Page 1

AUTOMh

TIC

OILING

BEADING

MACHINE

• m

Jl

OPERATION MANUAL

PARTS

dllil

ZOJE

iJ.·

itt:

• m

SEWING

~JJ

=R

••

BOOK

ll

~il

~!II

iliRRR

MACHINE

ftl

J1ij

Bl E 61

CO.,

LTD.

Page 2

iY!fflibtOO

Instructions

~f4f-F*

Parts

Book

For

.. · ........ · .. · ........... · ........ · ..

1.1JL%?HI3.f4

Arm

Bed

Components

z .

..t.~

~

:J:Jfi~?Hf:l

Main

Shaft &

3.$i"M!Jffi.J'il$#

Feed

regulating

Thread

Contents

Operation

f4

Take-Up

components

···

···

···············

.. · ..... · .. · ................. · ..... · ........ · ........... · .. · .......................

Components

........... · ...............................................

······

···

................................................

··

....... · .. · .. · ........ · .. · ........... · .. · ................. · 14

...

...... ......

.........

...

......

...

...

......

...... ......

·

.............. · ..

·

· 18

2

14

16

4JIUJ~-t~

s

.ff~-1-?Hf:l

63~;f-I.?HI3.

7

.WUf:7HI3.

8jlfH.i~

9.fJL~~H4

10

..

lLfJL~~

~~?HIH4

Fabric

Piercing

Hook Drivirig Shaft

f4

Presser

Bar

Components

f4

Feed

Machanism

Components

f4

Lubrication

Oil

Reservoir & Knee

Machine

~~?HI3.#

Bobbin

Machine

Components

~t€tff.IJ!P?HIH4

Lifter

Head

Accessories

Winder & Thread

~li~

Jt!.~:7HlH4

Stand;

Table & Electric

Components

.. · ..

· ·

.. · .... · .. · .. · .. · .. · .. · ..

.. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · ..

.. · .. · ..

· ·

.. · .... · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · .. · 26

Compcnents

.. · .. · .. · ..

Stand

· ·

.... · .. · .. · .. · ..

unit

Components ·

Appliance

.................... · .....................

· ·

..... · ........ · .............. · ........ · .. · .... · ............

· ·

..

· · ·

Components

.... · ..

· ·

....

· ·

.. · .. · .... · .. · .. · ........ · .. · ·..

· ·

.... · .. · .. · .. · ..

.. · ....

· ·

.... · .. · ........

.. · .. · .. · ..

· ·

....

..........................................

· .. ·

· ·

.. · ..

....

· · · · ·

··

..........

· ... ·

.. · .. · .. · .. · 24

· .. ·

..

· ·• ·

....

· · · · · · · · · ·

20

22

· 28

.. · .. · 30

32

34

-1-

Page 3

Instructions

For

Operation

BEFOREOPERATION

I.illtil!

~

*:bn

i1fl

~:lf'fm:rf

2.tJL~~~ll'.J-,

3.1±~-

4.li}i'JiA.

101!

l.N

ever

2.After

1:

the

counterclockwise

motor

setting

needle

down,

3.Do

not

4.Confirm

namaeplate.

.M....t.tffi7'HJ!tl~~[fl]E\I1;J~!Jt#:/J[fl],

r.J

<P,

:;r:;~-m.m:k.R.

7#JtJLtjMJ._t.P.Jft~

operate

the

up

and

turn

as

observed

use a lager

that

the

:$

l'f!ff.l)t;f§

machine

the

maching,check

the

power

from

motor

pulley

voltage

and

o

tt~'

:lf'~~{f!J~o

-t~1'1!7J!JtJL&:w!ffi

f:IT.~~

unless

its

oil

pan

the

direction

switch

ON

the

handwhee1

for

the

first

phase

(single

.iE

1i}ij

0

has

while

observing

side.)

cme

mouth.

Jr

3-phase)are

o

been

of

motor

filled

rotation.

with oil.

the

correct

to

handwheel.(The

by

check

it,

checking

turn

hand

them

the

handwheel

wheel

against

should

the

by

hand

turn

ratings

to

showm

bring

on

the

OPERATION

l.*:im

1'1!~7f3CE.JGtJL:H:iE~llt,

2.tJL~~~!Jt,

3.tJL*lllll~liUIF-=:114&:wat,

4.:f*fl:::f;\!g:7HIL~Ilt,

s.m~~~WHEil,

6./l'*.fflW~7k~il!l7*:fffl-!f.f5fiJ:J~HJ!GtJL~~i'lil

LKeep

your

2.Do

not

3.Be

sure

4.

When

5.During

vbelt,bobbin

6.Don't

clean

1.*Jlwi¥-J~~(I~l1

iJ!f0J~'f-~{$.A:f}6~;fHP~~o

~'m-ImE!Yflt7N.o

tt~/Gfti'fffW.Aa9*E.lG=¥-l~U.iZ.fffiii*W$ur_t~

hands

away from

put

your

fingers

into

to

turn

the

power

an

operation

operator,be

winder

leaves

careful

or motor or motor.Also,do

the

face

of

machine

...

~2

l.INSTALLATION{Fig.l,

*¥cl!fiil:3'<~:

1)

¥!llfiil:Ellm!tEI

2)

:imOO.P.Jr1.K,

l§J

JEtEB-)ft(ffl

3)

)j1J.tJL~:li:m~CD;Ii)(:.AJE:i:f1fl'Lri3,

1!14)

"

Installing

1

)The

oil

2)Fix

two

B(hinged

machine

3)Fix

side)using

hingeCDinto

head

fti:t

[!!];ft\\i!mJ§

*tWJ7JjJ:!!fiil:j:J*CD.ffl¥J:!!:&:J.i~®~JEtEA-:IiL(tllt*fl:fl:::f-)ft),

:tlL~:ii*~*.g--)ft),

the

oil

pan

pan

should

rest

on

rubber

seats

CDon

nails®.

Then

the

opening

on

cushions®on

itii.P~'f-;li)(:¥Utt-a':rFl'!l5o

-JE~-13J1lj)fJt:fJL7f3Co

o

the

needle

the

switch

from

not

to allow your

...

thread

OFF

the

machine,

head

~3

...

when you

take-up

before

with

~4)

tilting

make

or

any

n<·t

place

thinner.

turn

cover

Fig.2,

c

~)§

jfl

irll

fiil:@;/i)(:tf;¢

.!:Ji:t:t&astJL~:li:m~J*®ff!W(~,

the

four

corners

of

the

machine

side

A(

operator's

place

in

the

machine

the

four corners.(:<ig.3,Fig.4)

oil

pan@on

side

bed,

)using

the

and

PRECAUTIONS

the

power

switch

while

the

machine

the

machine

sure

other

anything

Fig.3,

nails®as

fixed

fit

the

head

to

turn

off

person's

close

Fig.4)

..t.

c (f!i 1

table

groove.

illustrated

seats.(Fig.l

machine

"V"

%&:'~if,

ON

or

while

is

operating.

or

removing

the

power.

head

or

heads

to

them.Doing

1!12)

~~tJL~~J

above.Fix

,Fig.2)

head

to

table

~~!ffi;f!li'f!~:fJLc

the

machine

the V belt.

to come

so may

close

to

be

dangerous.

is

operating.

the

hand

~WJ.Rilfl:&:J*1/J®.ffl¥i:!!fiil:J*~®

lmRt¥1

J:i9t!L~J*1/J®

two

cushion

seats®

rubber

hinge\])before

placing

wheel,

..

L

on

side

(1!13

the

-2-

Page 4

OOFig.l

®--.

00Fig.3

,,

00Fig.2

2

Jll

w

Jr.]

ifiJ5ff

(

~

5' ~ 6)

