Page 1

358000NU

35800DRU

m

35800PZ

358000WW

35800DZ

HIGH SPEED

il

m

JACKET

il

SEWING MACHINE

aJJ

OPERATION

PARTS

Ul~·UlJI~il~?lliliRD2ffi~BH~EI

ZOJE

SEWING

MANUAL

BOOK

MACHINE

CO

.. L

TO

.

Page 2

SAFFTY RULES

1.

Before putting the machines described in this manual into service, carefully read the instructions. The

starting

2.

3.

4. All safety devices must be in positi

5. Wear safety

6.

7. The warning hints in the instructions are marked with one

of

each machine is only permitted after taking notice of the instructions and by qualified operator

IMPORTANT! Before putting the machine into service,also read the safety rules and instructions from

the motor

Observe the national safety rules valid for your country.

The

until it has been ascertained that the sewing units which these sewing machines will be built into,have

conformed with the

the machine without the appertaining safety devices is prohibited.

In

case

and changes are made

supplier.

sew

ing machines described in this instruc:ion manual are prohibited from being put into service

EC Counc

glasses.

of

machine conversions and changes

il

Directives (89/3

at

your own risk.

92/EEC,Annex

on

when the machine is ready for word

all

valid safety rules must be considered. Conversions

11 B).

of

these two symbols:

or

in operation.Operation

s.

of

8. When doing the following the machine has to

ma

in switch

8.1

When threading needle(s),looper,spreader etc.

8.2 When

needle guard,folder,fabric guide etc.

8.3 When

8.4 When doing maintenance work.

8.5 When using

9. Maintenance ,repair and conversion work (see item 8)mu

special skilled personnel under consideration

10.

Any

work on the electrical equipment must be done by an electrician

of

special skilled personnel.

11. Work

described in the

12. Before doing maintenance

disconnected from the compressed air supp

disconnecting form compressed air supply (l,e.pneumatic equipment wi

to be removed by

or

by pulling out the main plug:

replacing any parts such as needle(s), presser foot. throat plate, looper, spreader, feed dog,

leaving the workplace and when the workplace is unattended .

clut

ch

motors without actuation lock,wait until the motor is stopped totally.

on

parts and equi

applicable sections

pment

bleeding.

under electrical

of

and

repair work

be

disconnected from the power supply by turning off the

st

be

done

of

the instructions.

power

standard sheet DIN VDE 0105 .

on

ly.

is

not

permitted. Permissible exceptions are

the pneumatic

In

case

of existi

only by trained technicians or

or

under direction and supervisi

equipment

ng

, the machine has to

residual a

th

ir

air tank

pressure,

),

the pressure has

on

be

after

I

Page 3

1. ffffltlltiz1ltr.

~~lffffl.fllnz1ltr.

2.

~*~~:tc~~Yl

3.

J!tijtii}}~~JiJT~&~J~~W.fJl.

flfg.fll§.Ritifiitffl.

~~, 9l1Ji~P}}~-tfl.fi~£litffl.fllti

4.

JiJT~~:tc~~-~~iPol~JlE?i1&f}i:Jl

5.

~i:Plll

6.

JiJTfif-tfl.fi:1Jiti~~jlt~~~tf.~i:~!l!IJ.

7.

~i2fif1m"F~f1!:

8.

t11Jr~:rr~if~

8.1

~~~

8.2

~f4=1f.t.

8.3

~7f$f8]§!$

8.4

~~H~m

8.5

~~~a~~~~~1tJ~idlzFo

9.

~~U~&f!J!liff&::'~fE~~~lt*.A.~i'£~~7tiffi~PJ)zFojzt~f

~fHI!lOO~J!ti~P}}

.

fitg.flliHC,~i'f~~~ff.A.~fHI!l~il*i~PJ)zl§;tt!MiAff.ffl

~~~~~~m~~~~~

iJ.

£,~1f~fiJ

EC.fllt~i.AiiEzl§:t~MAf!Jf.l

litffl~fJI.fii'fJti~P}}·1Lt~

.

.

~J§:t~7f~mif

.

~!l!IJ.I§~~H~

.

.

a

£,~tJJ~~i]j§!=if*~~**

gq:tmtt

lf.1

.

~ff&ll

.

f

8]7t.A.If.t

.

.

ttt& .

Ji~H. ~*43f. t?tt~:a

.

:

.

"STYLES

OF

MACHINES

.

~ititii~hlff

.

.

.

fJTDH

(

~~~ 8 ~

.

(89/

392/EEC, 1!#1.Jo

"

~~

.

1m~i~~~l:7CJ!t

.

~~~loJR~

).

.

118)

.

10.

JiJTfif.E3~-T~Ifif*rt-li

11.

~Jl1£~1Jl'liHY.J.gc#~i..Q:.l:Iff

12.1f$~~i*~~ffi~•zntr.

if~~IE~i:t~~iJII~(fJ.A.*iMl"

.

M<7i'ff;f-/t~~

£,~tJJtmffi~~'f;t;(f)i3tm.

.

DIN VDE 0105

~~l±l~'f;t;~~~fifJtJ~~ffit¥.ff

tiJtflf!Jtt-.J~ffl$*

.

.

II

Page 4

Contents

1

t'lni~PJJ

2

f4!~m~

3

fll.H~-5

4

~'{9

5

-'Jf!fi~P}J

6

it .............

1 m~ ..................

8

*li:

9

}t

.......................

10

)ii]iff~!ft

11

3f~

12

~~i~II}J

13m~~*·

14

tt~~}ttr..J

15

l9~tt~

16

lt~ltt&l:tr..l1L.sl-i:~

17

~tJ.;cc:p,c.,

18

~~~lt

19

~~~lf(2

20

i~ii}tff~nt

21

H~~tl.~~~tr..J~~

24

~~~~~nr

25

i~•ittf.J~-f¥j}'l~JI

26

.ffiM41~

27

...1:~~-®~tt-.J~~

28

...1:

~*4-®~tr..J~~

29

~~H

30

~f;fjt£~J

........

. . .

...........

......................

......................

1]

..

....

.. .... ........

......................

.. ..

....

· ....

.....................

.....................

.........................

.....................

....................

f.ilnM

..

;',

.... .. .

..............

)

..................

.................

.......

Inllfftf.Ji,ijj

.......................

.......

...........

:·

................

........

.....

......

!&

...........

.............

(

2)

..........

.............

1

1

1

2

CLASS DESCRIPTON ............................................ 1

1

3 STYLE OF MACHINES ........................................... 1

......

2

4 ILLUSTRATIONS ..................................................... 2

3

5 IDENTIFYING PARTS ............................................. 3

.......

...... ..

.......

.......

......

..

...

....

10

10

10

11

11

. 12

3

6 NEEDLES ................................................................. 3

3

7DESCRIPTION .......................................................... 3

3

8 TERMS ..................................................................... 3

4

9 NEEDLES ............................................................... 4

4

10 LUBRICATION ................... .................................... 4

7

11

7

12 ADJUSTING INSTRUCTIONS ............................... ?

7

13 TORQUE REQUIREMENTS ................................. ?

1

14

MOTIONS .................................................................... ?

9

15 TIGHTENING NEEDLE HEAD ................. ............. 9

16

SLOTS ................................................................ 10

17 CENTERING THE CYLINDER ......................... 10

18 SETTING THE LOOPER ................................ 1 0

19 SETTING THE LOOPER(CONT) .....................

20 SETTING

21

........................................................................... 12

22

FEED

23

FEED(CONT) ...................................................... 13

..... 14 24 CHANGING ST ITCH LENGTH ........................

.....

14 25 SWTTING READ NEEDLE GUARD .................

1 5

16

16 28 UPPER FEED ROLLER ADJUSTMENT(CONT) ..

17

1 s

26

ADJUSTMENT

27 UPPER FEED ROLLER ADJUSTMENT. .........

...........................................................................

29 THREAD TENSION AND RELEASE ................

30 DIFFERENTIAL CONTROL ............................. 18

IDENTIFICATION OF MACHINES ........................... 1

THREADING .......................................................

SYNCHRONIZING

ALIGNING

SETTING THE FEED DOGS FOR PLAIN FEED .

SETTING THE FEED DOGS FOR DIFFERENTIAL

................................................................

SETTING THE FEED DOGS FOR DIFFERENTIAL

PRESSER

NEEDLES

HELGHT

FOOT

........... ............ ............................

NEEDLE

IN

OF

NEEDLE ....................

AND

AND

THROAT

PRESSER

LOOPER

..

PLATE

11

11

12

14

14

BAR

15

16

16

17

?

m

Page 5

31

je~~t~H~

32

r.g~t~t~~~

33

~~1fi~H

34

~mitt~

~ft!~.

~

ilf~H.

~

iiTAH

~

RTlPfft~~i~

9~flt&.

..............................

..............................

.

..............................

~-~--H~.

#

..............................

fi~~~~.

1t~~i'W~#

~i'W~~~.~~~~.~i'W~~ffl.J:

tr..J~~'L'H~#

•~~~m..ttr.J~~~zwm#,r.gn

~zwmi~~r.gn

~zwl!~m..t~r.gH.

~:m~i~~r.gH~iJ:m

i4

..............................

..tmM

$1~

~m•.~mm.~~H&~~H~M

tl..ft.J

~~fie#

~~

•.

...........................

...........................

..............

jl{jf*,

......

J:~~t&

.................

...................

if

...................

