Page 1

ZJ1850

MACHINE

SERIES

TACKING

INDUSTRIAL

SEWING

fJ!Ift

OPERATION

!S!

PARTS

itt=-

i~BA

.EJ=.

=It

MANUAL

flf}

BOOK

m

111-m

ZOJ

E

11

&ill!ll

SEWING

mn

nsr

fR

MACHINE

15iBe

~51

CO

.,

LTD

.

Page 2

§

~

CONI'ENIS

e

~..fflmf!ij..:t:5

·

··········

··

· ···

·········

·

····

· ~ ·

· ·····

·· ·····

· ·

;····1

INSTRUCTI

e

~§~·······

PARTS

ON

LIST

MANUAL

·

············

··

····

··

·········

·

······

·

·········26

Page 3

Tacking Industrial Sewing Machine

INSTRUCTION MANUAL

Thank

you for buying a sewing machine. Please

usinj

this

Wlit

order 10

get

lhe

most

out

of

it

and

read

10

enjoy using

this lnsttuction Manual

it

for

along

euefully

time.

befon:

t~Ht:iWl!~JJ!Pi

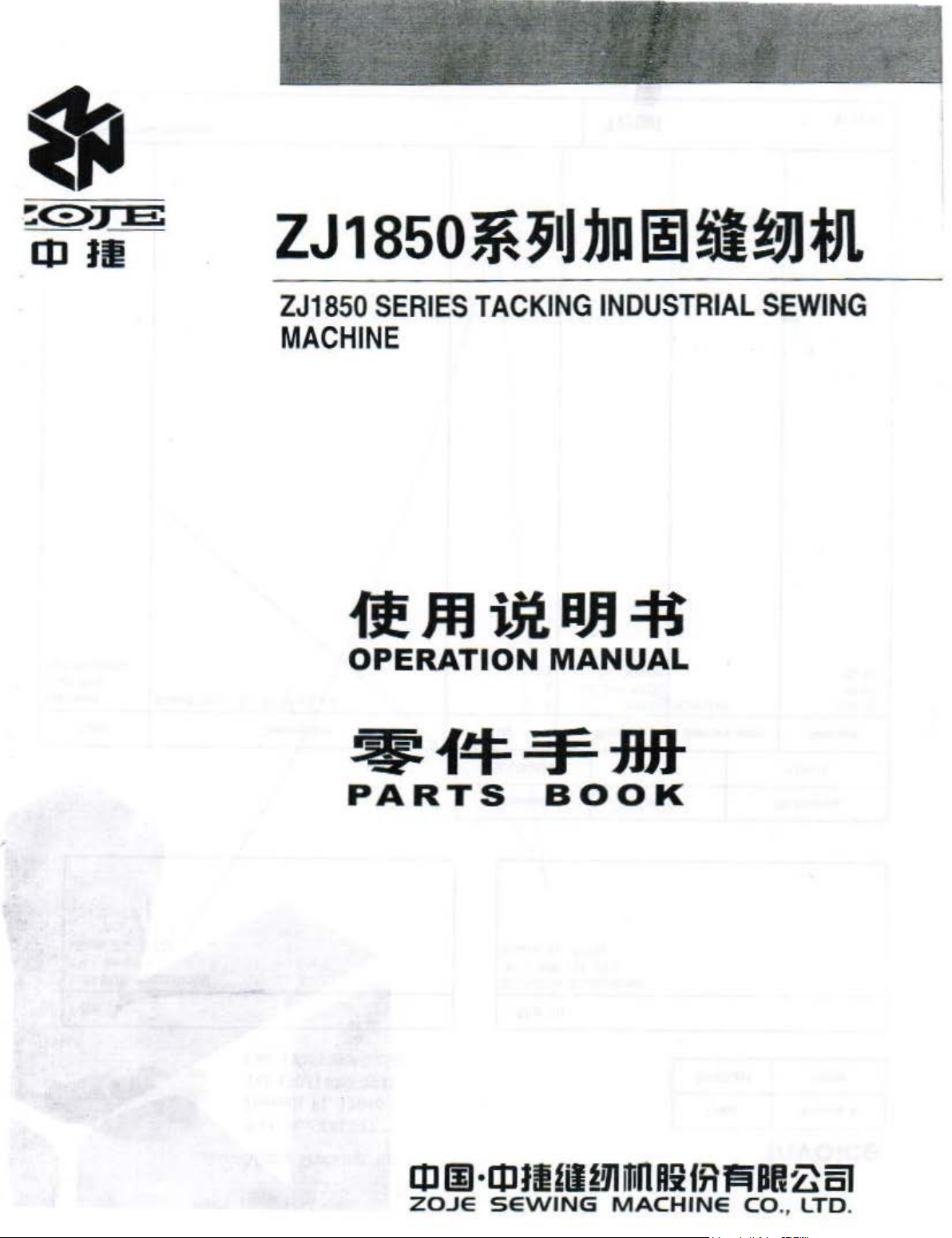

1.

Do

not

hold

the

belt

cover

canying

!he

sewing

machine.

CAUTIONS BEFORE OPERA TlON

whe

n

2.

The

run

Never

run

sewing

in the

allow

11

the

machine

arrowed

the

machine

reverse

should

directoon.

to

direction.

3.

If

the

from

supply

-

the

ing

oil

just

to

gauge

red

color

above

the

lubrication

' 9.

1ubrlcatlon

is

when

observed

looking

the

oil

o;J

' •

in

down

gauge

accord

,

_,

_

Page 4

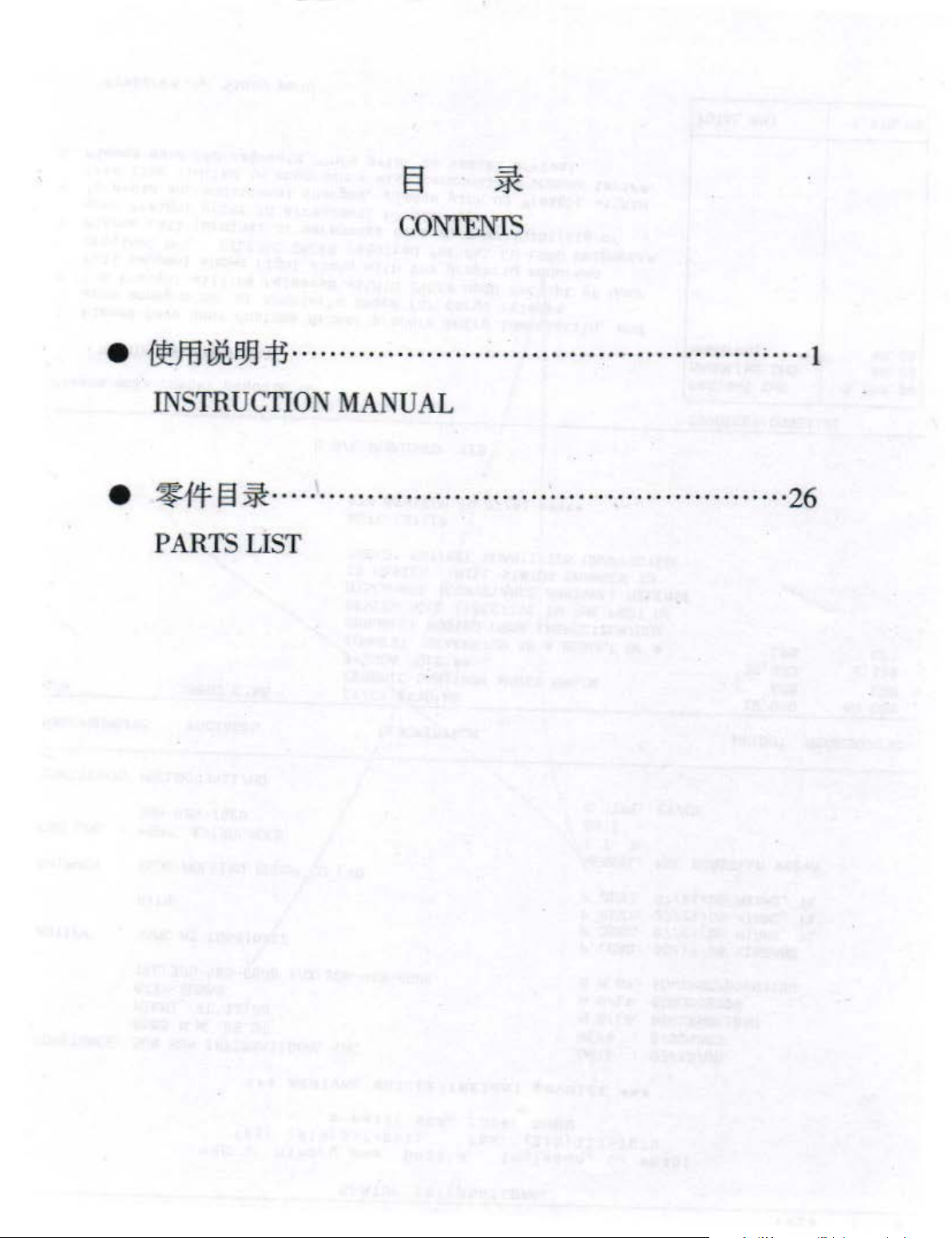

4.Before

time,apply a few

the

starting a machine

racing surface& of

drops

of

the

which

the

lubricating

shuttle

has

race.

been

newly

oil

to

set

main

up

or

shaft

components

has

not

been

used

for a long

through

hole

8 ,

period

one

drop

of

to

HH'f:!fla9jil!4JJ.9l

I.

"tE~fl;tll.$l:l:t!l

3.

'tE

lii!

fl'llt

tHJ:~rp.

4.

M

tll.tli~t-t

1 .

Do

not place your fingers near the

foot while the machine is in operation

3.

Never bring

pl

ace

any- thi

bobbin winder wheel

it may lead

r:f'

W~

~-'F~tti!t

:f

~~

:f

:tli~

.

m~~~~~. ll'm:tc~~&!/'

your

fingers

ng

on the handwheel, V-belt,

to

serious personal injuries.

or hair clo

or

motor during op

CAUTIONS

.fUJ

e

~

2ti!iliffi"J$~

worl< clamp

se

lo,

or

IN

#J

{'l'.

llittc~a

OPERATION

2.

Jli:

~Jt.U

jll]VI.I'litflf~tltt:~

Jii:r.,

· 2. Make sure

the belt cover.

4.

It

your machine is provided with a be

and

eo

~

lion,

them removed.

f~

iltr

.

.*

ok:·~

.

to

tum

off

eye

guard, neve operate

't

-1f

XJ<tf.

~:!e~1:.~lJ~

th-e

power switch

your

,

.

befor

e removing

lt

cover, finger guard

machi

ne

with

any

of

-2

-

Page 5

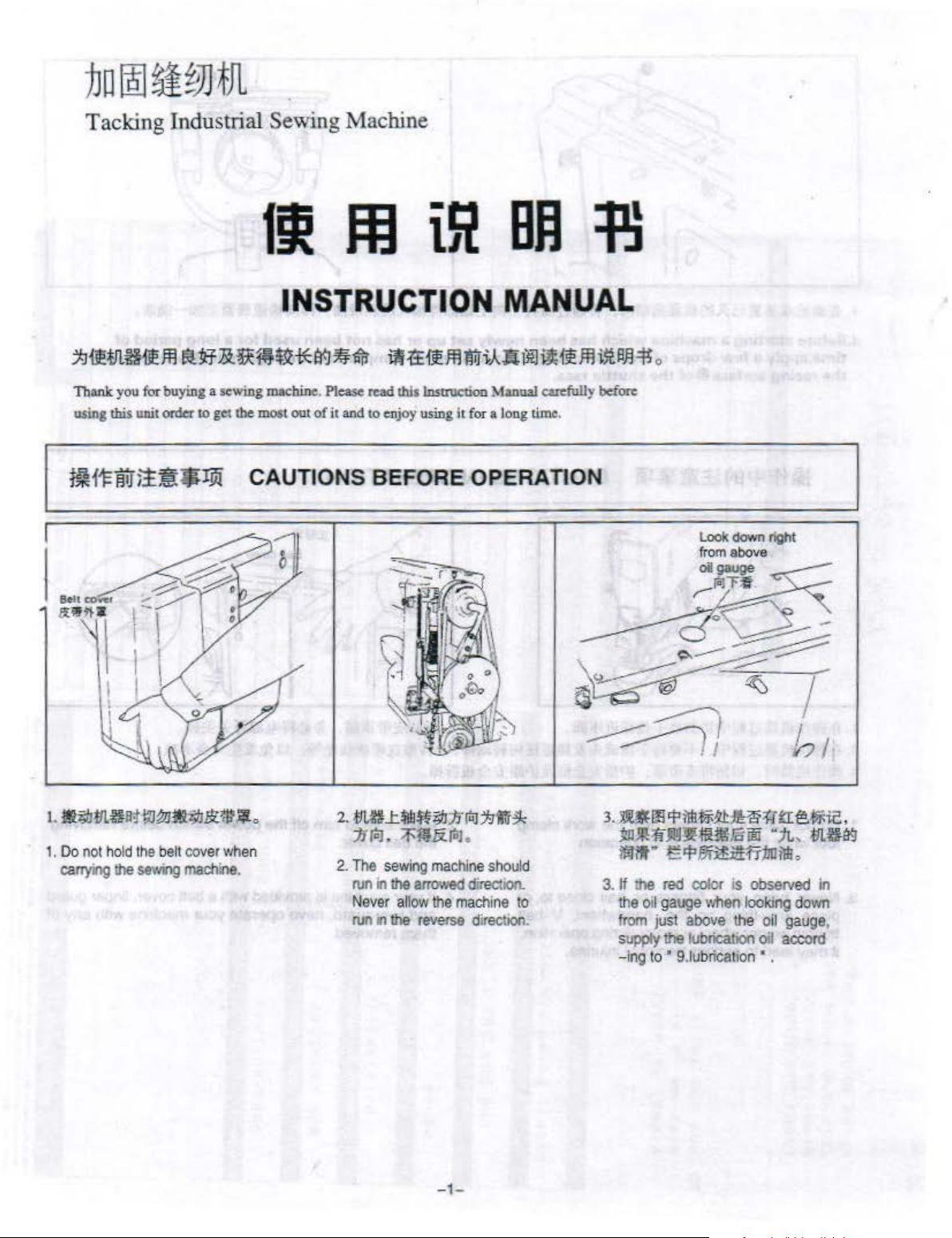

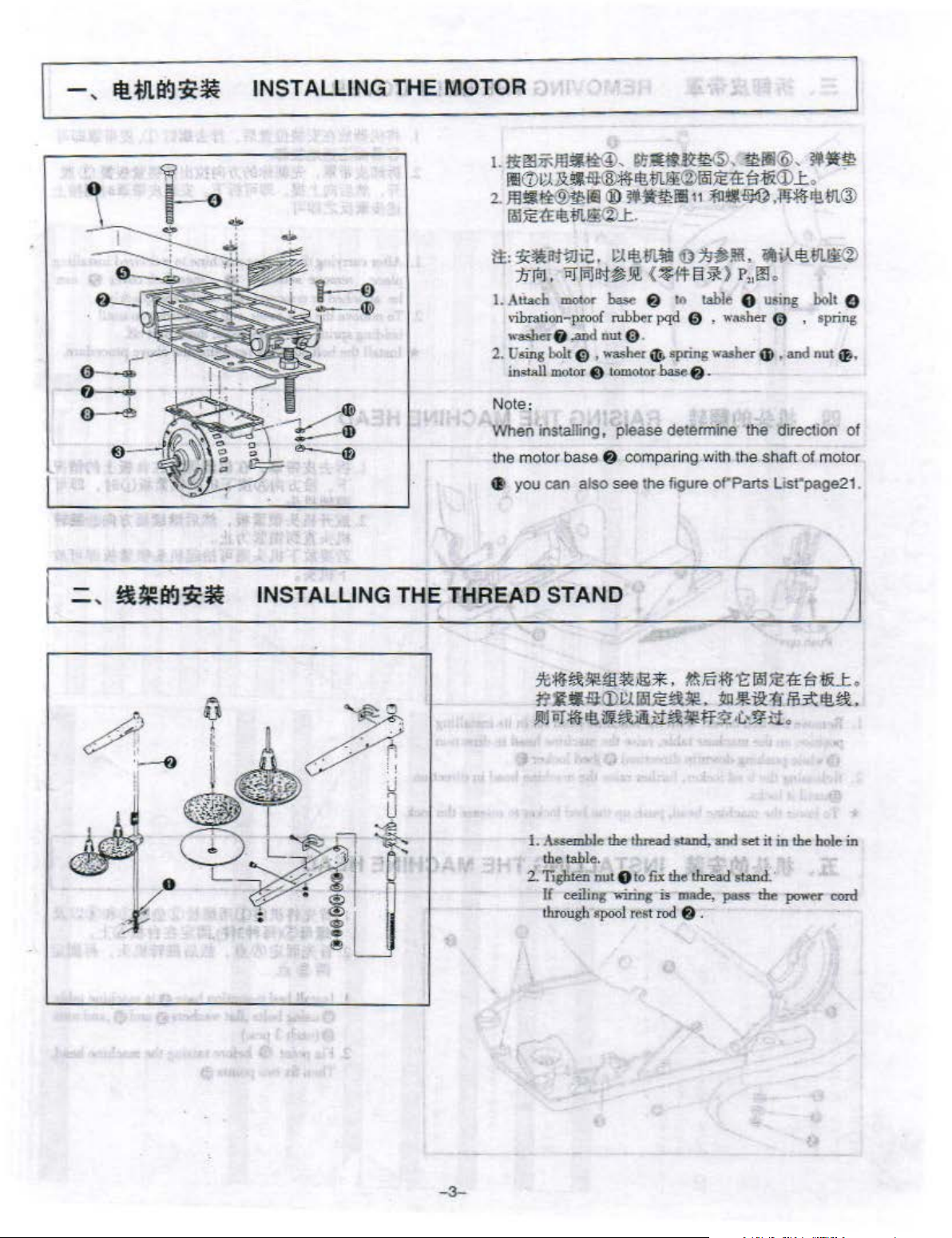

INST A LUNG

THE

MOTOR

_ ,

INSTALLING THE

l.ti~;;;.m

~~~~~

2 .

..lll~ti®mlli

fQl~:tEEI!.tll.~®k.

tt::~-~ic,

1f

I.

Attach

vibration-proof

wa...ber 8

2.

!ising bolt

insWlmotor

Note:

When installing, please detennine the direction

the mot

e

you

THREAD

~

~t®-GF.~~,~~~®,~

~~~~~~~~~~

®

~811111

1;.(~~

(.]

