Page 1

{1.

MAIN SPECIFICATION

Sewing

Stitch length

Needle

Presser foot lift

speed

bar

stroke

2000s.p.m.

0-9mrn

33.2mm

8rnm

(Manual)

t5mrn (Knee)

Needle

Lubrication

Reverse

feeding mechanism

DPX

17

Automatic

Have

22"'

l

and the mach

2000spm can

work.

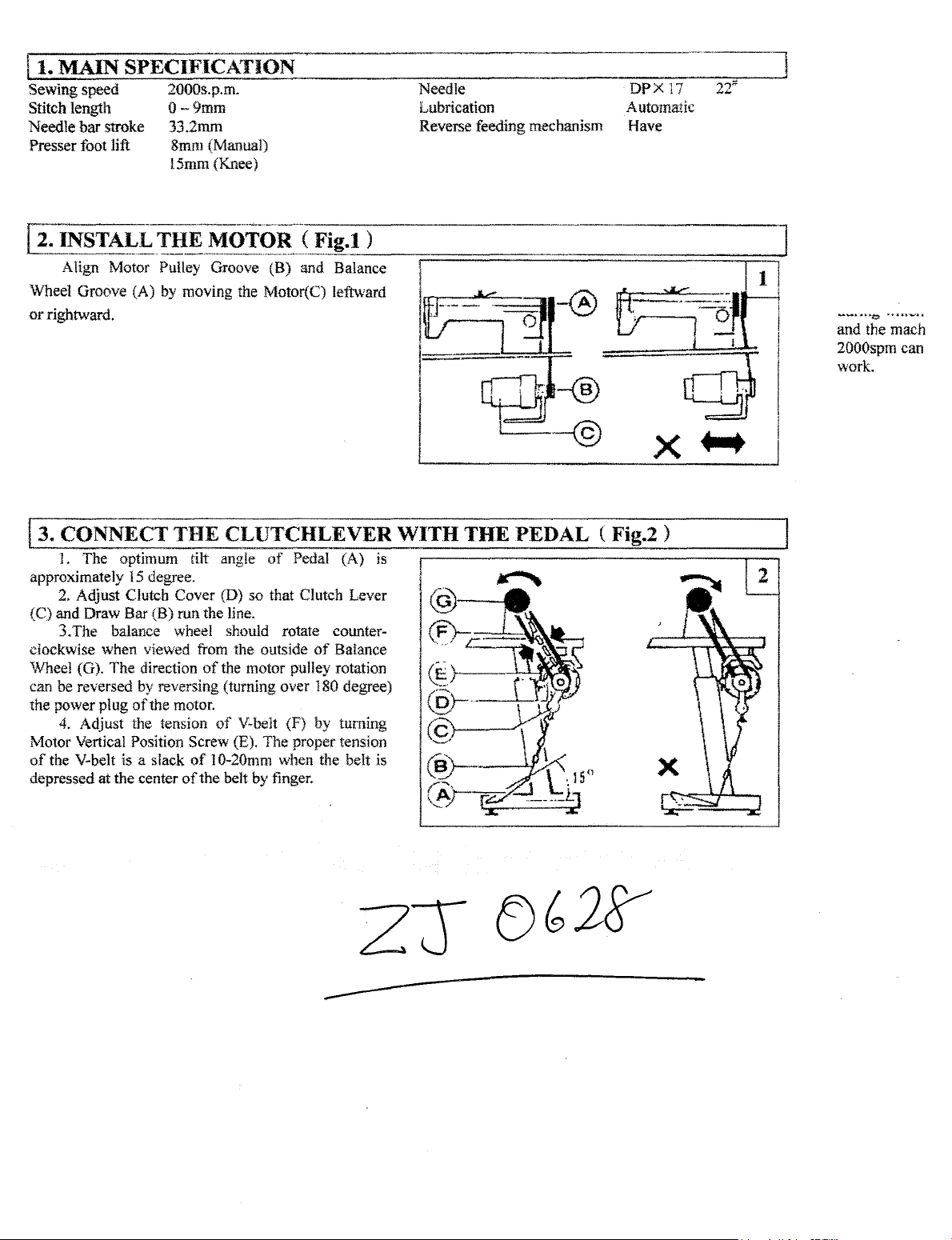

3. CONNECT THE CLUTCHLEVER WITH THE PEDAL ( Fig.2 )

L The optimum tilt ang!e

15

approximately

2. Adjust

{C)

and

Draw

3.The

clockwise

'Wheel (G).

be reversed

can

the

power

plug

4. Adjust the tension

Motor Vertical

of

the V-belt is a slack

depressed

at

degree.

Clutch

Bar (B)

balance wheel should rotate counter-

when

The

the

Cover

run

viewed from the outside

direction

by

reversing (turning over 180 degree)

of

the motor.

Position Screw (E).

center

of

the

of

of

of

1 0-20mm when the belt is

the

of

Pedal

(A)

is

(D)

so

that Clutch Lever

line.

of

Baiance

the motor pulley rotation

V-belt (F)

The

belt

by

by

proper tension

finger.

turning

Page 2

REPARATION

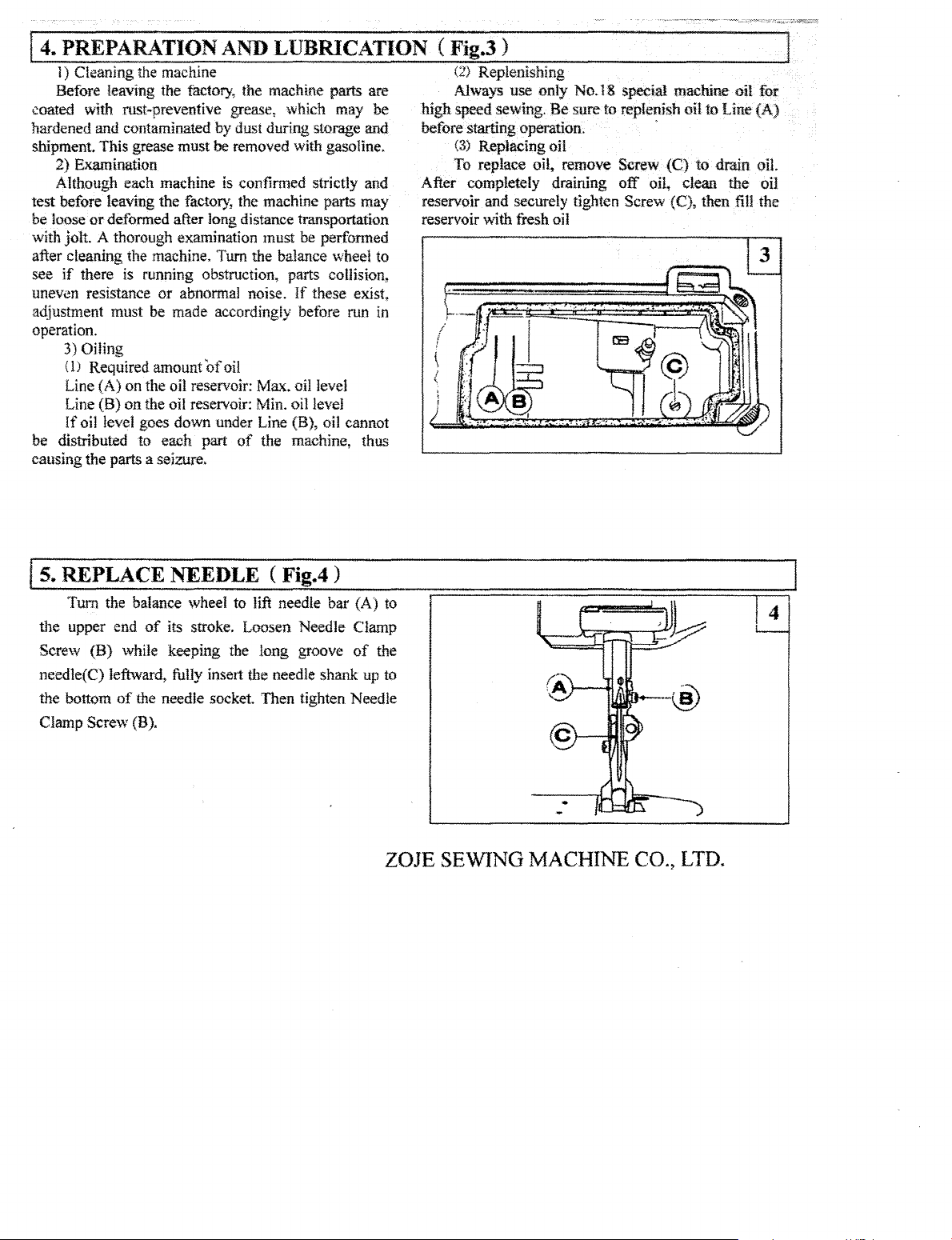

l)

Cleaning the machine

Before leaving

coated with

hardened and contaminated by dust during storage and

shipment.

test

be

This

2}

Examination

Although each machine is confirmed strictly and

before leaving the factory, the machine parts may

loose

or

deformed after long distance transportation

the factory, the machine parts are

rust~preventive

grease must be removed with gasoline.

AND

LUBRICATION ( Fig.3 )

grease, which may

be

with jolt. A thorough examination must be performed

after cleaning

see

if

uneven resistance or abnormal noise.

adjustment must

operation.

3)0iling

( l) Required amount

Line (A)

Line

the machine. Tum the balance wheel to

there is running obstruction, parts collision,

If

these exist,

be

made

accordingly before run in

of

oil

on

the oil reservoir: Max. oil level

(B)

on the oil reservoir:

Min.

oil level

If oil level goes down under Line (B), oil cannot

be distributed

causing

the parts a seizure.

to

each

part

of

the machine, thus

C:!>

Replenishing

Always

high

speed sewing.

use

only

Be

No.l8

special machine

sure

to replenish oil

before starting operation. ·

(3) Replacing oil

To

replace oil, remove Screw

After completely draining off

reservoir

reservoir with fresh oil

and

securely tighten Screw (C), then

oiL,

to

(C)

to drain oil.

clean

oil

Line

the

fill

for

(A)

oil

the

js.

