Page 1

::Z:<:>.J

m ,.

EO:

HIGH

.SP

EED MULTI-NEE

DLE

INTERLOCK

SEWING

MACHINE SERI

ES

-

f!

m

il

aJJ

~

~i!J:Ef.M

OPERATION

PARTS

ttJIIJ·ttllltilmillllifR~BR~61

ZO

JE

SEW

IN

G

MANUAL

BOOK

MACHIN

E

CO

.,

LT

D .

Page 2

*~m•~~~~~·M~•

The

descripijon covered in this operation manual and parts book is subject to change for improvement

the commodity without notice.

.

~7~•~~~~~"•~~

- I .

.

~~~~ffl

.

of

Page 3

I

:

illlll!t

ll}l OPERATION GUIDE

I

I

:

~iiUDfol~~

I

I

I

~Jti!liit)\~)!~

itl!~

TO

INSTALL A MACHI

LUBHICANT OIL FILLING AND REPLACEMENT 2

TO

REPLACE NEEDLES 2

NE

1

~tl1Jit

THREADING 3

ti!!!iiUl THREAD TENSION ADJUSTMNET 3

!!BI!i/18!1

.Bi!.IIJHi::tJllll\lll.

~!!Ill

~t&lll

~~~~·iji\!ti!Jl

~f&f.J:!l

*~#:it.

