Page 1

AUTO-OIL FILLED ZIGZAG SEWING MACHINE

flmma_ij~

OPERATION

'11**¥*

PARTS

llllll·lll JiiUil

ZOJE

SEWING

!fl

m

MACHINE

MANUAL

BOOK

ft2

fR

fEi

BIJ

CO

~

61

.. L TO.

Page 2

-,

_,

_,

J@"iZi!

••••••••••••••••••

~

~ti

ff'-Ij)i

tli'F M

fJl

aq

Ha-g

ililii ... o o o 0 • • •

1t

~

oooooooooo••••••••

...

.

0. 0 •••••••••••••••••••••••

.-Ijij'

........

••••••••

o o

ooooooooooooooooooo

0

••••••••••••••• 0 •••

o

•••••••••••••••••••

..............................•.....

o

ooooooooooooooooooooooooooooooooooooooooo•······

0 0

••••••••••

••

•••••••••••••••••••••••••••••••••••••••••••••••

o o

0

..... o ...

••••••••••••••••••

o. o ••..

o o

0

•••••••••

•

...... o ........

••••••

o 0 0 0

1

1

1

l

0 0

tt~~~m

'f::;.,if1ttt~3t-········•

--t,

htt'ff··········••••o•••••••••••••••••oooooooo••••···················

)"',

~~·t,t:tt

ft,

~,c_,~~-·········

+'

JJW~·······••o••••••••o••···

+-,

+=

+

+IZ!I,~t~•~*1.1&fr~tt:JiP-l~

+

+~

+-t'

t;l~-tE:Jla9i}!)~

...

ffiiJtllffijJag~~·························

.=,

oo~~~::tJa9~;;-

.li'

If£

t:l

...

ttm.~~~

-tt

!e(J!P

.....................................................

00000

••••••·•································•o••················•••o•••············•ooo

.................

~

jJ

iJiJ

..............

iltt

o•••·····················•ooooooooooo

· · ·

············································

···· ····

...............

..

o

....•••......................•

oo

ootOOttooootoottt

oooooo••••••···············

·

···········································•

........................................................................

-;;-

0 0

•••• 0 •••••••••••••

0

••• 0 ••••••••

o••••········••••o••······················

~.§[

)~i}l];;

.....................

JO

.

....•.......

0

•••••••••••••

•

•••••0••0•••••••••••••••••••••••••••••

··

····························•o••••••

o

oo•••••••

·

·················••oooooooooooooooooo

··

·················•••ooooooo•••••····

OOO

t

toooooooooooooooooootoo••············••••ooo

·

····

·······

·································

0

0

o.o···

•••••••••

•

••••••

0 • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 5

-·

···•ooooo•••··························

..

········••ooooooooooooooooooo•·••••••••o••••••

000

···············o··

0 2

2.

l

2

3

3

4

••··············

4

4

s

5

6

+

)"',

tll.~-ftiJ.*jfB:M:~ii!J':;J'

+n

"'

a-m:aag:iie~·········o········

= +'

= +-,

= +

-+-

--

-~$1*~~~.....................................

Jl..f!'~~:n;t~llffi!ftt:J~Jil

=,

tllHIY:J~i?

.=.,

±.~tt*~~····••o••························•o•••••····

..........................................................................................

·•••o••····························

·

·····

·

·····················

·

···········································

·

···

·

.

........................................

.................................................................

··

- I -

6

·····

·

·······

·

·······················

················•o••••••••••••o••••••

6

..

....

7

7

9

9

Page 3

CONTE NTS

1. Applic.

2.

Secure

3.

Caut

4.

Lubr

Se

5.

6. Inserting

7. Replacing

8.

Tbread

9.

The installation of

I 0.

11

. A djustiog

12. Adjusting presser foot pressure ............................................ ..................... 4

13. Adju sting needle

ation

ion

ication ••.•

lection

Thread

....•.......•.••.••••••••.•••••••••••.•••.•.••.•.•••.••.•.••••.....•.....•.•.•••.•......••.•••••••.

operation........................................

befoe operation..........................................................

••.•....•••......•••..•••.••......••••..••.•.••••...•..••...................••.......••.••.•• 1

of

needle

of needl...........

bobbin

the bobbin case .......................•...................••...............•..........•..•..•• 2

surface stitches ....................................................................... ....... 3

stitch

and

t.hread .......................... ......................................... 2

...........................................................

.................. _

the

bobbin

length............................................................................. 4

thread

.,

....................................•.........•....................• 2

..................................................................... 3

tension ................................................................ 4

.................................................

.

....................

...

................

1

1

2

14.

Regulate

15.

Adjust

16.

Adju.st

The adjustment

17.

18.

To

mount

Assemblage

19.

20.

2l.

22.

23.

Mont

Modes

Maintain

I\1ain

knee

specification ................................. .................................................... 9

the

length

bobbin

needle position ......................................... _ ••••.•••.•.....•..

of

thread

thread

of

belt cover .................•................•...................•................... 6

lifter ....................................................................................... 7

seve

ral

of machine

and

tendion

tendion

of

horizontal distaoce ...................................................... 6

uowinder ........................................................................ 6

sew

ing

stitch

.................................................................................

of

take-up

...................•...........•..................•..........•.... 5

and

application

-

n-

spring .............................. 5

••.

•••..•••••••••••

of

accessory ................... 7

5

9

Page 4

-,

I'll~

I

APPU:CATIO~

iJE~Li~Rlfl!Q~~-

~M.

~-~~~~~-~~-§~aR~.

!i<lll

7

iilim

!1t

~ T

~41<i!HH~tl~~~~i!

This

series of :rigzag

zigzag, embroidery

and thick material f

towels

and

waU

Ex

tra accurate mechanical transmission and

control

.wing

range

embroidery stitch.

=,

:rt:i:lii'F·~

2.

SECURE

I.Jift!A

OPERATIO~

9Uli~;&

II<J:JIJ~.

lfJln.

H

IV

~fll'fl

sew

and

lockstitch

or

garment, bed articles, shoes.

carpet.

unit

asaue

~lftiJIHHfiSifRJ

¥.li11l.

~~IJ$~J'JIIIllill4l

.

ing machine

on

many

\J~

1ilifM;

2.8!1ftln.IIIH,

3.~~~lilllifllf!!:

fiJI!!<.>~

~

ti

this manual \'ery well before operating.

'\\'ell while

while urlfi:dg soe

needle plate,

thread

) . ~

I'll

<1!.

Jil

*

~

4

.Vt

~!i'J!ltJ.

;

L) The operator should

2)

All security equipemnts should be

3) Turn

and

no

'l<i:~~,e.i>ji~l§~~;

(~u:

tJL

tt.

JJi,llll,

tl,

i:IH

G:.l:X

ll

ft:

A~

1£

ii!Z

w r It! tit

running

off the

feed

operator

liti

!J..

~l'l~

:X:

be

the machine.

DOWer

aooe600r'.es

d

og

and

is

at

:

ft'.e>ll!II'V!II:tt;t:AJAilt

rtained. and U!'l

or

draw tile l)o

(like

.-!le.

bobbin sase). win ding

the workplace maintalning

the machine.

4) Maintenance

should

by

be

5)

Th

managed

carried

e electricity equipment should

by

and

adjustment of the machine

by

professional teChnician

wireman

or

ptolessional technician •

't

rll.

~!!~

~

is

used to

thin. n•wdiun

knee-

kinds

or

perlect

~ffl

i$1.19l~Jfi.

#!!f.

illl'f.!f

i~Ul

.(!If,

£.i>ji

de

i$Wld

ILxed

very

wer off.

prtSSet

be

fooL

managed

1)

Please clean

oil belore first

2)

Check

be

fore first

3)

The upper

facing

the

11!1

'

til

R

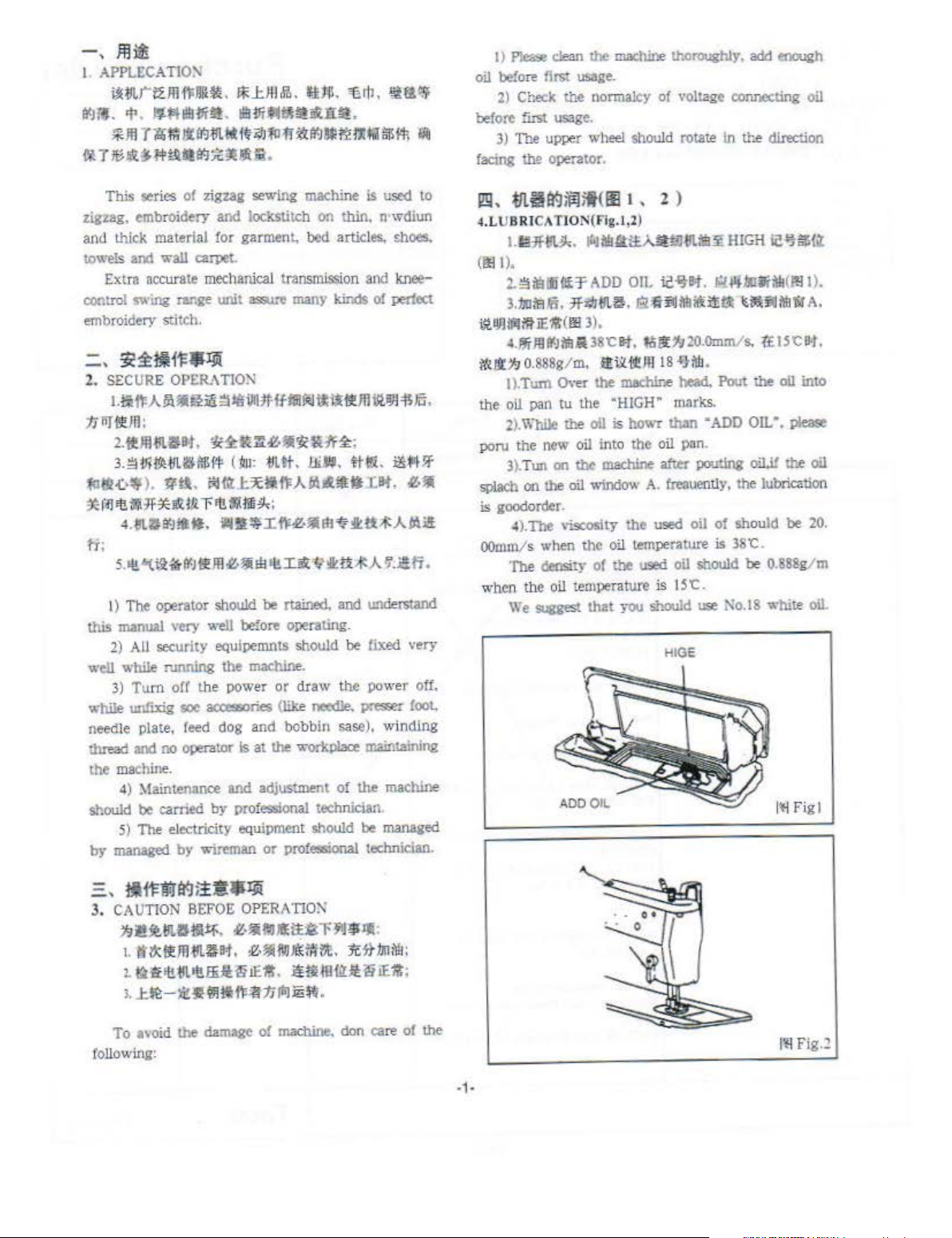

~.LUBRICA

!.13:/fVI.:'h.

(!Ill).

l.~il!llliflf::f

3.!XJ~.fi.

ili.LJil

ifil !It

iUWE

4./jf

JI1

t(<Jjt)\7

O.

SSSg/m,

I).Tum Over the machine head.

the oil pan

2).

\\hiJe

po

ru

the n

3).

Tun on the

SPiaCh

on

is goodorder.

4).The

oomm/ s when tile oil temperature is

Tile

the oil temperature is 15 'C.

when

We suggest

the

machine thoroughly,

usa11e.

the

normal

cy

of voltage

usage.

wh

eel

should rotate in the d.irec'Jon

operator.

tt.J

iii!

if(

Ill I ' 2 )

TION

(flg

.l,l)

tloJii!IJt~WIIlil!lx

ADD

OIL

iC

~".

*llllVI.l!J,

3),

iltJili!.li

tu

the

the

ew

oil into the oil pan.

the

oil window A. freauemly, the lubrication

>iscosity

denSily

J!i

'lfi!il

llllilll

it~

38

C li't, f&gfJ(; 20.0mm/s.

ll!\i£~11ll8

"HIGH" marks.

oU

is llowr

m&.hine

the

or

the

that

you should use

ol}llb.

than

·ADD

a!'.er pouting

used oil o! should

used

oil should

HIGE

add

enough

connecting

HIGH

~lli.IIIJilllt(l'!ll).

