Page 1

ZJ2628

CYLINDER

BED

SEWING

COMPOUND

OPERATING

FEED

MACHINE

LOCKSTITCH

INSTRUCTIONS

Page 2

1.

MAIN SPECIFICATION

Sewing speed

Stitch length

Needle bar stroke

Presser foot lift

12.

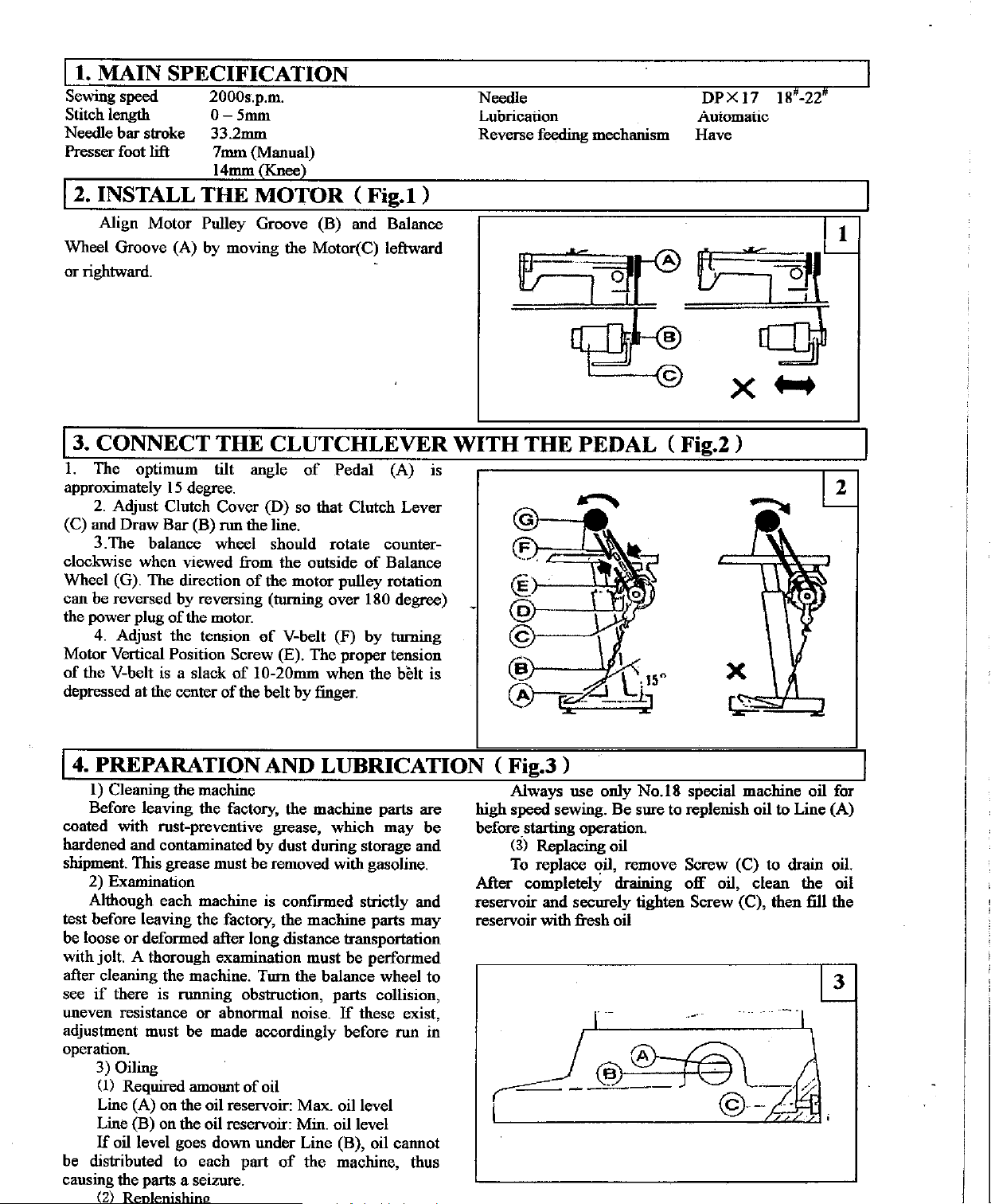

INSTALL THE MOTOR ( Fig.1 )

Align Motor Pulley Groove (B) and Balance

Wheel Groove (A) by moving the Motor(C) leftward

or

rightward.

2000s.p.m.

0-5mm

33.2mm

7mm (Manual)

14mm(Knee)

Needle

Lubrication

Reverse feeding mechanism

DPX

Auiomatic

Have

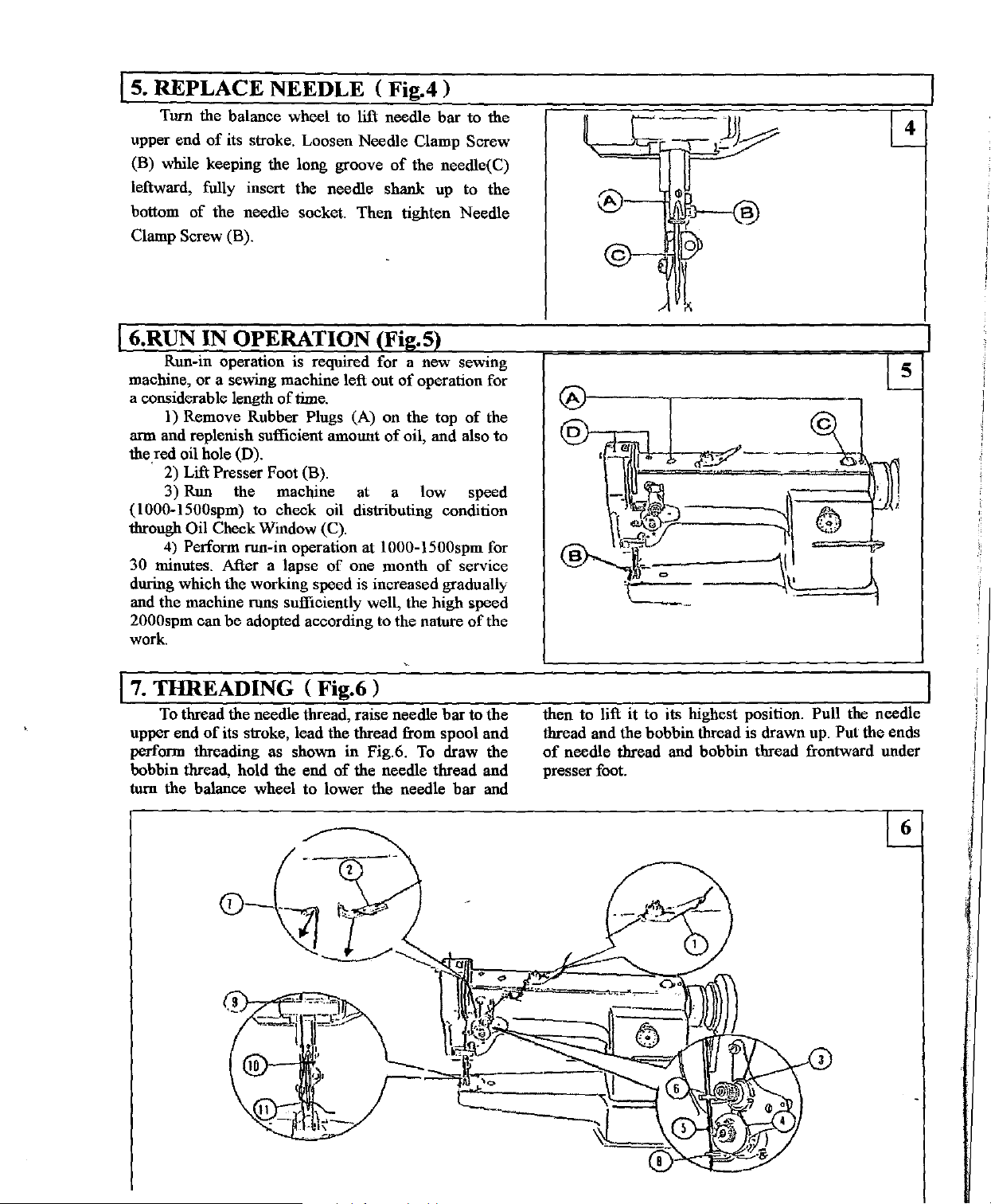

13. CONNECT THE CLUTCHLEVER WITH THE PEDAL ( Fig.2 )

1.

