

20-03-021

20-03-022

20-03-023

20-03-024

20-03-025

20-03-026

20-03-027

20-03...,.028

20-03-029

20-03-030

20-03-031

20-03-032

20-03-033

20-03-034

20-03-035

20-03-036

20-03-037

20-03-038

20-03-039

20-03-040

20-03-041

20-03-042

20-03-043

20-03-044

20-03-045

20-03-046

20-03-047

l'~lb

Hook

shaft

l'~lb~lb~

l'~IE~~(:ti

:f~3f~~!I!I~J

"1'~11~

l'~IE~~!fl,~J

l'~~IE~(li:)

l'~lbfE3*~

7EI3

m.

1EI3mifc.IT.i!l!I~J

1'~1±!~71±1~

l'~IE~fm~!l!Jn

ME*~£§.14=

ME~m.mn

if~~

~~~£§.14=

*i~t~if.&

tt~5il!ii

*i~

t3if.&!I!Jn5il!iimJ:t

:1=3*-&!I!Jn

:!=~

3f~

:t~

3f~lb

:fit

3f~m

1it3f~11~

1~3f~~~!l!Jn

:fa

3f~~IE~

~

3f~r!!it\:Jt

~Jfl5i!!•ti--F-~

:tit

3f~m

1it3f

1~

3f

ME~~fTI:~!I!Jn

ME~jEfil:~

~:ff.i~m

ail;Wj~ff~fit~!l!lfl

~:ff.i~

fl11;Wj~*f~fit~

~*li-~IE

12S*ll-~tm~

3f~

3f~

3f~fiE;Wjf.ffl1Jf;·~r!!!l!ln

3f~m~

3f~£§.14=

~*ll-3f

~}f43f!l!lfl

( :ti )

bushing

)

fm

~1l~

Set

Collar

Oil

ifcFrn-'-•

Rotating

Screw

Bobbin

Guide

Plunger

Plunger

Screw

liE

1p:j

at!

;Wj

liE

;fp:j~m~

shaft

Jl...

Feed

Jl...!l!lfl

at!

;Wj"(;fi)

at!

;Wj"(:ti)~n

Feed

at!

;Wj

Crank

liE

;Wjf.ffllJL'~rfl

Washer

Feed

Feed dog

for

Set

bushing(left)

seal

spring

Oil

Filter

Filter

Bobbin case

plate

( :ti )

( :ti ) !I!Jn

Collar

Screw

Bushing

Washer

C-type

lifting

Screw

Screw

positioner

crank(

Short

rock

Bushing

for

Eccentric

bar

Screw

on

screw

hook

shaft

screw

adjusting

screw

hook

complete

spring

Washer

crank(

shaft

Screw

Hinge

stop ring

rock

right)

Set

screw

Screw

pin

feed

Screw

right)

shaft

crank

bar

pipe

screw

shaft

~

1

1

3

2

1

2

~

1

2

2

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

~

1

1

1

1

1

1

1

2

1

3

1

1

1

1

1

2

1

1

1

1

1

1

1

1

-

13-

Page 16

ll~l.

~tlfe:i]aJ'T.i'~B14=

Stitch

Length

Regulating

Mechanism

-

14-

Page 17

J¥~

No.

Part

I::!

~

?

number

f.fj{

~

Name

~;_

Qt.

t

jf

~

Remark

1

2

3

4

5

6

7

8

9

10

1 1

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

20-04-001

20-04-002

20-04-003

20-04-004

20-04-005

20-04-006

20-04-007

20-04-008

20-04-009

20-04-010

20-04-011

20-04-012

20-04-013

20-04-014

20-04-015

20-04-016

20-04-017

20-04-018

20-04-019

20-04-020

20-04-021

20-04-:022

.

20-04-023

20-04-024

