Page 1

II

}]

ftlj

Il

*Jl

YXP-3

LEATHER

fJ!

SKIVING

Jft

}jt

OPERATION

MACHINE

RA

~

MANUAL

1111!1·111

ZOJE

Ill

81

SEWING

m

iliR

MACHINE

ft!l

fR

iEi

Be~

CO.,

61

LTD.

Page 2

I .Features and uses

of

the machine.

JS-801 Leather Skiving Machine with circular knife is suitable for edge-skiving and

skiving

caps, bags, garments, belts, gloves and

above goods. garments, belts, gloves and sports goods etc.

above goods.

life etc.

of

any kinds

The

machine has features

of

leather as well as plastic cloth, synthetic leather, felted wool and rubber for shoes,

sports goods etc.

of

noiseless stable perfoimance, easy operation. high productivity

It

It

is one

is one

of

necessary equipments whick make

of

necessary equipments

II .Main Technical Specifications.

YXP-3

rotating speed

skiving

size

of

the

net

weight

motor power

size

of

circular knife

ill.

To

prepare for using.

!.Assembling

The machine head. frame and

motor

at

the

and align their positions. Thighten all screws and nuts.

2.Cleaning grease dirt.

The

machine are coated with anti-rust grease

through long time storage and long

accumulate

cloth after unpacking.

Check

observe wheather the feeding wheel and the grinding wheel impact

there is any impact,adjust

wheel and

for testing,

On

3.Checkingthe

The

machine may

the machine completely after cleaning it ,

the

4.Filling oil and testing.

Before starting

The

of

main shaft (circular knife)

width

machine head

of

the

machine head

motor

etc.are packed separately. First assemble

long hole

it ,

grinding wheel keep a clearance with

belt pulley

of

the

The

grease on

machine

get

the

the

machine, fill oil

of

frame beam, and fix it with screw.

way

transport, the grease may become hardened

the

surface

strong shaking

machine according

the

main

of

in

the

at

oil holes and moving parts.

shaft sttould fum clockwise.( observe from

11

4-15mm

550X370X400mm

45kg

370w

0ll7X54X0ll4mm

to

p~vint

the

machine

transport leading

Tum

the belt pulley

to

the

methods

the

edge

00-1200'J)m

Then

place

the

if

from rusiting before packing. But it may be

must

be cleaned with gasoline and clean soft

to

loosening

of

the

main shaft with hand and

the

edge

of

the. circular knife

of

this instruction book, make

ofthe

knife.

Let

the

machine run a few minutes

the

frame,thcn set

table

and

or

shifting

the

t?ght

whole

surface

which

make

and

long

machine head

or

dust may

of

its parts.

or

not,

the

feeding

of

operator)

the

If

IV

.How to use and adjust the machine.

l.To adjust the position

of

the circular knife.

