ZMD ASI4U Datasheet

ASI4U

ASIP

ASIN

0V

IRD

FID

OSC1

OSC2

DO3

DO2

DO1

DO0

GND

P3

P2

UIN

UOUT

U5R

CAP

LED1

LED2

DSR

PST

DI3

DI2

DI1

DI0

P0

P1

1µF

10µF

47nF

ASI+

ASI-

8/16 MHz

IR Addressing

nel

Universal Actuator-Sensor Interface IC

Datasheet

Features

Universal application in AS-i Slave, Mas-

•

ter, Repeater and Bus-Monitor components

Support of AS-i Complete Specification

•

V3.0, including all optional features

-

Synchronous Data I/O Mode

4 Input / 4 Output operation in

-

Extended Address Mode

User write protection for

-

Extended ID-Code 1

Multiplexed Parameter Port

-

Special AS-i Safety Mode

•

Floating AS-i Transmitter and Receiver for

•

high symmetrical high power applications

On chip electronic inductor with current

•

drive capability of 55mA

Configurable LED outputs supporting all

•

status indication modes defined by AS-i

Complete Specification V3.0

Several data preprocessing functions, in-

•

cluding configurable data input filters and

bit selective data inverting

Improved additional addressing channel

•

for easy module setup

IR and CMOS input mode

-

Activation by magic sequence

-

Support of 8 / 16 MHz crystals by auto-

•

matic frequency detection

Clock Watchdog for high System Security

•

Pin and function compatible to A²SI

•

Description

ASI4U is a monolithic CMOS integrated circuit

certified for AS-i (Actuator Sensor Interface)

networks. AS-i networks are used for industrial

automation.

AS-i is designed for easy and simple interconnection of binary sensors and actuators. It

uses a two-wire unshielded cable to transport

power and information.

ASI4U is a direct successor of the A²SI IC and

can replace the A²SI.

AS-i Safety applications can use the special

AS-i Safety Mode if fault reaction time is a

concern.

The device is available in SSOP28 package.

Application Support

Configuration of the chip is handled through

programming of the on-chip E²PROM.

ZMD provides a special

AS-Interface Programmer Tool

(Ordering Code: ZMD ASI-Programmer )

to ease product evaluation and selection of

different operation modes.

Further application support is available through

the e-mail hotline asi@zmd.de

BZV55C39

Chan

Copyright © 2006, ZMD AG, Rev. 1.5

All rights reserved. T he material contained herein may not be reprod uced, adapted, merged, translated, stored, or used without the pri or written co nsent of the co pyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

TEMD5000

1/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

Table of Contents

0 READ THIS FIRST ...........................................................................................................................................4

0.1 I

0.2 ASI-S

0.3 R

1 GENERAL DEVICE SPECIFICATION.............................................................................................................5

1.1 A

1.2 O

1.3 Q

1.4 P

2 BASIC FUNCTIONAL DESCRIPTION ............................................................................................................9

2.1 F

2.2 G

2.3 S

2.4 M

2.5 E²PROM ..................................................................................................................................................18

3 DETAILED FUNCTIONAL DESCRIPTION ...................................................................................................21

3.1 AS-I R

3.2 AS-I T

3.3 A

3.4 D

3.5 D

3.6 P

3.7 D

MPORTANT NOTICE

AFETY APPLICATIONS

EPAIR OF

BSOLUTE MAXIMUM RATINGS (NON OPERATING

PERATING CONDITIONS

UALITY STANDARDS

ACKAGE PIN ASSIGNMENT

UNCTIONAL BLOCK DIAGRAM

ENERAL OPERATIONAL MODES

LAVE MODE

2.3.1 AS-i communication channel ...........................................................................................................11

2.3.2 IRD communication channel ............................................................................................................12

2.3.3 Parameter Port Pins.........................................................................................................................12

2.3.4 Data Port Pins ..................................................................................................................................12

2.3.5 Data Input Inversion .........................................................................................................................13

2.3.6 Data Input Filtering...........................................................................................................................13

2.3.7 Fixed Data Output Driving................................................................................................................13

2.3.8 Synchronous Data I/O Mode............................................................................................................13

2.3.9 4 Input / 4 Output processing in Extended Address Mode ..............................................................13

2.3.10 AS-i Safety Mode .............................................................................................................................14

2.3.11 Enhanced LED Status Indication .....................................................................................................14

2.3.12 Communication Monitor/Watchdog ..................................................................................................14

2.3.13 Write protection of ID_Code_Extension_1 .......................................................................................14

2.3.14 Summary of Master Calls.................................................................................................................14

ASTER MODE

DDRESSING CHANNEL INPUT

3.3.1 General Slave Mode Functionality ...................................................................................................22

3.3.2 AC Current Input Mode ....................................................................................................................23

3.3.3 CMOS Input Mode ...........................................................................................................................23

3.3.4 Master-, Repeater- and Monitor-Mode.............................................................................................24

IGITAL INPUTS

IGITAL OUTPUTS

ARAMETER PORT AND

3.6.1 Slave Mode ......................................................................................................................................26

3.6.2 Parameter Multiplex Mode ...............................................................................................................27

3.6.3 Special function of P0, P1 and P2 ...................................................................................................27

3.6.4 Master-, Repeater-, Monitor Mode ...................................................................................................28

ATA PORT AND

3.7.1 Slave Mode ......................................................................................................................................29

3.7.2 Input Data Pre-Processing ...............................................................................................................30

3.7.3 Fixed Output Data Driving................................................................................................................32

3.7.4 Synchronous Data I/O Mode............................................................................................................32

3.7.5 Support of 4I/4O processing in Extended Address Mode, Profile 7.A.x.E .......................................34

3.7.6 Safety Mode Operation ....................................................................................................................34

3.7.7 Master-, Repeater-, Monitor Mode ...................................................................................................38

3.7.8 Special function of DSR ...................................................................................................................38

ASI-S

.............................................................................................................................................11

..........................................................................................................................................17

ECEIVER

RANSMITTER

..........................................................................................................................................21

.....................................................................................................................................4

.........................................................................................................................4

AFETY MODULES

.............................................................................................................................6

..................................................................................................................................6

..........................................................................................................................7

....................................................................................................................................21

- DC C

HARACTERISTICS

- DC C

DSR PIN.........................................................................................................................29

HARACTERISTICS

PST PIN................................................................................................................26

...............................................................................................................4

) ........................................................................................5

......................................................................................................................9

................................................................................................................11

IRD .............................................................................................................22

....................................................................................................25

................................................................................................25

Page

Copyright © 2006, ZMD AG, Rev.1.5

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

2/57

Datasheet

3.8 F

3.9 LED

3.10

3.11

3.12

3.13

3.14

3.15

3.16

3.17

3.18

4 APPLICATION CIRCUITS .............................................................................................................................51

5 PACKAGE OUTLINE.....................................................................................................................................54

6 PACKAGE MARKING ...................................................................................................................................55

7 ORDERING INFORMATION..........................................................................................................................55

8 RELATED DOCUMENTS ..............................................................................................................................56

9 RELATED PRODUCTS .................................................................................................................................56

10 CONTACT INFORMATION ........................................................................................................................56

10.1

10.2

10.3

10.4

AULT INDICATION INPUT PIN

3.8.1 Slave Mode ......................................................................................................................................39

3.8.2 Master- and Monitor Mode ...............................................................................................................39

3.9.1 Slave Mode ......................................................................................................................................40

3.9.2 Communication via Addressing Channel.........................................................................................41

3.9.3 Master-, Repeater-, Monitor Mode...................................................................................................41

O

IC R

3.11.1 Power On Reset...............................................................................................................................42

3.11.2 Logic controlled Reset .....................................................................................................................43

3.11.3 External Reset .................................................................................................................................43

UART ...................................................................................................................................................44

3.12.1 AS- i input channel ...........................................................................................................................44

3.12.2 Addressing Channel.........................................................................................................................46

M

C

T

W

P

3.17.1 Voltage Output Pins UOUT and U5R ..............................................................................................49

3.17.2 Input Impedance (AS-i bus load) .....................................................................................................50

T

ZMD S

ZMD AS-I

AS-I

ZMD D

OUTPUTS

SCILLATOR PINS

ESET

AIN STATE MACHINE

OMMUNICATION MONITOR/WATCHDOG

OGGLE WATCHDOG FOR

RITE PROTECTION OF

OWER SUPPLY

HERMAL AND OVERLOAD PROTECTION

NTERNATIONAL ASSOCIATION

...........................................................................................................................................40