STITCH LENGTH ADJUSTMENT 4

ADJUSTI'~G

THREADING DIAGRAM

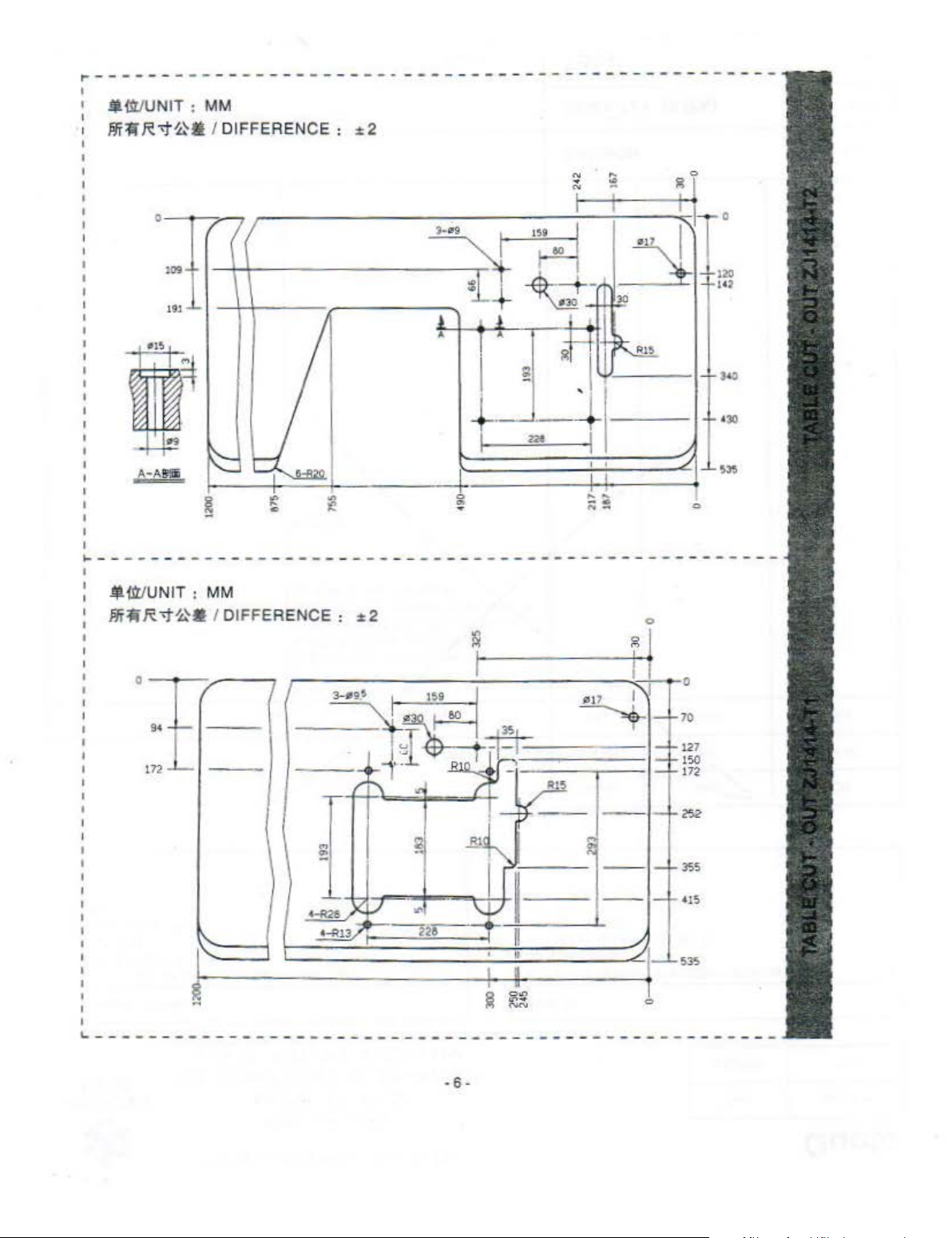

TABLE

IM

PORT SAFETY INSTRUCTlON

CONVERSION CHART

PARTSUST

CUT

THE

-OUT

PRESSURE

OF

PRESSER FOOT

4

5

6

10

11

13

-n -

Page 4

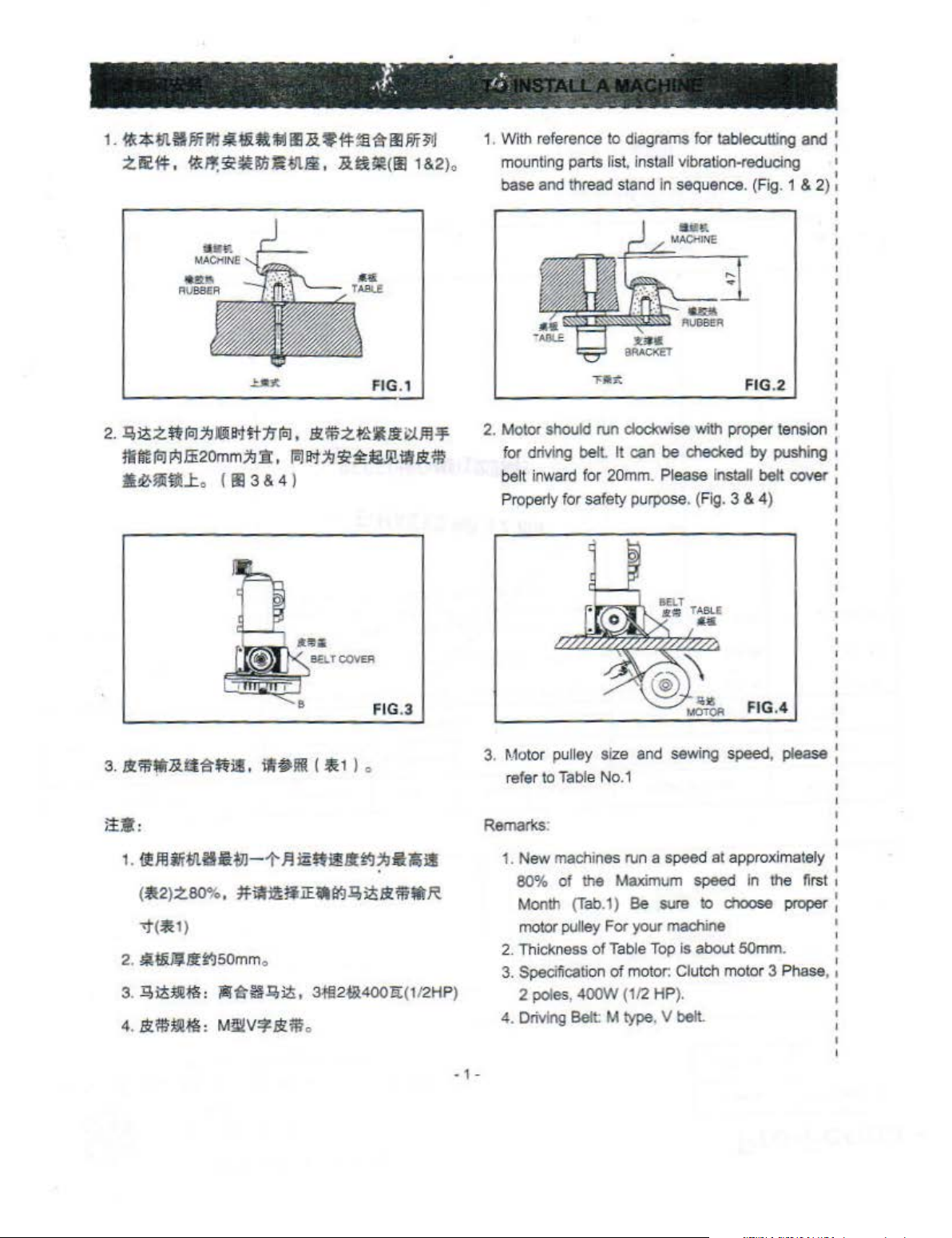

1.

~*l1LBmNI~~UUAIIl&~i*~\%iii.IWJtl

zli'.#.

~l'.~lUU~l1tlli.

&ti~(fll

t

&2).

1. With reference lo diagrams

moun

ting

parts li

base

and thread

for

tablecutting

st.

install vibration-redu

stand

ln sequence. (Ag. 1 & 2

,

....

BRACKET

cing

FIG.2

and

),

I

:

•

'

'

2.

.E;

it

z

*l

toJ

;~J

JOl

t-Ht

:1i

toJ

•

Jt

fi1

z

rca

lf

~.;LJ!l

tti~toJJI;Jffi20mm;IJil:.

·~llli~J:

.

( Ill 3 & 4 )

falil't;~J'iCHmlftJtm

COVER

FIG.3

it.:

1. ilJ!liil1tiliU7J-

!*2):2:80%.

'i"

(t<1)

2.

~!&l1Jnf~50mm

3.

];!it~#!:

4.

s.:m~#l:

1'

~

m*lil!!~~;~JiU~i!

~ilmtf.iE~U',)R,J;!;JtmttR

.

illlit~!l,l;!;

M~i!V!¥&

,

3:Kl2t!l400!i:(t12HP)

m

.

lf.

2. Motor should run clockwise with proper tension

for driving be

belt

inward

Properly for safety purpose. (Fig. 3 & 4)

3. Mr;tor pulley size

refer

to

Remarks:

1.

New machines run a speed at

80% of

Month (Tab.

motor pulley For your machine

2.

Thickness

3.

Specification

2

poles

4. Driv

ing

Tab

,

Belt

ll

II

can

be

checked

for

20mm

. Please Install belt oover

and

sewing speed, please

le No.I

aPProximately

the

Maximum speed in the first

I)

Be

sure

to

c:l1oose

of

Tab

le

Top

is about 50mm.

of

moto

r: Clutch motor 3 Phase.

400W

(112

HP).

M

type

. V belt.

by pushing

F

IG.4

proper

• 1 •

Page 5

:~m

a~

~n

~e~

I

iltr~~JmAiiilit~

I

~(A

)at!

7f

,

!.;L

lt~fflMOBIL#10lt

1JD.A.

.