,

PJfiljl!<j~..W.,

mol0<

,and

Cl)

,

e tomotor

or

base

cen also s

(

~

~

f)

rubber

pqd

nut 0 .

washer

~

base f).

f)

comparing with t

ee

the

~-~

o~m~.

13

~}

to table 8 U!ing bolt 8

0 , WMher 0 ,

spring

washer G ,

figure

of'

STAND

P

Parts List"page21.

•m

L

o

.

,f!i::ilf~.fll.®

•v..~-lll.li®

1!l

o

11

sp

ring

and

nut

~

.

of

he

shaft

of

motor

1. Assemble

rhe table.

2.

1i8luen

If ceiling

rhrough

the

nut

,.,.;,;ng

•poo

thread

e to

l r

est rod

fix

is

otand,

the

made,

and

set

thread stand..

pass

8 .

it

in

the bole

the

power eon!

in

Page 6

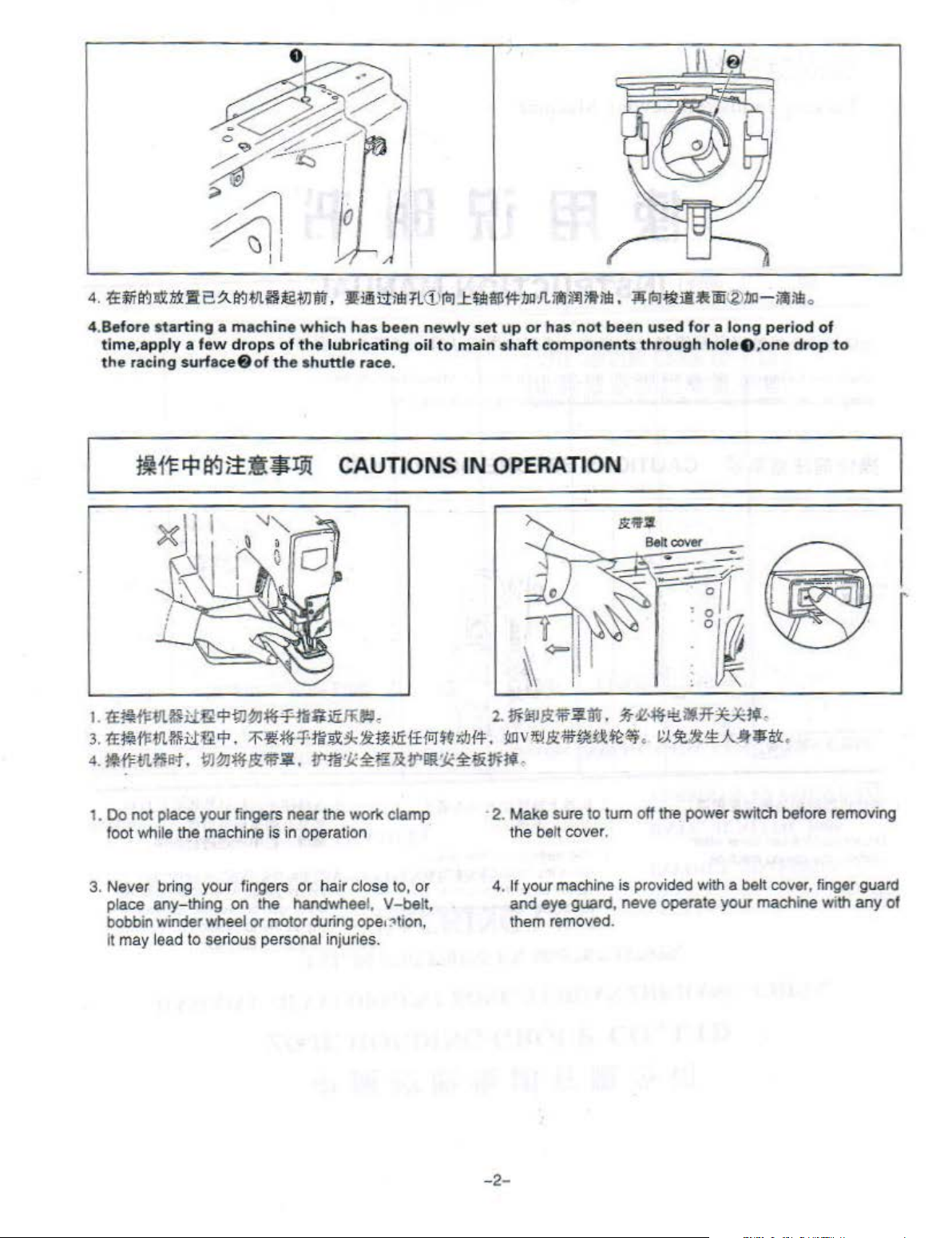

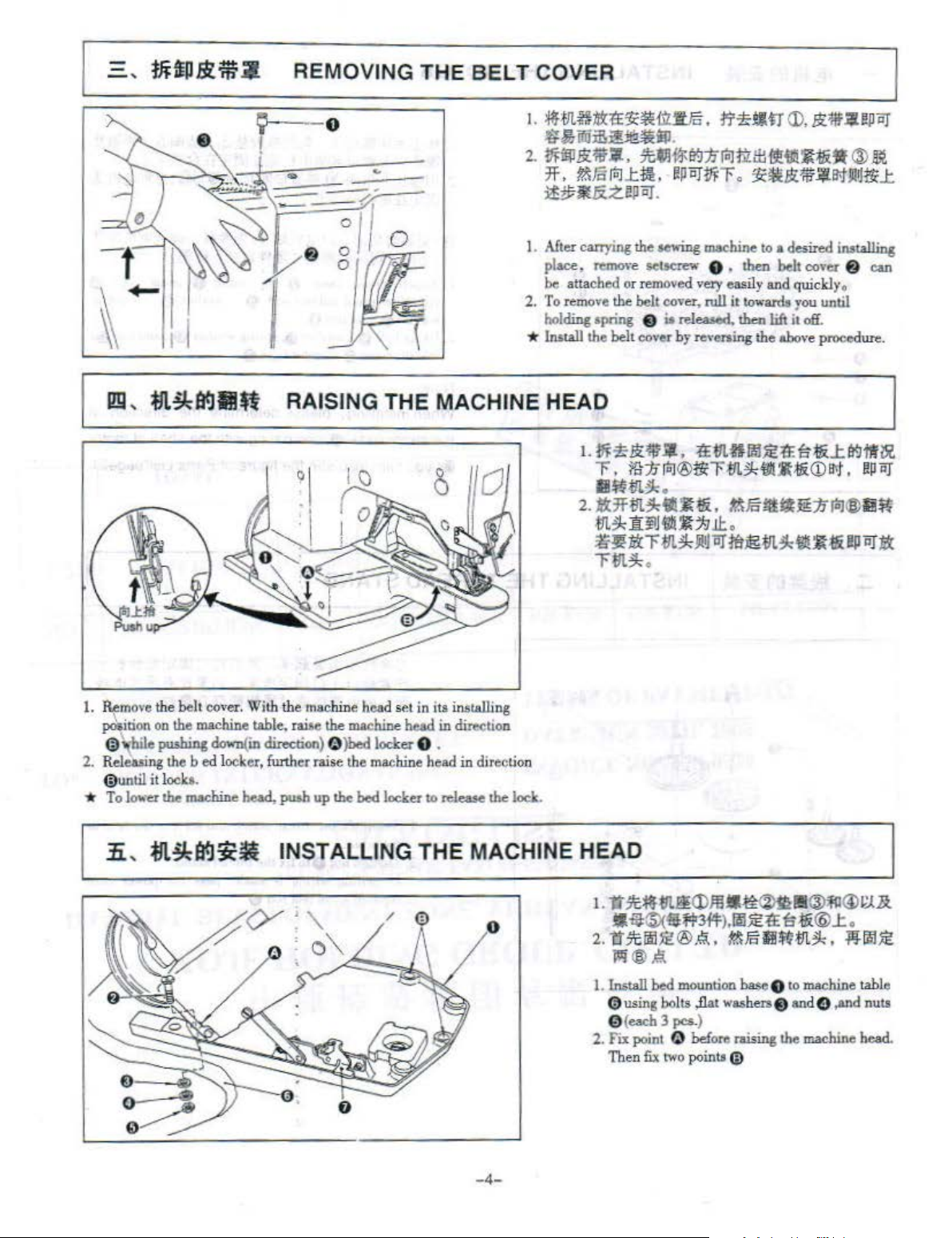

_ ,

REMOVING THE BELT COVER

~---o

lm

,

:M.!ktfi.JIUl

RAISING

0

THE

1. After

2.

*

carrying

pW:e,

be attached or

To

ho

lrutall

remove lleiJCrew O . then

remove

lding apring 0 is released,

the

MACHINE HEAD

the

belt

the

aewing

removed

belt

cover,

cover

machine

very

rull

by

rever-ling the

to

a desired imtall.ing

belt

cover

easily and quickly.

it

towardo

then

lift

above

you

it

off

.

procedure.

until

8

eon

I.

Remove the belt

~ilion

{il

2.

Rel~ng

{il

*

To

1i

on

the

\-bile

pu-'hing

the b ed locker, funhcr raise the machine head in direction

until

it l

ocke

lo..-er

the machine head,

,

:M.!ktfl.l~~

cover.

With the

machine table.

down(in

.

direction)

machine

~.

pu..h

up

head

set in

the machine hesd

f)

)bed locker 0 .

the

bed locker

to

its

in_.talJing

in

direction

release the

lock

.

INSTALLING THE MACHINE HEAD

0

1. install bed mountion base 0 to machine table

(l)

using

0 {

e3Ch

2.

Fix

point

Then fix

bolts

,flat washers& and

3 pes.)

f)

before raising the

two

points

CiJ

C)

,and

machine

nuts

head..

-4-

Page 7

-

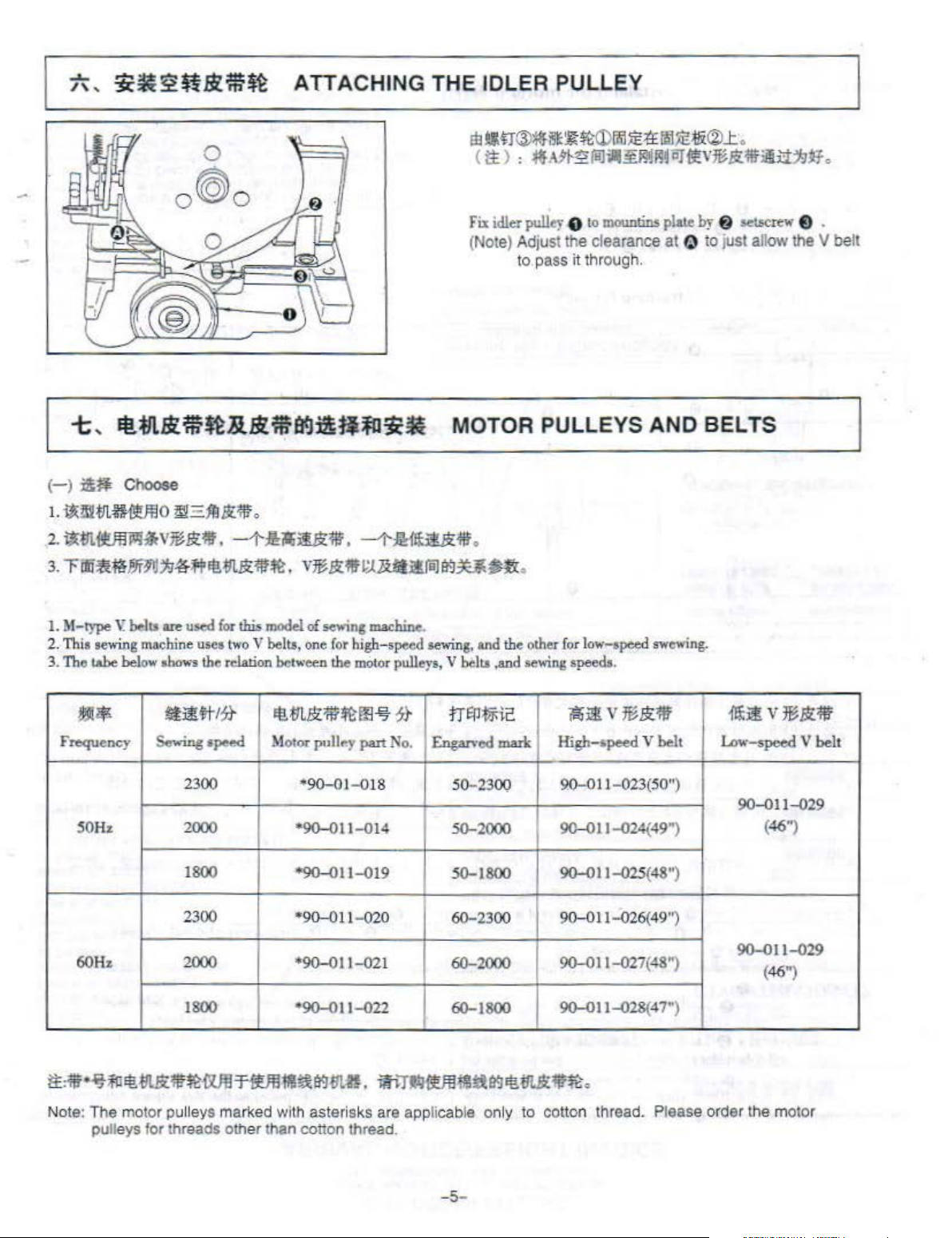

ATTACHING THE IDLER PULLEY

Fix idler

(Note) Adjust the clearance at 0

pull

ey

8

to

to

pass it through.

mountins

plate

by

6

to

just allow

set.&crew

the V belt

e .

t ,

(-

)

I.

~l!iltll.mv!lO

2.

M~*v~&:'lf

3.

rili%i~ef~1i~f+tt!Ail&:1f~,

I.

M-type

2. This

3.

The

F~"""Y

EUII.&:om:~B.!t'lira<:J~ffl~J1C~

:il~

Choose

~-Rl&:~.

,

sewing

t.ohe

JI!M$.

SOH•

\:

~hs

are used

machine uses

below

•bows

Sewing •peed

-1':1!iQiU1f

for

this

model

two

V

~I!Js,

the relation het,.·een the

IJ!l!W?t

2300

2000

1800

El!.m&:;.w~m

Motoc

*90-01t-014

*90-011-019

.

--1'-Hi'ltlt{f

v~&:f!f

of sewing machine.

one

'"

90-01-0!8

for

high-speed

motor

pull~

y

i

;Ut!itj&ruJa!JU~

pulleys, V heltt

.§J

7}

part

No

sewing,

.

Engarved

MOTOR PULLEYS AND BELTS

.

.

and

the

other

for

,and

tr

t:n

m

50-230Q

50-2000

50-1800

r:

mark

low-speed

sewing

speeds.

?aiJ:iV~&;'l!l'

High-speed V

9.0-0

11

90-011-024(49

90-0

11-025{48

swcwing.

~It

-023(50")

")

")

{li:ifV*&;'lll'

lAw-speed V belt

90-011-029

(46j

60H•

Note:

The

motor pulle

pulleys

2300

2000

1800

ys

marked with asterisks are applicable only

for

threads other than cotton thread .

..