The optimum tilt angle

approximately

2.

Adjust Clutch Cover (D) so that Clutch Lever

(C) and Draw

3. The balance wheel should rotate counter-

clockwise when viewed from the outside

Wheel (G). The direction

can be reversed by reversing (tnrning over

the power plug

4.

Adjust the tension

Motor Vertical

of

the V-belt is a slack

depressed at the center

15

degree.

Bar

(B) run the line.

of

of

the motor.

Position Screw (E). The proper tension

of

10-20mm when the belt is

of

the belt by finger.

of

Pedal (A) is

of

Balance

the motor pulley rotation

180 degree)

of

V-belt (F) by tnrning

17 18'-22"

1

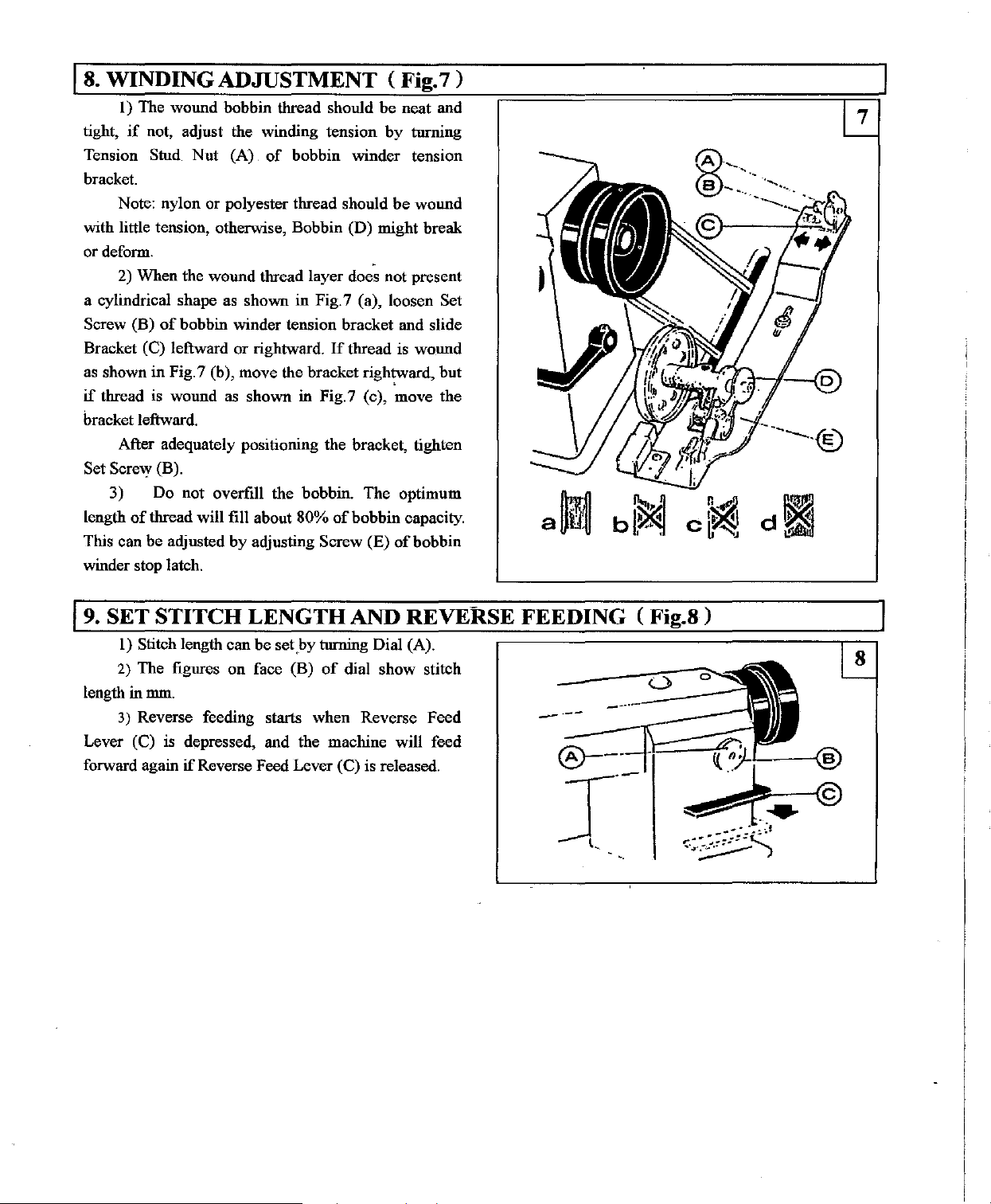

14. PREPARATION AND LUBRICATION ( Fig.3 )

l)

Cleaning the machine

Before leaving the factory, the machine parts are

coated with rust-preventive grease, which may

hardened and contaminated

shipment. This grease must be removed with gasoline.

2) Examination

Although each machine is

test before leaving the factory, the machine parts may

be loose

with jolt. A thorough examination must be performed

after cleaning the machine. Turn the balance wheel

see

uneven resistance

adjustment must be made accordingly before run in

operation.

be distributed to each part

causing the parts a seizure.

or

deformed after long distance transportation

if

there is running obstruction, parts collision,

or

3) Oiling

(1)

Required amount

Line (A) on the oil reservoir: Max. oil level

Line (B) on the oil reservoir: Min. oil level

If

oil level goes down under Line (B), oil cannot

2

by

dust during storage and

confirmed strictly and

abnormal noise.

of

oil

of

the machine, thus

If

these exist,

be

to

Always use only

high speed sewing.

before starting operation.

Ci)

Replacing oil

To

replace oil, remove Screw (C) to drain oil.

After

reservoir and securely tighten

reservoir with fresh oil

completely draining

--

__

No.l8

Be

sure to replenish oil to Line (A)

special machine oil for

off

oil, clean the oil

Screw (C), then fill the

-~.

Q:J_~---

l

--

©·-

/;.

...

Page 3

Is.

REPLACE NEEDLE <

Turn the balance wheel to lift needle

of

upper end

(B) while keeping the long groove

leftward, fnlly insert the needle shank up to the

bottom

Clamp Screw (B).

its stroke. Loosen Needle Clamp Screw

of

the needle socket. Then tighten Needle

Fig.4)

bar

of

the needle(C)

to the

I 6.RUN IN OPERATION (Fig.5)

Run-in operation is required for a new sewing

machine,

a considerable length

arm and replenish sufficient amount

the red oil hole (D).

(I

000-1500spm) to check oil distributing condition

through

30

during which the working speed is increased gradually

and the machine runs sufficiently well, the high speed

2000spm can

work.

or

a sewing machine left out

of

time.

I)

Remove Rubber Plugs (A) on the top

· 2) Lift Presser Foot (B).

3)

Run the machine at a low speed

Oil Check Window (C).

4)

Perform run-in operation at

minutes. After a lapse

be

adopted according to the nature

of

one month

of

operation for

of

oil, and also

I000-\500spm

of

of

service

of

the

to

for

the

I

7.

