Page 1

IDGH-SPEED

Jf)i$iBJ.I

if

INSTR

CHA.INSTITCHER

UCT

IO N

SE~1'1G

MANU

AL

t\'lz\CI:lll\"E

~~,?B~oK

Ill

JifUil~ft

ZOJE

SE

WIN

mn

112

G

MACHINE

fH

~

oe

CO.,

~51

LTD.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

To

get

the most out of the many tunc;ions of this machine and operate it in safety.

to use this macnine

Please

your machine for a long tim

Please remember to keep !his manual in a safe place.

1. Observe the basic safe:y measures, including, but nee limited to the following ones, whenever

you u

2.Read

you use

anytime when necessary.

3.Use the machine at:er it has been ascertained

valid in your country.

4.AII

operation without the

5.This macr.in

6.F

7.For t

the receptacl

7·

7·2 F

7-3 For repa

7

S.lf

with your eyes

areas and consult a medical doctor.

read this Instruction

se the

all the mstructions, incluo:n

the machine, In addition. keep this Instruction Manual so that you may read •t at

s.afety

devices mu

or

your personal protection. we recommend that you wear safeiy glasses.

he

iollowmg, turn ott the power switch

1 F

orthr

or

replacing part (

·4

W'l

en lea

you should allow oil, grease. etc. used with the machi 1e and devices to come in con

C·Yrectly.

machine.

st

speciiied safety devices is n

e sha

ll

be

e.

eadi

ng

needle (s).

ir

war~

,

v1ng

tne working place of when t

or

skin or swallow any of scch liquid by mistake. immediately wash t

M

a n~

al

carefully beiore use.

e.

g,

but not limi;eo to this Instruction Manual before before

that it conforms with safe

be

in posi!ion when the mach1ne is redady tor work or in operation. The

ot

operated by appropria!ely·trained operators.

oi

disconnect t

S)

of needle, presser foot, ihroat plate. feed dog, cloth gui

he

working place is unattended.

allov1ed

Whe

nope you wi

.

he

power plug

ty

oi

it

is necessary

ll

enjoy the use of

rules/standards

the machine fr

de

etc,

he

contacted

om

tac

t

Tam

pering witn the live

9.

isprohibited.

10.Repair,

tec

11.

General maintenance a

1 2.Repair and maintenance works of

elec

Whenever you find a failu

1

3.Periodically

remodeli

hmcians or special

tr

ic

technic ians

clear

pans

and devices. regardless of whether t

ng

and adjustme

ly

skilled personnel.

nd inspection works have to be done by appropriately trained personnel.

or

under

re

of any

the macnme

nt

wokrs must

electrical components shall

the

audit

and guidance

of

electncal components, immediately stop the machine.

throughout

- 1-

the pe

only

rio

be done

oi

speciall

d of use.

he

by

appropriate

be

conducted

y skiiled personne

machi

ne

is powered,

ly trained

by

qua

lified

l.

Page 3

14.Grounding the machine

machine has to

as high-frequency welder.

; S.An appropnate

ug

has to

pl

be

operated in an

power

be

connected to a grounded receptacle.

is

plug

always

has

to

nece

ssary

enVJvro

be

attached

fot :he

normal

nment that ts free from strong noise sources sucn

to

the machine

o~erahon

by

of

the machme.

electric technicians, Power

The

'

&;]

16. The machine

t7.Remodel or

all t

he

effocuve

remodeling

18.Wa;rng

hir.:s are

IS only alloweo to

modtfy the machine in accordar.ce wttn the safety rules/standards while

safety

or

modification

measures

mar-<ed

Danger of injury to

It

ems

be

used t

or

the purpose Intended 0;1'\er used are

. We

assumes

of

the mach:ne.

witn toe r.vo shown symbOls.

ope

rator

requtrlng speCial a:tention

no

or serv

responsib

ice staft

not a.iowed,

ili

ty

for

dama

ge

caused

tak

ing

by

Page 4

,.

t

f,1

;i

FOR SAFE OPERATION

•'

~

~-

'

I•

~'

~~

r~'

&

'

'

~·

~,·

·

r

~:

rc·:

li:

I'

,,

I

l'r:

l:r

It

~··

h.

..

I~

I

l.To avo

1.To

2.To ::e·,er.: posstb.e pecscra ir;u:ies caLssd by be

3.To

..

4.-c

s:T

6.To

7.To

8.1f

no

s:a

9.To

10.7c p:e·.ent ;:osstble

:J

alectncal

·

~r

:~e

...,otor nor :oJcn

a,c·::: persona

c::·:a', l

ycur f

,·,hila

0\

•:.ri,e

re

pcssib.e injLry to nands.

tt>e

ma~l"ir:

- ac··-e

t1e

co

t"i.::

c~7:c~er.:

01

"1f;:er

n~ers,head

:re

machine

a·:o'c

::ersonalln,vy,

Jot

:.-~

po·.·.-er

<--~·:::

;)erso.1al i:-,L:y, nev

t

...

e

rr:achi~e

·::o;:>er

rotat

O:)per

dunng oporation.ln addit.on,

\·

..

a·::~

pcss:ote

...

a:o·c

;oss

p~:.er

ver

e.1d

:he

ycur

macnine is oqu

sa

·:.

1ile the rr.achtr.e

r:

oi -,e

a

·.c

= e!ectr

;~c

...

~d

o:

:

l:o

power

s•,oc~

·.~ry.

sua~c

of

safe~

ard

clo

15

opera!ic1. In aon

s·.-.1tcr

s i.i

es

at a h

hen

re~·a:in~

~arsenal

,e~

1

'r;

ras

tl

e acc1der.:s

to :he "13ch:ne wh en tiltir.G t1e macn:'le head

V be :.

p;ed

mach.re,

wire

(s).

be

ca

s~oc~

~0"

t"!e

accide,t

tJr1

OrF

:::1

Jg.

hazards. neitner open

t~e

cor.;Jonents

"e•er

ope

y

oa.e-...:ces

t1es away lrocn tna nandwheel, V belt

neve·

~u:

or

c::.era

te

e·

p:

o::;eia:ion.

gh

s~eed

be

sure to

t1e

lo

cpe

irJur'es,

rg t-e

1s

st.re to :Lrn OFF

'1a

pO\·~er

the

rra~r

::e:a_se

w.t~

at rest. To a·•old possiole a::cidents

za·cs. re•.ac opera!e

s

....

s becaJse o! e.oc:r.c

pow

er

mou,ted 1nsioe the electrical box.

·a:e :ne

yoJr

:re

ycv

while the mach.ne

kee:>

...

:Je

a

serv

~ply

s

wi:c~

-ac~

..

emO\·&d.

.t

en, place

nand u1der the needle wnen you turn

"Tlacnir.e.

rnge·s

you•

rand

be

suro to turn

care!.JI no: to a: low

re

reac.

::'

a::r'"pt

o·mot

or,

t.1e

;;ower to the machine.

re-eved .

in prior

thG

cover

of

the electncal box

~e

v.i~'l

any

o'

th

e be.t

ng

caug

ht

in the machme.

and the motor

no1l1in

g around them.

.:1:0

the

thr

ead

take-

up

is,, opera

s away from the VICinity of

OFF

s:art

ol

the

the motor

:l'e se·Ning machine with

shoe~

to

tl1e

connectrionldisconnecti

tion, To prevent

the

power to the

your

fingers in the

machine,n.rr

or

remoVing t

does

not produce

due

to a

or

camaged electrica.

'<eep

cover

OFF

he

belt

bru

pt

w

•·

r··

t

-3

-

~[

Page 5

B

EFORE

l.

Pre-s

tan

che

cks

..

· · · · · · · · · ·

2.

Operaling

3.Specification

-Unstalla1ion

S.Oi ling. .

6.

Ho"

on

the fac e plate

i.

The threadi

The

8.

9.Thread tension asm.

1

O.Prcsser

ll.T

o adjust stitch length

l:2.Sening-u

!3.Adju>tment

l4.Adju

l 5.The timing

16

.Adjus

I 7.Ad

18.T

he

1

9.Thr~ad·vuidin£

20.Th.: clearance ofloopct·

instuctions

..........................

of

the machine

........

to r

egulate

threading

foot

stment

tmem

justmem

timing

' - .

.....................

oil

ng

ofneedk

of

......

p

of

the

of

tbe

of

the heigrnur' the

of feed

of

the h

oithe

of

looper

..........

amount

.................. · .... · ......

i!·,rcad

bobbin

!hr

..

................................................................

·· · ....................

......

needle

heighr

dog

eight

needle and looper

jn

amoumof

and

··ercrence

Contents

..

· · · · · · · · · · · · · · · · · · ·

· · ·

..

· .. .. ·

..

· .. ·

.............

..

· ·

....

........................

....

.............

b~

means

ead

.. ·

....................

oft

he

needle

,lfneedle

the

!o:Jer

and

needle ..

of

manipulating

· ..

......................................................

.. ·

..

·"

......

· .. · .. ·

..

· ·

...................... · .. " .. · .......... · ........

pre:;ser

feed

ba~

dog

........

bar ....

.........................................

to

ne::dle

.................

........ · ....

...... · ......

..............

....

........ · ...... · .......... · ....

.. ..

·..............

.. · ..

· ·

....... .................................

............

.....

..... · ....

.. ..

· .. ..

...........

..

· ·

··

·"

.. · ........

........

...

· .. · ·

......................

.................................

elements

......

...... " ..

· ··· .. ···

........

.. ·

............

...... · ..

.. · .... · .. · ..............

...........................

..

· ···· ...

.. ·

.. · .. · ..

.. · .. · ....

.................

.. ..

....

.... ....

· ·

........

...... ... 8

·..........

.....

.... · ..

"..

····

.........................

....

...

....

·..

.. ..

..

.

· I

· l

.. 2

· 2

2

3

3

4

5

6

· 7

7

8

9

9

9

10

10

11

CAUTIC

To

avoid

n

•

Before

thorough!)

Remov

Confi

jesignate

set

shall be i

warni

•

Confir

•

1\e,er

•

Confi

Operat

•

-up

1, P

!)

2) T

e a'

nn

.

re-

The

ng

ti

d

h<

ruming ch

3)

The

4J Cht

"ith

the n

2, Ope

1)

Do not

r

s

2l.Thetimingofneedkguard

~2.Position

23.Loper

2-!.The position ofthread-am-.:>unt

:ake-up lever

2 5.

Frame

26. Repbccmcm

27.:--.

taimena.n

2

8.Common

of

needle

thread

thread

ce

t::tk

e-up

........ · ..

eye)et

of throat

ofth.:

breakdo,\ns and

guard

ca:n

..........

.. · ..

plat<' · ..

machine

..................

.............

.........

.. · ....

· .. · ·

..

· .. ·

.......

measures

..

.......

..................... .............

......

........ · ....

~djusting

.. · ....

.........

plate

of

the thread

· · ·

....

.. · ..

.. ..

...... · .. · ...... · ....

..

· · ·

.... · ..

· " ·

· .. ·

....

· .. ·

.. · .. · ·"

..

.........

oftro;.~bie

..... .....

>h.:-o:in; .... .

.............

.. ..

....

..

· · · • ·

.. ...

..............

.. ..

..

.... ....

.. ".. ..

...... · ....

......... ......

..

..........

•·

...........

....

.....

...

......

..

" ·

..

..... ·..

......

.....

...

..

11

11

12

12

13

13

14

15

2)

Do

3)

On!)

-1

) After

fo

5)

Keep a·

6)

Do

guard. •

not

''

tl

r a "

not

Page 6

BEFORE OPERATION

CAUTION

To avoid malfunct ion and damage

• Before

thorough!).

Remo,·e all dust gather

• Contltm that the

Confirm

• 1\e,·

designat

• Confirm

• Operate ,·our machine at the

set-up.

er

ed

\Otl

that

usc

one.

:

of

put the machine into

ing

during transportation and 0ii

\·Oltagc

the

po\\er plug has

the machine in :he state

tha

t

t!-.e

direction ofro:ation of:l;e motor pulley is correct

has been

bee-n

no~i:ial

the ma.:hinc.

op<:rmion for the 1irst

~orrectl:

properly connected

5<!\\ing

--------

1 ,

Pre-start

I) The machine shall not be s:aned running until

2)

The rotating directi

shall

be

in coumer-ciockwise one. (Vie" from the right side

warning shall be

check

giYen

- -

on

of

th~

in

ad,ar.c~

b~.lance

against making

~onfinn

set.

"here

r\1~

speeJ or les; for the fir;t

the fc:tow

tim~

it

well.

tl'

Yoitage

-

_

the

completion

'.\heel.

•.

,·hen

the

tf:<:

machine run while balance

ing:

after ;he

the po"·er suppl) .

t:

pe

i:;

.<et-up

different

momh

--

____

··----

of

oiling.

_

___

machine is started runni

of

the bdance

. clean

;'rom

the

aiter the

--·---

"heel.)

