Page 1

ZJ

108

~

AUTO-SHARPENING

t

f~

~

OPERATION MANUAL

PARTS

CUTTING

Jfl

i5i

1tF

MACHINE

a~

-¥

BOOK

~

iffi

[

...1::

iii

ttl

l~

fil

~!11

SHANGHAI

ZOJE

SEWING

iliR

f.5i

MACHINE

BR

~

CO

.,

61

L

TO.

Page 2

D

-1-

Page 3

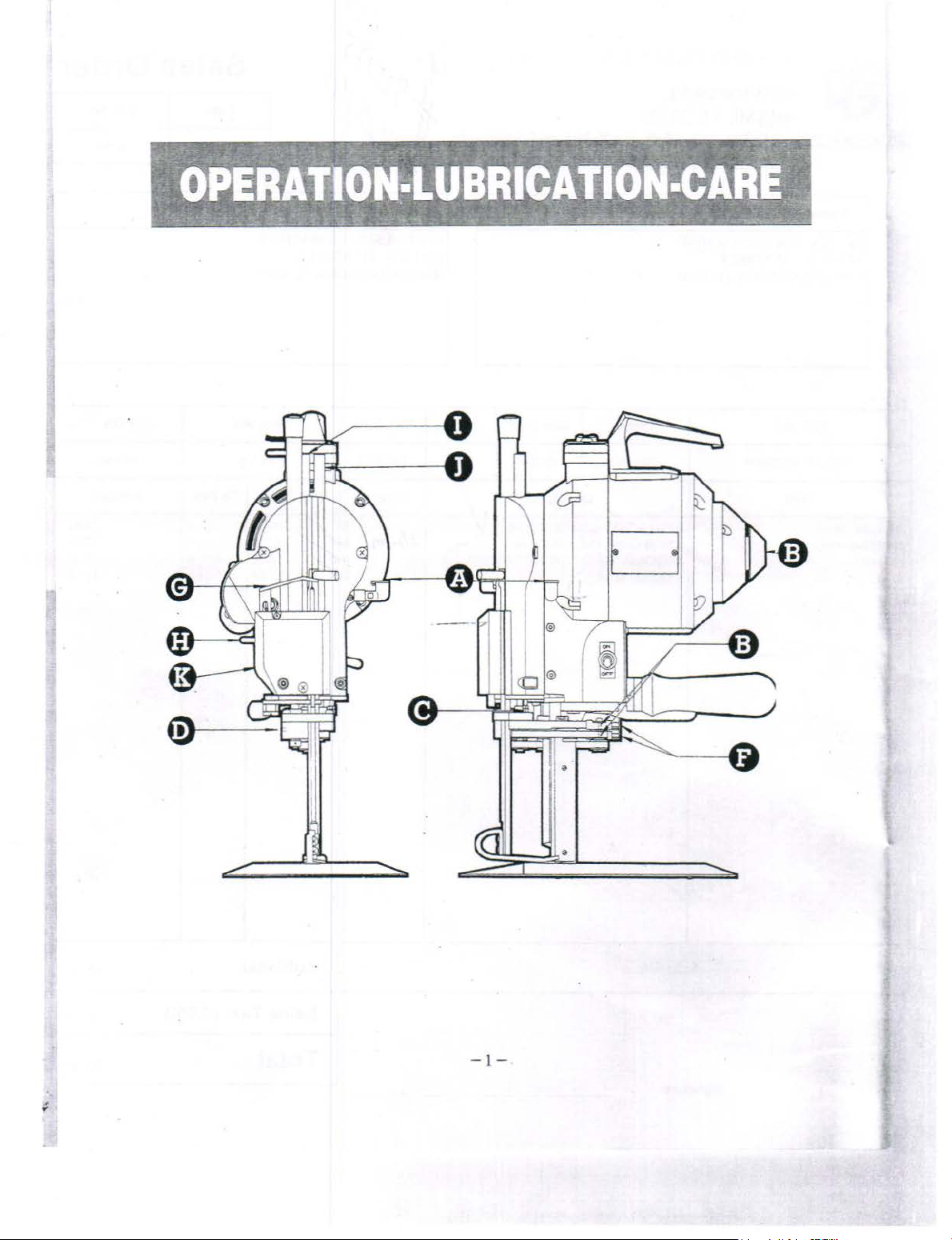

START ON

1.