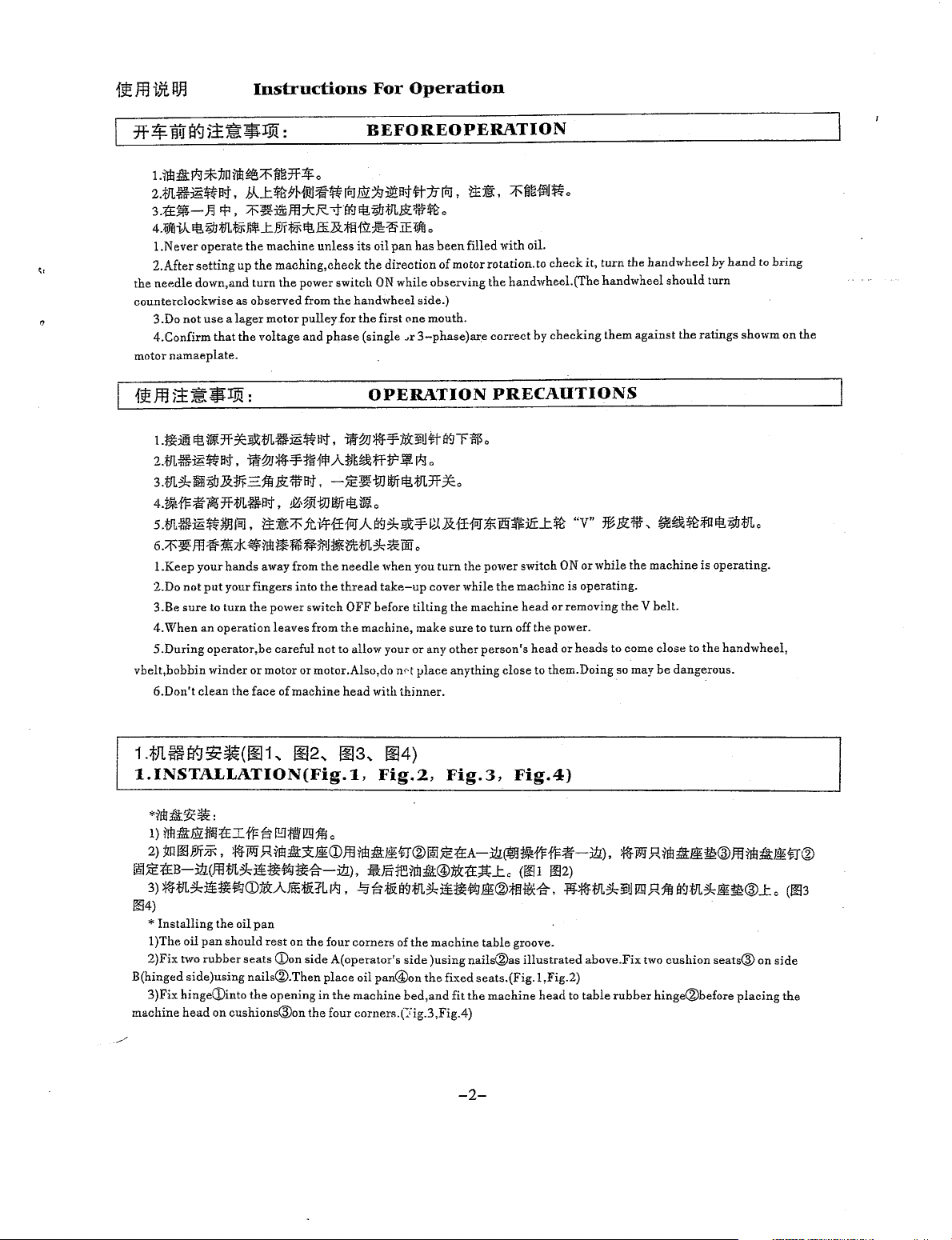

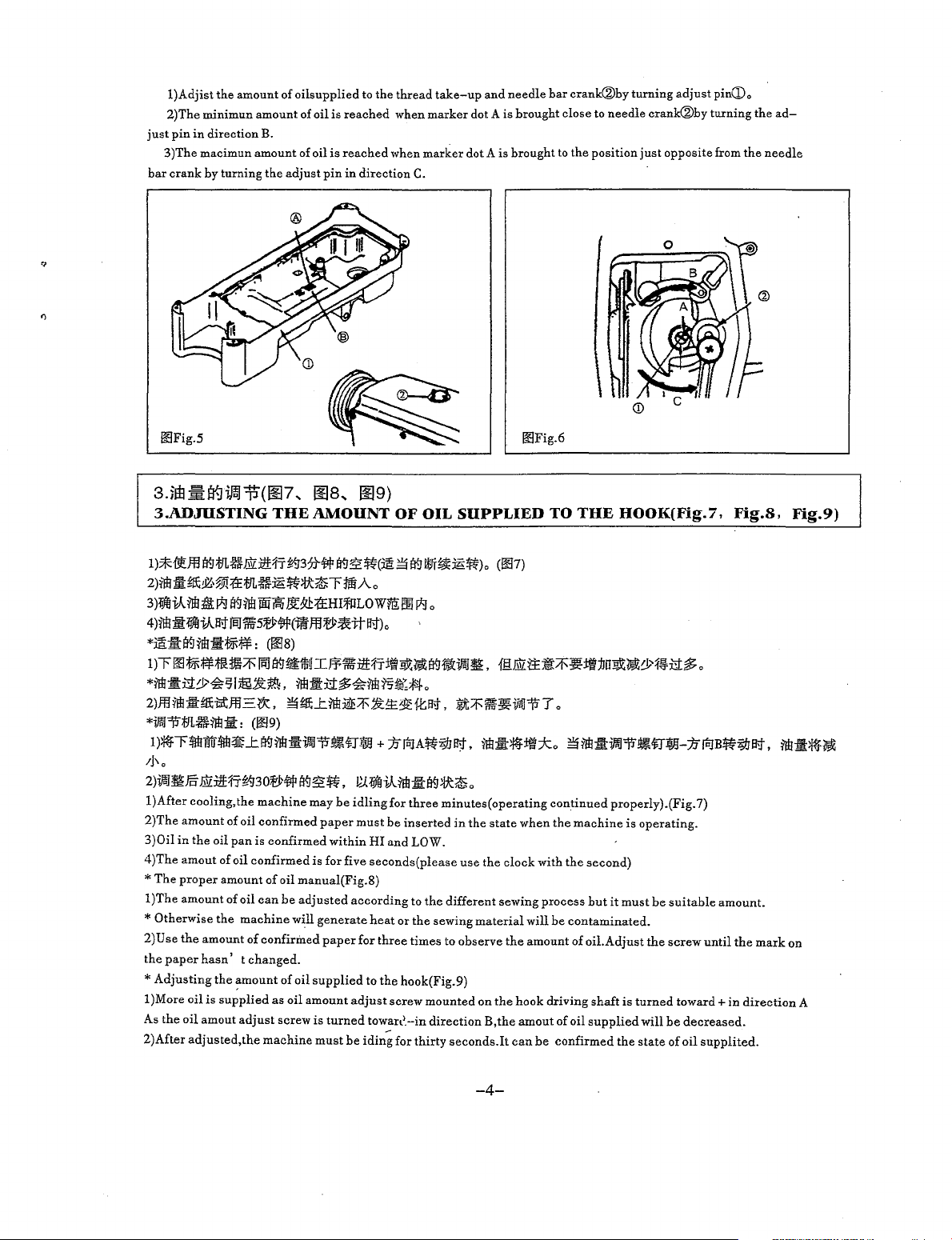

2.LIIBRICATION(Fig.5,

LW'H~~~:

I)rPJ~Il!:Cl!:CDJi;J:IJO~~tlL#l(7%

2)~ilt!ilfffl£T-LOWie!%B,

3):1Jnilt!J§.

~~T-~lY&~rmt•~~Aamrmt$~~~0

(005)

:TF~m~.

J.ili;a-i!Jrm~~lY&i!Jrm'OO"®...t.

Fig.6}

B#l)~HIGHie!%$ii'ZAo

J.ill~:IJO#l:l:o

00Fig.4

(005)

i>t~WJm.JE~

o

*i±il.:

f!ffl~tfLffB.l(;=i!f*Wl*f!ffl:lil¥1tlL~a;j,

2.1fliJi'fiii$M:I::

~~~···~·(D,~~-~--~-®1¥J~rJE·o

2)#ll\tifiil~.fMJ3B::tfrPJ~~,

3)#l:l:ifiil~if!l$1C:1J[t;]~~,

!.Information

* Before

l)Fill

2)When

3

lubrication

4)Note

*

When

3,500s.p.m.for

2.Adjusting

starting

oil

pan

the

)When

you

that

Precaution

you

first

(006)

on Iubrication(Fig.S)

the

machine

CD

with sewing

oillevellowers

operate

is

adequate.

the

amount of

operate

about

the

amount of

the

your

10

below LOW

machine

the

machine

minutes

oil

~JgA~ili:=PJ~R~Mil;f,

~h';(A1t~=PJ~~ftl!Ma;J,

machine

after

splashig

for

the

supplied

J.ili:tE&?tilf!l000-1500#"l¥J~~TiietlLff:i£1l'+?ti*ti::t:il¥JiaJ.illt!::IE~o

M:l::i!i!J!l,Nio

im:l::i!i!J~:;ktio

oil (7 white oil)

mark

lubrication,you

oil

is

unrelated

after

set

purpose

to

the

B,refill

up

or

of

face

plate

up

to

HIGH

the

oil

will

to

the

after

an

break-in.

parts ( Fig.6)

mark

pan

with

see

splashing

amount of

extended

A.

the

specified

oil through oil

the

lubricating

period

of

oil.

sight

oil.

disuse,run

window®

your

machine

if

the

at3,000s.p.m.to

-3-

Page 5

l)Adjist

2)The

just

3)The

bar

i!!Fig.5 i!!Fig.6

pin

crank

the

minimun

in

direction

macimun

by

turning

amount

amount

B.

amount

the

of

oilsupplied

of

oil

of

oil

adjust

is

is

pin

to

the

reached

reached

in

direction

thread

when

when

marker

marker

C.

take-up

dot A is

and

dot A is

needle

brought

brought

bar

crank®by

close

to

the

to

needle

position

turning

crank®by

just

adjust

opposite

pin\Do

turning

from

the

the

needle

ad-

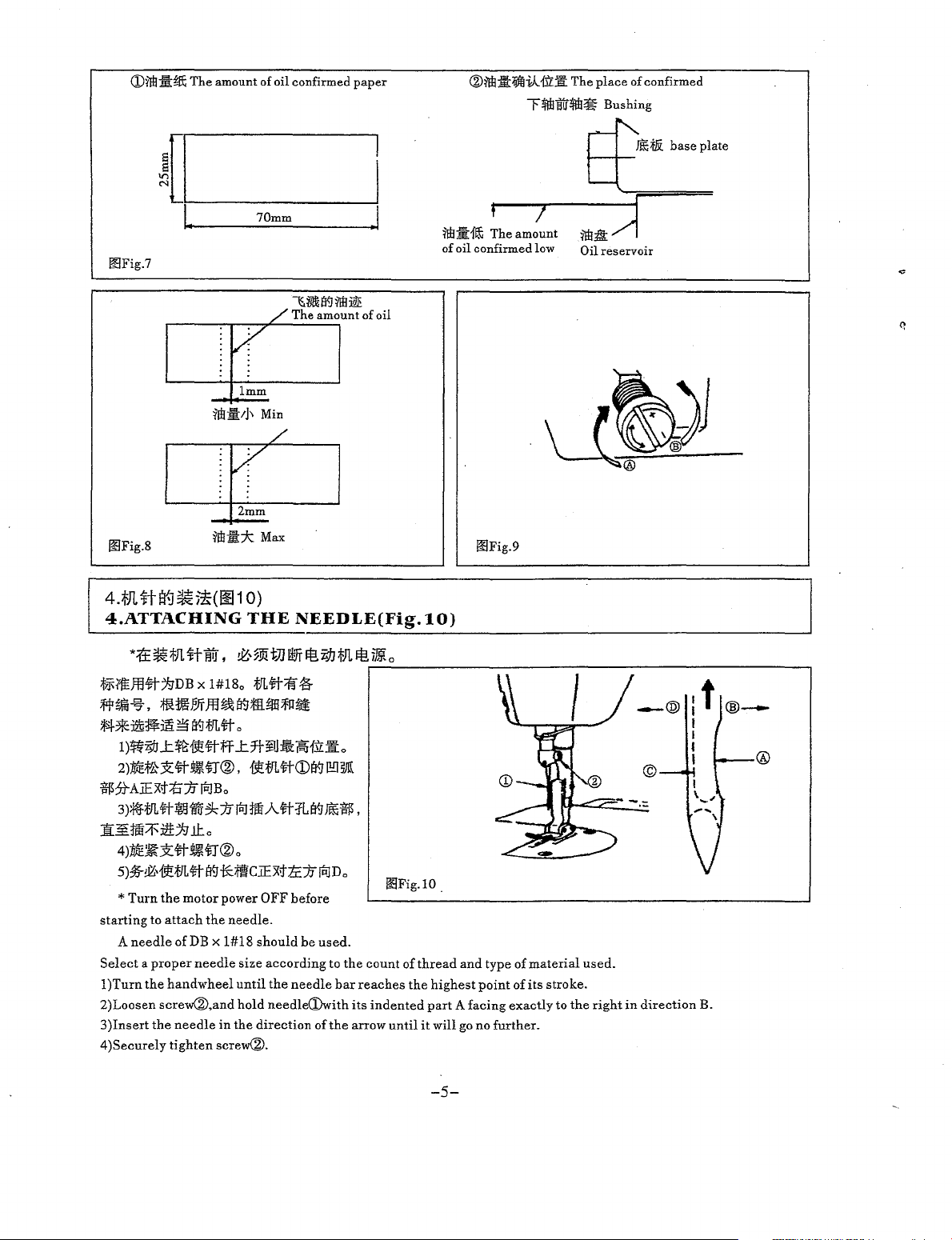

3-fm.m~ifcJT.i(~?

3.ADffiSTING

I)*fieJ13aMJL~J.llZ:ll'H7~37t#EI9:£~(:iS~Ef9J:l;ff~~~)o

2)~Jl1£~~,®!:B:m~~~tt~r:MiAo

3)lifliV.~i,l~

4)~:J:lifJiV.13;JjSJ]%'5;et#(il!f.ffl;et~tta;J)o

Ei9~Wi!11ii3t5d:13:HI~LOWV!100

*mili:EI9rwttr-¥-F

l)r00~¥-F1LHJii~lm

*~~:CI:Y~sl:®it~,

2)ff.IM:ltm;m.m.=:~.

*ifo111*1L~~:fit:

I):#fr~nfu"~~..t.EI9¥fllill:i}IJJ11~~:®J

;j\

0

2)ifoJ~}j§'

l)After

2)The

3)0il

4)The

*The

l)The

*

2)

the

*Adjusting

l)More

As

2)After

J.llZ:ltt:f'J~f.J30;et#Ef9:£~,

cooling,

the

amount

of oil

in

the

oil

pan

amout

of oil

proper

amount

amount

of oil

Otherwise

Use

paper

the

the

machine

the

amount

of

hasn' t changed.

the

~mount

oil

is

supplied

oil

amout

adjust

adjusted,the

..

~s

..

~9)

THE

AMOUNT

OF OIL

SUPPLIED

TO

THE

HOOK(Fig.7,

Fig.8,

Fig.9}

(007)

~

o

=

coos)

El9~111tl.IJ¥1%':itt1'J:Jt:W;~EI91Jlll:i!lll~,

nll~:Ct$-~~fi~~;{!:..J.o

~m;..t.~:IQE/F~~1£f.ta;J,

@.J.llZti:~~~:tl:f:JUgj(;~y:f~:Ct$-o

:tt/F\ff~iffi111T

o

(009)

+

machine

confirmed

is

confirmed

confirmed

of

oil

manual(Fig.8)

can

be

adjusted

will

confirmed

of

oil

as

oil

screw

machine

may

be

paper

within

is

for five

generate

paper

supplied

amount

is

turned

must

)Jrf;JA~~Ei't,

P..(lifJiR~:Jr~)j;IC~o

idling

for

three

must

be

inserted

HI

and

LOW.

seconds(please

according

for

adjust

be

iding

to

heat

or

the

three

times

to

the

hook(Fig.9)

screw

towan'.-in

for

the

mounted

direction

thirty

naill:~:tl:ko

minutes(operating

in

the

state

use

the

different

sewing

to

seconds.It

material

observe

on

B,the

sewing

the

when

clock

the

hook

amout

can

continued

the

with

process

will

be

amount

driving

of

be

confirmed

~~:iti!llll1~~:®J-}Jrf;JB~~a;J,

properly).(Fig.

machine

the

contaminated.

of

oil

is

second)

but

it

must

oil.Adjust

shaft

is

supplied

the

operating.

the

turned

will

state

be

suitable

screw

be

of

7)

amount.

until

toward+

decreased.

oil

supplited.

in

~:fi:#f~

the

mark

on

direction

A

-4-

Page 6

Q)M:;I:~

The

amount of oil confirmed

paper

®~i!:1if0il1fllt

The

place

of confirmed

r4lirB!i$~

Bushing

r"-i'-

Jt(;;fli

+---+--

base

plate

~[I

L

00Fig.7

00Fig.8

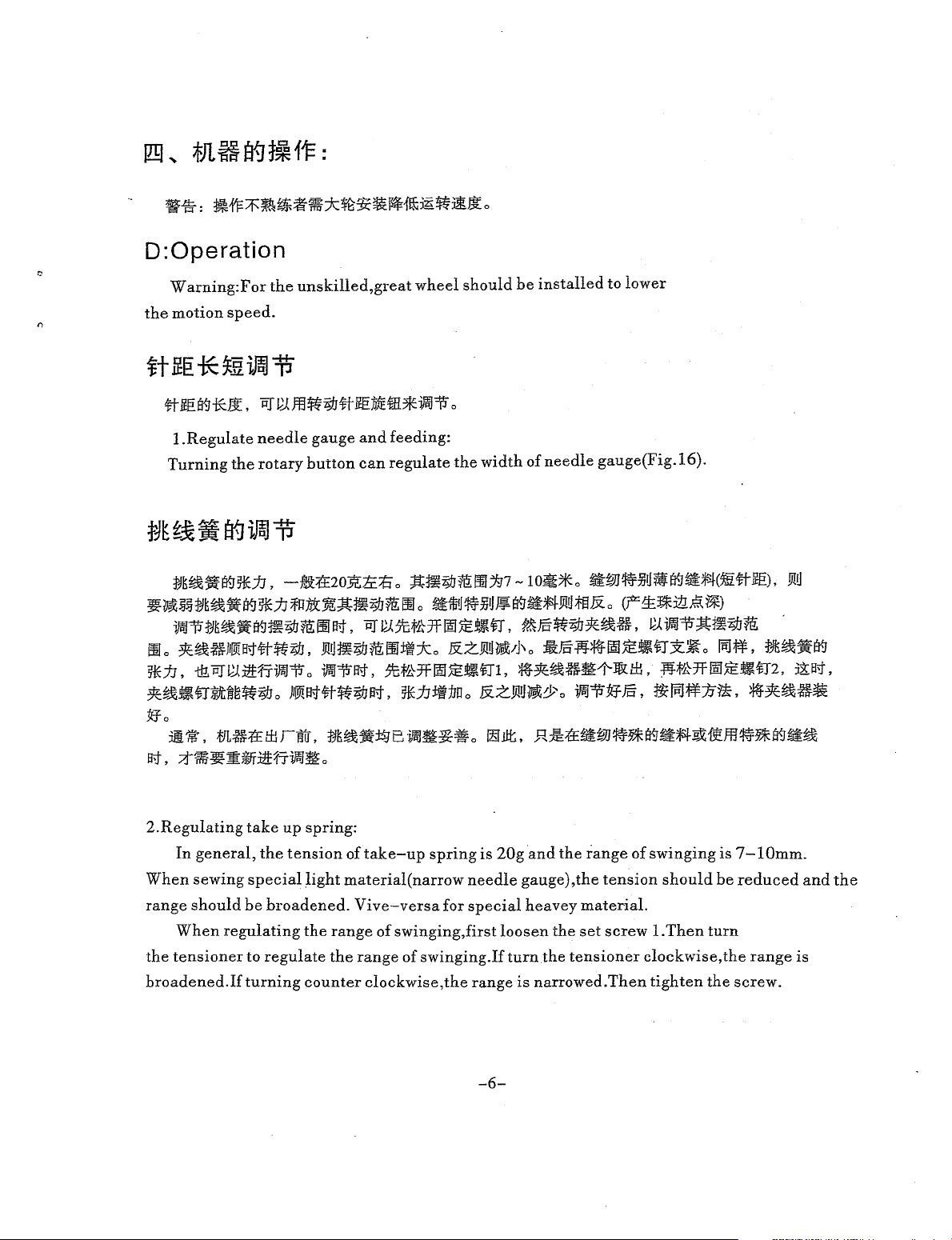

4.fJHt!Y-J~i!(~1

4.ATTACHING

70mm

~jj&a<JMiQE

/ The amount of oil

v

lmm

2mm

O)

THE

NEEDLE(Fig.tO)

I

.I

:1!!!:1:-fffi

of oil confirmed low

Tr-h_e_a_m_?'"1un-t--~-fi"l,:-/i-1

00Fig.9

'--......._,;;;;;;;;;;;===

Oil reservoir

*1±

~

*Jl.

H

~W • ~,

fjf,{'fE)fj<fj-jgDB

ff~%,

Jf:-1-*z~~~

1)ff:;IJ...t~ft#iff

2):itEf'~st#"~$J®,

X

11HI;!iMffl~i¥.J;ffi£JH5fl:rt.t

~Y-.Jmtt-

~

tJJ

wr

~

i9J

*Mg

71*

o

1#18

;fJL<fj-;ff~

0

o

...t7t~J:I!i~1:\IJL

r---------------------------------------------~

{t;f!L#Q)a<JI!!JW

$?1-AJEx;j:ti:/Jrt.!Bo

3~;f!L#GC~:/Jrt.JMA#~i¥.J~$,

][~M:If':itf::;fg

4)1iJE~)t<fj-~$J®o

5)%-!Z,ft;f!L#"a<J*;flcJEx>ttc:/Jrt.IDo

*Turn

starting

A

needle

Select a proper

l)Turn

2)Loosen

3)Insert

4)Securely

ll::c

the

motor

to

attach

of

DB

the

handwheel

screw®,and

the

needle

tighten

power

the

x

1#18

needle

in

screw®.

OFF

needle.

should

size

until

hold

the

direction

before

be

used.

according

the

needle<Dwith

needle

of

to

bar

the

the

reaches

its

arrow

00Fig.10.

count

of

indented

until

thread

the

it

and

type

highest

point

part A facing

will go

no

further.

-5-

of

material

of

its

exactly

stroke.

to

the

used.

right

in

direction

@

B.

Page 7

D:Operation

W

arning:F

the

I)

motion

or

speed.

the

unskilled,

great

wheel

should

be

installed

to

lower

l.Regulate

Turning

:f!J~~~i¥J5iUJ,