lj\1{,

~i'W~~ffl.tr..Jfll;!el.i~*t

fiil~~flltr..ltl.;!Cl.i~M

....................

~~~~ffl.J:tr..J~~~

.....

..................

fflffi~~H~~~~-~

......................

........

.........

~~l.it&~*t

~m•~~-~~

········ .......

............

r.gn~~.

..

............

......

...

1s

18

19

19

20

24

28

32

36

38

40

44

l!~

48

50

54

58

60

....

62

31

FRAr.JE EYELET.. ................................................. 18

32

33 FOLDER ADJUSTMENT.. .................................

34 AIR

MAIN

MISCELLANEOUS

FOLDER, CYLINDER COVERS AND BUSHINGS FOR

DIFFERENTIAL

FOLDER,CYLINDER COVERS AND BUSHINGS FOR

PLAIN

DETACHABLE

OILING ,NEEDLE

SHAFT PARTS

PLAIN

COMPONENTS FOR PLAIN FEED .................... .... 38

DIFFERENTI

ECCENTR

FEED

COMPONENTS

LOOPERS,LOOPER

AND

FE

ED

UPPER ROLLER FEED,FOOT LIFTER AND THREAD

TENSION PARTS .................................................. 50

PULLY,CRANKSHAFT,CLUTCH AND CLUTCH DRIVING

MECHANISM

SEWING PARTS .................................................... 58

THREAD STAND .................................................... 60

ACCESSORIES ...................................................... 62

SETTING

LOOPER THREAD TAKE-UP ADJUSTMENT.. ... 18

BLOWER

FRAME,CAST-OFF

FEED ........................................................... 28

FEED

AL

IC

ASSEMBLY

DRIVE

LOO

PER

.............................................. ........................ 48

NEEDLE

TUBE ADJUSTMENT.. ................ 19

COVERS

FEED ........................................... 24

HEAD ASSEMBLY .......................... 32

LEVER,CRANKSHAFT

........................................................ 36

BAR,FEED

FEED

COMPONENTS,LOOPER

AND

LOOPERS

HOLDERS,FEED DRIVE \;OMPONENTS

AVOID

....

COMPONENTS

.......................................................

THREAD

BAR,MA

FOR

DIFFERENTIAL

TAKE-UP

PLATE,EYELETS

AND BUSHINGS ...... 20

AND

MAIN

LIFT&FE

IN

FEED

FOR

ED

DRIVE

BAR,FEED

FEED

...... .40

DRIVE

PLAIN

FEED

.......

FOR DIFFERENTIAL

AND

19

,

LIFT

44

54

IV

Page 6

(-)

IDENTIFICATION OF MACHINES/

*11.ii'Uta})

Each machine is identified by a style number which is stamped into the style plate affixed to the middle

the machine under the tension assembly.

The serial number is stamped

•8~mm$•~~

.~~-~~~<*~·•••~~~~

-~~a••~~ama~~~w~

(

=)

CLASS

High speed,Feed-off-The-Arm High Throw Machines,Two and Three Needle,Left Needle In Front.Light

Weight Presser Bar Mechanism,Adjustable Looper Avoid,Space In Front

Disc Looper Thread Take-up,Automatic Enclosed Type Oiling System and Filter Type Oil Pump, Visual

Sight Oil Action and Supply Gauges.

~ii.

ilim~~tJL~••

~~;.tJ

(=)

35800DNU DOUBLE LAP SEAM .Three needle, high capacity ,differential feed with upper driven

8" (203.2mm)

STYLE

DESCR I PTON

--~jt~&tt•.

OF

roller feed (.468WIDE).-Typical Application-For

garments.Seam Specification 401 LSC-3.Standard gauge Numbers

(9/64",3.6mm).Recommend needle 130GS,size 140/054.Maximum recommended speed

4500R.P.M ... 094 step sewing parts. 468(15/32,11.9mm)narrow roller.

~~·~~S".

-$ift~~-,EfFH:il~!$*4£(.J~ff!li~.

2mm)

f09

P .M···094

in

the casting at the right rear base

of the machine.

~~

>~•~~mtt••~M

.

/

fstl

~-~

.

jJijjt~=-

jt.

lt:iti~ttawrw

~i';IJ

I~H*~~IB-~Uo~~~~IB*·

.

~~.ffi*tm~.

MACHINES/*11,8B::I.~

in

and out seaming

:=_jt,

~ti~~.

(9/

64",

3.6mm)

!V~i2f.

~;.t]

~i';IJJ!~S3

. jlf¥ff,Eij 130GS,

468 (15/ 32, 11. 9mm)

~

W~~~t&~~i';IJ*~~

~.g-~~401LSC-3

j:

Jj\;.t}

140/054~tf.lll:*:5ti!f~Ji4500A.

~~~~tS$t

ama~~

of

Needles8"{203.2mm),Single

iPol!f~ttifii!:~•.

t!t~iif~51Bil~51Bil~.

on

heavy weight denim

8(1

/8",3.2mm) and 9

<~

••

.liALil2:!:f!8 (1/ 8

.

jt~litrw

$t~~;.tJ

of

.

468).

",

3.

.

35800DZ

35800DRU DOUBLE LAP SEAM.Three needle,high capacity,plain feed,upper feed,upperdriven,

35800PZ

Same as 35800DNU except with reverse teeth roller.

l!;t-7~~1Jjc]~

rollerfeed,FeedDogshave higher teeth on front.-Typical Application-For seat seaming,in

and out seams

3,Standard gauge Numbers

130GS.size 140/054.Maximum recommended speed 4500R.P.M ... 094 step sewing parts ...

468(15/32.11.9mm) narrow roller.

~~-~~~.:=.n.•ttn.~~mM.

-~f.l~~~Hf.

~S'~t!401

j:1j\;.t} 140/ 054

9mm

)

~~~~.

Same as 35800DRU except with reverse teeth roller.

~7~M1Jic1~

35800DNU

on

medium to heavy weight denim garments.Seam Specifications

tf!&Jt~-~

8(1

/8",3.2mm)and 9(9/64 ",3.6mm),Recommended needle

.

S3~w~mMc~•M~M.~~M•~•w

-$ ~~~

LSC-3

.•

~jt. fl:*:]ti!f~J.i;.t)

35800DNU

-ma~'!-T~tU13~ft

li£.Jil2:!:f!8

tf!<~-~

( 1 /

8",

4500R.P .M

.

3.

2mm)

.

1£~~~t.ttiM'tl~Vft~llit:ffHU~.

llJ

9 (9/ 64

..

·094

!V~i2t. ~;.t]

",

3.

401

6).

jlf¥'{f,Eij 1 30GS,

468 (15/ 32, 11.

LSC-

- l-

Page 7

35800DWW DOUBLE LAP SEAM.Three needle ,high capacity ,differential feed,high lift feed eccentric,

upper drivun ,roll

with

Typical Application-For use on heavy weight denim garments.Seam

3,Standard gauge Numbe rs 8(1/8",3.2mm) and 9(9/64",3.6mm).Recommended needle

130GS,size 140/054.Maximum recommended speed 4500R.P.M ... 094 step sewing parts

558(9/16

~m~~~~.~H.att~.~~~M.~m*~"•~~m•. ~~oo~~M•~•

~~Mc~•~)o~~~~M~~mw~Mo-$~~~-mr~~~Mm~~~~~ff

~i~. ~~~~401LSC-3, .tF/llt.fl~!¥8

f!ii!,Eij

14mm

",

14mm)wide roller.

130GS

I :;klj\;t) 1

)

~~M-~

er

feed (wide roller

).

Fee-ds have hi

gher

(1/ 8" I 3.2mm)

40/054~if 0 B~fti~~]i4500R.

.

p.

M.

teeth on front

Specmcations

~Q

9 (9/64". 3.6mm

094~~i21!···558"

of

feeds.-

401

). m

(9/16".

LSC-

..

(1m)

This manual has been arranged to simplify ordering repair parts. Exploded views

the mechanism are shown so t

page opposite the illustration

the number

~-~~-~7••*#~nnom~~•m~•*e~BBffllli*

-~~~~~-#~#~.~&·~~-~~~~~

Numbers in the first column are reference numbers only ,and merely indicate the position

the illustration.The reference number should never be used in ordering parts. Always use

listed in the second co lumn.

~-~F*:l~~~&~~~.

Component parts or sub-assemblies which can be furnished for repairs are indicated by indenting their

descriptions under the description of the main sub-assembly.As an example refer to the foll

m.stMB(f)$i!f(f)i.$iPJL~1£::E

1

11

It will be noted in the previous example that the cam follower ,bushing and cam gui

looper drive shaft

recommended ,so the complete upper looper,drive shaft assembly should be ordered.

~'-'-1-*i*:::f'~£~

Rlmfl~tlH*

When a part is common to a

description.However,when the

mentioned in the description and ,

•M*-~$#~~WMH*8W.m~~W::f5&~a~m·~~

ILLUSTRATIONS/~

of

pieces required in the particular view being shown.

1&:lt'91Jlli~i*~~~trrw

9 A3588-314 Gasket!

0 A3588 -373 Screw/ tilT

A3588-082

Top

are no t listed.

~~m

Cover,fron

.

Rfit!!mi*·

·

ll

iJ!J

of

var

ious sections of

hat

the parts

will be found a listing

~m~

Sf*

.......................

...........................

tl

m1Di~

The

machines covered in this manual,no specific usage will be mentioned in the

parts for the various machines are not the same ,the specific usage will be

if

necessary,the difference will be shown in the illustration .

may

be seen in their actual position in the machine. On the

of

the parts with their part numbers ,description and

.

~~~·#~~~~•.~•~~

.

of

the part in

th

e part number

.

~~~::f~m•n9!ij~i!f

(f)i.$iajj

reason is that repl

* m

3

.4

........

. 1

jWjm(f)#ii~~

*~.st~fil

acement

of

i.$iPJJ

these

.

RJmm~=~F*:l~~~

ow

ing text:

((.]

o

jz[]"F)l:PJT~

de

and the upper

parts individu

ally

:

is

not

~t3Uli.$iC!~M~Mf~**i~~C!~ioJiUO..tt1ilif~f;lrff5i~91Jlli

.

@~*~~(f)~

.

::f~~-1£~~

.

.

*llffl

.

-2

-

Page 8

(.li)

IDENTIFYING

PARTS

/ *'i*UtM

Where the construction permits,each part is marked with its part number.

not

and on those where construction does

letter is marked in to distinguish the part from similar ones.

RJUa~~f8Jfti!fa9~.

I&~H~11!1.tl9*1!f

PLEASE NOTE: Part numbers represent the same part ,regardless

orders please include part number ,name and style of machine for which the art was ordered.

.

4it1'*14:~tFJ:~#~

permit,an identificati-On does

.

-~'J'SI#~ifl"i!P.:iJtFJ:*#~,

~~-=~*S1'*#~R·~~a9~#.~~~~·-~--~-

Htr.J~~. ~if-=Fre~.A

(*)

Each needle has both a type and size number .The type number denotes the kind

groove finish and

diameter

number represent the

Z0JE.

4itRH~fl"~~~*'J'.

itff

'@~~J:~

NEEDLES/ft

of

the blade measured between the shank and the eye .Collectively the type number and size

J:·~1fff~HPltZ.f8J~lYl~?J.Ja9il:*lU£

l:tj

7 :i:®tF$ 0

.

other

details.The size number,stamped on the needle shank,denote4s the largest

complete symbol which is given on the label

~~r8:~ita9f!ll~

.

'@ffiit~.

•.

~,z

*fft. M.

.

~~~*d'tt•~tt~iil~~a9PJTfl"ita9¥.HiE

On

some

of

the smaller parts

not

permit,an identification

-1'iRJ}IJ-*1a~JlB~

of

which manual they appear. On all

-

~fl"~--~~*'f*~

of

shank ,point,length,

of

all needles packed and sold

~~~lt'EVf~IIB~*'l

.

:kd,~fiS!lif

.

~-~~

by

.

1£

(-t;)DESCRIPTION /

130GS

(}\.)TERMS /

Prices are net cash and subject to change without notice. A charge is made to cover postage and insurance.

~~~~~.~~~§ffi~~~lO~~~

Short,double

Si

ze

available 080/032,090/036, 1 00/040,

To

have needles promptly and accurately filled, an empty package ,a needle sample ,

the type and size number should be forwarded. Use the description on the label . A complete

order should read

~tr.J.

~•"·

040, 110/ 044 , 125/

~7•~~*retr.J~~PJT~~tr.JH

fO=*:J)\ii

125/ 049" .

;lit

-~

groove,struce groove,ball eye ,spotted, government point ,chromium plated-

11

0/044,125/049,140/054 , 150/060 .

as

follows :

l!flM.

049,

.

{fJl.ltF~l:~-*-Htlii£

"1

00 needles,type 130GS,size 125/049".

ffP~.

tile.

~~.~-

140/ 054, 150/ 060 .

.

~~m•-1'~-E!•.PJT~H~~a•m•H~~~

.

-1'~~~~-~1':

.

•~*'J'

.