REPLACE NEEDLE ( Fig.4 )

Turn the balance wheel to lift needle

the

upper end

Screw (B) while keeping the

needle(C) leftward,

the bottom

Clamp Screw (B).

of

its stroke. Loosen Needle Clamp

long

fully insert the needle shank up to

of

the needle socket. Then tighten Needle

bar

groove

(A) to

of

the

ZOJE

SEWING

MACHINE

CO.,

LTD.

Page 3

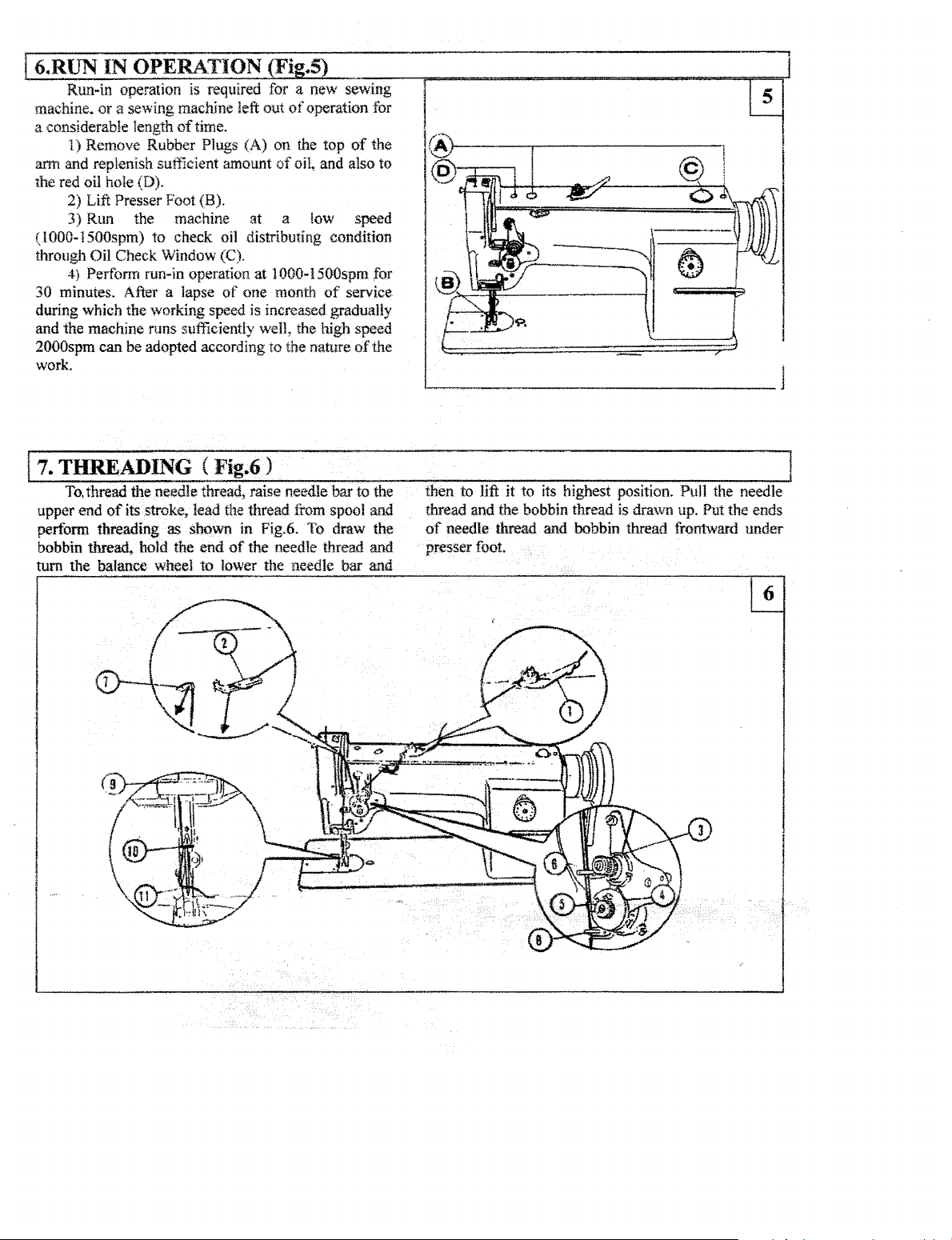

6.RUN IN OPERATION (Fi .5)

Run-in operation is required for a new sewing

machine.

a considerable length

arm

the red oil hole (D).

( l 000-1500spm)

through Oil Check Window (C).

30 minutes. After a lapse

during which the working speed is increased

and the machine runs sufficiently well, the high speed

2000spm

work.

or

a sewing machine !eft out

of

time.

1) Remove Rubber Plugs (A) on the

and replenish sufficient amount

2) Lift Presser Foot (B).

3)

Run the machine at a low speed

to

check oil distributing condition

4)

Perform run-in operation at 1000-i500spm for

of

can

be adopted according to the nature

of

operation for

of

oil, and also to

one month

top

of

gradually

of

the

service

of

the

7. THREADING ( Fig.6 )

To.

thread the needle thread, raise needle

of

its

upper end

perform threading

bobbin thread, hold the

tum

the balance wheel to lower the needle

stroke, lead the thread from spool and

as

shown in Fig.6. To draw the

end

of

the needle thread and

bar

bar

to the

and

~-®----

~-~----·

then to lift

thread and the bobbin thread is drawn up.

of

needle thread and bobbin thread frontward

presser foot.

it

to

its

highest position. Pull the needle

~

--==~,

-~

?

Put

the ends

under

Page 4

Js.

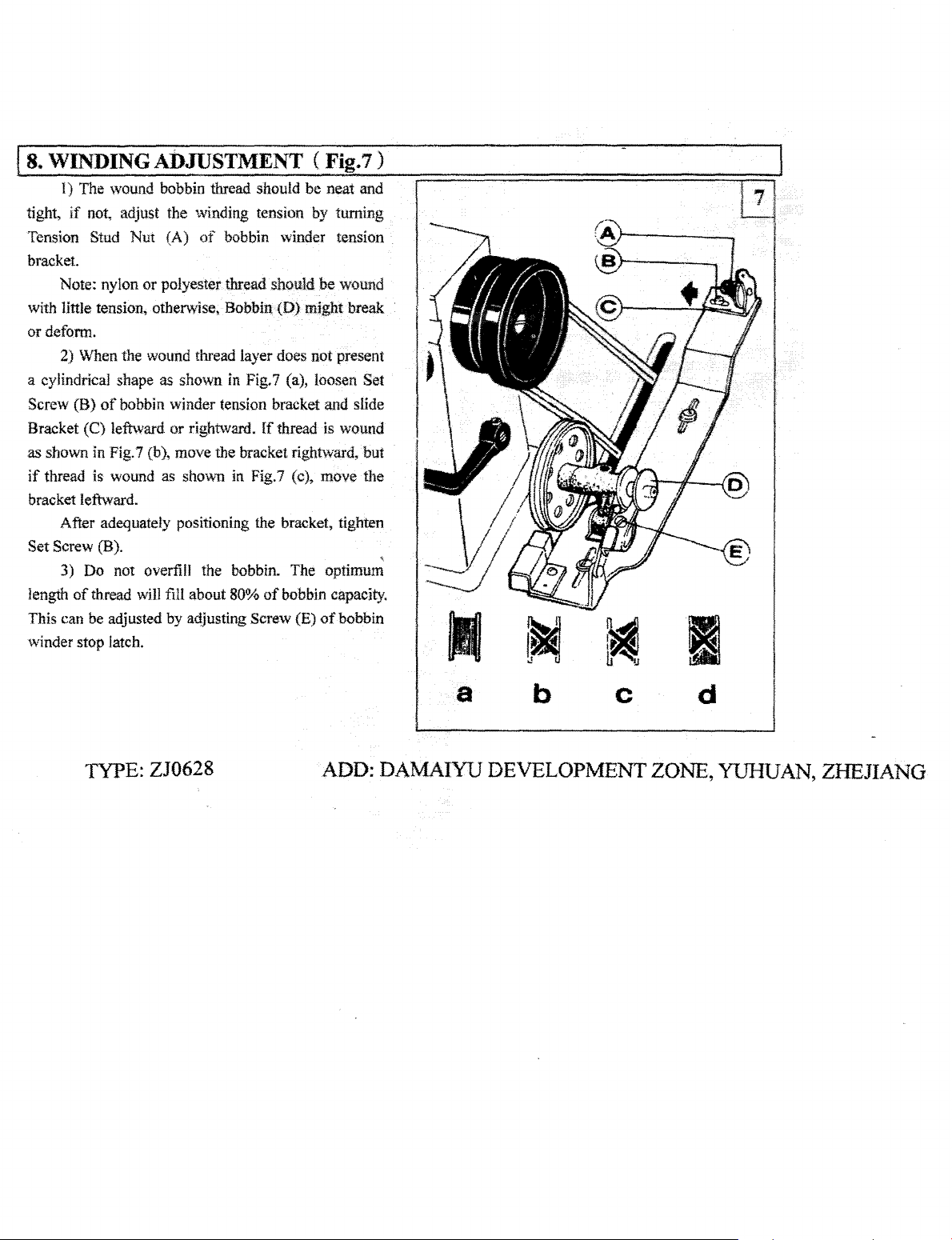

WINDING ADJUSTMENT (

l)

The wound bobbin thread should

tight, if not, adjust the winding tension by turning

Tension

bracket.

with little tension, otherwise, Bobbin

or deform.

a cylindrical shape as shown in Fig.7 (a), loosen Set

Screw (B)

Bracket (C) leftward

as

if

bracket leftward.

Set

length

This can be adjusted by adjusting Screw (E)

winder stop latch.