~!!U~llll11!

Pout

the

OIL·.

oiJJf

3S'C.

be

No.I&

oil

iC't~

A.

1'£

1 S

'C

1J.t.

oU

into

please

the

oil

be

20.

0.88Sg/m

wb.ite

oU.

I~Fig

l

.=..tti'FlllJtl9it~-~

3.

CAUTION

.l!Ji!Stlil8

1.

1t

t~

l.

J:.

To

avoid

!ollowinJI:

BEFOE

~~~~.

IX

~rn~~".

E'll.~~~

~-)j!·~-fll~;lj

the

OPERA

£•jjj

iVl

&Mi

~~$.

damage o!

TIO:\

Jltt~l'

twI

ll<

ill~

~~W~~

(ll]

~ft

.

madtine.

Jll$ Jl;

.

'i'

Mr

1Jilm:

N~~:

don care

of

the

.

1.

l'f!Fig

.l

Page 5

1i.

H~((.J~ill

S.

S

£LECTI

Mll!

~~IRI:t<

iil!l~!l!!

ON

OF

::r-lll!SU4.

1:

fit+

ailtlll m e{r

~EtDL£

AN

i41'fJin.

'l'~tt

D THREAD

tt·

&

111~.

it<

)q:

*+

1ft!

1

Make

sure its long groove faces toward the

front.

Tighten

-t;, d

needle

•L)lf(IIJ

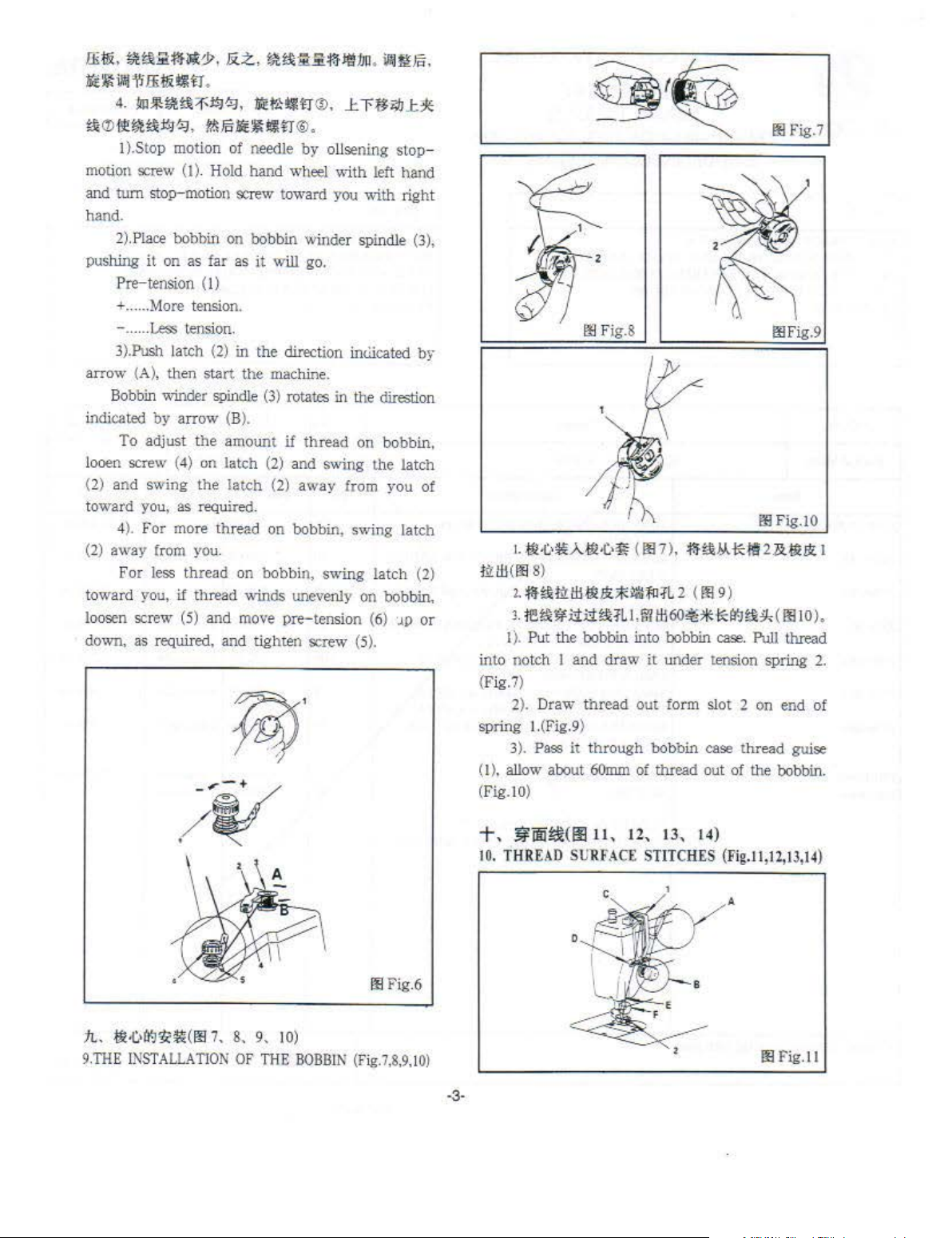

7.REPLAC1:-<G

set

screw

4, Ill

5)

BOBBIN CASE

.

I securely.

(Fig.4,

S)

~UIItt~

lll.tt.k'T

(1/lOOmm)

mtl

~1lf

nJIII

:lt

It~

!lUll~

Select the apropriate

aceording to the

120

#10

l910- 05(135x9)

l'fJ

different sewing material as

60

#12-

116

(8Q-l00) (110- 120)

tt~

thre

ad

following:

Applicable

of

Max

Needle size #12-

(1/IOOmm)

1\eedle

w:etial

si2e

thread

type

ltiJld

of

Thin

l20

#10

~12<lium

191Q-05(135x9)

hea;-y

rntttrial

60

116

(80-100)

Other equal suitable si2e thread usable.

,\

,

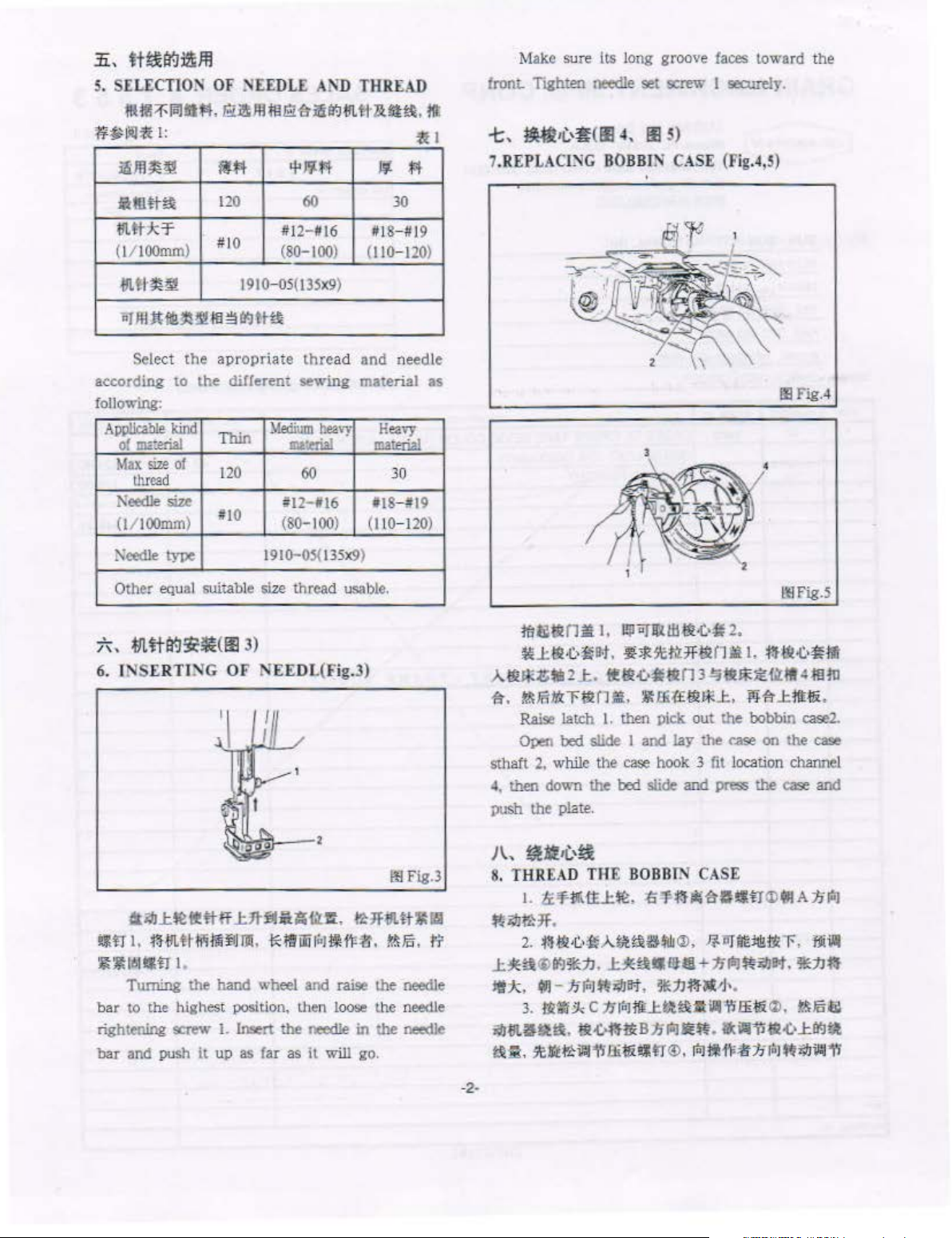

t'ltt((.J:it~(~

6. TNS£RT1

:-JG

3)

OF

NEEDL(Fig.3)

30

*!8

- #19

and needle

Hea>-y

material

30

tl8-1!19

(1

10-120)

II!Fig.4

3

4

00Fig.5

tt!fiH!!

nit

I.

1!jl

UJlf,(

lfi~·Nf

~.J:~·D15D<t,

A~~•2.t..~~~~~f13~~*~~~4mm

{i'.

~ffl~~~nm.

Raise latch

Open

bed

Sthatt

2,

while the

4.

then down the bed slide

push

the plate.

~*9G~:Tftf<f1iR

~~~~*.l:·

!.

then pick out the bobbin case2.

slide I

case

and

hook

lay

2.

I,

f.U.i4)~tilt

N~.J:~~.

the

r.ase

on the case

3 fit location channel

and

press the case

and

Jl.,

~Ah:-tl

8.

THREAD THE

l.

$t~tHf.

2.

L~~~~*~

~ttx.

3.

~m_a~~.

t.t

~,

-

2·

ti

'

Hl

~~-t,.gMUil!S~al.

M-

ntol

11<::1!1.

S'ea:ltci!\1

et~.J:tetfttff

!UTI

, f.lin.ttWi!ii'lJlili.

~:llt61ilt

r

1,

.J:"'fUU~IU

*ffJiiilul~fl!.fl,

i, I*:Tf~tt~flol

Turning the hand wheel and raise the needle

bar

to

the

rightening

bar

and

highest position. then loose

screw

1.

push

Insert the

it

up as far as

needle

it

will

in

go.

the

the

00

Fig.3

t~Fa.

f'i'

needle

needle

'f:E.J:It,

BOBBIN

:6'

'f

:r.f

Ill

CASE

ftiUUJ

<D411

A 1i

J1.1!Tfii!JI!!I1ir.

. .J:~~•~a+n~~~-~~~

ftilllat.

c

ntaJJ!U~tJ<

!!l~~~B:Htolll!Ut

~

ilit!U.UT

*~f.l-'J'.

:Il!:!/4~.ffil!i

.

®.

taJ

ltili:I!:H

a>.

~!66:

lll:il!l'\1ll.C•.J:i!C.J~

ttl

ft

i\fJi!\1

iOJ

ffi~

'1'1

Page 6

!E:fli.

t'ttl-'l:r..~:P.

it

~

il!ll'i

JJi

:f1i

~ ~.

4-m*t't~~~~.

tli

a>f!l!~

~~l~.