..............................................................................................................................................42

.....................................................................................................................................49

ALES

..........................................................................................................................................56

NTERFACE APPLICATION SUPPORT

ISTRIBUTION PARTNERS

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

FID...............................................................................................................39

OSC1, OSC2 ...........................................................................................................41

............................................................................................................................47

.................................................................................................47

4I/4O

PROCESSING IN EXTENDED ADDRESS MODE

ID_C

ODE_EXTENSION

..........................................................................................................56

..............................................................................................................57

_1 ...................................................................................47

..................................................................................................50

..........................................................................................56

...........................................47

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adap ted, merged, translated, stored, or used without the prior written consent of the copyright owner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

3/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

0 Read this First

0.1 Important Notice

Products sold by ZMD are covered exclusively by the warranty, patent indemnification and other provisions appearing in ZMD standard "Terms of Sale". ZMD makes no warranty (express, statutory, implied and/or by description), including without limitation any warranties of merchantability and/or fitness for a particular purpose,

regarding the information set forth in the Materials pertaining to ZMD products, or regarding the freedom of any

products described in the Materials from patent and/or other infringement. ZMD reserves the right to discontinue

production and change specifications and prices of its products at any time and without notice. ZMD products

are intended for use in commercial applications. Applications requiring extended temperature range, unusual

environmental requirements, or high reliability applications, such as military, medical life-support or lifesustaining equipment, are specifically not recommended without additional mutually agreed upon processing by

ZMD for such applications.

ZMD reserves the right to change the detail specifications as may be required to permit improvements in the

design of its products.

0.2 ASI-Safety Applications

SAFETY-ADVICE

The ASI4U is designed to allow replacement of A²SI ICs in existing board layouts and applications. However,

since the ASI4U provides additional data preprocessing functions at the data input channel, the fault reaction

time of an AS-i Safety module could increase by 40ms if some of the new features become activated by intention, by accident or hardware fault.

ZMD strongly recommends the use of the new ASI4U Safety-Mode, if the ASI4U shall replace the A²SI in existing ASI-Safety designs. Only then, the same fault reaction times as with the A²SI are guaranteed. For compatibility with the modified data input routing in Safety Mode, the user has to adapt the safety code table stored in

the external micro controller. Only such Safety Code Sequences that contain the value 1110 are permitted.

If the IC is operated in Safety Mode, the user must pay special attention that the Synchronous Data I/O Mode as

well as the Data Input Filters remain disabled by appropriate E²PROM configuration.

Application of the ASI4U in Standard Mode (no Safety Mode enabled) for AS-i Safety products is basically possible, if an additional Fault Reaction Time of 40ms is taken into account.

The user shall also obey the additional security advice regarding “Production and Repair of AS-i Safety Slaves”

that is available as an additional document form the ZMD web page www.zmd.biz .

0.3 Repair of ASI-Safety Modules

If an A²SI based ASI-Safety Module shall be repaired, it is explicitly prohibited to replace the A²SI IC with the

newer ASI4U IC. This is to exclude safety relevant deviations of module properties that can result from the different data input paths an the above mentioned possible increase in Fault Reaction Time.

The user shall also obey the additional security advice regarding “Production and Repair of AS-i Safety Slaves”

that is available as an additional document form the ZMD web page www.zmd.biz .

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

4/57

Figure

1

: Ptot = f(

θ

)

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

1 General Device Specification

1.1 Absolute Maximum Ratings (Non Operating)

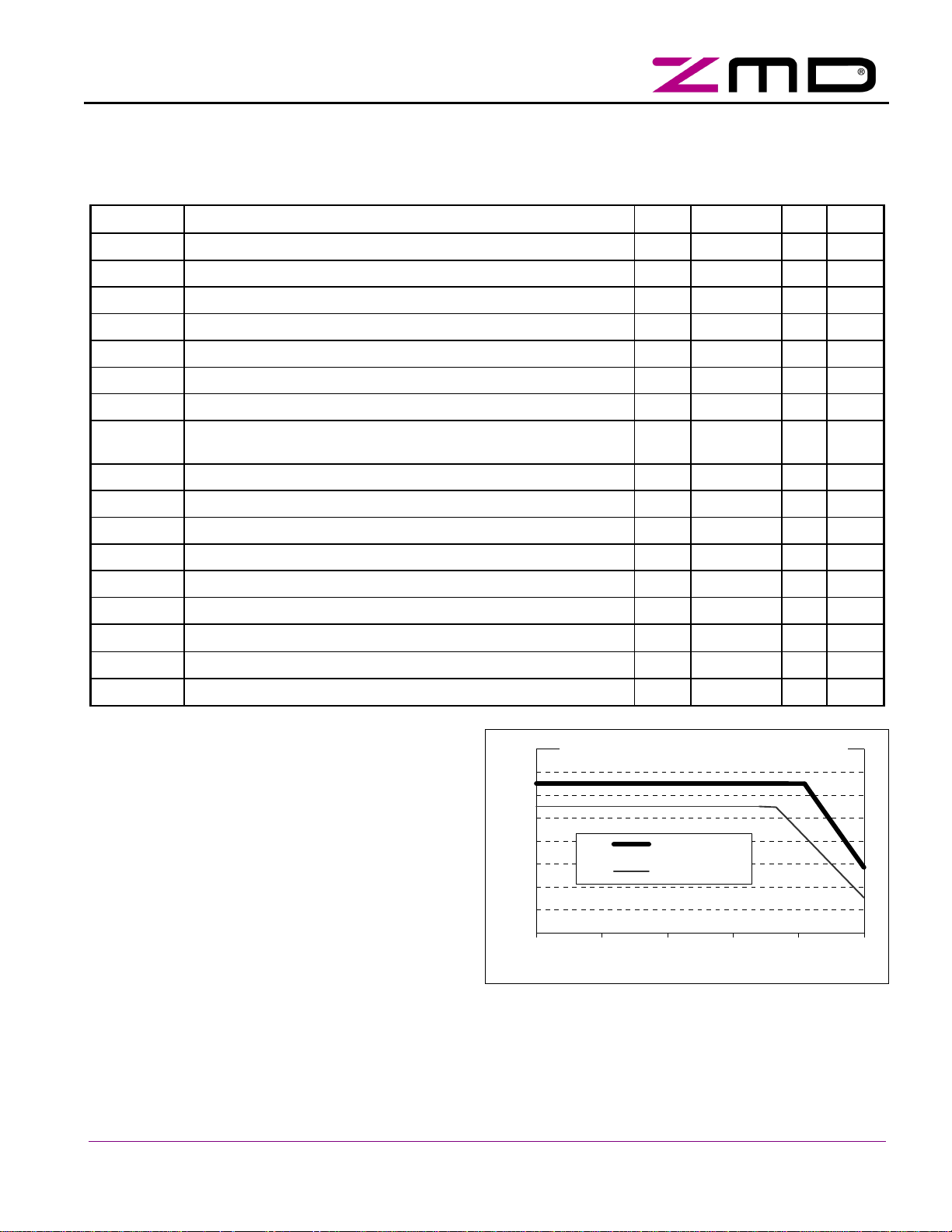

Table 1: Absolute Maximum Ratings

Symbol Parameter Min Max Unit Note

V0V, V

V

ASIP-ASIN

V

ASIP-ASIN_P

V

ASIP

V

ASIN

V

UIN

V

UIN_P

V

inputs1

V

inputs2

Iin Input current into any pin except supply pins -50 50 mA

H Humidity non-condensing

V

HBM1

V

HBM2

V

EDM

θ

STG

P

tot

R

thj

Voltage reference 0 0 V

GND

Voltage difference between ASIP and ASIN (V

Pulse voltage between ASIP and ASIN (V

Pulse voltage between ASIP and 0V (V

Voltage between ASIN and 0V (V

– V0V) -6.0 6.0 V

ASIN

ASIP

– V0V) -0.3 50 V

ASIP

ASIP

- V

- V

ASIN

) -0.3 40 V

ASIN

) -0.3 50 V

Power supply input voltage -0.3 40 V

Pulse voltage at power supply input -0.3 50 V

Voltage at pins DI3 ... DI0, DO3 ... DO0, P3 ... P0, DSR, PST,

-0.3 V

+ 0.3 V

UOUT

LED1, LED2, FID, IRD, UOUT

Voltage at pins OSC1, OSC2, CAP, U5R -0.3 7 V

Electrostatic discharge – Human Body Model (HBM1) 3500 V

Electrostatic discharge – Human Body Model (HBM2) 2000 V

Electrostatic discharge – Equipment Discharge Model (EDM) 400 V

Storage temperature -55 125 °C

Total power dissipation 0.85 W

Thermal resistance of SSOP 28 package 40 80 K/W

1

2

2, 3

3

2

4

5

6

7

8

9

10

1

reverse polarity protection has to be performed

externally

2

pulse with ≤ 50µs, repetition rate ≤ 0.5 Hz

3

V

ASIP-ASIN

4

Latch-up resistance, reference pin is 0V

5

Level 4 according to JEDEC-020A is guaranteed

6

HBM1: C = 100pF charged to V

and V

ASIP-ASIN_P

must not be violated

with resistor

HBM1

R = 1.5kΩ in series, valid for ASIP-ASIN only.