Stud Nut (A)

Note: nylon

2) When the wound thread layer does not present

shown in Fig.7 (b), move the bracket rightward, but

thread is wound as shmvn in Fig.7 (c), move the

After adequately positioning the bracket, tighten

Screw (B).

3) Do not overfill the bobbin. The optimum

of

thread

or

of

bobbin winder tension bracket and slide

will

of

bobbin winder tension

polyester thread should

(D)

or

rightward.

fill about

ff

thread is wound

SO%

of

Fig.7)

be

neat and

be

wound

might break

bobbin capacity.

of

bobbin

'

~

TYPE:

ZJ0628

ADD:

a

DAMAIYU

b

c

DEVELOPMENT

d

ZONE,

YUHUAN,

ZHEJIANG

Page 5

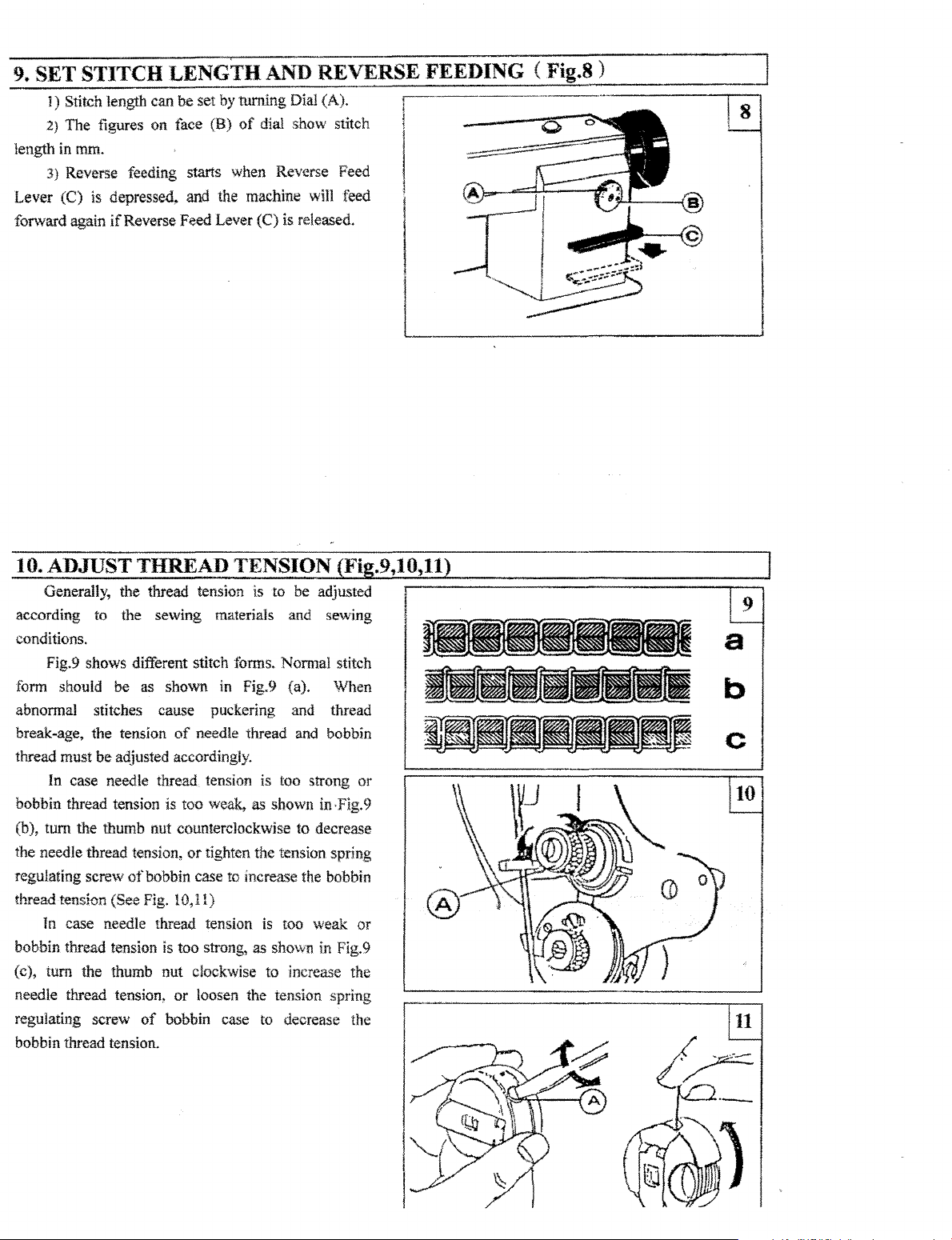

..:..9.:...:S::.:.E:.:T:......:S:.:T:.;.:IT.::..C.::.H=·

i)

Stitch length can

2}

The figures on face (B)

length in mm.

3)

Reverse feeding starts when Reverse Feed

Lever (C) is depressed,

forward again

if

-=L=E:.::...N:....:G:....:T...:::.H:.:..::A...:::.N_;_D~R-=EV_ERS

be

set by turning Dial (A).

of

dial show stitch

and

the machine

Reverse Feed Lever (C) is released.

will

teed

_____

"E_FE_E_D_I_N_G_(

F_i~g._8_)

-----·~

10. ADJUST THREAD TENSION

Generally, the thread tension is to be adjusted

according

conditions.

form

abnormal stitches cause puckering and thread

break-age, the tension

thread must

bobbin thread tension is

(b), turn the thumb nut counterclockwise

the needle thread tension,

regulating screw

thread tension (See Fig. 10,11)

In

bobbin thread tension is too strong, as shown in Fig. 9

turn the thumb nut clockwise

(c),

needle thread tension,

regulating screw

bobbin thread tension.

to the sewing materials and sewing

Fig.9 shows different stitch

should be as shown

of

be

adjusted accordingly.

In case needle thread tension is too strong

too

of

bobbin

case needle thread tension

or

of

bobbin case to decrease the

forms.

Normal stitch

in

Fig.9 (a). When

needle thread and bobbin

weak, as shown in·Fig.9

or

tighten the tension spring

ca..<;e

to

increa<se

is

too weak

to

increase the

loosen the tension spring

(J3'i

to

decrease

the bobbin

or

or

Page 6

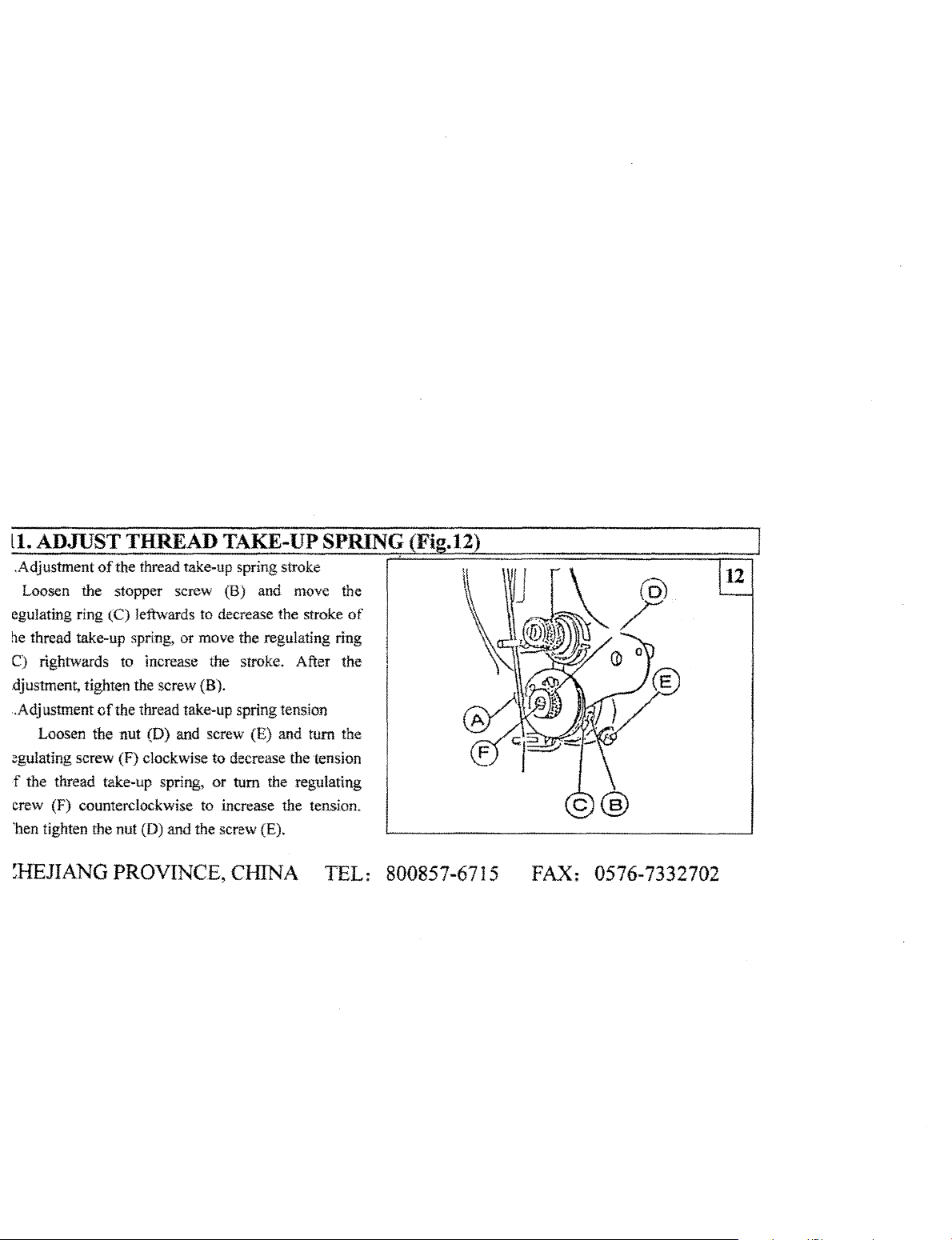

.Adjustment

Loosen the stopper screw (B) and

egulating ring

he

thread take-up spring, or move the regulating ring

C) rightwards to increase the

djustment, tighten the screw

. Adjustment

Loosen the nut

egulating screw (F) clockwise to decrease the tension

f the thread take-up spring,

crew

'hen tighten the nut (D)

of

the thread take-up spring stroke

move the

(C)

leftwards to decrease the stroke

stroke. After the

(B)