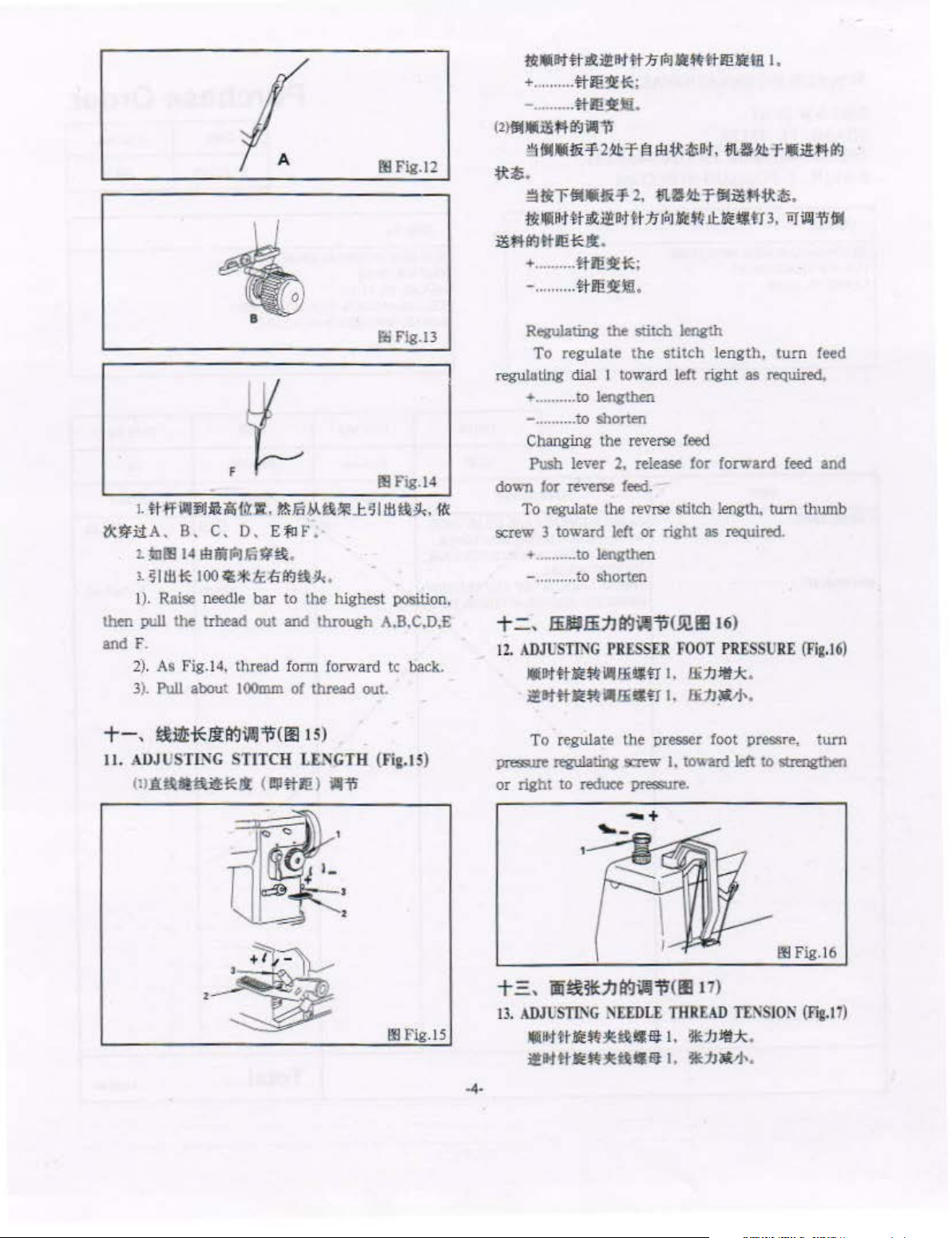

I ).St

op

motion of needle

motion

and

screw (

tum

stop-motion screw toward you

Ji.:t,

tH~:;t;l:r..Jt!ho

~~~~®.

1'1.\f.i

liUUUT

®.

by oUse

1)

. Hold hand wheel with left hand

.

~r~~~*

ning

"IVith

hand.

2).Place bobbin

pushing

it

on

on

as far as

bobbin winder spindle

it

will go.

Pre-tension (IJ

+

......

More tension.

- ......

Less

tension.

larch (

2)

3).Push

arrow

(A),

th

en

in the direction inwcated

start

the

machine.

Bobbin winder spindle (3) rotates in the direstion

indicated

looen screw (

(2)

by

To adjust

and

swing

arrow (B).

the

amount

4)

on latch {

the latch (2)

if

thread

2)

and swing the latch

away

on

from

toward you, as required .

).

for

4

(2)

away from you.

For less thread on bobbin,

toward you,

loosen screw

down,

more thread on bobbin , swing latch

swing

if

thread

(5)

as

required, and tighten screw (5

"'inds

unevenly on bobbin,

and

move pre- tension (

).

iii.J~f.i.

stop

-

right

(3),

by

bobbin,

you

of

latch (2)

6) '.lll

or

li!lii(

into notch I and

(Fig.7)

spring

(1).

(Fig.!O)

00

Fig.S

I .

.lfl.f.•~A..ftl·N~

J!l

8)

2.

:13-tliti!tll.ftl.!t;t<ll!l;fo'fL

>

lf!!'(~JtittliJLI.m

1 ). Put the bobbin into bobbin

2

).

Draw

thread

I.

(Fig.9)

( J!l7 ),

i:Jj60~**~tlg..

draw

it

under tension spring 2.

our form slot 2

:r..tli

2 (

00

»-.

9 J

case.

00

Fig.9

00

Fig.!O

*Hf2}l.ftl!IU

(

m

IO

PuU

thread

on

end of

3). Pass it through bobbin case thread guise

aUow

about

60mm

of

thread out of the bobbin.

J.

t-,

~

i!ii~(l:l:Jll,

10.

;h..

9.

THE

~·

t>~~~(

I

NSTALLATION

J!l7

.

8,

OF

9,

THE

10)

BOBBIN

J!l

Fig.6

(Fig.7,8.9.!0

THREAD

)

-3-

SURFACE

0

12,

13,

STITCHES

'

14)

(F

ig.ll,ll,l3,14)

A

00

Fig. II

Page 7

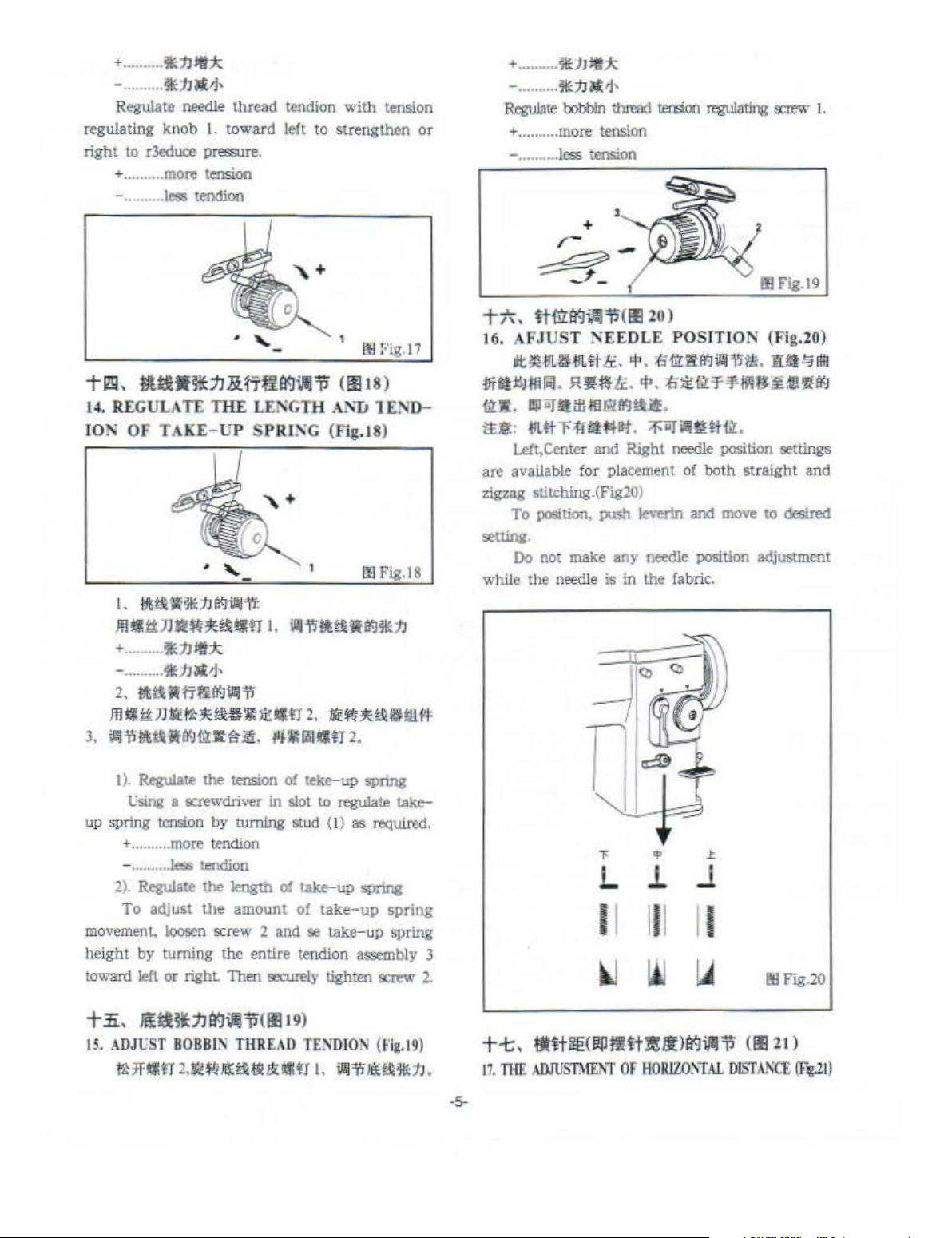

A

~

8

'~

].

ttffillliiJ~if;!j{!):~.

!X~i!A.

then

and

B. C.

t

~lll14

l.

sltll~

1). Raise needle

pull

f.

2). As

3). Pull

flliilr.JGf#~

IOOiU:li:~~~!)c

the

trhcad

Fig.l4

, thread

abou

t 100mm

D.

bar

out

~

lf;bl.f&~.t~llll~:il..

E~F.

.

.

to

(he

highest

and

through

fo

rm

forward

or

thread

00

Fig.12

&i

Fig.l3

1f1

Fig.14

position.

A.B,C,D,E

tc

out

back.

It<

11<

llill<ttt

~i!

B>t

tt

:17

ioJ

a~

+ ..........

-

(2)

1!lJ

.lllli!U~

"'!fjlliJiJ&~2~'f

.

.v:~

~ttrl!lllliJ&"f

'It<

itil+~

+

-

Regulating

regulaUng

+ ........

- ..........

down

To

screw 3

+=,

12.

ADJt:SIDG

#21!~~;

........

..

ttll!~li

(l(J

illll!

~

A<t

tt

mt

ttll!

*ll

......

....

tt11!1l*;

..........

~Hu~l!i.

To

regulate

dial

..

to

to

Changing the reverse

Push

lever 2, release for

for rever.;e

regulate the re\'rse stitch length,

toward

~

..........

to

- .......... to shorten

Uffi1ltr.J~i1

.

E!lllil!~H·t

2.

!ILD~'fl!lliti.M.V:~

a!

O;f

H

:17

J

ol

Me$'¢

·

the

stitch length

the

stitch

1 (Oward left

lengthen

shorten

feed

feed

.

left

or

right

le1\i1hen

(.!4l.

lllt6

PRESSER

FOOT

Jlllllttti1Etti.IIF.Ii*ltr I. .li1l

.i!tt#rft!lilUli

lltr

I.

Ei1l~J-

tt

i'l!llii!tll

,

tltl5~

1

1Jlf

IUT 3,

length,

right

as

forward

as

required.

)

PRE

SSURE

l!:k

.

.

'·

'flllii!

*'l~

.

iiJ

\Ill

'1'i

1M

turn feed

reQuired,

feed

and

turn

lliumb

(Fig.l6}

+-,

II.

t!tl2HE

AUJUSTING

(11

.«~8tl~*ll:

ffttr.Jilll

iHiil 1 s)

STITCH

(

LENGTH

I!Pttli'!!

)

ill~

(F

i&.IS

1!1

Fig

)

.15

To

l)reSlSW'e regulating

or

right

+

.=:,

lfi~~:htr.JW~

13.

ADJt:STING

,l(jllloftl'JUH~tU'll!i

i!P<ttt

-4-

regulate the presser foot

screw

I. toward lett to

to

reduce pressu.ce.

C

II!

11}

NEEDLE

lfUt~tHI~

THREAD

I,

~:h~;:k

l,

~JJ~

pres.<~re,

turn

strengthen

00

Fig.l6

TENSION (Fig.l7

.

.

)

Page 8

+ ..........

-

regulating

right

+

-.......... less tendion

~:tlltl*

......

.... ~ :1J

Regul

ate

knob

to r3educe pressure.

..........

more tension

llttl'

needle

l.

thread

toward

tendion

left

to

with

tension

strengthen

or

+ .......... *JJI!I;k

-.......

...

~:tJlll!J'

Regulate

+

- .......... less tension

..........

bobbin

more tensi

thread

on

tension

regulatiflg

s::rew

Ill

Fig.l9

1.

.

...

'

t-l!!l,

14.

ION Of TAKE- UP

3,

up

movement. loosen screw 2

height

toward le!t

~Ul.*.1J

lH'f~

REGULATE THE LENGTH

S

L

jjtt!l~~

m~ttn•~~~~nt.

+ ....

......

-

........

2,

ft~

Jll~

ttJ

lllli'ift

1). Regulate

t.:sing a screwdriver in slot

Sl)ring tension

+

......

- .......... less tendion

2). Regulate

To

a<ljust

by

:t

~:tl

..

ilr:

JJ

JJi9~1'i

ll*

.

:

,]>

Rftfi(l(J iiJ'P

J.rl!tk~~~'Rili!ijl

~ifli<Jill:

....

tuming

or

=-8'~.

lhe

tension of

by

turning stud

more tendion

lhe

length

the

amount

the

entire tendion

right

Then

'

00

17

tt-l~

i5' <11

118)

Al'\TJ

lEN

D-

PRI

~G

(Fig.18)

IJI

18

~1'i~~Rii9~:tJ

tJ

2.

ME~~~umf<!'

l>'i.*161~fJ