20-04-025

20-04-026

20-04-027

20-04-028

20-04-029

20-04-030

20-04-031

20-04-032

20-04-033

20-04-034

20-04-035

~tfEEifc.l"T.i~fF~~n

~t

fEE

ifcJ

"T.i:tlff

~ift~~~T~~!l!~~T

~tfEEifcJ"T.i~*T!l!~~T

~tfEEifcl

~trEE

ttfEEifcl:Ptlffi~iii~

ttfEE~fF

fitl~t*~MfF

1itl~it*~Mff5~ttffi

fitl~ii*~iff

~tl~ii~~ff

~tl~it*~ff~.R~rt!O~~

~tl~ii*~ff~.R~rtl

f~Hiii~fFReverse

i1Hit*~*f3Z~!l!I~T

~tl~ii~~JA*f~ffl!l!lfl

~tl~ii~~}A*f

rfil;ffJ;J*~*f

!IE

r±a

~t

tt

J:E1li~~!l!~fl

tt

~*f~!l!lfl

rfil;ffJ;J~*f!l!ltT

S;E;fiJ;J~li~ffl~

~*f~

*~:&:!l!~t'J

it

ttlEEifcJ:P!tllff

~t

ll::itfJt~s!Ji

ll::~t~

"T.itlfF~rtl~

ifcJ

"T.itlff~rtl~!lllfl

Feed

a±!

a±!

r±a

m

Feed

1pg~fi~fF

;fiJ;J~fF~fi~~

lEE

ifcJ

fEE

ifcJ

lEE

ifcJ

fEE~ffJ:

lEE

ifcl

Feed

15"

!IE

*pg

"T.i

!IE

;ffJ;J ~ ffl

Screw

15"

!IE

;ffJ;J ~ ffl

Screw

11)~rtl

shaft

Screw

Stitch

"T.i

!Ill

*TO~~

it

Spring

Positioning

Connecting

Feed

regulator

Screw

Screw

bushing

screw

Hinge

regulator

1pg

Crank

14:

stud

;ffJ;Jty:~

;ffJ;J!l!~~T

~!l!lfl

Pin

Level

Screw

Feed

Adjust

Spring

Screw

Short

stitching

Screw

Screw

Screw

tock

tock

reg u Ia

~~

(~)

~~

( ti:) pin ( L)

link

length

screw

0 ring

pin

0 ring

shaft

arm

link

pin ( R) -

dial

stud

pin

rod

lever

link

tor

stud

1

1

1

1

-

1

1

1

1

'

1

1

1

1

1

1

1

1•

1

f

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

t

-

15-

-

Page 18

12---t

16 •

lS==-

1

28

29

-

16-

Page 19

!¥~

[

No.

1

2

3

4

5

6

7

8

9

10

1 i

I

12

'!3

i4

15

16

I

17

18

19

20

21

22

23

24

25

!

26

27

28

I

~

Part

number

20-05-001

20-05-002

I

20-05-003

I

t

20-05-004

20-05-005

20-05-006

I

20-05-007

I

20-05-008

20-05-009

20-05-010

20-05-011

20-05--012

20-05-013

I

a

20-05-014

I

20-05-015

I

I

20-05-016

!

20-05-017

!

20-05-018

I

I

I

20-05-019

20-05-020

20-05--02'1

I

20-05-022

20-05-023

20-05-024

20-05-025

I

:

(

20-05-026

l

20-05-027

20-05-028

l

I

t::l

'"9

;g

~1

Name

ffiH!!Jg.§.1!f:

ffim!J!fi!~T

ff~;ff~~

ff~ff

lli~*F~~

ffi~*fJI:¥~!llJ!IT

::k~~

7-:Ji~!I!J.fl

ff!mlti7tC!~t

ff}!!J~Jt-tJ$~0~~

ffMPt~-=¥

ffiJJillt.&

ff~iff5-'ji

ffi~iff5-'ji~tt

i~lli~fl

iw.l

lli

if'~f&*=f

*'~~~*t!llln

t~~CJ$t

~:t~m:tt-*I*f(tc:)

W~mrr*Iiff(tc:)!it~fl

t3tt.i~!l!~t'J