Fill oil cup A,

2. Push

3. The sharpener must

in

surfaces.

be

sure oil goes into smooth,

E and turn the machine by hand for a

be

always up in locked position when starting.

1f

rot

, remove obstruction.

few

revolu1ions to make sure the oil is spread over contact

BE CAREFUL

a. Keep the machine in warm place in cold weather.

b.

Repeat short

between contact surfaces.

c.

Do

not use too much oil.

d. In case your cutter is of DUAL SPEED TYPE, please take care of

(1) Be sure to

revolution has been attained , to

The switch is put off

(2) The continuous operation at low speed (LO) should

OPERATE FOR

on & off

select

before permitting the machine to run

Do

not

use sewing machine oil. Use a least good grade

the

swi1ch

by

MORE

to the upper high speed (HI) in starting,

the

lower

speed

selecting the intermediate

THAN

30

MINUTES.

cont

inuously lor preventi

(LO)

OFF

be

LUBRICATION

the followi

no

more than

of

ng

two points:

and

30

ng

excessive friction

No.

30

motor oil.

then, when full

minutes.

DO

NOT

1. Fill oil tank

(no

at connecting r

beanng) 3.

SHAPENER OPERATION

1 . Put the machine away from pil

2.

Drop pressure foot

3. Press lever G downward firm but not too quick.

need

A

to oil

od

es

of material.

by

lever located next to operating handle

One drop oil to:

1

Tubes-1

2.Turn

Pulley

4.8elt Pull

& J

Knob·E

Shatt-C

eys-B

Remove

insert

grease

tube

. Gi

s1

ze

amount

o

pem

ng.

0 plug

ve

a pea·

to

and

the

BE CAREFUL

a.

Do not operate sharpener without knife in machine.

b.

Do

·

..,

not operate sharpener with cutting material laid in machine.

c. Do not shut

d.

If lever G is locked in ha.lfway

CARE

1 . Blow li

2.

Lint around screw mechani

3. Clean the kni

4. Ramove lint from rollers

rollers

off

motor while sharpener is in motion.

by

too quick operation, lift lever H to unlock and start again.

nt

out

of motor and sharpener

sm

fe

slide by slot cleaner once a day.

In

base plate.

stick

~

remove from plate and wash in cleaning solvent.

by

blower

or

of sharpener inside cover K

To

prevent undue accumulation of lint,

something alike twice a week.

must

be

cleaned once a week .

do

not oil plate rollers.