of

of

and

oocurely tighten

teke-up

lD

regulate take-

(I)

take-up

take-up

se

take-up

2.

spring

as

required.

spring

spring

Spring

assembly 3

screw

2.

t-7\,

1

~-~~~.~~~~-~-:ts~fi!:r~m8~~~(j(J

-ill:

~~

are available

rigzag stitching.(Fig20)

setting

while

ttura<Jvrrp<lll

6.

AFJUST NEEDLE POSITION (Fig.20)

llt~lll~tll.tth:.

:5!

,

1!11

iiJ

ft

I!H!I.el

=

m.ffr~-~~

Left.Center

To position,

.

Do

not

th~

and

for

push

make

needle is in

1'

L

20

>

ojo,

:ts

fi!:§:pqiJ.Ilfj

Ji9

~it

.

.

~~-tt~

Right

needle position settings

placement

any

oi

le'-erin

and

needle position adjustment

the

fabric.

"'

J.

both

move

.t

..1

.

straight and

l\1:,

to

Ji~!.'illll

dEsired

II Ill II

Ill

~

~

l.4

Fig.10

t-

2i,

liUl*.1Jtt-l~i5'

15.

ADJt.:ST

l'il7H~

n

BOBBIN

2.

rt

tli

(

11!

19

)

THREAD

»);~If!

TE~DION

1.t

1:11

• r

1.

il.1!

i'i

(Fig,l9)

IIi':

~

•J

tt:IJ •

-

5-

t--t,

17. THE

iJtttlie:(llflflttMCfltt-l~'P

AMJSTWENT

OF

HORIZOI'iTA1

(11121

>

DISTANCE

(f~l)

Page 9

~

t:

lf

ill :tl

dli

l1rst

(I!J

I*

tUI!N; - AHi:llt,

ii<i!rr:

(1)1'}:

Jfllttlti

(2)

r.fl!lftf-l&

(;)tJ!ltflttli;fit~U

(4)

1'}:1ff!U~fft~tr

ISJ

.IItltlit~lf!fi'f

16J

~llU~f!tt~fl(tJ.tr

'¥

'¥

3l1i

~

fl'£1iltf 2;

¥:

0 flt (

2;

I;

3 ~ B

1.

ll!l

A

@ft

!i'lft;

);

Ill

Fig.21

1IJ

~r

-t

ft.,

&:ffi.ii$!J~il

19. ASSEMBLAGE

@I!LI::

t~.>

1J

l'i'

~t

fg

.!li'f:

On

with

belt

t;

nder

covenn

fJ!'F~

~

n.

~~.ttL

the

table:whUe

co,·er,

the

tabl

the

wheel

tighten

00

Fig.22

<

lll2

3)

OF

BELT COVER

V

~&:flfitl&:l!fD"'ll~

11

Hll!ri

Fl!.

tll$B'~

the

V

thge

screw.

e:

after

the

assemblage

and

belt

should

(Fig.23)

it

~-ltUH

type

belt is

rotate

-

ll~.

I

Jill

line

of

belt

freely.

,

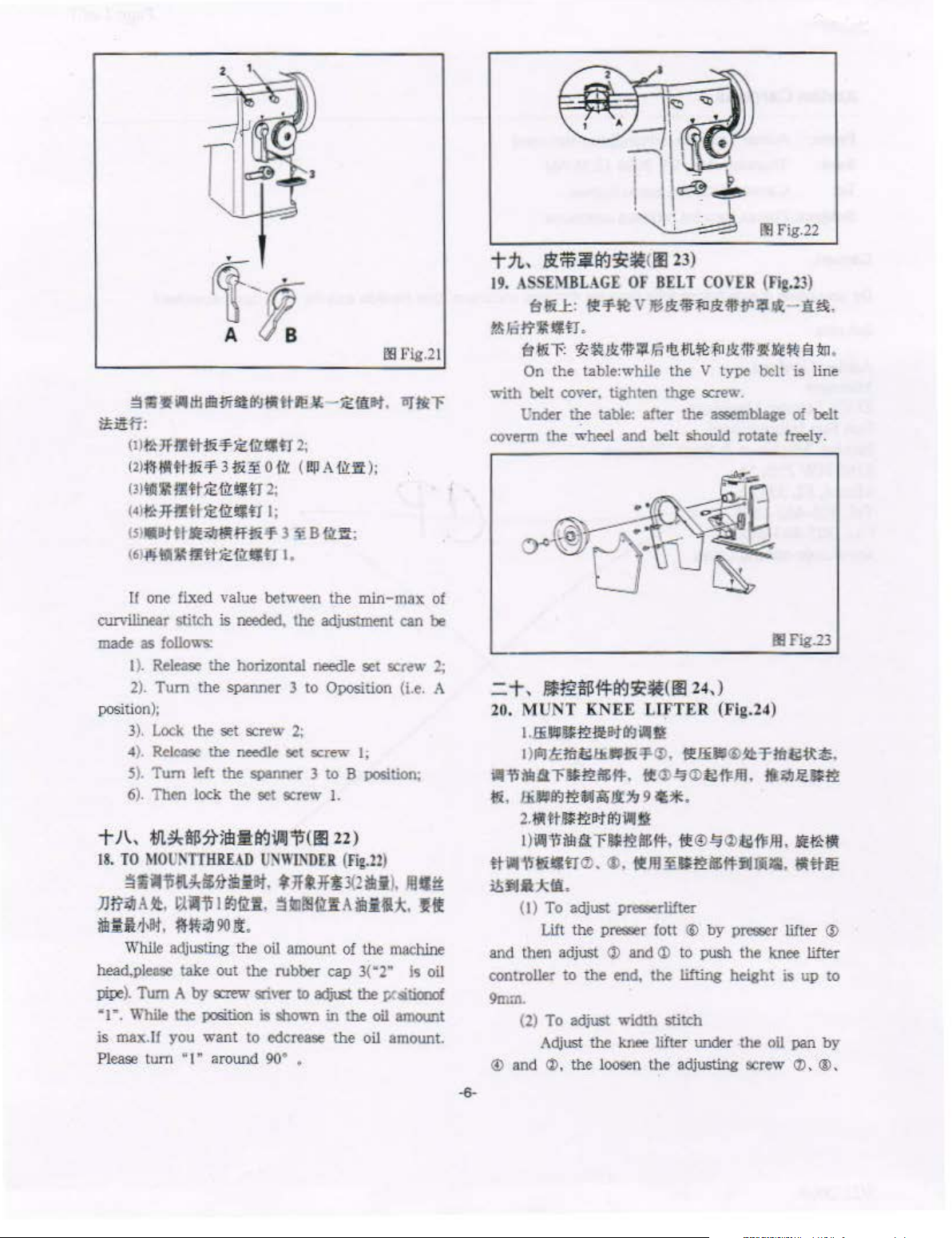

U one fbced value

curviliru!ar

made as follows:

position);

-t

Jl..,

18

. TO

~iUfiMJ7tllll

sti

tch is needed,

1 ).

Rele=

2).

Tum

3).

Lock

4). Release

5

).

Tum

left

6

).

Then lock

t11.

:9t&ll

MOUNTT

the

the

the

the

~;II!~$!JlJIJ'P

HREAD

nrr~A~.~-~~~~

iili~IH,a·J.

While adjusting

head,plense

pipe

).

"I".

is

max.H

Please

Turn A

While

turra

l&ft~

take

out

by

s:rew Sliver to adjust

the

position is shown

you want

..-1"

arotu1d

between

the

horizontal needle

spanner

3

to

set screw 2;

needle

set

the

spanner 3

the

set

screw

U:'<WJNDE

i

&t

,

UU:~

.

~~mm~Ailll

90

~.

the

oil

amount

the

rubber

to

edcrease

90• ,

the

adjll$1ment

ODOSition

screw

to

B position;

I.

!I

Il22)

R (fi

3(

21lll~

of

cap

in

the

the

min-max

set

can

screw

of

be

2;

(i.e. A

I:

g.22)

l.

Jlll!t

••*·~*

the machine

3(

"2" is oil

the

r.r<Sitionof

oil amount

oil

amount.

Ill

Fig.2J

=-t

,

~~!JJ#$!J3i:!l

20. MUNT KN

1 •

..$.1lll!!H'll1£1ltll9

I )flil l£

tlill:J:Illl~l!i

~~~&r~~~~

l!i.

IJi.llffltJJ!l!

2 .llut

lilt

l)illli'iMiltr~t'!&il~.

~illl~lli~U®.$.~J!I~"~~~~~~

EE L

$ll~

lil:

~lit

Jl9

(i

ll24

TTIT

ER (Fig.24)

ill!l

:J'

Q),

fi!.BiJfl

. ~a>~a>

, 9 •* .

\tl

t.t

ff@~a>~~J!I.

,)

~~ "fffl.ti:tl:~

~~m

.

*~~"~

.

.

Ji

tkl!t

!*tt~

i1ifilil:J;;:Ii.

(I

)

To

adjust presserlifter

Lift

the

and

then

controller

9m:n.

(2) To adjust

Adjust

®

and

<21.

adjust

to

the

the

the

presser fott $

Q)

and

<D

end,

the

width

knee lifter Wlder

loosen

the

by

to

push

lifting

stitch

adjusting

presser lifter

the

knee lifter

height

the

oil

screw

is

up

pan

<2J,

<D

to

by

®,

-6·

Page 10

Push

the knee lifter controller to t

stitch

is

up to Max.

he

end,

t!

."

m Fig.24

=

+-'

20

. MODES

PPLICATION OF

A

ffl~~~ffi!111

flilll1i:

Jf

.

presser foot, needle

using multi- function ones.(Fig

Jl

fitl

~~

j'jitl

~

ll#f4:89fii!Jil

OF

SEV

ERAL SEWING

STITC

H AND

ACCESSORY

(20U33/ 43/ 53/ 63 )

l.

][!ii

;!t!ll~ffla91l:~.Eii!111,

,

~~~~*'1-Jf*fiE~.

iiHr

.JU!il't.

"#

I . Linear

In care of linear sewing, using

While do linear

flut iil

ffli!

iill~".

se"'ing

H:llii.!1.iti*'fJf(

U69lli

i1!1

~

o,

~u:~J:~.mffi

and

feeding dog is

.25)

sew

ing,

the

IE25),

~~~ft

*ifllt~-wl

.

l!l;i.

~l!i.

the

linear sweing

better

hori2ontal

width

width

It*

.

~ ~

;

nt

than

-sb,>uld be adjust to 0 position,

unit

with

swaying

can

be

used

in

l

ocking

with

feeding tooth.

needle

spe:ial presser foot. needle plate

rack

combination wish

shaft can

the

of locking

swaying

be

used

in

linear

needle

comb

and

locki

ng

shaft

rack

of

ination

material

L,~::.~

l~~~

llilFig.25

2.

$!]~

2.

Embr

oidery

<V

<IZ•iiiltl!

li(fUB

~~M

·

-

ft

:k.t.

J

iili:E~

il!l'i1

,le:§:

mi!:~:!E

~a9Jfl7;1J

tl!Jil;~J.>U

~&

be

min-m

position

make-the

sway

feeding dog, then change

your left hand,

plate.

between

frames, otherwise, may

breaking or material creased.(Fig.

ofl£.