13

Page 3

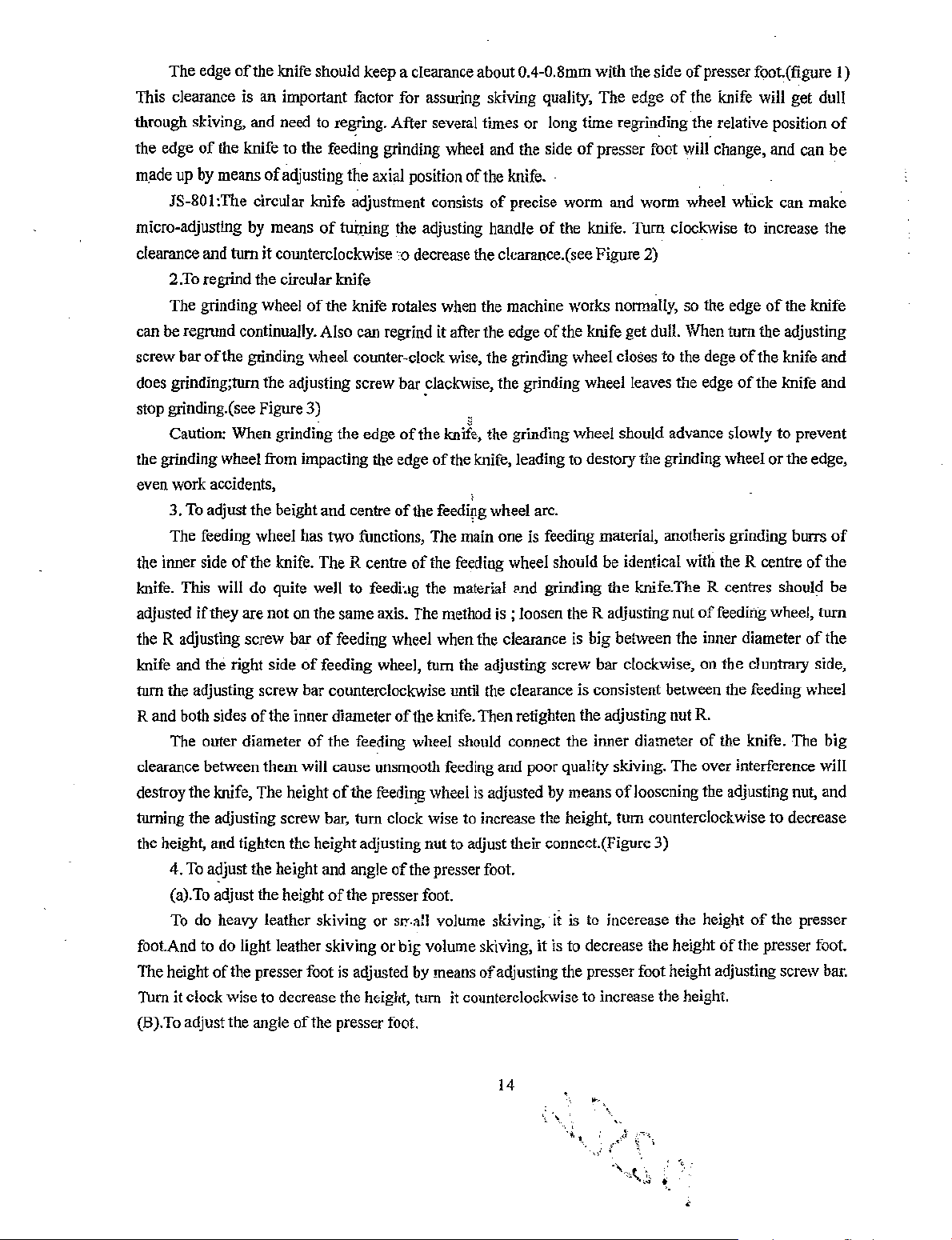

The edge

This clearance is an important factor for assuring skiving quality, The edge

through skiving, and need to regring. After several times or long time regrinding the relative position

the edge

m.ade

up by means

JS-80 1 :The circular knife adjustment consists

micro-adjusting by means

clearance and tum it counterclockwise

2.To regrind the

The grinding wheel

be

regrund continually. Also can regrind it after the edge

can

screw bar

does grinding;turn the adjusting screw bar

stop grinding.(see Figure

Caution: When grinding the

the grinding wheel from impacting the edge

of

the knife should keep a clearance about 0.4-0.Smm with the side

of

of

the knife to the feeding grinding wheel and the side

of

adjusting the axial position

of

tui:t_ting

the adjusting handle

··o

decrease the clearance.( see Figure 2)

of

the knife.

of

precise worm and worm wheel whick can make

of

presser foot will change, and can

of

the knife. Turn clockwise to increase the

circular knjfe

of

the knife rotales when the machine works normally, so the edge

of

the knife get dull. When

of

the grinding wheel counter-clock wise, the grinding wheel closes to the dege

_clackwise,

the grinding wheel leaves

t.t'l.e

3)

edge

of

the knife, the grinding wheel should advance slowly

of

the knife, leading to destory the grinding wheel or the edge,

of

presser foot(figure

the knife will get dull

of

the knife

tum

the adjusting

of

the knife and

edge

of

the knife and

to

prevent

of

be

even work accidents,

To

adjust the beight and centre

3.