Uiltll

~~~. ~ftmH~m

S~ii

P'l

Jili

ESS0#32

W

<Cl

P'lzEil!!~tl<llil

JHUf(A).

2.

~ll~1lllz:t:~,

<ll3J

PH

Zai

~ l!fiilltil!!

~i&z~l!iltil!!

lljliiT.

t~~

s

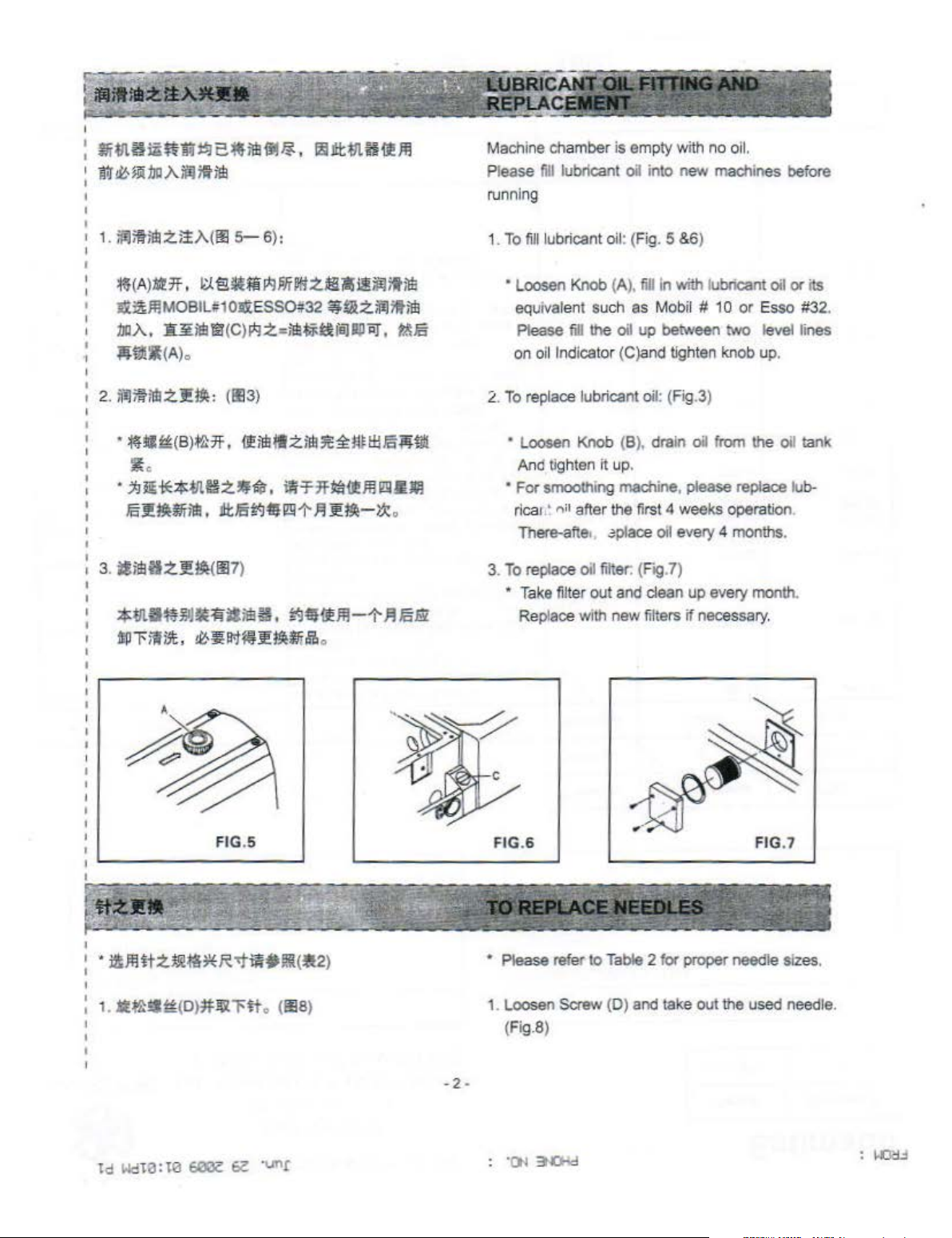

Machine chamber is empty with no oil.

Plea

se

fill lubricant

running

To

fill

1.

2.

lubricant oil: (Fig. 5 &6)

• Loosen

equival

Please

on

To replace lubricant oil: (Fig.3)

Knob

en

fill

oil Ind

oa

into new machines before

(A), fill

in

with lublicant oil

t such as Mobil #

the

oil up between

ica

tor (C)and tighten knob up.

10

two

or

or

its

Esso #32.

level tines

• ~ jjzi:to(B)tl}7f •

~

<

·~~**~ez•$·*

IS~~~ilb.~J5~-~~~£~-~

I

I

I

1 3.

atiJUJzJ!~<IIl7l

I

If

ilb

II

z

ilb

~

~

t4Hil!S

T*

~~m~•~

11Uii1

.

*m•~~~~-illl~.~•{fm-~~.15&

~"Fililt,

~~111f3

FIG

.5

£~~oib

.

• Loosen Knob (B

And

ti

ghten it up.

• For smoothing machine, please replaoe lub-

ricao

.·

" " after the first 4 weeks operation.

There-afle1,

3.

To

replace oil filter. (

•

Take

filter out and clean up every month.

Replace with new filters

FIG

.6 FIG.7

),

drain