#illlflf~~lillmllil

.

®

l!P

"F

ffi!!11.

»:llii;fo

® mti ·

Hn

iliT

t

l!i

1L

.P

®

l'ill~fll?

~-*4~illf

Preparation before embroidery

~

).

H should be noted threat any

made

ax,

of needle.(

2). Dis:l1arge

3). Hold firmly the

4). To

fo

!!lll~

.

< m

at the

and

the

horiZontal needle

set

the

will

component control

fig.24

the

tum

make sure

int

ernal and

~*'I-*.

~~""'.

ti

adjust

the out

ffl

'HI!

til.

~

~t4lllll7!:,

26

J

vertical

presser for and needle plate and

end

needle

the

)

if

w

ith

of the

from

'to

stretchtightly

external

be

cause skipptng and stitches

24)

,1fli'-fflH~$1lm

~J:.tJl.U:~

a

c.111al~iill

-l!iMUft'Jiii:.!lt~,

free

distance

knee- controlparts ro

the

movemem

embroidering plate.

surtace

the

hoks of

26

)

.

J:.~.

regulation can

between

distance

stitches with

the

embroidering

to 0

of

the

needle

material

the

1!!i

-7-

Page 11

l.~

U

J,

ZTPPER£0 SEWING

alti'lilt\lll!Ul.Bi!lf(

J!l,

#

JE~-fTB

~

ill

!I

A !It,

iiJ~!Il'flll28

nus

mode is preferable to make

pr~r

stitches

then

iool (see

more

acoessib

release the screw

,

~27), ifH~XI!;f11

illl

i'i!li

.llll

Fig.32

) in a

le

to

B.

and set the needle to the p

needle to left

f

oot

The

sewing.(Fig

mode

.37)

and

right grooves A of the presser

is

exJ)eeted

.

if-I!L

tHH!ii

<P

JU'I'1;~

use

bid

to

the p

roj

ectiong stitches ,

regulate

resse

to suit

the

r foot and set the

for

00

Fig. 26

i1i

~

:.tl

~

.i$

~£.

.

of

:r.ippered

make

the

presser

foot

the foll6"''ing

In this mode, the hem-wrapping

be

used

as

we wish (fig.29)

Remove the multi-functional presser foot

pre$eT

foot.can

and

replace it With the hem- wrapping one. This is

al$)

a

mode

the

can

cenrtal

be

effeded

of linear sewing

positio

n;

the

.(Fig.30)

with

the

needle

set to

hem-wraJ)I:li.ng operat

Ill

Fig.29

1!1

Fig.30

ion

4.

8itlll

4.

HEM-WRAPPING

~

i:!lst

Jt\

Ill ~

ill

Eli

Ill!

~~~~~~.~L~i!l

m

;r;~<Pfiil

.

4tiiJ

I;J.

i!tfilll3o

!'>iO

DE

( Ill 29 )

.Bi

.illl

~~i!let

Ill

Fig.27

Ill

Fig.28

,

Jt\II!

K»~.~

.

5.

E!lffi

S.

STEM-W

iiH

'i'Sff!I&

t+

~ (

111

31

r*J

,

re

-

~l'Ji.11l.A9tll!fU~

:i!tfi~.lf·

During

wrapping!ll

foot

needle

be

pu

t into use(fig.31). the neel

to

position

3

mm,

central

set

RAPPING MODE

P.t

,

li'H"J:'!i'ffl~@Alfli!lll

), ttfl£i1Uf'i'

( lti 32).

the

sewing

ode, the s

plate

and

and

and

then

pecial

material feeding tooth

the horizontal

fiil.

tllttll!fl

.ii

Silt

.Bi.llf~

*it A ,

wi

th

stem-wrapping presser

de

is set to the

needle

run

the rougb.er

through the small groove A on the stem

presser

be smoothlY conducted

foot so that the sewing

..

of

this

"P

the

-wra

.

ttl!i

3I

3

mm

it

stem -

should

distan

thread

mode

. :ili ·

Z.

llJ'

IiJ.

ce

pping

will

Page 12

>.

~l$!il(lli

6.

OECORA

AJH~~t£,

1!J

Ill

I!Hnm

If

the

can

be hreely changeable

distance skillfully controlled,

decoration

7.

:Jt

ft!!-~~

1.

OTHER

The

machine

remo,·e

around

use

lim

the

should

~~

33)

TIO'i

SEWl:-IC(fig.JJ

.P.

:6{1tJtlll'c&!!M~<l231llll*i!!·

361¥l

m~.

left,

central

sewing

MODES

and fiulf. which may

working

be

oiled

and

and

will be well achieved.

lll!ilit([ll34)

Of

PRACTICH

shou

ld be cleaned periokicaJJy to

paru.. A machine

freQuenUr

~~]

right

needle POSitions

the

horizontal

the

patterns

SEWI."'G (Fig.H)

have

)

needle

of

ffi

Fig

.33

accumulated

in

continuous

.it

the

=+=.;Jl

r!

{l'.}~if'

22. -"'AJ:-;TAI:-; OF :vtACHlN£

~~

!FIIJ;it.J'I:I'\'1

~•-*

r,;m~ii!lta.

e,·ery

accumulated

loot.

machine

cleaned frequently.

=

23. MAI

~-~~w~~~

mitf.

You

should

day.

Remove

around

llEI!dle

+=-

tf"i!l:~~:

~~~~: .ll!JII~

l

ll.ft£~:

'!'lll'EJ!~Il:1Ull!

1:~:

I

Ift~Ji;J~)jl::

)\i

plate.

in

continuou>

.

;E~~*

J>; SPECIF

V M{iffe 74mm

lf.S!JOJ:W.l!:

JdHe

:

la,ili!!l.i!Y!:

Tte

mode

Tt.e

mode

Tte

specification

The

height

pper

U

The

The

The

wheel:model V

height

max

highest

~.

*£.I!*

x~~~

trotect

lint

the

!eed

your

machine,

and

nulf whi

working

dOi

and

use

should

~f&

ICATION

~lllfli'<

!!!.~

I

:

6.35mm

2llmm(20Ul

130mm

Ji!.lllf

;;'<

~lllf~

oi

stitches:see

of

machine:see

of

of

hand

of work: 130mm

of

needle clistance:see

sewing

43:289mm)

the

the

needle:see

lifter

presser fool:6.35mm

belt

speed:see t

If. ·lkf.ii:t. liH<

llt~.~~.~~

pens

rotating

enclooed

wheel

and

ch

may

like presser

hook.

be

oiled

enclooed

upper

74mm

the

enclllosed

he

enclooed

clean it

hace

A

and

figure

~

11.

· ENCLO

#~

Model Stitch

ZJ20U93

JDH.iW

00Fig.34

SED

FIGURE:

H~lM'l

mOdes

Ma'l:.of speed

2000UI#

V\N

2000.r.p.m

0T.Ii!U!

~

Max

.horizontaJ needle distance

~

*

-

9mm

·9·

tt

1P..

~fi:~Jil:{f:J!(

Length of

stitches

Smm

114!!!;!

ffi!Wt%71-il':i

Height

of

9mm

Jl

lifter

Page 13

·1~-¥M

PARTS

LIST

Page 14

FACE PLACE, ARM TOP COVER, J.RM

SIDE COVER

ff:~

NO.

PART

1

2

3

4

5

6

7

8

9

lUi

NO. QTY

DESCRIPTION

Page 15

THR

EAD TAKE-UP, ARM ,

·-- - - --- - - -

HAND

-·

WHEEL

rr

/•

~17

OESCAIPnON

GR1431/1

1

GH200-8

2

GH143-8 1

3

GH141-8 1

4

5 GS166-8

GH160-8 1

6

7 G0511-8 1

GA143315-8 1

8

G$160-8 1

9

_ G§!6..)-§. _ 1

_ 1Q-

GZ142-8

11

G0141-8

12

13 GH144-8 1

14

GX

15

16

17

18

19 GZ248-8

20 GA1435/4·9 _1_

"

21 -GSlsB

22

23

24

25 G0143-8

26

27

28

29

30

31

32

33 GT\53-8

34

35 G0510-8

36 G0209-8

37 GS380-8

38

144-8 1

G$

147-8 1

GK254-8 1

G$132-8

~GA1434/5·8

-8 - -

GS404-8 1

G$404-8 1

GS169-8

GR143613-8 1

G$167·8

GA1437/3·8

GS170-8 2

GR1438-8 1

GS25i-8-GS251-8

GS277-8

GE380·8

Thread

18.\!-q>

comp

1

1

1

om'""'-...

1

1

2

1

1

1

1

1

2

1

---

- - - -

... ... ...

--

- -

- - - -

----

Thread~

Thread~

Thraad

lake-up

Neede

b81

conn

Needl~[e

~bat~con~nec~clf~ng~

t!

t..eeclle

tilt

Nee:le

blf

Thread

lal<e-up

Thread

leke·up

Thread

take-up

.......

b8r

Needle

bar

Arm

shaH

Arm

I

-~b!·~<!lk.f'O!TE:

(hO<rZontal)

shaH

(horizonla

.

lever

dllnr.d

!eYes

....

lever

ton

k

eclilg

Wl

k

1\l!nged

W:!~

IM

:

~g

00Yoacll19

""''""'

cor.necOOng

aanll

lever

lever

srud

st.d

(;nk h'"ge

ir

<

9 "''

frll:

and

)

eye«

busting

eyelel

busling

cap

screw

I:W~

nin]eJi!l~N-

......

""

99

p;n

hinge

pin

goioe

guide

neede bar

-

--

.

pon

pll

oasiler

.

set

sete'•

screw

crank

.--

- ----

<>

<llg

...

comp

......

.

_

-

tr~

geaJCOOIP

gea·

sel

screw

comp

.

.

setraew

·2·

Page 16

il'-tt

NO. PART

39

40

41

---

---

D.l

-lt

NO. QT'I

GP 15

1·8

GR279-8 1 Jit;

GP142·8

- - ---- -

--

- - - -

~-

1

Ji'€;tl

fr

•J,

1

--

--

IIU

.t~

------

--------------------- --

4S

-- --

f3\

-----------

I

~SlOp

Oa:np

m>p

H~l

--

------

--

DESCRIPTION

mofun~saew

ll'tlWl

Slop

(fct

screw

moiOI

dnve)

-- -- ----- --

--

------------ -----

--+------

I

I

--

--

------------

-- --

---

----

--

---------------

·3·

Page 17

NEEDLE BAR ,

PRE

SSER BAR, THROAT PLATE

r

--it!""'

"-If

NO.

~~~~~~~~

1

2

3

4

5

6

7 GS164-8 1

8 GX143-8

9

10

11

12 GR466-8 1

13 GS289-8 1

15

16

17

18

19

20

21

22

23 GA1394-8 1

24

25

26

27 GS338-8 2

28

29

30 GW130·8 1

31

-32 +(3'R476

33

34

35

36

lil!ii

PART NO.

GZ223-8

GR485/5-8 1

GR251-8 1

GA255-8 1

GS163-8 2

GS158-8

GA484/4-8 1

GA487-8

<35290-8

GV130-8 1

GR

GS384-8 1

GC

GZ187-8 1

GW

~--

~£1!3~~

GS232-8 1

GR465/4-8 1

GS231-8 1

GM156-8 1

GR477/4-8 1

GM130-8 1

SG255-8 2

GM132-8 1

GW131-8 1

GM156-8 2

GR1384-8 1

____

144012-8

178-8 2

153-8 1

-~-

i4-

8-

---

u~

l._...)..

10

1

, ,

J.

9-

• I

"l

_j

r,, .,

~2

!

\

30-{

L

II

........

I

2'-d~

\..,

~

~

!~l·-1

.I

. I

..

13

.

L/

tta

OTY

1

1

1

1

1_

1

_1_

-1-

v " I · .,, I

'U I

I 1 _

__,

"'

I

' "

,-

,/·

--

--

--

-,

6-1

~

' I ,~

--·

h~

·

-·

y

··

}-

-

~

-......

.....

1

l l . I

I I

3

'~-J

~---

1

~

~

~~~-

------

~

L

v

.....

k_

31

I "

J

r\

~

·

16

--

~~~

;

t -

~l

Nae<1e

bar

Need<>

bar

Neec:e

bar

Needle

bar

Need

le

bar

Zigzag

s-~cll

Needle

bar

Needle

bar

Needle

clamp

Neede

aarrtll

~~~~---

Neede

Cla."''