If

-

2-

Page 4

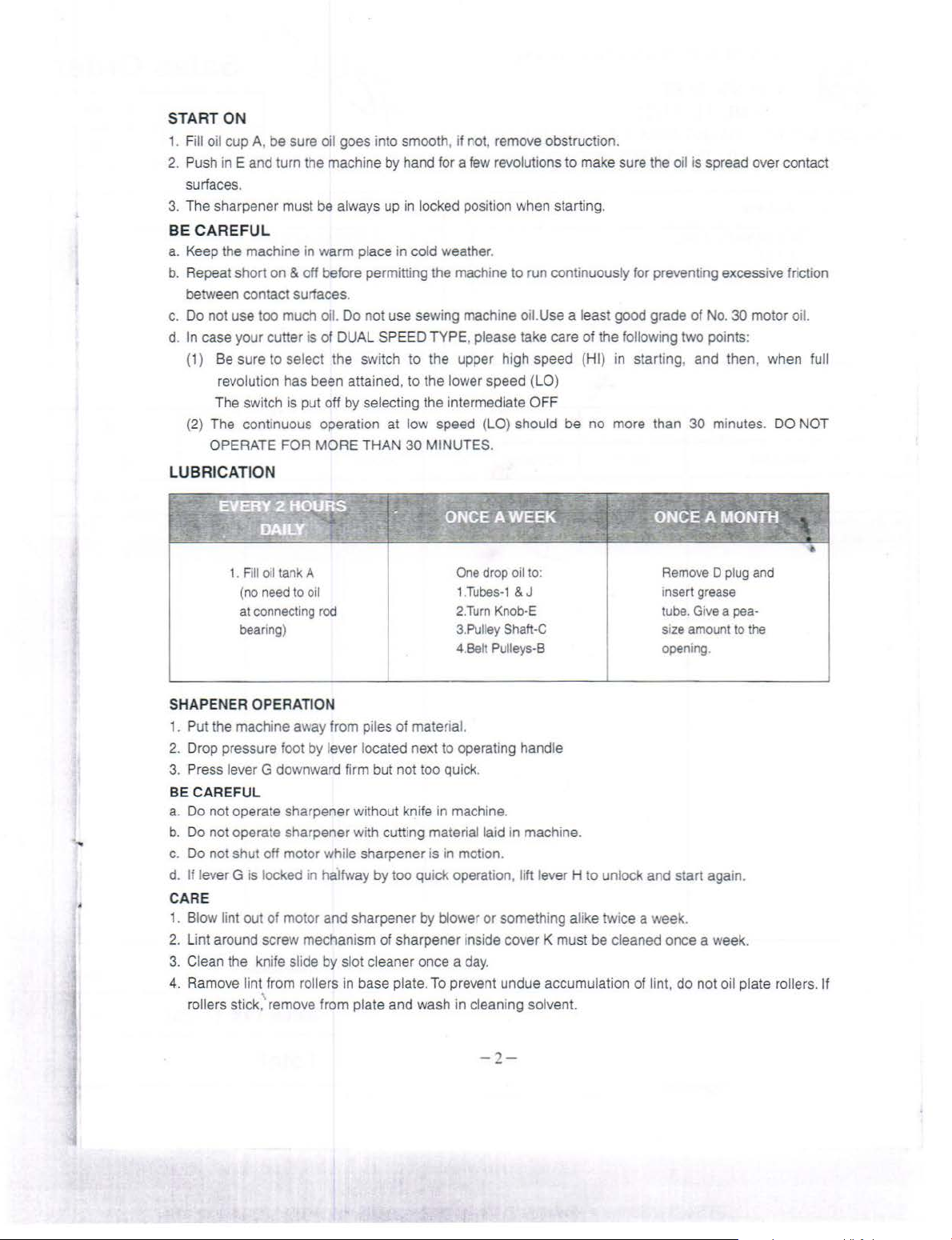

ICD-7

KD-22

KD-1

KD-2

KD-3

KD-4

KD-5

KD-6

KD-7

KD-8

KD-9

KD-10

KD-10P

KD-10C

KD-10CS

KD-12

KD-14

KD-15

KD-16

KD-17

KD-18

KD-18P

KD-20

KD-21

KD-22

KD-23

KD-24

KD-25

KD-26

KD-57

KD-64

KD-65

Capacitor -Stator

Carrying Handle Screws

Rotor Fan

Rotor with

Cut-Out Switch to Bearing Screw

Dust Cap Screw

Rear Bearing Housing

Dust

Turning Knob

Cut-Out

Insulated

Insulated Cover

Set Screw for Insulated Cover

Automatic

Front to Rear Bearing Screw

Carrying Handle

Capacitor Cover

Screw for Capacitor Cover

Capacitor

Paper

Switch

Clutch Spring

Retaining Ring

Rear

Rear Ball Bearing

Clutch Nut

Shaft Lock Nut

Front

Front Ball Bearing

Front Ball Bearing Retainer

Shaft

Cap

Switch

Plate

Cut-Out

Ball Bearing

Spring Washer

Ball Bearing Retainer Screw

-3-

'

"

Page 5

KD-13

KD-27 Crank

KD-28 Crank

KD-29 Crank Ball Bearing Lock Nut

KD-30 Screw for Brg Shaft

KD-31

KD-32 Oil Pad Holder

KD-33

KD-34

KD-35

KD-36 Connecting Rod

KD-37 Shakeproof Washer

KD-38 Connecting Rod

:-

-

..

--

..

...

.

.