"hed

it

_j

ng

A

.

turning cloc

3) The machine sha

4) Check power source.

with the ratings on the name plate

2 , Operating

l)

Do

Do not

2)

Only \\

3)

4)

After the motor

ior a

5}

Keep away f:·om

6)

Do

guard. etc.

no1

"hilc.

not

k"ise.

ll

be under operarion

\Oltag.::

instructions

put

your hands under the lower

put

your

heP.

start

fin,<.ers

the

machin<'

S\\!;ch

B~

carek:

the

run.11lnt£

i•no

the

stops can : ou turn the balance "h<?d

being

n->'

to

hne

batance whee

the

:ncc

3c

less than 4.500 S.

. and

phas.::

number to see whether they

of

the mo:or to

---

pan

thread take-up Je,·er coYer when the machine

cumco

hjne

of!: Jt:e 10 inertia. the motor will continue to rotate

th~

machine tilted unless is stops.

!.

\'

·b·~H.

dL:ring

b~

used.

----

of

th<!

ne<:!dle

"inder

tnounting

and t

-

or

P.YI.

for the

-

--

---

--

--

- -

"hen

tht: machine is r

by

hand.

he

motor.

r~placing

the

bet!

are

----

--

Jim

momh.

in

accordance

---

unnin!?,

is

<.O\er

.

running.

.

finger

Page 7

3, s

pecifi

cat

ion

Stitch type

Speed

1\cedle

Stitch

Stroke

Gauges

Chain stitch

Thread take-up ~ pe

Looper Separately adjustable

~eedle

Oil supply Impeller-type pump

length

of

needle bar

of

double-ro' \

guard Oscillating type and rigid

Light ciearance o

Lubricating oil

4,

installation

:'knee

of

fwo-t:cedle dot-1-le-

Max.

4,500

T

VX7

I.~-4mm

30mr:1.

];8

;\eedle

!iite

r 8-

"2

the

ma

'9-'21

''

5i32" 3. 16'' 7'

bar thread take up type

!0mm

''

hile oil

chi

s.p.m.

ne(Fig.l )

re>"

chain s:itch

3/8

.,

of

1·2'

I 8

..

to 1

:!

'

3'2

l/4" 5116

t)

pc, for the range

t:pe

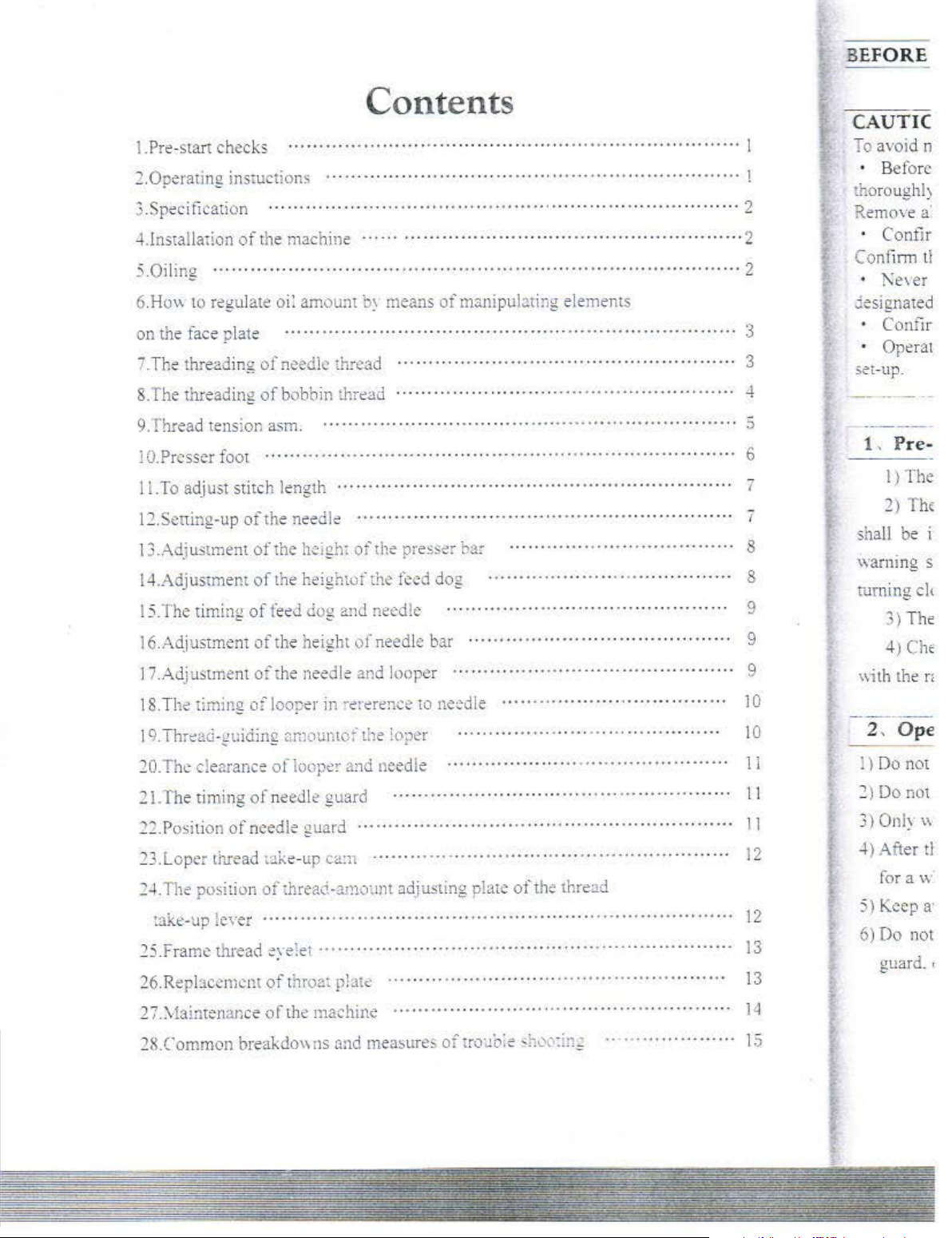

I.

To install the oil reservoir:

the oil reservoir rubber cushion

Put

C"G

and oi I

four comers

rix them

install the oil

2.

Put the machine connecting hooks into

the holes to engage

hinges seated in the table. then place the

machine

re~ervoi

of

"ilh

reservoir (Fig

on

the four cushions.

the

the

r

opening

wood

felt cushion ~

of

the table.

screws %. then

I)

respecti

\ely

t\\

on

o

c

5.

O

ilino

- ---

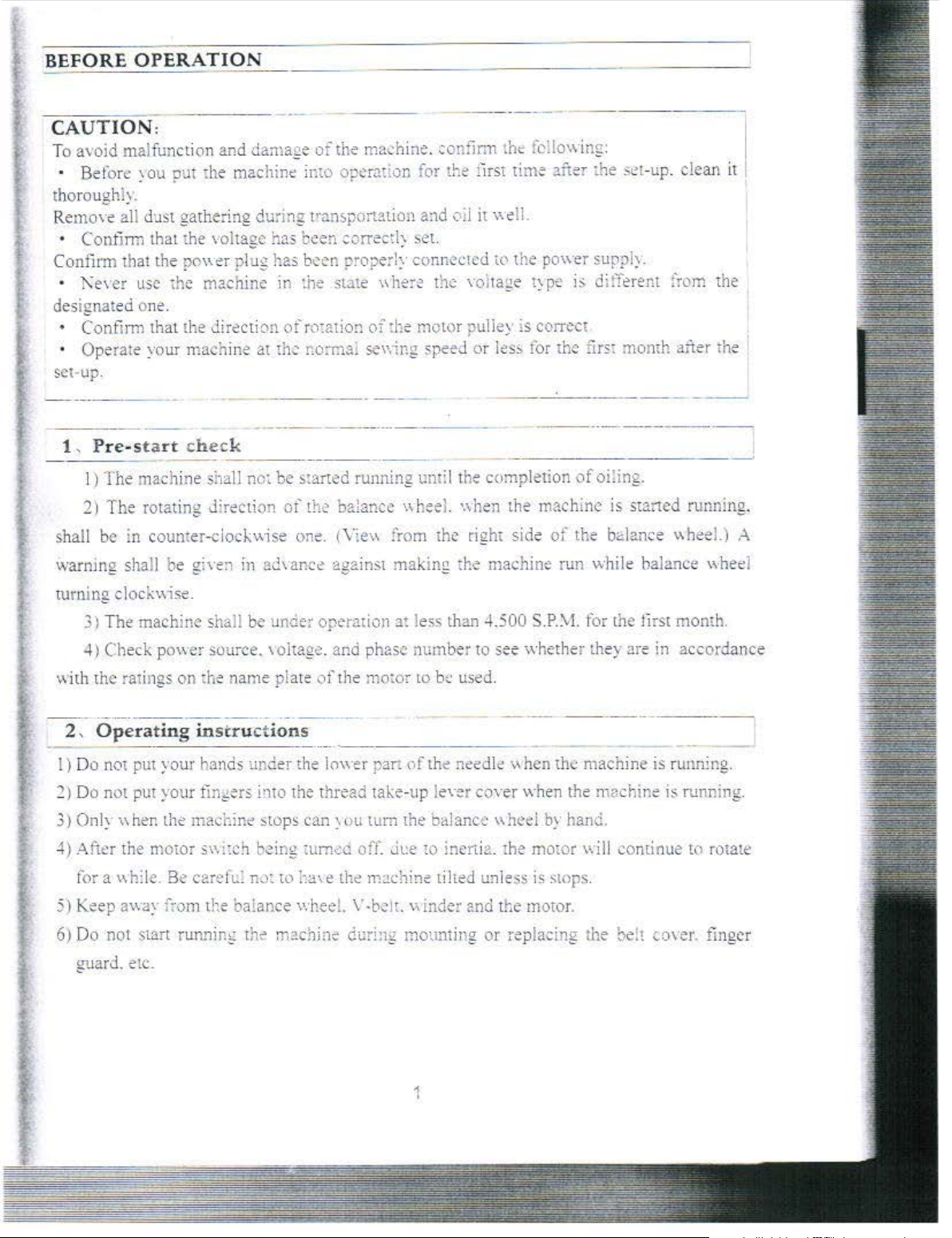

I.

Oiling shall

and the oil surface also be made to

le'

el

the mark

machine is mr:ec ru;ming (Fig.2)

1.

Oiling

surface h3S

mark

··~

be

mad.: in oil res.:n·oir

"H

igh

..

sha

ll oe kept

on

bee:1 hought abovf! the

(\\\

· -·

...

·

2

before the

until the oil

~

To th

I J

Page 8

Fig.3

.>

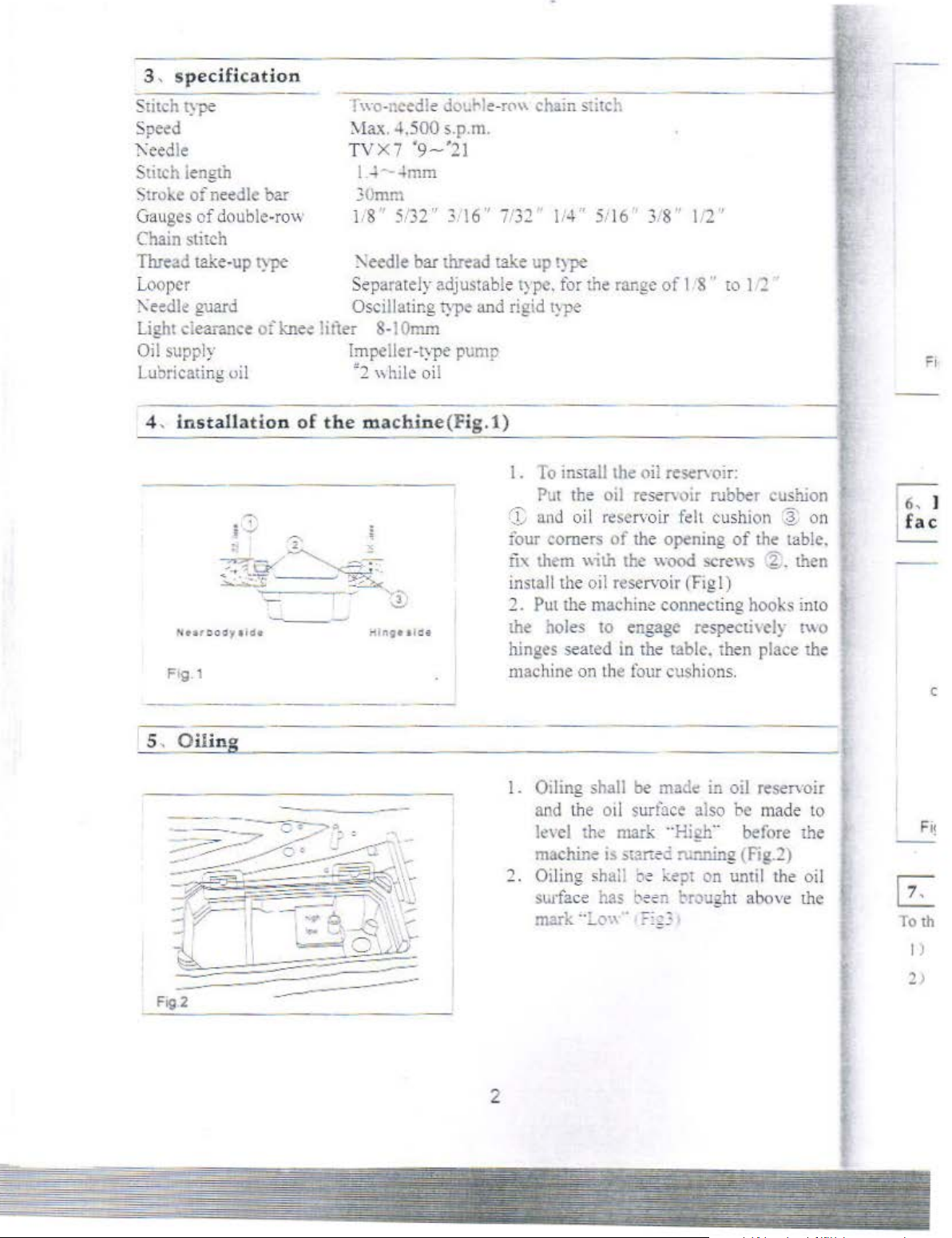

. The normal

the oil shall spra) or.to

amcur'i

not

at :tlf propordon1l

oi

oil in the oil rese;·vo

:o

worr) about.