~~~U~:f!J~~~I¥J~iJ;f!JJ1Jc~;tt:~?ijjm;~~Jo

•~•~•I¥J•?ijjm:~~J~.~~~-*~~•n.•~•?ijj~~•.

Ill

o

~~@JIIDiB'.t#ff?ijj,

5!EJJ,

ill~~:llHJ--~

~~•n8.Jt~~ff?ijjo

the

needle

rotary

gauge

and

feeding:

button

-~:t£2o3'ltc:E

o

)I!IIif:!;j"#ff?ijj~,

can

regulate

o

Ji!tl~Z9Jm;

lft.J~Bt,

Effi:lt:ko

~tt-*~k:-ni,

~j]:ft:flDo

the

width

;!t~~MiHID]'g7

~1liiJ~JiUJ¥E!~~t-I-Ji!U;fEJ&o

&zJi!tl~/j\

&zJi!tl~&o

of

-Io~*o

o

*~~-~~llJU£,

needle

gauge(Fig.16).

~WJ~jjUiii¥J~;f;J.(m#lf.E),

(F1:~:Itl;~~1*)

Ji!tl

~-~;!t•?ijj~

li~W*~k:·n~~

JffiJ~M-~,

~~¥-¥1Jrt,

o

iiiJ;f-F,

:f:JK~iti¥1

Wtt-*~k:-n2,

J!B-f,

*~~-~

"!Efo

••.

at,

2.Regulating

When

range

the

broadened.If

mB:tEilirfi.m~W~B··~-o~~.R~:tE~W~Ri¥J~#~~ffl~R~~~

~$~~J~JTJlt171J;iJ.o

take

up

spring:

In

general,

sewing

should

When

tensioner

the

tension

special

be

broadened.

regulating

to

regulate

turning

of

light

material(

the

range

the

counter

take-up

Vive-versa

of

range

clockwise,the

spring

narrow

swinging,first

of

swinging.If

for

is

20g

needle

special

loosen

turn

range

and

the

range

gauge),the

heavey

is

material.

the

set

the

tensioner

narrowed.Then

of

tension

screw

clockwise,

swinging

should

l.Then

tighten

the

is

7-lOmm.

be

turn

the

screw.

reduced

range

and

is

the

-6-

Page 8

When

sioner.

crease

regulating

Then

loosen

tension.

the

set

Turning

tension

screw

counter

of

take

2,so

the

clockwise

up

spring,first

tension

can

serew

reduce

loosen

can

be

tension.

set

screw

turned.

1,

Turning

and

tade

clockwise

out

the

can

tenin-

ff)jijl~ffh.····~~~&~~-·o·W~M~.~~*ff)jijl~ffhc~~.ey~-m~

JJHf~~-ff!P,It]',

Jftilff!Pltr'

ff}jijl~ffh,~~-~-·*·~~&,~~-~@-®o

~~7(J¥)JYfffi"ftf~:/J(riJ~?ijjo

~~;j\l:[)jijl~ffh

0

,OCZ,

·~*-!-~,

ey~002l(~)JYf7F~jjiPJ,

~;fj

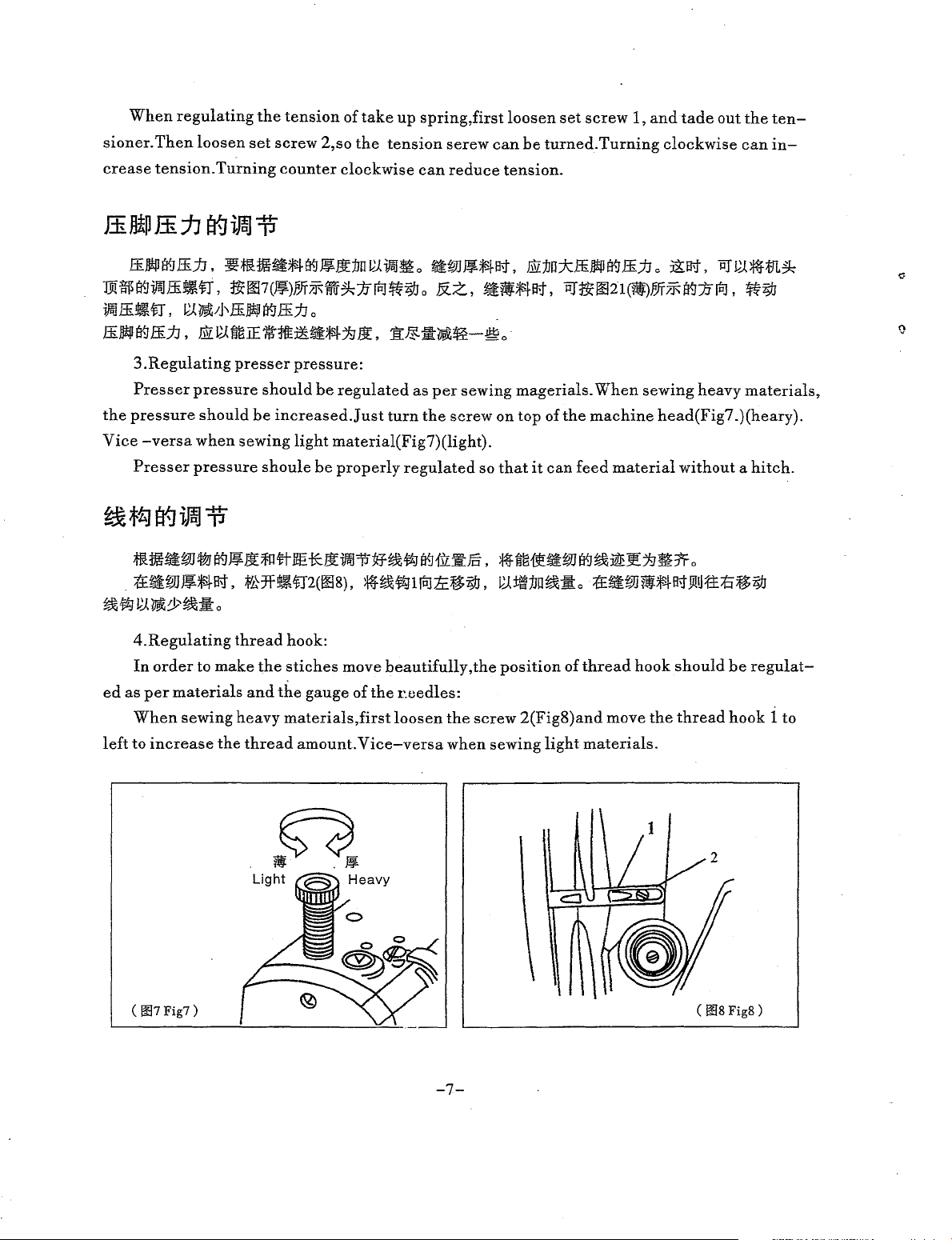

3.Regulating

Presser

the

pressure

Vice

-versa

Presser

presser

pressure

should

when

sewing

pressure

pressure:

should

be

be

increased.Just

light

shoule

be

regulated

turn

as

per

the

sewing

screw

material(Fig7)(light).

properly

regulated

so

magerials.

on

top

that

it

of

can

the

feed

When

sewing

machine

material

heavy

head(Fig7.)(heary).

without a hitch.

