ZMD ZMD31020, ZMD31030, ZMD31035, ZMD31050 User Manual

ZMD31XXX – Evaluation KIT

Datasheet ZMD31XXX Evaluation Board

Features

• “plug & play” capability

• power supply of the SSC evaluation board by

communication board

• screw terminal for external bridge sensor element

• access to all I/O-signal lines of the ZMD-SSC-IC

on board

• on-board-LEDs display the status of 5 VDC –

power supply

• ZIF-socket for simple interchange of SSC-IC

(optional)

Benefits

• “plug & play” – capability allows simple installation

and interchange of SSC evaluation board

• ZIF-socket allows simple interchange of SSC-IC

• system evaluation with sensor dummy or external

bridge sensor element

Example: ZMD31020 USB-Evaluation Board

Brief Description

The new modular evaluation kit system of ZMD’s

sensor signal conditioner ICs allows the user a very

simple and intuitive handling of both, evaluation

hardware and software. For the evaluation of different

SSC-ICs only this IC-specific SSC evaluation board

and software has to be interchanged, the other parts

of the evaluation hardware (communication board and

bridge simulator) are almost the same.

The SSC evaluation board allows a simple-to-installevaluation of ZMD’s SSC-IC matching with this board.

Either this IC is assembled directly on the PCB by

soldering (standard version), or is connected via a

common SSOP-ZIF-socket for simple IC-interchange

(optional).

On board there are two 50-pin-connectors for “plug &

play” – connection to the communication board and (if

necessary) to the sensor replacement board.

Alternatively, by the on-board-screw terminal an

external bridge sensor element can be connected too

for a more realistic evaluation.

On-board-LEDs display the status of 5 VDC-power

supply and (depending on SSC-IC-type) the status of

digital outputs (e.g. ALARM 1 and 2 at ZMD31050).

Several strips allow the access to all signal-I/O-lines of

the SSC-IC for a simple system check.

Every SSC-evaluation board type is hard-coded, this

allows its identification by the µC of the

communication board.

Copyright © 2005, ZMD AG, Rev. 1.00, 2005-05-23

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

1/10

reason of usage of trade, custom or course of dealing.

ZMD31XXX – Evaluation KIT

Datasheet ZMD31XXX Evaluation Board

Important Note

Restrictions in Use

The ZMD31XXX USB Evaluation Kit hardware and ZMD31XXX USB Evaluation Kit software

is designed for IC evaluation, laboratory setup and module development only.

The ZMD31XXX USB Evaluation Kit hard- and software must not be used for module

production and production test setups.

Disclaimer

ZMD AG shall not be liable for any damages arising out of defects resulting from (i)

delivered hard- and software (ii) non-observance of instructions contained in this manual,

or (iii) misuse, abuse, use under abnormal conditions or alteration by anyone other than

ZMD AG. To the extent permitted by law ZMD AG hereby expressly disclaims and user

expressly waives any and all warranties, wether express, implied or statutory, including,

without limitation, implied warranties of merchantability and of fitness for a particular

purpose, statutory warranty of non-infringement and any other warranty that may arise by

CONTENT PAGE

1.