7

HBM2: C = 100pF charged to V

with resistor

HBM2

R = 1.5kΩ in series, valid for all pins except ASIP-

ASIN

8

EDM: C = 200pF charged to V

with no resistor

EDM

in series, valid for ASIP-ASIN only

9

at max. operating temperature, the allowed total

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

P

= f (Ta); 1L / 2L = 1 layer / 2 layer PCB

tot

Ptot (2L)

Ptot (1L)

-25 0 25 50 75 100

Ta

power dissipation depends on additional thermal

resistance from package to ambient and on the operation ambient temperature as shown in Figure 1.

10

Single layer board, P

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adap ted, merged, translated, stored, or used without the prior written consent of the copyright owner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

= 0.5W; air velocity = 0m/s ⇒ max. value; air velocity = 2.5m/s ⇒ min. value

tot

5/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

1.2 Operating Conditions

Table 2: Operating Conditions

Symbol Parameter Min Max. Unit Note

V

Positive supply voltage for IC operation 16 33.1 V

UIN

V0V, V

V

ASIP

V

ASIN

I

UIN

I

CL1

I

CL2

θ

amb

1

DC-Parameter: V

V

Below V

Negative supply voltage 0 0 V

GND

DC voltage at ASIP relating to V0V 16 33.1 V

DC voltage at ASIN relating to V0V -4 4 V

Operating current at V

= 30V 6 mA

UIN

Max. output sink current at pins DO3...DO0, DSR 10 mA

Max. output sink current at pins P0...P3, PST 10 mA

Ambient temperature range, operating range -25 85 °C

= V

UINmin

= V

UINmax

the power supply block may not be able to provide the specified output currents at

UINmin

UOUTmin

UOUTmax

+ V

+ V

DROPmax

DROPmin

UOUT and U5R.

2

Outside of these limits the send current shape and send current amplitude cannot be guaranteed.

3

fc = 8.000 MHz, no load at any pin, transmitter turned off, digital state machine is in idle state

Table 3: Crystal Frequency

1

2

2

3

Symbol Parameter Nom. Unit Note

fc Crystal frequency 8.000/16.000 MHz

4

The IC automatically detects whether the crystal frequency is 8.000MHz or 16.000MHz and controls the

4

internal clock circuit accordingly. The frequency detection is locked as soon as one AS-i telegram was

correctly received at any input channel. It can be reset by Power On Reset only.

Note: In Slave Mode the locking occurs if a Master Call was received. In Master-/ Repeater-/Monitor

Mode a Master Call or a Slave Response that was received on any input channel, triggers the frequency

locking.

The ASI4U supports an integrated clock watchdog. If no crystal or clock oscillation is recognized for 150µs the

IC generates a RESET event until clock oscillation is available.

More detailed oscillator pin definitions can be found in chapter 3.10 on page 41.

1.3 Quality Standards

The quality of the IC will be ensured according to the ZMD quality standards. Functional device parameters are

valid for device operating conditions specified in chapter 1.2. Production device tests are performed within the

recommended ranges of V

otherwise stated.

ASIP

- V

, VIN - V0V, θamb = + 25°C (+ 85°C and - 25°C on sample base only) unless

ASIN

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

6/57

i Transmitter/Receiver input, to be connected to

d to

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

1.4 Package Pin Assignment

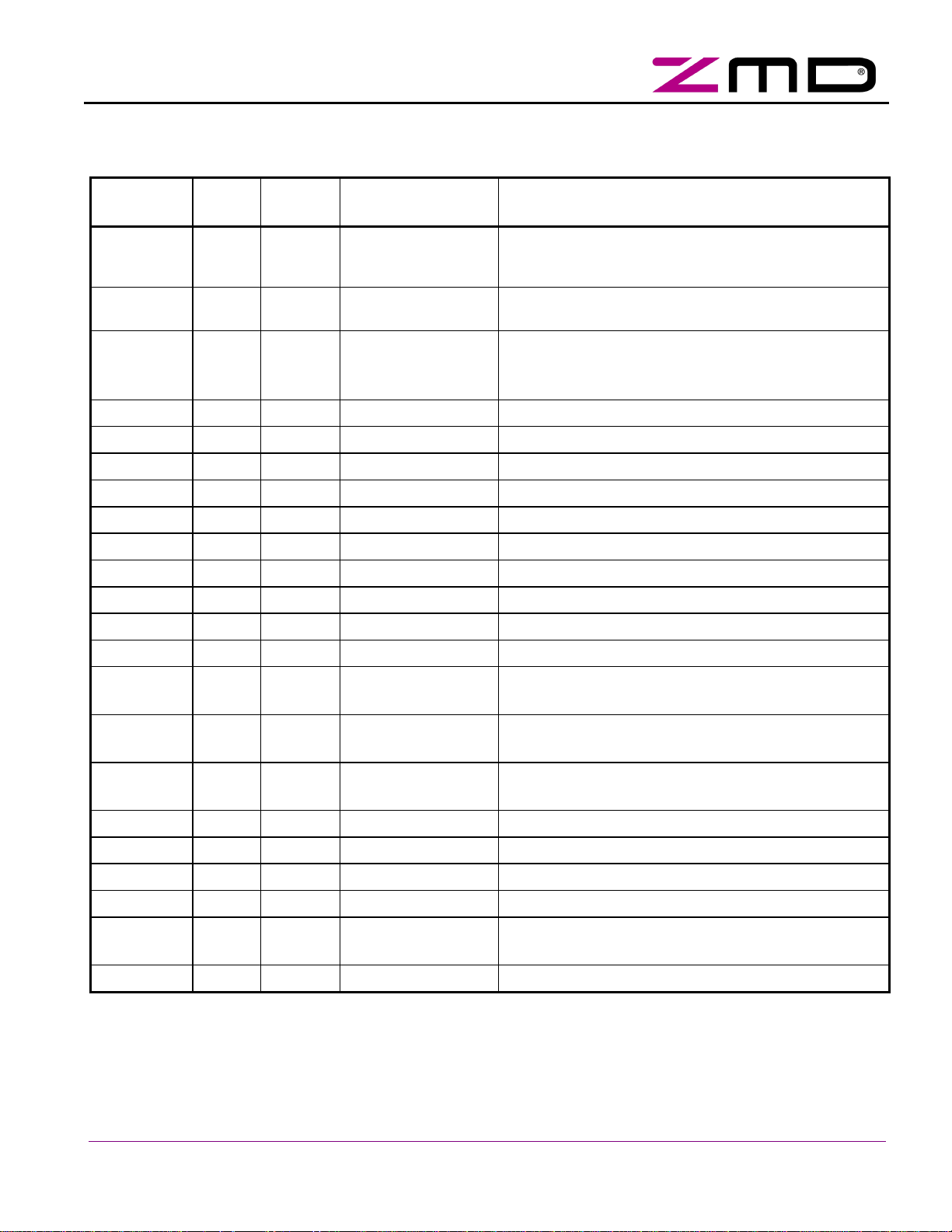

Table 4: ASI4U Pin List

“ASI for you” IC

Package

Name Direction Type Description

pin number

1 ASIP IN Analog AS-

ASI+ lead of AS-i cable, via reverse polarity protection diode

2 ASIN OUT Analog AS-i Transmitter/Receiver output, to be connecte

ASI- lead of AS-i cable

3 0V SUPPLY IC Ground

Common ground for all IC ports except ASIP/ASIN,

To be connected to ASIN if no external coils are used

4 IRD IN Analog / CMOS (5V) Addressing Channel input

5 FID IN Pull-up Periphery Fault input

6 OSC2 OUT Analog (5V) Crystal oscillator

7 OSC1 IN Analog / CMOS (5V) Crystal oscillator / External clock input

8 DO3 OUT Open Drain Data port output D3

9 DO2 OUT Open Drain Data port output D2

10 DO1 OUT Open Drain Data port output D1

11 DO0 OUT Open Drain Data port output D0

12 GND SUPPLY Digital I/O ground, to be connected with 0V

13 P3 I/O Pull-up/Open Drain Parameter port P3

14 P2 I/O Pull-up/Open Drain Parameter port P2 /

Receive Strobe output in Master Mode

15 P1 I/O Pull-up/Open Drain Parameter port P1 /

Power Fail output in Master Mode

16 P0 I/O Pull-up/Open Drain Parameter port P0 /

Data Clock output in Master Mode

17 DI0 IN Pull-up Data port input D0

18 DI1 IN Pull-up Data port input D1

19 DI2 IN Pull-up Data port input D2

20 DI3 IN Pull-up Data port input D3

21 PST I/O Pull-up/Open Drain Parameter Strobe output

(input function used for IC test purposes only)