.

of

the thread take-up spring tension

(D) and screw (E) and turn the

or

tum

the regulating

(F) counterclockwise to increase the tension.

and the screw (E).

of

~HEJIANG

PROVINCE,

CHINA

TEL: 800857-6715

FPLX:

0576-7332702

Page 7

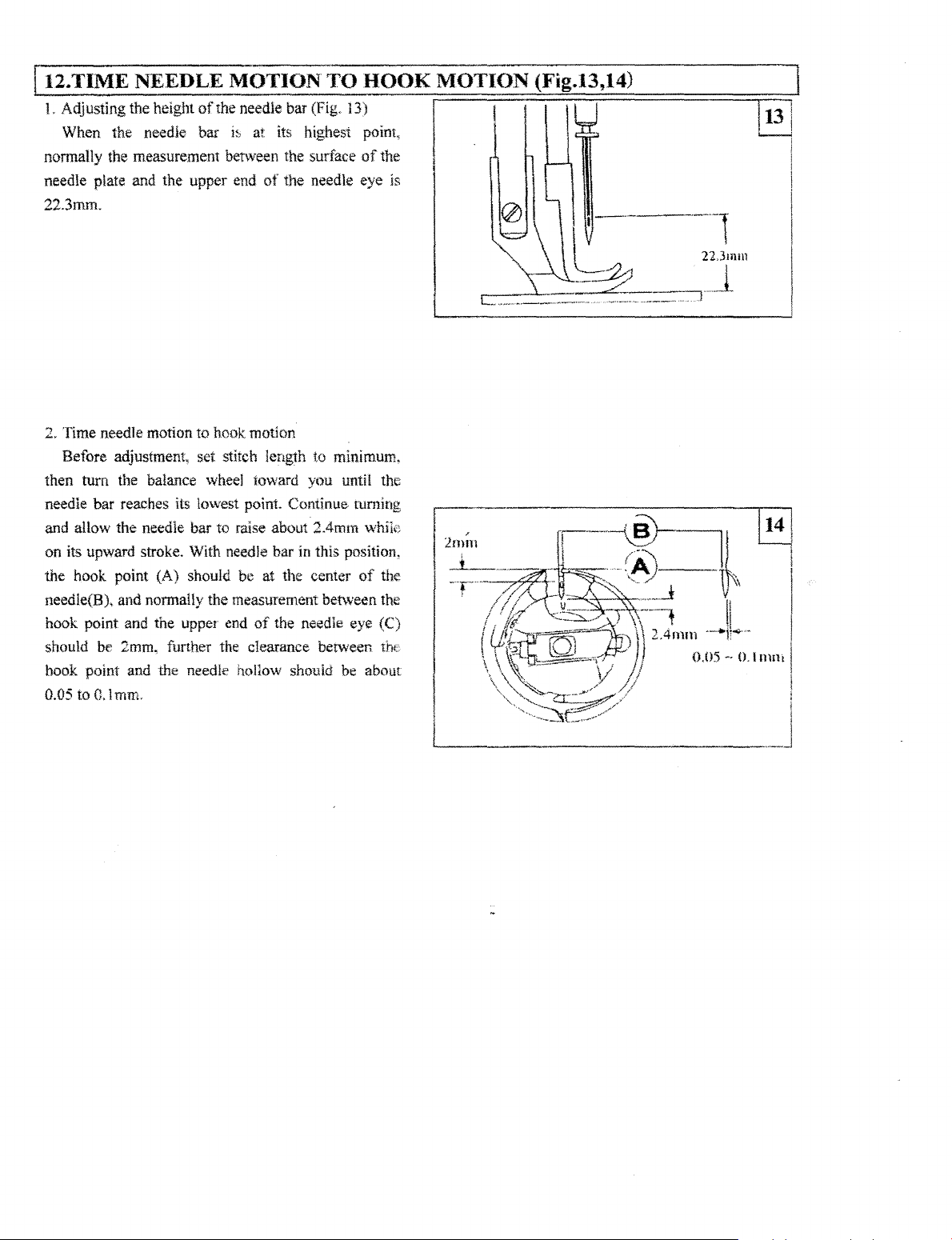

!t2.TIME

L Adjusting the height

When the needle bar

nonnally the measurement between the surface

needle plate and the upper end

22.3mm.

2. Time needle motion to hook motion

Before adjustment,

then turn the

needle bar reaches its lowest point. Continue turning

and allow the

on its upward stroke. With needle bar in this position.

the hook point (A) should be at the center

needle{B),

hook point and the upper

should be 2mm. further the clearance berween

book point and the needle hollow shouid be about

0.05

to

NEEDLE MOTION TO HOOK MOTION

of

the needle bar (Fig. 13)

i~,

at its highest point,

of

of

the needle eye ls

set stitch length to minimum,

balance wheel toward you until the

needle bar to raise about 2.4mm whik;

of

and nonnaily the measurement between the

end

of

the needle eye (C)

0,

l mm.

(Fig.l3,l4)

I I

the

------------------------------

the

the

Page 8

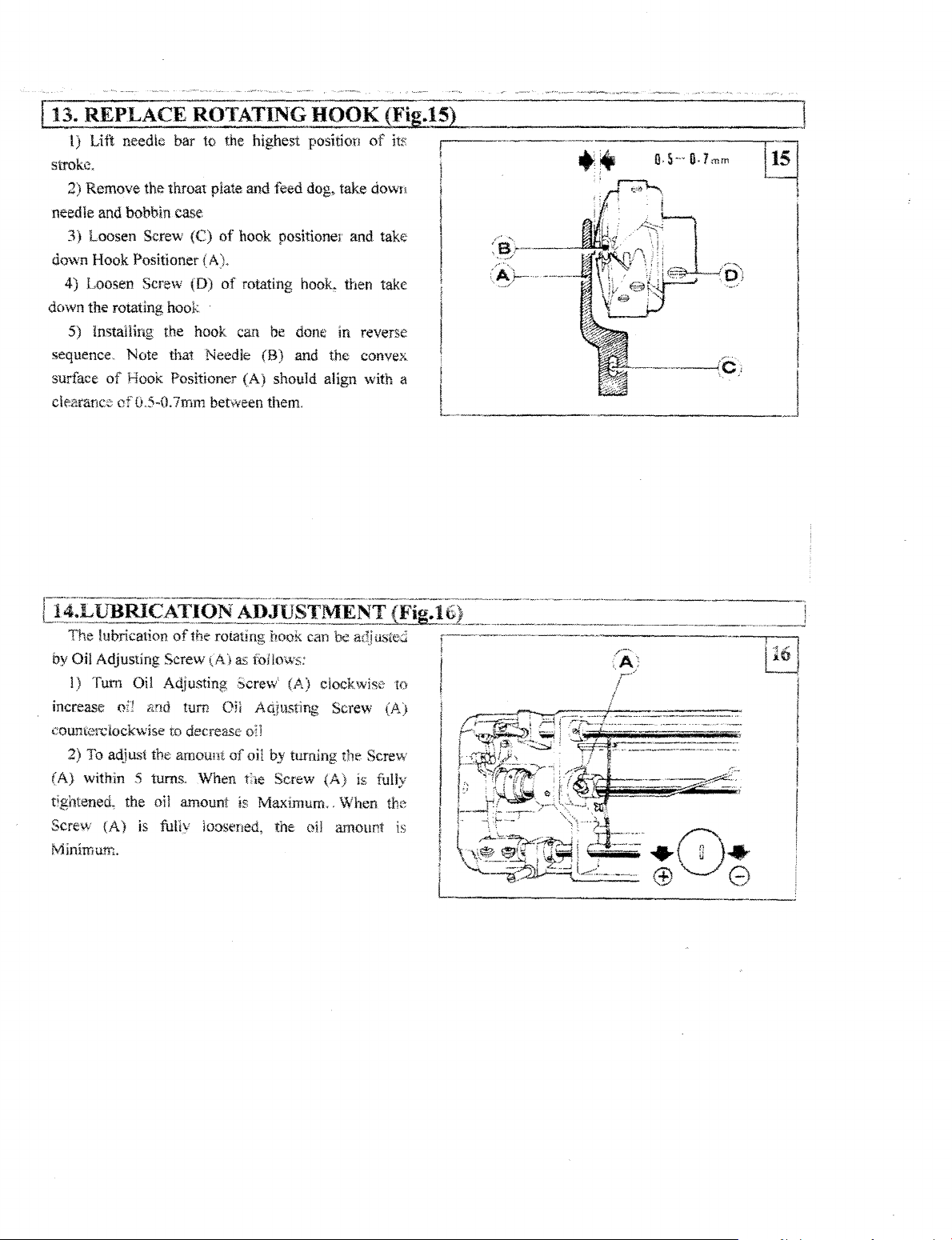

3. REPLACE ROTATING

l)

Lift

needle bar to the highest position

strok.::.

2)

Remove

needle and bobbin case

3)

Loosen Screw

down Hook Positioner

4) Loosen Screw (D)

down the rotating hook

5) lnstaiiing the hook can be done in reverse

sequence. Note that Needle

surface

clenrance of0.5-D.7mm

the throat plate and feed dog, take down

(C)

of

hook positionel and take

{A).

of

rotating

(B)

of

Hook Positioner (A) should align

between them.

HOOK

hooL

then take

and the convex

(Fig.15)

of

its

\Vith

a

I

I

L

++

:)~}····--

(~}-

__

..

___

..

·-

..