•••w•~~&®~m*&Jftil$~-~~~-~.••~•w~••E~•*o

.

;frti:WJ¥~-1-a-f,

:f'kfft~fi"2(~8),

.Mt¢;JlfriJ:le~;tJ,

~~:JJO

••

c

:tEatm~~~Ji!Uf:l:i(:i~;tJ

-~~~Y-·o

4.Regulating

In

order

ed

as

per

When

left

to

increase

materials

sewing

to

thread

make

heavy

the

the

and

the

thread

hook:

stiches

move

gauge

materials

amount.

beautifully

of

the

r.eedles:

,first

loosen

Vice-versa

,the

the

screw

when

position

2(Fig8)and

sewing

of

light

thread

hook

move

materials.

the

should

thread

be

hook

materials,

regulat-

1 to

(

007

Fig7)

-7-

(

008

Fig&)

Page 9

3i

..

*Jl

~+

Et-.1

~

*

••~••m#~.·m~~~~-~.~#ff~~••&•.~mm*r~~~•

~n.~m#~~•~n•Hm•~~~~w~•~m#o

C

1)

m*tBfW&,@lrtJl:.~Jl:~li.

C

2)

m#i¥.J-K;ftbtrOOrtltco

(1Pl~J#ffiL1!£);

J'G-1!#,

Ja.#T#

o

~m#•l:£,.m&~n@•~•~~-.~~-#~•.~•~#;ft~rtJ~~~.

~~~~~.5P(#7f'{±}tJ-~1[fTiifl:o

~-~m#.l:£~~~--~.~-~m#i¥.J#R;ft7!'$~M.-&M~~~~

~~ffl-~JL,

Wf~ik~JJ!P~~~·?J~d.>,

~Ji.!Um:~J!·lffm#,

-~:

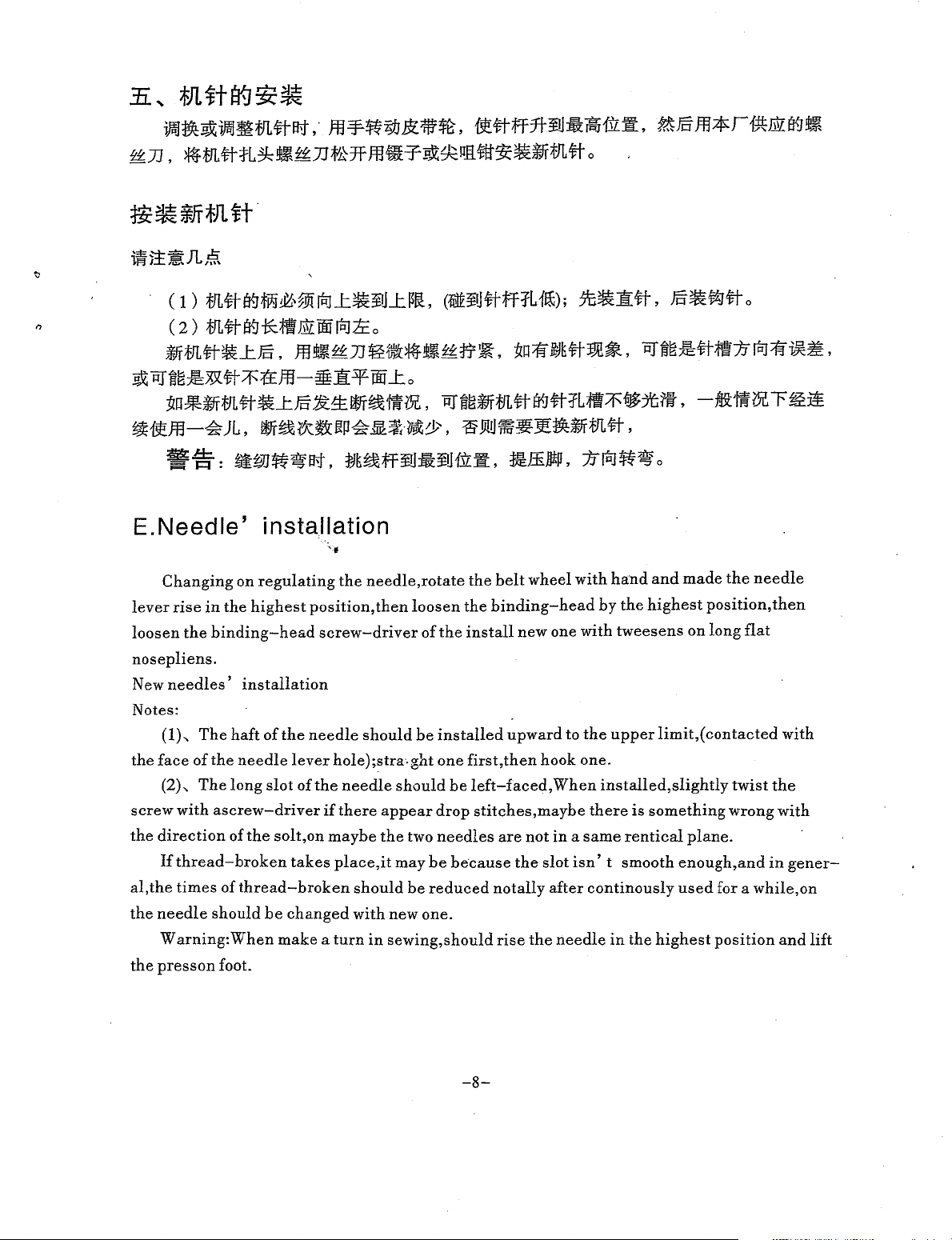

E.Needle'

Changing

lever

rise

in

the

loosen

nosepliens.

New

Notes:

the

screw

the

al,the

the

the

the

binding-head

needles'

(1),

The

haft

face

of

the

(2)-.

The

long

with

ascrew-driver

direction

If

thread-broken

times

needle

Warning:

presson

of

of

should

When

foot.

~W~~~,

~~-ff¥U-~H.il:•,

installation

'f

on

regulating

highest

installation

of

the

needle

slot

the

solt,on

thread-broken

be

changed

make a turn

the

position,

screw-driver

needle

lever

hole);stra.ght

of

the

needle

if

there

maybe

takes

place,it

should

with

needle,rotate

then

loosen

of

the

should

be

installed

one

should

appear

the

in

sewing,should

two

may

be

new

drop

needles

be

reduced

one.

:r£ffiJW,

the

belt

the

binding-head

install

first,

be

because

new

upward

then

left-faced,

stitches,maybe

are

the

no

tally

rise

wheel

one

hook

When

not

in a same

slot

after

the

needle

to

~rtl~~

with

by

with

the

one.

installed,slightly

there

isn' t smooth

continously

o

hand

and

the

highest

tweesens

upper

limit,(

is

something

rentical

in

the

highest

made

on

plane.

enough,

used

the

needle

position,

long

flat

contacted

twist

wrong

and

for a

while,

position

then

with

the

with

in

gener-

and

on

lift

-8-

Page 10

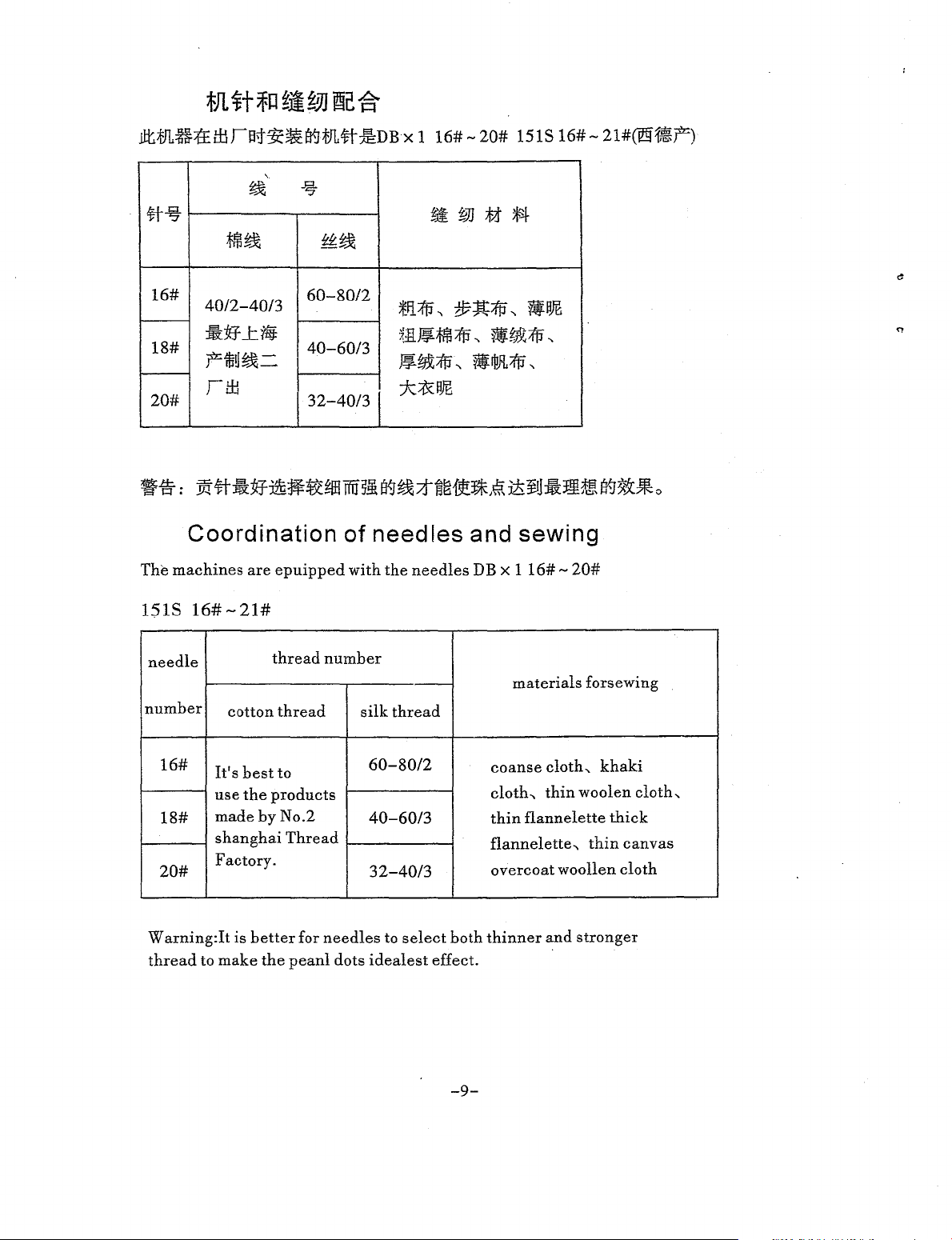

*ll

~t

~ll

~~

gg]

Eli~~

Jl:t;f]L~:tftfj

~%

16#

rat~~J¥j;f}L~~DB

'

~

tm~

40/2-40/3

-~

~~

60-80/2

ji:llf_t7BJ

18#

20#

~illtl~=

r!±l

Coordination of

The

machines

are

40-60/3

32-40/31

epuipped

needles

with

xI

I6#-

20#

ISIS

m

~JJ

:fi

JlSl.

;Efi{!J"

~ll~;tm{tl

~fJX;f!J

t/7;lt{tl"

'\

ti~1!J

'\

ti

rjiJL

{tJ

jc;;&!W.

and sewing

the

needles

DB x

116#-

I6#-

1iP~

'\

'\

20#

21#([91,~~)

151S

needle

number

16#

18#

20#

W

arning:It

thread

16#-21#

cotton

It's

best

use

the

made

shanghai

Factory.

is

better

to make

thread

thread

to

products

by No.2

Thread

for

the

peanl

number

silk

60-80/2

40-60/3

32-40/3

needles

dots

idealest

·-

thread

to

select

both

effect.

materials

coanse

cloth._

thin

flannelette._

overcoat

thinner

cloth._

thin

flannelette

woollen

and

forsewing

khaki

woolen

thick

thin

canvas

cloth

stronger

cloth,

-9-

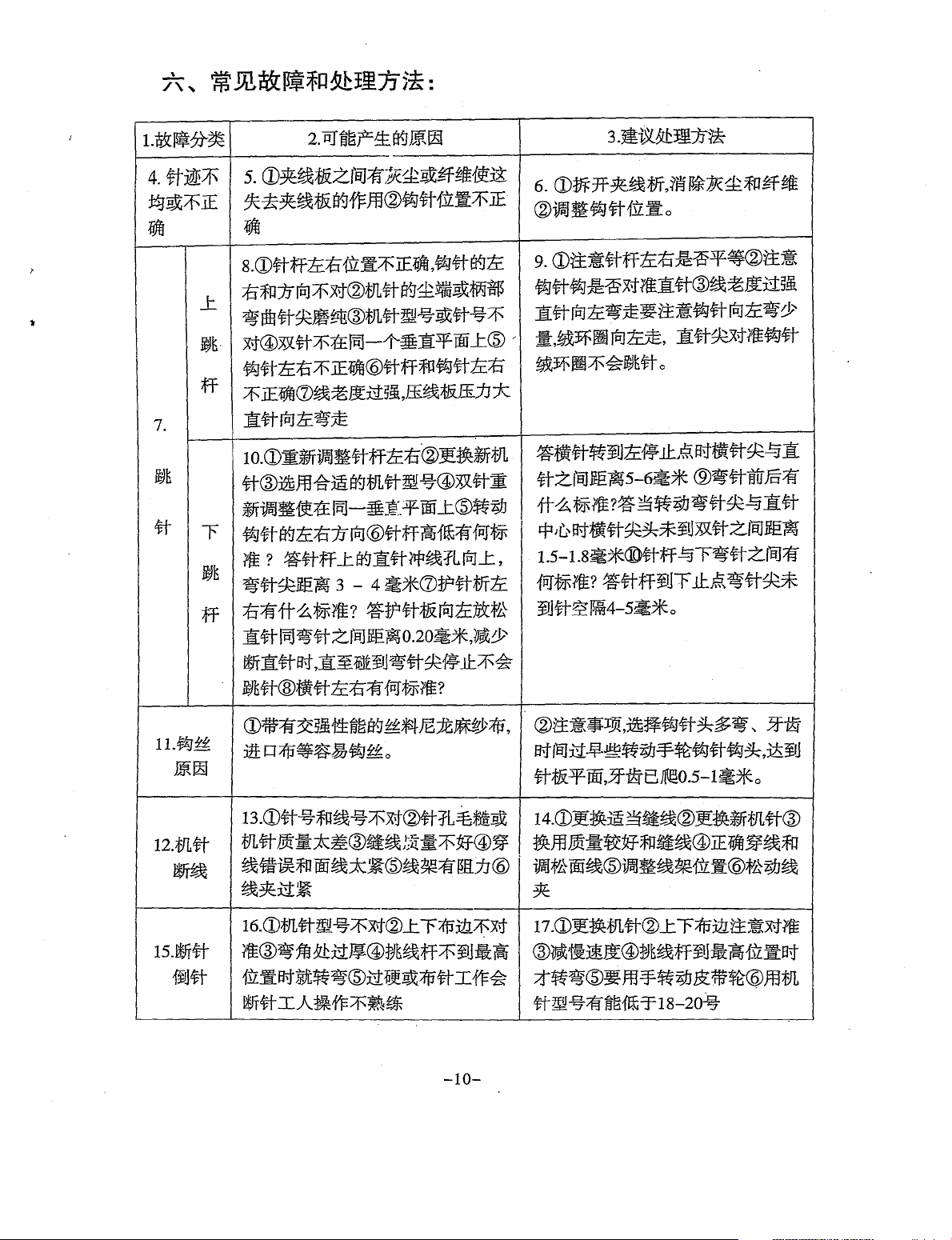

Page 11

2.

PI

§~tc

~

1¥.1

~

l."Mc$Jt?R

5.

4.

#JdE;r\

:f::t]~~iE

~

_t

1r

w~

ff

7.

CD~~f&ZfBJ1f:&<~~fffME1tl!