22 DSR I/O Pull-up/Open Drain Data Strobe output / Reset input

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adap ted, merged, translated, stored, or used without the prior written consent of the copyright owner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

7/57

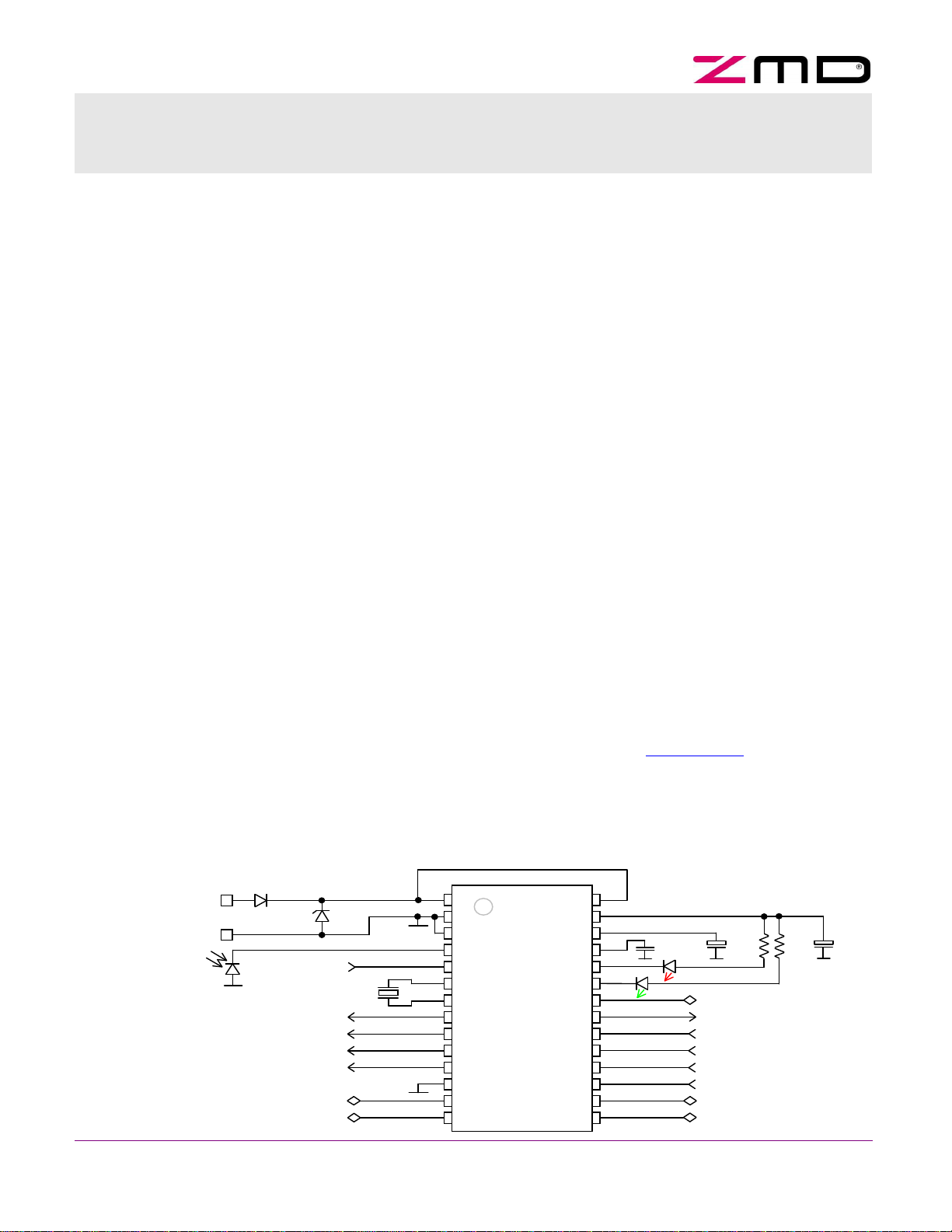

LED output "Enhanced Diagnosis", to be activated by

bit in the Firmware region of the

ASIP

ASIN

0V

IRD

FID

OSC2

OSC1

O3

DO2

DO1

DO0

GND

P3

P2

UOUT

LED2

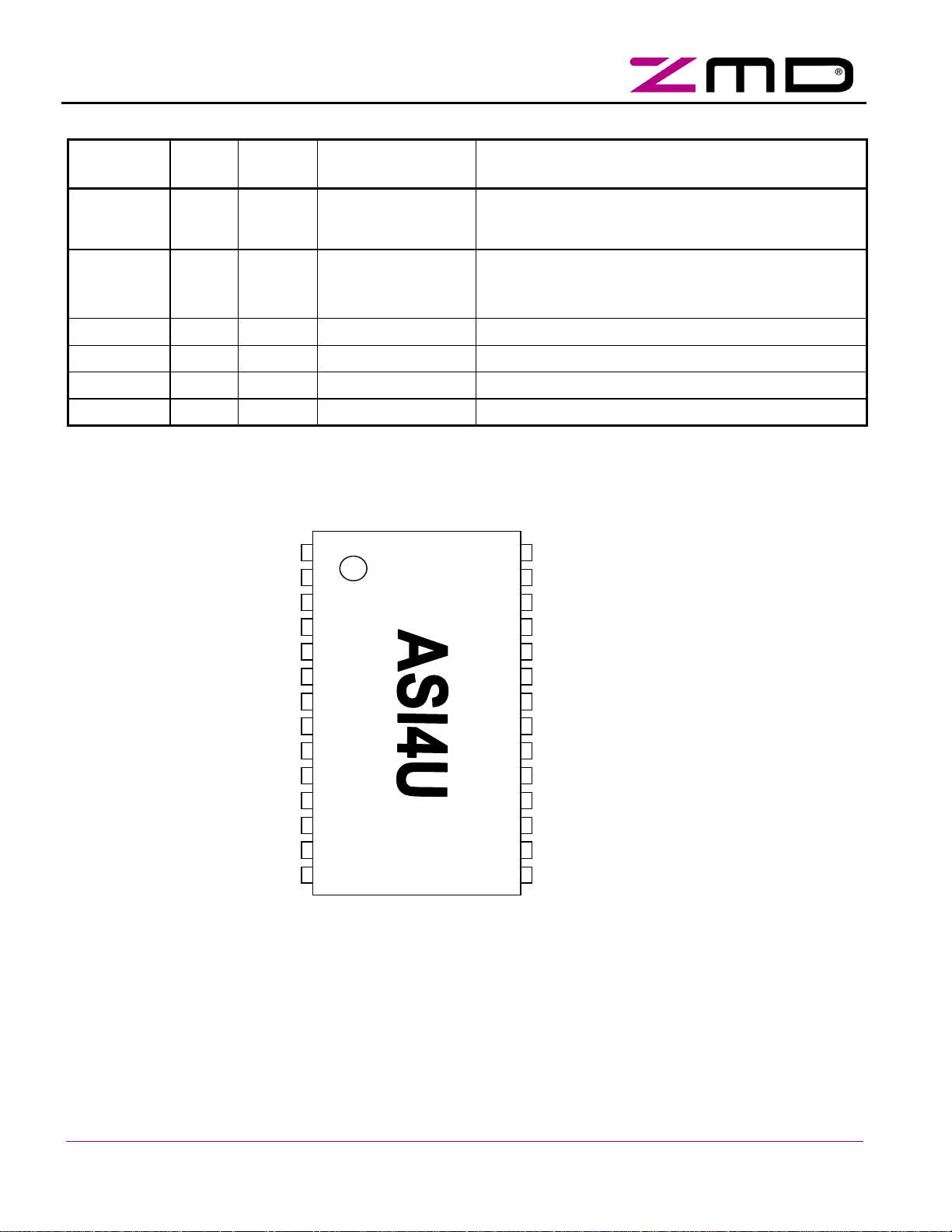

Figure

2

:

Package Pin Assignment

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

Package

Name Direction Type Description

pin number

23 LED2 OUT Open Drain

LED2_Active

E²PROM

24 LED1 I/O Pull-up/Open Drain LED output "AS-i-Diagnosis" /

Addressing channel output

(input function used for IC test purposes only)

25 CAP I/O Analog Filter control (Electronic Inductor)

26 U5R OUT Analog Regulated internal/external 5V supply

27 UOUT OUT Analog Decoupled Actuator/Sensor supply

28 UIN SUPPLY Power supply input

All open drain outputs are NMOS based. Pull-up properties at input stages are achieved by current sources

referring to U5R.

UIN

U5R

CAP

LED1

D

ASI4U

DSR

PST

DI3

DI2

DI1

DI0

P0

P1

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

8/57

POWER

SUPPLY

OSCILLATOR

AGND

OUTPUT

STAGE

INPUT

STAGE

I/O

STAGE

OUTPUT

STAGE

INPUT

STAGE

OUTPUT

STAGE

AC

FAULT_IN

ELECTRONIC

INDUCTOR

ANA DIG

FID LED2

LED1

IRD GND 0V

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

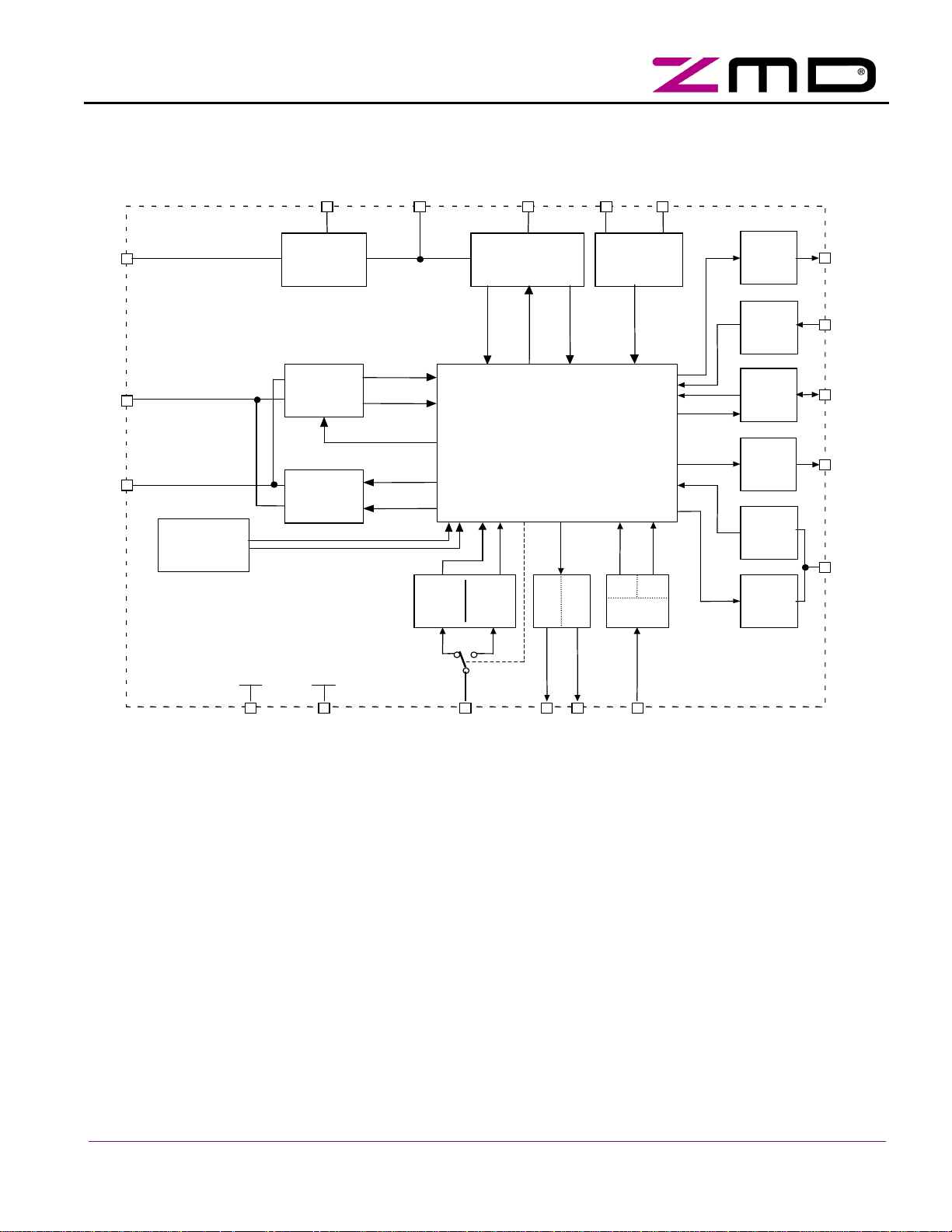

2 Basic Functional Description

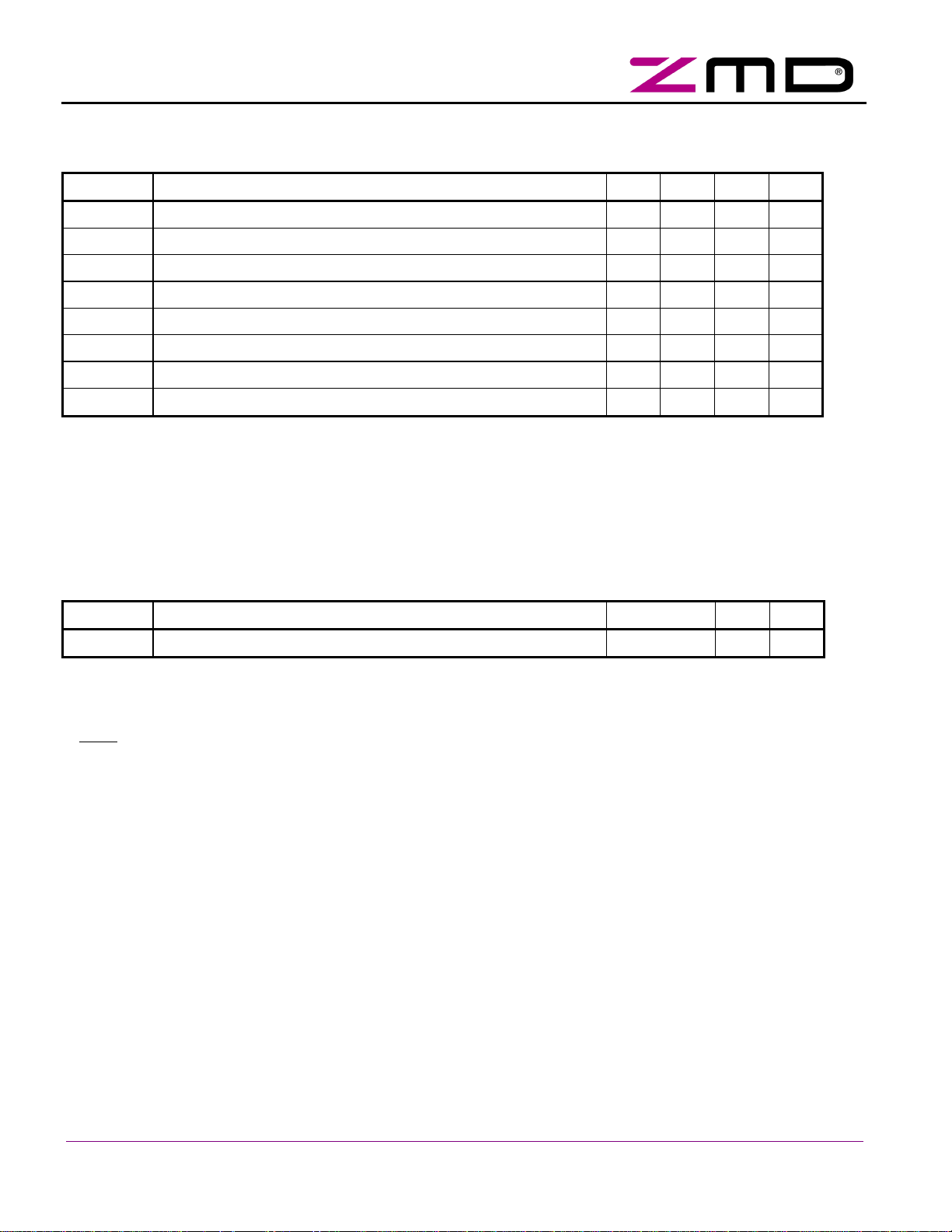

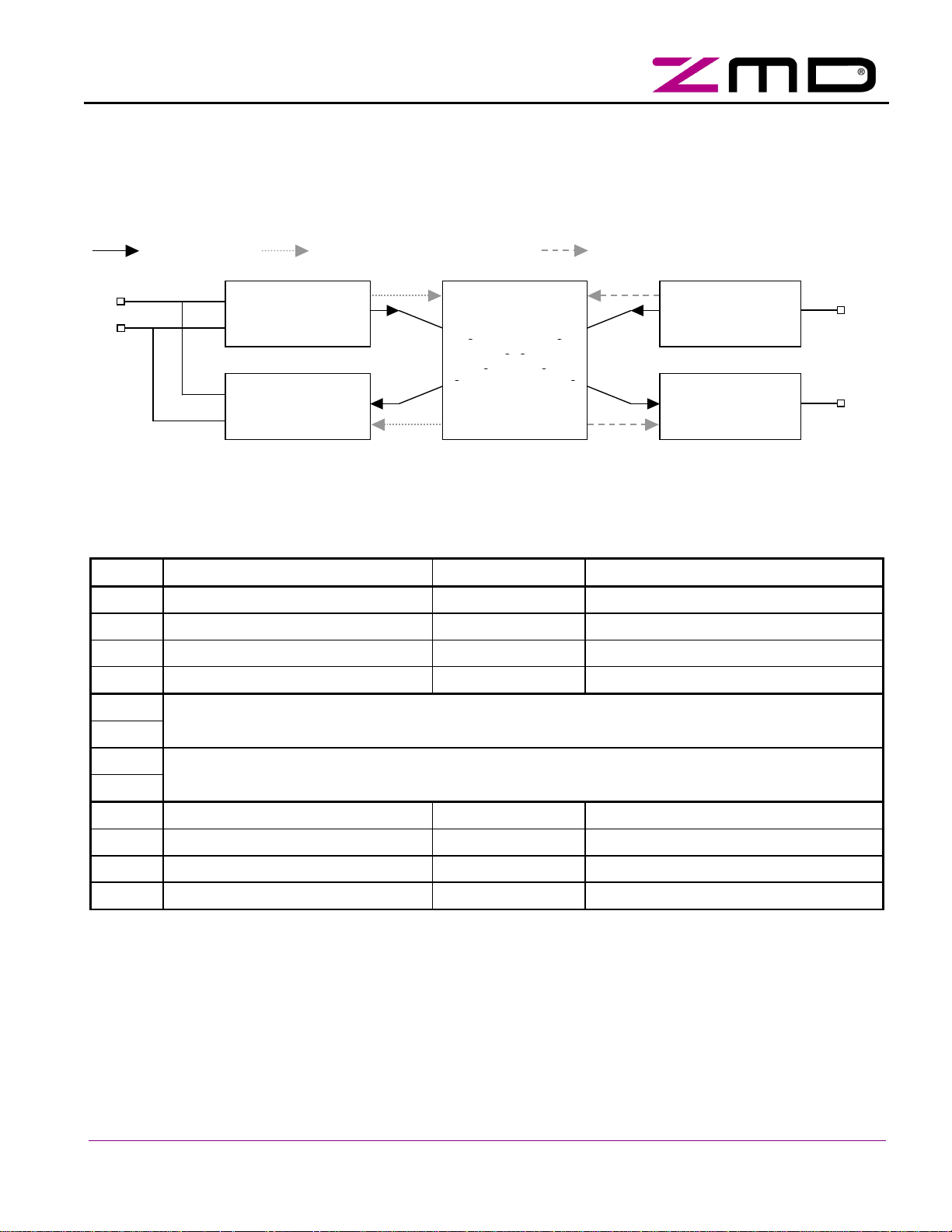

2.1 Functional Block Diagram

U

IN

U

OUT

U5R

OSC1/2

CAP

ASI4U

DO(3:0)

ASIP

ASIN

THERMAL /

OVERLOAD

PROTECTION

RECEIVE

TRANSMIT

P-PULSE

N-PULSE

REC-RESET

SEND-D

SEND-SBY

OVER-LOAD

OVER-HEAT

CMOS

INPUT

STAGE

-ON

RESET

DIGITAL

IRD_IN

Current

INPUT

U5RD

-DOWN

OUT

LOGIC

LED

OUTPUT

STAGE

DATA-OUT

RESET

DATA-STRB

-IN

DI(3:0)

DSR

OUT

INPUT

STAGE

PARAM

STRB

PST

PARAM

P(3:0)

LGND

Figure 3: Functional Block Diagram

Following device functions are associated with the different blocks of the IC:

RECEIVE

The receive block converts the analog telegram waveform from the AS-i bus to a digital

pulse coded signal that can be processed further by a digital UART circuit.

The RECEIVE block is directly connected to the AS-i line pins ASIP and ASIN. It converts

the differential AS-i telegram to a single ended signal and removes the DC offset by high

pass filtering. To adapt quickly on changing signal amplitudes in telegrams from different

network users, the amplitude of the first telegram pulse is measured by a 3 bit flash ADC

and the threshold of a positive and a negative comparator is set accordingly to about 50% of

the measured level. The comparators generate the P-Pulse and N-Pulse signals.

TRANSMIT

The transmit block transforms a digital response signal to a correctly shaped send current

signal which is applied to the AS-i bus. Due to the inductive network behavior of the network