~m

oso;o32,

"1

00 R

it.

o9ofo3s,

~~

130GS. :k1j'

100

or

1

-3-

Page 9

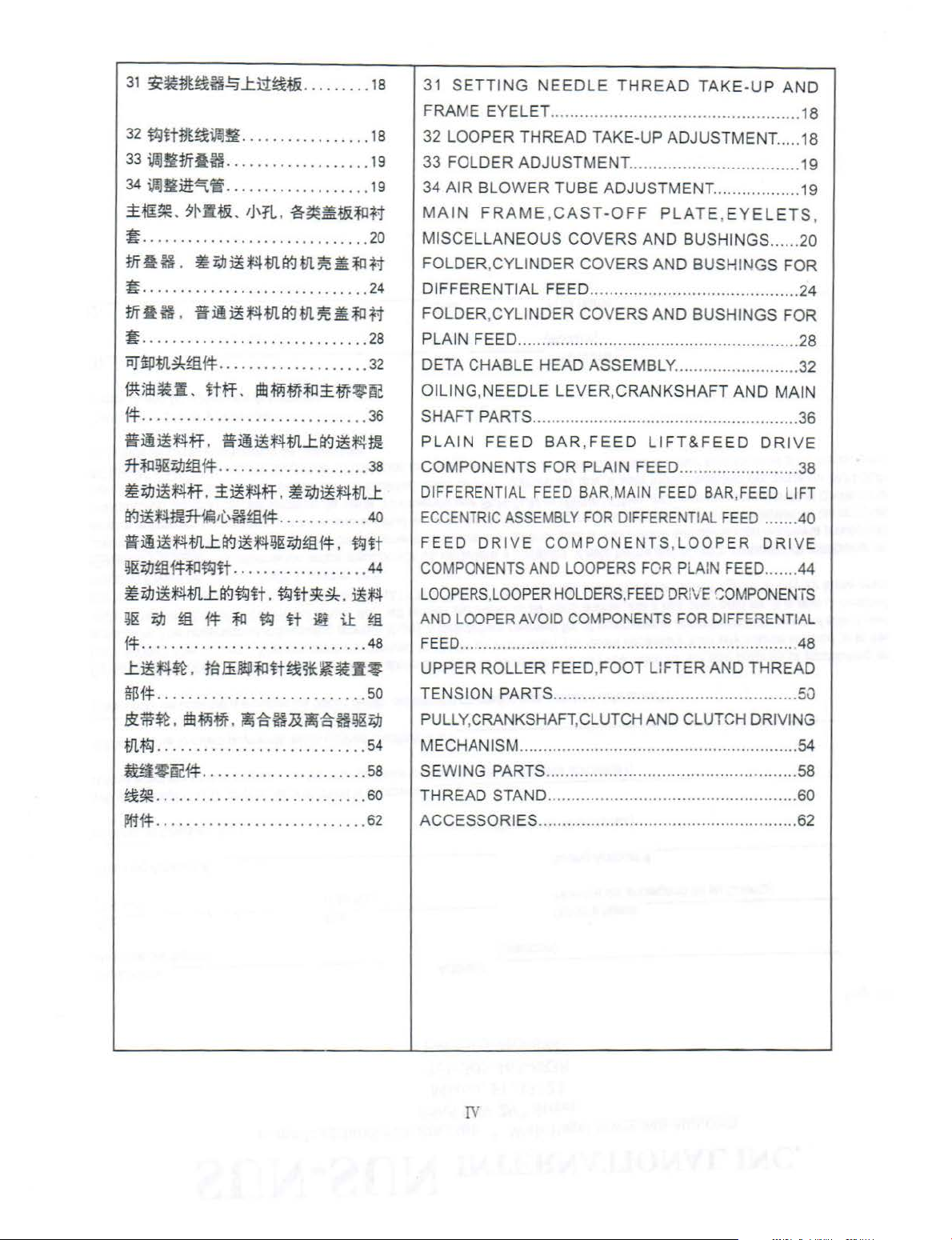

Needle Type

Description

Sizes Available

lt~

130GS

( iL)

NEEDLES

Selecti

on

of proper needle size is determined by size of thread used ,Thread should pass freely through

the needle eye

~~~lt~--~~~M'Ifm~~

Each needle has both a type and size number. The ty

groove,finish and other details. The si

of

blade,measu r

complete symbol whi

MACHINES" for the standard recommended needle type & size for your machine .

4it-1'fttrifl"~~~::k!J'

1£lttf

..t~iiD~~3'!

fllt~¥.HiE

To

have needle orders promptly and accurately filled ,

and size number should be forwarded.Use the description on the

" 1000 Needles,Type 130GS,Size140/054

.

1£'€!~~..t~lli~$~;t

~7•~~*~~~~PJT~~~lt

~~..ttt-.JJI~

.

m~

Short

double groove,struck groove,ba

eye,spotted,government point,chromium

plated. 140/ 054 , 150/

~-~mm

w~

/

tt

in

order to produce a good stitch formation.

ed

midway between shank and eye.Collectively, type and size number represent the

ch

is given on the label

.

1J

fitf~ltPR~~

-1-:lt~tt-.J:iE~~l'

.

;

IPiffHtL

.

~~•••~lt~~~~•fi

ze

number ,stamped on the needle shank,denotes largest diameter

~~1&5Httt-.J~~.

fBJPJTilj!

.

.

~~mm-t-2'€!•

"1000

itt~. 0~,~

1/

Table

of all

~

pe

needles packaged and sold by Z0JE.See "STYLE OF

'€!t!~t~.

~

3J

tt-.lft::k1if£

iW~!ffi

".

"

.fJl.Hif.J~-€5-

JUt

.

~~

tl

-

1

.

number denotes the ki

*li

.

fl

• .

~.z.. ~~1ft~::k,Haft~~i!0iSJPJT~~PJT

"

ffH~~~~H~~::k'J'm~1$tt-.ltll.H

an

empty package ,a sample needle ,or the type

label .A complete order would read:

.

m~H~~B•mmH~~~~*!J'mo•m

130GS,

:::bJ'

'!fffl~m

080/032, 090/036

100/040,125/049

~&~~-·~~~~•.

nd

of

.

Mmi~Jt'E:ltFm~~

140/ 054" .

060

shank ,point ,length,

.

::k!J,ti:ili~P

.

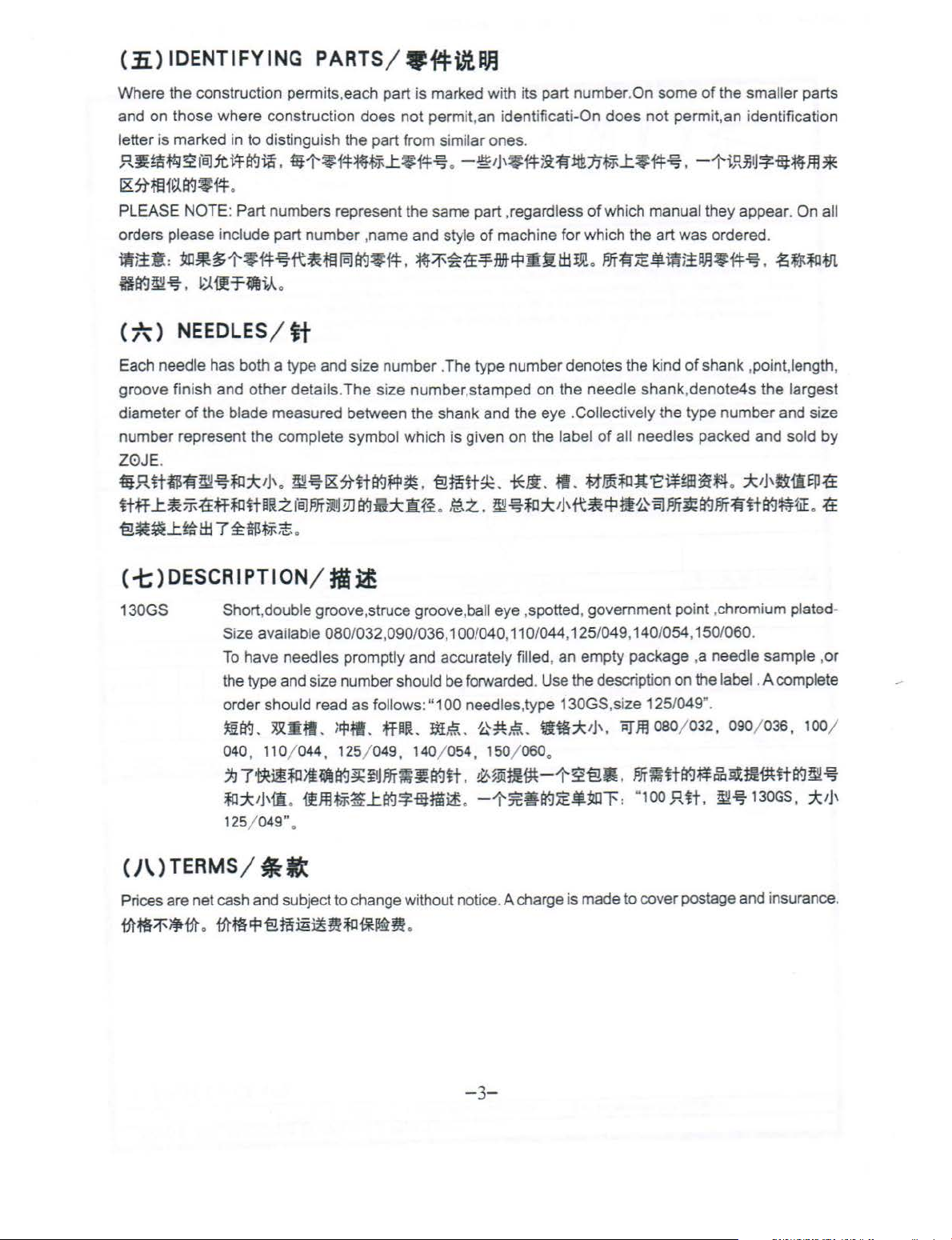

The o

il

has

bei3n

drained from the mach ine before sh

beginning to operate. Use a straight mineral oil with a Saybolt viscosity

Fahrenhei

.fllH~~t!trzlltr2*t

~1i;/;J

Oil is filled at o

between the red lines of the

1f5mf!~tJ~

The machine is equipped with a continuous running rotary driven o

observed through

t.

Z0JE

90-125

Part No.28604R.

5

1Mdl-=f

.

m1£•mtt-.~z

fJ;

o

*14~

il

caps (A&D,Fig.1

;

m

<

oo.

oil sight(A) and (D) in the front and back top covers.

1 •

~NO

ga

A~

o)

,

28604R.

).

The level1s checked

uges.

;m

f

BJ~,~!ii~no~;m

i!~

(B)

~

i;:>

ping and the reservoirs must be fill ed before

.

PJT~:J.1i.FJHit~;m1£NIE\:

at

sight gauges(B) and (E).Maintain the oil level

<E)

~

1iT~~JR

.

il5m®f*ffl1fiYltl•tl~z

il

pump. The action

-4-

of

90 to 125 seconds at 100°

37.

1a

· c

71!~1'~

fBJ

0

of

the oil can be

Page 10

THREADING & OILING FOR PLAIN FEED

·li~M~R9·~R.iJtjfb

I

or

2 drops

or

oil twice o week

-

Jil~1!!1~/X

' I

I

\

""--

2 3 1

---

//

CI J

A Oil Fill Cop & Oil Sight

B Oil Lovel Goge

C Pump Primer Screws

0 Oil Fill Cop & Oil Sight

E Oil

level

Goge

FArm

Oil Drain Plug

G Looper Position Knob

/

J

(

I

I

""--

__

;::/

~illil

l!!!~*.;:p:~

ifil~!Si;IJit~~ItU"J

~fiji]'

;J1111*.if1.~

1-l~l!!!~

~tt:lEttt!~

\

FI

G.1

MINIMUM OIL LEVEL

.

1"'

at

I

I

MAXIMUM OIL LEVEL - -

~-

- 5-

Page 11

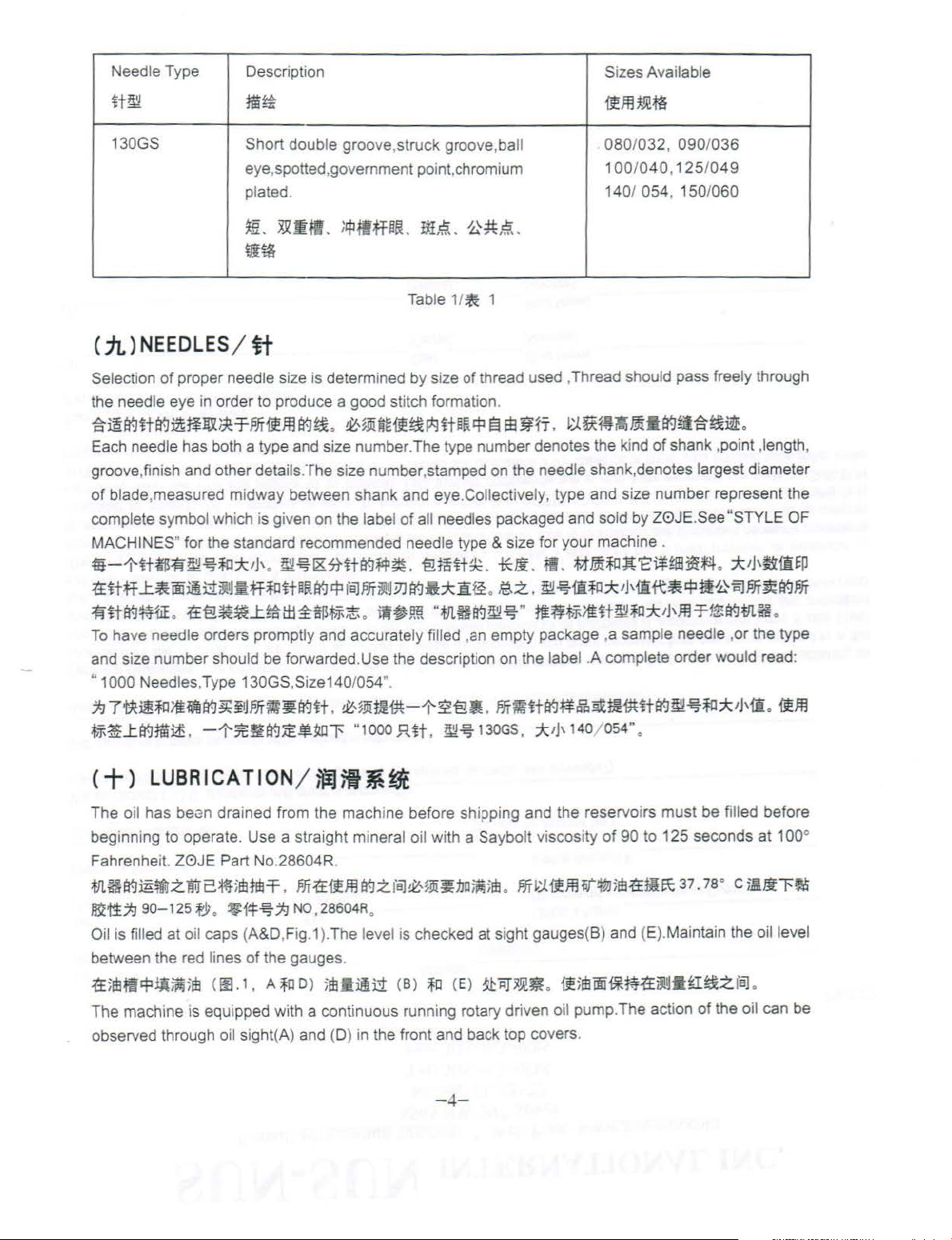

TliREADING & OILING FOR DIFFERENTIAL FEED

-~~~fll.tf9J1tlR.~jJij

::x

2 drops

or

x

LNice

o

week

-JI~;}Ijjiij~

•

•

A

Oi

Fdl Cop & Oil Sight

B

Oi

Lovel Goge

C

?t.:mp

Primer Screws

:>

Oi

RIJ

Cop & Oil St

E

Oi

leve

l Goge

F Ami Oil Drain Plug

G Looper Positi

on

_j

,/

&

I '

(

I I

\ I

"'-.._

__

ght

Knob

s0,

)_

/

FIG.1

MINIMUM OIL LEVEL

.,J,;ma

MAXIMUM OIL LEVEL

il::*:illla

- 6-

Page 12

mti~R7

w-~.f£~~1§-mB

When starting a new machine. beginning filling the reservoirs

that has been

screws(C).Apply oil to these holes and operate machine

.Replace screws(C

~~mMmHdmH~I-~~~J§-~A~ffl~~~~~~.~~~~~~-~~-

S*~~~~~fl(C

(C).

CAUTION:

~~=

Oil may be drained from the machine

and plug screw(G )at the back

~~fi~J.A.tJI.Htt-l~?~imHfi

~1¥-JJ§-W.

••

@ft··~~~~-.~~~-~.~~@~~~~~~82(A)~(D)-~~~~~

!

U.!.il.~

.

·i

dle for some time • it may be necessary to prime the pump.

).

l . .f±R~-~#A@.mBI~~-S~~~~~~~~~

If

oil does not bubble when machine is running , the circulating pump is inoperative.

~•~mH~H~~-~~~M•~•In

at

two places ,plug screw(F)Iocated in the bottom

of

the main frame below the handwheel.

. -~~!.!~~fl

(

F)

-E-TIEf!I¥-JJiUU~

of

when beginning to operate a machine

To

do this ,remove the two plug

until bubbling can be observed at the windows

-

~7-~I~.~

.

~-~-~~~fl

.