The feeding wheel has two functions, The main one is feeding material, anotheris grinding burrs

the inner side

Tills will do quite well

knife.

adjusted

the R adjusting screw bar

knife and the right side

of

the knife. The R centre

if

they are not on the same axis.

of

feeding wheel when the clearance

of

feeding wheel, tum the adjusting screw bar clockwise,

of

the

feedi~g

of

the feeding wheel should be identical with the R centre

to

feedi'.lg the material

The

method

wheel arc.

md

grinding the knife.The R centres should be

is;

loosen the R adjusting nut

is

big between the inner diameter

of

feeding wheel,

on

the cluntrary side,

of

of

of

the

turn

the

turn the adjusting screw bar counterclockwise until the clearance is consistent between the feeding wheel

Rand

both sides

The outer diameter

of

the inner diameter

of

the feeding wheel should connect the inner diameter

of

the knife. Then retighten the adjusting nut

R.

of

the knife. The big

clearance between them will cause unsmooth feeding and poor quality skiving. The over interference will

of

destroy the knife, The height

the feedif!g wheel

turning the adjusting screw bar, tum clock wise to increase the height, turn counterclockwise

is

adjusted by means

of

loosening the adjusting nut, and

to

decrease

the height, and tighten the height adjusting nut to adjust their connect.(Figure 3)

To

adjust the height

4.

To

adjust the height

(a).

To

do heavy leather skiving or

foot.And to do light leather skiving or

of

The height

the presser foot

Tum it clock wise to decrease the

(B).

To

adjust the angle

and

angle

of

the presser foot.

is

adjusted by means

height, tum it counterclockwise to increase the height.

of

the presser foot.

of

the presser foot.

srr.n!J

volume skiving, ii is to incerease the height

big volume skiving, it is to decrease the height

of

adjusting the presser foot height adjusting screw bar.

of

the presser

of

the presser foot.

l)

14

...

'·

•

,.•" '

< •

';

-

..

:

•

,,.-

Page 4

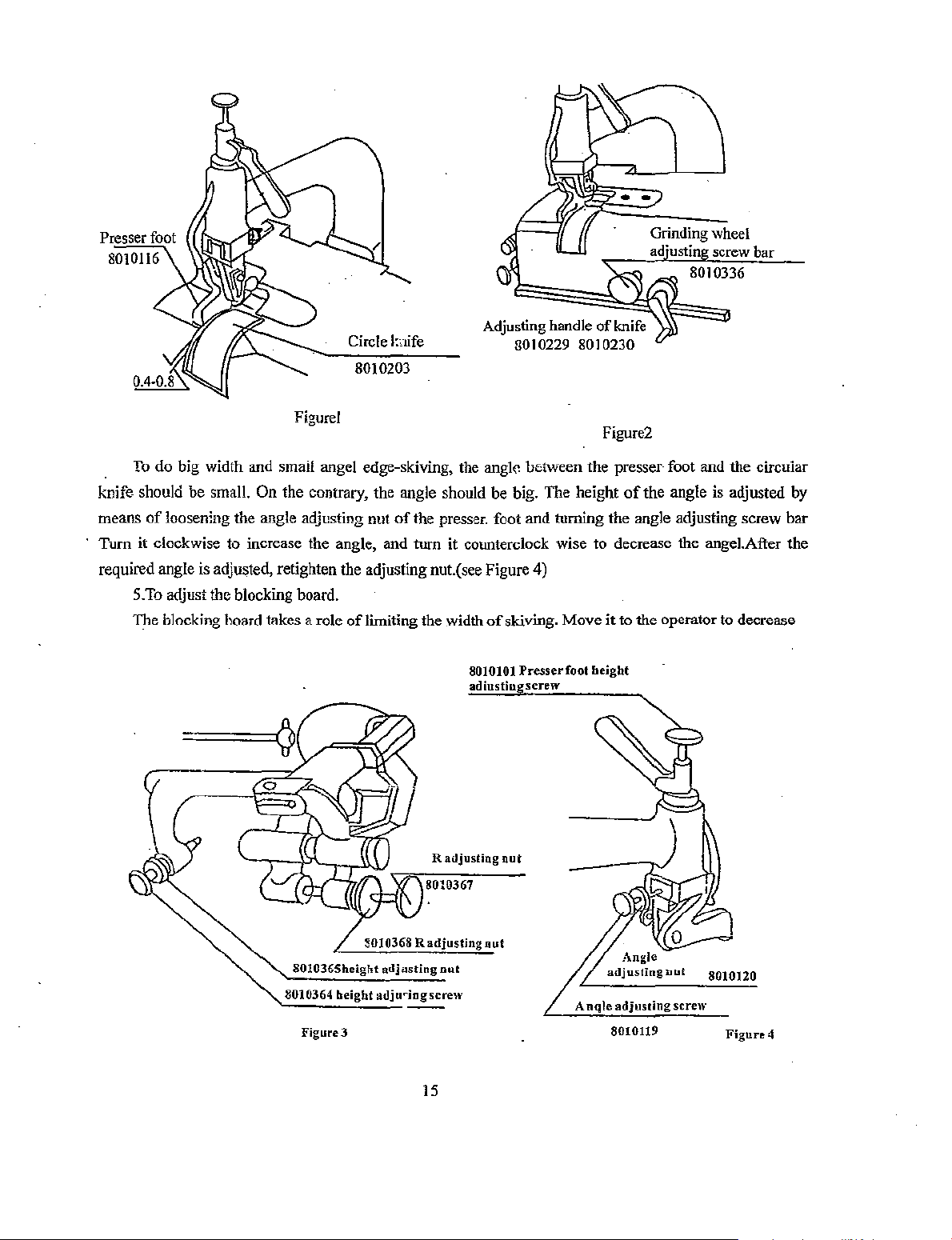

Presser foot

80101l6

--

Grinding wheel

ad·ustin screw bar

Circle

l:c1ife

Adjusting handle

8010229 8010230

of

knife

80!0203

Figure!

Figure2

To

do big width and smail angel edge-skiving, the

knife should

means

Tum

it clockwise to increase the angle, and turn it counterclock wise to decrease the angei.After the

required angle is

be

small. On the contrary, the angle should be big. The height

of

loosening the angle adjusting nut

adjusted, retighten the adjusting nut.( see Figure 4)

of

the presser. foot and turning the angle adjusting screw bar

5.To adjust the blocking board.

The blocking hoard takes a role

of

limiting the width

angl<!