4.

Ont.. when

loos

e~~"

dra::,~d

S.

\V11

en a

for long

shall

m:nmes

be

of

oil spra;

and

out

and

n~"

rime

:ifted

.

cor.d!tion

is

1he

drain

taken

new

model

co

be

and run

of

lubricati

the

oil sight. The

ing

omo the

~o

ti

1e

total amot:nt

ir.

There

cover

off

ca~

old

oil

i;

supplied

or

those standing idle

operat

ed,

presser

idle

for

on

is

th

uiJ

~ight

is

nothing

scre\v

•>il

again

foor

ai>out ten

at

is

is

be

.

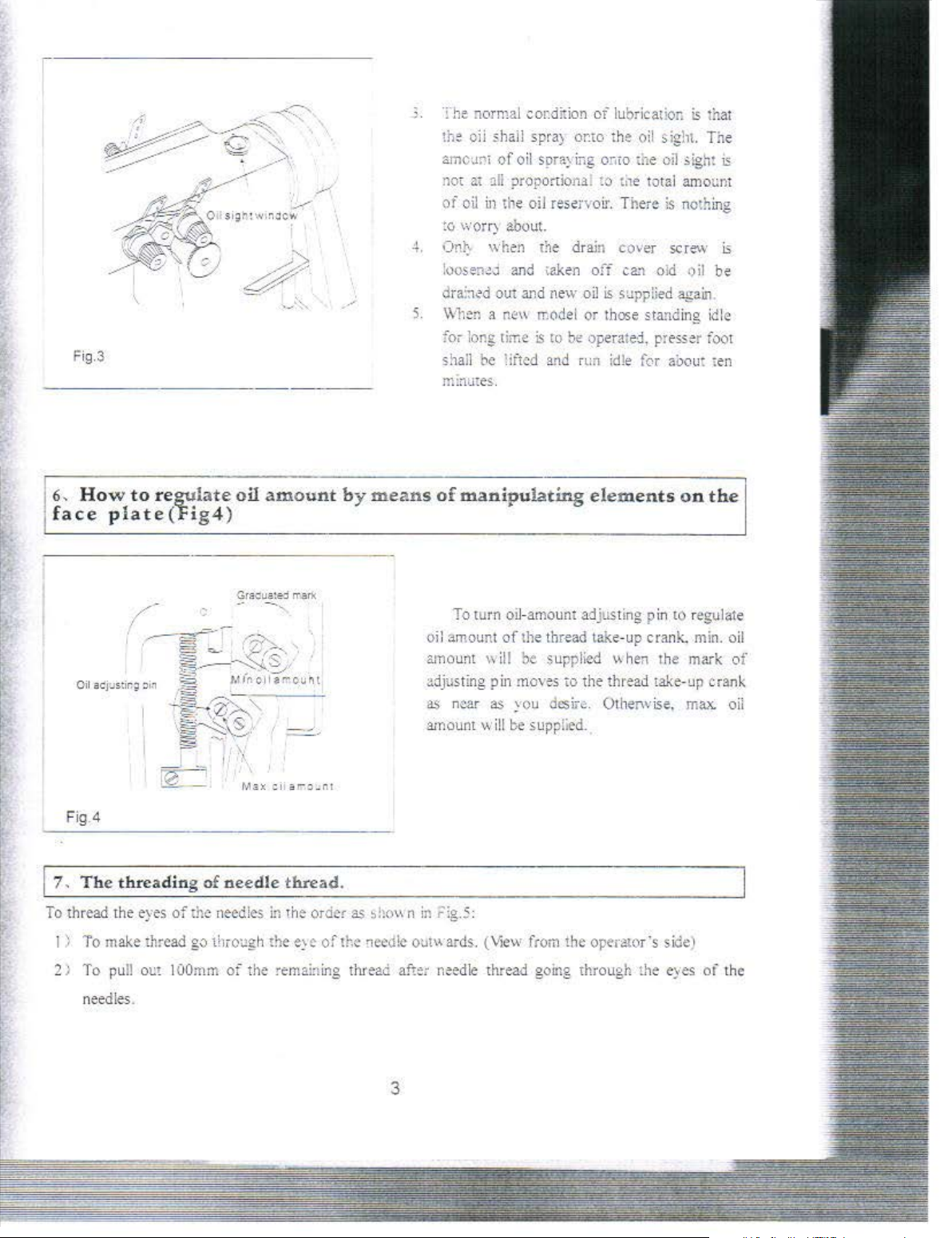

6,

How to regulate

f

ace

plate(Fi

(

' I ,

,.--

Oil

ac

'j:Jstir.~

;,i~

Fig.4

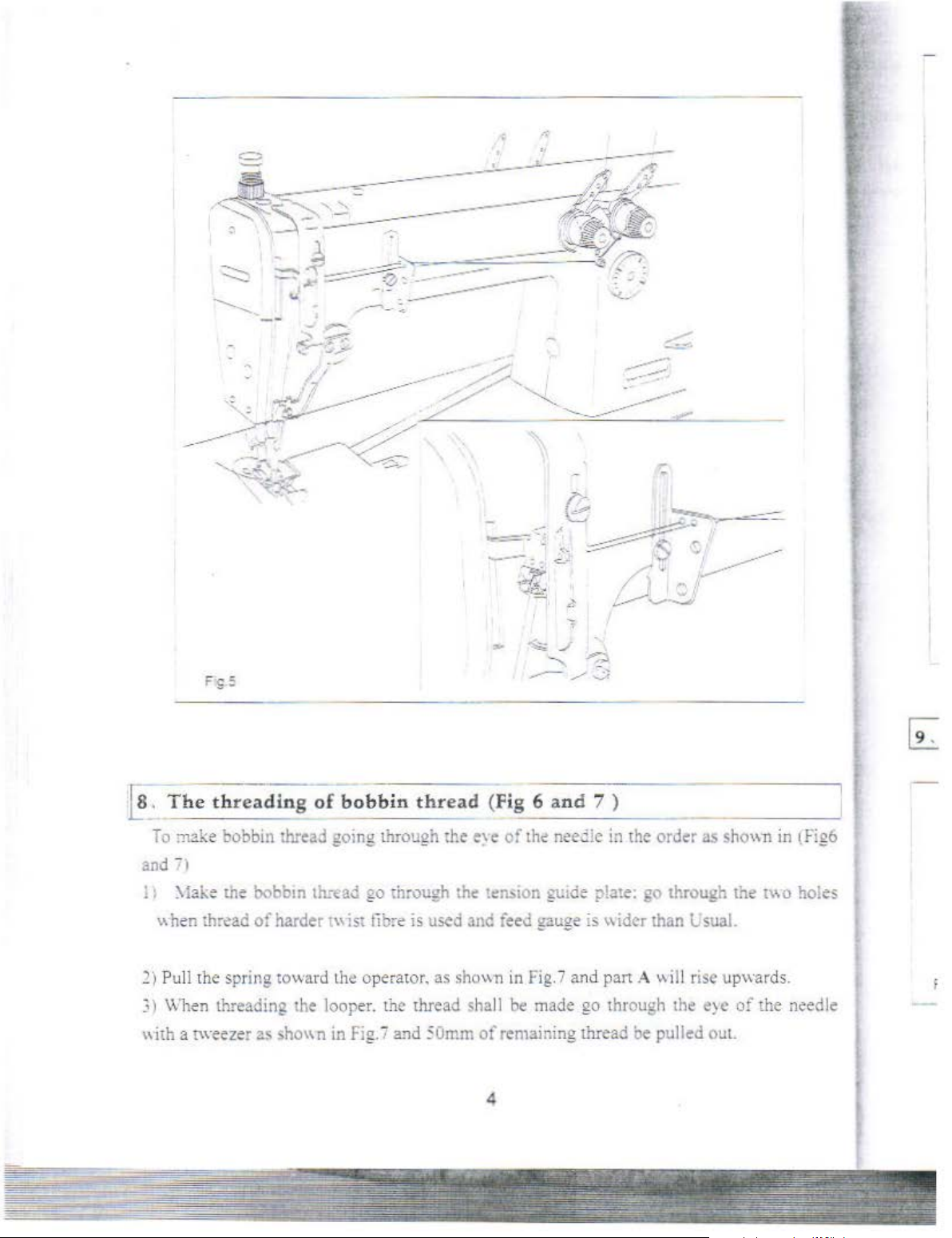

7, The

To

thread

threading of

the

eyes

~

of

g4)

. • I

·

(he

needles

oil

need

amoun

le

thread.

in

the order as

t

by

means

oil amount

~hO\\

n

in Flg.5

of

manip

To

amoum

adjusting pin moves

as

n~ar

amount

turn

\\ill

w i!l

ulatir..g

oil-

of

as

~ou

be

amoum

the

thread take-up crank. min. oil

be

supplied

desir~. Othef\vi.se~

supplied.

:

elem

ents

adjusting pin

"hen

to

the

thread take-up crank

the

on

tO

regulate

mark

max.

the

of

oil

~

~~.:::=-~---

·

I )

To

2 I

make thread

To pull

needles

out lOOmm

.

go

through the e:c

of

the

of

the oeed!c

remabing thread after

0\lt\\ards

. (\.1ew from

n~edle

thread going

the

through

3

oper&or's side1

L~

e

eyes

of

the

Page 9

. ,

~,

The

threa

~

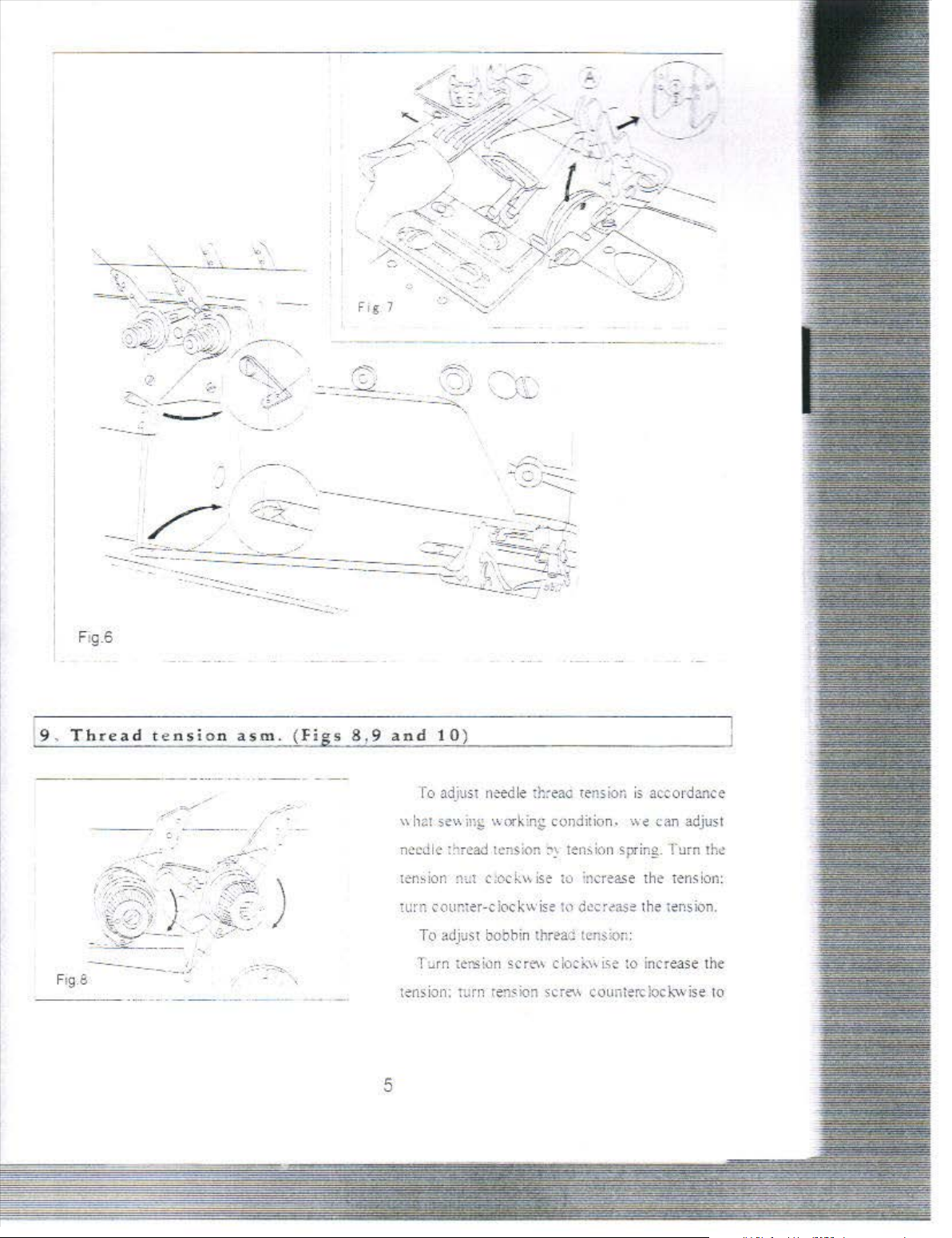

To

:nake bobbin thread going through the e\'e

and

71

11

:\lake the bobbm th:tad

thr~ad

when

2)