~plaoe

FIQ

oil

eve

.7)

oU

from

ry

4

months.

if

necessary.

the

oil tank

I

•

: •

i!fflitz~~~R-.t~•lll<!l2

1.

td

jltl}.t!

Wc:na:

(D)

t0

#!ill"Ftt

eooc:

6G

o (IllS)

·unr

)

-2

Please refer to

1. Loosen Screw (D) and take out the used needle.

(Fig.8)

-

Table

2 for proper needle sizes.

Page 6

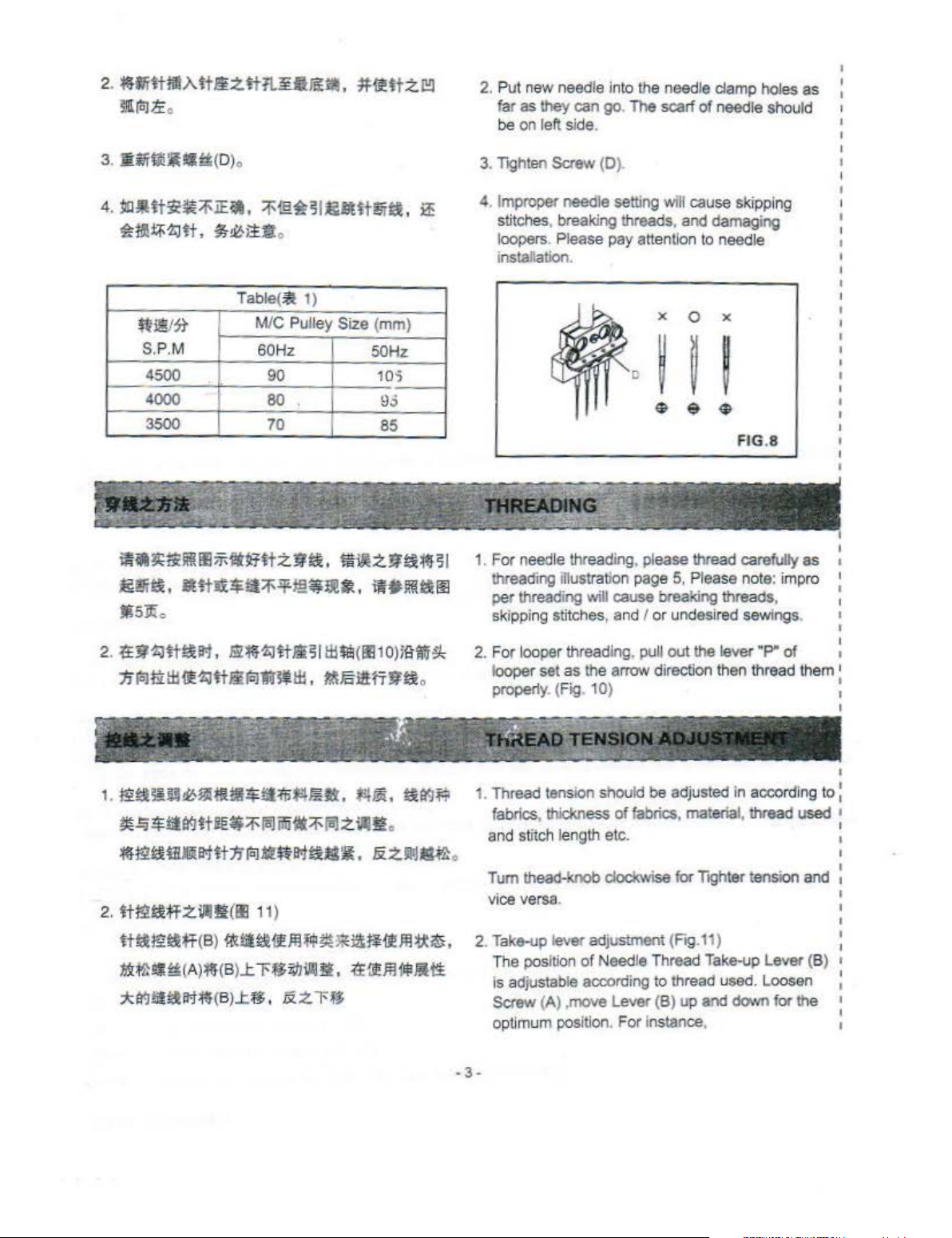

2.

~llitt!i.Mtl1£ztHt.~•~~•.

ii!Itolti:

.

3.

_.iiU!!\UI~(D)

4.

~-tt:ie~:fiHil,

~t!~Zltt,

https://manualmachine.com/:St

S.P.M

4500

4000

3500

o

:f@~~I81Jttf#jiti,

~&&iUt

.

Table(

M/C

60Hz

90

80

70

~

Pulley

1)

~~ttzl!!l

i1E

SiZe

{mm)

50Hz

105

g.;

85

2.

Pu1

new

needle into

far as

be

on left side.

Toghten

3.

4.

lmpi"O?Eir

lhey can

Screw (D).

go.

The scarf

needle setting wifl

stitches, breaking threads,

loopers. Please

installation.

pay

the

needle

and

attention

X 0 X

k--~··

~

sr_,t.-

-

~

-::..'

damp

of

needle should

cause

skipping

damaging

to

needle

FIG.8

~~

,

.•

..

holes as

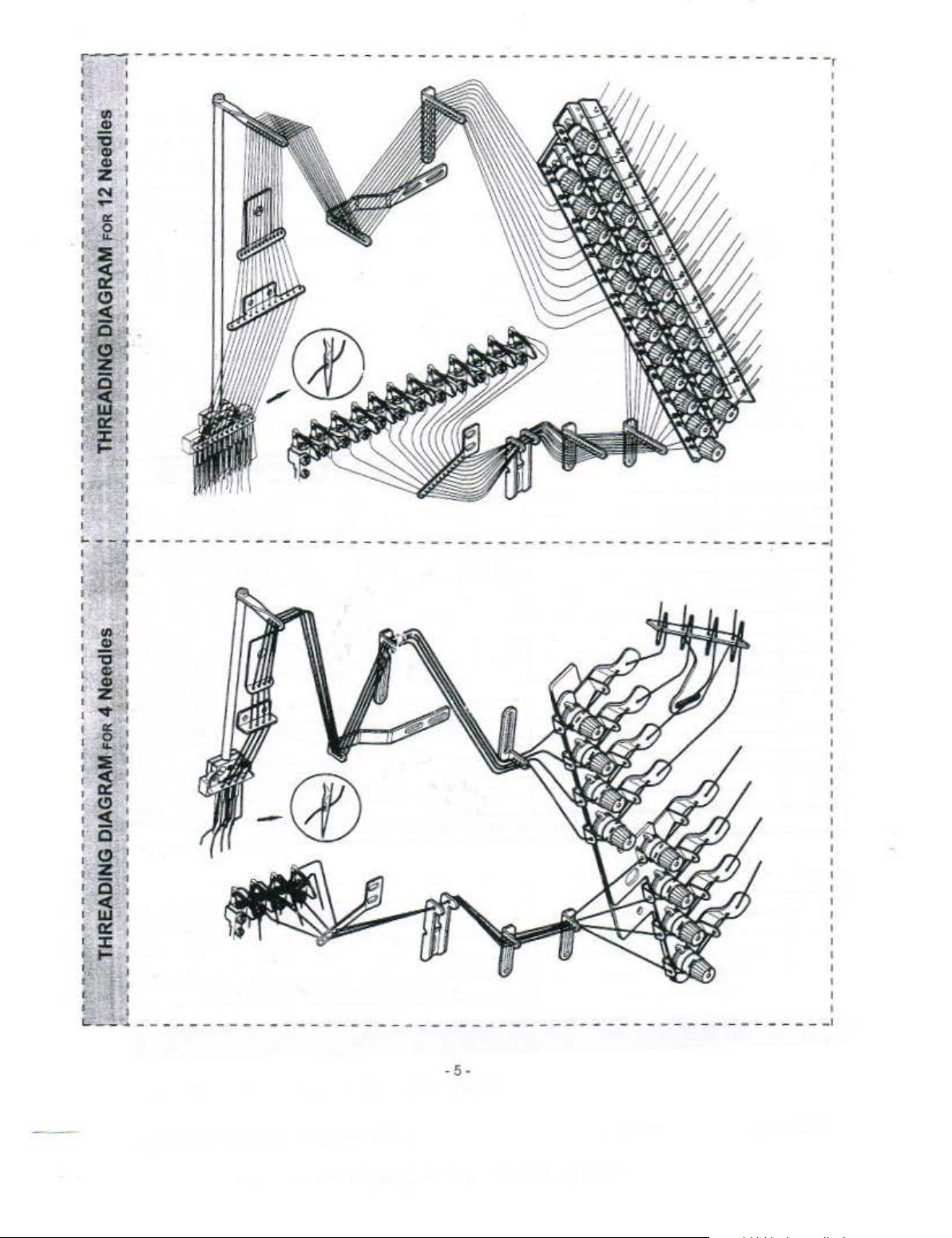

1. For

~-~~llllil:if-iit~ttzJJt:!!.

m~z!!1~~5

1