~~~~:Ft-f.~*T

~~~m7!-*Iiff<~)

~~fH:7t*I*f(tl)!filfl

!lHEl

5-'iitff Pin

mH~t~fr:it€*t

Presser

Screw

Presser

Presser

Thread

Screw

Presser

.:f.

!It~

n

Spring

Adjust

!it~

fl

tw

~

Tension

Tension

Screw

tJiEft-

*I

*f

for

foot

·

bar

bar

guide

bracket

Screw

guide

lifter

crank

0 ring

bar

Screw

Spring

screw

91~-&

N u t

release

Screw

releasing

lifter(L)

connecting

lifter(R)

(:f:i

)5~

ji

spring

Knee

lifter

assy

bush·

lifter

guide

bar

Screw

rod

Screw

Spring

bar

-

cam

-

~..!'§..

~

.....

m

Qt.

-1

I

i

1

1

1

i

1

1

I

1

1

1

1

1

1

1

1

1

1

1

1

1

i

2

1

..,

I

1

1

1

l

i

Remark

I

I

I

I

I

f

I

*

1

1

r

53:

I

I

!

!

I

I

I

I

l

I

I

I

i

t

,

I

I

I

I

I

'

~

I I

' 1

I I

I ' .

L_jl_

_

__L,_

______

i---"----T*__j

-

17-

;

I

!

II

Page 20

/\..

tJJJJf~ffitl~B1tf:

Knife

Control

Mechanism

32

43

3~

30

~

. I

.

~

38

~--37

....

28

\

~.l<U~-qj

L-;

39

-

18-

Page 21

~~.

---~----------~----------~----------------,-----r--£---,1-~±~

I

ff-s-

~

\lo

! ! .

I

I

! 2

l

~~

5

! 6

~

j 7

~

8

I 9

~

iO

1 i

12

"13

i4

15

i6

17

18

i9

20

21

22

23

24

25

26

27

28

29

30

31

321!

33

34

35

36

37

nr-'

0()

39

40

41 !

42: I 20-06-042

43 1

~JJ

Part

number

20-06-001

20-06-002

20-06-003

20-06-004

20-06-005

20-06-006

20-06-007

20-06-008

20-06-009

20-06-0!0

20-06-01

20-06-012

20-06-0i

20-06-0i

20-06-0i

20-06-016

20-06-017

20-06-018

20-06-0i

20-06-020

20-06-02i

20-06-022

20-06-023

20-06-024

20-06-025

20-06-026

20-06-027

20-06-028

20-06-029

20-06-030

20-06-031

20-06-032

20-06-033

20-06-034

20-06-035

1

20-06-036

I

20-06-037

,

20-06-038

20-06-·039

20-06-040

1

20-06-04

20-06-043

~

~JJ~rtl1ll:!ltitTScrew

f~JJffOperating

E~f~

.

~JJ:i=&-=¥1B.itSpring

f~JJ:tfi:~Nut

~

fc:l

~

fc:l

~

fc]

~tc:J~:f:il:jl!l!JtTScrew

~ic:l~t.ll:if!ll,&Nut

~i

JJ

J:t

tJJ

JJ

3 f;JJJJCutting

4

JJ

~Knife

5

JJ

~ffiltTScrew

JJ~~icJ~Guide

~[CJ

~~!l!lfl~~Washer

9

%flJJ~~~~~mlnSet

~fc:l~t~iMt~Pin

*IifftiSpring

E~t~

tJJ

JJ~iM*I*fLever

*Iff~:tlt§Pin

f~f#U*IM~~Guiding

JJ*f~rtl~Bushing

JJ*fKnife

JJ

*f1i~Knife

.7J

*f:tl~!l!lfiScrew

ii}~~§Pin

JJ*f~~tEccentric

JJ;ff~H:connecting

*:fi-~mi¥:Needle

Cl

$~:ri:J:tThrust

~~~.:£~~Bobbin

~~~.:E~~t!li~flScrew

J"J;ff~~)ffi.~~!FJJ.Guide

JJ*tr~·~-d~·:f:j~JltJSet

JJ~f~~~:t.*Siide

JJ

i

t~5if!