Pull the spri

))

\\ 11en threading the looper. the thread sha

"ith

a tweezer as

of

ng

of

bobbin

go

through the

harder t\\ist tibre is used and ieed gaugers \\idcr than UsuaL

toward the operator, as shown in F

.ho"n

in Fig.7 and

thread

~

Omm

.,.,

...

.,/

.......

~

---/.:;;

(Fig 6

ten~ion

ll

of

remaining thread be pulled out.

4

and

7 )

of

the nee .:lc

gt:id:

ig.

7 and

be

made go through the

in

;>!ate:

pan A "ill

the

ord~r

go through the tv.o holes

as

•ho"n

rise upwards.

e)e

in l

of

the needle

F!g6

Page 10

--------··

Ftg.6

_

--

~--·

-.......

r;::-

---·~-

-

~

~

___

__

:._:,__

,;~;-..,

~.::.-:::

~ ~

·-......,.

J'

\.

,-

...__;.:':._

..

9 . T

F•g.a

----~

hre

-----

ad

-----

t e

·-

nsi

..

·~

o n

asm.

-

--

(Fi

gs

8 ,9

and

10

)

ro adjust

\\

he1

necJic

ten~

ion

n~edle ~h~eao

se\

•.

m~

v.:ork:ng

\hread

l~nSiOn

:H.:t

c

:oc k '"

wrn coun;er-ciockwise

To

adjust bobbin

Turn t

e-ns

km

sc rt\' clot

tension:

rurn

renskm

tension

condition.

:"1~

tension spring. f

ise-

to

~ncreas

hJ

dec:rC"ase

thr~ao

ton;klr::

f..:\\

ise

screv.

counterdock."Wise

is

accordance

-..ve

can

e

the

the

H:msion.

to

incr

:.Jm

tens

eas

adjust

th~

ion:

e t

he

to

5

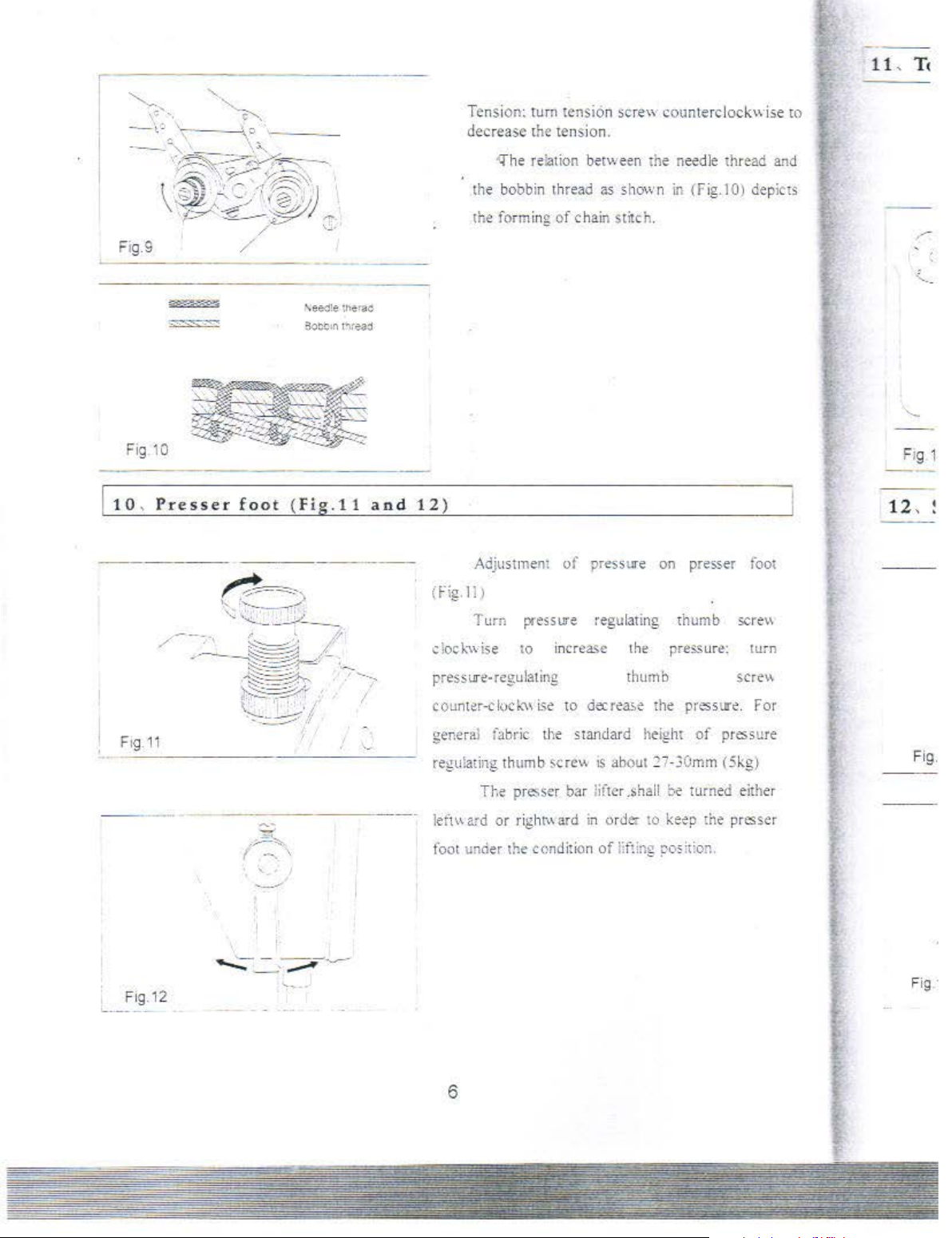

Page 11

.--

Fig

-----

10

--

\ee<l'!e

E!o:t

1n

tMr

l"'te3j

ac

Tensi

on~

decrease

-Q'he

the

bobbin

the

forming

turn tension

the

tension.

relation

thread as shown in (Fig.IO) depicts

of

::;crew

between

chain stitch.

counterclockwise

<he

needle thre

ad

ro

and

10, Presser

flg.11

foo

t {f ig.ll

'

and

1 2 )

Ad

jusilnem of pressure on presser foot

(Fig. ll

dock."\\·ise

J

T u

rn

p.

·essure regulati

i.O

pressure

counter-cloch.'\\

general i

regul

left"

foot under the condition

..

regulating thumb

Lie

abric

the

ati

ng thu

mb

sere"

TJ·.e

pre.ser bar l

ard

or

right\\ ard in or de. to

increa~e

to

standard height

the

decrea~e

1S

ahout

ifte

r

.shall

of iif!ing

ng

thumb sere\\

pres..~ur~:

sere''

the presstl'e.

of

pressu

2i-3

0mm (5kg)

be tumed e

keep

the presser

pos

it:o

n.

turn

For

ithe

re

Fig

.

r

F1g.12

6

Fig ·

Page 12

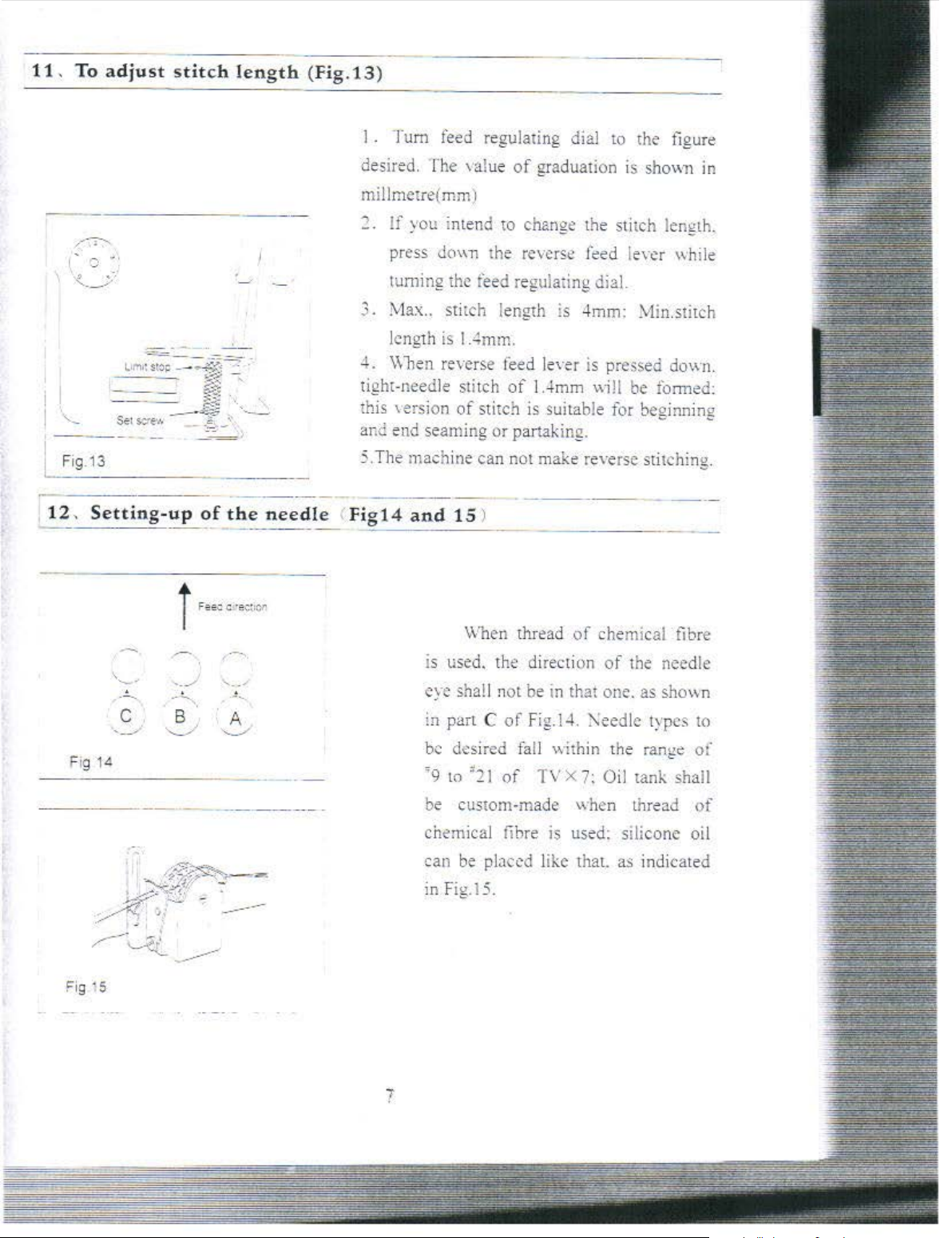

1 L To

adjust stitch

length (Fig.13

)

/-~

I

..

.)

'Z._Y

Fig.13

12

,

Setting-up

..

..

I . Tum

desired. The ,·aJue

feed

regulating dial

of

graduation

to

the figure

is

sh0\\1

1 in

millmetre(mm)

..,

If you intend to change the stitch length .

press

'

do"n

tuming

3. Max.. stitch length is

length

-+.

\\

l1en re,·erse

tight-needle stitch

this

'ersion

ana

e

nd

seaming or partaking.

of

the

needle <Fig14

5.The

machine can not

and

the reverse

the feed regu

is

1.4mm.

fe

ed

of

of

stitch

15

)

f~ed

le,·cr while

lating dial.