~~~.-tt~$~:f~~~~~.~-llll~~

Jl\5~

.

2.

-?±;J~tt~ll't,

~toJttlti~~tt.litoJn~w.~s~rr!J~

1.

~t!lsU~&&~~~~*!!<ii~~•.

~

~

$tlll(Jtt

:tlf~tUl!UIIofttJ'ftoltt~B<JtU!IIIl(

Q:tlf~tt.li511ti~(lll10)iSliU:'k

.

Jll!§>.

~

ll(Jf:i

ietf:f

liJ

illii!H

liJ

z i.ll§.

. &z"'Jill~

.

needle

threading inustration page

per threading

skipping stitches,

2. For looper threading, pull out the lever "P" of

looper set as

properly. (Fig. 10)

1. Thread

fabrics,

and

stitch length etc.

threading. please thread carefully as

will cause breaking threads,

the

tensiOn

should be adjusted in

tl1ickness

Tum thead-knob dockwise for

vice versa.

2.

tt~t&~:tW§(III

tttl!£tl~(B)

~loll

f%!i

(A)~(B)l:

:kll(J!il!lt'.t~<B>..t3.

1

1)

R'<tiU!!~Jll

1'3

ifl!l

i;l)iiiJ

&z

~

*iiU

Jl ,

l'.\J

~if

lfltl:~,

f:E

(i}ll1'$Jit!£

2. T

akiH.I

p lever adjustment (Fig.11)

The position of Needle Thread

is adjustable according

Screw

(A) ,move Lever (B) up

optimum position. For instance,

5.

Please note: impro

and I or

undesired sewings.

arrow direction then thread them

accondlng

to :

of fabrics. material, thread used 1

T~ghter

to

thread used.

tension

Take-up

and

down for the

and

Lever (B) 1

Loosen

I

1

I

:

·3·

Page 7

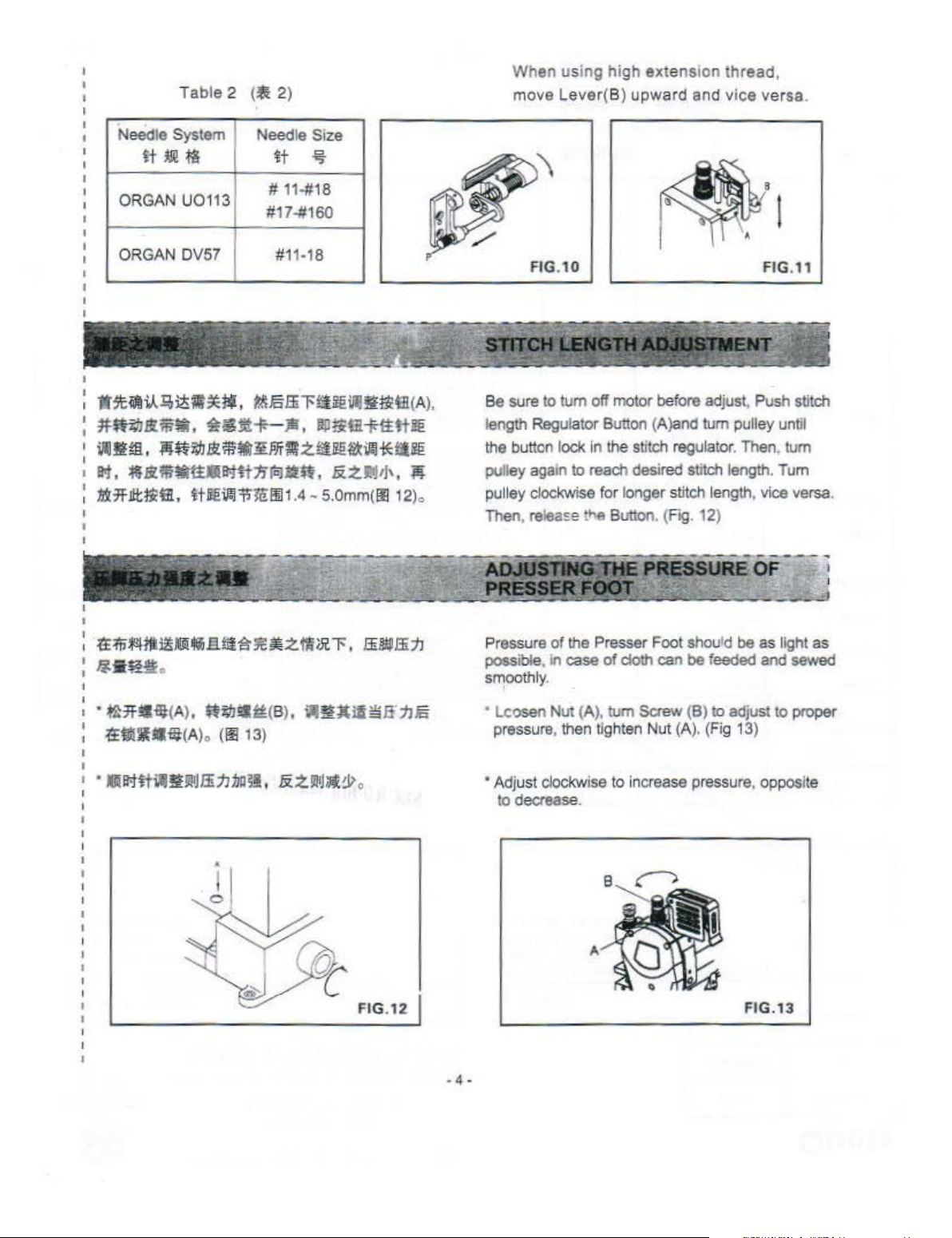

Table

When using high

2

(

~

2)

move

Lever(

B)

upward

extension

and

thread

vice

,

versa

.

Needle System Needle Size

»~~

ORGAN

ORGAN OV57

..

- .. . •

·~l'l.li,.l..!;oii;:~~~.

U01

. . - .

13

-~."f~

r

....

. :

~~:_

t.lilaffil'!il!aiJU~li~(A)

:~~affl~.~s~~-~.~~m~~~~

:

~•m.~~~am~~~~z~~~~*~~

I

111.

=M.Itf!Uifitt•~t-ttt1iicl1l$t.

:

$7flltlitl!.

~t~Vll~m!i1

c

...,.

»

# 11-#18

#17-#160

#11·18

.=.

-

,,

..

.4-

s.omm(lil12).

&Zflllj\.

~

,

length Regulator Button (A }and tum pulley until

pulley aga

pulley clockwise for longer stitch length. vice versa.

~I

FIG.10

Be

sure to

the button lock In the stitch regulator. Then, tum

Then,

tum

off

motor

before adjust, Push stitch

in

to reach desired stitch length. Tum

relea£e

~fl

Button. (

FIQ

. 12)