Needle

03."'0

Needle

{szel14 )

Presse

l

regulalrlg

Presse.

regulabng

Preaae<

~

Presser

bar

Pre$Ser bar

P~!

il!'~u~de-~~~~~-

Presser

oar

Presser

oar

Presser

loot

Presser

'ool

rr.w

pla:e

n-

.w

p1a:e

Sed

plole

Sed~.e

Bed

plate

~~te-~el_~~

Sed

slide

Bed

slide

Bed

s

lide

Bed

slide

Needle

torr

v'

OESCRIPnON

~--------

{hclllolo

)

lrame

camp

frame

li!MQ

lndlcakl<

lndlcalor

~

ICQitllric

pin

set

screw

poo

pld

p:d

thumb

~e"•

thrumb

lhumb

Bracket

and

nt'-ng

H.nged)

______

oil

!eft

pla:e

pla!e

screw

COillledicn pin

~&

savw

nut

SCI'CW

WVtf

nUl

___ __ ___ _

SCf&'N

lew

Como

.

timng

regllial!lt'

frame

lra11'.e

camp.

CVNd

I!VeaCI

Snng

quide

lt.lng

(

Soong

saew

saew

CQT4)

.

bla<:ket

eomp.

spring

spring

SCrt'N

lrama

-- --

oomp.

bred<et

_

--

set

----

___

--4

screw

_ _

Page 18

ZIGZAG TRINGULAR CAM,

r-

--,-

---,---

I¥

~

NO.

1 GS147

2

3 GZ219·8 1

4

5

6

7

8

9 GR1386-8 1

10

11

12 GR1387·8 1

13 GR1391·8 1

14

15

16 G$212-8 1

17

18 GX155-8 1

19

20

~~~~

PART NO.

GR1441/2-8 1

GZ221

GR145/5·8 1

GR1442/3·8

G$2

23-8 2

GS132-8 1

GR1386-8

-=------

GR1390-8 1

GK1

95·8 1

G$

258·8 1

GR288-8

G$291-8 1

GR978-8 1

------

·8

·8

-.-:-,-,-

CUt

QTY

1

- -

--

-

---

1

llt

t11Uiu

llftiil!l

:;illitl

lit

1

1

l!!ii*

: =

Jj\L

II

li!I

IJ

,f-ili.l

,J,

illliltmf't

J)

\il!iil;

J)\ i

dif:i<~i&

J

)\illl

tt

••n

llttt

!If"-

•

;,.

tt=~·

)~

~~~~

HOOK

lt.tn

tJ

0~

11

if

-- -- -- - -- -- --- -

ADVANCING

- -

~

--

~

tl

:i<~i&!lfT

tan

- - - - - ----

---

----

CRANK

Zigzag~

Zigzag

triang.t'al

Zigzag

triangUlar

Zigzag

triangular

Zigzag

triangular camp

Zigzag

triangljar

~

tf.angu2<

eseMlir

~

lliaf9.ia1

-~-~~

01

reserroir

Oi

ReseMli'

Ol

reservoir

CW

rosarvoir

()II

reseMli'

()II

,_....,;,

Zigzag*'~

Zigzag

stildl

~

ampliWde

~~

~~~

DESCR

cam

cam

camp

camp

cam

cam

set

sere~<

CI/T4)111aft

-------

1Qp

cover

comp

.

oil

wick

lllaft

slla!1

shaft

$haft

$haft

shaft

shaft

•

IPTION

sa

screw

~

oil

wick

cil

comp

ccllec

coli«

om.

.

cornp.

set

JiatB

plats

sot

plats

~

..

$Ide

boodc

sctt'Hibaci<

"""'

Iori<

Iori<

)

fiOrt)

ea:entJJ:anldOir

cap

screw

~~----

.

SCt!W

---

-- --

pr1

--

------

·5-

Page 19

ZIGZAC TRIANGULAR CAM,

HOOK

ADVANCING

CRANK

At~

NO. PAAT NO.

1 GS256-8

2 G0174-8

3 GR289-8

4 GL1S3-8

5 GS215·8

Ail~

6 GS213·8

7 GW142·8

8 GR290-8

9 GA291-8

10

GR294-8

--

-

--

11 GS383·8

12

13

14

15 G0140-8

16 GR298·8

17

18

19

20

21

22 GR296·8

23 GX154·8

24

25

26

27 GR731·8

28

29

30

31

32

33 GS281·8

34

35

36 GR621·8

37

38

---

GW141·8

GA521-8

GA519-8

GS185·8

GR29213·8

GS214·8

Gl-i178-8

-(;5216-8-

GA144213-8

GR218-8

G0286-8

GS278·8

G0217·8

-~£1~68-

_8- -

GS223-8

GR1385

GL163·8

GS32N!

GR619-8

GZ263-8

-

-

· 8

n•

QTY

~

~

DESCRIPTION

·6-

Page 20

"~

NO.

39

40 G0420-8 1

--

PART

G0512-8

-

------

~~~

NO. QTY

Itt

1

·~~l'fli~$1U~

Itt

l¥$iliO~I!Il

--

---------------------

~

#

DESCRIPTION

Sleeve

of

hom!l

().rin

g

of""'"""'

component

o1

sw

shaft

aying

neede

--------- -----

-------

---

--

-

............

-

----

......

-

--

---------------------

--

-------------------

--

-------------------

--

---------------------

-7-

Page 21

ARM SHAFT (UPRIGHT), ROTATING HOOK DRIVE SHAFT

'

If~ At~

NO

. PARTNO.

1 GR14441J-8

2 GS199-8

3 G022B-8

4

GZ224·8

5 G0229-8

6 GR1445/3·8

7 GS199·8

8 GR144613·8

9 GS199·8

10

G0231-8

11

GSl4l·S- -

12 GR1447

13

GS199-8

14 GZ225-8

15 G0162-8

16 GS147·8

17 GR1448/3-8

18 GS199·8

19

GZ168-8

20 GZ269-8

2i -

GW272:8

22 GK196·8

23

GS687·8

24

GR1396-8

13-

8

- -

DES

O

TY

CRIPTI

ON

---~------

--

Page 22

HOOK,BOBBIN CASE

i-----,

I

I

I

]

••

~

l

I

I

I

r--_;----

I I

I

~

- I

·

:

~

"~

NO

. PARTNO. I

I GR1449f3.8 2

2

3

4 G01 65-B 1

5

6

7 GS201·8

8

9 GZ164-8

10

11

12

13

14

15

16

~

GS202

·8

G$20

1·8 1

G

R145013

GS167·8

G01 63-8 1

GK130-8 1

------

GS132-8 1

GN135-8 1

GW131-8 1

GN135-8 1

GR278-8

GS256-8 1

·8 1

,

tti

On

4

2

1

1

1

~

~

~

"':

~m

·

&..._

,

~

I;

~~!~

,_

~r~7

_--

tltrn

~

------------

·--~-----

I

Rola:ing

1\oiaSng

Rola>

Ro

ta>ng

Rotat

Rolal

Ro13ling hool<

~

-

Ra.2lilg

Ro;atr-g

Ro-.Jrg

Rola!ilg

Rot.atng

Rotallng

~ .~.·

'---

- '

DESCRIPTION

hook

shaflcelaoner

hook

shafl

ng

hook

shafl

hook

s~~ar.

ing hool<

slla11

ing

hoo'l

s

t.an

shafl

hoQ'<

shaft

~

~sl'.a,'

~~~-~-------

hook

m'

""'*

ooiPl

hook

Roca:rog

hook

bolllil

book

boiJbin

hook

llobbilhlder

OCioer

r

e1alnef

eoler

bulllng l

buSI*lg

beVel

gear

beVel

gea

bosNng

gusNng

bMI

gear-

hook

case

xrw

case

!aNIOn

poslllon

COI11'

saell'

$11017)

set

stiOI7)

comp.

r set

setew

=

~

HI

boollro

case

spring

b-aa

wew

scm'

·

screw

l*ier

ntad<

screw

~

et

---

1------- --

---1-----

-- --

-----

------

------ --

----

-------

------

------

·9-

-----

--

---

-----------

-----

-------------

---

Page 23

fl'

'i

NO.

1 GW167-8

2 G$685-8

3 G$684-8

4 GR738·8

5 G0380-8

6 G$387-8

7 GX302·8

8 GR1452/2-8

9 GR1451/2-8

10

-

1,-

12

13 GH

14

15 G$168·8

16

17

18 G$142-8

19

2Q

-21

22 GR735-8

23

24 GW200-8

25 GR737-8

26

27

28 GS386-8

29 G0514-8

30 GR655·8

-3, -GOS1-4:-8-

fl~

PART

G$263-8

GCl4-2-8- GS188-8

157

-8

GR267-8

GC142-8

GR341212

GW166·8

GR339-8

- G-52*6- -

G$1453/3-8

GS42

GR738-8

NO.

·8

-

QTY

,.--A

DESCRIPTION

Page 24

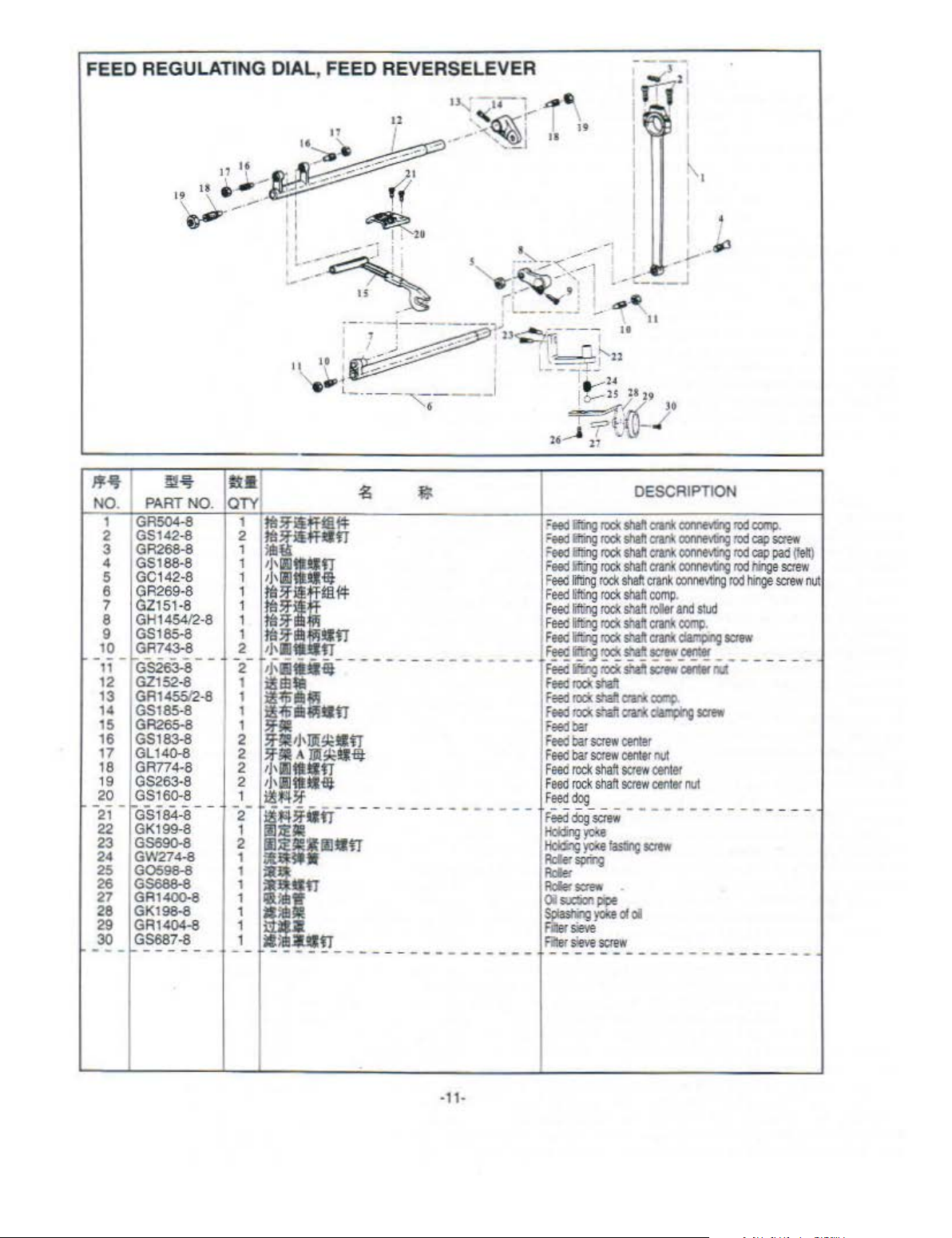

FEED REGULATING DIAL, FEED REVERSELEVER

\ ,

....

NO.

I

2

3

4

5

6 GR269·8 1

7

8

9

10

---

1 1

12 GZ152-8 I

13

14

15 GR265-8

16

17

18

19

20

"21-

22

23

24

25

26

27 GR1400-8 1

28 GK198-8 1

29

30

---

!II~

PART NO.

GR504-8

GS142-8

GR268-8 1

GS188·8 1

GC142-8

GZI51·8

GH1454/2-8

GS185·8 1

GR743-8

as263-s

GRI455/2-8 1

GS185-8 1

GS183-8

GL140-8

GR774-8

GS263-8 2

GS160-8

GSt84

GK199-8

GS690-8

GW274-8 1

G0598-8

GS688-8 1

GR1404-8

GS687-8

-----

- -

-8 - -

-

bt

OTY

1

11Bfiil~i1ii*

2

!fl3fiil

jJfl

~

~

itUii

1J'IIllliln

1)

\11]

1

1

1

2

-2-

1

2

2

2

1

2

1

2

1

1

1

--

ii-B;

m;llili~

11131'

11131'=

1)\11

~~~riiuef

iUU~

~:=l•n

31'!1

3fjli)\]J9<ilfl

3f!lAIJI!9<ilii;

1)\IIJiilfJ

tNII

ilfl

fJ

- - --- - - -- - -- - - -

II-&;

i!f'l

i~~-fJ-----------

!Ill!