ZMD31020 – USB – EVALUATION BOARD ..............................................3

1.1 ZMD31020 USB EVALUATION BOARD DESCRIPTION ........................................3

1.2 ZMD31020 USB EVALUATION BOARD – SCHEMATICS .....................................3

1.3 ZMD31020 USB EVALUATION BOARD – PCB ................................................4

2. ZMD31030 – USB – EVALUATION BOARD ............................................. 5

2.1 ZMD31030 USB EVALUATION BOARD DESCRIPTION ........................................5

2.2 ZMD31030 USB EVALUATION BOARD – SCHEMATICS .....................................5

2.3 ZMD31030 USB EVALUATION BOARD – PCB ................................................6

3. ZMD31035 – USB – EVALUATION BOARD ..............................................7

3.1 ZMD31035 – EVALUATION BOARD DESCRIPTION..............................................7

3.2 ZMD31035 USB EVALUATION BOARD – SCHEMATICS .....................................7

3.3 ZMD31035 USB EVALUATION BOARD – PCB ................................................8

4. ZMD31035 – USB – EVALUATION BOARD ..............................................9

4.1 ZMD31050 – EVALUATION BOARD DESCRIPTION..............................................9

4.2 ZMD31050 USB EVALUATION BOARD – SCHEMATICS .....................................9

4.3 ZMD31050 USB EVALUATION BOARD – PCB ..............................................10

Copyright © 2005, ZMD AG, Rev. 1.00, 2005-05-23 2/10

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

GND

ZMD31XXX – Evaluation KIT

Datasheet ZMD31XXX Evaluation Board

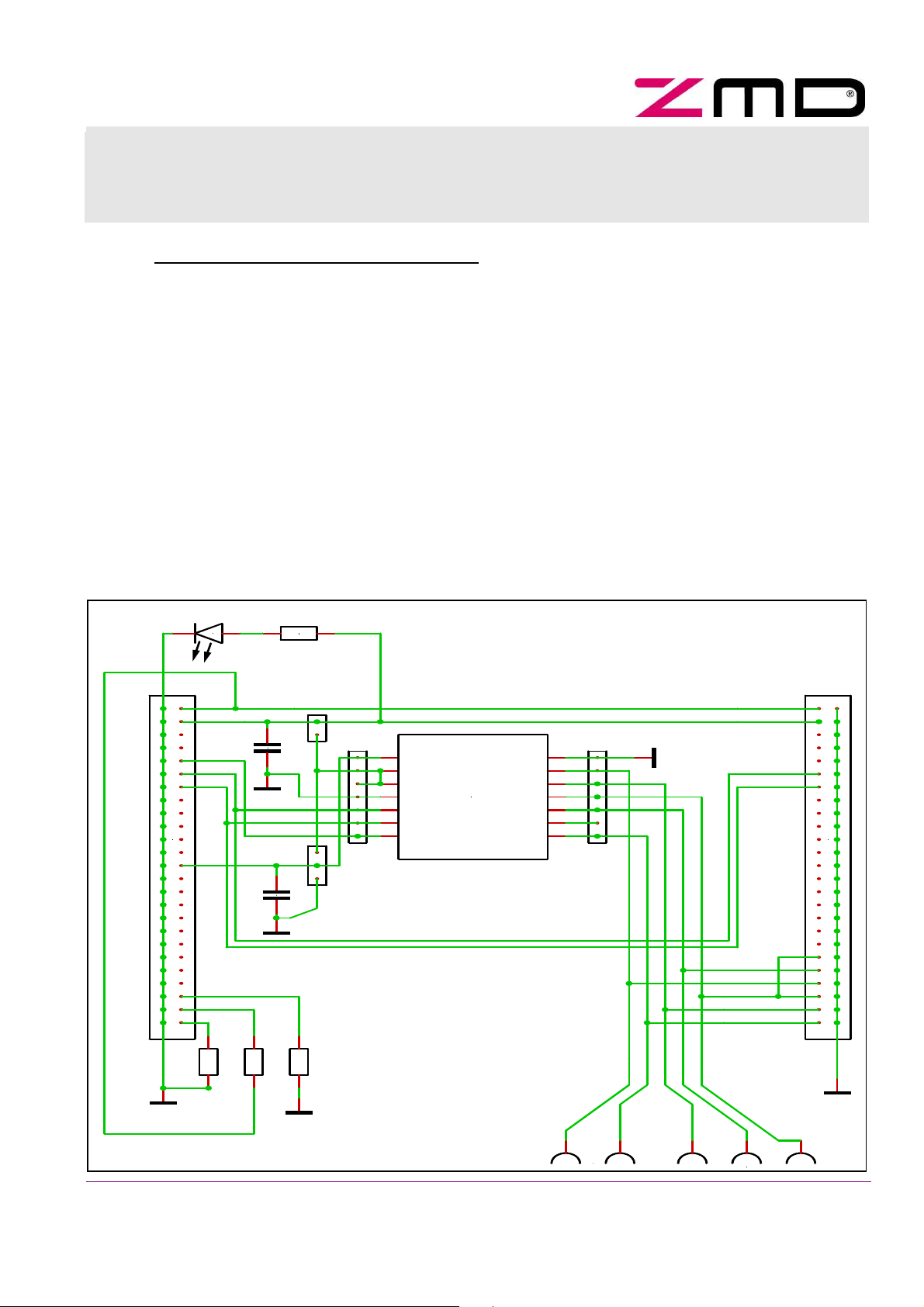

1. ZMD31020 – USB – Evaluation board

1.1 ZMD31020 USB Evaluation board description

The ZMD31020 Evaluation board is supplied by the regulated 5 VDC-power line controlled by the µC

via a relay of the communication board. Additionally, an on-board-jumper allows the manual cut of the

IC-power supply and a simple measurement of the supply current of the ZMD31020. A red LED

displays the power supply status, its forward current is not included in the measured supply current.

2

The I

stimulus values and the configuration of the ZMD31020. The EEPROM programming voltage VPP is

supplied by the communication board too. The analog output voltage VOUT of the ZMD31020 is

connected with µC-input “ADC 0”, thus a direct processing of this analog signal by the µC is possible.

This board is hard-coded by three resistors on (D7=L / D6 = H / D5 = L). It is connected to the

communication board via a 50-pin-connector (female). On-board there are two strips for a simple

access on bridge sensor signals, VOUT and bridge power supply voltage. Via a second 50-pinconnector (male) the sensor replacement board can be connected. Alternatively, an external bridge

sensor element is connectable by the on-board screw terminal.

1.2 ZMD31020 USB Evaluation Board – Schematics

C-communication between µC and ZMD31020 allows both, the digital readout of measured

L-934LD-rt

2 1

D1

R4

1k

KS5V

21

ZMD31020 SENSOR BOARD

K1

2

4 3

6 5

8 7

10 9

12 11

14 13

16 15

18 17

20 19

22 21

24 23

26 25

28 27

30 29

32 31

34 33

36 35

38 37

40 39

42 41

44 43

46 45

48 47

50 49

GND

1

10kR1

VPP

VOUT

D5

D6

D7

2

1

10kR2

C1

GND

VDDA

10nC2

2

1

5P

K5

1

1

2

2

220n

3

2

K4

1

1

2

GND

2

10kR3

1

K6

1

2

3

4

5

6

7

IC1

VOUT

1

VDDA

2

VDD

3

VSS

4

SCL

5

SDA

6

VPP

7

ZMD31020

VSSA

VSSB

VBP

VDDB1

VTN

VDDB2

VBN

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GND

K7

VBN

VBP

VSSB

VTN

VTN

VSSB

VDDB1

VBP

VBN

VDDB1

5P5P

KS5VKS5V

SCLSCL

SDASDA

1

2

43

65

87

109

1211

1413

1615

1817

2019

2221

2423

2625

2827

3029

3231

3433

3635

3837

4039

4241

4443

4645

4847

5049

GND

K2

21

KL2

KL1

321

Copyright © 2005, ZMD AG, Rev. 1.00, 2005-05-23 3/10

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior

written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

Loading...

Loading...