~~~Cap

.!f~4191J-a;J:Nut

~

fcJ

:g

.

~

Name

lever

liE-type

~t!Ji

~~il:-Spring

~tfi:it!I!JtJ(_..t)

@JJEffiltJSet

m#Gasket

~Jffif*ll.Guiding

~E-type

ring

ffil~~{_t)

scerw

knife

holder

bracket

ring

for

bar

bar

bearing

plate

· Qt.

for

knife

Nut(

upper)

Screw(upper)

block

scerw

for knife 1

bushing

knife

bar

adaptor

cam 1

rod 1

wheel

rail 1

scerw

block

~Spring

~~ttGuide

plunger

~~

1

1

1

1

1

1

1

i

1

1

2

1

1

1

1

1

1

2

2

i

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

i

1

1

-a:~-

Remark

~

I

i

.!

~

I

j

l

t

..

w:.Y

I

.. -......

~·-··--1~

~-=-:.2-----l------

-

19-

Page 22

-1::.

iJ!JWf~1!f:

Lubrication Mechanism

I

I

I

I

I

I

!

l

I

!

I

I

!

I

I

~

!

I

I

I

I

I

.,_9

1

&

2

3

4

5

-20-

Page 23

]¥;-?}

r

i

No.

fT

'

fj

l L

l

3

I

4

i

5

I

6

l

l

7

I

8

I

9

10

13

14-

15

16

i7

r

~

Part

number

20-07-001

~

i

20--07-002

I

20-07-003

I

20-07-004

20-07-·005

I

!

20-07-006

20··-07-007

20-07-008

20-07-009

I

20-07-010

I

20-07'-011

20-07-0i2

20-07-013

20-07-014

20-07--015

20-07-0"!

20-07-0i?

t::l

-z::;,·

7ffJt

~

Name

1!!1

*1*

Oil

pump

ifii

~

f;$:f.l·t!f't'

~Y,i~~~~n

iffi*i*~*&

im~1~:7~im

1m.;

ililil:ifaJ~~i~fl5~'t1!§~

I

1m*'f*~*-&.!1!1fl

l

irE

*f*ffilfl

l'

$.1!

..t$m1m~giH4

1i±l~ffifl}Ef&:km14=

iT£1

r&

@lftt:l.g

!£1

6

i!E

!E:liS:!~iliU9:

frtl~

Screw

~»tJ

iJW1~-*&

7ft

00

'if§~

Wick

Oil

1if

~

1*

J.Et&!i!IU

Oil

return

body

Oil

pump

pump

Oil

Oil

pump

adjusting

Screw

Screw

pipe

0 i I

on

pipe

Oii

Screw

pipe

Pipe

holder

Felt pouch

propeller

fitting

screen

plate

washer

braid

plate

assy

~:&

Qt.

~

*

~-

i

Rem~l

J

l

i

1

I

1

i

~

!

!

i

1

I

3

I

l

3

I

3

.;

I

1

1

2

1

1

1

1

I

r

I

1

!

I

I

i

I

l

'

!

l

~

i

!

l

I

I

I

I

l

I

I

·I

I

I

I

5

I

I

f,

j

t

r

I

I

l

I

I

I

1

-

21

-

I

I

I

I

!