..

--·-·-

--

.....

-

~:

KD-39 Wrist Pin

KD-

40

KD-41

KD-42 Nuts for Guide Screw

KD-43 Guide Washer

KD-44 Connecting Rod washer

KD-45

KD-46

KD-47 Guide Lock Screw

KD.-48 R.H.Guide

KD-49 L.H.Guide

KD-50 Cross Head

KD-51 Kni

KD-52 Terminal Block Screw

KD-53 Ground

KD-54 Set Screw

KD-55 Front Bearing Housing

KD-58 Oil Pad Holder Screw

KD-59

KD-61 L Stud Lower L.H.Mountaing(L)

KD-61R

KD-66

KD-69 Attachment Plug(Complete)

KD-70 Tetminal Block(Complete)

KD-71 Terminal Sleeve

KD-72 Terminal Contact with Pin.

KD-73

KD

-75

KD-76

Front to Rear Bearing Nut

Ba

ll Bearing

Shaft for Ball Bearin9

Oil Cup

Oil Tube for Wrist Pin( Copper)

Oil Tube for Wrist Pin

Clamp Screw

Wrist Pin Plug

Knife Lock Washer

Gu

ide Adjusting Screw

id

e Adjusting

Gu

fe

Lock Bolt

Clip Screw

Gu

ide Hold Down Screw

Stud Lower L.H.Mountaing(R)

Ground

Operating

Sw

Sw

Clip

itch Cover Screw

itch Cover

Nut

Handle

-4-

Page 6

KD

·63

Ko-ns

KD-77L Plate

KD-80C Roller

KD-80R Rubber

KD-81 Hinge Pin Short-

KD-82 Hinge Pin Clamp Screw

KD-83

KD-84 Knife Slide Screw

K0-85 Standard

KD-86 Knife Slide

KD-87 Screw for Throat Plate

KD-88 Throat Plate

KD-90S Plate Screw

K0-90N Plate Nut

KD-191

Standard-to-Bearing Screw

Plate Wing

Plate Wing Tension Spring

Knife

Page 7

l

J

~fl,~"'!H

~~;

.:..}~~v-~.~

~HARP:ENER

.

...

...

~~"

-·~.._

___

•, .

-

~

~.t-1!-,...

i

HOUSIN~

-:.~

·-.

.;

~~-

~.::'.

~

.

.-.--,_-.

MECHANI~M

. .

...

-

~-

~T

i

:

·

KD-96

KD-

97

KD-98

KD-99

KD-109

KD-110

KD-111

KD-112

KD-113

KD-114

KD-115

KD-116

KD-117

KD-118C

KD-

118L

KD-118S

KD-119S

KD-119SW

KD-119W

KD-120

KD-121S

KD-121N

KD-122

KD-123

KD

-124

KD-125

Screw for Latch

Shaft for Cam

Shaft Spring Screw

Cam

Foot Lock Bracket Screw

Pres

for Pressure Foot Lock

Spring

Spring for Latch

Spring

Cam

Pressure Foot Rod

Screw for Pressure Foot Shoe

Pressure Foot Lever

Pressure Foot Lever Screw

for Pressure Foot Lever

Spring

Set Screw for Cam

Cam

Release Lever

Screw for Cam

Lock Screw for Release Lever

Spring Washer

Washer

Lock(only)Pressure Foot

Screw for Pres Ft Lock

Pres Ft Lock

Nut for

Pressure Foot Lock Bracket

Slide tor Pressure Foot Rod

Latch for Cam

Pressure Foot Shoe

KD-12S

-

6-

Page 8

~k0·92

KD-56 Sharpener Hold Down Screw

KD-60

KD-62

KD-92

KD-93 Driving

KD-94 Right and Lett Hand Follower

KD-100S Screw for Cover(S)