the changing send current induces voltage pulses on the network line that overlay the DC

operating voltage. The voltage pulses shall have sin²-wave shapes. Hence, the send current

shape must follow the integral of the sin²-wave function.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adap ted, merged, translated, stored, or used without the prior written consent of the copyright owner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

9/57

Datasheet

DIGITAL LOGIC

ELECTRONIC

INDUCTOR

POWER

SUPPLY

OSCILLATOR

THERMAL /

OVERLOAD

PROTECTION

IRD CMOS /

AC CURRENT

INPUT

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

The digital logic block contains UART, Main State Machine, E²PROM memory and other

control logic. E²PROM write access and other I/O operations of the Main State Machine are

supported in Slave Mode only (see description of general IC operational modes below). In

Master Mode the IC is basically equivalent to a physical layer transceiver.

If Slave Mode is activated, the UART demodulates the received telegrams, verifies telegram

syntax and timing and controls a register interface to the Main State Machine. After reception of a correct telegram, the UART generates appropriate Receive Strobe signals, that tell

the Main State Machine to start further processing. The Main State Machine decodes the

telegram information and starts respective I/O processes or E²PROM access. A second

register interface is used to send data back to the UART for construction of a telegram response. The UART modulates the response data into a Manchester-II-coded bit stream that

is used to control the TRANSMIT unit.

The electronic inductor is basically a gyrator circuit. It provides an inductive behavior between the IC pins UIN and UOUT while the inductance is controlled by the capacitor on pin

CAP. The inductor shall decouple the power regulator of the IC as well as the external load

circuit from the AS-i bus and hence prevent cross talk or switching noise from disturbing the

telegram communication on the bus.

The AS-i Complete Specification describes the input impedance behavior of a slave module

by an equivalent circuit that consists of R, L and C in parallel. For example, a slave module

in Extended Address Mode shall have R > 13.5 kOhm, L > 13.5 mH and C < 50pF. The

electronic inductor of the ASI4U delivers values that are well within the required ranges for

output currents up to 55mA. More detailed parameters can be found in chapter 3.17.2.

The electronic inductor requires an external capacitor of 10µF at pin UOUT for stability.