Page 24

J\...

im

:&:

~1~1!f:

Oil

Reservoir & knee

Lifter

Components

I

I

I

27

32~33

35

~

36

'

•

I

i

l·

\-=-~~34

30

I

29~

31

d

i---2

-----3

43

~

~39

~38

-

22-

f)

r--.._

/6

~~)

1~=:~

19

Tl

~

~13

11

~5

u;

14

14

A~k:~

\j))\!J=-

16

Page 25

~

J~~

l

___

N~~--L_P_a_.rt_.n_u_m_b_e_r-+----~---------N

!

i 2

3

4

9

1 i

12

1

~·-·

-!

.•..

lC

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

4i

42

43

~

-i5-

20-08-001

20-08--002

20-08-003

20-08-004

20-08-005

20-08-006

20-08-007

20-os-ooa

20-08-008

20-08-0i

.20-08-0i

20-08-012

20-08-0i

20-08-014

20-08-0 i .5

20--08-0i

20-08-017

20-08-018

20-08-0i

20-08-020

20-08-021

20-08-022

20-08-023

20-08-024

20-08-025

20-08-026

20-08-027

20-08-028

20-08-028

20-08-030

20-08-031

20-08-032

20-08-033

20-08-034

20·-08-035

20-08-036

20-08-037

20-08-038

20-08-038

20-08-040

20-0B-04

20-08-042

20-08-043

~

~

__

am

__ e ____________

1rfl

~Oil

reservoir asm. 1 I

1

JJ~ilil

!I!Jfl Oil

I

J]~}m!I:Jfl~~

·ilil:&~

%~5~*&~~*!1!tnvvood

mH~~.stm~fh

~t2:~

JmH2:~Nfft~

JMH~~lHTI:iJ~lt!I!Jfl

0

i.Fc.l:P!I!!-1#

1 .

MH~!)JHfl:~.ffi)lJ

Jl~H~~7f-

3

~±)C~ift~~

iil±fi!:~*tti~!lll~T

~~

~t~~I±}C~;ff

6

JJ:j:2:i!If!±}C

l

~~~Knee

1

~liJt~t~n

8 1

1iiif!±J~J§

I

1f

0

f~

l

&:-;:j;~ffif!f:

I

Bl.!~!FltH:J\)

$:

ffl

~~ltrm:~

Jt

·;;

~!il..,fl(:*)

*~tr

~~~f!:j:

1m~~

Lubricating unit .case asm.

~:ljc

Magnet

Jj\jffi

~

*Jl~rih~~±R:(:k)

*ll~~@~~±Jc(!J')

*JL~~*-&~~f~

~:li~WJ~9i'~f~

•

~14:~

~~Bobbin

*lltt

Needle

•n~-T(:*)

!I!Jflj@-=f(r:p)

!l!Jfl~-T(tj\)

~;~m-1:&~~

i

~~itt&

.@~mt&!l!~fl

~~~tim-a

1

drain

screw 1 I

Oli

drain cap gasket 1

Paxking i

screw 1

Knee press rod 1

ffl:s!t!~

[;

spring J 1 f

Lifting

Positioning screw j

Nut 2

Lifting

IV!

iff

Knee press lifter rod

Bearing bracket 1

Knee lifter plate rod

Knee

lifter plate

lifter plate cover joint

Screw

Knee lifter plate cover

Thrust ring

Belt cover

Screw

Washre

screw

asm.

lamp screw

Screw

\Nood screw

Duple-thread

Oiler

Rubbre cushion

Accessort bag

Screw

Screw driver(M)

Screw

Waste material chute holder

Waste material chute

Screw

Waste material chute

spool stand asm.

Oil reservoir rubber cushion

Oil

reservoir felt cushion

Heed hingr

driver(L)

driver(S)

joint

-T

~

·

~!l

5:

__

a

___

't~.:~r--R_e_m_.a_rk_._J

1

2

1

j

1

,

,,

1

2

1

1

1

i

2

2

2

2

1

1

1

1

2

2

2

2

1

4

i

I

1

1

1

4

1

fk

'~--l

'

1

I

I

I I

! I

L--~·------L-------------------~--~-----

-

23-

t

f

Loading...

Loading...