-

~~~$1fl

(G)

-=¥~1¥-J~W

of

the cylinder

.

.t.tJI.

<+-)

A convenient means for threading the looper has been provided. When loopers are at the left end of their

travel,press the knob(H,Fig.

the machine as illustrated in (Fig

flt.]j{l~Jr5!.f£f1ilit

~~3~B1fi7. ~Ill

<+=

NOTE : Instructions stating direction

relative to operator's position at the machine .The handwheel rotates counterclockwise

direction ; when viewed from the right end of machin

~=~M3m~~ma~&~~~~m•.M~M.J§-.~.S#A~ili-em~mH~~H~M~tt-Jm•

~~-~MmHtt-J~J§-wt~

<+=>

Torque specifications gives in this catalog are measured In inch-pounds or Newton-meters.AII straps and

eccentrics must be tightened to 19-21 in .l bs.(2.1-2.3Nm)Unless otherwise noted.AII nuts ,bolts ,screws,

etc,without torque specifications must be secured

torque specifications for connecting rods,links,screws etc

illJ:~t!Mt~~*~~ilitt-l~m~~'i"

L:t-·*)

!J'!i!'Jii~~~~rr$

THREADING

/

~ti

1)

and loopers will back out

.1

).After threading ,push loopers back into position.

.t~~. ~

<11!.1)

f1iltt~'8~~1¥-J!l~itl

PJT?f-.

~31~~1§-. tef1ilttfl~I*Ui

) ADJUSTING INSTRUCTI

of

location ,such a sright, left, front

.

-=¥~~¥-J~ff~~~~~n••

TORQUE

t:R~tl~.

REQUIREMENTS

·

~~.!:f::

~~1:1fa'8i)t.P.ij

.

~~~:•a-ei5lP.ij

.

~H!PJT1ftt-lil¢~.

.

~~m~m*~ti*T.

of

position,leaving them easily accessible . Thread

.

ti~OO~tit-'¥

ONS

/

~~i$tM

e.

·

/

tfl~~*

as

tightly as possible,unless otherwise noted.Special

..

are shown on the parts illustration

·*·

JiJT1f&:$~~1ia~L.'n~~m

t~tt

.

t~fl~if?.~,~~~

!1'.

(H.

Ill.

1 ) •

.

or

rear

19-21

S~n~.

~~"i*tt-llllir-.

f1iltt~lc:JJ§-8tfH~

of

machine .are given

~'i"·~

.

~-5i·~~iR~::k

,i

n operating

s.

(2.

1-3.2

C+

1m)

SYNCHRON

IZING

NEEDLE

AND

LOOPER

tt~~tta9fcl'!Vm~

- 7-

MOTIONS

Page 13

NOTE: Needle and looper mechanisms are carefully synchronized with precision gauges before leaving

the factory to insure the best possible sewing conditions.

~=~7~~~~~~~••.m~~~r~Mm••~~~*••~~~~~.~ff~~ff~M~~~

~

.

Should it become necessary to disassemble the main shaft or

replace components of the needle or looper drive mechanisms,

FIG.2 (00

FIG.3 (III 3)

2)

re-synchronization

proper sewing adjustments. This is accomplished by means

an adjustable split coupling located beneath the rear top cover,

connecting

the looper mechanism.

~*~~m7f

the

~ff~rqff~~~tt

-~~~m~~mm~w~~~~-H.

m.

t::~rqnm~~~~~~•

To

synchronize the machine,remove the needles,presser foot ,

throat plate, feed dogs and upper feed roller mechanism.Rotate

handwheel in the operating direction

the bottom of its stroke and just begins its upward travel .Loosen

screw(A,Fig.2) and remove the looper for the

from the looper holder.lnsert a strai

9mm) or 11/64"(4.3mm) diameter by 2-1/2"(63.5mm) long into

looper holder

the rod (B) is at the extreme left and reinstall the throat plate.

Loosen screw(F)in looper holder and move the ho l

right

until the nght side of the rod is approximately 5/32"(4.0mm)

from the left edge

handwheel in

rod(B)comes

point,clamp

(D),flush against the underside of the machine casting(E).Rotate

handwheel in the opposite direction

contacts

clearance between gauge and casting

is .005"(

~7~ff~rqfi~~~M.~*ff

~"l!t~fJ1~.1Sm~l"1floJ$tM~~1U1Jffff~'2~~~T$Jtii~ii

i1Bt7:J.l1:

).Arq~tfi~~lfl.

~. *1l7:J63.5mmitt.A.rqit~tt:.§.m:~tt1\Hitr

~li~Jff

(F)

the edge

0.1

mm).

. t/l7Hitr (

(B)

jf:

.§.te!~

of

the machine will be required to facilitate

of

crankshaft to the main shaft, which in turn drives

::EffE!£~H§.trqH~~Mmf~~~IWt.

.

~-~~~~~~-~-~--.~~

~~Mm~::tffm•

.

until the needle

ght

steel rod (

and

retighten screw(A).Rotate the handwheel until

of

the throat plate,tighten screw(F).Tum the

the operating direction ,with needle

in

contact with the edge

lin

ing gauge No.TI147(C)around the needle

of

the

throat plate.Maximum

A,

lfl2)

fj)...][WJ~

of

the throat plate.At this

until needle

or

rod and throat plate

.

ff~.n•.mM~~~m

1f:.§.3Mrqff,

(B)

][@~

3.

.fffi1.iit!tf:.§.ff~lt•~.l1:.

loJti§.tloJ{i~Mli~Jff~;(:lit!~it•~

~~~Q

bar

is at

left hand needle

8)5

/32"(

3.

der

left or

bar

rising until

bar

bar

or

the rod

allowable

fflti~1Erqff

9mm

§!