-+

mm:

.:vl

in.stitch

Je,·er

is

pre

ssed

1.4

mm

"ill

be formed:

is

suitable for beginning

make

re,·ersc stitching.

down.

Fig

1<~

Fig ·s

c

> •

_

......,_

B

-..._/

\Vhen

IS used. the direction

../

.....

.. /

, _

A

'-._/.

eye

sha!l

in part

be

desired fall within the range of

'9

1o

'21

be

cus10m-made when thread

chemical fibre

can

be

ig.

in F

thread

of

chemical

of

not be in that one. as

C

of

Fig.!

-1

. ?\eedle tvpes

of

TV X

7:

Oil tank shall

is

used: s

placed like that.

l5.

t

he

ili

cone oil

as

indicated

fib

need

sho"

re

le

n

to

of

7

Page 13

-

_

-13

-

,

_

A

_

d_

j

_

-u-

s

-

~_r_n

-

e

_

n

_

t

_

o

_

f

__

t

_

ll

_

e_h

-

~-~

g

-h

_

t

_

'!_!._t

_

h

__ e ___ p_r

_e_s_s_e_r_b_a

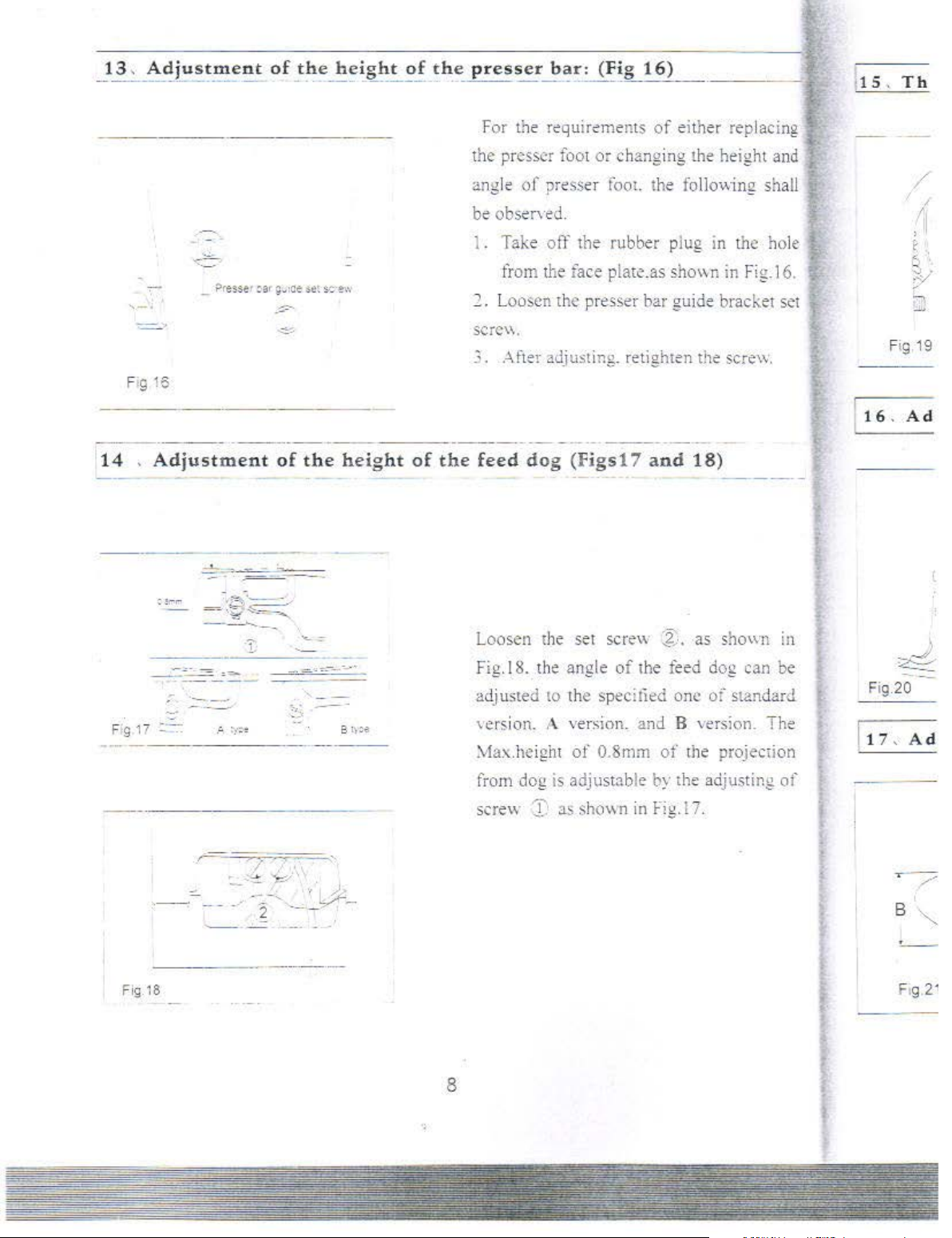

F

or

the requirements

__

r-:-(F-~

-

g

-

1

_

6

_

)

-

-

.==1

of

either replaci ng

•15.

Th

Fg

16

-

--

---

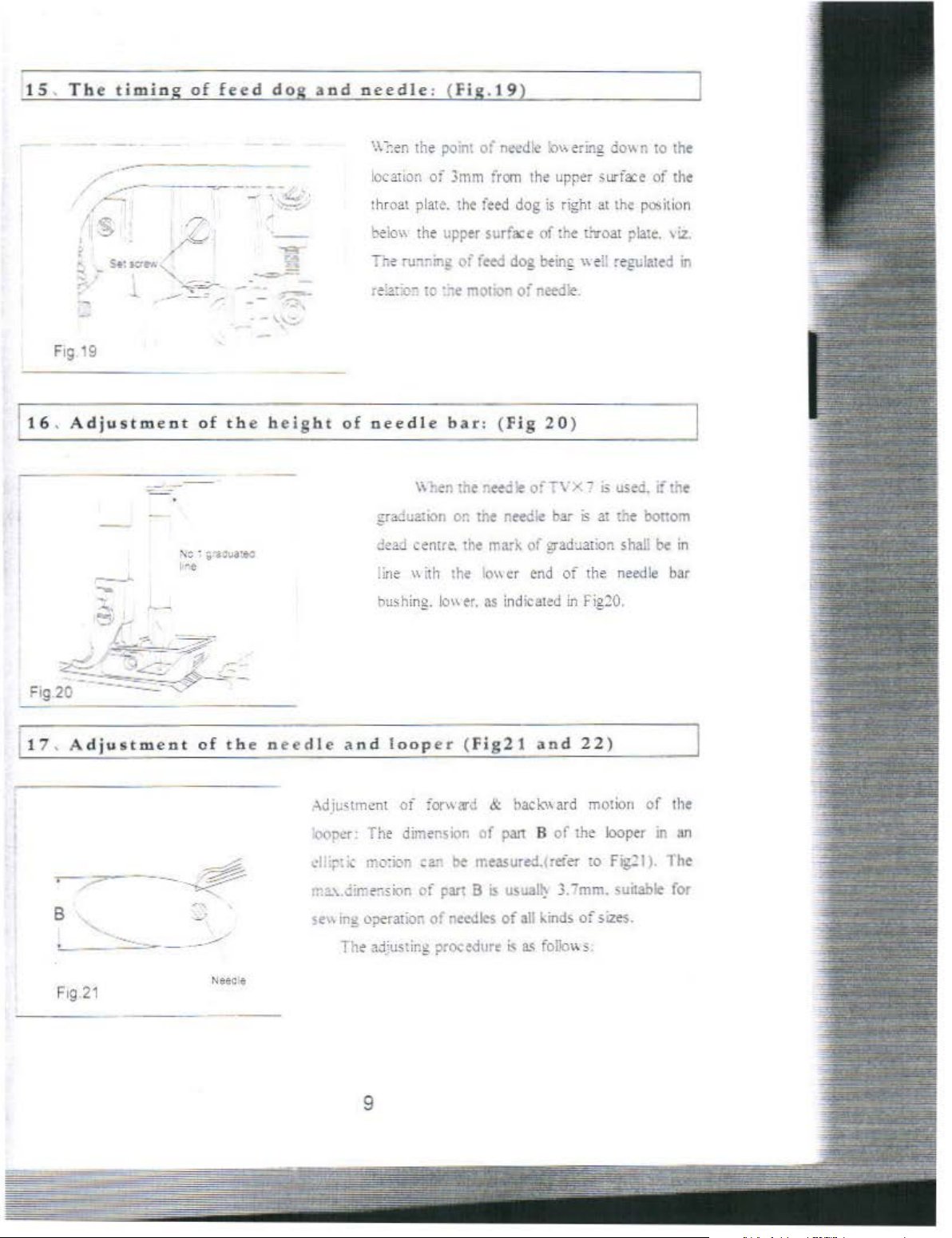

14 . Adjustment

_

::.""~

---

-

----

-~--=~;,·

=-:~-~

-

---

.:

.,__

--

I

-

of

==

-

~

~

the

-'

• .

, __

~'

~.

- -

-- -

height

,..

_ --.

the presser

angle

be

obs

1 . Take off the rubber piug in the hole

from

~.

Loosen the presser bar guide bracket set

SCTC\\,

3. After adjusting. retighten the sere\\.

----

..

of

-

----

the

feed

Loosen

Fig.

adju

'e

:vtax.hc ight

I

sted

rsion. A version.

fo01

or

changing the height and

of

presser

erwd.

t

he

-------

dog

the

8.

the angle

to the speci lied one

fooL

face plate.as shown

--

(Figs17

set

screw

of

of 0.8mm

the

fo

llov.ing shall

----

and

18)

:.?.:.

as

the f

eed

and B ve

of

the projection

in

Fi

g.16.

-

sh0\\11

dog can be

of

standard

rsion. The

in

Fig 19

lt6.

Fig.20

1

17

,

/

Ad

Ad

from

dog is adjusta ble

scr

ew

J• as shov. n

r-==r=;='F'

-:.!...

~

,\1

"-

·- - - _.-2 ·--""':' -

-= -:

'I

~

- -

- - - - - - -

Fig.18

----

8

by

the adjusting

in

Fig. t 7.

of

8

·-

"--

-

Page 14

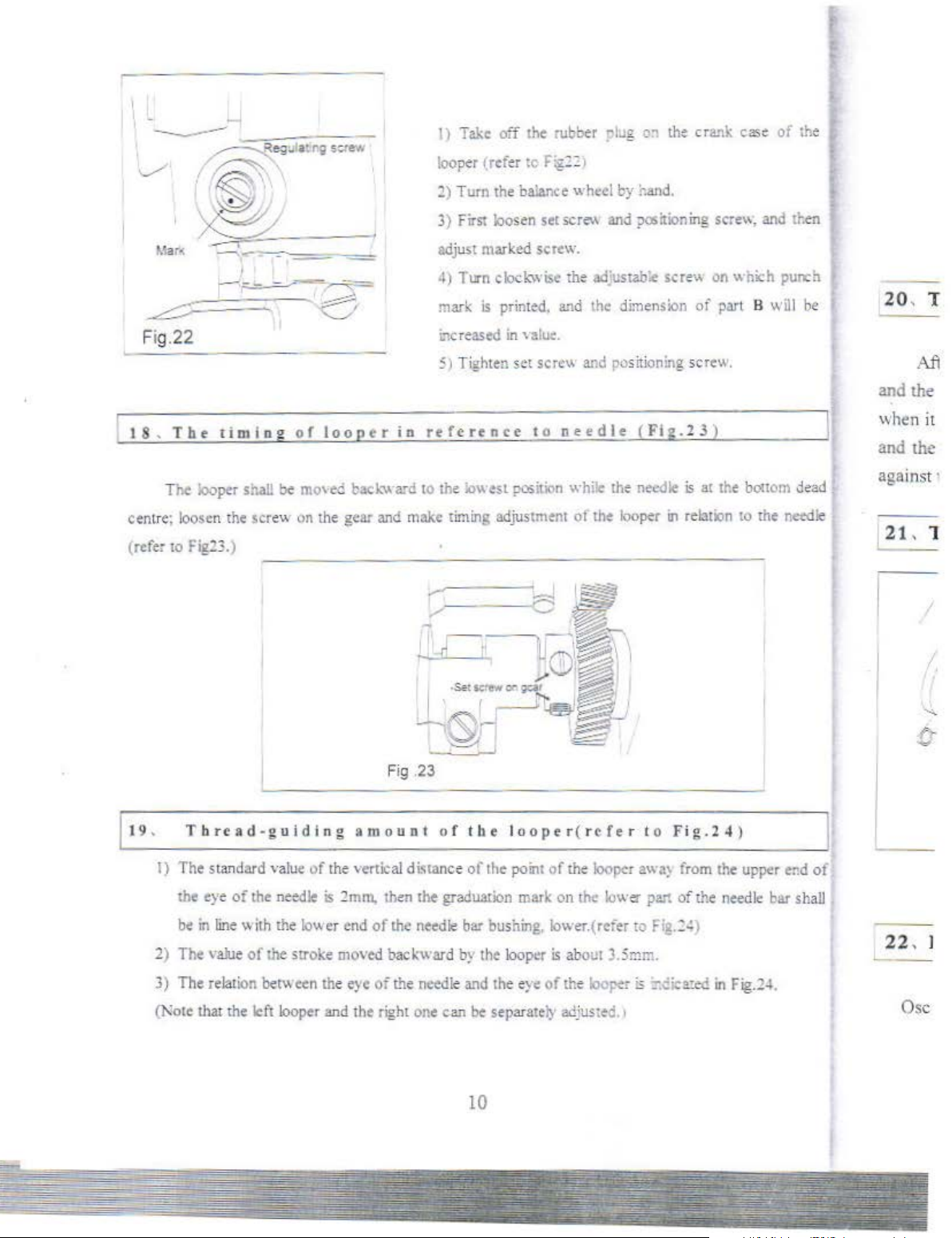

15

. T

he

timing

of

feed

dog

and

needle

'.\:-.en

: (

Fig.19

the point

)

of

n~dlc

~\\

ering

do\'

n to the

16. Adjustment

--

--

i\:;

1·-e

of

•

. -

the

;~:va•ec

-

-

--

\.....:...-

height

-.

location

throat

~eio"

lJ;e

r"!:~~:v-

of

needle

.gra~w::ion

Jead

line

bushing.

of

plat~.

the

upper surface of the

ruor.ing

iO

·~e

~entre.