~~~~if&B3fFffl(2)~<ftfilif~IE

~

s.CD#ffietl&if~IE1ijij,~#I¥.Jft:

tt~JrtnJ

~Ilirtt-9Cm£II!®mtt-~%~tt-%/f-

m@~tr/f-1£1PJ--t-~1I¥W...t®-

~#1Ctl~iE1iif!@#fff0~#1C:ti

~

iE1ffrlCV~~~:l:15£,~if:liff.:fJ-:k:

~xtC2>trL#I¥.J~i'iffii~;JW=ff!S

1ifl-tnJ1C"11J5E

I2Sl

6.

CDm7f~~vr.t~~:Yc~fngf£t

(2)iflil

9.

CDf:l:~#ffie:tl~:e1Jl.~C2>tt~

~#~~~x1fiH#®~~.OC:l:15£

1I#fnlie~~~a:~~#[O]ii."11Jd>

:t:J;x:DFliltnJtv£,

~Yf\111~~&~#

3.Yi~~H1!!Jr~

~~#{ill[

0

1Itt-~>tf'1E~tt-

c

&~

#

r

&~

ff

li.#Jff

Jlf.J§

12.fJL#

~

lO.CDlB:JfifliJ~#ff1Ctl®£~~m

#®:®ffl~ms1rf1L#~%@~

jfiflij~{t{E

~#

f{{J1Ct!JrfnJ

ff£?

~#~ie~

tl:tr

tr

1I#IPJ~#;Gfa]JEE~0.20~*·~j>

Wi-1I#M

&t#®~#ic:;fi:fl

Q)iff:fl5l:5&'11:§~~

:itf:r::::r;fif~$&~£'£0

IPJ-~~:.f-

@#ff~1!£:ff

~#:ff

J:f{{J1i#ilP~:JLfnJJ:,

3 - 4

~

~m?

,1l.3HiJJU~#gc{~

~~H?tt-;t&

Tiff

~*CV!P#:tlfie

fPJt~fi?

£"£*1-M:Jt~y;;{jl,

tt-:m:

_t

@~~

filJ;f,.j

tnJ

ti:ti~tc

Jl~~

13.CD#%~~%~.xt®rrJL~*i~

tJL#

M:i::*~®~~t~:i:~~@3f:

~~~fOOO~:*~®~~:fflill.:fJ@

~*:1:1:~

~:tft#~¥1Jief¥

#Z.fBJNEt*f5-6~*

tr~t~i'l?~~~~~ft~-Ej:ft#

q:.Jr..'at~#gc~*¥IJ~trzfBJNE~

1.5-l.s~*®fl-;ff

1PJtjf'1£?

¥IJtt-~IWi4-5~*0

®&~$=0!,:12t~~#~$"1JJ'

a'.tfa.J:lt

#1i1Jl.W,3f-&Bjjlg!0.5-l~*o

14.CD£~m~~~®£~Jrm#®

~ffll!ltl:!€it%-~~~@JE1ifij3f:~~

1ftiltkoo~®1ftil~~~m~®ttZ)}J~

~

~#ff¥Irf

lf!..®~~-¥~~#~~

JL~M:tft<ft~~H

®"1JJ#IWJB:ff

~r~fl-zfBJ:ff

ll::B

~#~*

3f-&

,:iii!U

15.J$T#

fftl#

I6.CD:fJL#~%

ll®~Jri~:ltW@~t~ff~¥1J!i~

11Iifa-JJ.l9t~~®J:i~~;fif

WT#

I.A.1*f'F::F~t~

~xif®...t

r:t!Ht!.~x>t

rr

IfF~

-10-

17.CD£~m#®...t

®~9Mt~.OC@1:Jt~ff¥IJ!i~f.1l~at

::t~~®~

rr~%;ff~M~ris-2o%

r:f!JJtJ.B:~xifi1E

JiFJ.~ZfJJE[w~®fflm

Page 12

/'\--. Usually malfuction and how to deal with

1.Malfaltion assort

2. The possble reason come into being.

3

.Advise

how

to

dead

with

4.The needle trace not well-distributed or incorrect

5. (1).Between thread board have ash or fibre let this losing

(2).The position of the hook needle incorrect

6. (l)Open the thread· board elin'.inate ash and fibre.

(2).Reguiat the position of the hook needle.

7--.

Drop stitches : upper ones

lower ones

8--.

(1).the position of the needle and its lever

and

the direction of

are all incorrect.

(2).the point of the needle is blunt and bended,and its haft as well.

(3).The type or the number of the needle is incorrect.

the

't

needle

(4).The

two

needles are not in a same vertical plane.

(5).The position of the hook needles are incorrect.

(6).Something wrong with the attched needle plate.

(?).Something wrong

9

...

(1).Regulate the position of the needle lever again.

with bith the honizoual and bend needles.

(2).Change a new needle.

(3).Select the correct tybe of the needle.

( 4).Adjust the

(5).Move the hook needle towards left

(6).Make adjustment of the screw

two

needles in a same vertical plane.

and

in

the attached needle plate.

right direction.

(7).Make adjustment of the working hours of both the honizaual and bend

needles.

10-..

Phread-broken

11--.

(1

).

The number of the needle is inconsistent with the number of the thread.

with the needle.

(2).The hole of the needle is rather crude on the quality of the needle is too poor.

(3)The thread is of

(4).Make wrong thread and the ball thread is

bad

quality.

too

tight.

(5).There is assistance with the thread-stand.

(6).The thread clamp is over tight.

-11-

Page 13

12., (1).Change suitable thread.

(2).Change new needles .

. (3).Change better quality thread.

M

thread

tPl

(4).Make

(5).Begulate the thread-f.teand.

(6).loosen the thread claimp.

13., (1).Needle-broken and needle-returned appear.

14., (l).Wrong thpe of the needle is used.

(2).The upper edge of cloth is not aligned with the lower one.

(3).The turn corner is

(4).The needle thrns when it isn't in its highest position.

( 5). The cloth

15., (l).Change the needle.

(2).Pay attention

(3).Lower the speed.

(4).Don't make the needle turn until it is in its highest.

(5).Move the belt wheel

l$

m

~

Easy-worn

correct and loosen the bali thread.

too

thick.

is

too hard.

to

the alignment with the upper and lower edge of cloth.

wi~h

hand.

E!ic

14

attachments:

0 0

T~-if

T:m-if Lower

Lower

#f&

needle

bend

needle

honizoual

plate

needle

1!:-if

~#

-12-

straight

hook

needle

needle

;f-[;!f tooth

ff.Hf!J

press

en

©

foot

Page 14

Figure

controling

of

regulating

the

position

left-deviation,rignt-deviation

of

upper

jumper

thread

pin

screw

and

left-devia6on

-$-~~--

wrong

pm

screw

~~=m*~~.~mx•~n~~.

W

arning:Don't

-driven

screw

for

regulating

in

order

revolve

not

to

lower

the

pin

make

jumper

screw

it

broken.

thread

~~m~•~

with

big

~*

bend

straight

.!Eiii

right

screw

needle

needle

ffi

,ight-deviation

11#

straight

needle

wrong

r~~#1ir:il~

figure

of

position

of

bend

-13-

needle

in

lower

hook

thread

needle

Page 15

.

..,

Model

(For

Medium

Heavy

Materials)

-14-

Page 16

46

-15-

Page 17

Arm

{tf%

Bed

Part

I.tJL7e?tm

!¥%

Ref. No

itt=

I OI.Ol.l-0

2 01.01.2-0(229-45356)

3 01.01.2-1(229-21308)

4 01.01.2-2(229-21407)

5 01.01.2-3(229-21704)

6 0.1.01.2-4(229-21803)

7 01.01.2-5(229-21506)

8 01.01.2-6(229-21209)

9 01.01.2-7(229-21605)

10

01.01.2-8(229-45307

11

01.01.2-9(SS-8090670-SP)

12 01.01.3(B3188-552-EOO)

13

01.01.4(229-00757)

14 01.01.4-1

01.01.4-2

15

01.01.5(SS-608041 0-SP)

16

01.01.6(229-00609)

17

01.01.7(SS-412615-SP)

18

01.01.8(229-00401)

19

01.01.9(SS-412915-SP)

20

01.01.10(110-00619)

21

Ol.Ol.ll(TA-2000502-RO)

22

01.01.12(TA-2101002-RO)

23

01.01.13(SS-8150710-SP)

24

01.01.14-0(229-32552)

25

26 01.01.14-1(229-32503)

27 01.01.14-2(229-32602)

28 01.01.14-3(229-32701)

29

01.01.14-4(SD-0380552-SL)

30 01.01.15(TA-1250705-RO)

31

01.01.16(229-20706)

32

01.0 1.17(229-02159)

33

01.01.18(229-02209)

34 0 1.01.19(229-20607)

35

01.0 1.20(229-20508)

36

01.01.21(110-01500)

37

OLOL22(TA-1250406-RO)

38

01.01.23-0(229-01250)

39

01.01.23-1(229-01201)

40

01.01.23-2(229-01300)

41

01.01.23-3(SS-6060210-SP)

42

01.01.24(110-28008)

43

01.01.25(SS-6060210-SP)

44

01.01.26(229-0 1003)

45

01.01.27(TA-0850604-RO)

46

01.01.28

47

01.01.29

48

49

Ol.OL30(II0-04109)

50

01.0 1.31(229-02605)

51

01.01.32(SS-7II0540-SP)

Components

No

tJL%'li'Mtf:························ Arm bed