4.3mm

(A).

:k

~M~

f'/l*rq~t~~tltJ

ti

it!:k~f.J

- 8-

Page 14

4.0mm

TI147

mm~~ttfr~ttf&tr.:litltiH»;.t.J.ll:

~~fJJ.ft~~~~~~~~~im~~~~:

and set screws.

the coupling . The holes in the main shaft end of the coupling are larger than the diameter

permitting severa l degrees

snug the uppermost horizontal clamp screw enough to hold coupling (A.Fig.3)in position, If the handwheel

is turned in reverse

casting(E)before rod(B)contacts the edge

which was snug ,while holding the coupling

synchronization. If the handwheel is turned in reverse of operating direction and the rod contacts the

edge

turn the handwheel slightly in the operating direction.Use

clamp screws(B.Fig.3)securely,and recheck both clearance points with .005"0.1 mm)shim gauge

,

rt~!lfl

(C)

~.ftttfr

If

machine is not synchronized the following applies :

Both ends of the adjustable split coupling are secured to the crankshaft and main shaft by spot screws

Loosen the three horizontal

handwheel slightly

of

the throat plate before the clamp gauge contacts the machine casting ,adjust as before ,except

1 mm)exists between gauge and casting or between rod and throat plate ,in both the operating

reverse directi

no slippage occurred

~~~1lHtr.:J~~$m~un~~~un~~~m~±fr~1l$~

~~~=

~~itFaJ~

lf~:~Ulfl~$il~1lH

ll!.

Ul:ft!MmJt~t&fltrt~~~t'fl

FaJ~tt

mtr.J

it-t&~fBJtr.:lfBJI!Jit~Sl:.t

1mm

4'tlfl (B)

•

2)

~fJL~

.

~~~~$~ft~.&:JJicl$tiM

-~.

•·-~~~•••tr.J~icl~•

tr.:J~R~iJiH.iE1£rt~tlflm5.2:1i~~~~

(F

),

i

S~ffJ)jo)fdi~~~]i~Jfr

(D)

J!lmJ!H1J.~/iiim

.

On

the main shaft end

of

rotation in either directi

clamp screws(B,Fig.3).With rod (B.Fig.2)at its farthest position to the left ,

of

operating direction and gauge(C.Fig.2)on needle bar (D)contacts the mach ine

in

reverse

ons

of

.ftLHf7]<1JL~A.l:tr.:J.::.

of

operating direction,snug the uppermost horizontal clamp screw(B),recheck

the handwheel. When th s setting has been made ,tighten the three horizontal

whi

le

tightening the screws.

tr.:ltfllL'f:ilkl~L

o

-1'~-~fl

(A, ll!.3)

(E)

~1llUtff

0.

1mm

(B)

~tt-t&li!tlti~~

(C

).

.

~~~~$.

(E)

~ll:ft~f/l;te~fr~tt-t&tr.:Jit:kfti~

of

the coupling(A,Fig.3)three screws(B) thread horizontally through

of

in

±+f~tl~.l:tr.:l:tUt:tlflli~:k

(B.

:iE:Ul:

.

~~-=f~iS~~-T~.&:JJicl$t1H3.itff

~~$£~tr.J.&iaJ~$t

.

ff~it*itl~1l~~n+r~•a~m~tr.:J1l~~

.

~~~~.&••a-t

(B)

tliif!Jttf&tr.:litl!'l;.t.J.ll:. Jit!M

.if~T

•

.&:JJio:Jtdi~~~]lf!

on

to properly synchronize the needle and looper.

the throat plate loosen horizontal clamp screw(B.Fig.3)

place with

!113

). il+f (B,

t9~7]<~~Atlfl

.

an

Allen wrench

sh

im stock to insure no more than .005"(0.

.

~±fr~1lH<A.

.

llJ2

)

Ul:-Tii~li!

•

.ft£1f~~tr.:l*lf~Atlfl

.

rt~*lf~Aitl:imtr.:J~fl

.

m~R~s~~•H~m~~~~+r~

(B.

00.

.

:iEIM~

J

iU~NO.

Jl§

.ft1lttfJJ.~tr.:l.l:$~ti"fr

f

BJMi~

o.

1 mm.

of

the screws,

in

set screw(C).Rotate the

and

to

assure

~3>~$.l:tr.:J

fti!fB:-:JJiclifJJi:tr.:ltdt~il~~t

.

il~itr-Tii:f-5~tr.:l*

(D)

1:~~-H

(B,

Ill

3),

¥H~itll~~~

(B).

.

~~~..tw~

3).

#.§.~4'.~tr.:li8JI!Jli.

(C,

~IJT~i!f

m

0.

C+

.li.)TIGHTENING

When replacement of the needle bar, and

bar 14-16 in

the purpose

torque rod in the hole at the upper end

suitable

bend,the needle bar head has been threaded into the needle bar properly.

~~Jt;~itfr~it~IM

N0.21227ARtll~ff'2!!~fJJ.H!MiifHiHi~tr.:J

.lbs.(1.6-1

of

too

l,

turn the needle bar wi

.8Nm)

eliminating the possibility

,

NEEDLE

or

use torque rod No.21227AR that has been supplied

th

bUt~f!J~tfftr.:Jtll~;.t.J

HEAD/rtatt§k

or

needle head is necessary,torque the needle head to needle

of

distorting the needle bar due to overtightening. Insert the

of

the needle bar, while holding the need le bar head with a

the torque rod onto the needle bar head. When the rod starts to

1

4-16

.

,Eft-T

~"t · ~

i

ili~~-Ti:l:~ii'iiilitff~!Hitr.:li~m

- 9-

(

1.6-1

with the machine ,for

.8

t:f

· *)

~~ilm~~;.t.J

.

~J§~m~IA

Page 15

Rtt~~~"~~~~•~w~n~mAmft~.mm•~••~~.~~*••~"·~~~•&•A

ttff

.

C+*)ALIGNING

tt~tt'-&.1:~1\..&l-B:t&

FIG.4

FIG.5

(00

(00

NEEDLES

4)

8

5)

IN

THROAT

Insert a new set

(B,Fig,4) slightly loosened,low

head as recuired until the needles are centered

plate needle hole slots . Tighten screw (B)torque to 19-21 in.

lbs.(2.1-2.4Nm).

1liU-...1Mt.

ff

(A)

jij

19-21

NOTE :

slots , the lower cylinder must be moved as stated below.

5:%:

~~at=1'~ttt&~~nfiX-1i:t£

2.~~~to*'J'

#S~~£31('~-tt~l[fijftift-Tltf&fL~tpJl,'jJJ.t.

~-t · ~

If

the needles can

PLATE

of

needles , type and size specified, with screw

(

2.1-2.4*

SLOTS

er

needle bar(A) and tum needle

in

.

~~f't}3H

not

be aligned

..

UJ

(B.IIJ.4),

· *>

~m~rt~UUJ

in

the throat plate

.

l'f11.~-;E1'£1'Wt&3i'JJ

the throat

~ifflt

(B).

7 .

C+-t)CENTERING

THE

CYLINDER

lE*'l.~~lt\

Remove the top front cover and gasket from the main frame.

Loosen cylinder holding screw(A,Fig.5).Turn eccentric screw

(B)clockwise

needles are centered in the needle holes.Tighten screws(A)

torque to 18 ft.lbs.and recheck settings.

~~m~

(A

.IJ].

~ttift-Tttt&n~rp~r.'

#

.§.JiiJT~~~gc

NOTE:The cylinder may not move freely when the eccentr

turned because the joint sealant compound has set.

ii::

~~~L.'$t~f;IJ"

a-tl'fJI.~~i!~!lt~~

or

counterclockwise to move the cylinder

<m~>

5)

.

~~m~~~m~*~

l®i"H~i$"ttJtffft'UiaJL'~n

.

mm~:tJ

.

.

~fJI.~iiJ!i~=1'~~~~3f;IJ

7!J.l!Hf'J

·~

*m~~~~~n

(B)

it.l:f11.~3f;IJ1!

1a~-t · ~~tt~t~n

<

is required, loosen screw (A,Fig.7) in looper holder,permitting

movement

dimension as shown in Fig .6.Retighten screw(A.Fig.7).Repeat

for other needles and loopers.

fi.APJf~~~~*'NfJilrtt

~~~tt. 3~ttW:Tjl1.£:illa:t.

tfJJ"Dt.am!ie3.

(C)

~~$j;'{!tf.Ji}IJ~

FIG.? (

Rotate handwheel

to touch but not deflect. This adjustment can be made by loosening screw{A.Fig. ?)in looper holder.

holder can be moved front to back to attain looper to needle setting.Aiways check the 9/64"(3.6mm)

looper gauge setting after setting the looper to the back

setting

of

the looper to the back

~~ft:n~•••~~~•~ttm~~~w~~tt-.Jttmm~m~•~~-

(A,

IE.

7)

tf.lt!}~*if.Jfl

tf.Jmi~~.

tt:E£sW:ll.iE~

The amount

the amount

contact the back

~tttr.l@l~lt

w 1 / 3

m

3.6mm~ttif.Jtift*~~

of

of

avoid it is recomended as a starting point ,to have the points

t:ar~i9:7-J

~

tfJ

~~~

7>1

00

7)

in

operating direction to assure that the looper point passes to the rear

of

.

~tt~~$1ltr~~M*R~~tt£~Jtttf.J~~iJU~

o

looper avo

of

~~

id

has been set at the factory to .110"(2.8mm).lf it becomes necessary to adjust

the lower 1/3 of the back

2.

Bmm

.

jzDW:~Jt;iJU~

,•:'Bltiltrrif.J

fl.

(A,

00.

ff.o

IHIT?9~~fl

the needle after setting the 9/64"(3.6mm)looper gauge.

o

#..Eim.&it?.

of

in

either

Smmo

fi}'ij~~j;J

7

).

ff -:1J

.

the looper blade.

@ill:.

icJtf.J~M~H*R~~fie~3.6mm,

(A.

of

the needle,and conversely,always check the

.{£~~~3.6mm~ttif.J~~~~~~.{£tt~tf.J~

t~t:r.¥m

B:tt~~~tt'Wimmtltttr.lffi:T~tt

direction

o

jzDW:if.Jfi~Jt;.

to

attain

I

-~stif.lfltiilltf.J~tt

fitt

NO.

21225-9164tfJ~ttif.Jflft

the 9/64"(

(B)

tf.Jtfl'L'~~tt

f'L}7f~tt~J:tfJ~fl

3.6mm)

(A.

fll,

6)

(

A)

jmi¥J.6Plf

007)

o

Jt~tf.J~tt~~tl11=£-.f$tf.l

of

the needle

o

~~~~~tt~tt~...ttt-.J~n

o .~d~:ttii.W~~tt~tt§im

of

the decending needles

o

looper

D'Jl'

<+it.)

:il.

NOTE:Whenever looper avoid is changed looper clearance to needle must also be reset.

~:

<=+)SETTING

The height

of

the looper, with the looper point even with the right side

SETTING

Coronec:t~.n;

Roc:t

O.f'erenta.

l!fifrt$JJ~~

3~tt@l~-~~§. ~tt~tttr.J~~~~-ENft

For

Feed

.· _ _

~~

FIG.8 (

of

the needle bar is correct when the top of

THE

'-'A

•

..