of

skiving. Move

8010101

adiustiu

Presser

between the presser- foot and the circular

of

the angle is adjusted by

it

to

the operator to decrease

foot

screw

beigbt

R

8010365height

8010364

height

Figure3

:':!010368

R

adju$ting

adj<~sting

adjuring

screw

adjusting

nul

nut

lint

A nqle adjusling

15

Angle

adjuslingnut

8010119

8010120

screw

Figure4

Page 5

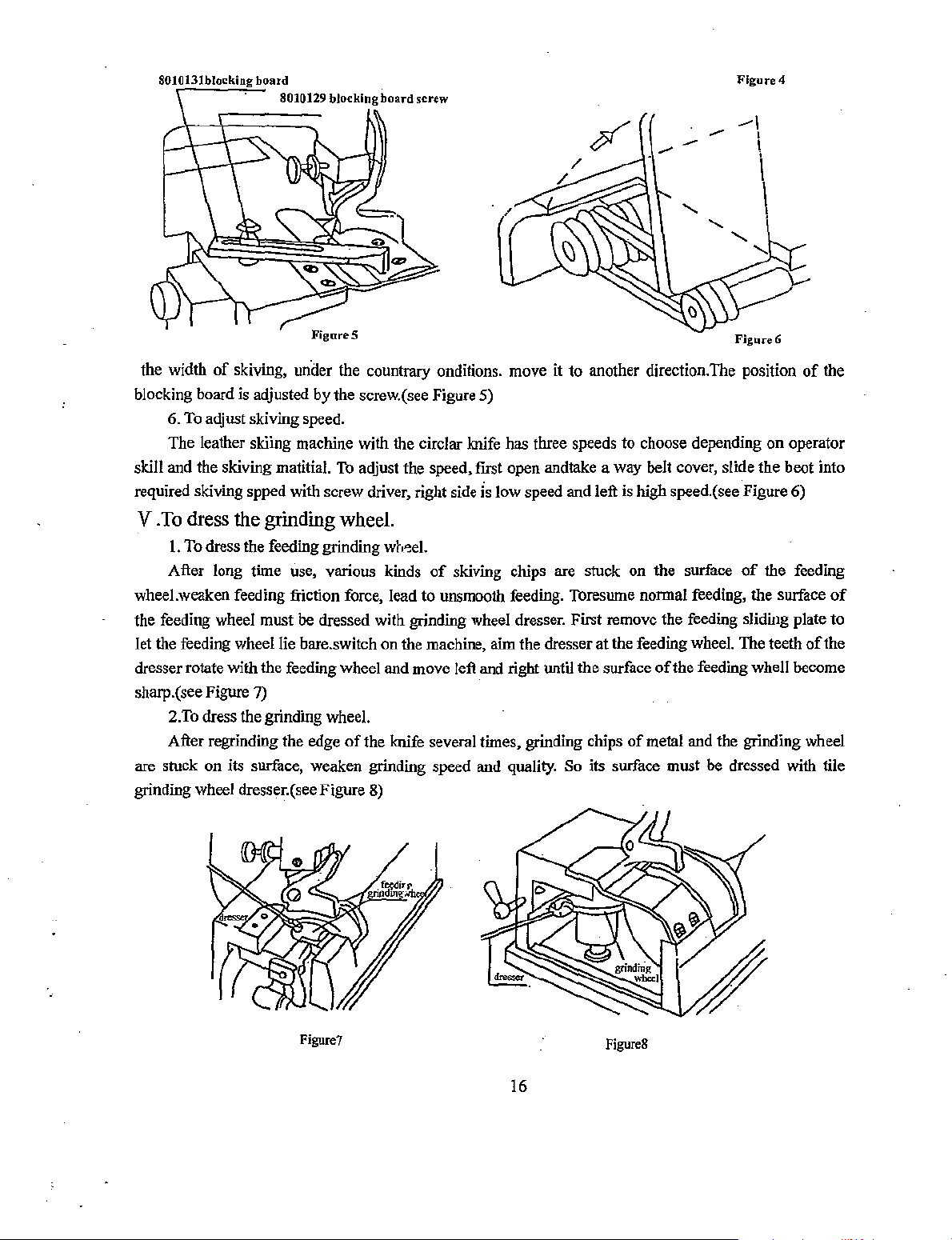

801013lblocking

board

8010129 blocking

FigureS

board

Figure4

screw

the width

blocking board is adjusted

skill and the skiving matitial.

required skiving spped with screw driver,

V

.To

wheel.weaken feeding friction force, lead to unsmooth feeding. Toresume normal feeding, the surface

of

skiving, under the countrary onditions. move

6.

To

adjust skiving speed.

by

the screw.(see Figure 5)

it

to

another direction. The position

The leather skiing machine with the circlar knife has three speeds to choose depending

To adjust the speed,

right side is low speed and left is high speed.( see Figure 6)

:frrst

open andtake a way belt cover, slide

dress the grinding wheel.

1.

To dress the feeding grinding wh'!el.

After long time use, various kinds

of

skiving chips are stuck on the surface

of

of

the

on

operator

the

beot into

the feeding

of

the feeding wheel must be dressed with grinding wheel dresser. First remove the feeding sliding plate to

let the feeding wheel lie bare.switch on the machine,

dresser rotate with the feeding wheel and move left

sharp.(see Figure 7)

aim the dresser

and

right until

at

the feeding wheel. The teeth

the

surface

of

the feeding whell become

of

the

2.To dress the grinding wheel.

of

After regrinding the edge

the knife several times, grinding chips

are stuck on its surface, weaken grinding speed

and quality. So its surface must

of

metal and the grinding wheel

be

dressed with tile

grinding wheel dresser.(see Figure 8)

Figure?

16

FigureS

Page 6

!.

PRESSER FOOT AND

Part

Item

I

2 8010102 Presser

3

4

5

6

7

8

9

10

11

12

13

14

15

16

18

19

No.

8010101 Presser

8010103

8010104 Presser

8010105

8010106

8010107

8010108 Presser bar spring I

8010109

8010110

8010111

8010112

8010113 Presser foot shaft hook metal hinge screw

8010114

8010115

8010116

8010118 Ann

8010119 Presser foot

Presser bar lifter bracket screws

Presser

Presser bar lifter lever

Presser bar cover screw I

Presser

Presser foot side plates

Presser foot side plates

Presser foot side plates screws 2

Presser foot shaft boot metal set screw

Presser foot shaft

Presser foot 40mm

OUTERATfA

bar

adjusting screw I

bar

lifter bracket I

bar

lifter pin I

bar

lifter

CHMENTS

~~-arne

of

Part

bar

.

•

hock

adjusti!J.g

adj

metal

-

screw

screws

Quan

2

I

I

I

2

4

I

I

I

I

I

I

Remarks

17

Page 7

Item

20

21

22

25

26

27

28

29

30

31

32

33

34

35

Part

No.