KD-100L

KD-101

KD

-126 Spring for Bell Crank

KD-127 Sharpener Housing

KD-128 Bottom

KD-129 Bottom Plate

KD-130 Oil Pad

KD-131

KD-132 Bell Crank With Pin & Bushing

KD-133

KD-134 Cover for Driver

KD-139

KD-140 Roll Pin for Push Rod

KD-141 Driver

KD-142 Screw for Spreader Pin

KD-143 Spreader Pin

KD-144 Gear & Shaft

KD-145 Bearing for Gear

KD-146

KD-148 Spur

KD-149

KD-150

KD-151 Thrust Washer for

KD-152 Lock Nut for Crank

KD-153 Shaft for Crank

KD-154 Washer for Crank

KD-155 Lock Nut for Ball Bearing

KD-156 Ldler

KD-157 L.H.Spiral Gear With Key

Lower L.H.Sharpener

Hold down Nut

Stud, Guide Rod Bracket

Cap for Tube

Shaft

for Cover(L)

Screw

Cover Over Cam

Plate Screw

& Holder

Screw for Oil Pad

Screw for Cover

Push Rod

Shaft With

Rubber Driver

Gear

Ball Bearing

Retaining Ring

Gear

Gear

& Driver

fo

r Crank

Spiral Gear

Shaft

Shaft

With Bushing

Pl,l

lley

-7-

;.

Page 9

:::~

KO-lOS~

KD-104

K~1n

KD-102

KD-103 Thrust Ball Bearing

KD-104

KD-105

KD-106

KD-107

KD-108

KD-135

KD-136

KD-137

KD-138

KD-138W

KD-158 Screw for

KD-160 Grease Plug

KD-161 Screw for Stabilizer

KD-162

KD-163 Screw for Slide Pulley

KD-164

KD-165N Adjusting Nut

KD-1655

KD-166

KD-167 Intermediate Gear

KD-168

KD-169 R.H.Shoe

KD-170 L.H.Shoe

KD-171 Set Screw for Sharpener Shoe

KD-172 Stabilizer

KD-173

KD-174 Washer for Guide Back

KD-175

KD-176 L.H.Siide With Pulley

KD-177 R.H.Siide With

KD-178 Neoprene Band

KD-179

KD-180 Roll Pin for Pulley

KD-181

KD-182 Screw for Clamping Arm

KD-183 Clamping Arm for Shoe

KD-184

KD-185

KD-186

KD-187

KD-188 Spring for Arm

KD-189 Abrasive Belts

Collar for Lower Screw Shaft

Nut

for Screw Shaft L.H.& R.H

Washer for Screw Shaft L.H.

Screw Shaft With Extension

Spacer Tube

Stop Nut for Screw Shaft

Right Hand Follower Nut

R.H.Square Shaft

left

Hand Follower Nut

L.H.Square Shaft

L.H.Square Shaft Washer

Gear

Cover

Lower Gear Bracket

Lower Gear Bracket Gear Cover

Adjusting Screw

Gear

on Screw Shaft

Bushing for Shoe

Guide Back

Screw for Guide Back

Front

Spring for Pulley Slide

Nut for Sharpener Shoe Screw

Screw for Sharpener Shoe

R.H.Sharpener Shoe Spring

L.H.Sharpener Shoe Spring

of

Standard

Pulle~

Pulle~

for Belts

-8-

Page 10

KD-189 Abrasive Belts

:.

:.·:"

.

ACCESS'ORY

~

~

' -

~

.

•"""

Ta

- -

..

•

KD-190

KD-191

KD-192

KD-194 Knife

KD-195 Screw Driver

KD-196

KD-199

Electric Corde Complete

Kni

fe

Slot Clea

Wrench for Shoe Set Screw

Oiler

ner

Bo

lt Wrench

fDill~

KO-ttt

Q

----

----

lr-

}~··

I

~=="""

K0-1M

="'

~*

===:=::::~!>,.,

-9-

A

J

Page 11

Page 12

l

...t:Ui

SHANGHAI

J:ii±lt

ADD:N0

Ill

ZOJE

:

..tif!~ifi#1t

.501A

JINGANG RD.

lil!ill~

SEWING

i

!lJ!f.DXif*ffil&~il!~501

PUOONG

mn

JSiBH

MACHINE

SHANGHAI

:G

CO

~A/i

Jll8~

:

P.C:201206

B1

., L TO

.

·

";

Loading...

Loading...