90-011

•90-011-021

*90-011-022

-02

0

60-2300

60-2000

60-1800

90

- 0

90-011-027

90-01

to

cotton thread. Please order the

-5-

11-026(49'~

(48")

1-028(47")

90-011-029

(46")

motor

Page 8

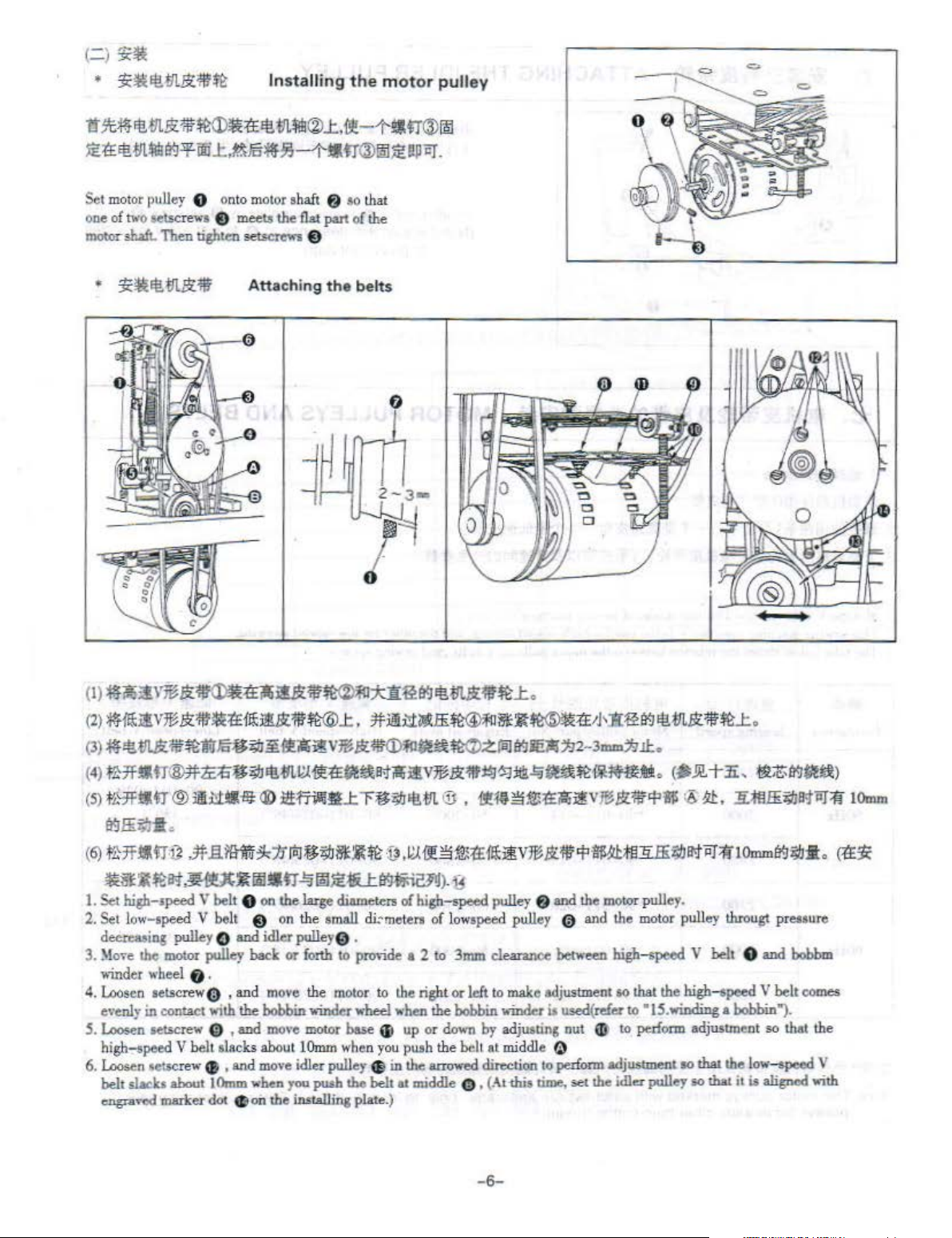

Installing

1i

1C:ml1!411.&1if~~~tl!-ln~®..l:.,{!l!-1-tUT@~

~:a:

ee

m~l'f.l+oo

Set

motor

pulley 0 onto m

one

of

two

setsc

motorsludt.

Then tighten setscrew-& e

.t.~li5:!8-§!--HJ-trCll~~

otor

shaft

rews e meet$

the

nat

the

f.J

so that

part of the

moto

apor.

r pulley

Attaching

the

belts

0

(I)

~~l.l\~&:~~iJ!iU~*ll~l'f.ll~.-flttk:~~l:.

(2)

HJ!V~

(3):meeU'Ii~1V~#;~J3[it•

(

4}

f13Hltr®:lttit::i#~

(5J

:I'Hfltl

&'ll'llil:tEf~iM&:'r!T~l:

IU-111.

l!.l~~ti!~B>till

tr ® JIIH'J:.lii-Bl:

®

l~H

rillifl

.

:lt.iitii~lli~~UH~(~~~'J'

ilv

~J!i.~tl!

i!V~I!i.~~~:lil~~~Ul~mt!.

..t

n;~~ll!.

atW>.Zr'iUI'f.lie1i!:h2

m

IE

•

~~

~~:a~Jlv% I!i.W<~'il!

11::f£1'f.J

-3mm:h!l:.

eetrr.Si'r!T~..t.

(#

JlL

+

.li,

tE

tit.

1LKIIE;~JB>tiiT:fl

~z

l'f.Jf,'ta)

1

0mm

l'f.llE~tt

(

6)

fl}jf

~~~~B<t~~~•n~~~~~~B

I.

Set

2. Set low-speed V belt e

deeteMing

:llo<e

3.

-.;nder

4.loosen setscrewtl) , and

evenly

5.

Loosen

high-speed V belt slacks about

6.

Loosen

belt slacks about I

engra,·cd marker dol

.

.II fJ.

j}

•

.:It

liffi-

lF.

high-speed V belt 0

pulley O

the

motor

wheel

in

contact ,.;th the bobbin

setscrew 0 ,

sellc

rew

pulley

O .

IJ ,

and

and

and

Omm

IE!

'!k

/J

[I;]

f$;1J~'Ut

on

the la.ge diameters of high-speed pulley

on

the small d

idler pulley0 .

back or

move

forth

the

winder

move

motor

!Omm

move

idler pulley

when

you

push the belt

on

the installina plate.)

~

to

provide

motor

wheel

base

when you

1J

·V

,!;.(

-f!1131.2::S:

eometen

to the right or

aJ

of

low

a 2

to

3mm

,..ben

the bobbin winder

up or

down

push

the

belL

in

the mowed dir«tioo

at

middle

(!)

il

i!V

~

&:'liT

<fH;f!l:JifEi:IJI!<J'iiT:fll

f.J

and the

speed pulley 0 and

clearance between high-speed V belt 0

left

to

make

adjustment so that the high-speed V belt

io

used(

by

adjustins

at middle 0

, (At

<his

nut

to

perform

time,

set the idler pulley

-6-

Omml'f.l~::i:.

motor

pulley.

the motor pull

refer to "15.

tD

to

perlorm adjmunent so that the

adjustment so that the low-speed V

ey

througt pretsure

winding

a bobbin").

so

that it is aligned with

and

bobbm

~

comes

Page 9

I\

'

~~~I!;

lei<

w~nr

ATTACHING THE CHAIN

Hook

S-$baped

stArting

S-shaped

lever

hook

.

hook

f)

~

into the hole in the tip of

,and

arU>

ch cbaia 0

to

I

th

e

JL,

f!

Ill

fi

Jilt!f!li!llt

I'

r.J

idl11.

*When

S

urply

<\ili<"nn

.

-\t

thi<\

timP

-t-,

i

1i1fft

~

1Jo)l.

using

""

...

r.

bHk r

tJL$-~~fF

LUBRICATION

«:~Hii

ii

illl.i!lt-ttUf-

the

nil

t

hrough

hCJ

f;l Btll:e :

thread

tthe

guide a

~mc"f'lrtP

thr~>a

d

OPERATING THE SEWING MACHINE

"Fe

nilluhri~ari

whi('h

~ilti:t!t

synthetic fiber

h.-~

ng

hol.-

f'iJSi>eo !

1:

.)(!

thrnu

fiiJ

thread

@)

"·

gh t

t.lt..tiii

hf':n u"m8

hrea

.:!Hilfiiidl.

and

cloth

thr

..

.ul

gu_ifi,.

cl

guid~

()

I_-

.Lubricate

lubncanng oil through lubricating hole 8 ' until

the n:d color in

-ears

2. Use oil for

ha!'!

Lht:

as

observed

0 for a

P.

illrnne oil

th~

machine once

oil

gauge 0 completely

from

sewing

machine.

~~

'Tl

lhf"ti

1"'111

c-

fi1w__r

it.

right

thread

e'VeJyday

above

the oil

. Supply the

daapp

PU&e.

!lfl'lnfi~:trar,

1 . n *

!l!il;af,9::

2. fl1tl

fii!1r

.i&;IJiltit!i

3.

Ji!!l~Ui;~Jlli:;IJ~!&.

4.

~

.\tt11.~7'fl&-

Operate the sewing machine in the

1. Tum

2. Depress the starting pedal a little, and the .. ·ork clamp

3, further depress the pedal,

4. When the machine has

on the

powe

release the

release the pedal.

and bobbin threads are trimmned befon: the machine stopo.

pedal.

.

.

,

Bi:!lll~fl.

JMln.ffl!ll7fM!ttit,

1'

.1mm!jGSHiJB;f,

r switch.

and

comple

~a~.lit.M\USI!Jifi.~.

i!lt-tJii

~l!lliHi

following

the sewing machine starts bar-tAcking. Immediately after the sewing machine starts hartacking,

ted the specified

f#J~~,

procedure:

bar-

§ltJ$:3f

!'!j~ffaiP~~.

ID!ill3~l'it®.

foo

t

will

come

Uicking

cycle. the

-

7-

~~

!PDJ

do~o-n.

When

you

work

clamp

foot

e

want

will

to

make the

automaitcally go up. and the needle

work

clamp

foot

go

up,

Page 10

(it~)

1.

~.m.H1f.ltit1Tlilill<t

iiiJ

iit

iJ:

~-B*·

2.

~a~~Jc~nuc~&.