!I

flll!ifflllllfl

iln

n·

.,.

··:

11=·

~)-

-!-i!!I!T

---------- ------

---

DESCRIPTION

:eed

ifting

reck

shall

aanl<

Feed

Feed

Feed

Feed

Feed

Feed

Feed

Feed

iffing

if!ing

if!ing

lifting

lifting

li1lillg

filling

li!tilg

reck

reck

rock

reck

rock

rock

reck

reck

shaft

shan

shan

shaft

shaft

shaft

shaft

shall

aan1<

crank

ct8llk

crank

ooni1Mng

comp

.

roller

and

cranl<

cranic

~rod

oonne-.1ing

oonnevtllg

connevling

s1Ud

canp.

cfamllrlg

F~~~~~~

feed

filgnxit

feed

nxit

feed

roct

f66ll

rock

Feed

be:r

Feed

bar

Feed

bar

Feed

reck

Feed

rock

Feed

dog

Fe.ddOg-scre·ii-

- -

Holding

fWng

sf1a,,

shaft

shaft

screw

screw

shalt

shan

yo~

yW

fasling

shall

acrow-

aw

~

aa.i<

~screw

center

center

nut

saew

center

screw

centet

nut

-------

SCteW

=$1Rlg

Reller

screw

01

$Wicn

$pasiWlg

FCier

Filer

Pl)e

yoke

of

sieve

sieve

al

screw

--------------- ----

rod

screw

--

ru

--

rod

rod

rod

- -

cornp.

cap

cap

hinge

hinge

--

- - -

Stmt

pad

screw

strew

UeJt)

nut

- -

--

--

·11·

Page 25

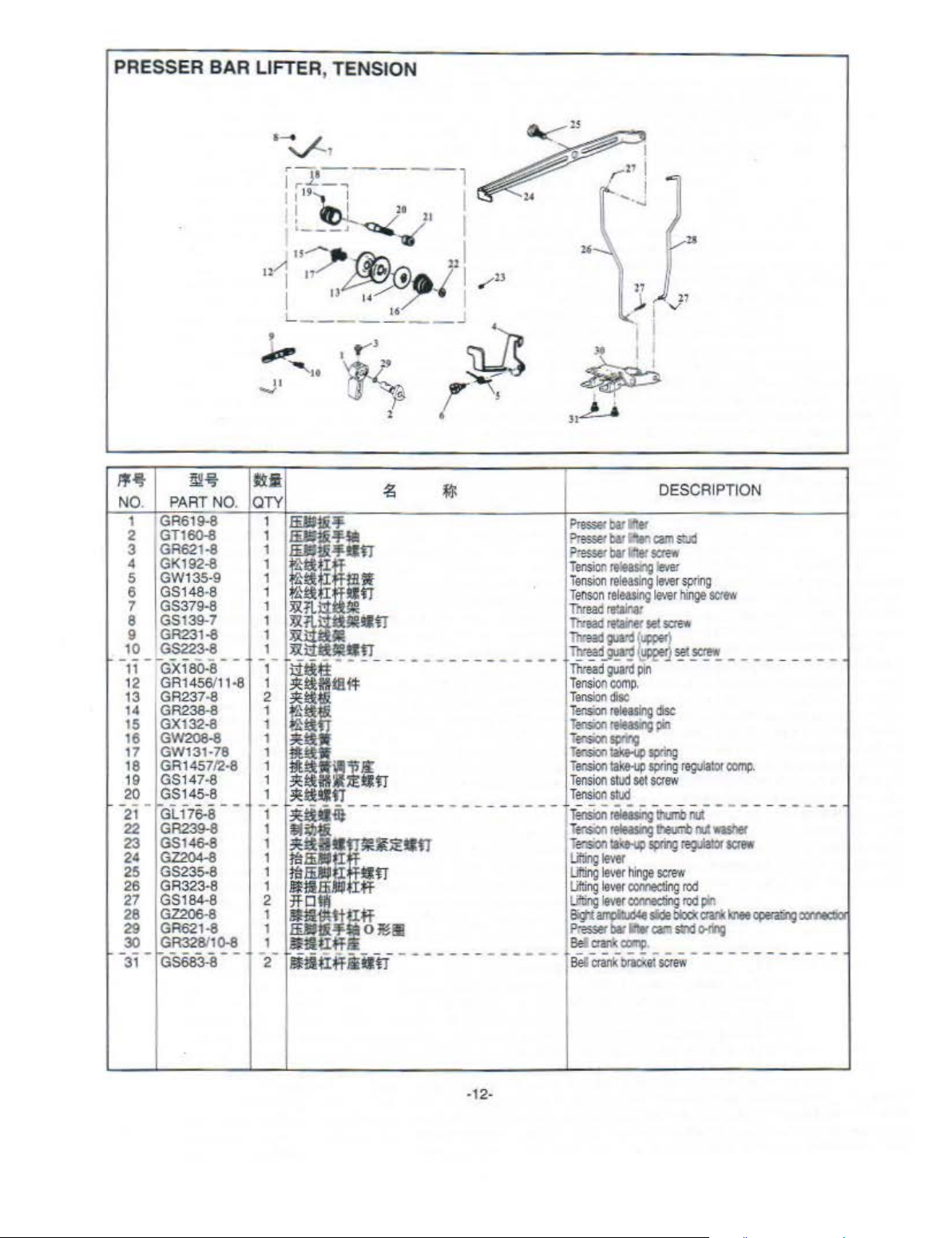

PRESSER BAR LIFTER, TENSION

ll

,J.

I

~

I

"

~

i

DESCRIPTION

2

3

4 92-8

5

GW

6 GS148-8

7 GS379-8

8 GS139-7

9 GR231-8

10 GS223-8

11

12

13

14

15

16

17

18

19

20

21

22

23

135-9

24

25

26

27

28

29

30

-12-

Page 26

~ll

r

~

-"4t

NO

.

1 1

2

3

4 GM172-8

5

6

1

8

9

10 FM132-8 2

---

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26 GR695-8 1

27

28

29

30

31

32

33

34

35

38

37

38

~-if

PART NO.

GV130·8 3

GF109-8

GM107!4-8 1

GM108·8 1

GM104-8

GM134-8 1

GM106-8 1

------

FG 111-8 1

GBA211-8 1

GH114-8

GF116-8

GR788-8 1

GR789-8 2

GR790-8 2

GR760125·8 1

GR1397-8 1

----

- - -

GS352·8

GP142-8

GR69Q/2·8 2

GR687·8 2

GBX141-8 2

GR694-8 1

GR693-8

GR692-8 1

GR691-8 1

GS358·8

GL 170-8

GR688·8

GW

196

·8

G$357-8 1

G$356-8 1

GU70-8

G$357-8 1

~

a

1

L.Bi,.lftf!f

1

tlll!lBil!l

ll'li.Bi!IJ!~f!f

1

~li~=

~

=nf45f

·~-

--

iii.

=:!lrfi

1

~]}

1

Qi&]}

----

(=*:)

(t)\)

TliHf7l

~t.tlilS

~~~~fill

~~~~lill~t!H4

*~~~~~

~~iu

1

Btl

1

2

~~·

I

~~

IIIII.

1

=m

2

11m

1

~

1

!!8

1

~·ill!

~iolill!

'lt(l!Jill!=ilfT

1

~18lill

~

_______

14

fT

mi

"11!1.

~·

Ill

1ft

b '

'W!I.dfT

rcsJ

~~

f:!r!J!J'\>!111&

!I

Hlfa!i

1:1!11

~f:!ri.'Jl>~H

Rlf:!ril!ll>~n

111

1111

illi

11

f:!ril!l

--

"Pi&rr

j,

~

LY"

~

~

~

I

u»

~

---

-------

____

______

,

17

DESCRIPTION

Ath!.ssory

Needle

Zi>Per

l'!esser

l'!esscr

Hemmerlool

Throat

Throat

Feed

~~~~--

Oiler

l12dl.r.e

s.--

Saew

&::re«

T<~read

T'l!ead

T'Vead unw

()ippan

~~le:e:

lip

Hand

Machine

Olpallseal

01

Colw'-'lllaeW<f!>

Ccrlrollevel

Ccrlrolplale

Control

Control

Position

q,en

Twisting

Tow-way

Position

P:xsition

(size

1oo1

ioo;

fOO(

p{ate

p{ale

dog

(alec

resl

on'e

<i'i\'e

dr'\oe

unwinder

unwinder

screw

wheel

I'Onge

par

"""'nal

level

level

adjusting

re1aining

lp~~

aan

adju$ng

Tow...ay

aank

adjusting

Poeiion

adjusti:lg

box

114

)

(SIIfinQ

h;n~)

(spri~

hln~)

com

le

(lor

mghl

(lor

entroide!y)

(

for

waight

st1Ching

filer

W'Dl

qe.

pin

(lor

ll'll:*ll

(Ia.

'gO

)

(SNI)

(for

lhoal

plate

spool

spool

inder

con'j)i~e

~npo~e~ts-

(f

or

ueadle

cl1sllon

o~

sere-.

nut

ol

nng

o1

pressure

of

to'rYIIay

screw

SCfliW

scrank

nut ~ _._,,

scnw

I~

__

comp

!for

comp.

fro

stildlfng)

)

----

rype

COl)

diM

)

)

cap

net

(for

two

spools)

________

opera110n

)

of

pressure

crank

-y

~

tiiO'nf

lifl

cran~

1ft

sllaft

etaJ\1(

crarlc

crank

:wo-w~

of

'i

' I

l

~

botton

holing)

s~aight

stitclling)

-----

!for

treade

--

~

_

__

-13-

Page 27

)¥~

NO.

39

40

41

42 454036·819 1

43

44

45

46 GR686-a 1

--

~~~

PART NO.

GK197-8

GZ270-8

54754 1

3U377

GX305-8 2

3U377

-

,..-

-----

r

.t

!!ll

lli

'*'

••

OTY

1

ffl

D~tall

,

ff!UUI

IB:illl*ltlm:

1Ri1Uit

1

iliiABirl!:

fflli.!lflJilili~

4

~~•m

idiArA

--

---------------------

DESCRIPTION

~.way

crar

.<

o1

Pressr

Oil

resei'IO

Oil

resei'IO

Oi

pan

T

op

pon

Ma

ciWle

Oi

pan

ohhafl

p<es$11-e

ir

dlain

pulg

ir

dlain

ol

jmSe

l'ead

pu

cushioo

r

ill

aJslion

seat

seal cushion

lg

----------

ll

&ere'N

screw

-----

gasl<el

------

---

--

----

- -

-

----

-- --

-----------------------------------

I

-

·14

·

Page 28

ACCESSRIES AND ATTACHMENT

,.------- --

I

I

I

I

.

~

I

I

I

I

I

'-

"~

NO. PART NO. Q

1 1

2

3 GA2330-8 1

4

5 GS3343·8 2

6 G02332·8 2

7

8 GR2332·7

9 GBS204-8 2

10 GBR210-8 2

11

12

13 GR1000-8 1

li!l~

GR2331-8 1

GS3342·8

GS3344-8

I'M

1~-

G$605-8 1

-

----

·~~

t)

l

-

--

llR

TY

JlilF~fli

.H~lllit

.t~.S~~

1

P1it!'ar£un

PJi?J'I

P1i

1

~un

1

It

It

J£l!Us~n•

--

§~m~

1

€iiH~!illfl

f*tt~

i .