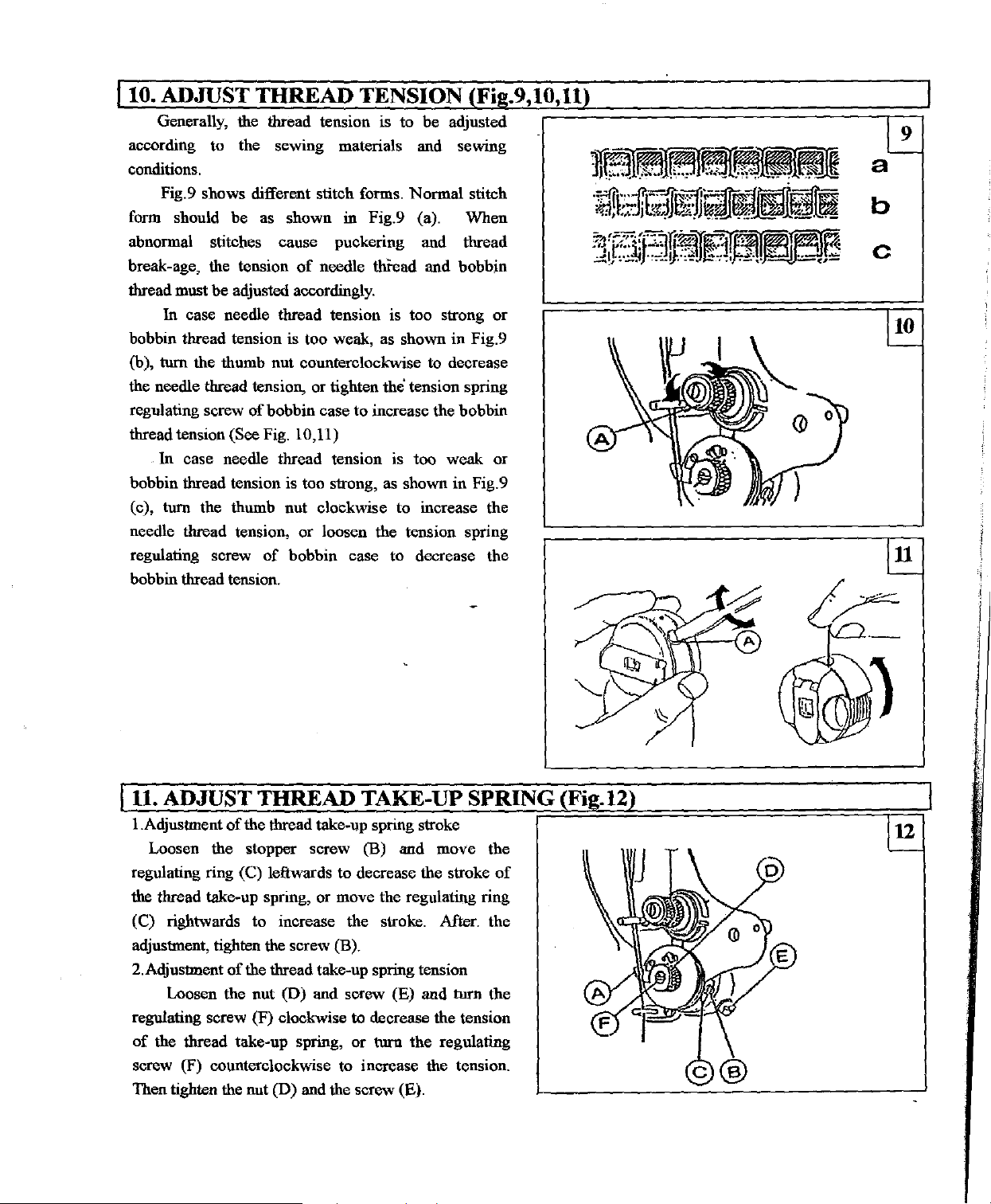

THREADING ( Fig.6 )

To thread the needle thread, raise needle

upper end

perform threading as shown in Fig.6.

bobbin thread, hold the end

tum

of

its stroke, lead the thread from spoo I

of

the needle thread and

the balance wheel to lower the needle

bar

To

draw the

then to lift

thread and

of

presser foot.

bar

to

the

and

and

·--L-=-

it

to its highest position. Pull the needle

the bobbin thread is drawn up. Put the ends

needle thread and bobbin thread frontward under

cv~~;;::..

Page 4

Is.

WINDING ADJUSTMENT <Fig.

I)

The wound bobbin thread should

if

tight,

Tension Stnd

bracket.

with little tension, otherwise, Bobbin (D) might break

or deform.

a cylindrical shape as shown in Fig.7 (a), loosen

Screw (B)

Bracket (C) leftward

as shown in Fig. 7 (b), move the bracket rightward, but

if

bracket leftward.

Set Screw (B).

length

This can be adjusted

winder stop latch.

not, adjust the winding tension

Nut

(A)

of

bobbin winder tension

Note: nylon or polyester thread should

2) When the wound thread layer does not present

of

bobbin winder tension bracket and slide

or

rightward.

thread is wound as shown in Fig. 7 (c), move the

After adequately positioning the bracket, tighten

3) Do not overfill the bobbin. The optimum

of

thread will fill about 80%

by

adjusting Screw (E)

be

neat and

by

turning

be

wound

If

thread is wound

of

bobbin capacity.

of

bobbin

1)

Set

----®

a~

19.

SET STITCH LENGTH

I)

Stitch length can be set

2)

The figures on face (B)

in

length

Lever (C) is depressed, and the machine will feed

forward again

mm.

3)

Reverse feeding starts when Reverse Feed

if

Reverse Feed Lever (C) is released.

_by

AND

turning Dial (A).

of

dial show stitch

REVERSE FEEDING (

Fig.8)

Page 5

Ito. ADJUST THREAD TENSION (Fig.9,10,U)

Generally, the thread tension is

according to the sewing materials and sewing

conditions.

Fig.9 shows different stitch forms.

form should be as shown in Fig.9 (a).

abnormal stitches cause puckering and thread

of

break-age, the tension

be

thread must

In

bobbin thread tension is too weak, as shown

(b),

tum

the needle thread

regulating screw

thread tension (See Fig.

In

case needle thread tension is too weak or

bobbin thread tension is too strong, as shown in Fig. 9

tum

(c),

needle thread

regulating screw

bobbin thread tension.

adjusted accordingly.

case needle thread tension is too strong

the thumb nut counterclockwise to decrease

tension, or tighten

of

bobbin case

the thumb nut clockwise

tension,

of

needle thread and bobbin

10,11)

or

loosen !he tension spring

bobbin case

to

be adjusted

Normal

in

the

tension spring

to

increase the bobbin

to

increase the

to

decrease

stitch

When

or

Fig.9

the

9

a

b

c

ju.

ADJUST THREAD TAKE-UP SPRING

!.Adjustment

Loosen the stopper screw (B) and move the

regulating ring (C) leftwards to decrease the stroke

!he thread take-up spring, or move the regulating ring

(C) rightwards to increase the stroke. Mter. the

adjustment, tighten

2.Adjustment

Loosen the nut

regulating screw (F) clockwise to decrease the tension

of

the thread take-up spring,

screw (F) counterclockwise to increase the tension.

Then tighten the nut (D) and the screw (E).

of

the thread take-up spring stroke

the screw (B).

of

the thread take-up spring tension

(D)

and screw (E) and

or

tum

the

of

tum

the

regulating

(Fig.l2)