Jc~i!!!liHBJllW:liH

3.

~~~i!irl;!~,

Ji'

W{ff

i!

li<:*~Q(J~!k/rt-lw~$ti!~

4.

~m~:te~iiiJJ[l.

mlll!alift,l'£l!Mlltr.

-¥i9J~~fi:

~*~··r-~iiiJL~.~!k/rt-J~~~~~

.Bi~UPfH,

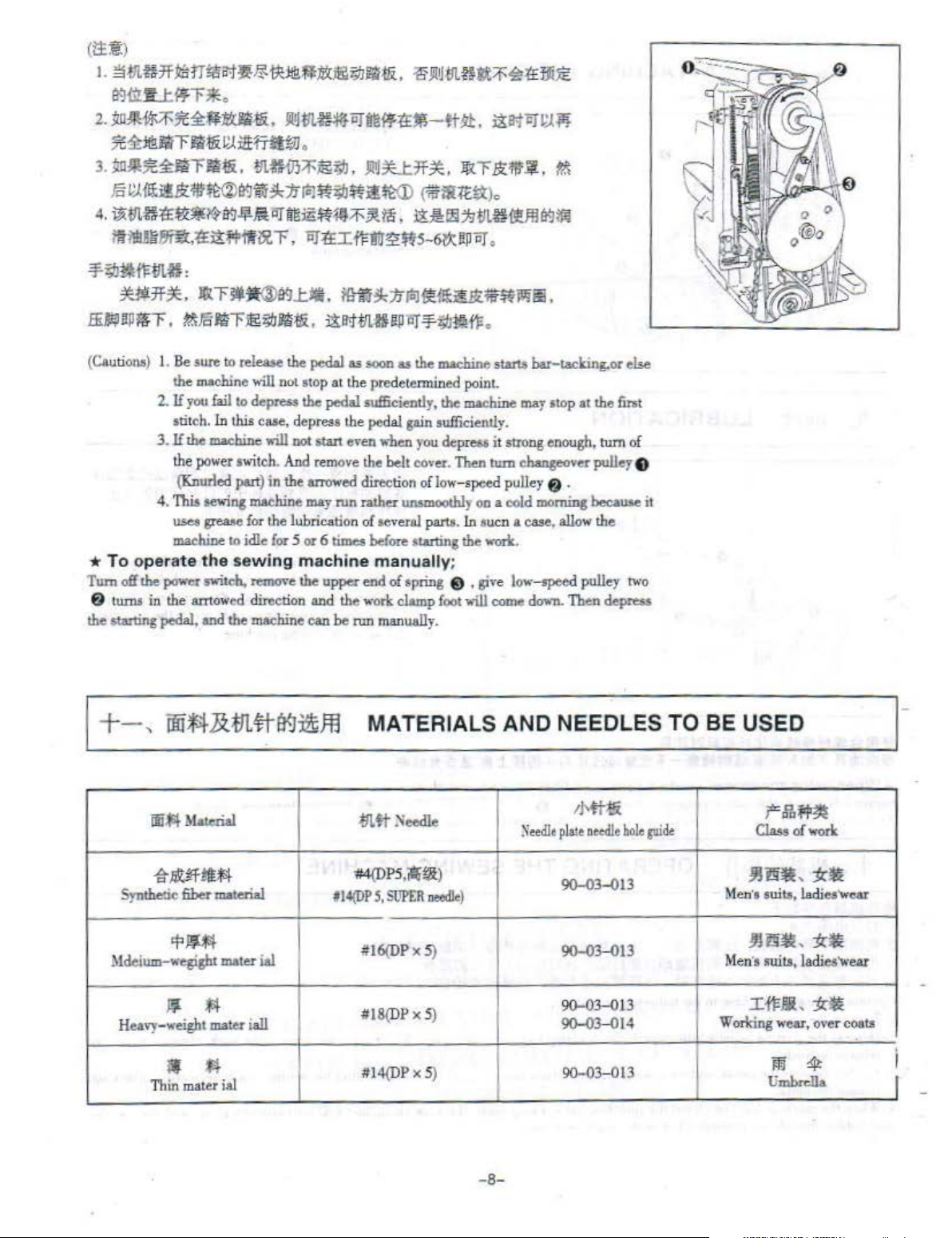

(Cauti

ons)

*To operate

Tum

off

f)

t

wm

the starting

f.llFc

I.

Be

the

2. H

you

stitch. In this case, dep

3. H the machine will

the power switch.

(Knurled part) in the errow

4.

This

uses grease for the lubrication of seve

madUne

lhe

power

in the azrtow

pedal,

~~

~i!!!~:$:J&i9Jm;~&.

J!4~:1ffOJD9fd-ft~.

r

ftlliJ

.

tll.H'!'J§~.

lit

BJ

~

iii~:f4-'f'

OJt£I~~ffs

ifl"il!l

z;i.J

B!Ii

:i&.

sure to release the pedal as soon as

moclrine

sewi"&

the

swit<:h,

and the

will not stop at the

fail

to depress

machine

to idle

for

sew

ing

rtmO\"e

ed

direction

moclrine

!he

res

DOl

start

An

d r

may

5 or 6

machine

lhe

4lld

can

.Jr~JU1f~.

9t m •

i!ll<ttrl.ti

pedalsuflieiently, the maehine

s the pedal gain sufficiently.

emove the belt cover. Then

run

times

upper

the work clamp

be

!!P

prede~

ev

en

when

ed

direction

rather

unsmoothly on

before starting the work.

man

end

of

run

man

~

Jtu.m.mt~4ltl'£til~

i!s-tCJ

~;~.

:ffn

E<:"ii'

!t

.

('?.fS~tt

l:ki!:llil

-

6V::!PCJ.

iiT-¥z;IJ~tF

lhe

machine stariS bar-tacking.or

rrnin

you

of low-speed pulley

ral parts. In 1

)

o

:'htll

~

.

ed

point.

de

press it

stro

tum

a cold morning because

ucn

U

Q(Jffil

~

.

may

ltop

ng

eno

changeover pulley e

f)

a case. allow the

ually;

spring $ , give low-speed pulley two

foot

will come

ually.

down.

~

ft.

at

the

lin

ugh,

tum

.

Then depress

else

t

of

it

+-,

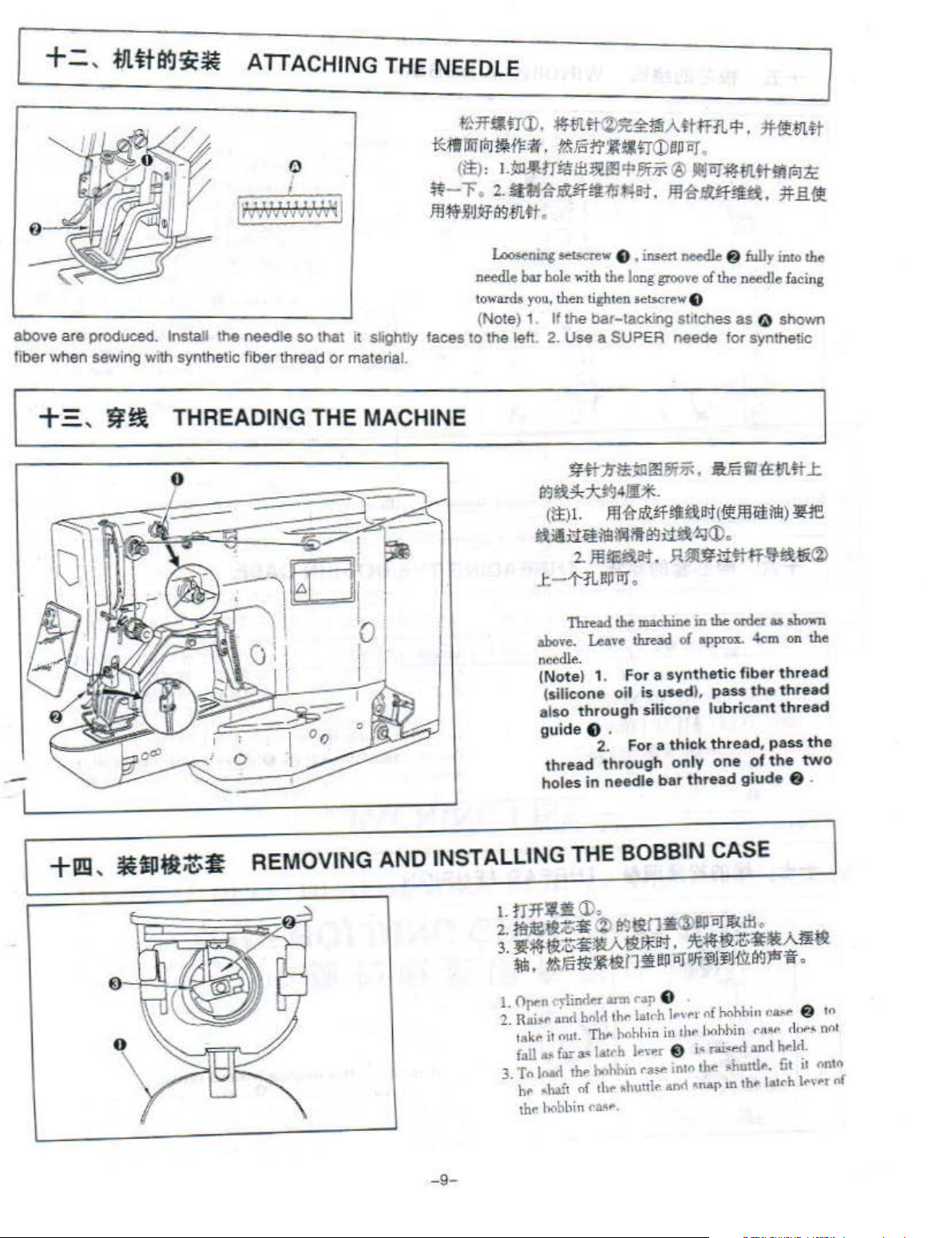

ili*'l-.&

iii$~

Ma!erial

it-~

§ff!t$1

Synthetic fiber material

'f'Q

Mcleium-wegisht mater

111

fl

Hea,-y-weight mater i

~

•

Th

in

mater

ial

t!L#

(!(J~

i&l

all

Jij

MATERIALS AND NEEDLES TO BE USED

/

-lnft

'#4{DP5

1

14(DP

#16(DPx5)

#18(DP x 5)

#1

:'i'eedle

,i0i

!;i

S,

SUPER netdle)

4(DP x 5)

Needle

)

Mt;Ui

plate oetdle

90-03...()13

90-03...()13

90-

90-03...014

90-03

hole pide

03-013

...0

13

-8-

f=,ff,

f'jl

Cia..o

of

~29~,

Men

's

aui

t.s

, ladies'W

~13~,j(~

Men

's sui

t.s,

ItFJliL

Working

wear, o

ji[ij

Umbrdla

~

work

:tc

ladi

:tc•

~

rt

es'

wear

ver

coa

car

ts

I

I

Page 11

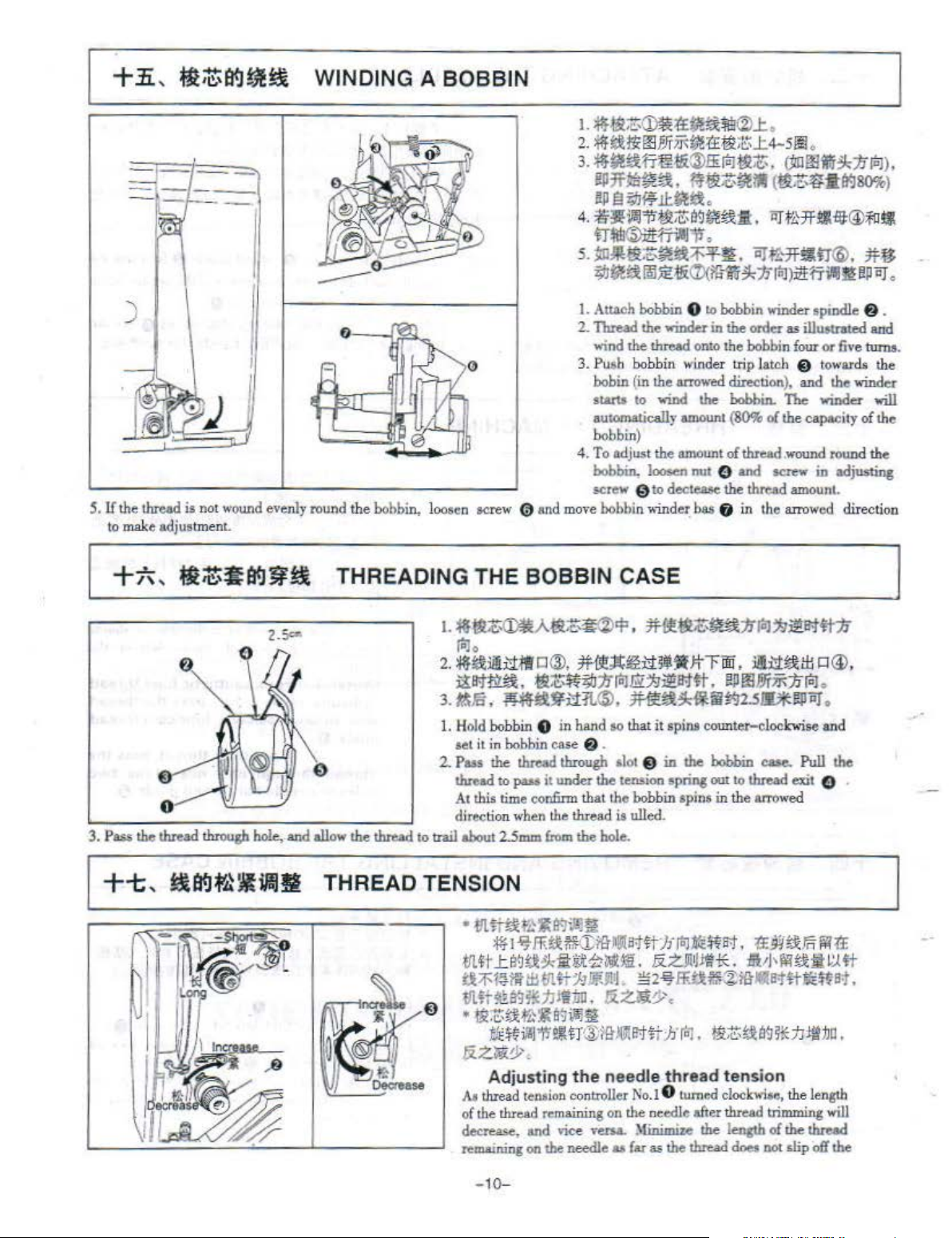

+=

,

fll.

tf-

99

~~

ATTACHING THE NEEDLE

above

are

produced. Install the

fiber when sewing

+~

,

~~

needle

wrth synthetic fiber thread

THREADING

so

THE

~~~

thai

it

or

material.

MACHINE

;

.f'C1f~na>.

i'::I!JiliiloJM=if.

<

!::!:>:

~.:m~rr!tlt~~~l!l<PP.JTii<

~-r

Jli~jiJ~t~Stn#

shghtly faces to the left.

.

2.!Htft~itf~~*4111.

loosening

needle bar

towards you,

(Note) 1. If the

~t~t~~~!fi.AtUT1L<P.

?&Fcti':l!lfl<DePar

.

seL<;erew

hole

then

2.

Use

~~~:;titJ

(i::I:)

!iliailt'i£l!!!ilil11t~~1;J(J).

C.

, insert

,.;th

the

lo

ng

tight

en setscrew Q

bar-tacking

a SUPER neede

~#n

~~m~~.

4

fi.

L

ffl~nlt

2.

Jli!S!iat.

.

®

Jlllor:m.mttm(u)1c

JIH~IRitfU.

needle

groove

of

Stitches

aFa~~111.#L

i'H

.t~Ji:t(

Jl.1J!$

Himf.!';!i-\!i®

Jftttn#

#il.it

@

fuUy

into the

the

needle

facing

as

Q shown

for

synthetic

~Jii

lel!!!)

JH~

.t-1'5LRPilJ.

-

+1!!1

,

·ill·~-

I

·o

Thread

above.

lhe

machine

Lea,·e thread of approL 4em

in the order as

needle.

I

(Note) 1. For a

(sili

cone

oil is

also

through

guide

e .

2. For a

threa

d t

hrough

holes

in

needle

synthetic

used

},

sili

cone

thick

only

bar thread

fiber t

pass

the

lubricant thre

thread, pass the

one

of t

giude

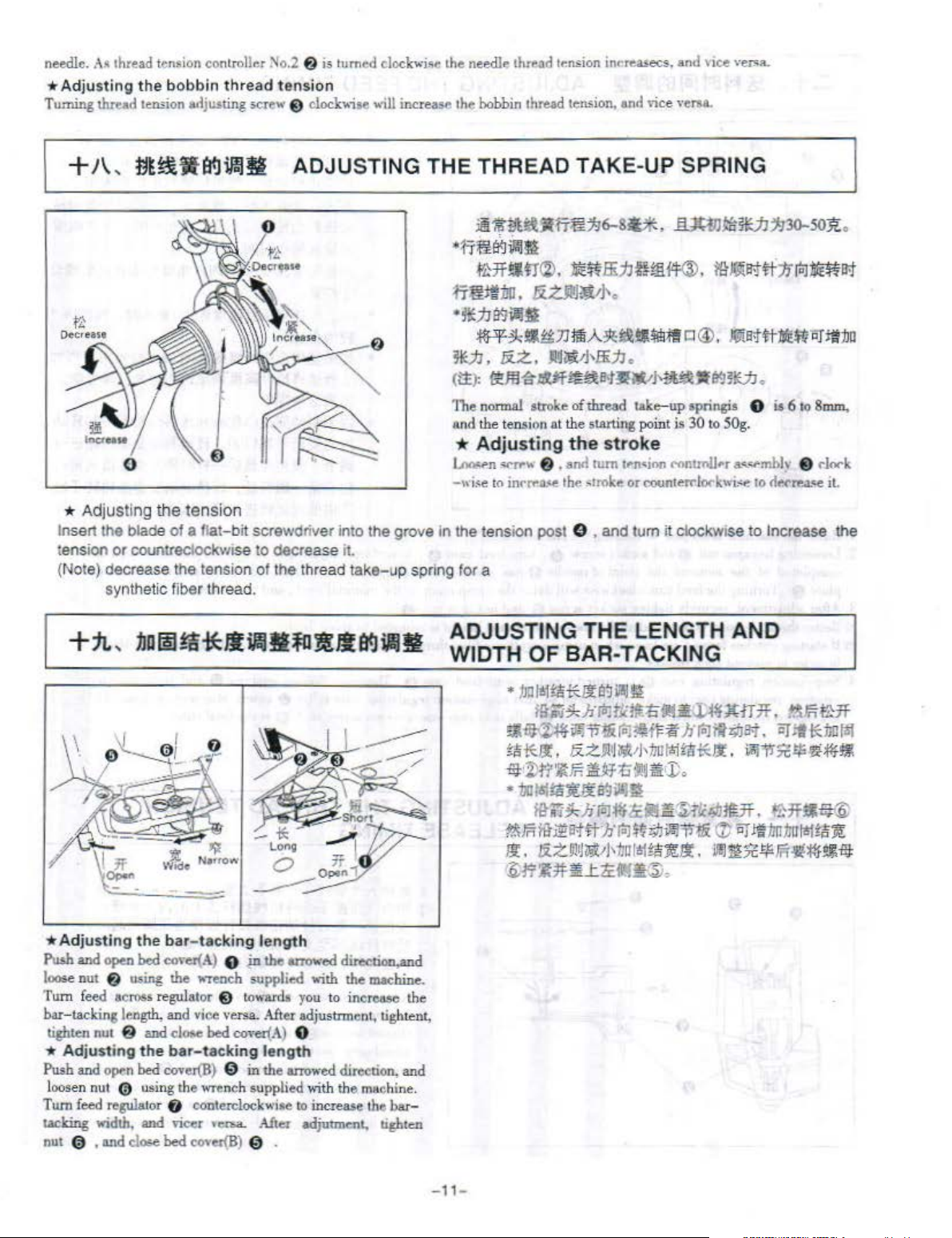

REMOVING AND INSTALLING THE BOBBIN CASE

I.

OJ"'

II

.,

ta

k

fall

T<>

hr

thr

·lind·r arm

.

f'

11

nu . ...-

••

far

!..ad

t.haft of

hobbin

t

a•

th•

2. Rai;.t. and bnlcllht' lat('h 1 ..

3

.

Th

latrh

l>oh

&ht>

('a_V

...

Lh

nu

hin

iihutt1(':

.

rap

e .

,.~

hin

in

lh,.

.

'"""

E)

ra"' int<>

anrl

,

n{

J;.,~hnt

h()h

hm

f"~tlu~

i•

rai•.e<l

and

tl..-

•hun!•.

-.nap

tn

lhf' l•tt'h

shown

on

hread

t

hread

he

& .

ra..:,t"

do~~

hrld.

fit

the

ad

two

& tn

nnt

ot

ont<>

1~\'Pf

nf

-

9-

Page 12

S.

+li

II

to

)

the

mak

,

~;t;~~ti

thread

is not

wound

evenly

e adjus

tme

nt.

WINDING A BOBBIN

round the bobbin, l

oosen

screw 0

1.

Attach bobbin 0 to bobbin

2.

Thread

wind

3. Pu&h bobbin wi

bobin (

starl.l

automatically

bobbin)

4.

To

bobbin, loosen

ocrew g to

&nd

move bobbin winder. bas 8 in the

the

winder

the

thread

in

the

to

wind

adjust the

in

onto

nde

arrowed

the

a:n<>unt

a:n<>unt

nut

dectea&e

0

win®

spindle 6 •

the order

the bobbin

r trip latch @

direction), and the

bobbiJt.

(80%

ofthresd.wound round the

ami

the thread amount.

as

iUU5trated

four

or

five

towar

The

wiode.r

of

the eapseity of the

screw

in

adjusting

arro

wed

direction

turns.

<Lo

windel-

ami

the

will

3. Pass

+t

2.5<&

the

thread

through

,

~~f~Wfi?.J!l

hole,.aml

allow

THREAD TENSION

THREADING THE BOBBIN CASE

I.

the

thread

~ttt~{~;~~cp'

tolo

2.

~~liti1~CJ@,

~~~.~~~~:fitoJ~~~~~.~m~:fitoJ.

3.

~.16'

~~:1111..®.

1.

Hold

bobb

in 0

set

it

in bobbin

2.

Pass the

thread

At

direction w

to trail about

•

.tll.~H.Ii~~!kiitilt~

ii;f~r.ftllt11WJ.J~~l

tJl;r~s~~

•

&z~&

thread

to

pass

this

time

hen

2.Smm

tn>

,

!!llt~ae:Ji.l!JJ.t

:!if

I~

~:t:~tG~a~Vil!!

trE~ii&l~!!l.tr@ltf~Bt#

.

Adjusting

At

thre

ad

ten•ion co

of

the

thresd remaining on the needle after thread trimming

decrease,

remaining on

ond

~~;lt~lfl!UlJf"F

in

hand

case

a .

through

it under the tension spring

confinn that the

the

thread is ulled.

from

the bole.

.A\

ill

~ii}

;t.J

Jtim.

the

ntroller

,;ce

vena.

the

needle

m!~blitol~i!t~li

~~lii~2.SII*!!JiiiJ

so

that it spins cotmter-eloc

slot @ in

bobbin

Jt3it~

ft

:/i

~Jai

.

&ZJ!•

22~

~Z.~?.

:

h'M.

need

le

thread tension

No.I

0

Minillliu the length of the

as

fu

a.s

the

ilii, :i!li~lll

the

bobbin case. Pull the

001

to

thread

spins

in the

arrowed

tol~

~Bt.

:G:91

llt

*.

S\'J'M~1'ii~~

ID.l~~iirJIB:tft!liffBt,

t!li:Z~a~*JJ:lt!JD.

turned

clockwi•o,

a®.

.

lcwi

se and

~~ 0 .

~Fn

W

H%

the

lensth

will

thread

thread

does

DOl slip ofi the

- 10-

Page 13

needle.