• j

-

00

8)

LOOPER(CONT) /

If

more or less looper avoid motion is required.remove cylinder

side cover(A,fig.8)1ocated

screwdriver to loosen looper avoid link ball joint(B).Moving ball

joint down

motlon ,moving it up acts the reverse.Retighten ball joint(B)

!

i

:~

·-·

securely.

~tt~u~~~~~~£~Jt;tt-.J.~""Fm~~imt£l'~tr.Jill~

(A . Ill.

~tt@l~J.i'~~ttl'~~@]~-~~.

~-~tf(2)

in

the lever slot increases the amount of looper avoid

B)

o

~iJ~JJtL}7f~tt@limf.1'~;fHI~tf.JJJ~~

(B).

o

HELGHT

OF

NEEDLE

the

BAR/\i.tttf-aJI

needle eye is 1/16"(1.6mm)below the underside

of

the needle

at

the lower front left side.Use a

jzDW:tt...t~~-~~~

.To

make adjustment loosen

-11-

(B)

.

fe!

Page 17

TORQUE.

19-21

1n

l

bs

(2 1

-2.4Nn

)

W\

8

A

screw(A.Fig.9)and move needle bar (B)as required to attain

dimension.

s

H~tU91fftri1il~t~

it.!ili'ili.~

M~ff

NOTE: Care must be taken not to disturb the alignment

needles when moving the needle bar either up or down.

;1,

.iE

ila9. s~~if.l~M.

(B)

f!Jiilf~;j((f){ftii

,J,/L.,a93M~

1 .

Smm

a-t.

l!P~i1il~~1£~a9~ltl.

t'LHUJ.tr

.

~

~t1\~a9B:~11sitff

1:

CA.

!E.S)

1'3MM

~ff

#iH~

of

the

.

FIG.9 (

(=+-)SETTING

00

9)

THE

FEED

DOGS

FOR

PLAIN

FEED

-ii~M*JL~M>fa9~-

Assemble the main feed dog and throat plate.Main feed dog

(A.Fig.11 )at its highest position,should be set to project above

of

the throat plate,the depth

screw(B)and front support screw(C)should be set

this setting.

~~±l!*-1~ft1~t&

a-r.

m~ue~*4*~Htt&~j;f~-~~

(B)

~fiiW(fJ~JJ~tJ

The feed should be set

the front

throat plate when the feed dog is at its most forward travel, The

same amount of clearance should be between the back

feed dog and

the feed dog is at its most rearward

loosen screws

a

counterclockwise to obtain proper setting. Tighten screws (A and

B),reinstall plug screw(D).

s~~*1£~~~~~mwa-r

FIG.11

a9iiEY~Tl!~~~W~~tt&~f+:rt.~~W~f8Jlle:k'J'

-T~tr

B)

(

D)

*!H~llti~JI

,

~1\f~-T~tJ

(D).

.

fflU~JJJ®ia1HP11$M~~~~~L.'ft

t&~~:rt.fiiW~f8Jlleii

screw

of

the feed dog and the front

driver

.

.

±i!*-1* (

the

back

(A

and B,Fig.10)and remove plug screw(O).Using

turn

ili::tf'L}ff

its teeth.The feed dog mounting

A.

00.11 )

.

(C)

~~it-t,

so

there is equal clearance between

of

the feed slot in the throat plate when

eccentr

.

i!~•m~Ti!~~~mw~~

.

si!f+~1£~~tlla9-!l~itia1,

gc

~i.ltr

(C)

~jJ~f!Ji~ti§la<J

EY~$~~-1-i~~

of

the feed slot in the

travel.

To

ic

pin

(C)

(

A~B.

to

maintain

{ftf~'T~a9l1t~~

l!~*a<:Hiflt'n

.

of

the

atta

in

this setting

clockwise

or

l!MA

l!l.10

)

#.§.3M~

.

f?~~tr

(A~

( = + =>SETTING

THE

FEED

DOGS

FOR

DIFFERENTIAL

~rJJ~Mm~M>fa9~-

Before assembling the main and differential feed dogs,set the feed bar eccentric pin (A,Fig.1 OA)Iocated

in the left side near center

of

cylinder,so that the slot in the head is

in

a horizontal position. This assures

-12-

FEED

Page 18

A

D•fferentral

FIG.10A

FIG.11A (l!fl lL.\)

(i!B

Feed

lOA

a neutra position

main and differential feed bars simultaneously.The feed

pin is retained in position by set screw(B).Assemble differential

feed dog (A,Fig.11 A),main feed dog(B) and throat

the main and differential feed dogs can be individually adjusted

to height.Main feed dog (B)at its highest position,should be set

project

to

adjustment is necessary loosen screw(D)and move feed dog

(B) up

)

should sLpport front

1£~f[]~JHJJ~*4~tr.J

1M)Q~~~~~J:m~~~~~~.~~M~~~M~~*

.ifLffi:.W

tF.lLffi:ii,

00.

ll

>ftr.J~

~.

3!0*i1U~~~.

&•rr~~~-~-.~M~tr.J~·~(C)$

mw

above

or

down to attain correct setting.Feed dog support(C)

.

~£7J

~t~tr

A)

i:~*4!}f

• •

i:i!M>f<B)~~fi-ffi:W".m~~--

.

of

eccentricity for the purpose tilting

the

throat

of

feed dog .

~

~iitr.

7~fll~HdJ~*4~!BJatf1§f~at,

(B)

ii~*4**tt~ift.

(B)

fCH-t&

tk7f~lr

plate,the

5tiJ:~*4*'J:~1fiijll,'§;t

.

~~ljif.Jfl~i!~~f[]

(D)

depth

#.ElJ:1'3fJJ~*4~

of

-f*iiE1fiij1L.'~~~

~~~fJJ~~>f

~

-1£~M~~

of

the

bar

plate ,Both

its

teeth.lf

(A,

00.

(A.

~fJJi! *4

-~>f

(B) ~

(=+=)SETTING

~i9J~Mm~~>Ftrn~

If adjustment is necessary loosen screw(E,Fig, 11A)in feed dog support(C) and move as required.Retighten

screw(E).The differential

loosen screw(F)and move feed dog up or down as required.Retighten screw(F).

j(Q*if.l~~~.

M~M~

ffl~M~M~. •fJfrt~t~tT

NOTE:Should the main feed dog require repositioni

rearward travel ,loosen set screw(C,Fig.10A)in main feed bar driving link(D),rotate main feed bar eccentric

driving stud(E)as required, Driving stud(E)has a thin hexagon head with cutouts on two

movement by tapping with a sharp pointed tool,when wrench21388AZ is not available.Whenever the

main feed

adjustment may be required.Retighten set screw(C). Position main feed dog support(C,Fig.11A)flush

against bottom of main feed dog (B ),tighten support screw(E)secLrely.

ii:

3lO*i:~M~1£icllitr~icJFo3Mat~~t&mtl"

J:~~~~fl

~~ti.Ai£M"~¥[§J..t,

~H$~~t,SI&fd.l*i~m'fi~~~~.

~M~tf:J~~~

faff~M~~f$~

(A)

RTtiE.ttt"~~i!M>f

bar

eccentric dnving stud position has been changed ,recheck

(C.

00

.lOA)

(

C.

00.

THE

fP.Pd

dog (A)may then be leveled with main feed dog (B

~~~;~(;ijjf~~~M-1fiijll,'~grJJtltt

s~

l1A)

FEED

(C)

(B)

(F).

21388AZt&ttt~1i~ii:!t~Mat.

liNJT~i!tittf:J-f,'iH?~I~:Jt~:ef~~iJUl

~~i!*'f~

DOGS

J:tr.J!2..~fl

1£!BJ

- :ifiiJ:.

FOR

~

c2>

(

E.~.l1A)

ng

due to contact with the throat plate in its forward

.

!i!lJ

DIFF

#.El~Jffi~*~TJJ.

3!0*if.l~~~.

~i!M~~I!iJT~t&

(E).

~~~IH&~tr.JI~~m~:Jt~M.

(B)

tr.J~im1f-¥.

f?$~~stlll

ERENTIAL

).

If

adjustment is necessary

!ti/Tf?~i_lfl

t41f~fl

rear

~jgfj)t~~

.

(E).

(F)

needle guard setting,

.

t41fi:i!~HHgM~

(

E)

1i:ifir?~~~Uifl

FEED ( CONT)

#.El~~~*n

of

the flats allowing

:fir-~iiit~IT/,~

(E).~

or

(D)

~l!f;£~

(C).

:£

-13-

Page 19

(=+1m)

NOTE: If plug screw(A) is replaced with a

Any stitch length change,requires resetting the needle guard.

it

:

jU]=*~~...t#TI¥J:*:~-T~JlJ

ffffl~~"*~l¥1~~m~*~m~~~~~~~I

CAUTION:When making stitch length adjustment

due to possible part damage.

CHANGING

FIG.12 (

00

1

2)

STITCH

When cha'lge in stitch length is required,remove farge plug

screw(A,Fig.12).Loosen feed rocker driving link screw(B)in fever

(C).

l

(A

).

9}1J~ll$lf~...tiia!ijH!iii1it

LENGTH

Moving

engthens

Retighten link screw(B)securely and replace plug screw(A).

s~*~~tit~"*oca-t

r.ifim

/

it~ti~*Jl

the feed rocker driving fink up in the lever slot

the stitch ,

(C)

...ti¥J1iU~~Jt~gfif.J~t~lJ

~.lt~fif.l~mn~~•fif.l~~~"*~•"*·&z~•.••~*

~...t!¥JSllJ

new

plug screw ,it shou ld be sealed with a silicone seal.

(B)

#iH~...t:*:a-TillJ

.

do not

exceed maximum recommended stitch length

mov

ing

it

down ,

.

37f*•.:rt~n

.

shortens

cA.II!.12)

(B).

(A

).

the stitch ,

.

f'J}fftt

if.lfimM'P~l!~

v1S':

*~••~Fc•fif.l•~~•

-ifl~mi¥Joof}}M~~~tl:ltiM

CAUTION:If stitch length is changed,needle guard must be reset.

w•:jz0•~~*•~~7.

NOTE:When insta

loosen screw(N,Fig.15)in needle head and rotate needle to attain adjustment(D,Fig.13).

it:

}t~l]Plf~;j(ag~I¥J

3~~*1i~fjgifolflilJfti!fi¥JB::*:tit~*Lta-t

C=+.li)SETTING

D

FIG.13 (

$:RI¥Jtta-¥~1'rl!*4P~PJr1£1¥J1l~

00

lli

ng

.

(0 , 11}.13).

READ

13

)

.

a~i'iJtm~tr..J$:R~•

Hl¥l•ifl••~~~~~~

the needle 1t should be parallel with the eye

NEEDLE

Set the rear r.eedle guard(A.Fig.13)horizontally

contacts needles(B)when

adjustment is necessary loosen screw(E)and move guard front

B to back as required. It should be set vertica

yet have its guarding surface in contact with the needles until

the points

the right side of the needles.

screw(F)and move guard and holder up or down as required.

$:~~!r.JFcWJ.I<.if~I

~~ltJlJf~ft~~MilJ~

.

jz[]=*~~~~f'J}ff~li

.

jz[]·~£il!lr.t

.

911Ji'iJtm£EBr*f~~*

7 .

GUARD/ii·tf~Ji§'-tp5t.

at

its extreme forward position.

ll

y as low as possible,

of

the loopers(C),moving to the right,are even with

If adjustment is necessary loosen

(

A.~.

13)

3'81£iliiliii!r.JW:Iilt-t

(B) 0

jz[]=*~~Jnijf'J}fftlll'

.

m•3~~~cc>~~•fif.la-t.~•i£~1¥l~~.

(F)

#..El~.!ffi~31<...tl'8fif.J·:f?~-~'8!r.J~

.

in

li

n~

of

feed.lf adjustment is necessary,

.

f'J}fftt~...ti¥JiJ.lJ

(N. !11.15)

so

that it barely

lf

I

fl

(E) I

~!m£

.

#..El!tE~tt~

-14-

Page 20

(=+*>PRESSER

FOOT AND

PRESSER

ffi-~ffii1Jtftro~•

or

8

FIG.14 (

FIG.15 (

Set upper stop collar(K)to contact casting,so the bottom

foot do not touch,at the bottom

00

00

14)

15)

of

the needle stroke when lifting foot. Tighten screw(C) .

Adjusting

Remove presser bar

screw(A,Fig.15)on presser bar guide(B ).Loosen screws(C)in

upper collar and screws(D) in needle lever thread pull-off lever

Slide Presser bar upward high enough

yoke(E)with foot attached and tighten screw(F)

bar.Positi

with the holes in the throat plate. Tighten screw (A).

if.l!ht~~ffi~:

31fffi~jt~

~~n

~IJ;fF

J:~tlfl

( E )

.{£

t~fi.ffiM.Il.l.~ttn!3tH&J:~n.o.t

Presser foot guide plates(G,.Fig.15)should be set so that entire

presser

with no

ffllt.llsl~±~

~~.fflt.l.~~~..t~3IJJ~~~~~3IJJ

With foot proper

guide(B,Fig.15)securely fastened to presser bar,adjust both

guide plates(G)to obtain above setting. Tighten four screws(H).

l!lBG-ffiB!Il.!:ittt&~~~.o.t-Jiti

.ffittrie~$00,

rr~~mt-ttn

Reinsta

foot resti

l!:ii#

ffllt4ltt.ff~H.&..t

Replacing Presser Foot:

on

foot so that the needle hol

C

A.

!i1

lt

.l.

EHtHJt

foot

and bar assembly has free movement up and down

left to right movement .

<G.~.

ll

presser bar spring(B,Fig.14)and knob(A),with presser

ng

on

BAR

(B,

. 15).

(D)

.

ffi.ft14J~J:iif~

iJJ

I fT $

1s>

ly ali

if.Jfl~i's[~i}C

<H

>.

throat plate.

I

of

the needle head and the top

ADJUSTMENT

leaf

spring(B,Fig.14)and

to

es

lf!.14

)