u

Page 6

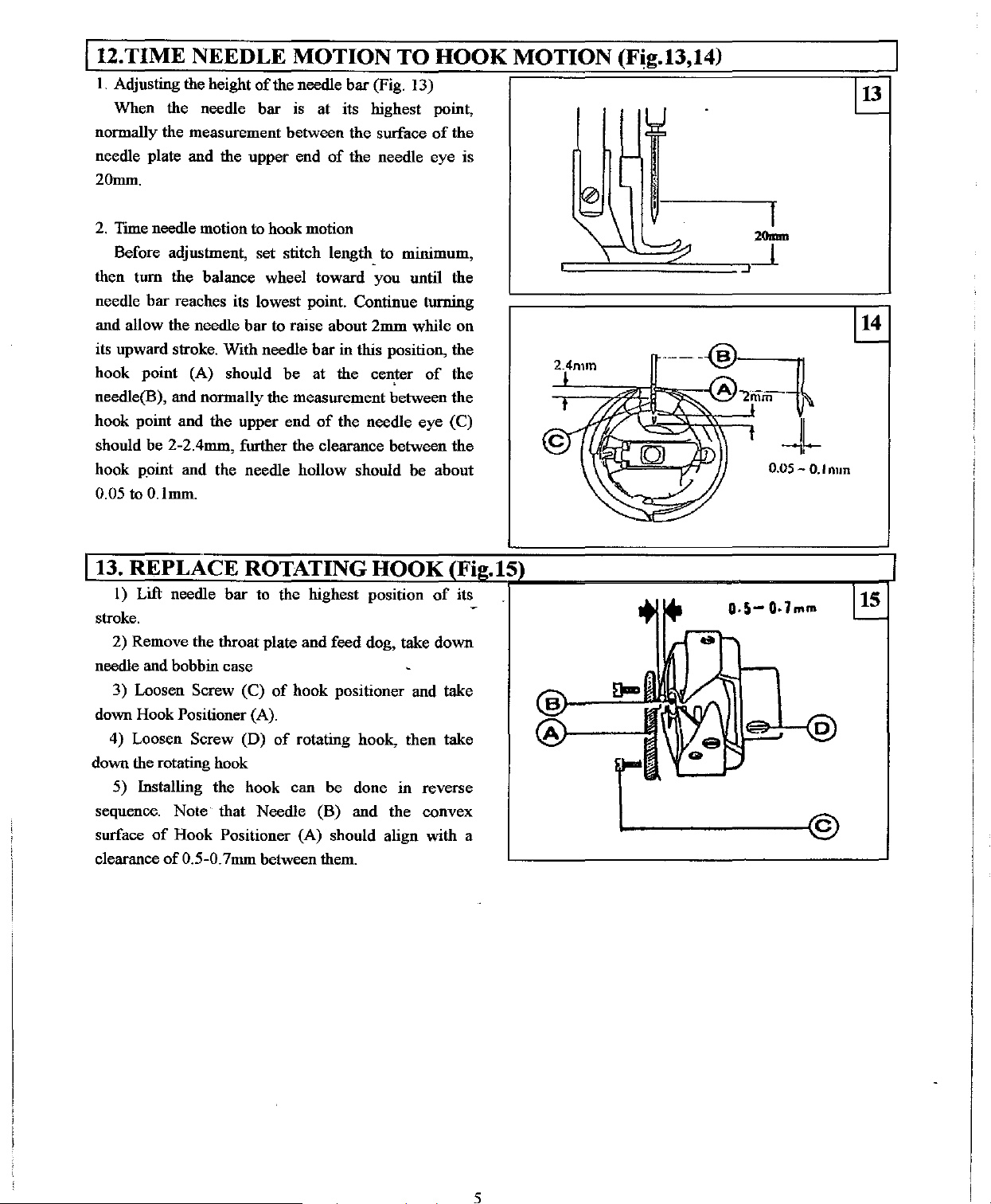

j12.TIME NEEDLE MOTION TO HOOK MOTION (Fig.13,14)

I.

Adjusting the height

When the needle

normally the measurement between the surface

needle plate and the upper end

20mm.

2.

Time needle motion to hook motion

Before adjustment, set stitch length_ to minimum,

then turn the balance wheel toward you

bar

needle

and allow the needle bar to raise about

its upward stroke. With needle

hook point (A) should be

needle(B), and normally the measurement between the

hook point and the upper end

should be

hook point and the needle hollow should be about

0.05 to O.lmm.

reaches its lowest point. Continue turning

2-2.4mrn, further the clearance between

of

the needle bar (Fig. 13)

bar

is

at its highest point,

of

the needle eye is

2mrn while on

bar

in this position, the

at

the center

of

the needle eye (C)

of

the

until the

of

the

the

0.05 - 0. I nun

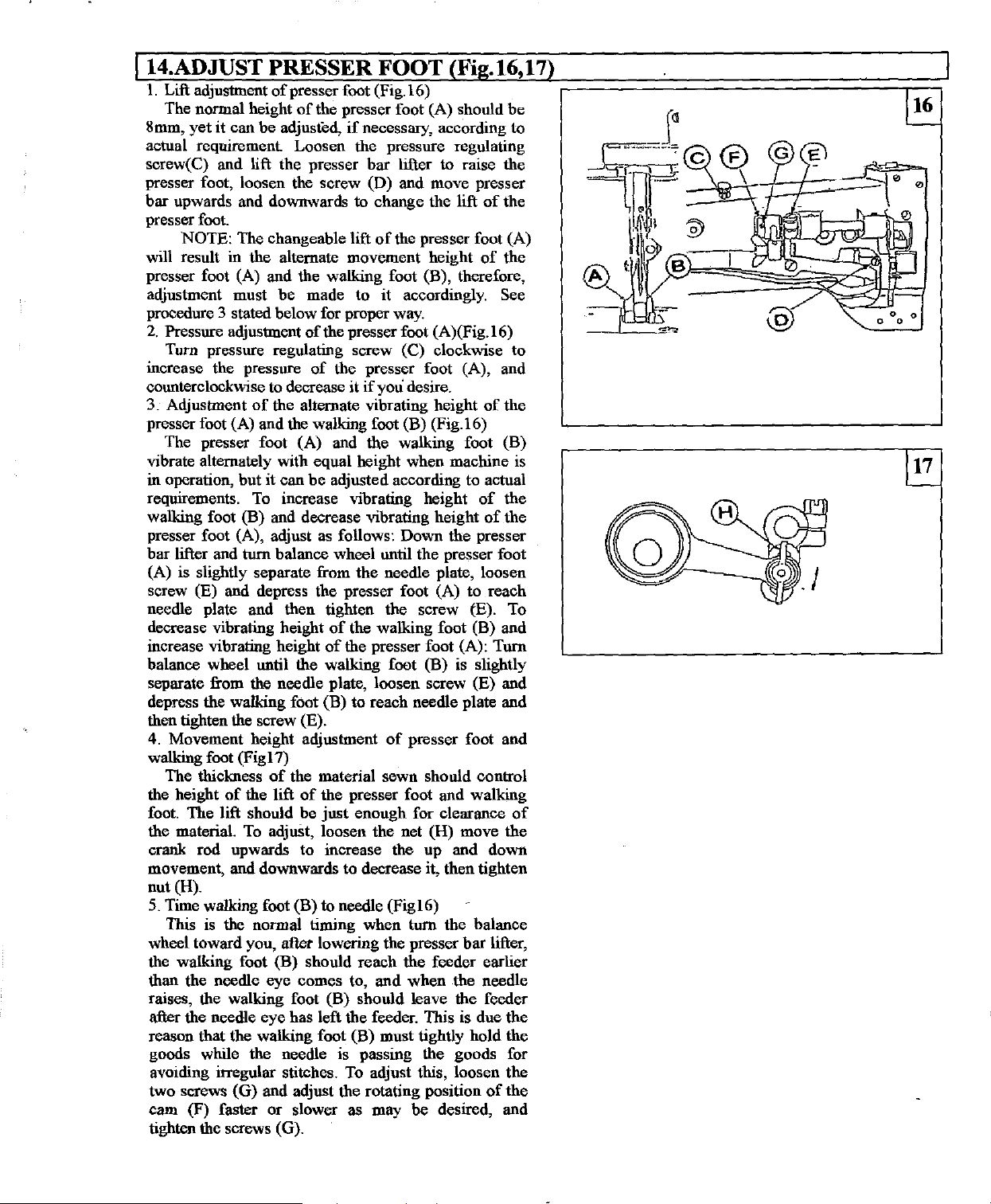

1) Lift needle

stroke.

2) Remove the throat plate

needle and bobbin case

3) Loosen Screw (C)

down Hook Positioner (A).