Turning

A~

thread tension controller No.2

*Adju

sting

thrud

+

/\,

*

Ad

justing the tension

Insert

the blade

tension

(Note) decrea

or

synthetic fiber thread.

f'J

is turnf"d clockwi!;e the needlP thr ..

the

bobbin

teruion adjusting screw E) clockwise

~UUftllJiJ!)g

of

countreclockwise to decrease it.

se the

thread

tension

ADJUSTING THE THREAD TAKE-UP SPRING

a flat-bit screwdriver into the grove

tension of t

he thread take-up spring for a

will

increase the bobbin thread

im

~iJUl)l~'i'

·~flei.Jiill§

~*~~~.

n:t~

il!

illl.

·

~}J89illl§

M

3*j]

'

!9-Z.

(tl:):

~~

The normal stroke of

and the tension at the

*

Adjust

~f"n

~11"\\

_,

,

i~e

to inrfftl$-e the

in

the tension post 0 , and tum

.ad

tr.nsion

in<"reasecs~

ten.<ion,

<b!

~U

&.<:ml!£,1-

~«iiJJ

lSiA

•

~l!;Xtl\!li~.

.ll!tif

~

and vice veroa.

7:16-SU,

ffi~fi~~.~~~

.

:lll:~

a.tJ-'I!ltNit.~

thxead

stArt

ing point is 30 to 50g.

ing the

6 • end

stroke

turn

lf"'n~ion

:-otmke

or

and

rut:W.tili!UJ

tl~;fl

lak

e-up

t•<mtmU,.r

counterrlO<'kwi~

it

clockwise to Increase the

,;ce

ver.:;.a.

1130-SO

~n

a@). ~~

-

eeJ~IEJJ .

springis 0 is 6 to

#

~ti;PJ

a-••.••f·mblo;

to

t!t<>n"'A.~

:it

.

~~~

l:lt.1JD

Smm.,

t)

r)CW'k

t

l.

*Ad

justing

Push

and

loose nut a using the ..-reoch supplied with the maclllne.

Turn feed

b

ar-ta

cking

tighten

*

Ad

justing the

Push and open

loosen nut @ using the wrench oupplied v;ith the machine.

Turn feed regulator 0 eonterolockw

laclring

nut

@ , and close bed eoHr{B) 0 .

the

open

bed

across regulator

lt.n

gth,

nut a and

bed

.ndth,

and

bar-tacking

<ȴ~A)

and vice versa. Aft

clOi<>

bed

bar-tacking

cover(B) 0

viC<:r

length

0

in

the

E)

towards you to

CO\•er(A)

length

in the

'"'""-

After adjutment, ughten

arJ'C)Wed

er

directi-d

in

erCMC

adj ustnnent, tightent,

0

anowed

ioe

direction, and

to increase the l>ar-

the

ADJU STING THE LENGTH

WIDTH OF

•

Stiilt'l.#fi!Al11~

~~*JJ:,

"l:•2lfi''lJF.~.A'f~~U~

•17aftll:a1t!i~lill~

r.&Fn

~.

~l1':l*~J:timffi~,

BAR

J;oJt!1ta

Hl~:!kh'

-TACKING

*

ll:e~illlm

tcltJilft:b

tllliJAlf

~ji,H

1'.W h ~ifl#J<J;f.

liZ§l']i1tt)•1itlftlitl*iJ: ,

•

J:o

iit~:!I-Ji(o)~<Xii!!~~Jc4Jillf.

lit

.i2!a<l#

!iZJi!lj~;J•1lUh!f

h'

~~~~Tit&

~~

Jl:.

(!) 'iif

iiiJfifC

AND

A-iT

.7f

•

t!Ri~.ff

iiflt

~:1m~

~11'51!.!/i~.#f

~m~ilP~

Jt1m

1m

EF

Fri.fi!~

§l

ftll:a

~

~-Hl:

-1

1-

Page 14

=+,

:i!~lt..tl'li.l~if.Jfl

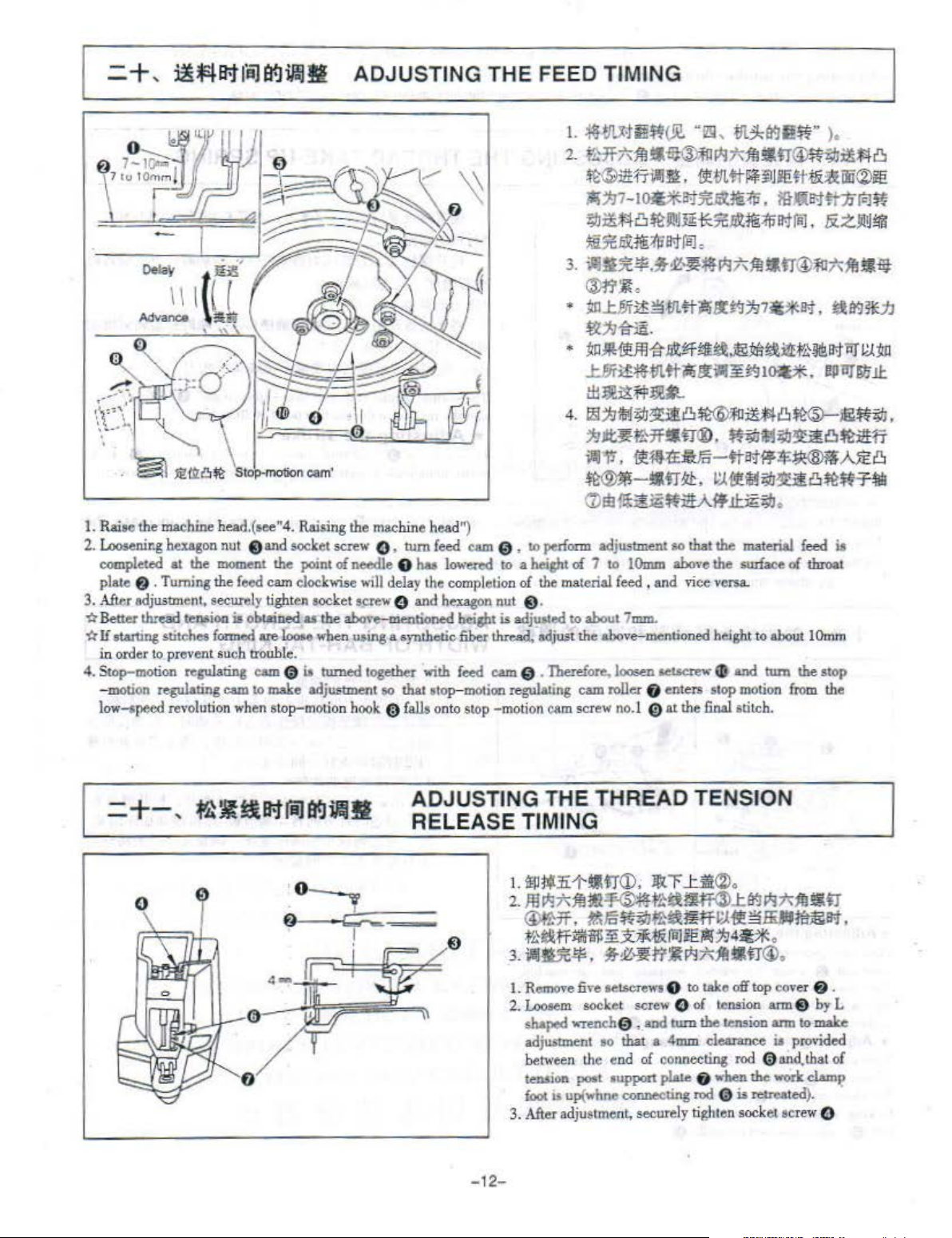

Delay

I I l

L Raise

2.

3.

-a

*If

4. Stop-motion

the

Loosening

compleud

6 . Turning the

plate

Aft

er

edj

ustm

Better

thread

.wting

in

order to pr

mAChine

hexagon

at

stitches

head.(see"4.

nut

the

moment

ont,

securely

ten$ioa;. obtained

formed

even

t such tro

reculalin&

-motion regulating cam 10

low-speed

revolution

ADJUSTING THE FEED TIMING

Stcil>-m<>tion

Cl

feed

are

cam 0 io

when

cam'

Rai$ing

and socket screw 0 , tum

the

cam

clockwise

tighten

loooe

uble.

molce

stop-motion

the machine head")

point of needle 8

will

soc

ket screw 0 and

as

the alxwe-mentioned h~t is

when u•ing a oyntbetic fiber thread.

~

adjustment

hook Q fa

feed

lw

delay the

together with

so

that

otop-tn<>'ion

lls o

cam

lowered

completion

hexagon

feed

= 0 .

nto

stOp

-motion

1.

2 .

3. liii§JC

•

•

4.

0 ,

to

petfozm

to a heisflt

of

nut

C).

edj~oted

regulating

of

the

material

to

odjw

t the

Therefore,

cam

cam

scr

~.tWintiJl!.

.j.ffi~fidJ~J;Ij~:ffdltr®*~ilUlft)

~l£~-Till~,

)1;1117-l~lt..tU~:{f;,

~iUi8~!i!llm*S:Ckm:{f;ll<tfiil.

~~~~.:{f;f!;jfBlo

!!J1.~1l·~=llfJ;Ij~1f!tltJ®f:o~~Ul-st

~~0

~li'i'i:i;?41-!Ji#tli!r~}J7Uat.

~111ni.

~Hili~

.tilf

~:t6'-Vl.

tlllli!.ffll~

flil1JiM~~J!t)~;f!IM8~.e~.

1J~~~*Stf®.~M~~8~fi

~~.~~~~-ttlt..t~$~~~8

"@

,

m~t¥JI!n"

~-Vt

ttl'-¥i1Jie:

l!t.QI>t#1n~Jft

.i&~!!l!t,Wil~:i!l:-f'CJ;f!;j<iJ

tt11fll·:1E~

IOit*. l!jltl]'fitj

>·

~t.f&

:

<IHii®ie:

&zJi!~ilil

~ll9*.1J

VJ~

J.!:

~~--tr~.~~~~~~8~~T~

(L)

EI!~NAifJ.!:;E~

adjUSlmelU

7 10

feed

about

above-mentioned

loosen seucrew e

roller 6 enters stop

ew no.J

IOmm

, and

7mm

0 at the

to

that

the

alxwe the surlace

vice

versa.

.

height to

final

material

and

motion

stitch.

.

about

tum

feed

of

the

from

i8

throat

1

Omm

stop

the

ADJUSTING THE THREAD TENSION

RELEASE TIMING

0

0

0

6

=:r-_

!

L Remove fi<e

2.

Lootem

shaped

wreneh

adju•tment

betw

een the e

tenoion

foo<

3. After adjustment. securely

poet

"up(whne

-12-

oetoerews

socket screw 0

0 ,

oo

nd

•upport

8 to take off

and

tum

that a

4mm

of oonneeting

p~

connecting

top

of

~nsion

the

tension

clearance ia

rod

0

6 when the

rod

0 is retreated).

tight

en socket screw 0

oo,·e

r 8 .

ann 8

by

onn

to

malce

provided

and.

that of

work

clam~;>

L

Page 15

=+=,

0

tJI.it~flfltf.J~~

NEEDLE-TO-S

v

HU

TTlE RELATION

0.

3-J.

S=>

(tll~i*itt~~~)

1.

JIPJi·~;;i.J*ll~l!1!ttff<D

2.llltT~~~,

3.

JD'ff\';IJ~iU'Iif~f!fl-ff<D~;mJJL.t:a

4.

~~~~1iHI),Iilltt#<D..ttl9"'F~U

ti.\JiifBfJl.n®o

s. jMIWHfl:QrutfT®.

(~· J:!l!;f

6.~~$~.

~m~~~

1.

f~*•n®.~ll't~

-https://manualmachine.com/

-"·C.

•n®.

1

I!PliTi1Hnlll

~~ottt:nM

~~M~BIJ:effl:-utJl(.!l!.

..iJ~I!HtffT~~ffl:-.

"

'3'-;;i.Jifk

fll-!ILf&"

l·

~.X'fl!HHfTMWljjlj

Jt~~:O.Ii:fi~tHJ:.

•. :f}l!~l!tl*lfl

m

l!.t~~~~~$~llmff®<P

·

~;;DfilLf:jll>:\flll"~

i!ll't~or~~"F.

·

C.·©

ll't.

Q.t

~mft-®~

m~cr>zreJ

f&JiiWU~~.

.

-!IL#®.!;jtQft®uumzreJ&:Hiill•·

·

~

fi;J

lilmltr®.

8.

ill§l~£#'.

<tt>

:l1a;t

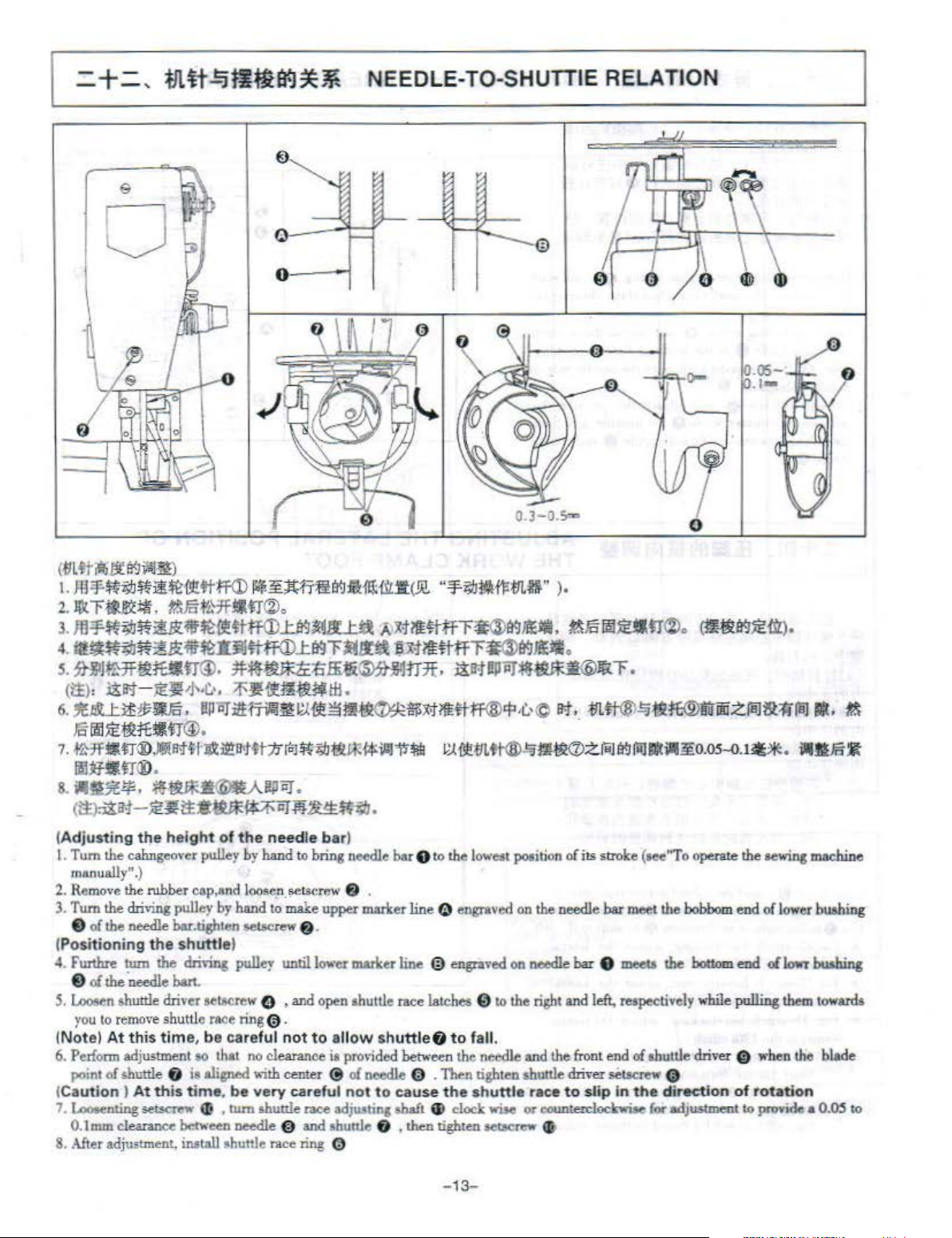

(Adjusting

l. Tum the cahngeover pulley by hand to bring needle bor e

manually".}

2.

Remove

3. Tum the chhing pulley by hand

e

of

(

Positioning

4.

F'wtbre

e

oi

S.

Loosen

you

to

(Note) At

6.

Perform

poinl

(

Caution

7. Loooenting setserew

0.1

DUn

8.

After

~~l!PPJ

-

~~tt•~~nttiiJ.

the

height

the rubber eap,

the needle bar.tishten

the

tum the drmng

the needle

shuttle driver

remove

of

adjustment, install shuttle

shuttle rMe ring

this

time, be

adjustment

shuttle

clearance

) At

f)

this

shuttle)

bart.

se~rew

oo

that

io

aligned

time. be

«;

between

of

the

needle

And

loo..e.n.