8010120

8010121

8010122

8010125

8010126

8010127

8010128

8010129

8010130

8010131

8010132

8010133

8010134

8010135

36 8010136

37 8010137

38

8010138

40 8010140

41

42

43

8010141

8010142

8010143

8010143-1 Belt

44

45

8010144

8010129 Ruler

8010129-1

46

47

49

so

51

52

8010146

8010147

8010149

8010150

8010151

8010152

Name

Presser

Presser

Presser

Presser

Presser

Worm

Fiat

Ruler

Ruler

Worm

Slide

Slide

Slide

Slide

Slide

Waster

Waster

Bad

Belt cover

Belt cover

Belt

Belt cover lid

Ruler

Hinges

Hinges pins

Hinges set screw

Waste

Transmission

Base

foot

adjusting

bar

spring

foot

spring

foot

spring

foot

shaft

c;mmbar

screw

set screw 1

set screw

cham

bar

plate

screws

plate

screws 2

plate

A 1

plate

B . I

plate

C

feeder

screw

feeder

stop

plate

plate

cov·1r

lid 1

em

er

lid 1

stopper

set

screw 1

set screw

feeder

metals

shaft

plate

ping

screvv-

plate

washer

plate

pin

screw

of

Part Quan

screw

nuts

Remarks

2

1

1

1

1

1

1

1

1

6

1

1

1

1

1

1

1

1

2

2

4

1

1

1

18

Page 8

568

9J4U

"

"

'

"

2.Knife

Item

I 8010201 Leather

2

3

4

5

and

belated parts

Part No.

8010202

Knife

8010203 Knife

8010204

8010205

Knife shaft I

Knife shaft key I

6 8010206 Knife

7

8

9

10

11

12

13

14

15

16

17

18

8010207 Screw

8010208

8010209

8010210

8010211

8010212

8010213

8010214

8010215

8010216

8010217

8010218

Pubber bushings

Pulley shaft flange holder(Left) I

Pulley shaft flange

Pulley shaft

Pulley shaft flange

Screw

Nut

Pulley shaft shaft

Pulley shaft I

Pulley shaft key(large) I

Hexagongal nut( A) I

of

Name

peeler

set

shaft

covet I

screws 4

-·

nuts

holder(

nut

key(

Part

right) I

small) I

Quan

I

2

I

I

2

I

·2

2

Remarks

19

Page 9

Item Part

20

23

24

25

26

27

28

29

30

31

32

33

35

36

37

38

39

No.

8010220

8010223

8010224

8010225

8010226

8010227

8010228

8010229

8010230

8010231

8010232

8010233

8010235

8010236

8010237

8010238

Trust bearing 2

Kinfe shaft lead pipe key 1

Knife shaft lead pine 1

Knife shaft worm wheel 1

Knife shaft worm 1

Screw 2

Knife adjust!

Knife adjusting handle 1

Knife adjusting handle knod 1

Pulley shaft bearings 2

Pulley shaft metal 1

Pulley shaft metal screws 3

Clutch

Pulley

Clutch slide block

Clutch slide block screw

8010239 Clutch arm·

40 8010240 Clutch

41

42

43

44

45

46

47

48

49

50

8010241

8010242

8010243

8010244

Clutch spring hook

Clutch slide block screw

Clutch lever screw

Clutch lever sb.aft

8010245 Clutch arm sr;rew

8010246 Clutch lever spring

8010247 Clutch lever spring waser

8010248 Clutch lever spring hinge screw

8010249

Clutch lever spring screw

8010250 Clutch lever

.~g

arm

Clutch spring

Name

knob 1

of

Part

Quan

1

1

1

1

1

1

1

nut

1

1

1

I

1

1

1

1

1

Remarks

20

Page 10

"

"

"

"

"

"~~~

____

,

6465

707122

61677)

f .

77788179!180

~-

3.GRINDSTONEAND ROLLERATED PARTS

Item

I

2 8010302

3

4

5 8010305

6

7

8

10

II

12

13

14

15

16

17

18

19

20

21

22 8010322 Grindtone

23

Part No.