4) Loosen Screw (D)

down the rotating hook

5) Installing the hook can be done in reverse

sequence. Note that Needle (B) and the convex

of

surface

clearance

Hook Positioner (A) should align with a

of

bar

to the highest position

and

feed dog, take down

of

hook positioner and take

of

rotating hook, then take

0.5-0. 7mm between them.

of

its

[1---'

-©

Q.5-

Q.}mm

5

Page 7

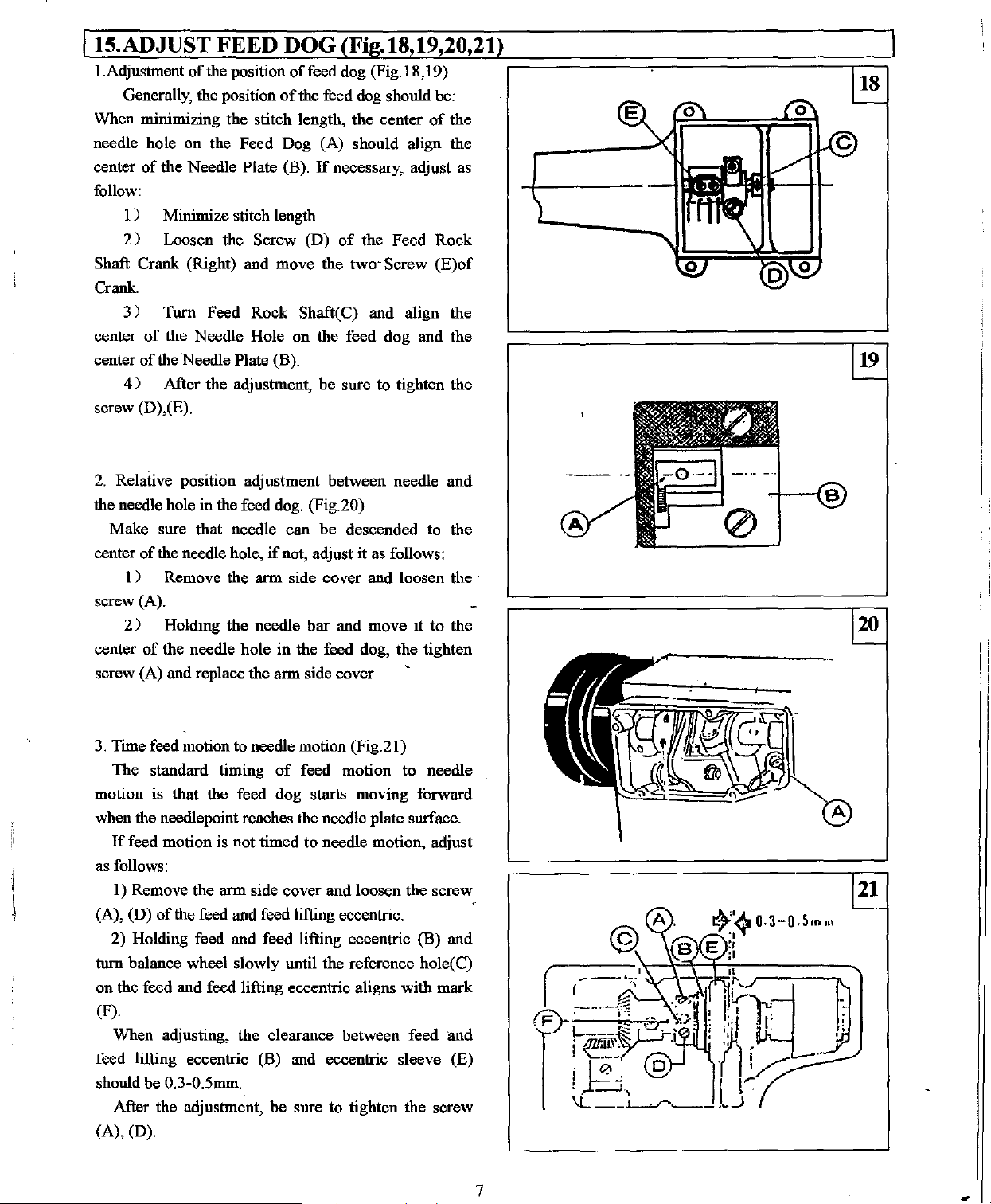

lt4.ADJUST PRESSER FOOT (Fig.l6,17)

1.

Lift adjustment

The normal height

8mm,

yet

it

actual requirement Loosen the pressure regulating

screw(C) and lift the presser

presser foot, loosen the screw (D) and move presser

bar

upwards and downwards to change the lift

presser foot.

NOTE: The changeable lift

will result in the alternate movement height

presser foot (A) and the walking foot (B), therefore,

adjustment must

procedure

2.

Pressure adjustment

Turn pressure regulating screw

increase the pressure

counterclockwise to decrease it

3. Adjustment

presser foot (A) and the walking foot

The presser foot (A) and the walking foot

vibrate alternately with equal height when machine is

in operation,

requirements. To increase vibrating height

walking foot

presser foot (A), adjust as follows: Down the presser

bar lifter and

(A) is slightly separate from

screw (E) and depress the presser foot (A) to reach

needle plate and then tighten the screw

decrease vibrating height

increase vibrating height

balance wheel until the walking foot

separate from the needle plate, loosen screw (E) and

depress the walking foot

then tighten

4.

Movement height adjustment

walking foot

The thickness

the height

foot. The lift should be

the material.

crank rod upwards to increase the up and down

movement, and downwards to decrease it,

nut (H).

5.

Time walking foot (B) to needle

This is

wheel toward you,

the walking foot (B) should

than the needle eye comes to,

raises, the walking foot (B) should leave the feeder

after the needle

reason that the walking foot (B) must tightly hold the

goods while the needle is passing the goods for

avoiding irregular stitches. To adjust this, loosen

two screws (G)

cam

tighten the screws (G).

3 stated below for proper way.

(F) faster

of

presser foot (Fig.l6)

of

the presser foot (A) should

can

be adjusted,

be

of

the alternate vibrating height

but

it can

(B)

and decrease vibrating height

if

necessary, according

bar

lifter to raise the

of

the presser foot (A)

made to

of

the presser foot (A)(Fig.l6)

of

be

adjusted according to actual

it

accordingly. See

(C) clockwise

the presser foot (A), and

if

you

desire.

(B)

(Fig.l6)

of

of

tum balance wheel until the presser foot

the

needle plate, loosen

(E). To

of

the walking foot

of

the presser foot (A): Turn

(B)

to

reach needle plate and

the

screw (E).

of

presser foot and

(Figl7)

of

the material sewn should control

of

the lift

To

the

of

the presser foot and walking

just

enough for clearance

adjuSt, loosen the net

(Figl6)

normal timing when tum the balance

after lowering the presser

reach

the feeder earlier

and

when the needle

eye

has left the feeder. This is due

and

adjust the rotating position

or

slower as may be desired, and

(B)

(H)

then

(B)

is slightly

move the

tighten

bar

of

the

the

of

the

(B)