!"'tserew

to

make

$015Crew

pulle~

until

G ,

@.

careful

,

tum

needle @ and shunJe

not

no

cleorance is provided

"ith

center @ nf

very

careful not

shuttle rnce adjusting shaft

race

.

bar

)

to

the

f)

.

upper mader

f)

.

lower

mader

and

open shuttle race latches 0 to the

to

allow

ring 0

line

~

engroved

line @ engraved

shuttle

needle

to

f)

f)

to

fall.

between

cause the

, then tighten

the

0 . Then rishten shuttle driver setscrew 0

~

clock wise or

lowt$t

poeition

on

needle

shuttle

SOIKf<:W

of

i!S

on

the

needle

needle

bar e meets the

right

and left, respectively

and

the

front

race

to

slip in

oounterclockwise

~

stroke (see"To operate the

bor

meet

end

nf

the dir

~~Ul).

m•?£o.os..o.t**.

sewing

the

bobbom

oh11ttle

ection

for

adjustment to

bottom

while

pulling

dri•er 0

of

end

of

lower

end

,.lowr bushing

when

totation

providf>

i.111!1Fo

machine

bushing

them

towards

the blade

a

0.0.5

ti.\

:xt

to

-13-

Page 16

=+

=,

fi~JJ~W-1§

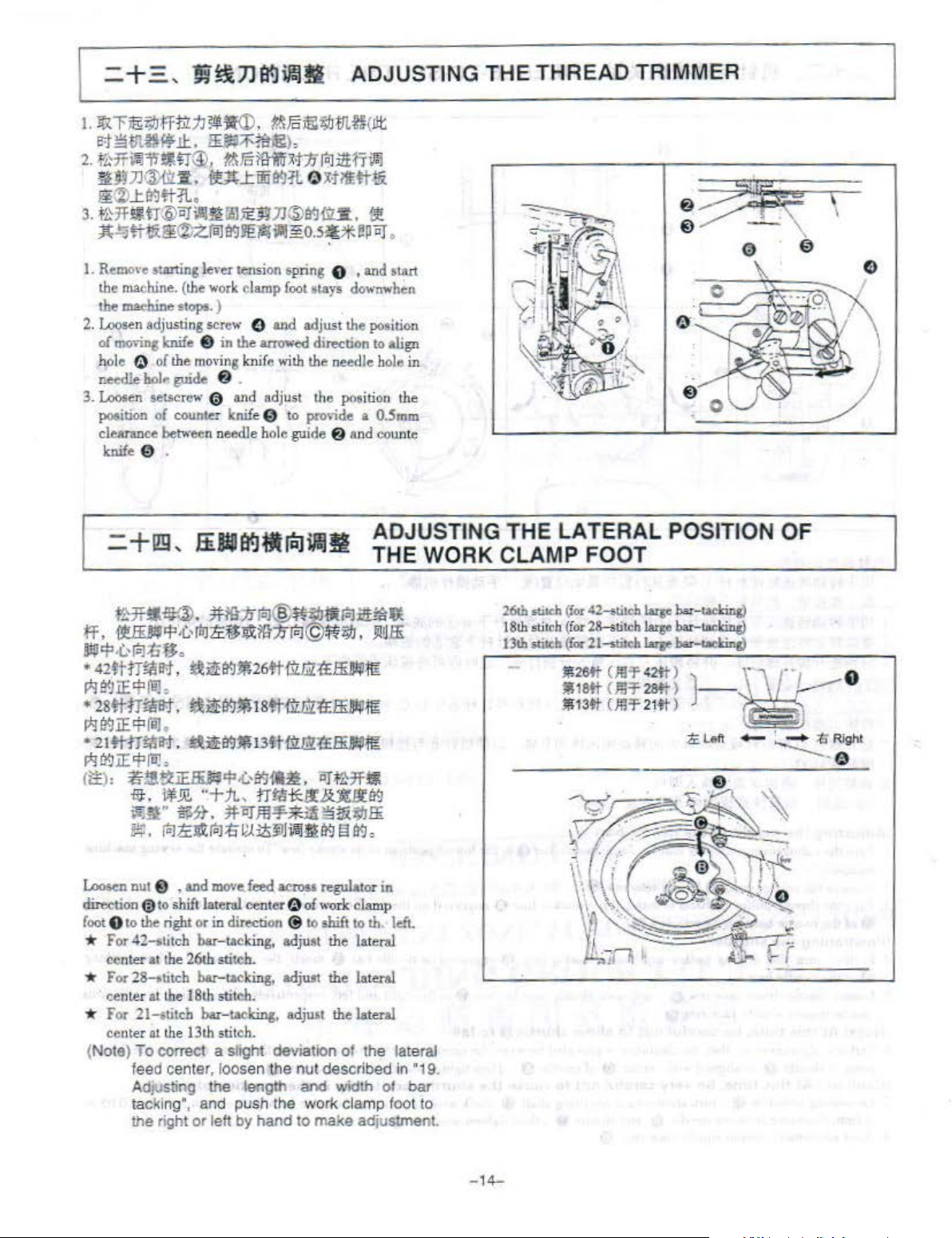

I.

Remove swting

the machine.

the

msebine

2.

Loosen

adjusting

of

mo,in!

0 of the

hole

needle hoi, guide a .

3.

Loosen

position of counter knife 0

clearance between needle

sel<C

knife 0 .

lever tension s

(the

work

stops. )

screw

knife 8 in the

moving

row

0 ond adjust the

ADJUSTING THE THREAD TRIMMER

pri

ng

C)

,

and

st•rt

clamp

£oot

•l4ys

downwhen

()

and adjust the position

~

knif e ,.;th the needle hole in

hol

direction

to

provide a

e guide a end counte

poo

to

ition

O.Smm

align

the

ADJUSTING

THE WORK CLAMP FOOT

Loosen

nut @ , and

direction {i)

foote to

to

the

right or in direction @

* For 42-stitch bar- ucking,

center at

* For28-.btch bar-tacking, adjust the

center

at

* For 21-ttitch bar- udcing,

center

at

(Note) To correct a shght deviatiOn of the lateral

feed center, loosen the nut described in

Ad

JUSting

tacking

the right

move.

feed

acro_ss

regulator in

shift lateral center 0 of

the

26th stitch.

the

18th

stitch.

the

13th

stitch.

the length and width

', and push the work clamp toot to

or

left by hand

work

clamp

to

shift to th. left.

&dju•t

the lateral

la

te ral

&djmt

the

lateral

to

make adjustment.

of

"19.

bar

THE

26th stioch

t

Slh

stit

ch

13lh

.U.:b

LATERAL POSITION

(Jor

42;titch

(for

28-sti~eh

(!or

21--stilcl>

.!il26

tt

*16ft

J!i13tt

laqc

bar-tadc

large

bor-taclci"C)

~

~

(}!!'f~2tt)

(J!!'f 28!t)

(J!l'f

21tt

) - I

inl!)

)

w--

--

~

1.&~ -~

· .. , 0

OF

---

;t;

Right

-e

-

14-

Page 17

3. Pu$b

4. Securely tighten socket

5.

(C.ution)

down

L-shaped

If

the right and left

pl6te 0 to

Be

If

the

le•·el

careful

work

"'Orl:

them.

not

clamp

wrench 8 to

ocrew

0 after adjustment.

clamp feet are not

to

cause

work

foot

lever supper plat" interferes

ADJUSTING THE LIFT

CLAMP FOOT

increase the

leveUed.

clamp

foot

.!EBIHil

;t;At;i;:

1.

:e:tn.ft:fifF·!'iil5t.r.

2.

J'ft

J;~:J

r-~

lli-'F~.

3.

lliJ

r

mi9JJ;~:J;F;~

lliJL~J;~:Jr-~

4

.111

!1Jf$.

5.

~O~li:;t:;ID

§5m~i9Jlli@,

·

(it):

!1!:~

~~~~ffHT~.ar~~tr®~~m~~

ffl)g

iii!f

The

lift of the

I.

'll:'ith

the

to

take

ofT

2. Apply L-shaped wrench 8

on

d loosen socket

lift

of

!he

work

clomp

fooL

or

pull it

loosen serew 8 and adjust the

lever •upport plate 0 to interfere

with

the wiper, readjust the height of wiper using setscrew

OF

THE WORK

OJ

llll31:

17ll*

tm!1l

l1i

~.

~+®.

~~WJ;~:Jr-ffl•n@ti'~.

!

Pf~tE-1'7)(lfiliiJ;I:J.

~~

.;1Jl!i®!9

0

work

clamp

ma<:hine

top cover 8 .

up

pooillon

with

feed

,

lfl:rli-t

.;IJllifl!ffa<.J

~ar~~~&

<~Jfl

!!Par

~~JE~

CD,

J;f:JMMI~@

lliJ

fBHitr

~~~li:~ffi.

foot

in •top

screw.

to decrease the

bracket 0

~tt-1'7)(lfiliiJ;I:J.

f.fi!!IJ~ll

eao be adjusted

mode.

remove

to

socket screw0 of clamp$

lift.

of

work

clamp

'Ff.Y,

five

foot

ll'lr

..tJft®.

.

.t:J&.&•ll ;

.

<1>

.

#til

~D

;!II:ffi.

up

to 17mm.

oet5crews

lever support

e

Gt

ADJUSTING THE SAFETY PLATE

(Wor~

R\11/ll~r

I.

tr~~!(ff(~)J!Ifilllll.

~~M.~~~~~~~~~z~~•

llilliil~v

-~& ~ ~

I.

Loosening

0.2

plate 0 audlifring lever 6 when the

at the tnne of stop motion, and a

clearance between

uo.2

..o.s

~

li.B!illl*~t&zliijW.iaJ

two

se!Serews

to

0.5mm lateral clearance is provided between safety

them

~:til.~~

*.

w~.!EJ!l!~st.

Jl:I

f!ij~

V~J

.lE:

fl;.

1.s-

.liJIIi

2.5ii*·

8 , perform adjustment so that a

work

clomp

1.5

to

2.5mm

lo~tudinal

when

the

wor

k clamp

foot

cltmp

~~

foot

is

i1

down.

foot

up

"down")

2.

~~ittr~.i:J:~<P.

~~~~~~~~

raJ

liil!lt:l!~~l

2. Check that

safety plate e and lifting lever &

2.5mm

during the high

,..ork

clomp

.5-2.5~*·

the

longitudinal clearance between

foot

is

down).

{l:EJiP~Tllrfi!J

~

~z~fi!J~

-speed

bar

taelcinc

io

1.5

to

(the

-1

5-

Page 18

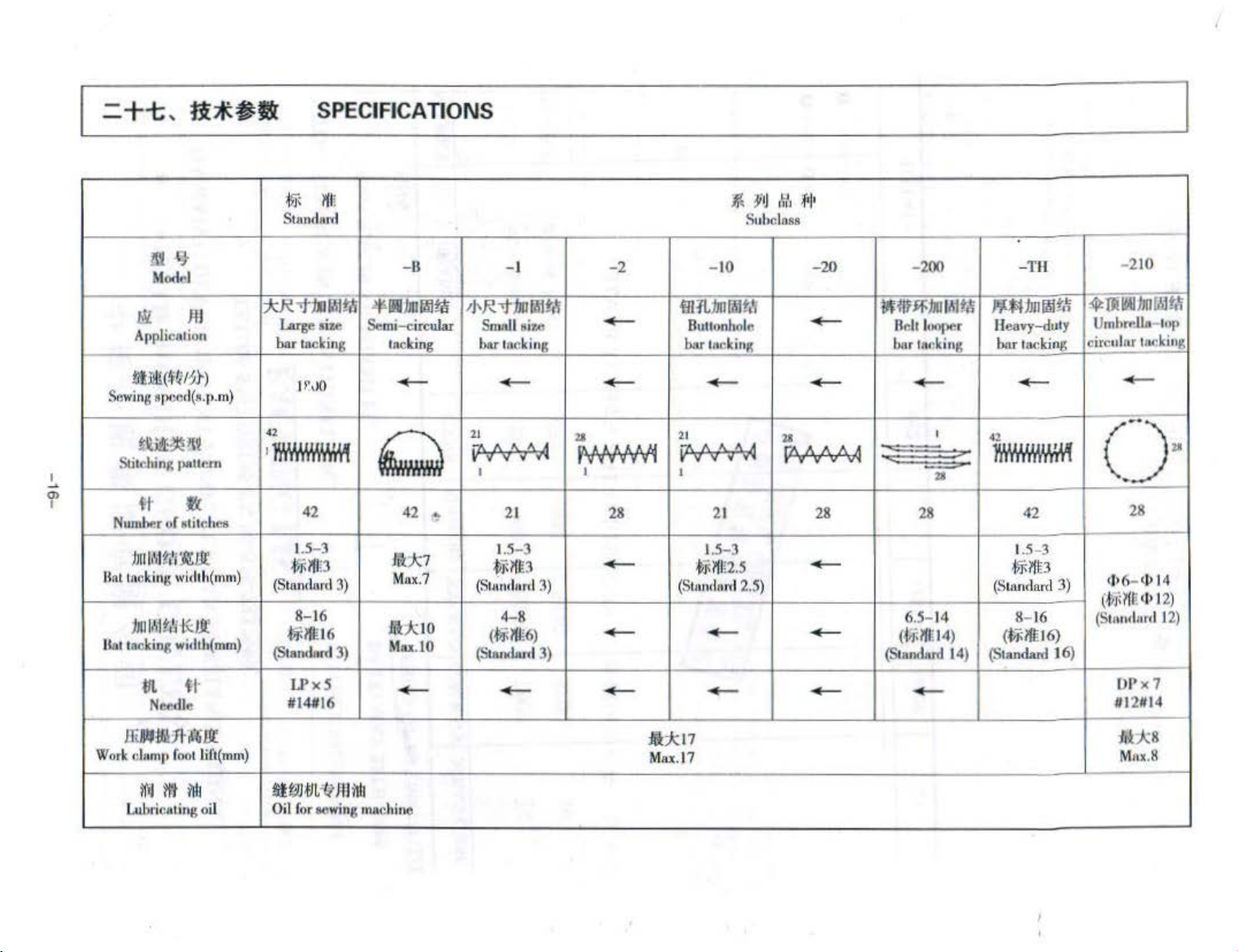

I =

+t

Jl!l}

.!ilL

Appli

,

ti*#~

Model

#I

cation

M

SPECIFICATIONS I

llll

~

St

nndom

"<f"

1JIIII

Larg

e size

bar

tAckin

g

ta

-8

~

IIB

JIII'M

ta

Semi-c

ircular

la

cking

-I

;J-.R-..t:tmfM~

Small •i

bar

zc

tac.~king

-2

-

~

:I'

)J

Subcla

- 10 -20

iH

1L:IliiWM

Bullonh

olo

bar tuc

kin

g bar tnr.

M,

ss

;f•l•

-

-200

~

llf$F:IIJ

B• h l

IM

~

oope

r

kin

g bar tac

--

-TH

J'»1:1mWl\~

Hea

vy-duty

king

-210

~

Uie~J

bn

UmbrPIJ3-l

circul

ar tt•e

r~

u"

OI>

kin

g

.!.

I

"'

!lUli(W?r)

Sewing

8(

)(;(l

d(•.(>.m)

~i!~ll'l

S.:i

tching ,,..u •

fl

Num

ber of •titches

)JIIl

.ll

Bat tucking width(mm

;h1Jih1f<H<:

llal tA

clcing

61.

Nefflle

ffi

llflf.IJtill

= +

J\,

ir.tEii~i'JJ~ffi

iJH(

!aii

)~iJi

tn;~

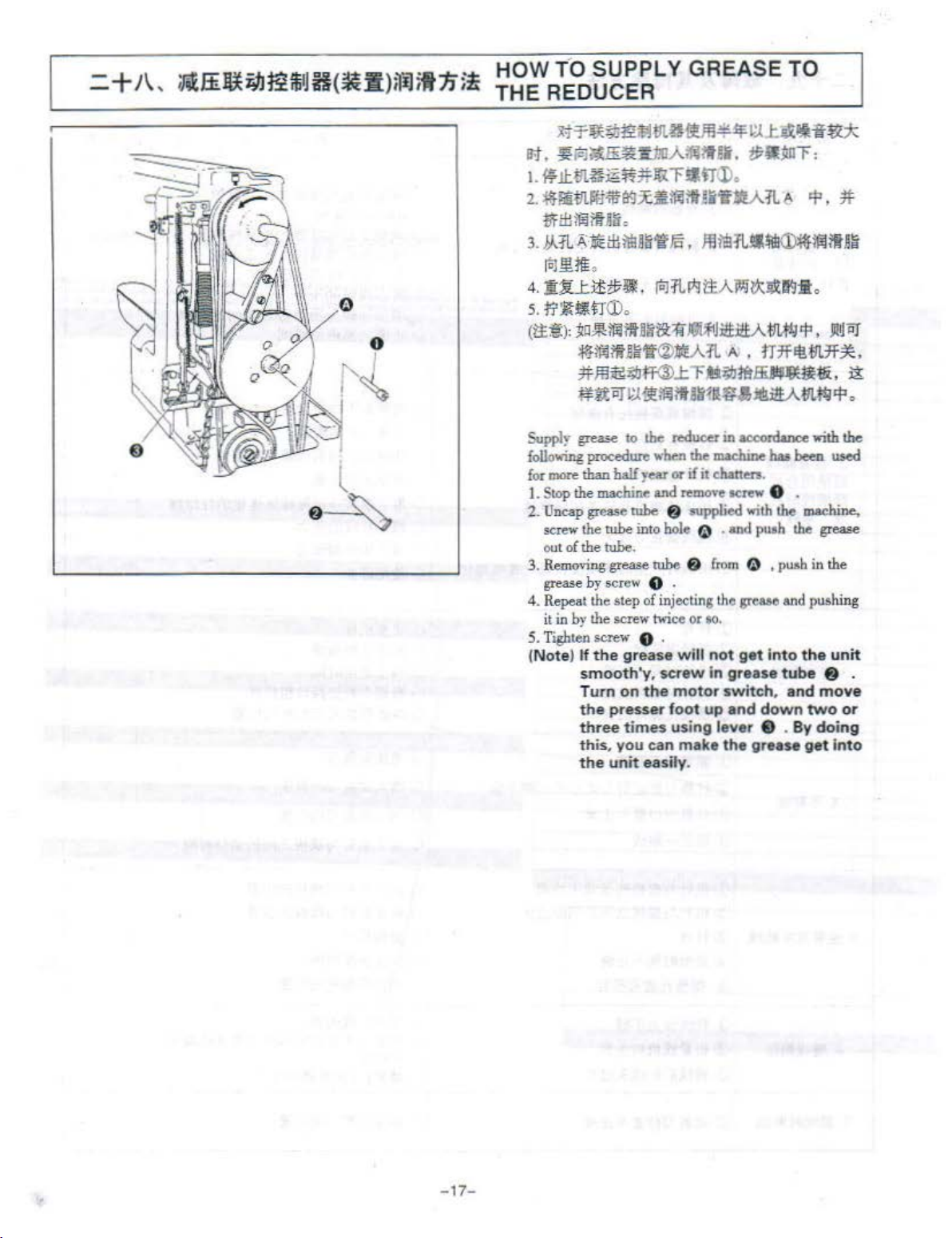

HOW T-0 SUPPLY GREASE TO

THE

REDUCER

M~~~~~ill.3~~~~L~~~~

~.~A~~~A~~G.~~~:

I.

.W.Itill~~~~~~-frl)

2.

~iiiill.Jit'lifa<Jxlljfijm!i'iflltA-11.~

~'HI:!

jfij

?ff!ir

o

L~UL

4.1:Ui!~lJ!

5.

(tt:§:):

~ii€1l:li'I!!B~'&'f<f.

toll!l.

M.

.

lol:rl~tl:AilJJ~~IfJ

lT~

~tr

(D.

~a~lfilit!liil1i

:tl}lfili!:Uii'lf(i)j!EA:rl A • rr7fil!*!L7f-*.

*~~~

~gtor~·.tliijma~r~~ajtgiitAM<P.

~Lr•~~~-

.

<P.

*

J!lti!!.JIJI~~iiilllt!

:fil:

JQi~JitH£A

~9',

li

.

Jl!~i'iJ