FIG.11

~~~~~~~g~~~~z~~"F.

~·

$!~

.

•

f'k7fC~

~l'li!!iUiilJ(A)

(A),

$t~ii~(B

o

(li!13)

).

;,llfUtilsli'nla

li

EE~ffin

FIG

.12

Pressure

possible, in case

smoothly.

of

the Presser Foot shou1d

of

doth

can

be

be

feeded

as light as

and

sewed

'

• Lcosen Nut (A

pressure, then tighten

• Adjust clockwise to increase pressure. opposite

to

decrease.

),

tum Screw (B) to adjust

Nut

(A). (Fig 13)

A

FIG.

to

proper

13

Page 8

r---,

f I

0 ' -

1 I

i

1 : I - - - - -

l !t;

r

, z

I N I

I

I

a:

..-

tr!

~

::E

- ------

----

--

- - - - -

-----

----------

----

- - -

---

--

~~I

o

Cl

'

~

f

:o"

:~4

~ol

I

o(

I

t W: I

~

~

:

-1

I

~--'--

1 i

' I

1 I - -

--------

1

I - - -

-----

- - - - -

--------

----------

'

: : I

I !i; 1

l

~

l

'Ot

l

I

l

~

1

~

::E

I

t < I

'

IX

I

o (!) I

"'(

I

I

s

·l

(!)

z

I Q

I

<(

o w

:

~

I

~

....

:

~-

I

I !

I

'

t,_.;;.

.t!

-------

----

- - - - -

-- -

- - - - -

----

---

-

----

---

----

-----

--

--------

I

-·

_,

-5

-

Page 9

r-------------------

/jl.tt/UNIT:

I

' I

fili'=MR'<t0.

o

MM

/ DIF F

7 1

j1

109

191

ERENCE:

---·----

:2

:'j

3d

l

A

--------------- ---------

I I 0

..

. g I

~

~·

eo

!

120

,.

,

I l

~

-

. '

~I

-

:]9

k

l.

~

"I

+

·-

I - I

6-">

f::::

~-----------------------------

..

Ill:!

UN

IT : MM

ffi:Ji

R

-.t0•

'

1T-

172

I DIFFERENCE : ± 2

.J_

n

'

-

------

1

1---------H7

~ij)eo!_

+I

_,_-

·

-

··

M

!!:

/"'\

.,.

;!

l

~

l

I .

RIO

.1':.

'

~

J

~

-

llli~

·

-~

' '

I

~ '

,..

_

--

- -

------------

0

l

L

L-

I I

'"

'

~

- -

~

- -

- -

,_

==

-

-

./

o

70

127

150

172

•30

c

c

-

Ki/

<-R26

~

I

"'

~ &

~

i

ll

' •

•

L--------------------------

-------------------------

• 6 -

- - - -

/ 1

-'-

0

•15

Page 10

Jjld

lt'UNIT

HT

'Ii

R~ ~-

0

: MM

I DIFFERENCE : : 2

I/

~

I

I

·1-r 0

109+

191 L

'·

r

...

1

I

ltJ]

~

-------------

.ilif:it'UNIT : MM

Plf:f.i

R~~~

I

DI

FFERENCE : : 2

~

-----

-

~

~~

l--

.,.

------ ----------

+ - -

1 ! -

l

1 = I

--H

~

!

221

II

-------

-

~

~

' .

~ ~

42

H

430

8

0

--- --------1

0

I

I

I

[\. .!:!ill./1

1

'-

--

-----------

. I

~

~

226

-

--------~

' n ./

·

-*

·

----

II

~

~~

------------------------------------------

. 1 .

1-

----

----

--/

11

·

-

0

---------

252

•15

~5

' I

-·

Page 11

---------

-

~UNIT:

Jl'i~R"1"0~

--------------

MM

I

DIFFERI;NCE:

:t2

--------- ------------------r-

0

/

~

-

17

2

1-

(•10)

~-------------

4t1iVUNIT : MM

ifi~ R "<t0~

0

~

•90

1\,

I DIFFEREN

-..---/--------,

~

~~-l-~~ft

_

..; ~ .

/

~

"'

~

r

I

I

2

- --------

I

I

'V,:::::i.i.,.XJ

1-

CE

:

:t

~--~------~----------~+,

t$9

..

~

---------

2

I

1Wl

Lr::

~""'

..!!!:

!"'-.

I I

'

l

'

-

~

~

!

./

II

I

~ ·

~

-----------------

-../

0

0

n

7

1-

1-

3$$

...

---

o

'

~

--

----

~~~

172-

'-

4-RtO

(<10) -

1-

-

~

490

I-

_

L-J.

\..

I I

---------------

--

-

~

-~

1

~

1

1

'-V

j----z2-e

t:==~==========~

-

--

1 RIO

+

~

!!

"'

- - -

-8-

,.,

~

-~

----

!

~

~-~-

~

-

-

-

/ -

1·

;:J!:-

~

---

r-

-

---

·

·-

-

~

--"-~

:==

:~7

1-

150

1-

17

- -

1-

25

~

--

i

-I-

3$5

- - !-1-•ts

i

...:.

---

·

==!

·

::::::::::

I I

-----

..1..

-----

~

~~

-----

~~

- -

2

2

--

-

Page 12

~-

-

~

,r~·~-

(

~";;;?'-

...

~

-

"'\

TABLE

..

..._

~

-

--

...

- - - - -

--. --- - -

CUT·

...,

..-;>.._.--"-

OUT

_.._

----

~~- -

ZJ1•U4·T7

..

___

-~ -

---

- -. --- - - .-.

':',a...!

·'•

·",

-.

-....~---

"::~~-:~

- ·

-- --

__._~.,

''1.~

~:

-.: ·

_

_._.,_

-=--

,\:·.·

..:~~'.::1'.~

-~3i~~~~~

..

--::'~~

;~' ~.'

~·-:~

~

~..,;:t-""'-

;,

'

;j,~

'··

l"!

~L:!:;c:

-

........

• '

·t~C!f

~D

..

:.c.

--.

I " _

...-

~

,--

..,_

~

,.-~·

-•,.;..\

.. ..._...

""""'-

--.-

.

---~---

'i.rl·ll~~,;-

, · '

---

-

.-

~

I'~"'

- -

-~J

"'

::!il.

Jill

@

::Uc

4~

t-)

--t

Alii:

••

- ~

0~

.....

.....

m

JJ

m

z

(")

m

I>

1\)

1200-r-

17

~

..

..

..

.

id

,--

I I

I

I

1

93

I

"~

!Jd;

~

s 1

300-l-ltJ..~

m+-

H-1-

0 I

~

\_

f I I

&~

----------------------------------------------------------------------

--

1a3

-P

= -r·

•-

' ' ' I '

293

I l Ill .

1~ ~~

~

I

I!!:

J

-r~

::

w

IJt

~

11-1-

----

...

~g ~ ~

l

-rl1~

-

~

-

iao

o

0

1.

I I

~ t~

l!!lft~~tln

1!!1¥1"~

ttm

l!!lt-~~0$

l!!lt-

I

~~:U

$

l!!lttflll:t$

l!!ltH1~

l!!l~tlllm~

1\U~tl:trl

+-=tt-~H;fJl

+-=t~~ttm

+-=ttWi>Tt$

1-

-=

tttli1'ti$

+-

tli'i'f;

:$

+-tH~U

+-tt

lt.!l1l!l

$

~~::::-:

1-E

H~tHil.

1-

-tli

~ill

in

-=

+-tt~trn

-=-

I-

li~t~t~:tll

-+

:::

t-l'l~~~*'!Jl

- +

.=.

~4~~~fi11l.

!11"!tll-1£i.l!.l!l,

611t~uia

$B

.

6141\!l&!:U:f.ttr~$

oo

11t¥<~. OOJit~iil~

n:t

&12ft

..