The power supply block consists of a bandgap referenced 5V-regulator as well as other

reverence voltage and bias current generators for internal use. The 5V regulator requires an

external capacitor at pin U5R of at least 1µF for stability. It can source up to 4mA for external use, however the power dissipation and the resulting device heating become a major

concern, if too much current is drawn from the regulator.

The oscillator supports direct connection of 8.000 MHz or 16.000 MHz crystals with a dedicated load capacity of 12pF and parasitic pin capacities of up to 8pF. The IC automatically

detects the oscillation frequency of the connected crystal and controls the internal clock

generator circuit accordingly.

After power-on reset the IC is set to 16.000 MHz operation by default. After about 200µs it

will either switch to 8.000 MHz operation or remain in the 16.000 MHz mode. The frequency

detection is active until the first AS-i telegram was successfully received in order to make

sure the IC found the correct clock frequency setting. The detection result is locked thereafter to increase resistance against burst or other interferences.

The oscillator unit also contains a clock watch dog circuit that can generate an unconditioned IC reset if there was no clock oscillation for more than about 20µs. This is to prevent

the IC from unpredicted behavior if no clock signal is available anymore.

The IC is self protected against thermal overheating and short circuiting of pin UOUT towards IC ground.

If the silicon die temperature rises above around 140°C for more than 2 seconds, the IC

detects thermal overheating, switches off the electronic inductor, performs an IC reset and

sets all analog blocks to power down mode. The 5V-regulator is of course also turned off in

this state, however, there will still remain a voltage of about 3 … 3.5V available at U5R that

is derived from the internal start circuitry. The overheat protection state can only be left by

power-cycling the AS-i voltage.

Shortcutting pin UOUT towards IC ground leads to the same IC behavior as thermal overheating.

The IRD pin is input for the additional addressing channel in Slave Mode (see description of

General IC Operational Modes below) or direct AS-i transmitter input in Master Mode. In

Slave Mode it can be operated either in CMOS Mode or AC-current input mode. The later is

provided for direct connection of a photo diode. More detailed information can be found in

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

10/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

chapter 3.3 Addressing Channel Input IRD.

FID DIGITAL /

ANALOG

STAGE

INPUT STAGE

Pin FID can be set to digital CMOS mode or analog voltage input mode. In Slave Mode it is

set to CMOS operation, in Master Mode it works in analog mode and acts as input for the

power fail comparator.

All digital inputs, except of the oscillator pins, have high voltage capabilities and partly

Schmitt-Trigger and Pull-Up features. For more details see chapter 3.4 Digital Inputs - DC

Characteristics.

OUTPUT

STAGE

All digital output stages, except of the oscillator pins, have high voltage capabilities and are

implemented as NMOS open drain buffers. Each pin can sink up to 10mA of current.

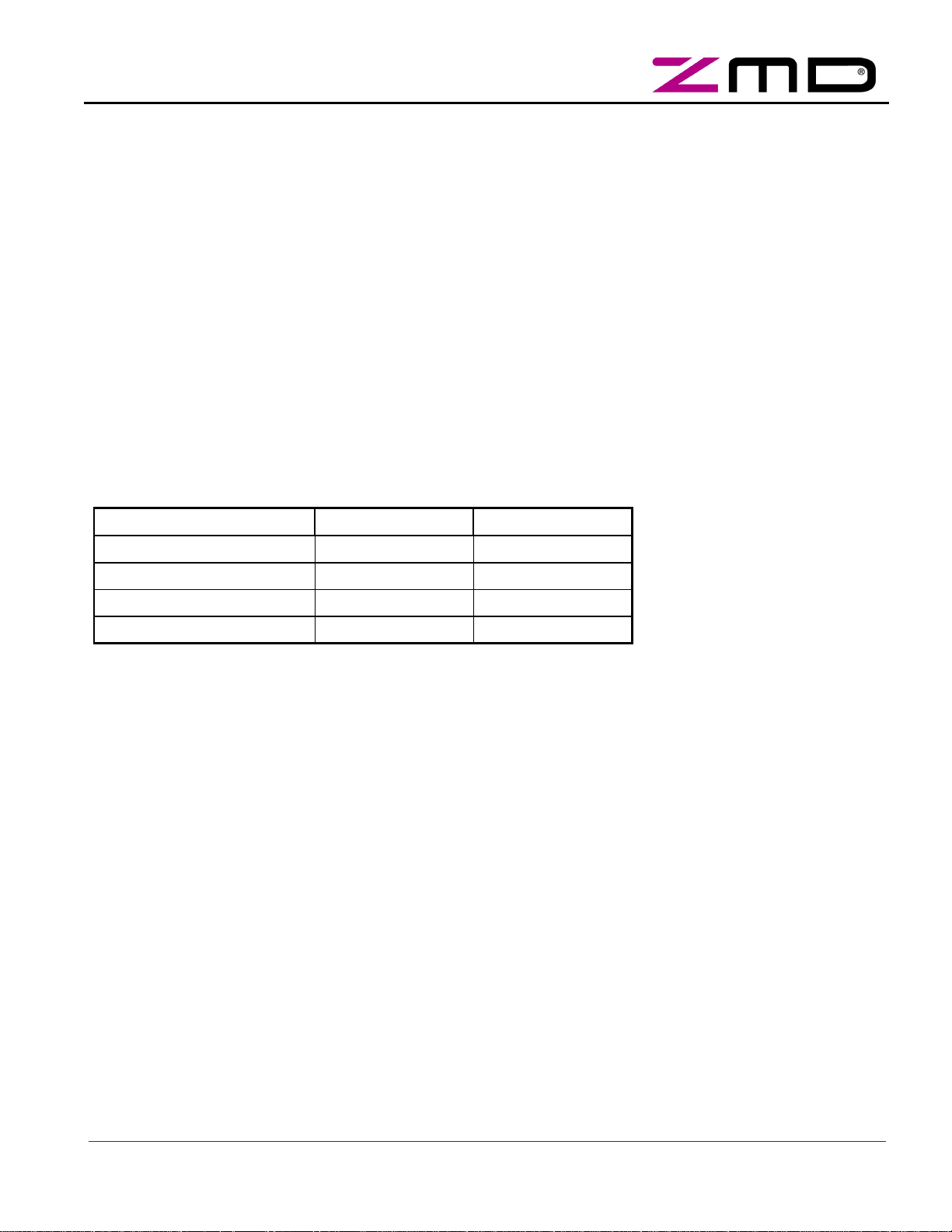

2.2 General Operational Modes

The ASI4U provides two main and two additional sub operational modes. Main operation modes divide in

Slave Mode and Master Mode. Sub operation modes divide in Repeater Mode and Monitor Mode. The later

were derived from Master Mode in providing different output signals at the Parameter Port.

A definition of which operational mode becomes active is made by programming the flags Master_Mode and

Repeater_Mode in the Firmware Area of the E²PROM (see also Table 7 on page 18). The E²PROM is read out

at every initialization of the IC. Online mode switching is not provided. The following configurations apply:

Table 5: Assignment of operational modes

Selected Operational Mode Master Mode Flag Repeater Mode Flag

Slave Mode 0 0

Master Mode 1 0

Repeater Mode 1 1

Monitor Mode 0 1

In Slave Mode the ASI4U operates as fully featured AS-i Slave IC according to AS-i Complete Specification

v3.0.

In Master Mode the ASI4U translates a digital output signal from the master control logic (etc. PLC, µP, …) to a

correctly shaped, analog AS-i pulse sequence and vice versa. Every AS-i telegram received is checked for consistency with the AS-i communication protocol specifications and if no errors were found, an appropriate receive

strobe signal is generated.

Master Mode and Monitor Mode differ in the kind of signaled telegrams. In Master Mode a single Receive

Strobe signal is provided validating every correctly received Slave Response while in Monitor Mode two different

Receive Strobe signals are available displaying every correctly received Master and Slave telegram separately.

The Monitor Mode is intended for use in intelligent slaves and bus monitors that provide own telegram decoding

mechanisms but do not check for correct telegram timing or syntax.

The Repeater Mode is specifically provided for AS-i bus repeater applications.

2.3 Slave Mode

The Slave Mode is probably the most complex operational mode of the IC. The ASI4U does not only support all

mandatory AS-i Slave functions but also a variety of additional features that shall make AS-i Slave module design very easy and flexible.