~~~.~

Supply

follo,.;,g procedure

for

1.

2..

3.

4. Repeat the

grea:-e

o:nore

Stop

the

Uncap grea.•e rube 8 •upplied

screw

out of the rube.

Removing

grease

it in

by

to

the reducer

wben

than

half

yeor

m.oclllne

the

rube

by

screw 0 .

Ule screw twice

in

grease

step

and

to

rube & from

of

injecting tho

the

or

if

remove

hole ~ • and

or

5. Tighten screw 0 .

(Note)

If

the

grease

smooth'y,

Turn

on

the

the

presser

three

times

this

. you can make

the

unit easily.

will

screw

motor

foot up and down

using lever 0 .

in

maclune

it

ehanen.

ocnw

so.

not gat

in

grease

switch,

the

acconlance

baa been

0 .

with

the

pu•h

the

~

,

p.ab

grea&e

and

into

tube

and

By

grease

with

the

used

m.oclllne,

grease

in

the

pushing

the

unit

8 .

move

two

or

doing

get

into

-17-

Page 20

$.

r.J

<lHHiletQ~

1.

mu

r!:i!i

B;f.tt~.Y-

mtt..t.Mltl:l

iZl

®

@

a>

~

2.~#~

~U{l-~

~!ti&B;f1L

!il(,~i;t

<3>

@

@ tJt!'lJf*:t.lif:k

~

~

::§

I

0

i.llf

0.05-{).1

o

J¥!!U

~·~~

li

:em

tt

J:l'l1l~

~;t;~!ki:m

~B;fli]~

iEiil

~~~:jHf~ll

::Jd:J:

liii

i.llm

o

lt:tm~

1]' I

o

llitiN!l~B9

o

it

0

iE

0

~;Kl!kT#Jil~

(

#i&1fi'Jj1j

-lll.ttaDf

~li!<I*!I

ffi-lll.#F~~N~~~~~M~

.!

IH

'r

~$

~tf!t~

O

J!ltk&:2<~:l!JM~

O

iii~U

o

.llltr

0

~Jj\#i;t~*:t.l

0

~~

o U

JJj

111'111<1f~

;HIUt~

.

..\lj

U

.Zi'BJ

t!IJ

liJ

It

~

*

2

~

1Elilffil9.J1ajtfiietoo

t-laH¥*1'l1l*.:IJ~tl'!'it

~

.ffi~fil'l1J.ffi.:IJ

£E}J

:tm

tt-lR

..!lj

life

T-J~

f6l~W

:i1t

!$

n

B;f

lliJ

M~~~

zlil

~

oo

lt

~

fl

<'fi)2<J4!11!{

~#lfi'li$ii'!~~

-

1*11

lit

ra

.IB.&9

~M£!1t

~

#~

$ -

tMttil!f

3.~#lt'f!'£

® iiHit

®:tll.

@

bf!:Qfl111l#

<D

~~W

<2>

4-~~~

5.~-nt~~d

6.

~laJ.fr

#t!i

<3l

;fJ

®

:liiFc-

<D

:til.#

<2>

mtt

®

#~

®

itti*II".JI'Iil:il'iE<,I€

®

~

<D

#~*

~

tk

®

~~Fcml~li*

B;f

fiil:il'iE

TI.I

#Xf;:f)if4::t.!JH

JJ~~

..!lj

!!!~

~

J]

99#

.lj!-[ii]~~&g

J1

JJU~iE!Ii

m~

..!lj~~&9

~

;b~t:J,ill

.!3DzliJ&91'1ilr;!tii::k

~~tim#

.:11

~

llt

~~

:tn.-lil~

0

}!l!k¥1.#

0

~iEB!.a$fa

0

*qiE

o

U<'li#

o

tJi

iEi~'t

o

J!~~nn

0

J:tl:!cZ.

Ot:l

iEi'JJ.#t

o ~

.u:

tnJt

O

tlliE:tll.#.!iiO~

tJiiE:!Q#

0

0

E.~-iM

:i:

Jtt~B;f

(lij

:ll!~~~~:tn.#

!H

t..\lj.Jn#l'l1lrul

~

JJ

&9"!f

JJ

~{JIR

l:Jl'J~z

~

Jit!lii'Jt!ri

t

[ii]

l'l1l

.iiiJbat[ii]

o isliEimietl'lil

0

ill

iEii.~~t!IJ«!

o

tthc#~~*.:h

0

~I:

-T :a:trttlti'Bl 2

~tk~

0

jf1JD

I~

ffi~ft(l9Bi;h

I

-i}

IE~

l\11

J!-

0

7.J:]ltl!;f~

(IJ i!fl}g

JJ

tiz

.l':

~ iE

lilt

- 1

8-

tJiiEi!!J

~

JJ!lg~

Page 21

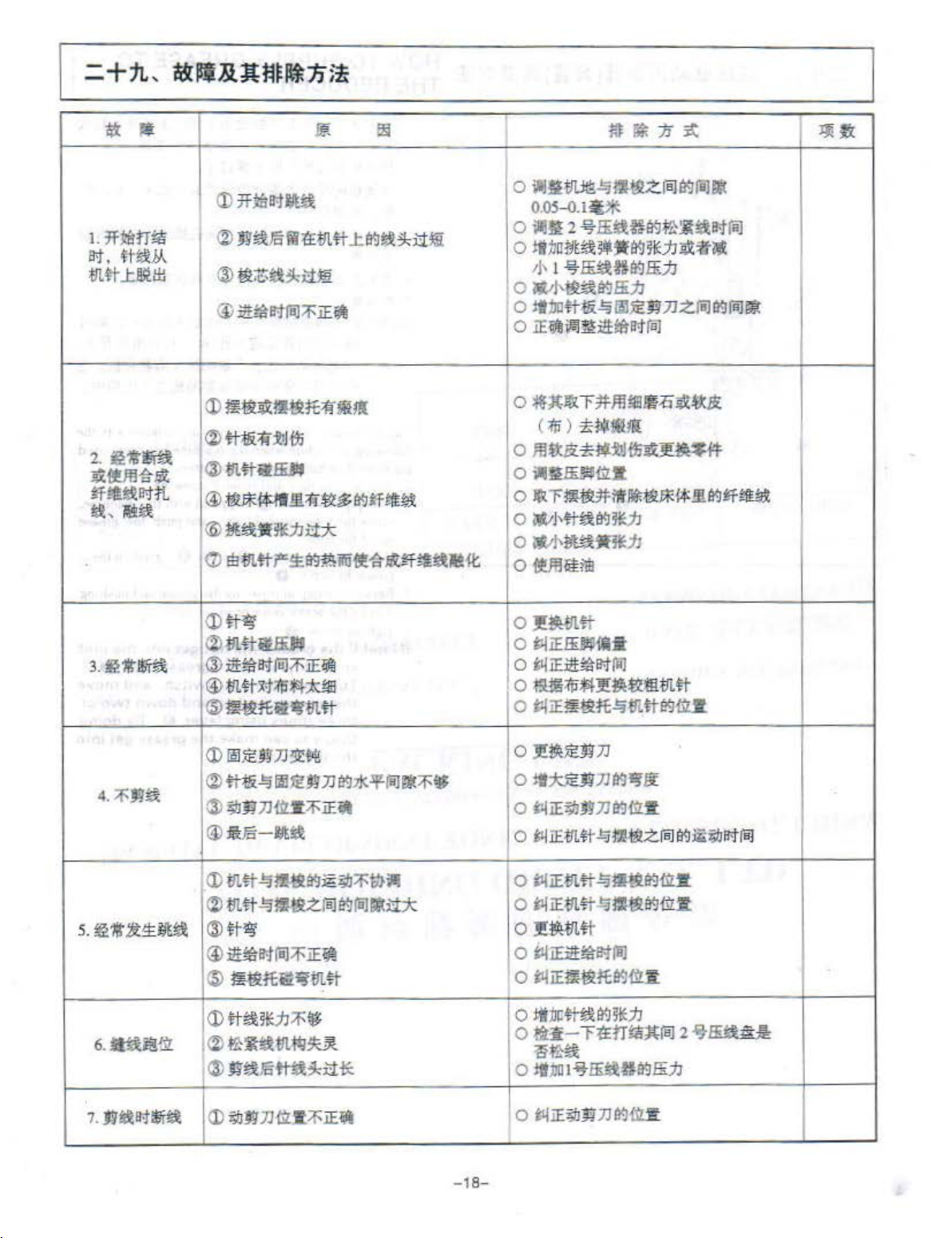

TROUBLES AND CORRECTIVE

Trouble

l.

The needle thread

slips

off

the

at the start

tackin

2.

Thrud

bareala

fiber

fmely

3.

The needle often

breaks.

4.

Threads

trimmed.

S.

Stitch skipping

often

6. The needle

comes out

wrong

inaterial.

g.

often

or

thread

.

occurs.

side

of

synthetic

ase

on

<D

Stitches are slapped at the stan.

(2)

The needle thread remaining

thread

needle

bar-

split.o

not

thread

the

of

the

after

@The bob

@ The feed rimming is bad.

<D

The shuttle

<%>

The needle bole guide haa scratches.

®The

@

Fil>rom

race.

<5>

The needle thread tension is

@The

too high.

CD

The synthetic fiber thread melu due 10 bea

generated on the needle.

<D

The needle is bent.

<2)

The needle hits the

@ The

@>

The needle is t

(5)

The

g?

The counter knife is

(2)

The difference

hole guide and the counter

@The

positiooed.

<i>

The last •titeh

(.1)

The

properly synchronized.

(2)

The clearance

is

@ The needle is bent.

® The

I@ The driver excessi,·elv ben

Q)

The needle

®

n,.

properl

@The

long.

bin

needle strikes the"'"!.: clamp

dust

tension

feed

driv

er excessivelv bends

~

motion!

too

large.

feed

tension

y.

needle

Cause

trimming

thread is

or

is

of

timing is bad.

of

timing is bad.

thread

release

thread

is

too

the drivdr hsa scratches.

in

the

groove

the

thread

work

oo

thin

for the material.

duU.

in

level

bas

lcinfe

is

•kipped.

the

needle and ahuule an:

between

tension

mechani

after

l'v4EA

on

the

too

short.

ohort.

foot

of

the shuttle

too

hith.

take-up spring u

clamp

foot.

tho

needle.

between

knife

the needle

i1

thread

is

been

ds the n

not

high

sm fails

trimming

the needle

not

improperly

and

oodle.

enough.

to

SURES

0

needle

0

0

0

0 In crease the clearance

0 Correct the

0 Take

0

.

0 Correct the position of the

0 Take out

0 Reduce the needle

0 Reduce the tension.

0

0 re

0 correct the

0

0 replace it

0

0 replace the counter knife.

0

.I.

0 conect the position

0 correcr the

not

0

ehullt

0

0

0

0

0 Increase

work

0

is

too

0 Increase the tension of the tension

Corrective

Adjust

the clearance

and lhe shuttle 10 0.05 to

Cotte<>t

of

lncrea.~e

spring

tension

Dec

hole

fine whetstone or

dust

the thread

the thead tension

the tension of the thread take-up

or decrease the tens

continue roller

rease the tension

guide and the counter

feed

it out and

Buff

or

replac;e

rhe

shuttle

from

the shuttle

measures

between

tension

controUer

of

rimmin

remove

buff~

it

.

and

n><:e.

No.1

thread

Use

silicone oil.

plar-e

the

bent needle 9

pos

ition

of

the

Correct

the material.

cotte<>tly

increase

shuttle.

Correct

Correct

Replace the bent needle.

Correct

C<>rrectly

Check

released during

coruroUer No.1.

the

feed

timing.

with

a thicker needle according

position the needle

the bend

the

the

the

position the driver.

the

whether or

of

the counter

of

tirnin&

be<Ween

positions

positions

bent

of

of

timing.

needle thread tension.

not the tension disc

.bar-t.aclci~

the

the

the

the

needle

0.1

mm.

release timing

Ko.2

.

ion

of

the thread

the

bobbin

thread.

between

g.

the scratches using a

the needle

knife.

work

elsmp

remcl\-e

tension.

work

clamp

and

moving

the needle

needle and

needle

foot.

the

fibrouo

foot.

the ahuttle.

knife.

i<nif

&.

and

ahuttle.

and

shuttle.

No.2

to

th

is

P

age

13

10

10

10

14

12

IS

13

10

11

7

IS

12

8

13

14

14

14

13

13

13

9

12

13

10

10

10

7.

Threads

time

trimming.

of

bresl:

thread

at

CD

The

PQ$itioned.

mo'ing

lcinfe

has

been improperly

- 1

0 Correct the position of

9-

the

mo•ing knife.

14

Page 22

Tacking Industrial Sewing Machine

~

PARTS

14

§

~

LIST

- 20-

Page 23

~

~

CONT

fir-It~

1.

~Jl!ileif~i!f

SEWING MACHINE COMPONENTS

2 .

..l:$~'a1Wf··

MAIN SHAFT·COMPONENTS

3.

~tfflllli!f·

NEEDLE BAR COMPONENTS

4.

t3tl'alWI:·

THREAN TENSlON RELEASE COMPONENTS

5.

1'$!11$i!f·

SHUTTLE DRIVER SHAFT COMPONENTS

6.

i!~f!ll:$t·

FEED MECHANISM COMPONENTS

7.

jl~fllli!f··

THREAM TRIMMING COMPONENTS

8.

l&\ili:Jt!t$111ill:$t···

~f*

!§!

~$7t

.............................................................................. .................... ·22

........................................................................................ , ........

.................................................................................................

· · .. · · ·

..

· · · · · .... · · · · ..... · .. ·

.................................................................................................

............................................... · ................................................... ·42

...

................................ , ................................. · ............................ 46

..

··

.............. , ........................................................................

.. · ..

ENT

· · · ·

..

· · · ·

S

..

· · .. · .. · .. · .... · · · · .. · · .... · · .... · · · ·

..

· · ...... · ·

26

·30

·34

·38

··48

PEDAL PRSSURE DECREASING

9. gili:JiJ$$:$t··

STOP-MOTION MECHANISM COMPONENTS

10.

iiilitt$~··

LUBRICATION MECHANISM COMPONENTS

11

.

m~~t&-

TABLE COMPONENT

12.

tl~f!ll~

THREAM TRJMMIG COMPONENTS

..

· .......................................................................................

................................................. _ ..................................... - ....

.=:Mt&ftili:Jf!ll~

........................................................................

.................................................

UNT

COMPONENTS

....

............................................ ·62

..

52

56

s8

-21-

Page 24

'

til.~

fll~

SEWING MACHINE COMPONENTS

l

@~

37

-22-

Page 25

.

REF

No

,!:f

"%

I

1

2

3

4

5

6

8

10

11

12

14

15 90-01- 015

17

18

19

20

21

22

23 90 -

2.4

25

26

27

28

29

30

31

32

33

34 90-01-034

35 99 -01-035

36

37

39

40 90-01- 040

41

42 90- 01-042

43 '90-01-043

44 90-01- 044

45 90-01-045

46 90-01- 046

47 90-01- 047

48 90-01- 048

49 90- 01-049

50

51

52

PART·

f!:j:

90-0190-01-002

90- 01-003

90-01- 004

90-01-005

90-01- 006

90-01

90-

·01- 010

90-0190-01-012

90-01-0

90-01-017

90-01- 018

90-0~..019

90-01-020

90- 01-021

90-01- 022

90-01-024.

90- 01-025

90-01-026

90- 01-027

90-01-028

90- 01-029

90- 01- 030

90- 01-031

90- 01-032 tjrj

90- 0l - 033

90- 01-036

90-01-037

90-01-- 039

90-01-041'

90-01-050

90-01 90-01-052

NO

0

..,

001

- 008

011

14

01-023

051

DESCRIPTION Q'TY

.;3

I

iii~.&

iliit&m

~.m

!.UT

ml!l

:£1l\ll

lli.

.till.

iill~t!f

~nr

~;;;$~

~ff

t.iliff~tr•

~ff

S,j!-!l;

tp~1;)

~-a;

~fi1;)

l:!~~

!!tn

~iii~~

!ltff

.tli~t&

!ltff

~-a;

.

~jj<fi

~ff

il.Ollrfi:

~~~

mll'!l

~~Iii!