"ith

lo"er.

3mm from

the feed

oi

feed dog beinf " e

r:'IOliO!'l

bar:

o~

tne

the rrark

the

lo"

th~

dog

o·-

(

Fig 20)

needk

of

cr

end

as indicated

upper ;urfoce

is

right at the

L'troat

!:

needle.

bar

is

at the bottom

grad~ation

oi

the needle bar

in

Fig20.

of

the

po>it

ion

plate. ':Z.

regulated in

shal: be

in

111.

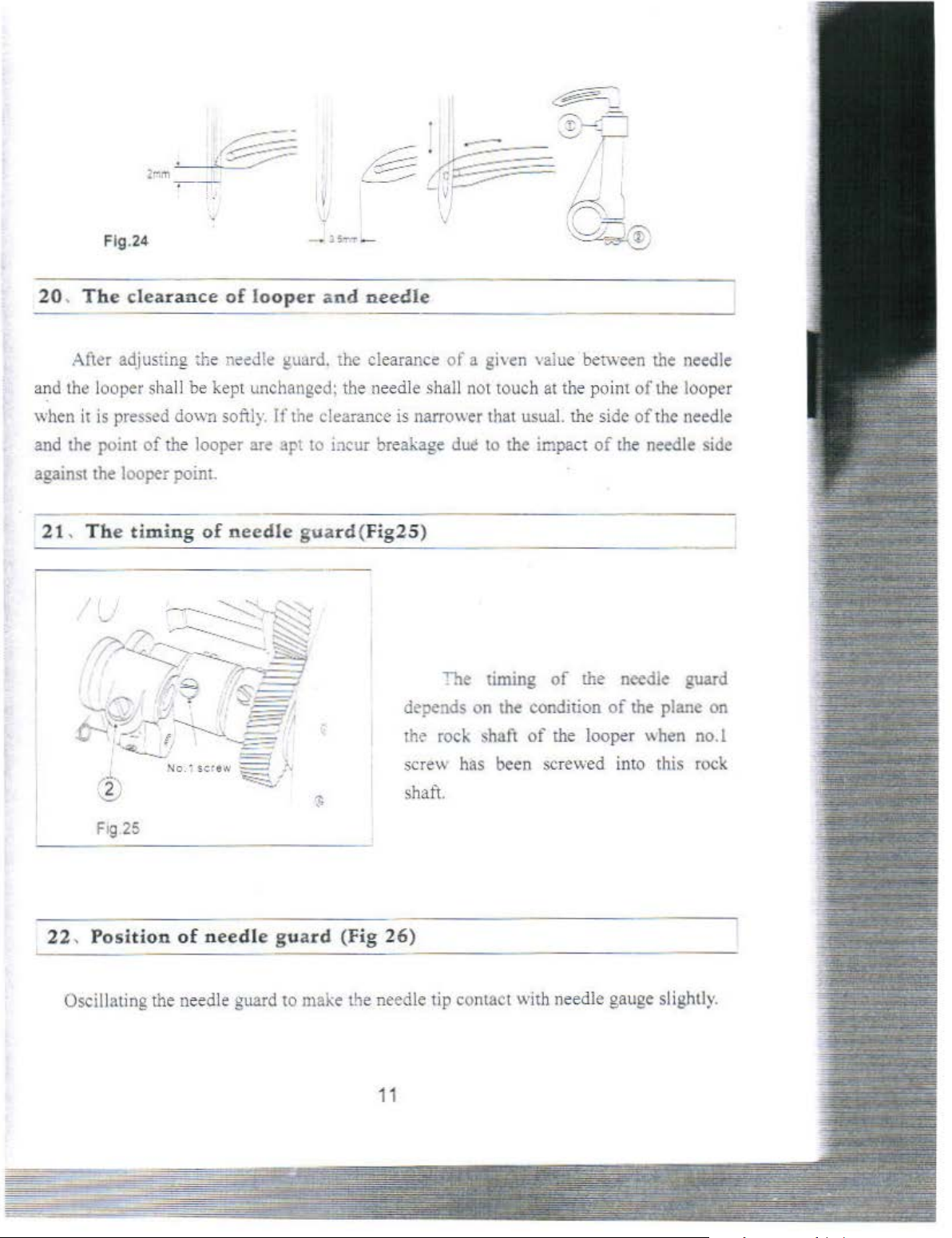

Adjustment

8

-·

-

--

F1g

21

~--

of the n e

__

__..

Neece

edle and

.~diu•tment

'oon

.or:

d!

~::C

tl:-\.

. .:irre"sicln

sew'"!; "i)Cration

The a.:l.'usting procedure

loop

oi

:orward &

The dimension

mo:i<m

'""

ci

9

er (Fig21

bac~"'ard

of

paJt B

be measured.< refer

part B

of

ne,'\fles

is

u~ual~

of

~II

i<

as fol!m• s.

and

of

3.-mm.

kinds

22)

motion

the

looper in an

to

Fig:

<unable for

of

;,,zes.

of

I).

the

The

Page 15

~C./

Fig.22

18

,

Tbe

I

~---.---..---=~~

.,-

-----------

tim log

of

~

looper

1)

Take

off the rubber "lug

loo

per lrefer

1)

Turn

the

3)

First

loos

adjust marked screw.

4)

Turn clod:wi:;e

mark

is

printed.

i:lcreased

5) Tighten set screw and

in

refe

in

renee

to

F1g:

2 1

balan

ce wheel

en

set sere-' and

the

and

valu:.

to

needle

o~

the

cra.~k

by nand

aJ;ustab~

the

dimension

po

?O>il

ioning

ser

siti

oning scre

(Ftg.

.

e"

of

2 3 )

case

screw,

on

which

pan

w.

of the

and then

punch

B will

be

20

, T

Ail

and

the

when

it

and the

The

centre;

(refer

19 .

loosen

to

l'ig23.)

Tbrcad-guidlng

I) The standard

the

be

2) The

looper

the

eye

in

line

value

shall be mo'

scr

ev.

1ln

,·aJue

of

the

needle

"ith

the lov.er

of

the stroke

ed

backward to the lowest

the

gear and make

Fig

amount

<lf

the

vertical distance

is :!mrn.

end

of

moved

then

the

backward

timing

adjustment ot

,-

---

I

·

5&·

~

-.,S.-J

-

~__j

.23

o f

the

of

the

the

graduation

needle

bar busning,lower.(reier

b~

the

position

while the

--<a

loo

per(tcfcr

point of

mark

looper

the looper

on the lower

is

abo

ut 3.5mm.

the

needle

looper

to

awa}

part

to

is

at the bonom de

111

relat

ion

Fig.24)

from the upper

of

the

fi~.:~)

to

needle

the

n.:edl

e~d

bar shall

ad

e

of

agains

21,

'-

- -

22

t ·

1

I

I

. I

3)

The

relation

(Note that

the

bem

left

een the

looper

eye

and the

of

right

the

needle and

one

the eye

can be separate

of

the

ly

adjusted. '

10

Ioeper 6 :-.cica:ed

in

Fig.2-1.

Osc

Page 16

Flg.

24

20, The

After adjusting the

and the looper sha

when

and the point

against

21, The

clearance

it

is pressed dov.n softly. If the clearance is narrower that usua

of the looper are

the looper point.

timing

of

looper and

needle

--------------------------

n~ed!e

ll

be kept unchanged: the needle shall not touch

of

needle

guard. the clearance

apt

to

bcur

breakage due to the impact

guard(F

ig25)

dl?pends

the rock shaft

of

a given

"':le timing

on the condition

\alue

at

t

he

l.

the side

of

of

the loope r

--

between the needle

point

of

the looper

of

the needle

of

the needle side

the needle guard

of

the plane on

\\hen

no. I

22, Position

Oscillating t

he

of

need

le

needle guard

sere\\ has been screwed into this rock

shaft.

guard

to

(Fig 26)

--

--------------

make the needle tip contact with needle gauge slightly.

11

--

Page 17

lt is re

commended

that

the

height

23

,

Looper

,·--

-

thread t

ake-up c

adj"Jstment shall not fall within

the left countGr needle guard. The

adjustment

ser

e"

left

needle guard is

the

clearance

the

range

needle shall

machine

am(Fig27)

can

be made

(!~and

count

;-Jote tl':at the forced

X. The

er needle guard

as

represenied in Fig

rrom

the needle falls within

of

0.1

ro

0.2 mm.

b.:-

prohibited

is

in

n1otlon

.

- - - - ·· -

the

b

~

relation

and

the

clamp

--

area

or

loosening

between

counter

26;

of

the

"hen

the

---

Fig.28

25,

Fr.

The

skipping

The

Conon

th

Fig.27

~--

-

24, The

position

of

--

the

thread-amo

Its position

fig.27

when

dead centre.

the steel

projec

ting

rise

at the

first loosen screw

adjustment. linall;- tighten

firmly. P

can

be se

en

the

needle bar is at the

the

planes

wir

e are in parallelism: the

part

of

angle

a'

close attention

of

the

cam can slightly

ot'

18

10

B.

and

rollowing: the needle tip

come

wh

into

the

rhread

en the

the projecting pan

bobbin

loop

thread rejecting from

of

the

cam.

as

shown

the

cam

::!0

degre

then

the

sha

ll entire!)

or

the looper

mak

sere\\

to

in

top

and

es.

the

Conan

Thread o

Thr

e

ead

th

o

26, RE

-

unt

adjusti

ng

plate of t

he

thre

ad

take-up

lever:

(Fig 28)

12

Page 18

Th

e thread-amount adjusiing plate will

retain the bobbin at thread when the needle bar

is

the bottom dead centre:

of

the needle thread is to become bigger when

the

n

e~dle

thread is hooked.

in

such a way the loop

In

addition to the

Flg.28

25

, F

rame thread

The improper-posit ioning

skipping stitch.

following location> are ge:J<'raliy

The

Cotton thread

Cotton thread

Thread

Thread

'80-'50

'80-'5

of

chemic

of

chemical fibre

a!

foregoing there is a function

of

eyele~:

(Fig,

-'2::.:

9'-')'-------

of tile

frame thread eyelet rna)

Graduation marked on the frame thread eyelet 2-3

the needle thread loop.

adjusting plate usually reduces

point when a thread liner than nonnal

"'ote

that take- up thread tension le,·

another name for thread-amoum adjusting plate.

-----

be

r~garded

as criteria (refer to Fig29)

The

the cause

0 Gradumion marked on the frame thread e

:i!:>rc '80

'8

-=s

o Graduation marked on the frame thread eyelet 1-2

0 -

-'50

Graduation marked on the frame thread e}elet 2-J

of

the light pulling

thread-amount

to

the

is

used.

-

--

of

occurrence

yelet3

--

]o,~est

er

IS

of

-4

/ -

·"(

,._

---::.

.

26, Replac

ement

of

throat

plate:

(Fig

.30

)

13

"

--==

--=-----:__--=----------

----~-

----=------

~--

-

Page 19

Fig

30

The

standard size

book. which

I

.; .equi,·alent to 6Amm.(Fig.30l

The

is

usuall)

gauge

of

ts stipulated

replacement

needed

double-row thread stitch.

1.:\eedle

3.