the

of

the

and

lifter,

of

be

to

to

of

the

the

the

Page 8

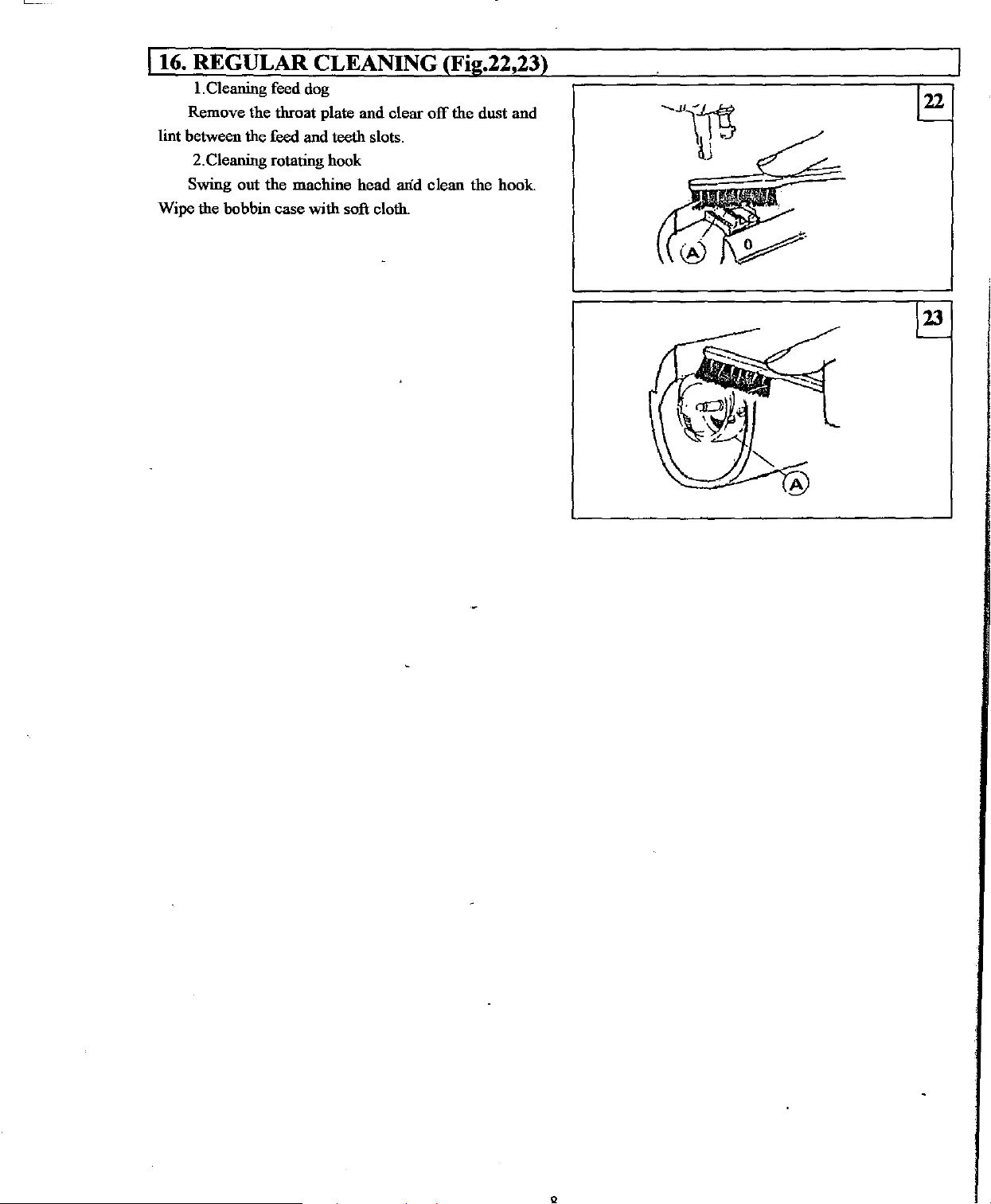

I15.ADJUST FEED DOG(Fig.18,19,20,21)

!.Adjustment

Generally,

When minimizing the stitch length, the center

needle hole on the Feed Dog (A) should align

center

follow:

l)

2)

Shaft Crank (Right) and move the two- Screw

Crank.

3)

center

center

of

4)

screw (D ),(E).

2.

Relative position adjustment between needle

the needle hole in the feed dog. (Fig.20)

Make sure that needle

center

of

l ) Remove

screw (A).

2 ) Holding

center

screw (A) and replace

of

the position

the position

of

the Needle Plate (B).

Minimize stitch length

Loosen the Screw (D)

Turn Feed Rock Shaft( C) and align the

of

the Needle Hole on the feed dog and the

the Needle Plate (B).

After the adjustment, be sure to tighten the

the needle hole,

the arm side cover and loosen the ·

the needle

of

the needle hole in the feed dog, the tighten

of

feed dog (Fig.l8,19)

of

the feed dog should he:

lf

necessary, adjust as

of

the Feed Rock

can

be

descended to the

if

not, adjust it as follows:

bar

and move

the arm side cover

it

of

the

the

(E)of

and

to

the

3.

Time feed motion to needle motion (Fig.2l)

of

The standard timing

the feed dog starts moving forward

the feed and feed lifting eccentric.

0.3-0.5mm.

I

I

motion is that

when

the needlepoint reaches the needle plate surface.

lf

feed motion is not timed to needle motion, adjust

as follows:

l)

Remove the arm side cover and loosen the screw

(A), (D)

turn balance wheel slowly until

on

(F).

feed lifting eccentric (B) and eccentric sleeve (E)

should be

(A),

of

2) Holding feed and feed lifting eccentric (B) and

the feed and feed lifting eccentric aligns with mark

When adjusting, the clearance between feed lltld

After the adjustment, be sure to tighten the screw

(D).

feed motion to needle

the

reference hole(C)

7

21

Page 9

lt6.

REGULAR CLEANING (Fig.22,23)

1.

Cleaning feed dog

and

clear

Remove the throat plate

lint between the feed and teeth slots.

2.Cleaning rotating hook

Swing out

Wipe the bobbin

the

case

machine

with

head

soft cloth.

off

arid clean the

the

dust

and

hook

Page 10

PARTS

LIST

Page 11

1.

ARM

BED

AND

ITS

ACCESSORIES

Page 12

1. ARM BED AND ITS ACCESSORIES

No.

I.

2.

3.

4. GB827-86

5.

6.

7.

8.

'

9.

10.

II.

12. 05-01-014

13. 05-01-015

14.

15.

16.

17.

18.

19.

20.

21. GB896

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32. 05-01-007C7

33.

34. 05-01-007C8-2

35.

36.

37.

38.

39.

40.

41. 05-01-009

42. 05-01-010

43. 05-01-011

44.

45.

46. 01-01-006

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

Ref. No.

05-0l-OOIA2

09-01-00 I B2

09-01-002

05-01-003

05-01-004

05-01-005

05-01-006

22TI-003C5

05-0J-013

22TI-003C6

Ann

Ann bed

Trade mark plate I

Trade mark plate rivot 2

Faceplate

screw 1

Set

Knock pin I

Thread guide (Up) I

Thread guide (Middle) I

Thread guide (Lower) 1

Set

screw

Description Pes

Ann side cover 1

Gasket for arm side cover I

72TI-017

12H1-007C1 Oil check window 1

12HI-007C2

22Tl-009El

22TI-009E2

22Tl-009E3

22Tl-009E4

22Tl-009E5

22Tl-010

22Tl-Oll

05-0I-007C1

05-0l-007C2

05-01-007C3

73Tl-002C1

05-0 1-007C4

05-01-007C5.

05-0 1-007C6

05-01-007C8-1

05-0 1-007C9

05-01-007C10

05-01-007Cil

05-01-007C12 Thread tension release pin 1

72Tl-013

05-01-008

05-01-016

22Tl-Oil

01-01-007

72Tl-017

09-01-003

72Tl-004C4

72Tl-009

72Tl-Oil

09-01-004

09-01-005

09-01-006 Bed

09-0l-007

72Tl-017

72Tl-017

22Tl-Oil

Set screw

0-ring

Screw type tension stud I

Spring for pretension I

Disc for pretension 2

Space for pretension 1

Stop ring I

Pretension tluead guide 1

Three-hole tluead guide 1

Set screw

Thread tension bracket

Thread tension stud 1

Tension regulating

Thread tension spring 1

Thread tension releasiiig disc

Thread tension disc 2

disc 1

Stop

Pin

Thread controller disc

Thread controller plate 1

Screw

Thread tension release plate

Screw

Screw

Thread controller stud

Thread take-up spring 1

Tension thumb nut 1

Thread take-up spring stup 1

Screw

Screw

Bed side cover I

Gasket for bed side cover

Set screw

Cap for bed face plate I

Rubber plug 8

Rubber ping

Rubber ping

Bed cover

Gasket for bed cover 1

rear

cover 1

Gasket for bed

Set screw 4

Set screw

Screw

-

rear

nut

cover

Remarks

I

1

1

3

8

1

1

1

1

1

1

1

1

1

2

1

1

I

1

1

6

I

I

I

1

4

l

Page 13

2.

NEEDLE

BAR

AND TAKE-UP

MECHANISM

··v

Page 14

2. NEEDLE BAR AND TAKE-UP MECHANISM

No.

1.

2.

3.

4.

5.

6.

7.

8.

9. 22T2-007

10. 05-02-006

11.

12. 05-02-007

13. 05-02-008

14.

15.

16.

17.

18. 05-o2-009B3

19.

20. 72T2-003

21.

22.

23. 22T2-002

24. 05-02-012

25.

26. 04-02-005

27.

28. 22T2-017

29.

30. 02-08-007

31. 09-02-00 I C2

32. 22T5-001A4

33.

34. 05-02-015 Bushing for rock shaft (Left) 1

35.

36.

37.

Ref. No.