~~~Q;

tLHfJ:W~fi14=..t~i.ln

.ffi

;fF

~~~~;t)

gned on throat plate and presser

ffi~.ffi;fF5!j1jf(B.

(B),

ftHfSI~.ffi;fF

.fE.$~iffi

iii

...1:

-

.

'l!.ffi!*.lls

(G)

J.iil:ffi.ft14JJ:~.ffiJ!141~

~tifT

1H&. rr~~n

7fi~t-

~~fi.t..titi8i!:St~~~

~.

nut

(B).Loosen

..

slip on presser foot

on flat

of

presser

in the foot line up

(B)

..t

c

c>

~13tr&m

(F) 0

00

~.ffi!!ll

ffiM.Il!3ffM.IlfF~~

.

l

~~

(8 . 11!.15) !3

14

)f[liJ~tL-¥

of

the presser

c A

>.

(A)

~

UL

bar

.

0

~-..t~IJJ~CK>~mti~~

m~.

rr:~un

The presser foot should be adjusted to be 1/8"(3.17mm)above the throat plate before the feed roller

mechanism begins to rise

guide as required to attain the specified point at whi

and maintain needle settings .

.ff~~~m~1f9ii...1:7tiWffiB!IIE~R~~tttt&~

15).

~!ffi~;}(7t~~~flisl~~ii~fti1JJ!*4i9-~F9ii...l:7t~11~1'Ul:il

cc>.

.

~ffillt.IJ&&H

..

Loosen screw(A,Fig, 15)

.

3.17mm.

fifi~BS!3X~~.~tt~~--~.ffillt4J~M$~~

in

presser bar lifter and guide (B),raise

ch

the feed roller begins to rise .Retighten screw(A)

fl}1f.ffifFti7tftl51~14=

-15-

.

rr:itlfl

or

CB

>

...l:~~n

(A)

#..El~R$tt

lower

CA. 00.

.

Page 21

NOTE : There should be a minimum 1/32"(0.8mm) clearance between screw (M,Fig.15)and the bottom

of

the slot in link(J).

Regulate the pressure on the presser foot by turning the presser spring regulating knob(A,Fig.14) located

of

on top

To

Needle lever thread pu

foot is resting on throat plate.

it:

i!l1:ME~.ffiffSfffNi..ttr..l~IIP!

3fJJIXJIJ;ttr..J.ffi~~~~lT

3

IfMIJ~.ffitt&J:If.t

(=

~~~~tY$tf!Jfe~..ttr..Jif7W~l':

te~TJJ~n

Jm.AJW~~fJJtYte

~ZfBJ~J\i!fft&te

i±~itl

~.-

#..Eltr~Ufl

pressure foot spring (

remove just the presser foot, remove screws (l ,Fig.15) and replace foot, retighten screws (l ).

ll

-off(P) should be set 1/16(1.6mm)above bottom

illY (

M.III

.15)

Ej)!1f~tr..!JlHL

(

.

~~~.lH~ltiJ~

+-i:)UPPER

<

.

fittfl

<E> m~

FIG.16 (

A.

.

(H).

00

oo

1s

)

~~1£i!fft&~~

(E)

**~i*tit

(F)

(G)

<1!*4t&$U~!IaiE~71.iioJJ:£19)

~~t!T$ttr.Jt£ii1!:ff~~wtr.Jt£ii1m~

B).

(J

)

tr..!llitNBJil*@;fJO.Smm

(

A.IIl.

14 )

~~ffiM4!~1Jo~3

L.!fl

.15)

jt:.§.J!t~.ffiM.P.

( P)

Ji!Z

tt~ 0 Jfiiiitr..JR.~

FEED

16)

ROLLER

Assembly of Roller to Roller Yoke :

Assemble

Place woodruff key(

dr

ive gear (E)on to shaft {D),make sure key(C)goes into slot in

gear

between

assembled components through frame. Make sure that shoulder

of roll

direction on

shoulder of shaft( D) against face of gear(E),make sure

of

is against right (inside) face

of

roller is against face of

shaft (D) and tighten screw(H).

<B> ..t.

(C)

iltA~~fJJtS"fe

1fi

.

te!~~tS"~ff

of

slot in cover (Q)when presser

.

tr..J.ffiJJ

.

IiJfrt~tlfl

ADJUSTMENT/

dr

iven

gear

(E).While holding feed roller frame (B)with steel roller(F)

tt"le

two

er

(F)is to the ri

roller )on the flat

tef.mlff~m

(E)

1¥-Jtittl*

(D)

~~~~~Hq:tll\li*

~ff

(

E)

<

1£~w~~i21m~

{L).

1 .

6mm

.

..t~MtS~tJ9~-

(A, Fig.16)through feed roller frame {B).

C) into slot

frame l

obs

ght

gear

cc>

fi5lf!Jj!f:tteff

·

a93Fimfit-~F

of

feed roller shaft (O).Siide

, sli

de

feed roller shaft(O) and

.Align screw (G) (first in

of

shaft (E).At the same time thrust

(E),make sure left edge

of

left lob .Secure screw(G) on flat

<D>

tr..Jt~M*

1£~~~-tatel¥1~

·

~~lf.ti!.Fkt!i~I¥-J~i:i'

.

IEJif.trt~ff

>.

¥r$ff

<D>

operat

(

B)

..ti¥-J"M

(D)

tr.J~i:i'Ej

..t

a9t~n

ing

left edge

of

roller

·

ff <D>

-t~

(F)

1b.

<G>

(=+)\.)UPPER

..t~MtS~tR:R•c

When feed roller mechanism (C,Fig.17) has been removed or replaced,.003

(0.13mm) maximum clearance should be maintained between roller and throat plate.

3i!fft!T$tfil.~

(

C.I!I

FEED

. 7)

3fJJ79!J!~

ROLLER

71f-t

ADJUSTMENT ( CONT)

2 >

.

Ji!Z~f.¥w~~tt.t&ff:JifV

13mm.

-

16-

ft(

0.08mm) minimum to

N

BJ~;f)o.osmm~•*

.oos

f

8J~=*.J

a

o.

Page 22

To

Adjust Guiding System for Roller:

Loosen

Mechanism(C)so that the roller is .003"(0.08mm)to .005"(0.

13mm) above throat plate.S iide rear guide finger(B)down so

that it sits

sure roller is

H

A

E

c

FIG.17 (III 17)

iftl

fl)!

~

t.9

$t

k

1¥-1

.ffi

1J

:

~i!~t.9~kbi1.Jo-~I¥-Jffi1Jif~'2fl.lE~I¥-Jff1Jf'Fffl~1llkiJ:J!~IYi~

$.1®ill1ttldf~JiliJ:i!~~ki¥-Jffi1J~1.Jo

Setting

Guide finger for roller should be set so that entire roller mechanism has free movement

no left to right movement .With roller properly aligned,the edge

in

Gui

guide plates (F}agai

place.

ifo]f!J!~i&~:

~fl-&~tr.Jsl~mmzifo1fltr.Ji.tm1-i!t+-&~mf~~~Etltr.Jkl'~~ii'il~~.tr:~~~

111.

a .

of

Feed Roller :

throat plate.

de

plates(F) must be thrusted against gu ide finger(B) to secure feed roller mechanism(C).Thrust

nst

guide finger(B) with eq ual oressure .Tighten fou r screws(E) to hold plates in

~1¥-Jiti~EY.lJ!.~l"-=fttf&~ftfl

mffisl~±.k

<F)

1!aX1sl~:fl1i

(A) to secure feed roller mechanism in place.

~iftl!lt.9~1¥-J51

t~1fWitltr

ttt.&~0

~~-~ (D)

~~Wi~tr(A)-fii!~w~m~oo~~~lir~k

Setting Pressure for Feed Roller:

Regulate the pressure on the feed roller so that it exerts

enough pressure on the fabric to feed the

Turning roller presser regulator (H,Fig, 17)

or

.