_

_________

J

The

lubrication

by

Oil Adjusting Screw (A) as

J) Tum Oil Aqjusting .:,crew' (A) clockwise

increase oil

coumcrciockwise

2) To adjust the amount

(A)

within 5 turns. When t;ie Screw (A) is fully

tightened,

Screw

Minimurn.

the

(A)

of

the rotating hook can be adj ustei

f(>Jlows:

<1nd

turn Oil A4jtLsting Screw (A)

to decrease

oil

amount

is

fullv loosened, the oil amount is

o;1

of

oil

is

Maximum<,

by

turning the Screw

When the

to

Page 9

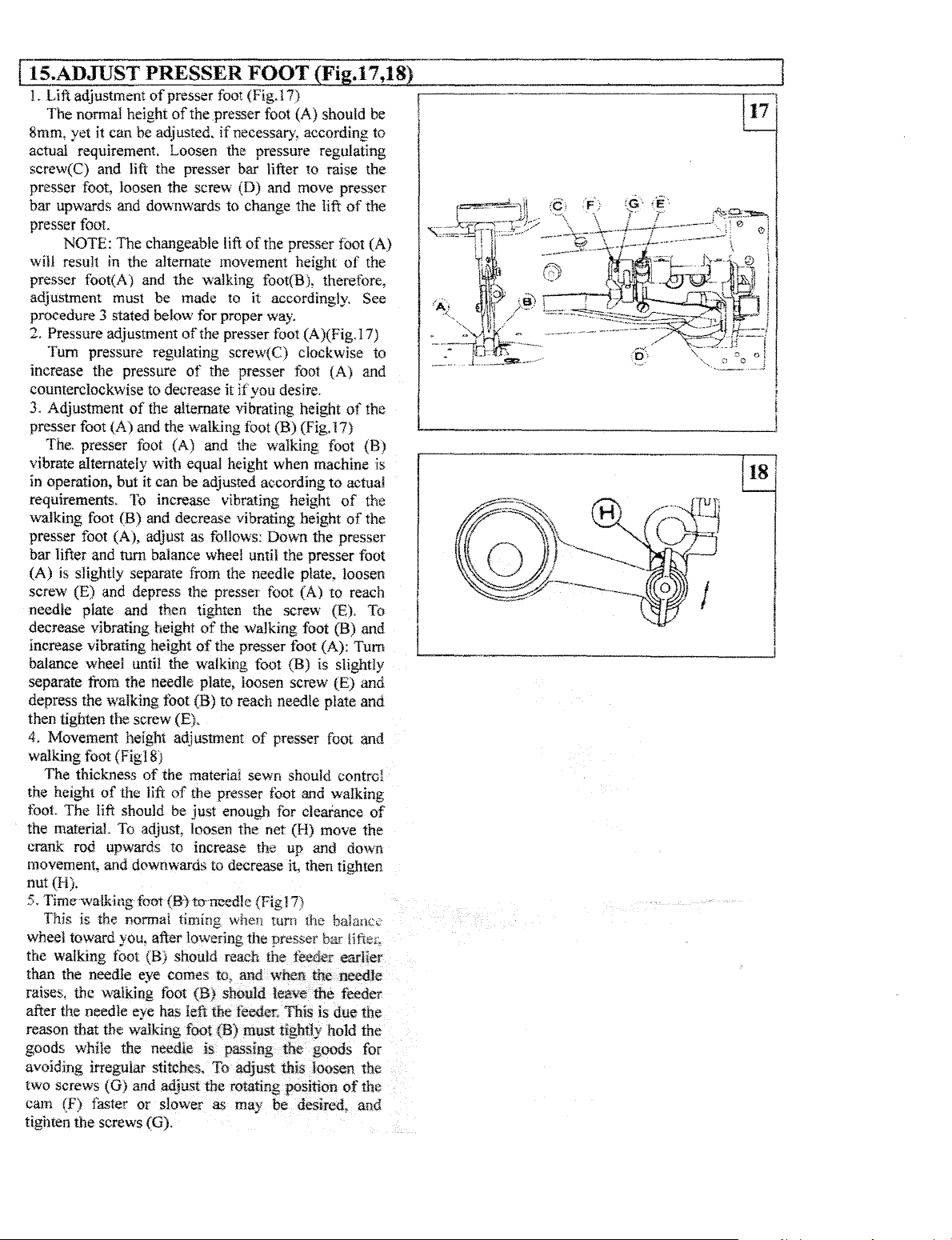

[t5.ADJUST

1.

Lift adjustment

The

normal height

8mm, yet

actual requirement. Loosen the pressure regulating

screw(C) and

presser foot, loosen the screw

bar upwards and downwards

presser

will

presser foot(A)

adjustment must be made

procedure 3 stated below for proper way.

Pressure adjustment

2.

Tum

increase the pressure

counterclockwise

3.

Adjustment

presser foot

The. presser foot {A)

vibrate altemateiy with equal height when machine is

in operation. but it can

requirements.

walking foot (B) and decrease vibrating height

presser foot (A), adjust

it

foot.

NOTE:

result

pressure regulating screw(C) clockwise to

PRESSER FOOT (Fig.17 ,18)

of

presser foot (Fig.17)

of

the presser foot (A) should be

can be adjusted.

lift the presser bar lifter

The changeable lift

in

the alternate movement height

and

to

decrease it

of

the aliemate vibrating height

(A)

and the walking foot

To

increase vibrating height

if

necessary. according to

to

(D)

and move presser

to change the lift

of

the presser foot (A)

the

walking foot(B), therefore,

to

it accordingly. See

of

the presser foot (A)(Fig.17)

of

the presser foot

lfyou

desire.

(B)

(Fig.17)

and

the

walking foot

be

adjusted according

as follows:

Down

the presser

raise the

{A)

to

of

of

of

actual

of

of

bar lifter and turn balance wheel until the presser foot

(A)

is

slightly separate from the needle plate, loosen

screw (E) and depress the presser foot (A)

needle plate and then tighten the screw (E). To

decrease vibrating height

increase vibrating

balance wheel until the walking foot (B) is slightly

separate

depress the walking foot (B)

then tighten the screw (E).

4. Movement height

walking foot (Fig

the

toot

the materiaL To adjust, loosen the net (H) move

from the needle plate, loosen screw (E)

The

thickness

height

of

The

lift should be

height

18)

of

the lift

of

the walking foot (B) and

of

the presser foot (A):

to

reach needle plate

adjusm1ent

the materia! sewn should control

of

the presser toot and walking

just

of

presser foot and

enough for clearance

to

reach

Tum

crank rod upwards to increase the up and down

movement, and downwards to decrease it, then tighten

nut (H).

5. Time walking foot

This is the normal timing when turn the balance

wheel toward you, after lowering the presser bar

the walking

than the needle eye comes to,

raises, the walking toot

toot

after the needle eye has left the feeder. This is

reason that the walking foot

goods while the needle

(B}toneedle

{Fig17)

(B) should reach the earlier

and

when me needle

(B)

should

(B)

must tightly hold

is

passing the·. goods for

me

due

feeder

avoiding irregular stitches. To adjust this loosen the

two screws

cam (F) faster

tighten the screws (G).

(G)

and adjust

or

slower

the

rotating position

as

may

be

desired,

of

and

the

the

and

the

(B)

the

the

and

and

of

the

the

the

the

Page 10

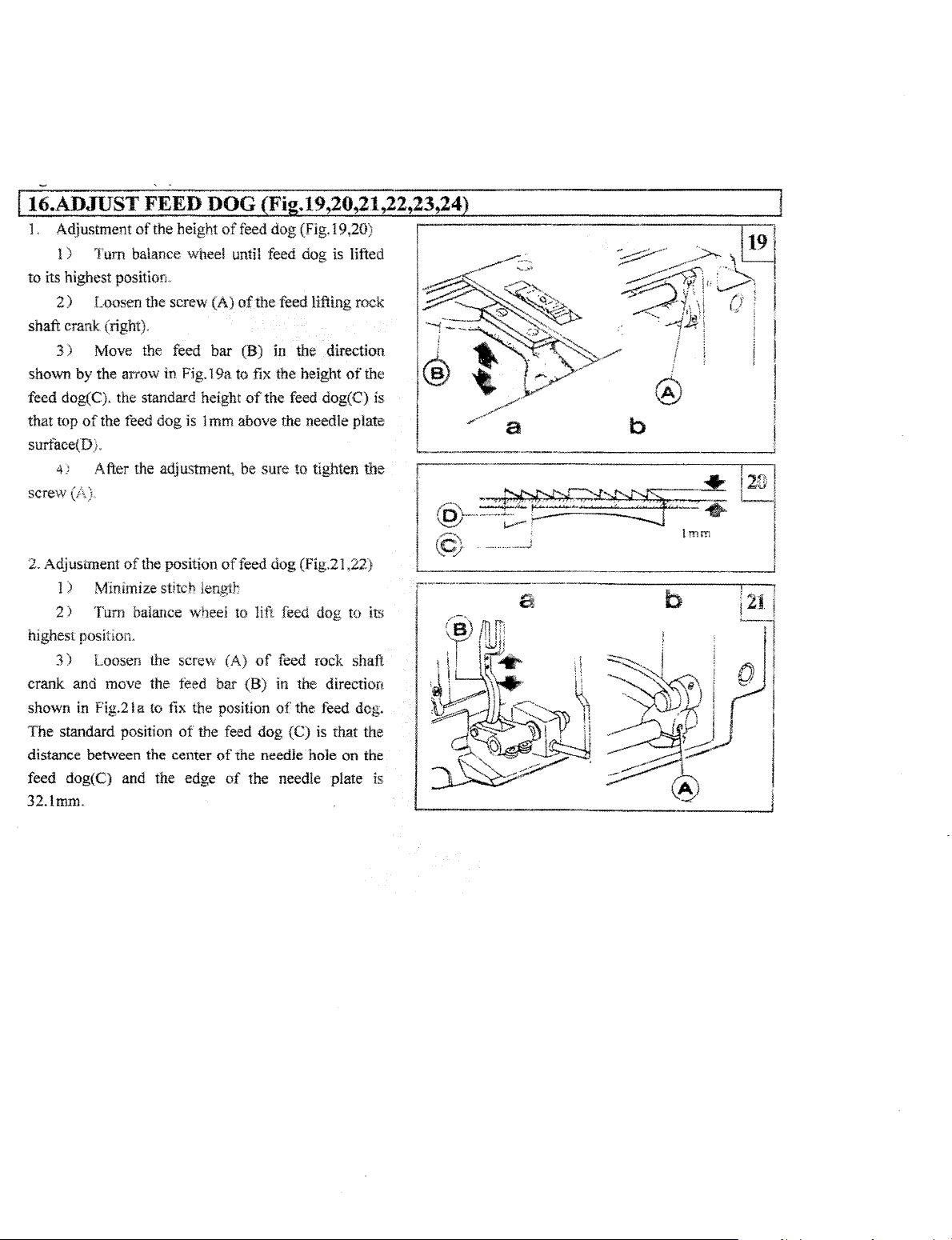

16.ADIDST FEED DOG Fi .19,20,21,22,23,24

1.