!J.ff

:t:i~lli.

~jjl:f.&

Wi~~

:<Eftr~

l!l:<E~!ll:fll:

~ff

ill!*

SifT

f.t~m

~lillf.tilll~

~lT

~m~m

!i!Jii!l

m~

:s<~~!ll:fll:

FACE PLATE

FACE

PACKI

SCREW 11/

HINGE SCREW D=6.35 H=4.7 2

WAVED WASHER 6.4 x

BED COVER B 1

TOP COVER

BELT

COVER

SCREW

BELT.

COVEF.!

SCREW 9/

THR!;:AD TAKE-UP LEVER OIL GAURD

SCREW 11/

NUT 9/64- 40

THREAD GUIDE

NUT 9/64- 40

l - SHAPED THREAD GUIDE A 1

ARM THREAD GUI

SCREW 9/64-40 L=6 1

BED FITIING HOOK

SCREW 11/64-

THREAD GUIDE PLATE

SCREW 15/

NUT 15/64-28

FIRST THREAD GUI

SCREW 15/64:-28 L=8

RUBBER WASHER 2

SPR

ING PIN 8 x 20 2

BASE

CONNEVTING PIN 2

WASHER 10.5.x.18 x 2 1

E- RING 6

SCREW 15 /64- 28 L=11

BEDCOVER'A

ST

AY

BED

ROCKER 1

STAY

ROCKER

STAY GUI

· HINGE SCREW 0=8 H=3.4

THR

EAD

SCREW 15/

VIBRATION-PROOF RUBBER 2

RUBBER BUSH 2

SCREW

WASHER 4.5 x 10 x 0.8

RUBBER

BED

FITIING

SAFETY PLATE ASM.

f*

ASM

.

NG

6<\

- 40 L=10 2

11

x 0.3 2

FIXING PAL TE

11/

64~40

64-40

64-40

64-28

DE

TENSION

64-28 L=1

RING

L:8

L:7

L=7.8 1

DE

A

40

L=8.3 2

L=7 1

DE

..

ASM.

SPRING

2

.BASE

·

li.

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

1

2

1

1

1

1

1

-

23-

Page 26

' «fe8f4:

SEWING

MACHINE

COMPONENTS

·

12·13

-24-

,

..

_

__

,..

__ __

,

Page 27

REF

No

"-it

53

54

55

56

57

58

59

60

61

62

63

64

65

66 90-

67

68

69

70

71

72

73

74

I

PART

90-01-053

90-01-.054

90909090-01-058

90-01-059

90-01-060

90-01-061

90-01--062

90-01--063

9090-01-065

9Q-01-067

90-01-068

90-01-069

90-01-070

90-01--071

90-01-072

90--01-073

90-01

..,

~

01-055

01-056

01-057

01-064

01-066

-074

NO

c

DESCRIPTION

~

$:~~

i«tr

ml!l

t~mm

lij

jt

~~

~~{&~

iltr

m

SAFETY PLATE

SCREW 11/

WASHER 4.5X10X0.8

HINGE SCREW

SPRINGER

WASHER

SAFETY PLATE INSTALLING PLATE 1

SCREW 11/64SPRING PIN 2 x 6 1

>lfl SCREW

~~a~

!tt!l:

!IJBl:

SAFETY PLATE INSTALLING BASE

NUT 11/64NUT 3116-28 1

rm SCREW

SifT

!!ttl

'Ftt1;J

!lm!l

~LUi

JJ!~~~t&

mil

;t.lil

ll

SCREW 15/64

SPRING RACK 1

ARM THREAD GUIDE B 1

HINGE SCREW

RUBBER PLUG 1

SPRING 2

WASHER 2

RUBBER PLUG 1

jij:

64-40

11/64-40

11/64

L=7 2

0=6

.H=0.2

40

L=7

L=7 2

40

- 40 L=7 2

-28

L=11

.5

0:8

H:6

.8

Q'

tt

TY

•

1

2

1

1

1

1

1

1

5

2

I

-25

-

.

Page 28

_ ,

..ttlkill~

MAIN

SHAFT COMPONENTS

-'1

/ I

- I

I

)

-26-

Page 29

REF

..

1

2

3

10

11

12

13

14

15

16

17

18

19

~

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

~

4

5

6

7

8

9

No

PART

90-02-001

90-02-00

90-02-003

9o:.:~z::'oo·

90-02

90-02-006

~02-007

90-02-008

90-02-009

90-02-Q10

90-02-011

90-02-Q12

90-Q2-013

90-02-Q14

90-02-Q15

90-02-Q16

90-02-Q1

90-02-Q18

90-02-Q

90-Q2-Q20

90-02-Q21

90-02-Q22

90-02-023

90-02-024

'90--02-025

90-02-Q26

90-02-Q27

90-02-Q28

90-0?-Q29

90-02-030

90.02-Q31

90

90-02-033

90-02-034

90-02-Q35

90-02-306

90-02-Q37

.

90-02-QlS

90-02-Q39

90-02-040

90-02-041

90-02-042

90-02-043

90-02-Q44

90-02-045

90-02-Q46

NO

c

..,.

f4:

2

'

f

:..

005

7

19

~02-Q32

\tlft1~Jt

!ItT

!ItT

jfUf

!ItT

ttffllliii

l:.$ilifi*

l:.$111

l:.$\i<P~

Mff

!ItT

ffllll

!ItT

$iliiM89102

$11i*KS151917

l:.$\1.6ff

!ItT

J'ltlCI~

!ItT

•n

!ItT

•n

!lltl

ltii!CI~l:llf4:

ltii'LCI

Jl:~ti

••

m

ili-a-Ill

•n

•m

~111(1)\)

~Ill

•i!'&:m~

$111~107

\lll>!AIII SHIM

!All(:*)

nlll

IIfii~

n!ll

$ti!!lm~l:llf4:

•n

~il&:m~

ttilll*~'*

•n

•-a-•

~

W

DESCRI

NEEDLE ROO CRANK WASHER 1

SCREW 15164-28 L=14

SCREW

SCREW 9/32- 28

SCREW 1/4-40

COUNTER WEIGHT

UPPER SHAFT FRONT METAL 1

MAIN SHAFT

UPPER SHAFT INNER METAL 1

WORKASM

SCREW 11/

THRUST

SCREW 11

UPPER SHAFT THRUST BEARING 2

MAIN SHAFT

UPPER SHAFT REAR METAL 1

SETSCREW

THREAD CUTTING CUM ASM. 1

SCREW

SCREW 1

SCREW 15164-26 L=12

SCREW 318-28 L=14.5 1

-SCREW 318-28

STOPSTOP-MOTION

STOP-MOnON

SAFETY PLATE STOPPER SPRING 1

PIN 1

HIGH SPEED CLUTCH PLATE ASM. 1

SCREW 11164-40 L=8

SCREW 11/64-40

SPACER 3

SPRING 2

HIGH SPEED PULLEY 1

BEARING

WASHER 2

RETAINING RING 32.2

.

SLOW SPEED PULLEY SPRING

RETAINING RING 66.2 2

PULLEY ASM.

SCREW

PU

LLE

PULLEY SHAFT 1

SCREW 1/

SLOW

PTION

¥$

s

1/4-40

MOnON

11/64-40

Y

SPEED PULLEY SHAFT

L=4.5

L:16.5

L=6

. 1

64-40

L=14

COLLAR

4-40

D--35

4-40

ASM

. D=15 W=10.8 1

L= 1

1·

NEEDLE BEARING B 1

L:19

.5

CAM ASM. 1

CAM 1

CAM LATCH

.5

L=5.5 1

x

62

L=5.5 3

L=6

O'TY

••

1

1

1

1

1·

1

4

2

1

1

1

1

1 .

2

~

4-6

3

1

1

1

1

·- 27-

Page 30

_ ,

JJ

tUllff

MAIN

SHAFT

COMPONENTS

18

'

'

. .

.

36

40

35

37

/ 64

(

~;

~ 1>

~

48

/.

,/

·

3

~-...-·1

•

I.

'

)

48

/'

-

28-

Page 31

RE

F No PART

1

ff~

47

48

49 9

50 90- 02-050

51

52

53

54

'1:

90-02- 047

90-02

0-02

90- 0290-02- 052

90-02

90

- 02-054

NO

0

"'

i:ltr

- 048

- 049 I!!

051

- 053

f!.t

~li!l

~

\lil

iltr

~'*

ill!

Bi:

~ ~

.g.~

tr

J:l<~

DESCR

SCREW 1i4-40 l = 11 1

SLOW SPEED PULLEY

SLOW SP

SPRI

NG

SCREW 2

BALL RETAINER

SCREW 9/64-40 L=7.2 2

STOP-HOTI

IPTION

:g

~

EED

PULLEY PLATE 1

WASHER 4.5 x 8.5 x 1

ON

BALL 1

-

Q'TY

·ij& .

1

2

1

-29-

Page 32

_ ,

tHl!Bi!f

NEEDLE BAR CO

MPONENTS

13

20

16

'

.J

~

17

;·----

·'

•

•

•

•

•

I

I

----

-30-

Page 33

REF

No

"'~

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

I

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

20

21

22

23

24

25

26

27

28

29

PART

90-03-001

90-03-002

909()..03-004

90-03-005

90-03

90-03-007

90-03-008

90-03-009

90-03-010

90-03-01

90-03-012

90-03-013

90-03-014

90-03-0

90-

90-03-017

90-03-020

90-03-021

90-03-022

90-03-023

.90-

90-03-025

9()..03-026

90-03-027

90-03-028

90-03-029

90-03-030

90

90-03-032

90-03-033

90-03-034

90-03-035

90-03-036

90-03-037

90-03-038

90-03-039

90-03-040

90-03-041

90-03-042

90-03-043

90-03-044

90-03-045

90-03-046

90-03-047

90-03-048

1*

03-003

03-016

03-024

-03-0

NO

0

~

-006

31

1

15

DESCRIPTION

liE

tiiff

:};J§

i4:

liEtiii!:f'HII

1.eaoum

ftffi!ff

~'iUt1\a

!ti!lliitili

liEE!ff!!H

CfT

Uff,l!tlif.&

CfT

!Iff

.f'Jtiili

jJ{i

jJff$t!J HI

t:llll

!IIlli

~KS0811

iilU~~KS081208

tf

jjlfT

ttff

..l:~fi;i

ttfflilitt

ttff

ttff"F1flilf

jJfT

~JUt

ftff~~

~tl!!li!J!itf

!ill!~

~tiiit~

~HU!

~ttitlf

tl!tiiB!!!f*

lf

LINK BALANCE ASM. 1

BALANCE CRANK PIN

LEFT SCREW 1

NEEDLE BAR CRANK

10 NEEDLE DRIVING LEVER BEARING C 1

NEEDLE BOD CRANK 1

NEEDLE BEARING

BALANCE

SCREW 15/64-28 L= 1 1 1

NEEDLE

NEEDLE

SCREW 91

NEEDLE BAR 1

NEEDLE ROD LOWER HETAL

SCREW 3132-56 L=4.5

NEEDLE BAR THREAD GUI

NEEDLE

SCREW 1/

SQUARE BLOCK

SCREW

THREAD GUIDE BRACKET ASM. 1

NUT 11/64-40 1

TH

READ

BOBBIN WINDER TENSION POST 1

BOBBIN WINDER TENSION DISC 2

BOBBIN WINDER TENSION SPRING

BOBBIN WINDER TENSION NUT 1

BOBBIN WINDER ASM. 1

NGE

NUTM6

NUT 11164-40

~

-8

ROO

ASM.

ROD

HETAL

ROD

HOLDER ASM.

64-40

DP

8-44

15164

GUIDE BRACKET 1

SCREW D=7.94 H=13.3 1

L=6 1

DE

x 5

#14

L=2.9 1

-28

L:9

O'

tl

JltT SCREW 1 1164-40 L=5

~ll:..Elifi

!l!ttll:.~ff

tl!tii~

il!tcUlll~

!Iff

tUt~f.&

jJff

BOBB.IN

BOBBIN WINDER BRAKE 1

BOBB

BOBBIN WINDER SPINDLE BUSHING

SCREW

BOBBIN WINDER BELT SUPPORT

SCREW 111

WINDEFI

IN

WIND

11164

.BRAKE PRESSURE P

ER WHEEL 1

-40 L=5

64-40

L=7.8 1

IIUlfTftli BOBBIN WINDER TRIP LATCH 1

t\\tl$lli

jJlJI

~-

~m

!l!t&tJI:iEf&

tifT

BOBBIN WINDER SHAFT 1

BUT 1/

SPRING 1

HINGE SCREW 0=7.24 H•1.9 1

BOBBIN

BOBBIN

4-40

WIND

WIND

ER BASE 1

ER ADJUSTING SCREW 1

TY

i

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

-31-

Page 34

_ ,

tHfi~i!f

NEE

.DLE BAR

16 'J

20

COM

PONE

;---

0

0

0

1

1

NTS

- 0

0

0

0

~

1

7

'

0

51-f

:

0

0

0

0

0

'

/

/

--

.-

0

0

0

I

0

1

1

-3

2-

Page 35

REF

No

l'f~

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

PART

90-03

90-03-050

9090-03

90-03-053

9090-03- 055

90-03

90-03- 057 itt§ NEEDLE PLATE

9090-03

90-03-060

90-

90

9090-03-064

90-03-065

9090-

1/f

~

-04

03-051

- 052'

03-054

- 056

03-058

-05

03-06

:;-03-0

03-063

03-066

03-067

NO

9

9

62

1

DESCRIPTION

~

;Ai:Uit:t§

!llff

ilfT

itt§~¥!=

;;i.JJJ

!!Iff

'Ht:t§

!llff

~JJ

!\Iff

;;i.JJJi!*t

;;I.JJJ*ftl!lt-1

;;I.JJJI!Il~

~

;;/.JJJft;;i.J*t

!!Iff

YHil

!llff

V!J!'it.'!lil

BOBBIN WINDER

SCREW 11/

SCREW 111

NEEDLE

MOVING KNI

HINGE SCREW

NEEDLE HOLE GUID 1

SCREW

FIXING KNI

SCREW 9/

MOVING

THREAD CUTI

THREAD CUTI

THREAD CUTTER LEVER ASM., LARG 1

SCREW 1

WASHER

SCREW 11/64-40 l=7

NG

MOVI

f;'F

64-40

64-40

PLA

TE ASM. 1

FE

3132

-56

FE

64-4

KNI

FE

1164

KNIFE WASHER C 1

Q'

TY

~ ·

TRIP

LATCH 1

L=9

L=5.5 4

ASM.

D=S

.O H=0.

L=2.2

ASM.

0 L';3.5

LINK 1

ING LEVER RING

ING

LEVER , SMALL 1

-40 L=4.0 1

9 1

2

1

2

1

1

2

1

1

1

-

-33-

Page 36

ll!L

t3

iUU

i*

THREAD TENSION RELEASE

COMPONENTS

-34-

Page 37

REF

No

"~

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

PART

90-049().-04-

90-04-003

90-04-004

90-04-005

90-04-006

9o-04-007

90-04-008

i'l=

NO

c>

..,.

001

002

90-04-009

90-04-010

90-04-011

90-04-012

90-04

- 0

13

90-04-014

90-04-015

90-04-016

90-04-017

90-04-018

90-04-019

.

90-o4-020

90-04-021

90-0

4-022

90-04-0

9().-0

90-04-025

90-04-026

90-04-027

90-04-028

90-04-029

90-0

90-04-03

. 9().-04-032

90-04-033

90-04-034

90-04-035

23

4-024

4-030

90-04-036