~~~~IHtf:·

~~-iij:·······

~~i!ifj

~~--

tk~;fti·······"'""'""''"'"'Thread

~~;J:&

~~-~

~~~-·

:fi~~J{i)iif'lJ~·--··········--·--Thread

~~~~-~

tk~~···

~~~~m_{tf:

;~'if~~~

~~

..............................

~W~~~-11-·----·········Screw

jl}~~fHF

:fi~~:tftp

-IY!tl'OO;fiii·

iY!tlW;f&·~·····

fJ!tlOO;f&m·······--········------·Gasket····

ff'J!E~3t*JL£--

:J2i;f~ff'J!E'im1J=i'L£--·

~~~-~

W~:l:t~~m_{tf:·

00'~:11~11

/j\~~;f&·····--·······--···--···Thread

/j\~~-·

/j\~~-11

#':tf!l!!;jpj

.:=.:B~:l:t~.zg

W1lV.

· · · · · · · · · · · · · · · · · · · · · · ·

WKt§

......................

llif;f&-':3<~-zg

;t:J~.zg

.....

~.zg--~

W;f&iJil'f'\J'=i'L£·

11E1Iim1tf:·········

1tE1Ji

....

· ...... · .................. Slide plate

tfE1fi1li(·

........

1fE1fiilt·~

#'1Ji"""

#'1Ji-~

Jli;1Ji·~·

:fi~~a:tfi1HL.£

W1Ji~1:1'!i1Ji

m.!%.Jll!!···

~%.Jll1!················

.:E!)!IJ~

......

a*1fi

...........................

a*•~·····

Description

assembly-································!

· ·· · · · · ·

·· · ······

..

.................

i9J;f&

.............. · ....

...

· ·

·.

· · · · · • · · · · ·

·Tension Complete subassembly·

Thread tension nut···--··--

--Thread disc rotation stopper

········Thread

tension

spring·····························

release disc·

........................... Thread tension disc

........................

·

..

· · ·

..

· ·

.......

...........

........................

.................

...... ·

.. · .. ··

,a··

..

··

.. · ..

~-~

........ · ....

..........................

................

...........

.....................

.. ·

..........

·

....................

· · · · · · · · · · · · · · ·

..

· · · · · · ·

..

..

:j'L£--

..

" ·

.. · .. · .. · .. ·

Tension sorew

···· ....

·Take-up spring · ·· · · · · · ·

·--·--·Set

screw··········

Tension release pin

·Oil packing subassembly

....................................

tension post socket

...... ·Oil packing cover ·

oil

wick

..........................................

................................................

···

.. · ..

--Thread take-up lever cover-

--Thread

take-up

Face plate asm

Screw

................................................

--Rubber plug

.........

Rubber plug

Thread tension

·Face plate thread retaining guide subassmbly--·I

Face plate thread guide retaining

········Thread

···

......

·Thread tension screw--··

......

·:Rubber plug needle drining crank hole ·

.........

Three hole thread eyeket·

·······Face

plate · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·1

----Face plte sealing gasket

lever cover screw .. ·

....................................

..... · .............................

......................................

......................................

screw"""""'"""'""""""1

tension

disc··--··--·····--·

tension spring"

..................... Face plate thread guide

· · · · · · · .. ·

..... · ..

........................

· .. ·

......

...............

· · .. " .. · .. · · .. ·

.....................

·"

"·

"·

.... · ....

............. ·

· · · · ·

'·

· · · · · · ·

...............

....

···

"··Thread

·······Rubber

..

"·"·Throat

·· ..

"Throat plate screw

.. · ..

·Bed screw stud

guide right·

Thread guide screw

plug"·

...

·····

Bed slide subassembly·······

.... · .. · ..

Silde plate

Slide plate spring screw

Rubher plug thread take-up lever link pin hole 2

spring"·

plate · .. ·

.. ··

.... · ........ · ......

........... · ...................

......

........................

............ : .................

............................

.................................

........... · .... · ............ · ..

..

... · ..

..

··-······"····

....

· .. · .. · .. ·

.........

...........................

········

......

........................

....................

..

· · · · · · .. · ·

........................

........................

..

··················

.................

·········"············

.. · ....

··

.....

...... · .......... · ........

...........................

...........................

···········

······

... · ..

..

.. · ......

.......................

.. · ..................

··

....

··

........ · ......

· .. ·

.. · ....

..........................................................................

........................ Brandplate··

..

.'

· · .... · .. · .. · .... · .. ·Main shaft bushing

..

........ Brand plate rivet··

Connectingrod

·········

..

······Screw

..

·····

.................................

..

··········-······

..................

....................................

................................................

..

· · ·

Amt.Req

"·········

··

······1

..

· · · · · · · ·

..

····

...... · ....

·· ·----··1

...............

··

....

······

.......

·········

··············2

··

.........

...... · ....

·····

..

····.·

·············2

.......... · ·1

~:I:

1

1

· 1

·1

2

I

· · ·1

!

···I

I

1

1

--·1

}

..

·I

· 1

1

8

·1

· 1

1

2

..

·I

1

· 1

1

1

!

1

·1

!

·1

·2

1

2

··

2

4

·I

l

I

2

-16-

Page 18

34

-17-

Page 19

Main

Shaft

Thread

Take-up

Components

i'F%

{tj:%

Part

Ref.

No

01.02.1-0(110-39070)

2 0 1.02.2(229-031 08)

01.02.3(55-8681650-TP)

3

4 OL02.4(SS-7681650-TP)

5

01.02.5(R0-0442401-00)

01.02.6(110-39062)

6

7 01.02.7(229-27206)

8

01.02.8(55-8151550-SP)

0 1.02.9(229-03504)

9

01.02.1 0(229-03405)

10

01.02.11

11

01.02.12

12

01.02.13

I3

14 01.02.14

I5

0 1.02.15(SS-866061 0-TP)

I6

01.02.16(229-04155)

0 1.02.17(229-03306)

17

18

0 L

02.18(SS-815II50-SP)

19

01.02.19(229-I9559)

20 01.02.20(CQ-3500000-FO)

21

OL02.2l(B

0 1.02.22-0(11

22

23

01.02.23(B1408-552-000)

24

0 1.02.24(b1905-541-BOO)

OL02.25(B

25

01.02.26-0

26

27

01.02.26-1(229-03900)

28 0

1.02.26-2(229-04007)

29

01.02.26-3(R0-0291801-00)

1903-552-000)

0-05204)

1212-552-000)

30 01.02.27(229-03702)

31

0 1.02.28(229-03207)

0 1.02.29(229-03009)

32

33

j

01.02.3I

No

~~AAffffl.

<ft;jfa!J~

#;jfa!J;JW~I§l~~

<ft;jfa!J';JW)Effl~~

~Ul-~O~fm

~~AA~ff

_t~

_t~~fi"

..t~lrrlfiit

..t~Fo~~g_llftj:

:lli4\J6!ffi-········· ······

JZ'.1tf6~~~

~fJZ_t1f~·-·

fit

_t~~fm~~

_t~~~

_t~

fi~AA:Jiff~~~

fi~AA~ffil\j

fi~AA~ff~rmAA

:t:JkAAa!J;JWii::afE~~

ti~AAa!J;JWffl.

<ft;jf~;jf

<ft;jf~ffi.

<ft;jfa!J;jWtp;fli

¥1!!itiJllfl'~ffl.{tj:

B:IJ;JW¥1!!itWJl'~

B:!J·~$:ftiJll!T.f~~

O~iWrmi&'itlll···

..t~$fg

..t~iltr~~gll.

_t~

_t~~Yffii-~

ftj:

·········

···

······

···

···

···

···

···

············

······

···

··· ···

···

··· ··· ···

······ ··· ......... Indented fork

3.f~;jf~

1m·-

...... ·

...............

.....................

"f=!~~

.................. Main shaft middle

..................

ftj:

···

.....................

.....................

...............

...............

ftj:

...........................

···

···

···---Thread

···

·········Needle

···

······Set

screw·······································

·········Screw·············································

············

0-Rubberring

······:·····Thread

·········Hand

·········

···Screw,hand

·· ·

··· ··· ···

Sealing

············

Mainshaftrearbushingsubassmbly-········1

······Cloth-feeding

······Screw·············································

.. · ..

· Collar feed driving connecting rod

Snap ring screw·--------·-·-

Main shaft thrust collar

............

Screw

Thread

............

....

Oil wick

.........

Endscrew,left-hand

:.

···

...

Thread

Needlebarcrankconnectingrool

Needle bearing

Needlebarcrankwearingplate

···

......

···Crank

...

···

...

··-Crank

·········Rubber

.........

0-Rubberring

······Main

· · · · · · · · · · · · Main shaft front bushing subassembly · · · · · · I

main shaft

............

Screw

Description

take-up

bar

subassembly

crank

···

···

···

······

·········

·········

·································!

take-up

wheel·································

.............................................

oil adjusting subassembly

oil adjusting pin

shaft felt ..

.................................

lever

link··················

wheel······························

ring·······-·---························

cam

······

···

······

···

...

······

...............

···

..

···

.. ··------·---- 1

........................

bushing·········

take-up

leverlink

..................

pin

...............

·--

.....................

...........................

take-up

crank subassembly

............

.................................

..

·····

............

.........

···

......

bushing·············

....................

.................................

·····

.....

···

..................

.......................................

Amt.Req

···

···

······1

···

··· ···

.........

..

· ·--·-· .. · 1

...

···

...

...

···

..

····"

··· ...

···

.........

~tl:

···

1

···

1

···1

1

···1

2

···1

1

2

1

1

·-·1

1

l

1

1

...

1

1

2

1

l-

1

1

I

·-·1

!

1

-18-

Page 20

1

,---~---------~

5

....

....

.....

....

.....

',,

'

'-

....

..

-- -----

3

2

'~--

-----

---------

,,--------'

9

I

'

'

::.,

Page 21

3 .