Throat plate

needle

the si

of

the width

guard

The

left

and

zes

of

I 8 "

In

addition

slide plate and

of

thread plate is on the increase.

of

the throat plate

by

the oanufactory. is

of

the

following components

at

the

time

when

clamp "

~.Feed

6.Curle~

right

to

to

the aforesaid.

cam

dog 5.Rear mo,ing

loop

ers \\ithin the

I '2 " are interchangeable.

cov

er shall be

changing

Hinged

the

replacement

made

in

pans

range

when

the

foot

of

:!8

~

i'

I

''

I

I

I

~

, o

mm

o

Brea.~down

Thread

brea~age

-

---

27, Maintenance

The

(I

I .

II

. Repairman shall

---

----

of the mac

follow~ng

)

Daily

The

oil shall spray onto the oil sight when the machine

shall

be

checking

be

machine.

(2)

I .

wi

th

I!

.To

the oil reservoir

Locations

To

take off throat plate. slide

to

be

a brush.

turn o\·er the

head

of

oil stain and dust.

In Loosen drain hole sere"

reoil

it.

1\

.Oil Je,.

V .The

eJ must

black

be

abo'e

powder. adhering

sponge cloth.

---

-

----

hine

adhered

sent

checked once a wee

to

in

order

to

keep

for

when abnormal sound

k:

pla

te. and cam co\ er;

rid both the oil filter screen

and

take it off; drain all

th~

lowest oil-level-indicating line marked

to

the

magn~t

-----

the

machine in

to

the

in

the

-

-----

good working

is

running.

is

heard during the operation

clean

dust of

on

the

oil

dtn~

oil

oil resen,oir shall

the slotted

pump

from

and

the interior

the oil resen oir and

..

Low

..

be

conditi

feed

wiped

on.

of

with

~

the

dog

of

~~

i•

I '.

-

I

1:

I

1:·

1:

Skipping

stitch

14

li

1·

:

Page 20

li

1

~

[2 8 , o m m o n

breakdowns

and

measures

of

trouble

shoo

ring.

I

'

:

~o.

I

::

,'

~

I

'

2

Breakdown

Thread

breakage

Skipping

stitch

Cause

I Poor thread quality

2

T~.read

3 Fusing thread due to h

temperature

caused

operation at

4 Tension

Breakage of

5

lo

oper. :hroat

needle guard

of

thread guide

6 Failure to adjust thread

amount

!.Skipping stitch

thread

due to

hook the needle thread)

being t

oo

thick

igh

of

needle

by

J:llt::hine

high

speed

being too higher

needle,

plaie.

at

the

of

(leaking of two stitches

the loopers failure to

and

location

needle

Measures

I.

Qu

ality

thread to

2. Replacement to

s

3.

Silicone

4. The tension nut to

5.

First grinding with oil stone

6.

Adjusting the thread

1,

2, Adjusting clearance between looper and needle.

3

...

4, Adjusting the thread-amount adjusting plate on

5,

6

'

7,

8,

oil

Adjusting thread-hooking amount

The

riming

arnoum changing conditions.

thread

Adjusting the

Checking

needle

is

To see

appropriate

regulated

To

see if the

way.

be

be

to

be

used

of need

frame

wh~ther

proper or not .

if

the location

way

in

relation

needle

ro

be

taken

used.

made

by

an

appropriate thread

anc!

speed to

be

loosened

and

an10unt adjusting

le

in

referenc

thread

the mounting position

of

and tbe t

to another.

thread threading

then

e to

eyelet.

need

iming

be

of

le guard

reduced

polishing

plate

looper .

looper.

of

it

is

in

of

the

is

in

an

is

weD

a proper

I)

2.skipping stitch

thread (leaking

needle

looper

J.Skippin¥ stitch when thread

of

failure

eyelet)

chemical frib

of

of

one stitch.

to

enter the

re being

bobbin

ht

use

Reference to

of the

stitch

To

sec

2)

we

t!

regulated.

3) Increasing tension

4)

To

see

correct

I) lising sillicone

2) Reducing

3) UsiM

need

the

above cases I

needle

of the

if

the

timing

of

if

the threadine of bobbin thread is in a

wav.

oil

spee<i

!e

for

threw of chemical

15

and

2.

as

needle

thread.

of

bobbin thread cam has

bobbin thread a bit

fibre.

to skipping

been

higher.

Page 21

3

s

Tv.

is

ted

sthches

Breakage

needle

Puekeril:g

.!,Sk.~pi:lg

of

po~ester

1.

~eedle

too

low.

stitch

"'cen

libre ;eing

thread

tensio~

2. Bobbin thread tension being

1

100

low

3. Sewing thread

thick

.J. Improper

f:-am~

5.

l:nproper postior.

:a{e-up

6. Throa1 olate

1) '\eedle

:!

) The openuion oi

thread

tension

being

poeiltion

C:)'eltt.

plate

bent.

beil:g not "eO regula:ed

refe

rence

to

the

needle.

3) Sening-up

of

4}

The problem

of

f()Ot

n<cdle

of

the presser

of

guard remain

unsolved

S)

l\ed[e

[00

6l

:-;eeele bein£ roo thick. 1

1

3

thread

tensi~n

bigh.

Ttr

ead tension

~ig;:.

Tne problem

of

the bobbin thread

~or

!0

t.'lread

be

guiding iaihng

solved.

The problem

fmish

arising

th

read

going 1 hrough the

par

ts on the thread

T

he

force on the

foo:

bem<:

too area!,

of

oi

from bobbin

're•j

~,

..,~

b~mg

being

tOO

of

the S, Readjusting

of

:hread

feed

dog

r.1otion

the

timing

being

bei:1g

too

the timing

cam

sunac<

guide.

pres.>cr

Re~::ci:15

Silicor:.:-

I,

Tightening

:!

. Tightening tension nut

3,

l\eedle

4,

Readjusting it to a proper posit

6.

The eye!e;

than

normal on

11

in

of

bg

'-:eedle to be :eplaced

~

l

Readjusting the timing to feed dog

n~cdle.

3)

To

ma.'<e

foot

and the

4)

The positioning

be

taken

5)

Relaxing

6)

Appropr'ate

I.

Decreas=:g

thread.

2.

Readjust'ng

proble~

3.

Surface

4.

Turning counter-clockwise

screw.

.;peed

o:J

!O

;e

-.)~..!

tension nut

of

large

size to

its

;lOS

of

throat

e.

both the centre

centre

of

8:

the tuning

into

account.

need!~

thread

needle

to

th."ead

of

the

'<f)

.

fmishing

all

of

needle

thread.

of

bobbin thrcdd.

be

u;cd.

ion.

ition

in

an

appropriate way .

plate

to

be

used

being

bigg

by

another

the

be

used.

t<nsion,

cam

of

the

eyelet

of

esp.

said

oi

proper size.

in

respect

hole

of the pres

of

the throat.

the

needle

t:nsion

to solve the

guard 1

oi

bobi>;

tim

tot

the parts on the thread guide.

the

pressure-regula

tin

I

I

$

in,

~

,,

),

~

6,

-1

7,

t

8,

~1

9,

11

10,

lL

12,

1

13,

14,

lii

Page 22

Contents

P

arts

l,

2,

3,

4,

5,

6,

7,

Book

Ann

Bed

Components · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

Main Shaft & Thread

Presser Bar Components ·· · · · · · · · · · · · · · · · · · · · · · · ·· · · · · · · · ·· · ·· · · · · · · · · · · · · · 5

Feed Mechanism Components ·· · ·· · ··· · · · ··· ··· ·· · ·· · ··· ·· · · ·· · · · ·· ·

Feed Re<>ulatina Components · · · · · · · · ·

Looper Thread Retainer Complete · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 11

Thread Take-up, Tension, And Tension Releasing Assembly

,

"'

Bar

Components ·· · ··· ·· ·

···

· · · · · ·

··· ··· ·

···

··

··· ·· · · ·· ··· ·· · ···3

· · · ·· · · · · ·· · · ·· · · · · · · · · · 9

···

·· · 7

complete

8, Lubrication Components · · · ·· · · · · · · · · · · · · · · · · · · · · · · · ·· · · · · · · · · ·

9,

Oil Reservoir & Knee Lifter Components · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·20

10,

Machine Head Accessories · .. .. · .. · ·

11,

Quadruple-thread Spool

12,

Machine Stand, Table, & Electric Appliance Components ·· · ·· · · · · ·· · 26

13, Model

14, ZJ3800N, ZJ3820N

One

-needle High Speed Chainstitcher · · · · · · · · · · · · · · · · · · · · · · · · · 28

· · · · · · · · · · · · ·· · · · · · · · · · · · · · · · · · · · ·· · ·· · · · · ·· · ·· · · · · ·· · ·· ·

..

. · · · · · · · · ·

....

Stand

List

.... · ....

Asm. · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 24

Throat

of

& Its Accessmies

· · ......

· · .. · .. ·

........

..

· ·· · 14

.. "31

18

· 22

Page 23

Arm bed components

L

Re

f. No.

I

2

3

4

5

6

7

8

9

10

I I

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Part -:o

GQ202fl3

GS01Z7

GR\823

GKI86

GR1812

GS

IOO

GR 1757/2

GR1758

GS!OO

GR1458

GR!813

GW287

GRI814

GS069

GM241 /\Ltachmenr

GW288

GSOi28

GS012

G\-!242/9

GM243

GW289

GW29

GS045

GR 1815

GS0129

GM244

GM245

GW291

GS045

GR1816

GS0

GW292

GS010

GR18

GS44

GRI8

GSOIO

GSO!O

GR146i

0

/6

!29

l7

1R

GRJ8!9

GR1462

GR

1~63

GR l

"o'"

GR1465

GR!466

GR19

!6/5

GRI923

GS0

!48

Description

Arm

bed

Bed sc

Bee s

Side p l

Gasket

Side

Face

F

Sc:evv

Rubber

Can

Spring

Spring

ace

rew

upport

ate

plate

;:>late as

plate

--

plug

cover

suspension

Scre'v

Spring

Screw

Screw

Cam

Cam

Cam

Sp:ing

Screw

Sc

cover

cover

cover

Cam cover

rew

slide

Bed

Bed

slide

Spring

Screw

Bed

siide

Scre\v

Bed

slide

Screw

La;:ch

Screw

Bed

oil

shie

Screcw

Bed

oil

shie

Scn

:w

Rubber

Rubber pl·

Rubber

Rubber plu

Rubber

Rubber

Folder

Gaske

Screw

t

cornpiete

stud

screw

m.

gasket

late~

installing

asm

guide

asm.

guid

e

lock

spri

ld

ld

plug

ug

~lug

g

plug

plug

ng

plate

Ann.

Req.

I

2

1

I

I

8

I

l

3

2

I

I

1

1

I

I

2

I

(!)

1

l

I

..

I

I

(1)

I

l

2

I

1

1

2

I

I

J

2

1

2

~

2

2

tK

;to-

42

~

32

~~

33

34

v r

35

~-:

1

l

Page 24

Page 25

2..

lVIain

shaft & needle bar co

Ref.No. Part No

l

2

3

4

5 GZ303

6

i

8

9

10

1 l

12

13

14

15

i6

17

!8

!9

20

21

22

23

24

25

26

_,

T

28

29

30

'.

.:'l

32

33

34

35

36 GSOl30

37

GS02

GPi 32

GS03

GRI-!68i2

G0262!2

GRI824

GS33

00265

GS05

G0303i2

GS04

GR1470

GX33-!

00269

GR147l

GH378

GS06

GRt472

GS07

GH379

GS48

G$

GH33.:i

G02i0

GS09

00271

GS012

GRi-!79

G0~88

GRi47~

GSO

GL168

GZ304

GR l

G

Vi8

041

826

l i

mp

onents

A

Description

End screw

-.vhee

Hand

Screw

Oii seal

Main

:Viain sna

:V1a:n

Screw

\fain

Screw

Main

Screw

ol

ler felr

R

Crznk oil adjus,ing pin

Rubber bushing

0-Ruboer

Counterweight asm.

Screw

0-Rubber

Screw

=-'eed

Screw

Scr.!w

~eed1e b~r

Needle roiier bearing

Left twist screw I

.Kcedle

Screw

Rub0er plug

:\ceoie

·'\eeri!e

Scn:w 1

Crank slide block

).leedle bar

:--ieed!~

Screw

!'\eedle

l

shaft

f<

bushing. rear

shaft

thru;t

shaft bushing intermediate

shaft

bushing. front

rir.~

ring

le crank

bar

bar

bi:ir

clamp(l/4"

colla

:

crank rod

bushing upper I

bushing. lower

~on~ection

asm.

)

rm.R

I

2

l

2

-!

I

2

1

l

l

I

I

l

I

I

I

1

I

1

I

' 1

2

2

eq.

15

1s 1 .

14

\ I

"-~6'

~

I

,.,--c::r-1

-~~:<'

~

12

~

~

L-

26

\

~-

3

Page 26

12 11

I

:~

1

30

____ I

----

<;:;'

34----

_j

~

"'

"

'

0

3

"'

Page 27

Presser bar components

3,

Ref.No.