. 615

---------

mr

Zl 1414-1 00

ZJI414

- I00-403-601-04085

ZJI414-100-403-601 -603-Q4034

ZJ 1414

-1 00-403-{;0 1-(J03-04085

7J 141

4-

100-403-

7J

1414-1 00-403-{;0 1-(,09-04641254

ZJ 1414-1 00-403-{i(JI-04A32

ZJ

1414-100-403-601-08064

7.

1 1

414-100-403·60

--

ZJ1dl4-

L.J

ZJ 1414- 100-403-601-613-12048

/'J 14 1

7.!

7.J

Zl1414-1 00-403-601-61

ZJ

z

7.JI4 14· 100-403-601- 1

ZJ

ZJ

7.J

ZJ 1414-100-403-601-614-33048

100-403-(,()l- 1

1414-1 00-403-<>0 1-612.()(>064

4-100-40

1

414-100-40:1~601-6

1

414-1~0

1414-100-401-{;0 1-

.r

1414-1 00-403-60 t- 1

1414-1~03-601

1414-100-40

1

414-100-403-{iQI -3

u .

6131~$$!1.

1~¥!11\ill~AO$

---

~

-403 -

C.O

60

3-601-

3-{i(JI·6

3-60

•~~. 609ft~nWM.

.

616fU;At!l1tt,15

-li}

1-04064

1-60'>-0464/1 <)I

1-1 204R

2064

61J-l2064

1

5-1

2048

1

5-1 20M

(,.12048

616-12064

3032

7032

-23

012

1-250.18

304~

o13~~

-

.

Page 13

1. Transportation

(1)

<UI~~=Jtit(f.JGU~:£~tllti~U~"'

ff>

.

I 3. tU!'l>

4.

lffr

ttM~ffi!r~

1.

tlli;i~fl;·~'

ff-

.:t

*

il

i!!l o

i#i!lt~J:.~!J"~Jl

.

( 1) The machine packed

that made

protect

(2) Put

(3)

Use

of

expanded polystyrene to

it.

the

machine into a carton.

a cart or by two men's hands to move

with

two

piece

covers

2. Storage

( 1) The machine must use duster -cover to oover

~

when it did not work.

(2) The machine avoid to storage

erature .. .ore than 45't

3. Working

Pay attention to this warning advice as

In

the

temp-

follow

a. Working area is dangerous.

b.

Never touch the needle

running.

c.

Be

careful

d.

Do not insert your finger between needle

and

if

you infeed fabri

roller

for transportation on fabric.

if

the machine is still

c.

it.

:

2-~~.~~.~§.ffl·~~i!·-

II!

il9.

0

~

-10·

Pay attention to this warning sticker:

a. Movable parts must

guard

b.

Pun

out the plug from socket when you adjust,

thread, change bobbin and needle dean.

when

you

be

enclosed

operate.

with

Page 14

-

~,~. ~{!'t;-_

t

;_ · ..

·--s.~r

··

·)

-~-

__,~·~Ci.#i.:!;?-.-P__!,:_;o::2~

I

I

I

I

I

I I

I

II

I -

•

MOD

I

~---

I

I

,_

•

I

•

I

I

I

I

I

1

----

I 1

~

I

I

I

1. -

I

I

I

I

I

I

ZJ1414-06/VPL

I

•

~

----

I

I

I

I

,_

I I

•

I

I I

I

I I

•

~.

________

EL

Mll'l

LJ1t.14-04

ZJ14H-0448

ZJ14

14

-0464

ZJ1414-12

--

-

·

-

r-

---

'

-

-

'----

- ·

____

~)~

Mit

SUB- NEEDLE

CLASS

·---

.IIlii

064P

08SP

095P

106P

127P

9tP

222P

254P

191P

1

27P

25

4P

048P

064P

048P

OSOP

064P 1/

..

GAUGE HOLDER

r--

tt~

1--

-----

3W

-

,.

t -

1/8

t

-·

1(4"

1-t/2

3/

16-3/4-3/16"

3116-7/1l

3116-1-3/16" M9404A E9404E

-

1/4-314-1/4" M9304A

1/4-

lfl

1/4· 1-1/4" M9104A E9104E D9104A P9104A

3/16"

114.

3/16"

5mm

4"

---------

.... __

-.--

~ -~

...

:...

_

~_. _ _,_,-~--

tiP

ilf;

• •

<Y

""':

-"'~ -----

~""!~~~"r.'F"""~ ~114_10_!1

CONVEASlON

........

~

..

CHART

' .

...

-·

I

-

.........

~

.,;..:;t:;;;;:

;;

~

~l£:.;~:...:~-~

!!

•

NEEDLE

--

ttlll

M9004

M9104 E6104D

" M9204

M9304 E93

2:f9404

M9504A

-3116" M9204A E9204E 09204A P9204A R9204A VESt VE49

-1/4"

M9004A D9004A

M9012 E9012 09012 P9412

M9112 E9112

M9012

M9612 E

M

9t12

·-

----

NEEDLE FEED

PLATE

tHi

~6001~

E92040

__

r!94

E~S04E

E9304E

E

9004E

E9012

9612

E9112

ia~lif

09004

---

09104

09204

'

....J:..

040

09404

04D

D9504A P9504A R9504A VaSt VC49

~09404A

09304A

r

09112

09012

09612

09112

r-

----

----

DOG

--

"'04

... ___

·

PRESSER

FOOT

IJ

P9004

--·-

P9104

P9204 R9204 VE51

P9304

--

P9404 R9404

--

P9404A

---

P9304A R9304A

P9004A R9004A

P9512

P95~

P9012

P9612 R9612

P9

----

RETAINER

-

r---

..

--

~93~-

HOLDER

lttUIII

R9004

R9104

LOOPER

-

9112

--

r

1--

--

~9404A

R9104A VE51 VE49 L9104A

R9012

---

R9112 VESt VE49 L9112 VE11P

R9012

112 R

----

NEEDLE

GUARD

f.ltt

VE51

VE51 VE49

VESt

VESt

l.Pttlt

1-

VE49

VE49

VE49

V&49

--·-

---

VE51 VE49

VE49

~:~-

VE51

VE51 VE49 L901? VE11P

VE51

ves

--

VE49 L9004A

-

VE49

VE49

-1-

VE4

9 L9112 VE1

----------------

~~:

~

~

--

LOOPE~

HOLDER BRACKET Uo113 :

~ttll

-

L9004

_l9104

__

r-:g~

l93'l4

L9404

c-!:9504A

L9204~

LWJ4A

~304A

LOOPER NEEDLE'

~"It!

;t

VE11

VEil

I-

VE11

-

VE11

VE11

Vall

VEil

---

VEil

~::;

,.Y

E11

L9012

VE11P #11- #

- I

-

L9612

VE11P

---

--

...2

'~·-·

~

-

-

1P

-

...