$t

Be

iftf'P

$

f4

FEED

I<.EGULATING

COMPONENTS

!¥%

1

2

~%

01.03.1

01.03.2

3 01.03.3

4

01.03.4

01.03.5

5

01.03.6

6

01.03.7

7

01.03.8

8

01.03.9

9

01.03.10

10

01.03.11

11

01.03.12

12

01.04.13

13

14

01.03.1:4

01.03.15

15

16

01.03.16

17

01.03.17

01.03.18

18

19

01.03.19

01.03.20

20

01.03.21

21

22

01.03.22

01.03.23

23

24 01.03.24

.15

~X®CfiiH!il

tl-RE:liff

tl-RE:l!;f§

~X®i:~!illl~tr

trREifo11lmff

tr

RE

trREifo113~;ff!illJ~

trREifo113~ff!illl~~n

tl-REifo113~ff®Ciii!illl

:ft&:~20

trREifo11J~;ff

tl-REifo113~$JO~Im

#REtj~

trRHj~~tr

#R§Ji-~:ft&:£;

lf:;!Jif!i

lf:i5biiH~-

fiiJ~~~ffm!illl

fftl~tt~ffm!illlo~

fiiJ~~~ff

fiiJ~~~fflft!mm*!illl

fiiJ~tt~ff

fftl~~~fflft!ffifrf54~~

fiij~jl~ff~tr

f$

®Ct:iH~!illl

ir.J1lmff ~ n

x4

~

1ft!

m

1ft!

mm*

feed

fock

the

stitch

gemel

shaft

screw

swinging

screw

shaft

bushing

adjusting

screw

hinge

shaft

adjusting

rubber

feed

regulator

o-ring

feed

dial

screw

stitch

dial

stopper

stopper

feed

reverse

rubber

reverse

reverse

slipe

block

feed

rever~e

feed

reverse

connecting

length

of

stitch

lever

of

pin

pitch

of swinging

pitch

plug

rubber

pin

pin

spring

shaft( short)

ring

feed

control

feed

control

spring

asm

link

for

adjusting

swinging

screw

acrew

length

lever

lever

shaft

lever

link

lever

pin

pitch

lever

for

lever

for 1

asm

asm

slipe

shaft

14~

1

1

1

1

2

1

1

1

1

1

1

1

.1

..

,

-20-

Page 22

33~

r-----_;_

I :

t

I · I

1

~~

----

~~

4 I

....

6

I

27

23

\ - l

I 35

~-

1

~;

I . o. I

I 4 : I

t

~

I

81'

l_

~30

r--

1

I 5 4

I . I

,~'

I I

I

~~'

t

t

(_

-----..;,L- '

~·

'-

---24

<:::.

:

.

<::;:)

J!

•'

----r-----_j.J

---

...,-

()

,:

. I

.dii_

4

.--

:;

--·--..J

-.

2~

;

. 1

----,

7 I

I

I

!

I

I

1

I

36

3

9

ytl

0

)

21

~<()

17

1

\

1'

~

--19

38

49

9

;

r?o

42CcP

···~0-t

44

o

47

~

50

~)

45

-21-

Page 23

Fabric-Piercing

Hook

Driving

Components

,

!¥%

Ref.No

01.04.1(SS-4110915-SP)

0 1.04.2(229-16407)

2

01.04.3(229-05202)

3

0 1.04.4(SS-866081 0-TP)

4

01.04.5(B1307-155-0AO)

5

01.04.6(229-05004)

6

01.04.7(B1308-155-0AO)

7

01.04.8(SS-4120915-SP)

8

01.04.9(229-16308)

9

01.04.1 O(SS-611

10

01.04.11(229-17157)

11

01.

04.12(229-1600

12

01.04.13-0(229-16100)

13

01.04.14(SS-8150432-TH)

14

01.04.15(SS-8110410-TP)

15

01.04.169(229-17058)

16

01.04.17(229-16605)

17

01.04.18(229-16506)

18

01.04.19

19

01.04.20

20

01.04.21

21

01.04.22

22

01.04.23(151S)

23

01.04.24

24

01.04.25

25

01.04.26A

26

01.04.23(229-06200)

27

01.04.24(SS-6090670-TP)

28

0 1.04.25(229-06457)

29

0 1.04.26(229-06507)

30

0 1.04.27(229-06002)

31

0 1.04.28(229-061 01)

32

0

1.04.29(229-0

33

0 1.04.30(B

34

01.04.31(B1306-155-0AO)

35

01.04.32(229-051 03)

36

01.04.37

37

01.04.38

38

01.04.39

39

01.04.40

40

01.04.41

41

01.04.42

42

01.04.43

43

01.04.44

44

01.04.45

45

01.04.46

46

01.04.47

47

01.04.48

48

01.04.49

49

01.04.50

50

1305-0

f4'%

1409)

Part

0420-

1)

12-0AO)

No

TP)

1?;

;lE{.fz.gt.f

~fil.;ff<

!lli:~rF~~

:$::-{i;f!fl:;jli;l'

!lli:~""F

!:\£~···························Upright

""F~:$::-{i;f!fl:;

~~_t~~'

""F~J§'~~

""F~Fo:JS!m•t.r

""F~Fo:JS!m

""F~

·····················Screw

························Rotating

···

··

••• • ••

:$=-&!A:;···············

·••

""F~Fo~~_mt.r

............ ···

.................. Hook driving shaftthrust coller

............ ··· ........... · Hook driving

""F~"fu'~~~!HtJ:

""F~"fu'~~-t.f

""F~au:JSIII•t.r

""F~"fu':JSII!

""F~~:7111~

""F

-l\ll

Ji!;1:.~

f.S1:.~.mt.f

mt~c

""F~ft

_t

fl;)ft

1i:

ft · ··

ft:'!k:~.mt.f

ft:'!k:~

ft:ff""F~

ft:ff:Ji~;f:l:tJ.t.f

ft:ff:)i~;f:l:

ft:ff:)i~;f:l:mtlc

ft:ff ......

.................. Hook driving shaft front thrust collar

................. · Oil wick

~

:7111 ~ t.f

................

...... ··· ......... slip

· ..... ""

...

........................

......

··· · ·· ··

.................. ·

.................. Screw

........................

..................... Needle

..

· .............. · Needle

···

.................. Needle

ft:ff ..t ~ .... · ...... ·

ft:ff

..t~:7111~

_t~:ijl::-{t;f!fl:;

_!l£~_t1jl:--{i;f!fl:;

!lli:"BB!..t~~

;k

rr$1g~

;k#$1g~gt.f

;kft$1g

:I:Jltft$1g

:flft ······

..................

.................. Upright shaft

· · ·

.. · ···

... : ........... Screw

..... ·

..

· ......... · .....

...

··

.................. · Across

·····················Across

;flftgt.f ..................... Screw

:flft$1g~

;flft$1g~~~

tlft$1g~~~-t.f

... ·

·· ··

...... ···

3f#:Ji:ff ... ··· ...

ffft:J!.;j:f~~

'*;lc

· .......... ·

'*;!c~'-.:_r

'*;lcgJ;t~'-

............... Screw

..

.....................

T-··

fF

· ···

··

· ···

···

Upright shaft lower

•••

·· •

•••

•·•

Set screw

Bevel gear

•••

•••

•••

•··

·••

Bevel pinion

..

· Hook driving shaft

............

.......

............ Set screw·

............ Screw

Screw"""'"'"'"'"'"'"'"""'"""""""'""

··"'Hook

Screw·································

driving shaft front

Description

·············································2

leanon

positioningfinger-···········1

bushing

···

···

···

···

··· ···

···

• • ·

shaft

····································I

··· ···

··· ··· ··· ···

rear

shaft"·

.........................................

.............................................

..........................................

···

···

··· ···

···

···

···

•· · ···

· ·· ·· ·

bushing

....................... · ...

hushing

.... · · · ........ Hook driving shaft front screw

,.

...... slip

"·

...

"•

...

· ......... upright hook needle.

...

·· · ..

............ Needle

..

· · ·

............... Rubber plug

...............

··

· · · · ... ...

· ... · ..... ·

···

...... ··· Across

···

......... Needle connecting rod

· ............ Hafu

· ........... · Hafu

head

head

·"Slip block

laybendneedle

..

·"Straight

clip-on

· ·

..

Screw·

..

· · Needle

Bevel gear

Bevel pinion

Macro-needle

Macro-needle

..

Across

··· Across

Hafubullet

bullet

..........................................

screw

........................

"'

............

needle

.............................................

needle

bar

lower

........

············

bar

connecting

bar

guide

bar"""

bar

upper

....................................

........................

....................................

upper

.............................................

.............................................

....

frame

frame

needle

frame

needle

....................................

needle

frame

needle

frame

needle

frame

.............................................

· · .. · ·

.... · ......................... · ....

.......................................

.. · .............................. · .....

••"

......

.................................

··· ...

··

· · ·

.....................

.................................

bushing

block···

.........

bushing"

.....................

...

··

............... · ...

pin""···

........ · ...

·•·

......

...... · ......

bushing

seat

...

...........................

..

· ·

....................

seat

·· · ........ · ......

seat

swinging

seat

swinging screW"' 2

........................

·· ·

··· ···

···

···

···

· · ·

···

···

· ··

·· • ••

··· ···

·· · ···

......

............

...............

subassembly ·

......

.. · ........ · ..

···

......

"'

••• ••• •••

................

··

..........

...............

···

......

···

.........

··

···

............

..................

··

................

.........

Amt.Req

·· · 1

·· · 8

· ·· · 1

1

2

I

2

!

1

..

1

1

2

I

I

·I

I

I

...

1

I

1

I

1

1

1

1

1

1

, .. 1

....

1

1

1

I

1

I

3

I

···

1

I

2

· .. I

I

I

!

1

1

I

-22-

f{:l:

Page 24

5

Page 25

Presser

Bar

Components

~%

Ref.

No

01.05.1 (SD-0721331-SP)

1

01.05.2

2

01.05.3(229-20409)

3

01.05.4

4

01.05.5

5

6

01.05.6(B1521-555-000)

7

01.05.7

01.05.8(110-18306)

8

01.05.9-0(B1524-012-0BA)

9

10

01.05. 10(SS-709110-SP)

01.05. 11(229-07000)

11

01.05.12(229-07208)

12

01 ,05. 13(229-07208)

13

01.05. 14(229-08008)

14

01.05.15(RE-0500000-KO)

15

01.05.16-0(229-08156)

16

01.05.

17

01.05. 18(229-07802)

18

01.05.19(229-07604)

19

01.05.20(229-07505)

20

01.05.21(229-20003)

21

01.05

22

01.05 .23(229-08800)

23

24

01

.05.24(229-09006)

25

01.05 .25(229-07703)

26

01.05

27

01.05.27(229-07406)

28

01.05.28(110-06509)

29

01.05.29 (229-20201)

01.05

30

01.05.31(229-07307)

31

32

01.05 .32(SS-866081

33

01.05 .33(SS-609091

14-%

(229-08909)

17-0(229-08552)

.22(229-083

.26(R0-0371801-00)

.30(11

0-181

05)

08)

Part

0-

TP)

0-SP)

No

Description

J§"lli!;J:iM!IJiil:~tJ············

tr:

tlJ:i;fPHll~

t~!,;lH~~lj!.it··················

tk~~mlm··················

ffi.ttJJ!I!:toc=F-~trmlm

:fitff)j!p:f.OC~~~············

tk~f~3fl:lt\il§l············

tk~~························

m

.ttJJ!I!til.

m.ttJJ!I!~~··················

ff;j:f

···

··· ······

14-·

· ·

···

···

· · · · · · · · · · · · · · · · · · · · · · · · ·

ffff'i= · · · · · · · · · · · · · · · · · · · · · · · ·

ff;j:f~~

ff)j!p~:ff-411J

3f

ffiffJJ!I!ti:ff~IH4·

:fit.ttJJ!I!

:[["';

iM]ff~iiJ:···

illi!ff~~

tk~t&························

ffiffB!IJ~ff···

:tit

:tit

illi!ff~ff·

ffiffB!IJ8~~¥Ifli-t···

illil.ttit

ffi

:f:H.it··

f'k~;t&~{i[:~~

00~~~~]

ff;j:f~~~$J

00~~~~~~

· · · · · · · · · · · · · · · · · · · · ·

·

·· ··

· · · ·

1:!

t\i

1§1

• • • • • • • • • • • • • • • • • • • • • Spring · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·6

··

8~W.

f4·· · ···

.'liB!IJ:f.OC ~ · · · · · · · · ·

···

···

···

· · · · · · · · · ·

··

··· ··· · ··

.ttJJ!I!