&Z.~~

.

si~±.k

<B)

Wi1-:tiioJ.ttr.Jf'Fffl1Jt€!~

two

screw

(A}

.Using shim(s)

on

top

of

rear guide support block(

parallel to throat plate slots. Tighten two screws

~~~1E:

(

A).

J'IH~R~Jl:J!~t9-~t1lt~

.

08mmi!J0.13mm

1¥-JNi~A.LL

counterclockwise to decrease the pressure.

.

(F)

!JC:,~1liioJiitrJ9Hisl~t§

o

ioJl'ii~Fcsl~tti

~i'fli11i*~~ltB~3JZ~l"T-ttf§AI

.

~.ffi~~-~$JJ~

of

roller should be parallel with feed slots

(B)

il:i!ft"W*tfft~

.

rr~~•~kl¥-1~1-t.~n

adjust

clockwise to increase

.

l!.ift:S~IXI'J~.sx

feed

D).

Check to make

(C)

if~i!~~~t

(B)

-filtliiT-Fc

.

work

up

and down with

(C)

roll

er

only

uniformly.

(

H.~

.17

-

m:r&

$~PT

<E)

.

o

)

<=

+

;h,)

THREAD

FIG.18 (

00

TENSION

18)

AND

The thread tension release is set correctly when it begins to

function at the point when the upper feed roller begins to rise.

When ad.ustment is necessary ,loosen screw (B,Fig.18) in lift

lever(C).Facing the tension release shaft (A) from the right end

of

screwdriver clockwise to raise pins(D)

lower pins . Retighten screw(B).

~

~t:Ui~ki!Mt.9~1f~k7ti¥-Jjj~1-~~1t~~f'Ffflll1

RELEASE

the machine ,insert screwdriver

/

-17-

~tiB

in

slot

in

shaft (A). Turn the

or

counterclockwi

se

to

.

~~12:

Page 23

ll*~~f'A~ll

.

~

~~ifoJ~a-t

.

tA7H~7tt£iti

J

K

(C)

_t~i.UT

•*(A)a9~~.~~~n~A~~-*(A)a9R~.~8

~?&

.

rr•~n

<B

>.

(B

.IE.

1 8

).

Wm$11l.H~$:tiiila9f'A

a1~~~--~~n~g(D)_tft-

,

&~

(.::,+)DIFFERENTIAL

FIG

.19 (

00

19)

i!i:t~ii

(A.

00

.

19

)

*l£*1J&M~ii. ~

tt*~*~--~·~4~5~ft··~~*.3B$M5~9flltft·~~~*

(A)atJ.MM~-~-~

~•.

~•$Mm•w•atJ•

(A)

(=+-)SETTING

CONTROL

/

~idJj2$1J

The

amo

unt

of

differential is controlled

adj

ust

ing pl

ate

is

from

numbers

The numbers

numbers

se

t to limit the movement

If top

ply

operat

or, if t

required.

f&t&_t~

1 to 4

from

5 to 9

produce a gather

of

mater

op

ply is

1

-91-f;f.ij-&

numbered

reverse

4 to 5

produce

of

lever( A)

ial is

coming

short ,move

.

3~.iie34

by

from

1 to 9.

differently

equal

ing

stitch.Screws

or

lock lever in

out long, move

lever

away

~ 1

~~a-tft~&ial~M~

-

~fl(B)~•mM&I

lever

When

or

stretching

feed

from

~a--t-~.~-~~*a1.$Mm~W*a9*.~~--~~~-~

.

~~--~~••~•~iaJ•

NEEDLE

THREAD

TAKE-UP

.

•~~*ifoJ~

AND

.

FRAME

~-mt&H~J:Mt&*i

Wi

th

the

D

_L

I

l 0

00

--

c

I l'

FI

G.20

(

00

20)

edge

of

the

need

le

lever

thread

adjust

lev

er

(D)

as

required to attain 1/16".Tighten screw (H).

f!J!~~*Ii00a9lt!UI,

f'a7filfl (H)

#-lm~*ifoJ!'IR•

}a~~

IT I

111

6"

6Mm'l

eyelet (C)(

(D)

Ei:1CR~tt~t~m~tlH

(D)

needle

frame needle thread eyelet (A,Fig.

of

eyelet

(B)

l

ever

thread eyelet (C) will

eyelet

or

With the needle

*tt~1.6mm~~i£i

(A) is

down

as

fl.iUHtff~rul~IIPti

~!],'~·. fi~~t~tt_ti:t~t&a9n~~t~t£itiJH

1la1.6X-1I~

13.•!m~*•M. milfrr•t~n

take-up (D) should

See

Insert). If

bar

at

the

top

of its

stroke

20

)in the l

so

the

need

le thread from eyelet (A) to

be

in a strai

necessary

required .Reti

.

~:~HI~ifojfi_t).:t~t&

bar

adjustment

(C)

loosen

,

i~lf_ttt~t&

at the bottom

be

set

ag:iil~

.

~~rt~ilfl

screw

ghten

screw

<K

of

its stroke, the needle thread

so

that

it

is 1/16

is

necessary

1.6mm (JA!jjfll

).

set

ower

ght line.lf

(K)

and

move

(K

).

(A)

~_ttt~t&

(A) Jl!IJf'AJfi.lfl

"{1.

6mm)

loosen screw

).

(H).

(A,Fig.19).The

the

lever

is

set

occurs.

stitching

one

lever

while

(B)

can

be

position.

toward

operator,as

EYELET

the

adjustab

mounting hole

the

adjustment

eyelet

(C)

above

jz[]*VIJIUI~.

needle

(

B)

_tag

(K) 1t

the

(H)

and

le

of

up

fit

(_+=>LOOPER

With the

machine

rotating in

THREAD

operat

ing di

TAKE-UP ADJUSTMENT/

rection

the looper thread take-up is in ti

-1

8-

tQtf~tt&\11.

me

when

the first

screw

Page 24

coming into view (A,Fig.21)

the

mair

shaft in the pulley .NOTE:screw (A) is accessable

through the

looper thread should cast-off

needles are safe ly

loosen twoscrews(A)

spot screw(B).lighten screws(A).

l!.l

Utma;s-m~-r:>JiaJm~

FIG.21 (

~:~tr<A>amr&M~~•iliwr&n

il

(C).

~~at~iJUl.

JUJTJ?iltlfl (

NOTE: Make sure take-up cam is centered left

~:

~i*~tr&t:J*titt:-T9~•MJ.A~i!J~I¥.J~,r~Ut:.-

A)

00

21

)

f'41fitt:~

.

#..El~

.

~~~~-~~~.str~~I¥.Jm~=•~~"·~H•mu

(C)

9~~UI~t(.fjJiji'tlfl

hole

in

the take-up . With this setti

in

±

Hffit*tJ:.i¥.J21fl

(A)

to

right

in

cast-off slot .

.

is

in

line with the spot screw

of

the take-up (C) when the

the triangle. If adjustment is necessary

in

take-up (C)position screws in line with

.

s~-1-t'-n

(B)

J5X.

-

1[~1¥.Jit-t~

illt~m*t~·S.'-fl

<

A.IE.

.

~tf/lit-t~tr&

(B)

(B)

on

ng

correct,the

zn

iztA.~r&

.SX.

- 11:•.

.

(_+=>FOLDER

FIG.22 (

c=+lm)AIR

FIG.

23

00

(

00

BLOWER

ADJUSTMENT

22

)

TUBE

23

)

/ \I!J§ilftlil

Slide folder (A,Fig.22) on arm .The folder should be as close

the front of presser foot (B) as possible ,making sure

the presser foot contacting the

seams.

entire

adjustment

position

f/i'~H

ift"M'imi¥.Jffill!!J

~~·~·~*~~~~~1f~n<c>~~~*~m~ami'

J.Ati:£:~m:J.A"M'f!JJ§~M

~t41ftlfJ

The air blower tube should be set left to right so it is parallel

with the throat plate .It should

feeding over a cross seam the presser foot does not contact

the tube

and posit ion air

(A).

~·iH:9:1f~J.A~£:~3¥~-T~Ht&

&Jmi:1:fi!Mi!Jiit-t

*f'41fttfJ (A.

If adjustment

folder left to right or front to back as required.

of

upper scroii(D) is needle loosen screw(E) and

scroll

to

(A.

00.

22 )

.

~i*s~.g.~tJ1i:1:1¥.JiM1~.

(E)

ADJUSTMENT

.If adjustment is necessary ,loosen screw(A,Fig.23)

is

necessary loosen screws(C)to move

obtain proper seam margin.

~MiiAl'trl~~t&

.

Jt:..El~-~~#JJ.Aii'iH~~.g.~(fJ!f.g.Jti

/

blower tube (B)

.

ffillill~~-~fiJ'if

!!J.23

)

-i1f~itt:iH:9:'if

fol

der

when

sew

ing across

.

1/i'DH@~~~(f]ti

ffil!ill

(B)

!3f/i'~ii

~*~~~m_twi¥.J~~#J

~fil!9:tf

be

set front to back so when

as

required. Retighten screw

.

EiJ.A'Rtr£:1§~·.

.

~*~~~-.

(

B),

Jt:j9~$,1fl

il~~if

to

to

avoid

If

just

<D).

Jj!IJ

.

~~~

(A).

-19

-

Page 25

MAIN

FRAME,

CAST-OFF

PLATE,

EYELETS,

MISCELLANEOUS

COVERS AND

BUSHINGS

2

/

±.:fm~, 9~·lli,

,J,~L,

~~ml&~M-

17

78

- 20-

. .

~~

.

I! 62

66

Torque

18ft

to

. lbs.

Page 26

.*-I}

----------------

I

2

3 3588A003

4 3588A004

5 3588A005

6 3588:\006

7

8 3588A008

9 3588:\009

10

II

12

13

14 3588AOI4

15

16

118

19

20 3588A020

21

22

?'

-~

24 3588A024

25

26

27

28

29

30 3588.\030

31

32

33

34

35 3588:\035

36 3588A036

37

38 3588A038

39

40 3588A040

41

42

.n

44 3588A044

45

46

47

48

49

50

51

52

-{4:-I}

3588AOOI

3588A002

3588A007

3588AOIO

3588AOII

3588A012

3588AOI3

3588A015

3588AOI6

3588A01-

3588A018

3588A019

3588A021

3588:\022

3588A023

3588:\025

3588A026

3588A027

3588A028

3588A029

3588A031

3588A032

3588A033

3588A034

3588A037

3588A039

3588A041

3588A042

3588A043

3588A045

3588:\046

3588A047

3588:\048

3588A049

3588A050

3588A051

3588AOS2

t.lt1

tJHi':!Hii~#

llliti'Hfiil

0~1\Ut!!!!

:f!il.nt!S

ffi.

~i:;~

~~

iltr

~n

l!i~~

iMUiE:l

t!il.ittlWf

0~1!1~1!9

'-In

~lfj~trtfr'f

lt~!a

~n

tur

1~affi1t.l!

1~1f:lli1Lm

*·~

tlfittlCJtJtr

0~\t't:t

ittltU.UT

~1!1

~n

illlillli;f-3~f4:

il!llr7lclJ'~

~tJ

tifT

...

.PUi~rlfii

tifT

!U!I

tifT I

-rttt:tJ&ii

l:i!J:t~ffi

Ui£l~.lt

!.'14.:1

5\tltl~tttt%~~

Sfll.lfH~ttM¥

-ltl~tttt

~n~~fll:

O~HHt

fl.fT

!ItT

l!iil'!a

o

l'lll~

~**

illl"itf'ii

~f$

-

l!l

~~

1fl

'f

1JE$UGt

l!l

!Hi:~

!!I

DESCRIPTION

-

-------------

Screw

Chamber

Crank

0

Oil

Presser

Gasket

Cover

Screw

Screw

Gasket

Top

Oil

'O '

Screw

Looper

Gasket

Screw

Screw

Cast-off

Cast-off

Cast-off

Oil

''O''Ring

Screw,

Washer

Screw 2

Cil

Oil

Screw 2

Screw 2

Top

~1iddle

Screw

:\u

l