~~

f

ft

#11•

~14

#11·

#t4

#11-

#t4

#It

• #14 I

#11· #t4

#11

• #14 I

#11· 114

#11

· #14 I

1--

__.

#11

· #14 I

1---

#11-1114 1

#11• #14 I

14P

--

#11·

#14PI

#11

· #14PI

#11-#14P

1111·1114P

_

___

I

I

I

•

I

I

.I

I

I

;

I

;

1

,

1

1

:

1

I

I

I

I

I

_I

I

I

Page 15

f--:

L .

~.';.-""--~ --~

~c

:;.:

-

~_,.._

l,.l'::_.;.;.~~·

....

~.~~ ~cl-'

... _ ••

_ _ .-_ - -

"1-

:;;

..

-

::.,2-

~·:f·.:·

--

, , .

-~ • ....:...-~ -~-

-

-;,;

:;_;;:~

7«m·rt-~

--

.... ~ ..............

--c;;~;RSicm

• _

-....;..__

..._

_...-

-c~

HA~T

;1"111;"

..;..-~...,......-

~--;f~~~

~---=

-~-~;

::;.~·

:;-

~-,·

:.;.

__ .

.........,.

.

'"~"

-;;

;:.

.

'~[l

r:

-

-~-;,..;.

~~r·':i7'~

..

~--,J.J.~:-'-·-

~~:J~I'".

~~

-j

1

....

-

':"

:-

I

MOD

EL

: CLASS

:

.fl!!l!!

L-

1

I ZJ1414·12 QP I

I 064P 1/

1

ZJ141

: 032P ,

1

1 ZJ1

1

:

ZJ1414-12A 03

I

..-

I I

..

----

1-

- - - - il

I I

I I

~

-----1---1-------->·--

1 I

I I

'--

---

I I

I I

I ·

I I

I I

I I

I I

!.

- -

N 048P 3/16" M

. -

4-12NPL I 064P

ZJ

.414·13 · _ . _

414

·04A 032P

ZJ1414·04 064P

ZJ1414

----

!--'-'

--

-12 064P 1/4"

--

1-

--

1-

--\--

-----

-

k--

wm

SUB- NE

AAJt~~

· -

064P

2P

-I-

-

I-

--+------

·-

I-

EDL

E NEEDLE

GAUGE

m~

4.

1/4

" _ M_

114·1f8.118

114-118·1f8.1/4"

1/4-116·118·114''

· .

· I

·11

1/4

" M9 213

114"

fJ!<S>

NEEDLE

4"

HOLDER

fHtl ttt.lt Jt.*'l>r

9012

M9112

9112

M9113

M

9113

M9213

M9113

M921

-l

--r--

--·-

PLATE

--

E92

E9312

E9112

E9113

E9213

E9113

E9213

E9113

3

E9213

-+---

r-

--

-f---

·-

1--

r-

- - -

----

--

- -

----

----

•t;

FEED PRESS

DOG

·-

~·--

12 D9012

09312

_ _ 09_1_12_1 P

09113 ?3113

09213

09113

_09_

2_13

D9113 P9113

09213

r---

4-

---1-----+----~--,~--~

'---

1-

· - '

----

FOOT

Rilltil

1--

P92

P9312

9512B

P9213

P9113

--·--·--

_ P9213

P9213

--

- -

----

ER

12

·

-1---

/

RETAINER

HOLDER

uatllil

--

R90

R9112

R9112

R9113

R9213

R9113

R9213

R9113

R9213

--

~

LOOP

~tt

-

~

·--

12

VE51

V£51 VE49

--

....'i..E_S

VE5

VE51

VE51"4

....;..c:_

~-51_"4_

VE51'6 VE49

VE51

c..._

L..---------'--

, I

!~

ER NEED

1_ V

1P

'6

LE

LOOPER

GUARD HOlDER BRACK

!Pi'l

f1

1;1ml!

1-

VE49 L9012

- -

E49

VE49

VE49

VE49 L9002"4

VE49

L9112

L9112

L9113

1..9213

--

L0002"4

1..9002'6

1..9002'6

--

--

--

---

----

-·------- --·--J

t~P

LOOPER N

~»=

VE1

1P

VE11P

VE

11P

VI..

tiP

VE11P

-

VE11Q

------.

VE11Q

VF11Q

VE11Q

--'-

·-

I!

EEDLE

ET

Uo113 :

tl :

1--·-'

/11

1·

n14

1111

·111

#11·_#1

#11· #14:

1111·1114

#11· #14

1111·

#14

#11·111

#11-#14

--

._,

___

4 I

_4

4

I

1

1

1

1

1

1

I

.

I

Page 16

~-

' -

~

'

i

----

-

--

-- - - -

---.

--

--_,

'

'

'

'

-

·13·

• . I

--

--

-

--

-

--

--

-

- I

-----·

Page 17

~---------- -

1 - -

1

---

- -

---

--

-----

-

--

---

-

---

- - - -

---

- - -

--

-

. 14.

Page 18

-- ----

--- ---

- - - - -

--- -

---

-------

-

----

--

-- ---

-·,

I

-

--

---

----

-

--

----

-

----------

--

-- --- - _,

- I

-

---

--- ---

-----

-

----

-- -------- -

- 15 -

----

-- --

- - - - - --- ---

_,

Page 19

Ol

r-·-------------

---T--

"

...

]

wu-c

----

-,

~

Pol

•)l

Page 20

I

I

I

---

- - J

-

--..J

'

0

0

'

- - - - g

- - - - 0

---

--

-

---

. 17.

·- - -

_,

Page 21

,.- -- --

---T-

1

I

------------------

VK1

8P

SM•

--

-,

l l

-00

.

--·-

VK(1)

..-

--:--

ORO!

VK0

4

~~

I

I

...

-- -.-~-·~

--

KG

( n 1

-

,

04

...

"r

5.11

431

~4

8

'¥1(0

4P

IIXI

OP

11

)

Page 22

- - -

--------

....

....

-

lliloleU.••

-

---

~

,.

--

_.

l

--------,-

- - I

0

-

- - -

---

---

-

--

- I

-------

-- --·

I •

I

-

--------------------~----

-

--

- - -

- - - - - - - - - - - - - - - II

I

--

-----

-

-- -- ---

-

19-

-

_____________ ;

--

I

Page 23

r--

'

I

I

------

-

---

-

--

~-------

1

I

1..

---

-

---

-

20-

Page 24

-----------------------------

------------------

-----1

I

--------------------------------------

•

21

•

--- ------~

Page 25

~---------

1

.

d

~-----

1

I

L------

--

------

------

--

-

-

22-

Page 26

w

"'

PARTS.a.lsT

~R

vcl.o(a)

o

RouP

VCL.Oi•

(VQ.

OI!IP.Q

~T I V

>J

I

Ct.

l/112

7~

VO. l~lll

ll) -~

~

'\

\

~

_

-----------------------------------------------------------------------

I

I

I

Page 27

Loading...

Loading...