Ac\justment of the height

l )

Tum

balance wheel until feed dog is lifted

to

its highest position"

2)

Loosen the screw (A)

shaft crank (right).

3)

Move the feed

shown by the arrow in Fig. 19a to fix the height

feed dog(C). the standard height

that top

surtace(D).

screw

of

the reed dog is 1 mm above the needle plate

4;

After the adjustment, be sure to tighten the

of

feed dog (Fig.19,20)

of

the

feed lifting rock

bar

(B) in the direction

of

the feed dog(C) is

ofthe

a b

2. Adjustment

1 ) Minimize stitch lengit

2 )

highest position.

3)

crank and move the

shown

The standard position

distance between the center

feed dog{C) and the edge

32.lmm.

of

the position

Tum

balance wheei to iift feed dog to its

Loosen the screw (A)

feed

in

Fig.21 a to fix the position

of

the feed

of

feed

dog

(Fig.21 ,22)

of

feed rock shaft

bar (B) in the direction

of

the feed dog.

dog

(C) is that the

of

the needie hole on the

of

the needle plate

is

Page 11

4 ) After the adjustment, be sure to tighten the

screw (A).

1

3. Relative

the

needle hole in the feed dog.(Fig.23)

Make sure that

center

1 ) Remove the arm side cover

screw(A).

2)

center

screw(

4. Time feed motion to needle motion (Fig.24)

The standard timing

motion is that the teed dog starts moving forward

when

If

feed motion

as follows:

I)

Remove the

(A), (D)

2) Holding feed and feed lifting eccentric {B) and

turn balance

on the feed and feed lifting eccentric aligns with mark

(F).

When

feed

should be 0.3*0.5mm.

After the adjustment, be sure to tighten the screw

(A),

(0).

position adjustment between needle and

needle can be descended to the

of

the

needle hole,

Holding the needle bar and move it to the

of

the needle hole

A)

and replace the

the needlepoint reaches the needle plate surface.

is

arm

of

the feed and teed lifting eccentric.

wheel slowly until the reference hole(C)

adjusting, the clearance between

lifting eccemric (B) and eccentric sleeve{E)

if

not, adjust

in

the feed dog.

arm

side cover

of

feed motion to needle

not timed

side cover and loosen the screw

to

it

as follows:

and

loosen the

the

tighten

needle motion, adjust

feed

and

I

32.lmm

Page 12

.

[j

7.

REGULAR-~~E~~G~-(Fig.25,2·6~27}

1

.C

eant·ng.

l

Rem~ve

lint between the

2.Cleaning rotating hook

Swing

out

Wipe

the bobbin case with soft cloth

3.Cleaning oil

Swing

out

ihe oil pump screen.

~'eed

do::r

the

~hroat

;;ate

and

dear

off

the dust and / l

feed

and teeth slots. t

the machine head and clean the hook.

pump screen

the machine head and clean the dirt on

-----------·-·······

========;::,

=·=··-.::

25

l

i

Page 13

----------------------------!!1

'

-

I

•

!

l

1

I

.

I

'

i

I

~

~

i

~

i

,,

1

'

j

I ,

' I

; i

i i

' I

t '

I I

~

!

! I

I I

: I

ll

i

!

l

I

I

I

I

I

'

I

I

I

I

I

i

I

I

I

I

I

I

Page 14

1.

AR:"l

BED

AND

No.

1

2

·'

4

5

6

1

8

9

10

l1

12

13

14

15

!6

17

18

!9

20

2~

I

22

:3

I

24

I

25

26

27

2R

19

30

J!

I

·~

·'·

33

3.:1.

35

36

37

38

39

4()

4l 7J05-0J..()l0

42

43

44

45

46

47

48

49

50

51

52

53

54

55

58

59 22T!-003C6

60

61

62

Ref.

-01

-001

l-004

\-{)()6

No

B2

7J05..()!-00!A:!

l.J07

I 7_!07-0!-002

!

GB827-&6

j

ZJOS-01·003

ZJOS-0

ZJ05-0 l-005

7..!05-0

I 22TI-003C6

! 22Tl-t)()3C5

\ 22Tl-003C6

ZJ05-0l-()l-l

.

ZJOS-01..\.l!

'

1 72Tl-Ol7

ll2Hl-007CI

ll2Hl-007C2

l22Tl-009E l

22Tl-009E2

122Tl-t'!()9EJ

i22TI-OG9E4

I GB896

!

22THXl9E5

I22TI-010

I22Tl-Oll

17.J05-0!-007Cl

I ZJ05-0HJ07C2

!

ZJ05-G!-OOIC3

73TI-002C!

ZJ05-01.007C4

ZJOS-lH-007C5

ZJ05-0l-007C6

7.J05-0l-001C7

ZJ05.0 l-007('8-l

ZJ05-0 l-007C8-2

7J05-0 J

ZJ05-ll l-007CHl

7.J05-0l-007C I l

ZJ05-0l-007CI2

72Tl-Ol3

ZJ05-0J-OO&

ZJ05-0

7J05-0l-01!

ZJOS-0

22Tl-011

72Tl-Ol4

72T1-0l3

22Tl-022

72Tl-O!O

GB93

ZJ07-0l-003

72Tl-019

22TI-021Gl

22Tl-02JG2 Slide

22TI-02JG3

ZJOS-Ol-013

ZJ03-02-00 l

72T!

72Tl-Oil

72Tl-009

.•

(}07C9

!-OtW

l -0! 6

-00-1C4

5

A3

ITS

ACCESSORIES

Descnp1ion

Arm

Ann

bed

Trade mark

Trade mark

Face

Set

Knock

Thread

Set

Thread

Set

Arm

Gasket

Set

Oil

0-ring

l

Screw

Spring

Disc

Space

Stop

Pretension thread guide

Three-hole

Set

Thread tension bracket

Thread tension

Tension

Thread

Thread

Thread tension disc

Stop

Pin

Thread'comroHer

Thread

Screw

Thread tension release plate

Screw

Thread

Screw

Thread

Thread take-up spring 1

Tension thumb

Thread

Screw

screw

Cloth guide plate l

Screw

Bed

Rubber Plug

Retaining washer

Needle

Screw

Slide

Screw

Thread guide

Felt

Set

Rubber

Rubber

Rubber plug

plate

plate

plate

screw

pin

guide

(up)

screw

guidi!"Tiiliddk)

screw

;ide

cover

for

arm

screw

check

window

type

tension

for

pretension

for

pretension

for

pretension

ring

thread

sere"·

regulating nut

tension

tension

releasmg

disc

controller

tension

controller

take-up

supportor

plate

board

board

spring

(Joy,-er)

for

thread guide (lower)

Screw

plug

plug

rivet

side

guide

stud

spring

dtsc

disc

release

stud

nut

spring

cov.:r

stud

disc

pin

srop

l

l

I

9 2.5 X S

2

l

!

!

1

SM9/64"

l

l

!

, SM9/64

l

'

i

'

l

\

I

I

l

1

SMlli64''

8

1

1

l

1

2

I

Ring 3

l

I

I

l

SMll/64"

1

l

1

l

l

I

~

'

1

1

1

I

SM3!32" (2.38)X

1

1

2

l

SMll/64"

l

1

I

1

SM5Y64"

1

SMll/64"

1

2

3

J

Washer6

3

1

SMll

2

l

l

SM3/32" (2.38) X 56!2.2

2

l

l

SM9!64

1

,p

11.8

4

1

"'5.7

tl>

8.8

1

Remark

(3 .57) X 40/6

~

.

.,

(3

57}

X 40/6

(07)X

40/9

(4.37)X 40!5

56

(4

37)X

4015.5

(3.57)X 40!6

(4.37)X 40/5

/64" ( 4.37) X 40/8

'·'

(3.57)X 40/6

ZOJE

SEWING

MACHINE

CO.,

L

Page 15

j2l

! I

l

·~--··-

I

I

I

j

l

Page 16

•

2.

NEEDLE

No.

1

ZJOS-02-{)0l

~

~

7J05.02.{)02

3

22T2-tl02

4

I ZJ05.02-l103

5

l ZJ05.02-004

6

2ZT8.0!iC4

.

7

ZJOS.02..005AI

s

22'1'2..(){16

9

22T2.007

10

l.JOS-4)2-006

'

ll

72T2-004B2

l2

ZJ05-02-007

.·

13

l..l05-02-(l08

14

22T7-0l5

!5 7JOS-02-oo9Bl

16

ZJ05.02-0G9B2

17

GBII7

.

l&

l.J05-02-009B3

19

ZJ05.02.009B4

72'1'2-003

20

ZJOS-02-010

21

lJ05-02-01l

22

22T2-002

23

·-·

ZJ05-02-0l2

24

..

ZJ05-02-n

25

27

2212-i)JI

28

ZJ07-02-iXl1Cl

29

7.J02-08..007

30

lJ07

3!