05-02-001

05-02-002

22T2-002

05-02-003 Thread take-up lever driving stud l

05-02-004

22T8-0llC4

05-02-005Al

22T2-006

72T2-004B2

22T7-0I5

05-02-009Bl

05-02-009B2 Crank (Left) 1

GBI17

05-02-009B4

05-02-010

05-02-0ll

04-02-004 Thread guide for needle

05-02-014Cl

05-05-003 Hinge pin (Upper) 1

05-02-016

22T2-002

22Tl-Oll

Thread take-up lever 1

Hinge pin l

Set screw

Oil guard

Set screw

Needle

Set screw

Set screw

Hinge

pin

Set screw

Needle

Needle

Set screw

Needle

Pin for crank

Slide block for needle

Position bracket

Screw

Needle

Hinge

Screw I

Needle

Screw

Needle

Needle clamp screw - I

Crank (Right) I

Screw

Crank level-link

Screw

Bushing for rock shaft (Right)

Screw

Screw

bar

bar

pin

(Right) 1

Description

bar

crank 1

bar

link 1

adaptor I

rock frame rock shaft

bar

rock frame

bar

rock frame I

bar

bar

Pcsl

Remarks

1

1

l

1

1

2

1

1

I

l

1

I

1

1

1

1

1

1

1

1

2

I

Page 15

3.

ARM

SHAFT

AND

VERTICAL

SHAFT

MECHANISM

~~

@

Page 16

3. ARM SHAFT AND VERTICAL SHAFT MECHANISM

No. Ref. No.

1.

05-03-00lAl

22T3-001A2

2.

22T6-005Bl

3.

4.

22T3-002B2

5.

22T3-003

6.

05-03-007

22T7-002

7.

8.

05-03-006 Ann shaft bushing (Right) 1

9.

22T3-006F

10. 02-03-001

11.

22T3-007C2

22T3-008

12.

09-03-00 I B 1

13.

14.

22T2-002

15.

09-03-001

16.

04-01-017

17.

09-03-00 1B2

22Tl-Oll

18.

19.

05-03-003

20.

21.

22. 22T2-005B3

23.

24.

25.

26.

27.

22T3-010E2a1-2

22T3-0l

22T3-010E2b1-2

22T3-0 1 OE2b2-2 Bevel

05-03-004 Vertical shaft bushing (Upper)

05-03-005

22T2-002

B3

OE2a2-2 Bevel

Description

Pcsl

Ann shaft 2

Rubber plug

Collar for arm shaft

screw 1

Set

Ann shaft bushing (Left) 1

Ann shaft bushing (Middle)

Set

screw

seal

Oil

Balance

Set

Set

Feed lifting eccentric 2

Set

Baflle plate 3

Set

Feed

Screw

Vertical shaft 1

Bevel gear for arm shaft 1

Set

Bevel

Vertical shaft bushing (Lower) 2

Set

wheel

screw 1

screw

screw

screw

link lever 1

gear

for vertical shaft (Upper)

screw

gear

for hook shaft 1

gear

for vertical shaft (Lower)

screw

-

Remarks

1

2

1

1 .

1

2

1

1

1

1

8

1

1

1

-

15

Page 17

4.

HOOK

SHAFT

MECHANISM

Page 18

4. HOOK SHAFT MECHANISM

No.

l.

2.

3.

4.

5.

6.

7.

8.

9.

10. 09-04-002Al

11.

12.

13.

14.

15.

16.

Ref. No. Description

09-04-001

09-04-007

09-04-008

22T4-001Alal

22T4-001Ala2

05-04-003

22T4-017

09-04-004

09-04-009 Hook shaft bushing (Right) I

22Tl-Oll

09-04-006

22T6-001Alb

09-04-003

09-04-005

Pes Remarks

Rotating hook shaft 1

Bearing block 1

Set screw

Filter screw 1

Filter 1

Rotating hook complete

Bobbin case 1

Bobbin

Collar for hook shaft (Left) 1

Collar for hook shaft (Right)

Set screw 2

Hook shaft bushing (Left) 1

Set screw 2

Rotating hook positioner

Set screw 2

4

1

1

1

1

I

ji

II

-

-

17

Page 19

5.

STITCH

LENGTH

REGULATING

t.---

MECHANISM

If\

\Y

---

...;----

---

----

....

'

....

_:::..

18

Page 20

5.STITCH LENGTH REGULATING MECHANISM

No. Ref. No.

09-05-003

I.

2.

09-05-001 Hinge pin

3.

GB896

4.

-05-06-003

22Tl-Oil

5.

08-05-002BI

6.

22T2-0I9

7.

05-06-001

05-06-005

8.

9.

09-05-002

IO.

12.

13.

14.

15.

16.

17.

18.

19.

20 ...

21.

22.

23.

24.

25. 22T5-012E1a1

26.

27.

28.

29.

72T5-003

ll.

04-06-002

22T5-006C4

22T5-006C2 Dial I

22T5-006C3

72T5-005

22T5-008

22T5-009

72T5-006CI Reverse feed lever 1

05-06-002D I

1

22T5-0

22T5-010D3

22T5-001A4

22T5-0il

22T5-012EI

22T5-012E1a2

22T5-012E2

22T5-013

22T5-014

OD2b

Description

Reverse feed link lever I

Retaining ring I

Bushing for reverse feed lever shaft 1

Set screw I

regulator 1

Feed

screw

Set

Feed regulator bushing 1

Set screw

Hinge pin for feed regulator I

Rubber plug

Feed regulator screw bar I

0-ring

Screw

Rubber plug 1

Stopper pin

Spring

Reverse feed lever shaft 1

0-ring

Screw

Screw

Washer

Reverse feed crank 1

Slide block pin

Slide block 1

Spring

Screw

Bracket for spring

for stopper pin 1

for reverse

fe"t:d

crank 1

Pes

2

2

Remarks

1

I

1

I

1

1

1

1

1

1

I

I

.

Q

Page 21

6.

FEED

LIFTIN

GMECHANISM

20

Page 22

6.FEED LIFTING MECHANISM

No.

I.

2.

3.

4. 09-06-003 B I

5.

6.

7.

8. 09-06-005

9. 09-06-019

10. 09-06-006

ll.

12. 09-06-007

13.

14. 09-06-009

15. 22T5-0IOD3

16.

17. 09-06-0

18.

19. 09-06-011 C3

20. 09-06-012

21. 09-06-013

22.

23.

24.

25.

26.

27.

28.

29.

30. 09-06-018

31.

32. 09-06-022

33. 09-06-021

34. 22T1-011

35.

36.

37.

38. 09-06-023

39.

40.

41.

42.

43. 09-06-017

Ref. No. Description

09-06-00

09-06-00IA2

09-06-002

09-06-00382

09-06-004

04-01-017

09-06-020

09-06-008

09-06-010

09-06-0l!C2

22Tl-Oll

09-06-014

09-06-015

22T6-001Alb

08-03-004014

22T1-0ll

09-06-016

22Tl-Oll

08-03-00407

08-03-004012

08-03-00409

08-03-00408

01-04-00282

22TI~OO!A9

08-03-004010

08-03-004011

ll

lAl

c 1

Pes

Feed

bar

bracket I

Stud bushing 1

Set

screw

Needle plate bracket 1

Screw 4

Needle plate 1

Screw 2

Feed dog 1

Screw·

Hinge

pin

Screw 2

Piping unit bracket 1

Spring

Washer I

Screw 1

Binder positioner

Piping unit base-plate I

Pin for belt 9

Screw

Feed rock shaft crank (Left) 1

Slide

Screw 2

Feed rock shaft I

Feed rock shaft crank (Rigbt) I

Screw

Short

Crank (Lower) 1

Set screw

Hinge pin •

Feed regulator

Hinge pin (Long) 1

Hinge pin (Short) 1

Screw 2

Crank link lever (Long) 2

Crank link lever (Short) 2

Eccentric shaft I

Collar for feed rock shaft (Left) 1

Screw 2

Pin for crank link lever (Short) I

Pin for crank link lever

Collar for feed rock shaft (Rigbt)

for

piping unit bracket 1

bar

pin

for

crank link lever 1

Screw

Screw 4

-

crank

2

2

2

2

Remarks

1

1

I

I

I

1

1

I

I

Page 23

7.

PRESSER

FOOT

MECHANISM

'

'

Page 24

7.PRESSER FOOT MECHANISM

No.

l.

2. 05-07-002

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14. 05-07-021

15.

16. 05-07-013

17. 05-07-014

18. 05-07-015

19. 05-07-016

20. · 22T7 -005-001

21. 05-07-017

22. 05-07-018

23.

24.

25. 05-07-019

26.

27. 05-07-022

28.

29.

30. 05-07-011

31. 22T2-002

Ref

No.