8010301

8010303

8010304

8010306

8010307

8010308

8010310

8010311

Worm wheel

Main

shaft

Main

shaft

Roller driving

Roller

Main shaft worm gear wheel screw

Main

Main

Main

Main

-

driving shaft metal

shaft

shaft

shaft

shaft

8010312 Main shaft

8010313

8010314

8010315

8010316

Main

shaft

Main

shaft

Main

shaft

Main shaft

8010317 Hexagonal

8010318

Main

shaft

8010319 Grindtone

8010320 Grindtone

8010321 Grindtone

8010323 Grindtone

Name

box

worm

gear

wheel

worm

gear

shaft

metal

worm

gear

chambar cove screw

front bushing

worm

g~,ar

chamer

key

key

bearing

deaning

pulley

nut

belt

set

set

shaft

shaft

screw

screw

pulley

holder

nut

of

Part

screw

screw

l1

36

)8

Quan

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

Remmks

21

Page 11

Item Part No.

24

25

26

8010324

8010325

8010326

27 8010327

28

29

30

31

8010328

8010329

8010330

8010331

32 8010332

33

8010333

34 8010334

35

36

37

38

39

8010335

8010336

8010337 Grindtone shaft

8010338

8010339

· Grindtone shaft pulley taper

Grindtone shaft bearings

Grindtone shaft bracket

Grindtone· shaft bearing roller

Grindtone shaft bracket

Bracket arm center screw nuts

Bracket arm

Grindtone shaft bracket arm spring

Grindto!le shaft bracket amsping screws

Grindtone shaft bracket screw

Grindtone adjusting screw pipe nuts

Grindtone adjusting screw

Grindtone adjusting screw I

Belt

guide pulley screws

Belt

guide pulley shafts

Name

cen~er

screws

belt

of

pipe

Part

pin

40 8010340 Belt guide pulley bearings

41

42

43

44

45

8010341

8010342

8010343

8010344

8010345

Belt

guide pulleys 2

Belt guide pulleys washers 2

Belt

guide pulley shaft screws 2

Belt guide br!.cket I

Belt guide bracket taper

..

pin

46 8010346 Belt guide bracket spring I

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

8010347 Belt guide hracket shaft

8010348

8010349

8010350

8010351 Roller driving shaft

8010352

8010353.

8010354

Belt

guide bracket ruming stoppers 2

Roller driving shaft

Roller driving shaft key

joint

Roller shaft oil wick

Roller shaft

Roller shaft oil seal plug I

8010355 Roller I

8010356 Roller washer I

8010357 Roller bracket I

8010358

8010359

Rollers haft screw I

Waste clear metal shaft screw

8010360 Roller bracket arm spring hooks(2) I

8010361

Roller bracket arm spring

8010362 Roller bracet arm spring books metal I

8010363

Roller bracket arm

64 8010364 Roller bracket arm adjusting screw

65

66 8010366 Roller bracket arm sprign hooks(

8010365 Roller bracket arm adjusting screw

I)

nut

Quan Remarks

I

2

I

I

I

3

3

I

2

I

2

I

I

2

2

4

I

I

I

I

I

I

I

I

I

I

I

I

2

22

Page 12

Item Part No.

67

68

69

70

71

72

73

8010367

8010368

8010369

8010370

8010371

8010372

8010373

74 8010374

75

76

77

78

79

80

81

82

83

84

8010375

8010376

8010377

8010378

8010379

8010380

8010381

8010382 Waste clear metal leather shaft I

8010383

8010383 Roller shaft screw

Name

Arm adjusting screv· I

Arm adjusting screw

Roller bracket turning arm

Roller bracket turning arm spring stopper 1

Roller

bracket

Turning arm spring adjusting nut 1

Turing arm spring adjusting screw 3

setscrew

Roller

Roller bracket arm center

Waste clear

Waste clear metal 1

Waste clear metal leather 2

Waste clear metal leather screws

Waste clear metal leather spring

Tape pin

bracket arm center pin

turning arm spring

metnalleather

nut

of

Part Quan

pin

screw I

nuts

I

1

1

3

1

2

2

Remarks

1

1

1

23

Page 13

3

2

6

4.ACCESSORIES

Item

I

2

3

4

5

6

7

8 80I0408 Presest

Part

No.

80I040I

80I0402

80I0403

80I0404

80I0405 Driver(large)

80I0406

80I0407

Grindstone diresser I

Grindstone nut spanner

Knifshaft spanner I

Knife inner cover remover I

Oiler

Presesr

foot 3

foot

Omm

;;omm.

Name

of

Part

7

Quan

I

I.

I

I

I

8

Remarks

I-I6B

I-I6C

24

Page 14

Loading...

Loading...