]§-!II!

;jjlg

• • • • • • • · • · · · · • · Lifting

ffB!IJ~;j:f

.ttB!IJ~

..

.. · ..

· ..... ·

{)I~

........ ·

···

...............

.. · .. · .. · ...

t]" .. · ·

.........................

···

........ · ·

... ···

............ Screw

Hingescrew

······Screw

Spring····························:·······

Washer

······Washer

Screw···················

Snapring

Pin

················································1

·· · ··· ···

Hinged

Screw·············································

·;

Presser

Presser

Presser

··

· ·

·· · ··

Lifting

···

··· ···

Connecting rod subassembly ··· · ··

··· ··· Hand

..

· · · · · · ·

Hand

··· ··· ···

Presser

· · ·

·· · ··

·

Presser

Tensionreleaselever··························

··· · · · Lifting

.. · .. · ..

· Lifting

Pressure

...... Lifting

Presser

....

· .. · Lifting

Sping··

.........

Hinger

.. · ··

..

· Thread

.........

Presser

····································1

···

···

······

··· ···

··········································1

··········································

·······································

presser

foot subassembly

bar

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

bar

bushing

bar

guide braket· · · · · · · · · · · · ·· · · · · · · · · · ·1

hook······································

lifer

cam

subassembly··················

lifer

lever

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 1

spring

regulator

spring

regulator·······················

lever

presser

rod························

lever

rear

crank

lever

presser

rod·

lever·

...........

lever

crank

shaft

spring"'· ..

lever

...........................................

screw····································

release

bar

.............................................

··

....

shaft

binger

finger

guide screw

······

······

···

···

..

························

··· ··· ···

· · · · · · · · · · · · · · · · · · · · · · · · · · · 1

···

· ·· ·· · ·· · 1

nut

···

· ··

··· ···

· · · · · · · · · · · · · · · · · · · · · · · · 1

....

· ... · · · .. · · · · .. · · · · 1

···

...

···

...... ······

screw······

· .. ·

..... · .....

screw .. · ·

... · .......

................. · ......

· .. ·:

......

· .. · .. · .. · 1

......

....

Amt.Req

~·

···

···

···1

.......

;.1

· ·· 1

·1

···

···

...

···

· · .. · 2

· .. · ·

..

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

-24-·

Page 26

20

-25-

Page 27

Feed

Machanism

Components

!¥%

Ref.

No

01.06.1

2 0

1.06.2(55-7111120-SP)

3 0

1.06.3(55-4080620-

4

01.06.4-0(229-13354)

5 01.06.5(B 1613-012-AOO)

6

01.06.6(RC-0150001-KP)

7 0 1.06.

01.06.8(229-04155)

8

9 0

1.06.9(55-866061 0-TP)

01.06.10(229-15201)

10

11

01.06.11(229-12901)

12

01.06.12(229-13156)

13

01.06.13(CQ-2520000-00)

14

01.06.14(55-7110740-

15

01.06.15(55-7121410-TP)

16 0

1.06.16(WP-0480856-SP)

01.06.17(229-13701)

17

18

01.06.18(229-11309)

19

01.06.19(SS-7110510-SP)

20

01.06.20(229-10202)

21 01.06.21

22 0 1.06.22(NS-668041

23

01.06.23(SD-1000801-SH)

24

01.06.2455-8660610-TP)

25 01.06.25

26

01.06.26(229-13206)

{tj=%

(229-15300)

79(229-13008)

(229-15003)

(SS-866061 0-TP)

PartNo

TP)

TP)

0-SP)

Description

X7fH~3.f(!lj;JW

X~1it3.f(!lj;JW.tJ

*if..J.3.f!llll\tJ

~

~m_

:i!*l-3.f···

*if-1-41lf,

*if..J.41lf,

*if-1-~,

~:mlli!!llll\t.f··············:···

:ffl'3.f41lf

**l-41lf · .. · ..

3.f$W:)]J£

3.f$W:41lf¥!ll~······"·

3.f~$!!J~~!Illl\tJ

3.f~Ji:-t.f

3.f~Ji:·t.f~Wl··

:f.!L:Jil:4i!J···"···

~7;/J1:1i}]l£;!\[{.lziif·

;!\[

{:lz:1:1i.tJ

mt-1-:li;ff

t{;.5f;li;jf

1it3.f!W:-flt

:J'it.::f!W:t.f

**l-41lftnll~-tf

:ffl'3.f41lf41lf~!~tJ

3.f~41lf

··· ··· ···

······Feed

·········Clamp

···

······ ···

······Feed

{t!=···

··· ··· ···

··

· ··· ···

···

···

··· ···

·· · ··

· ···

1it3.f41lf~ff.l¥=fil!

1it3.f41lf41lf~

1it.ffi~f=lll!!!

··

······ Thrnst

........................ Feed driving shaft

· · ............ ·

... ···

........ · ......... Feed

......... Oil wick

··· ··· ··· ...

...

··· ··· ···

··· ···

·

···

· .....

................ Guide

........... Spring··

· .... ·

·· · ".' · .. · ..

lifting shaft

screw····································

dog

screw·································

Feed

bar

body subassembly ·· ·

Feed

dog"·····································

Shap

ring·······································

· ·

··

Feed

rocker

shaft

ardfeed

collar····································

Screw···························

..

· Feed

rocker

shaft ·

rocker"'

Screw···············

Screw···

Washer

Scre-iv

...............

.....................

......

····································

· · ·

··· ···

.............................................

...........................................

.. ·

........

· .. · .. · .. · .. · ·

crank························

driving shaft

..............................

...... · .. · ......

...

·········

···

·· · · · · ·· ·

..................... Feed rocking shaft connecting rod

.....................

.....................

.....................

...

............ Feed lifting shaft,

........................

Feed

Feed

Feed

; ........ Feed

Feed

lifting connecting rod

lifting

nut

.................................

lifting rock screw

rocker

shaft,bushing

holder

shaft

............ " ..

bushing

···

............

screw

screw

···

···

bushing··

..

·····

...........

· ·

......

···

...

··············

·····················!

......

·········

···

.........

....

· .. · · · · ·

...

..................

...........

............

"·

···

Amt.Req

· ··

···

· · · · · 1

··· ···

.......

·········

· · ··

....

.. ·

......

~it

1

1

2

· ·· 1

···1

···2

·2

2

4

!

·1

···1

1

·· ·1

l

1

· 2

1

1

1

1

· 1

1

1

-26-

Page 28

\

I

l

j

-27-

Page 29

Lubrication

Components

1¥%

Ref.

No

01.07.1

1

01.07.2

2

01.07 .3(229-24153)

3

01.07

4

01.07

5

01.07.5-1

6

01.07.5-2

7

01.07

8

01.07

9

01.07

10

01.07.5-6(229-23502)

11

01.07

12

01.07

13

01.07

14

GB818-76(SL-4030851-SF)

15

GB862-76

16

8B845-76(SE-4301041-SR)

17

8B845-6(SS-6111010-TP)

18

8B845-7(229-24609)

19

8B

845

20

8B845-9(229-23304)

21

8B845-10(SS-4150915-SP)

22

8B845-11(229-24807)

23

8B845-12(229-24500)

24

8B845-13(229-25002)

25

8B845-14(229-24906)

26

27

8B845-15(229-25101)

28

8B845-16(229-24153)

8B845-17(229-24302)

29

30

8B845-18(SS-41206I5-SP)

8B845-19

3I

32

GB

I235-76(R0-195240I-OO)

{lj=-%

(~29-24708)

(229-24401)

.4(229-24005)

.5-0(229-23056)

.5-3(229-23700)

.5-4(229-

.5-5(229-23403)

.5-7(229-23601)

.5-8(229-23809)

.5-9(229-23205)

-8(229-

23007)

23908)

PartNo

Description

nb'Cif

· · · · · · ·· · · · · · · · ·· · · ·· · · · · · · Oil sight window · · · ·· · · · · · · ·

_t.~~nb'lf

@!:liJ:l'lf

:lil3*.3ttt · · · ·· · · · ·

:liB*m

:liB*.~~~

:liB~

:liB*Ilf~·····················

:liB*f*···

@!riiitt~·····················

@!:liJ:li)lif11@~···············

@1$1:1:£···················

nll*llf~~;fli

$*Jl'ii.

:liB*J!i:~@~M3

nll*3i:~@~mll!I3·········Washer

:liB*Jl'if.@~A3

:liB*:E"@~··················

$

~t:=:::im

:liJ:lfi':fj§:*·· ·

nil*~························

@n···························

"F$.!l'illl'lf~Jt

"F~

$:1:i)lif11@~···············

$:1:i)lif11~····

@!

#:!!

@!$§;

@!:liJ:l'lf'lf*··················

$1f*~~

@!:liJ:l'lf

O~i&'itll!l

· · · · · · · ·· · · · · · · ·· · Main shaft oil tube ·· · · · · · ·· ·· · · · · · ·· · · · · · · · · · · · · 1

··· ··· ···

··· ··· ···

··· ···

Oil return

···

· · · · ·· ·· · Oil pump installing base · · · · · · · · · · · · ·· · · · · · ·· 1

{lj=-

· • • • • · • • · • · • • · •

· ·· · · · · · · · · · ·· · · ·· Oil pump

f*W~···

··· ···

· · · · · · · · · · · · · · · ·· · · · · · · · Lubricating oil pump

•••

••

• Lubrication oil pump

·

·· ·· · ·· · ··· · ··

··· ··· ··· ··· ···

· · · ·· · · · · · · · · · · Oil pump impeller

X 8

X

10·········

Oil pump body bushing · ·· · ·· · · · · ·· · ·· ·· · · · · · ·· I

Oilpumpimpeller

Lubrication oil pump

Oilreturnpumppluger

Oiladjustingscrew······························l

Spring·············································!

···

· · ·

Screw·············································

Screw

Screw·············································

· · · · · · · · · · · · · · · · · · · · · Oil pump

···

···

··· ···

··· ···

Rubber joint

Oilpumpholder································

Screw·············································

· · · · · · · · · · · · · · · Oil pump impeller

~:liB

'1f

· · · · · · · · · · · · · · · · · · Oil tube · · · · · · · · · · · · · · · · · · · · · · · · · · · ·· · · · · · · · · · · · ·

Oiladjustingscrew

··· ··· ···

···

Spring··········································

§;*

· · · · · · · · · · · · · · · · · · · · · Oil return tube

···

··· ···

··· ···

·· ·

···

···

Oil return tube

Oil

·· · ·· ·

···

···

···

···

Screw·············································

.ffi:;fli

···

···

··· ··· ··· ···

24x2.4·········0-ring·············································l

Oil returm clamp

tube

holder

screen·································

······························I

cover······················

························

.............................................

three

way············

···

··· ···

cover······················

holder·····

plate

return

tube

holder··

···

···

· · · · · · · · · · · · · · · 1

··· ··· ···

··· ···

subassembly···········

··· ··· ···

·· ·

··· ···

························!

cover···················

··················

· · · · · · · · · · · · · · · · ·

···

·· ·

··· ···

··· ···

···························

· · · · · · · · · · · · · · · · · · · ·

··· ··· ··· ···

··· ··· ··· ···

···

···

.. ······················!

···

·· ·

Amt.Req

···

·· ·

···

·· · · ··

·· · ···

···

······I

·········I

~:tl

1

·1

1

···1

·I

·I

3

3

3

1

·1

···

1

1

2

·1

·1

1

···1

·1

2

-28-

Page 30

Oil

Reservoil & knee

~--23

@--24

Lifter

22--Q

Components

3

!¥%

Ref.

No

1

0 1.08.1(110-23017)

01.08.2(229-31703)

2

01.08.3(110-47107)

3

4 01.08.4(110-24700)

01.08.5(55-6700710-5H)

5

GB

1235-76(R0-1082401-00)

6

GB

1235-6(SM

7

GB

1235-(NM-6060001-SE)

8

GB1235-7(SM-9061853-SR)

9

GB1235-8(110-24016)

10

GB1235-9(RE-1000000-KO)

11

GB1235-10(110-24205)

12

13 GB1235-11(110-24510)

14

GB

1235-(SM

15

GB1235-I2(110-24015)

16

GB

1235-I3(229-34608)

17

GB1235-14(229-34509)

I8

GB1235-15(229-34202)

19