--

-- --

i*

~tMlfl

fl!.atH!!

ttllt

Fc~

.ra•~••

--

--

-

---..,

I

~

I

I

I

I

I

,

I

~

.

I

I

I

··

•

----------·

4!1

it

Jt

---------------

~

11

I)

~

~

'

II

DESCR

Bell

~a:l!

comp

Belt

gua'd

Bek gua:d

Beh

guam

Belt

guar

Belt

g

uam

8ellguam

555

Cloln

QliCe

C1c4h

guide

Fln9=•

.

(

upper)

(

upper!

C

••p

per

d

(up

per

(upper screw

(uppe~

l

lhumb

guam

CO'N

ocr

ew

scre

w

washer

screw

stud

==~

screw

IPTI

ON

----

-

--

---

---

- - -

--

--------------------- ------- --------------

·

15-

Page 29

!

·:L.J3k

5

':'L..J':

.::.t-.r

.;: :

v ve z 3

':':-~ J B.._:.: •

Cn~<:..

Ol·t:•1y~

11

•

Lt;

~A

.S€1r~G·..,2t·:,;

:q:."~54

~;~"

;-:

:<~

~ 1 n~v

.'.

Xi:OilrcF;.: t:Mx

:, 1

:l:O:

Eb7r.fVi

z·l ·

T =

·~~·

~11:

.:;n:-:!

XC~.4P.S•..;9r.?:-.rr

t:xp~

EB

.J',.d..!

nZO~~Yl

71

LSJD!-10x3JZ1 (

H

Hi

Y;: 7 ..

1/1

ax

1-1

1 wkXt-.

!">

I

1-'

h5

KdCl.r

a7t:mwB+

Z/..i;+

"b

'iU~v;zkc€2

1

Yr.:<OI

A:;;:;

:C

'!

f

tJ3-/

!t:

/U:

= /BP,TiVOyy 12

!:uG·:

r

jt)q

t.K?-~·~r.z

:·CCJ:ny•

:2~Z:~~·t•

X

~4rrPx11HewJ1::=:z?.

1J4

IF'.uXr2lbp+r.L.·:t~XX•;r;.:.Z~·1-

lilu2u2l•r:+:

•

yK5!"r:..~~v:~aZQP

!:r

i_

6G:.t~~.;~

..

-tc~.

~: t ~

..

:,

~

'='~-x~t

-~l·v::

.,..!.":

r~·;~~~cr-:::l"~o."ln~

zYL·

,;..J...

;s I 4::t.L

'T;)EmrnVA-c·~

wXpi'

0""1

.....

.....

1:

:,i'-1-Vt'l';::

TTJOOetVD?'t\q..: I

t15C.C7

"p;·:.>

E.E:<

i I

4.::

!.J:<.:·_:.·.LlH

xiiY

::t

~~:~:.i

:-:OV:

=.;-:~

~GLK

'J

;_::F

JcC:~-

J

w\

...

~.

::;:-:-

!'

~tJl

··.22y6 _

j +

/6RK~Pb•35N.

PAZ

.

..1V!36C· 1 J08scJpd

...

·rN:~C":.

:.V SG

X2

rY'

S.s

:OeLvk~y4

1

:E:S':

sK

... v .JS

;.:at

U~\'tMd.:pw

?l\!f~:t=,:u:'t:>KqL;;.~::-

~<jOCqT'!./OqTL

:_

:;~.x:r_..·~

=-=

~

3:: •

:.·.~-

SJ.E.·./

t::

nt..f.

~~,.-~.;

=·.<:>t~4

,•JdK:.; v

!:R'Jrr.znc.:.zo6_

-

~.HVca!.

J

.:

-:r

a•A· , ....

t J -'-t:HX

:xx~:~·:Jh-··~o:w•I"}.S!..

:.fiO:

:0-:t~··~~;;

i':. ~ :-'

:-:.:

'.J3Xf..:

~:;.:~ ·

~c

Y Db·..;b:;

jL4

-:-:1I~QOk6

sTesl":-:.t

•1

s3U/

xl

J.Bd..:..k·.·r,.

Crt.:'F

~.:

!V.;.£:7.:::.d;s:,·:kF :r:-

~-~-::-·~

....

s.u:·;6~:.;_

~

y\.

nn.:;1 >1jv+.JPONct-

s':'ZSL

('

...

!.~.:.

9~

:!..y1:..J

t-

.

.:

:.vx'

FH

.i

=.s

S-1~

yr

...

,vd~:.

,::.;~·!::·~·('•;

...

':...

:li~

a·

i-F

:F.:

01

F

r"

~

19

.:>St

'~o'c::-2!:'L:!B.:!O~\;.·=:·:ct

113:)

:.SSt•6:(9~J

I~

1,,

t'SJ8

::.i

- t'CI..:;/H

r s:<::

kP-:-

~

•:.&r.:

!:nk3q::;

zj

?NN5 9

;.,?.co: ·:·FJ-:

FKz.~>.::

•.;

E::-.s:."'

~=·-2

3g' ~ v

:...;x8

J

lq.JA<ivHXHcy3:

lCdA:;

'Jy7azc•/

!e.,.c:r~zi

•V:.-..:.

Bl

co~SSH:nX~.l:

Cv:2.Rinr.:·lT'-1-R

~c:r

.. -..

•

"'

- g c::s.::

'1'"""VdX;-:J•_f-:r-

J!'

2!

9V:!x:.;

So/4

!c·:SShT

tG:>?,.,. =

12

?i'

1/\ZVD02o~·

r...,

KP..Oo/

Zc

I:':\

c::.::~~F

-~

:)J

1,~

/:";t

:\v

'-=:

-:·:.SNL: 2;:-:"';.,N6 I

=!·~8:-lcdbGUi't~j;-:t

lp4

q'XCOC<',<. I

:Al

qA : I zT·::2v<iJ:nv

'.lb- 98JfJv'?!

~C:1Jh·ib:·tiR!J~-fqy;:i

..

-:

~<-'t:G

-.~.aS-=

Sx':' ?r.'.c:

:r

-~:

~~~l£FI;_;:;:..

c.C~o(._;,.:.;~·J:

tCC

z 1 G

~-

s :

~

2=-::·:·.;_!:.x:;

::

i e

:iE91~-'

e I

Loz:

1 "r-V9Cj

!S'

1

i1

~94.,

I 1 l

fj

;,·z~cc

ys::t::.R2•·•j

c;

::~7.~Q:-:s::

3x

-:J

:;.sxv::

~5q 1 (~~

Y=

4CEn

:1o::-2u2~

o·:~

-:

:t

:·:Y

:e:b:3~.

vHQY'

·.:

JE

:.e

o·

...

..

y _ K·:6:.·?; .. r:

a~~

r a

ZE

9::y"r

1-...·r.~;.

y.=O::l

....

.S. ~ 1:;

d9=zC-<P.-

:'

xiV:Cr.t;!)z./ L

:1Y=:·;~;.,Xt

r~·.trlx:

2;<9.~N~;

t·~C;

·:·

-:t4

'J5

·

:S?.x3.:..r-.W:.>!!

=

,...

=~x::;,-.Jx~

~13vJ::i?Voi

6~".\·":;'i:·:KCC'.

:..::-='ir

9~l-

:.·.;;

, ~ ..

't

....

-

~I

+:·u~·

~-:

'fEr.j

~V:?x:~;·;~

1

.;:

!ki\d

:SC::~.t:·:::J-

1

Yyr-

·

i (;6d.D!-:IJ:..:K

• :MuSQ <p

1 n·••l O ...

.

..::

~Or-S£:-::.

"'!

1'.2

.3z,:an·.-·:.3t.r .:Ku:..:;:t.:

•,.·r.lC

~:.

"lr:

:ui.;

la.

x:,·~.::'l.

J-: ::·>x

...

~.

F':" i •3011

r:nJX~-KI!

...:s.:.

:'1.·;:-:t

~·--1..!-!~bo,j.;

:~:.:o:;·,.~r

s r

JV

-.':..

':.

;

·:rY

'r:•,..

Z 8

OJ= R ?C·.·!J:

Z~

Jrt

T i

~.

fl

·;r.

f,P3!\3y•7x6sgyam7.:":B

l.-t:.J.J

R51SrHQ'!'~·;'7.~!-

;·.r·~6

....

Lr~'l'H!.N5c.!:·:.;OB

Jd~t:!·:B

:;ttJ~-:

..

;CJMt.

a -XXKf.l:x£:1

g··x.~·:"~:,

wi

::;;XGK::Nq7o•...,•Ci·h!L~6l!1C•·J_

f6:.J

cp

1

.1

..

3:,

'I'

::.J:·~~~~

·J

J JY l S

~?

..

~.:

i<.

fi

=2w~:;P•:r

F24

...

-lw

$/·JKt-.X r b

~z6NqN~OzCo:<T:~tGvdyVKN

:R+vdqE: l B'

t-it.:-

icy~. 7 oJ.Yr.P·lf<Tb~/Fli\LJd:j

i~v·

.CL

Yl'-. i ,::,t•rb

kt

Y Z

3~

:.=f

t'"

...

GJ:r:.:-

r~

·.;r:•l.;~

kwSY

hI?~

.;;·tOv.,:;cr.Z

~V

3:

BS

Tf.

90,

;;.VH

q)c I ip-

I

V.2q?.!~i

G~5:

:~.

f.V";;K:-:..:..

ro.:a·.K::<.!.V\;

9Zh-J~~·!p-..l-PI

::::.:

·-;

t':

'i

or:t~2'••/qf)L'Y.l'

fL~\vi

j,

( t

UEAH

9-:

~a~~~:;l/~

£·::.:

FTUrOF-r

1

'9::>:

J:

Jc

lt..:.r...x

SG:f!

.:.It;"'

FnG1:::1?9Y.t.=6: EF.r

t..;..;C:.~Yrl

lY~t·I~:ysr.:6bX~7.~-;"

9(.;ix/

y

o~:"l

!t

-:··t.•J.::::;~:·;·:X:!)BJ;kc

512

·:·:!:

..

~t:

d:

-;:

:'i.~~C/

...

:. ;

-...

_

:pz~,f.

"';::

~:1

- Sri

:.=

1''7.r.XY~

YY-s

·.:r

:::·:-t2

t.:

F.t

=~

'):

v

=-

~r:-mr

'"'~

.J·.c;N2B;

"'

1-

S·?~·Oc.:.:

r

~zUo3R'i!"".L!

:--;

sx~::..;:7_:()UYgOSXfbC~":'V~1f,>J::

. -

..

1~

,;;:

J~x.~=x~.:fipr::AF.:-!~Pyr.~J:·,-~:-.~zxr·axr:hd:..CKV

)i:/

r:.

Jw·~

•.

::·;

(":<:':!'Vr:

~vc-G51

P:.;0LFe22D'r"T'

[ F

~

_ -= :x3 J

rr.

r'j

....

~:C:<!

rl·!s:r.~::.Z:-~0:~:;,

::<..:1::5.;:.,:

reF

~OC"S.K.h'·-

~Z.d!1Xk·J7

D

lllJT

L<:

zlljE+cFP

?7VOi318 z

'f:RqZ5!.Xti'iM6Z:·:T6

i

-~~1z:

b::

y-

~~-...

!:(?

:=::J.;c- · z ;)£

v = c.?C2

''

J -,•:p3

m

r~

'C:'t2xuX I

LXHC'k:1S

7.:-:pe:;:·~M~6~.:9•:8:.~.s·:

..::--.=-c::c;:x:.-:-;

lsc5=X:B!;S€?b.J\<iEV;

~?

"': ....

t

~~E·,~~:

~:

t--;v

:x-:.:.!tK·.:y·:··.~s335:::·~...,Lg~?;!a

1

~·1""

~1:.·~-Jr

~:8-_';:·r.

·~ r :>-,··,:·:L~;.:.

:~aqzq?F:i1r'l3V_l..,

SliNl,.t-11::0

j,

r:'Gf

UvTO:C

x~

~

-i!-11

s;.; tJb;·r:-::c

v::.·:

1 ~ _ :

;.;zc:.6HO"."-·

y"

:J::·S

Z2lLl7'.l

-

-3:S5

:;:q..,

·:=·:lF52sHAn'.~$F"<;q:

NkqrVF

;'RCqSh)

3T.Jl-'!l·\6 I

R~·:p

lp:

_

bJ

<SGO"t

t::

I

;·12

i:

1!-.r.:::;

1/y•

-~.;,.,.8

.:-

~

t:

:.

- J r

fp-:1

21yEr~·:t:

F O:OJ'::'Q'l r>cXx.id·:.VD-e ~ iXG.305Cmu:.

·

l1'U.:;i8C'lr

1r::;·~:1

:j

:'~-::~

3

:J::

':'.,.