12T3-005Dl

32

ZJ05.{15-003

:>3

7.J05-03·0l5

34

ZJ05-02-0 16

35

22'1'2-002

36

BAR

Ref

No

-02..00 I

AND

TAKE-UP MECHANISM

! - Description

,

Thread take-up lever

I

Hinge

pin

I Set screw

I

Thread

take-up

Oil-guard

Set

screw

I Needle

bar

crank

Set screw

Set

screw

hinge pin 1

Setscrew

Needle bar

Needle bar adaptor

Set screw

·

Needle

Crank (left)

Pin

Slideblockforneedlelr..rrockfrn.me

Position bracket

Screw

Needle

Hinge pin l

Screw

Needle

Thread guide for

l?

Needle

Needie clamp screw

Crank

Screw

C2

Crank

a3

Screw

Hinge

Bushing

Bushing for rock shaft (right)

Screw

link

bar

rock

for

crank

bar

rock

bar

(right)

lever

(right)

pin

(upper)

for rock shaft {left)

lever

frame

link

driving

frame

needle

(3.57)X

..

(7.14)X

(7.14)X

(6.3S)X

.,

(3.57)X

A3 X 16

(4.37)X

(5.95}X 28J!O

17 12 #

(3.l8)X

''

{6.15)X

(5.9S)X 28!6

(5.95)X

Remark

IPi~cci

1 I

1

I SM15!64" {5.95)X

~

I

l

stud

!

'

l

I

1

SM9/64"

l

SM9/32"

l

SM9/32"

l

2

SMl/4"

l

1

I

I

SM9i64

I

I

rock

shaft

!

1

1

Taper pin

1

l

SMJ1!64"

1

l

1

SM15/64"

l

1

bar

1

DPX

SM!i8"

l

1

SMli4

l

1

1

SMl5!64"

1

1

l

SMl5164"

2

ECJ

2

28il0

2

4014.5

28/13

28114

40/6

40/J 1

40!8

44/4,5

24/16

23/JO

TYPE:

ZJ0628

Dl

Page 17

l

f F 1

'f

13\

I I !

~~

I l

I

I

l

'

I

a

@

@@

IC!?I

t J t /

, , 1

~

A

I

I

Page 18

3.

ARM

SHAl'T

No.

ZJ05..03..001A!

l

2

22TI..OO!A2

3 22T6-005Bl

4

2213-00282

5

21T3·003

6

ZJ05..03..007

'"

7

:2:?:T2""'J02

8

ZJOS-03·006

9

22T3·006F

~22T3-006F2

-~

ZJ02..03..00l

10

11

122T3-007C2

12

2213-008

72T3..005Dla3

1.3

!4 l 1H3-002Blal Feed lifting eccentric 1

·:;

15

72T3-005Dla1 Eccentric

:

22T3-009Dl b

16

17

ZJ04-03..002A2

JS

ZJQ7.Q3-00!B2

;

19 ZJ05-03-003

22T3-0JOE2al-2

20

22T3-0lOE2a2-2

21

~0

~~

I 22T2-005B3

j

23

122T3-010E2bl-Z

24

22T3-0 l

·'

\:

25

ZJ05-03-\l04

-~

26 ZJ05-03-005

27

22T2-002

1

Ref

AND

No

OE2b2-

VERTICAL

Ann shaft

Rubber

ol!ar

C

Set

screw

Ann shaft

Arm shaft bushing (middle)

s;;rscrew··

Arm

Oil

seal

Spring for

Balance

Set

screw

Set

screw

Ser

screw

Retaining

Crank

Feed

Venical

Bevel

Bevel

Set

screw

Bevel gear

Bevel

2

Vertical

Vertical

I

Set

screw

SHAFT

Description

plug

tor

arm

shaft 1

hushing

'

~haft

bu5hing

oil

seal

whc~l

sleeve

ring

rod

fur

feed

forked

connection

shaft l

gear

for

arm

gear

for

vertical

for

hook

gearforverw;al

shaft

bushing

shall

hushing

(left) !

(right)

lifting

shaft l

shaft

shaft

shaft

(upper)

(]ower)

M:ECH..<\NISM

:1

2

SM!/4 ''

I

1

1

1

i

l SM15/64'' (5.95)X 28/10

'

·I

1

J

1

2

SMJ5!64" (5.95)X 2Sil.2

l SMJ !!32" (8.73)X 28/iO

2

SMl5!64"

l

1

rock

1

I

(upper)

J

g

SM1!4 '' (6.35)X 40i7

l

(lower)

1

l

J

SMl5!64

2

Remark

(6.35)X 40/4

(5.95)X 2S/7

.,

(5.95)X

28ti0

;

i

••

,.

ZJ0628

I

f

I

i

AI)D:

·.·

;·:

DAMAli!J.J:)EVELOPMENT ZONE, YUHUAN, ZHETIANG PR(

Page 19

I

I

14l

l · I

\ !

l j

f

t

I

I

I

I

r-_

.. _ ... _ ..

......

........

..........

"'.

"",.,.-,..,.,.

l

'

l

'

-

~---

~--.-

-·---

...J

... -...

--

....

...

--

...

,...,..

,..

...

-

..

-·

...

...

--

!

I

I

I

Page 20

4.

HOOK

SHAFT

Ref

No.j

i

1

2

3

4 22T4·001Alal

1

5

6

122T4-003G

]

! 22':'4AJU4

8 1

9

122T4-006

10

1

tl

12

l3

14

lllH4-001

15

16

l

l

No

lJ05...()4..1)()1

72T4·002B!

12T4-002B2

~2T4·00!Ala2

nT4-ow

7..107-04--l){)

zzn-oo2

HSM-A(5)

BC-STH

74<4-004

22T4·015 Set screw

MECHANISM

I

I Rotating hook shaft

' -

J

Description

Collar

for

hook

se1

screw

Filter screw

Filter

Oilseal

for

rotating

i

Honk

.>naft

bushing

oii adjtt>ting screw l

Spring

for

ml

adjuster

Hook

shaft bushing (right) l

Set screw

Rotating hook complete i

Bobbin case

Bobbin

Rotating hook positioner

shaft

hook

shaft

(left)

:;;; res

~

4

i

l

l

\

l

1

l

l

!

1

I

I

I SMl5164.,

I

SM3!l6'

t

I

SM!5!64"

SMll/64"

Remark

(5.95)X

(4

76)X

(5.95)X

(4.3/)X

28!4.5

32

28!10

40/lO

i

.,

1

:]'

!

n

l

i

'

I

I

!

i

I

!

!

I

I

Page 21

r

,

I I

I I

' }

:

5

I

l

I

l

I

!

Page 22

5.

FEED

LIFTING

No. i

2 72T6-00!A6

3

4 ZJ07-05-0C>l

6

;

lO

J

!l

j

i2

-,,--

14

15

-~

16

i p

19

1

c

2!

24

25

.;

··~

26

27

'·i

28

.c,

29

/

30 GBS94

t

31

']

32

34

35

36

3 7 22T6-00 l A6

38

39

40

41

Ref

, I

21T6-0tl!Ala

ZJll-0&-00JAi

5 22T6-00 l/14

llHt-004

f 22T2-019

S

llH6-007

72T6-00lA5

llH6·006

22T5-00iA4

l1H6-00!

llH6-00S

72T4-002B2

GBS94

22T15-005Bl

22T3-002B2

ZJ07-05-003 !8

22T6-00llllb

7.J07-05-002

31H4-0!4

72T6-002B! b

GB70

72T6-007D

72T6-002B4

72T6-002B2

llHMllO

54T6-002

22T6-0l2

22T2-002

22T6-il13

22T6-005Bl

:Z2T3-002B2

72T6-003C 1

22T6-007

22T6-00lA1h

72T4-002B:Z

ZJ02-08-012

ZJ02-08-048

72T6-007Dlh

MECHANISM

No

j

!

! Screw

·Feed

ia

feed bar

Screw

Feed

bar

hed

dog

Shall

thr

Screw

Bushing

Oil braid

Bushing

Scr~w

Fe~d

rock

Bushing

Screw

C-typc stop

Collar

rock

Screw

Feed

liflingrock

Hmge

Screw

Feed

lifting

Oii

bratd

FeNi

lil1ing

Bushing

Screw

C -eype stop ring

Washer

Collar

Screw

Feed

lifting

Hinge pin 1

Screw

Washer

Screw

Washer

Screw

Washer

Description

~rank

f~ect

for

feed

for

f~d

shaft

fer

feed

ling

for

feed

shaft crank

pin

connecti;m

rock

fer

feed

forfeeJ

rock

nut

bar

rock

shaft(let1)

rock

shafl(nght)

ro<:k

rock

shafm;;nk

shaft

lifiing

lifting

shaft

crank

shaft

shaft

sleeve

rock

rock

SM3!16

I HG128-C

1

2

SMiiS

1

1

SMlli64"

1

2 5 X

SMl5i64'

SMJ5t64'"

I :

ring

SMlf4"

SM3!l6"

(left)

i i

M5 X 12

shaft

1

SM!5164" (5.95\X 28!10

'

ring

sllaft

SMl/4"

2

(right)

l

2 SMJ!l6" (4.76)X

!

l SMl5!64

l

1

SMJ5i64"

l

¢2.5

.,

(4.76)X

'·

(3 IS) X

(4.37}X

315

(5.95)X

f5.95)X

l5

(6.35)X

(4.76)X

X 265

15

1,6.35)X 40/4

,,

(5,95)X

(5.95)X

Remark

44,15

4014

28!1

4018

23/10

18!4.5

2&!11

28!12

28!43

2.8

5

Page 23

&I

I

'

J

:®

;

Page 24

6.

STITCH LENGTH REGVLATING MECHANISM

I!'<\,

!

.!.

l.j

ji'

: S

IS

Ref

1

lzJOl-Ot>-00lAl

ZJfll·Ot>-OU\t\2

DOl

·t'6·0U)

I

'

i

22'f5~00lA4

( 73T5-(hJ2B!