1

2

3

4

5

6

7

g

9

10

il

12

i3

14

15

16

17

18

19

20

21

22 GR I 5

23

24

r

26

27

28

29

30

31

32

33

34

35

Pan

No.

GS018

GL18

GRI494

GW253

GZ305

GR

I82

7

GS0!9

G0273

GR1525

GM246

GS020

GR

1832

GR1833

GS0129

GR1499

GS021

GRISOO

GRI50l/2

GRI503

GRt504

GS022

05

GS023

GS024

GR

1506

GRI508

GRI507

GRJ834

GS025

GRI510

GRI835

GS0131

GR

183 6

GX378

GLl9

/5

Description

Presser spring r

Nut

Pr

esser bar

Pre

sser

Presser

Presser

sc~ew

Press

er

Oil

wick

Presser

Sc

rew

Thread

Thread

Screw

Hand

Screw

Washer

Hand iifter

Rubber ring

Lifting

Hinge

Lifting

Hinge

Hinge

Lifting lever

S

:1ap

Snap

Lifting lever

Screw

Snap

Lifting lever link

Hinge

Swivel

Lifting

:>Jut

spring

bar

bar

bar

foot

knife

knife

lifter

lever

screv..-

link

screw

pin

ring

ring

ring

screw

lever

guide

guide

bush

asm.

guide

cam

for

gasket

connecting

connecting

egulator

bar

bracke

ing, lowe

asm

.

lifting

rea

r

.t

asm.

r

lever

rod

rod,

Amt.Req.

vertical

I

I

1

1

1

1

1

1

I

1

1

1

1

2

2

I

I _;,

1

I

24

~

22

-

1-

2-

4-

3........___

6

?

...............

~

~

o.--

v

8-

s--

11

--""

~-

~

I I \

14

13

12

""

I

"

5

Page 28

24

32

---@.1_

16

33

35

34

---®

- -

'

"%

I

I

I

I

'I

I i

II

II

5

11

~.,.,

~~~~

14

13

12

~

10

6

'J

Page 29

4.

Feed

mechanism components

Ref.No.

l

"

'

~

<

6

i GH3SO

8

i

]()

1'

12

13

!

~

:5

;s

'

.8 GSG39

19

20

2: GS040

22

23

24

~:5

~

6

,-

_,

23

29

30

31

32

33

34

35

36

37 GSO

38

:,9

4(i

.!j

~2

43

4.;

45

46

47

48

.w

50

,.

_,

52

53

54

55

5~

57

58

59

60

61

62

63

64

65

66

67

Pan

GT!61

GS035

='o.

GT l60

GS03

GR!5:?. 1

GH335

GX340

GS036

GR

GR t 523

GX3

GX'342

i l 0

4

152

c

41

GS037

GS05

GZ.~79

GS035

GL7

GH337

GZ280

GR

1890

GS032

OR

151~

G0235

GS41

GRP69

GS39

G0286

GR I &38

GS

040

G.Rt528

CL20

G R 1

839

OX396

iOO

GR I

S3

G~2d7

GR

G$019

GN!24.8

GSv4~

GH3S

GRi

GSO

GH39

GSG39

GL7

OSO~O

GZ306

OR!

002&5

GS48

7

15211

i

340

i : 5

-.

837

GR!469

GS39

G030

0

GS04

G0306

GH

382

GSO

132

GH383

GR!84l

GS0!3

GR l S37

GRi 842

GSO

133

Description

Feed

eccentric

Feed.

eccentric cam

S..::ew

eed

eccent

F

Screw

Feed

roc

Connectj

Conr..ecting pi;,

Sere\\·

reed

drivin~

Retd dri

Hi

nge

Screw

Hinge p:n

Sc:ew

Hin~

e

Screw

Hi

ngc scre

!\u

l

Feed

rocker

Screw

Feed

rocket

Thrust

Screw

Rct::dr·.ing

Bushin~

Screw

Thrust

Screw

Feed rocker

Feed

Screw

\Vas

her

:-;

ut

Feed

Fee

d bar

Si:re\v

Oil

wick

Reed

\Vasher -

Screw

Throat pla<e

Sere"

Feed

F~·e.d

Screw

Fe.ed

H'nge

,. .

.•

Ui

Screw

Feed

Oil

•>ick

B!!shin~.

Screw

Thrust

Screw

Bushin£.

Screw

Feed

Feed

Screw

Feed bar li

Thrust

Screw

Oi

l

wick

Counlcr~s:.m

Screw

ric thr u

ker

shzfl

r:g

rod

dr.'S!

stud

'

p1n

w

;;haft crank

shaft

collar

dne

rear

collar

rocker

bar

dog

drivi

drinng

driving

drivir.g shaft

rocker

rocker

;haft

ihaft

(114)

(l/4)

n::r

scr

ew

rtar

_,

coJhu

inte·mediate

...

shaft

shaft

nk

collar

k

cam

asm

st

conne

r

ock

er

rocker

...

shaft

eccentric

.shaft

a

bushing.

coonectin2

cra

bushing,

crank

washer

Amt.Req .

.

washer

cti

ng

~m

rod

front

1

1

2

3

1

1

i

I

1

1

'

'

i

l

1

2

1

!

2

I

l

j

I

I

I

1

l

1

1

2

I

1

1

~

l

l

I

I

I

l

1

I

I

2

thrusl"wa~hcr

r~C

nk re ar

iront

~

1

1

~

~

l

2

!

2

1

1

2

I

I

I

I

l

!

1

l

l

I

I

I

I

I

4

35

36

'

~

.

.....---

~

32

I

'

30

I

[)

~

Gt:?

~

--62"i"'

~~

~

QJik

' i

59

'

~

60

'

'

7

Page 30

35

41

\)

40

39

~

1

~

---

---------t-

1 2 :

'::

""'

';illr ·

----

~"

~''

--------

'

%····

:.,;

;~

-

-----

4

~

~

~~§

I

3~

:::.:J

~t

....

\ \ I I

67

v 1

~

38 \'\ ' -

~-

66

43

~

32

I j3 37 1

'

3o

~

~

-

~

I I

1'"\

~

~

~---.~

34

31

r!

- J

~

~

~:

:

i(

I

~~~

50

I

~~

49

I

1

L-

---;::::

')i

~

13

~

-- ----- ;

~

Ill

\1

45

19

~

48"

:

20

\

~~

a

·

_

)l

9

47

::::::

:::::::::=~

'<L0 _-___ --

12 I

11

r

-Ht-<C::::]~

..___..

17

!'

15

(-

..

":.

...

-

~~~

c--

S

\1

'\

18

~A

7

~1o

~

-~

-'

1•6

IL-\

-=

..

------------------------

'-

--

-

~

1G~~

s9

.. ---------

62

;!-

64

63

-~

~'

60

-----

/

65

52

-~~~~==~~0

_

61

rv

!

-.._

.

..

--

-

--------

57

-

sa

---------------------

------

-- -

51

52

8

22

2s

---

29

"

. "'

,.

27

)'

51•;

25

2~

""

24

-

Page 31

S, Feed regulating components

Ref.~o.

1

2

3

4

5

6

7

8

9

10

i 1

12

13

14

15

!6

17

18

19

20

~,

_,

22

'>'

~

.l

24

?-

_;)

26

T

_ /

28

29

30

.J

l

" GL21

,,

.l-

33

34

.15

36

37

38

39

40

4!

Part

GR

GS046

GS047

GR1538

GX34~

GW257

GR 18

GX346

GS48

GH34!

GS048

GL20

GRI540

GS

!OO

GH342

GS049

GS48

GW258

GR

154

GS

O!

GZ282

GRI542

GR 1

543

GR1544

GS050

GS

033

GS051

GR15.45

GS013

GRJ599

GRJ

844

GSOi35

GR1845

GH344

GS48

GS04Y

GH345

GS052

GR

15,~6

GL20

:\o.

15361:'

43

7

4

Description

S

titch

dial

Screw

Feed

regulating

0 -

Rubber

Stitch

Stitch

Feed

Hinge

Screw

Feed

Hinge screw

0:'ut

Tension spring

Sc

Tension

Clamp

Screw

Tension

Suspensi

Screw

Reverse

Rubber

Waved

Reverse

Screw

Sc

Ena s

:.(.i.!

S::r.:.•v

W~<her

:--1 , ••

L:;vc.r

Screw

Il-.!bb

Control

Screw

.'icre\.v

Feed

S..:rei'-.

W

asher

Nu£

di2i

dial Jock

regulator

pin

regulator

rew

spring suspension crank

screw

spring

on brac

feed control lever

ring~

washer

feed control leve

rew

crew

~ber

plu

g

stoppe:-

er

cushi

lever

driving rocker arm

asm.

ring

lock

spring

connecting

suspension

ket

large

on

crank,

.;crew

pin

r"a

rod

stud

shaft

r

r

connecting

Amt.Req.

1

l

1

1

l

l

;

'

1

2

l

1

I

i

1

1

l1i

IJ

28

27

~

14

9

Page 32

'! , I

37

17

/

16

t

I

36

~

35

r~,

22

23

26 25

I

I ;

24

\ \

or~,

~~~.

I I

14

~

18

19

/~

·---"'""

,

21

20

----¢;

'

1

~38

I

\I

~

lO

32

29

__

.fll

~

\

I

33

Page 33

6,

Looper thread retainer compo

ne

nts

Ref. No.

2

3

4

5

6

7

Pan

l\o.

GC168

GCI67

G0283

0028012

GS04

GCJ67

02307

Description

Gear

a;m

Pinion asm

Bu~bmg.

Bushing, lower

Screw

Gear asm.

Upright,

upper

shaf

t

8 GS033 Bushing, front asm, screw

9 GC169

10

II

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30 GS033

3 I

32

33

34

35

36

37

38

GZ308 Lower shaft asm.

G0307

GSO~

GR1S47

00308/2

0504

GR1848

GS033 Screw

G031

GS04

GR1849

GRI850

GZ309

G0308/2

GS04

00314/2

GS48

OR

18-18

GS033

CCI70

GCi71

GS033

GH384

GS033

GS0136

GRI85!/5

GZ3l0t:

oso:oo

J/2

Gear asm

Bushing, rear

S"re"

Felt

BushiDg, intermediate

Screw

Thrust

Bushing, front

Screw

Looper thread

Oil seal

Looper rocker shaft

Bushing. intermediate

Screw

Sushmg.

Screw

Thrust

Screw

Gear

Screw

Gear

Screw

Looper

Screw

Looper

Trunnion

Loop::r rocker

Screw

collar

collar

a~m.

a sm. lower

c~ank

crank

asm

guard

front

asm

~pper

asm.

adjusung

a~m

.

shait

bushing

sere;.,

asm

Amt.Req.

I

2

1

l

8

1

I

I -

I -

I

2

I

I

l

I

1

I

2

2

2

I

2

I

I

4

Ref.

t'

39

4(

41

4:

4:

4<

4.

4

4

4

.!.

"

-

'

.

'

ll

Page 34

Ref. No.

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

6!

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

Part

No.

GR1837

GR 18

54

GR1855

G$

0137

G03

18

GS032

GH385

GS040

GN169

GS0138

GH386

GS040

GN170

G

K187!7

GSOJ39

GR

1462

IS

GR

GT162

GS48

GH387

GH388

GS

0!9

GX380

GR!837

GS

032

G03

19

GS48

GZ3

12

GRJ837

GH389

GS

040

GRi857

GSOlOO

GR

1858

GS030

GRI859

GR1860

GSOll

56

De

scription

Oii

,,·i·

:k

S

nap

ring

Looper

Scre

Bushing.

Screw

Looper

Scr-ew

Loop

Scr-;.v,

Looper

Screw

Looper (rig

Crank

Screw

Rubber

Vinyl

Needle

Screw

Needle

Rear

Screw

Pin

Jr.ounting

w

holder

er

(lef

holder

cover

plug

tube

guard

guard

n~edle

Oil wick

Scre\v

Bushing

Screw

:-.ieed!"

Oil wi

Rear

Scre\v

Driving

Screw

guard

ck

needle

Needle guard

Screw

Counter

Counter

Screw

rear

t)

ht)

asm

guard

guard

n.ocd!e

needle

needle

base

asm. (ief

asm.

(right)

can1

asm.

crank

driving

rod

rocker

rocker

guard

ba~e

guard,

guard.

t)

fork

shaft

asm

arm

(!/4

)

lef

t

rig~t

Amt.Req.

1

2

1

4

2

2

1

1

1

2

1

1

l

3

1

l

1

2

1

1

1

1

1

asm.

1

j

1

2

1

1

2

12

Page 35

7,

Th

Ref.

I

2

3

.

'

'

1

1

I

74

76 I ffi

73

72

,,

~~

~~_I/'

-

~t>-

1

m i

'

76

f.-

75

~

5

13

Page 36

7,

Thread

take-up, tension, and tension releasing assembly complete

Ref.

No.

1

2

3

4

5

6

~

I

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33 GR 1873

34

35

36

37

38

39

40