05-07-001

05-07-003

05-07-004

05-07-005

05-07-006

22T2-001A9

05-07-007

22T6-008-D3

05-07-008

05-07-009Al

05-07-009A2

05-07-010

09-07-001

22T9-001A9

22T9-00

05-07-020

02-08-007

05-07-023

lAl

Description

Presser foot lifter l

screw 1

Set

Presser

Presser bar bushing (Upper)

Presser

Presser

Screw

Presser

Screw

Presser

Tbread tension release slide

Pin for thread tension release slide 1

Bracket for presser

Screw I

Out presser foot 1

Screw

Presser

Screw

}Cneelil\erliftinglever

Screw

Retracting spring for lever 1

Retracting spring bracket 1

Screw

0

Nnt

Pressure regulating screw 1

Thread

Presser

Screw

Pin

Presser bar bushing (Lower) I

Screw

bar

position guide 1

bar

bar

position guide bracket 1

bar

lifting bracket 1

-

bar

spring I

bar

spring 1

bar

spring (Flat) 1

tension release pin

bar

lifting bracket guide 1

Pes· Remarks

I

1

1

I

I

I

1

1

1

1

1

I

1

1

3

I

I

Page 25

8.

PRESSER

LIFTING

MECHANISM

Page 26

8. PRESSER LIFTING MECHANISM

No. Ref. No. Description

05-08-00IAI

1.

22T3-002B2

2.

3.

05-08-00

05-08-00IA3

4.

5.

GB893

05-08-00281

6.

7.

05-08-00282 Set screw

8.

05-08-003 Screw for lifting eccentric connecting collar

05-08-004 Lifting eccentric connecting collar

9.

10.

II.

12.

13.

14.

15.

16.

17.

18.

19.

20. 05-08-013 Vibrating presser

21.

22.

23.

24.

25.

26.

27.

28.

29.

30. 05-08-021

31.

32.

33.

05-08-005

05-08-006

05-08-007 Lifting rock shaft

02-08-004 Lifting rock shaft bushing (Right)

22Tl-Oll

05-08-008

05-08-009

05-08-010 Lifting bell crank link

05-08-011

05-08-012

.

09-08-001

22T2-004

05-08-015

05-08-016

05-08-017

05-08-018

22T2-00IA.9

05-08-019 Slide block for vibrating presser

05-08-020

22T2-004

GB97

05-08-022

IA2

Lifting eccentric

Screw

Lifting eccentric connection

Needle bearing

Retaffiing ring

Adjusting crank for eccentric connection

Washer

Nut

Screw

Hinge pin

Hinge pin nut

Lifting

Presser lifting

Vibrating presser foot

Screw

Vibrating presser

Spring guide rod

Adjusting bolt

Guide for slide block

Screw

Screw

Oil seal plate

Screw

Washer

Lifting rock shaft bushing (Left)

bell crank

link

bar

bar

spring

bar

Pes

1

2

I

1

1

1

I

I

I

I

I

I

I

2

I

1

I

I

I

I

I

I

I

I

I

I

2

I

I

I

1

I

I

Remarks

' \

'

25

Page 27

9. LUBRICATING

MECHANISM

3

r-----,

'

'

I

'

I

I

I

I

I

I

I

L-------J

26

Page 28

9.LUBRICATING MECHANISM

No.

1.

2.

3.

4.

5.

6.

7.

8.

9. 22T4-007C2 Pipe connection

10.

11.

12.

13. GB70

14.

15.

16.

17.

Ref. No.

Ol-08-00IA2 Oil pump shaft I

01-08-00 IA3

Ol-08-00IA4

Ol-08-00IA5 Gear for oil pump (I) I

OI-08-00IA6 Gear for oil pump (II) I

Ol-08-00IA7

11H8-008B

11H8-0IO

01-08-002

22T2-0I9 Screw 3

22T2-019

72T8-002Bl Oil pipe I

05-09-001 Oil pipe for arm shaft I

OI-08-004 Pipe holder for arm shaft I

72T2-003

Oil pump body

pump body (II)

Oil

pump cover

Oil

pump screen

Oil

Set screw

Oil pump

Set screw

Set screw

Set screw

body plate

Description Pes

(!)

3

3

3

3

Remarks

I

I

I

I

1

I

-

-

27

Page 29

lO.OIL

RESERVOIR

AND

OTHER

ACCESSORIES

28

Page 30

10. OIL RESERVOIR AND OTHER ACCESSORIES

No.

I.

2.

3.

4.

5.

6.

7.

8.

9.

10.

ll.

12.

13.

14.

15. 22T9-003B2

16.

17.

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35 Chain I

36

Ref. No. Description

01-09-001 Oil reservoir I

GB70 Screw 4

01-09-002

01-09-003 Oil window I

22T9-00IA2

22T9-001A3

22T9-003Bl

01-09-005

05-10-001

GB896

22T9-00IA7

22T9-00IA8

22T3-007C2 Screw I

22T9-00IA9

22T9-00IAIO

22T9-003B3

72T9-0\8

22T9-003B5 Knee lifter plate I

22T9-003B6

22T9-003B7 Set screw 1

22T9-003B8

01-09-006

01-09-007

01-09-008 Bracket (3

01-09-008 Bracket (294) I

GB93 Washer

GB52

GB12 Screw 4

GB93 Washer 4

GB52

GB70

05-10-003

05-10-002 Knee lifter

GB84-88 . Set screw 2

05-I0-004a

05-10-004 Chain hook I

Gasket

Oil drain

Washer 1

Oil-proof cover I

Knee lifter

Hinge

Stop ring I

Retracting spring for knee lifter I

Knee lifter stop

Adjusting

Locknut

Knee

Joint for knee lifter bell

Set

Bracket for knee lifter plate I

Pad

Rubber

Pin

for oil reservoir I

screw

bracket

pin

for

knee

lifter

bracket

screw

lifter bell

screw

for knee

cushion

24)

crank

crank

lifter

plate I

-

Nut

Nut

Screw

Plate for knee liftei bracket

rod

crank I

Chain hook (Upper) I

Pes Remarks

I

I

I

I

2

2

I

I

2

4

4

I

4

4

4

4

I

-

Page 31

11. ACCESSORIES

No. Ref.

72T9-022

I.

22T9-017

2.

22T9-018

3.

01-09-009

4.

5.

22T9-0ll

6.

22T9-012

7.

72T9-007

8.

72T9-020

9.

10. 72T9-021

No.

Double-end wrench

Oil

container

Vinyl cover

Wrench

Needle

Oiler

Magnet

Screw driver (Long)

Screw

driver ( Medium)

Screw

driver (Short)

Description

Pes

Remarks

I

I

I

I

4

I

I

I

I

I

Page 32

12. BOBBIN WINDER MECHANISM

'

.•'

.·

--

I

No. Ref. No.

I.

22T9-006Dl

22T9-006D2

2.

22T9-006D3

22T9-006D4

3.

22T9-006D5

22T9-006D6

4.

5.

22T9-006D7

6.

22T9-006D8

7.

22T9-006D9

8.

22T9-006Dl

9. 22T9-006D

10. 22T9-006D 12

ll.

22T9-006Dl3

12.

13.

14.

20. 22T9-006D22

21.

22.

23.

15.

16.

17.

18.

19.

22T9-006Dl4

22T9-006Dl5

22T9-006D 16

22T9-006D 17

22T9-006Dl8

22T9-006D19

22T9-006D20

22T9-006D21

22T9-006D23

0

11

®

~

~

e "

1

@

Bobbin winder base

Bobbin winder arm

Shaft

Spring

Bobbin winder spindle

Bobbin winder pulley

Screw

Bobbin winder stop latch lever

Bobbin winder connecting

Rivet

Screw

Bobbin winder stop latch

Adjusting screw

Stopper block 1

Fixture for stopper block

Set screw 1

Bobbin winder tension bracket 1

Bobbin winder tension stud

Bobbin winder tension disc

'

Tension stud bushing

Bobbin winder tension spring

Tension stud nut

Tension bracket screw

Wood screw

Washer

~

-~

for bobbin winder arm

...........

•.•

--.,

Description

.

.......

__

bar

__

Pes Remarks

1

1

1

1

1

1

1

1

1

2

1

I

1

1

1

2

I

1

1

1

2

2

Loading...

Loading...