I

LH!5~06-tl07

I

'2T~·OU

71T5-006C

Li07-Ut\-OfJ:ZDI

N"

I

!

j

\

flin;t

!-~~d

Fted

Hwge

Rubber

Spnng

Dt~.:ripnvn

pn

regulator

!cgu!ator

hushing

pm

f0r

teed

regulator

piug

!Or

stopper

pm

; X l Y

\Vas

he•

Page 25

-

r I

I I

' I . l .

-----~!

~I

~

I

I ! I

l

l

I

~)

I

I

I

I

!

!

I

®

I

I

J

!

i

i

f

!

l

'

~

'L_

____________

""'\

\

\

'

\

__

~

j

!

(

\

'

I

j

l

i

l

Page 26

:.

PRESSER

7)05-07

..

i

iJ05-DU02

- i

ZJ05-07 -009 A i

7J05-D7-009A2

ZJ05-07..(JIO

ZJ05-D7

ZJ05-D7-UB

J.J05-07-Dl4

l~f05-07-01~

2.!1,5-D?-0!6

22T7-005.(l0! i

ZJ05.07-(ll

Z:ZT9-l.lOiNf

ZJ05..()7..(Jl9

25

FOOT

MECHANISM

..()01

..(J2l i Screv

Presser

Presser bar bushing l upper;

Screw

?r~sser

:>cr~"

Kne·:

~;;~w

ii

:'\e:rac:ing s;mng

s,·'""

! Nut

Des(.;nptiQn

kH)t

hftt>r

t-ar

spnng {ilaL

!iller litlmg

lever

hracke'

IP•ecesi

1

I

i

' ;

!

l I S,\i!

I

SMl5i64.

5}64

I

1:

I'

I

I

I

,.

(i.

-?5)

;, 2Si28

(5

95lX

2~

I

?B

ZJ02-08-00 7

29 ZJ05-D7-023

3()

ZJ05..()7-0ll

3!

Page 27

I ,

. 'a!

.I~

l

8.

PRESSER

!

No.

l

! ZJ05-08-00 l A 1

2 I 22T3-002B2

3 I

ZJOS-08-00

4 I

ZJOS-0&-00

5

GB893

o i ZJ05-08-ti02Bl

I

ZJ05~08-002B2

I

8 \ ZJOS-08-003

9

2::J05-08-0Q.J.

i C

ZJ05-0S-00:5

i 1

ZJ05-08...oo6

1

:1

ZJ05-08-00I

1 -

D02-0!\-004

22Ti-O; 1

i5

ZJ05-08-008

lf

ZJ05-08-00':I

!7

ZJ05-08-0lC

13

ZJ05-0l!-01l

ZJ05-08-0 l

ZJ05-DS-0!

22T2-00lA9

23

ZJ05-08-l'

ZJ05-08-0H'

2:'

ZJ05-(Ig.(J

26

ZJ05-0&..0

22T:;>OOiAS

2S

ZJ05-08-0F'

2¥

ZJDS-08-020

30

ZJOS-08-02;

~-. 12T24•~).: t ~crt-\'

32

G'f~-~·r! ~ \i{a~he~

,

<-::

ZJOS-08-022

t

···-··~-·--

Re~·

.......

~~-

LIFTING

No

1

A2

l A3

MECHANISM

[ Descriptio"

I

~irting

Screw

I

,

Lifting

i

Needle

I Retawing

!

Adjusting

I Set

scr"e\c

I

Screw

for!ifhmre;x'dlmco..xmecringroUar

i

Lifting

!

iVash<::

. I

N'J~

L1ftmg

Lifting

Sere;•·

Hmge

Hinge

Liftmg

lifting

o

...

~{'·:-c..":"'

~ • -·~·'""'~

:

't

.

.t

15

1T

ll',

....

V;orating

Vibrating

SCf¢\'\-

Vibrariug

Spring guide

'-.:;rev.

Shdebtickf()rqc;a;;::g

Scr"'"

i

·~·I>

seal

I

L\ftingrock:

---_1__-··-·----------'----'--

eccentric .

ecc:ennic

bearm£

ronnecnon ·

1 i

ring

crank

for

eccentric

oonnection

I

tece;,tnc

connectmg

rock

shaY

rock

shaft

bushing

pn:

pill

nut

l:Jeli

cranK

be!i

cran ;

;!p.-;'1"!:2"'

1;"'\C~

......

~~

......

t'!

...

pressi"r

presser

pres~<";·

ro.:l

pJ!\r.

s~aft

busmng

~llar

I !

! l

;nght'

ilni

~

$

ba-

foo:

~""

sp"ng

;;:~s;.;r'::;;

<)er(

!,Pi~ces:

.

Remark

1

~~~

2

1.

SM

L'4

'' ( 6.35) x 40/4

j

I'

:

i

i i

Ring 30

1

1

SM3.'!6'

!

l

~

"'

J

SJ\111/64

iSM

i

!

'

'

!

!

I

i SM 9!64

I

SM

SlVl

Wasi~c~

(4.76)X2~

;,

t-+.37)>:~

1!4.

(6.35)x

,.

13

~

9/64 ! 3

11

/o~

< 14.37)

5

57) X 40/6

57!>.:

I

4-0;~5.5~

4C

.

40'(-

~

..

~

40

:5_

')

Page 28

~

@--~

"-'

' .

---

!3

-~

--------

_

__.,

9.

LUBRICATING

No

Ref

7J03-09-00 i

7..107-09-002

12Tl-007

:-

'72T2-00~?

4

ZJ03-09-00:?

;

ZJ

03-09-D03

6

;

lHS-008Bl

k

i

H8-fJtf!

c

"2T2-00::'

9

'

lC

;

'

ZJ07-(19-003A

! '

22T8-010B'

i

~";,

ZJOS-09-00

!4

ZJ07-09-IJ04Bl

:22T8-013D::

ZJO

i

''

~

t.~

-0&-00-:;

7:271-Cr~.>

MECHAMSM

No

011

Oil

Wash~;

Sere\\

Oil

Oil

Oii

Gear

Oil

l

Oil

i

Cd

;

!

Pi:Je

i

Pipe

Description

;:n1mp

body

pump

body

pump shaf'

pump

body

pump

screen

(inner)

pipe

for

hook

J.npe

for

am1

pme

fOr

arm

connectton for

hotd

for

arm

plate

guide

piare

shaft

shaft (upper)

shaft

(!ower)

arm

s'::l;':.

shan

Remark

1

Sivfl

8

.,

(3.

18) X

3

3

4H

Page 29

. .

110

l f;.

OIL

r

I

:;-,;,;.,

!

l -

RESERVOIR

-~--·--·--,.......-

Ref

No

AND

OTHER

Oil reservoir

01l drain

ACCESSO~!£;~

Description

scr0w

. i

P1ecesj

I

:

i

Gaske~

l~'r

oil

reservoiq

22T9

..

;

l

f

~

! .

: 5 ; 22T9-003B6

lci

l 9 ,

:?C

~

, ;

.,~

i

::3

2L

l

25

.

!

26

f

?.

....

i

t.c~-.,.------·-·--..._

COiA5

; 22Ti!-003Bl

!

12l"9

..

Q03

B1.

! 221'9-00385

22T9-0NC

l

i 22TY-004C2

'

7~T

1

..

en

:

i 72T9-028 Screv·

l GN896 Stop

l

Z..J05~10-002

1.

GB84 Set screw !

, Chs;n I

GN1"'1

GoJketfo::\·11

Hmge

~t~acung

Kn'Z:~

Loc><

Knee

Knee

Set

screw

Bracket

Knee

Set

5c:rew

Pad

Beit

Belt

Screw

Knee

C'hain

______

rc~ervoir~smalr,

n·~

:';::

5-rxmg

liner

src:p

nu·

iifter Utin?

1ificr

ocU

for

knee lifter

lifter

plnc

for

knee

cover

bracke[

cover

plii·e

nng

lifter

rod

hool{

_._..,...

~':t'e

1·urknee

crac

cran:~

lifter

crank

...

__

b1g;

iifw·

ilr\t:;

~;,,.,

rod

plate.

plate

_...~,.,

...

_____

I

2

3

~

I

2

_.._........,

~

Page 30

{f.'J:

L

..

._:

,~-'"'

........-....

,., .

"~

.....

~.,

\

j

/j

··.~,·

i

!

t

'

i

t

i

!

I

Page 31

11.

ACCESSORIES

Ref

No

22T9-007F1

.,

72T9-004Ci

-

.;

7219-005 Rubber cushion (big)

7219-006 Rubber cushion (small)

5

2219-0! i

6

7 22T9-012

8

7219-007

9 7219-020

lC

7219-02:

No

Hmge

Rubber

Oiler

Magnet

Screw

Screw

Screw

of

driver

driver

driver

Description l Pieces

machine

socket

for

head

hinge

I

I

I

2

~~

..,

"

(long)

(medium)

(short)

11

''

!""'~

1~

,,:

~..:

72T9-022

2219-0

I-:-

2219-0i?

DP

X

17

21#

Double-end

Oil

container

Vinyl

cover

Needle

wrench

4

Page 32

~~

I

I

I

I

i

~

~

@;--..,_ _

_,

~

f

I

I

'

~

@)--~"'·--

:

12

. .BOBBIN WINDER MECHANISM

Ref

No

Z::T'J-00607

22T9-006D~

..

Bobbin

Sprinf

Screv.

fUvet

Sen.·\\

Bnhb1n

....

____

winder

winder stop

~·

DescripnoP

base

latch

P\eces!

J l

~

1

'

Bohbm

winder tension bracket

Tenswn stud bushing

22T9-006D2

22T9-006D22

i

Bobbin wmder tensmn spnng

Tension stud

Tension

bracke~

\!food

screw

Washer

nui

scrh~·

2

2

Loading...

Loading...