2.3.1 AS-i communication channel

In slave mode the ASI4U can work on two different communication channels, the AS-i channel and the IRD

channel. The AS-i channel is directly connected to AS-i Bus via the pins ASIP and ASIN. A receiver and a

transmitter unit are connected in parallel to the pins that allow fully bi-directional communication through ASIP

and ASIN.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adap ted, merged, translated, stored, or used without the prior written consent of the copyright owner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

11/57

ASI+

ASI

-

i IC

ASI+

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

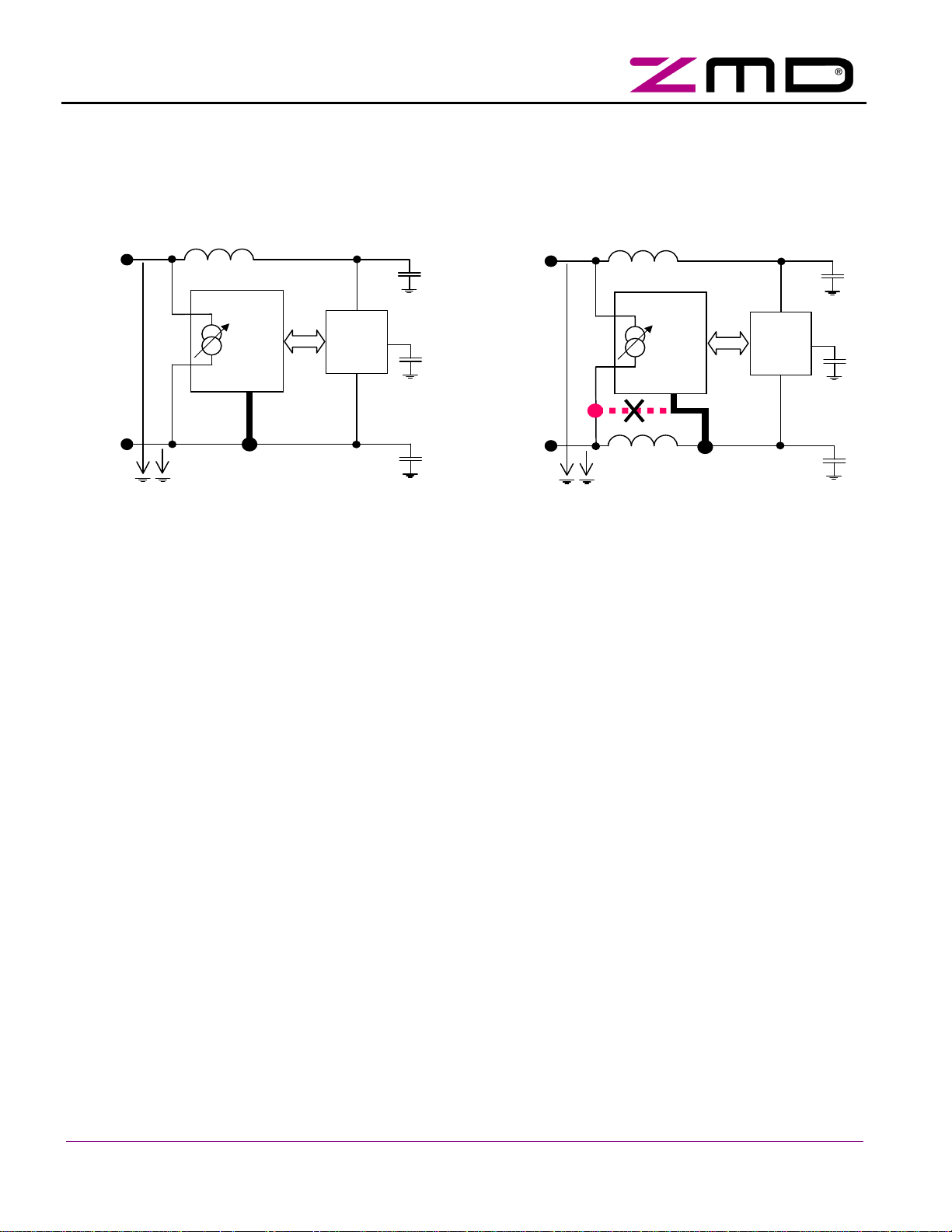

The ASI4U is the first IC that supports floating operation of the AS-i receiver and transmitter (within certain limits) in relation to IC ground. Thus far, the ASIN pin always had to be on the same potential like IC ground, preventing full symmetrical input circuits with external coils. The following figures illustrate the new functionality. If

one compares the relation Z1 / Z2, which is a measure for symmetry of the AS-i module input towards machine

ground, it becomes obvious that the new circuit is more symmetrical since Z1 and Z2 are more equal than in the

conventional solution. Please note, that this is not a complete application circuit.

Z1

AS-i

Slave

IC

Load

Z1

AS-i

Slave

IC

Load

GND

GND

Z2

ASI-

Z2

Figure 5: Conventional application of AS-i IC

with one external coil

Figure 4: Newly supported application of AS-

with two external coils

2.3.2 IRD communication channel

Besides the AS-i communication channel the ASI4U can also operate on a second input channel, the so called

IRD Input Channel or Addressing Channel. In this mode the IRD pin is input for an AS-i signal in Manchester-IIcoded format. The signal can either be an AC-current signal generated by a photo diode or a 5V-CMOS signal.

The IC automatically detects the type of the signal and switches the input path accordingly.

Output pin in IRD communication mode is LED1. It transmits the slave response as inverted Manchester-IIcoded AS-i signal. The red LED, which is normally connected to LED1, can form the response transmitter in an

optical communication system or LED1 can be directly connected to some external circuitry.

Activation of the IRD communication channel is achieved by a so called magic sequence, that is sent in advance of the desired communication. The construction of a magic sequence is described in detail in chapter 3.3

Addressing Channel Input IRD on page 22. The IRD communication mode is basically left by IC reset, except in

one special case that is also described in that chapter.

2.3.3 Parameter Port Pins

The ASI4U features a 4-bit wide parameter port and a related parameter strobe signal pin PST. There is a defined phase relation between a parameter output event, the parameter input sampling and the activation of the

PST signal. Thus it can be used to trigger external logic or a micro controller to process the received parameter

data or to provide new input data for the AS-i slave response.

AS-i Complete Specification V3.0 newly defines a bidirectional mode for parameter data. The ASI4U supports

this feature, that can be activated by special E²PROM setting.

See chapter 3.6 Parameter Port and PST on page 26 for further details.

2.3.4 Data Port Pins

An important feature of the ASI4U is the 8-bit wide data port that consists of a 4-bit wide input section and a 4bit wide output section. The input and output sections work independently from each other allowing a maximum

of 8 devices (4 input and 4 output devices) to be connected to the ASI4U. For special applications (compatibility), the so called Multiplex Mode can be activated that limits the output activation to a certain time frame. Thus,

a 4-bit wide bi-directional data I/O Port can be realized by external connection of the corresponding data input

and output pins.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

12/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

The data port is accompanied by the data strobe signal DSR. There is a defined phase relation between a data

output event, the input data sampling and the activation of the DSR signal. Thus, it can be used to trigger external logic or a micro controller to process the received data or to provide new input data for the AS-i slave response. See chapter 3.7 Data Port and DSR on page 29 for further details.

2.3.5 Data Input Inversion

By default the logic signal (HIGH / LOW) that is present at the data input pins during the input sampling phase is

transferred without modification to the send register, which is interfaced by the UART. By that, the signal becomes directly part of the slave response.

Some applications work with inverted logic levels. To avoid additional external inverters, the input signal can be

inverted by the ASI4U before transferring it to the send register. The inversion of the input signals can either be

done bit selective or jointly for all data input pins. See chapter 3.7.2 Input Data Pre-Processing on page 30.

2.3.6 Data Input Filtering

To prevent input signal bouncing from being transferred to the AS-i Master, the data input signals can be digitally filtered. Filter times can be configured in 7 steps from 128µs up to 8.192ms. Additionally there is a so called

AS-i Cycle Mode available. If activated, the filter time is determined by the actual AS-i cycle time. For more detailed information refer to chapter 3.7.2 Input Data Pre-Processing on page 30.

The filter function can be enabled bit selective. Activation of the filters is done jointly either by E²PROM configuration or by the logic state of parameter port pin P2. See chapter 3.7.2 Input Data Pre-Processing on page 30.

2.3.7 Fixed Data Output Driving

The fixed data output driving feature is thought to ease board level design for similar products that do not require the full data output port width. The user can select one or more bits from the data output port to be driven

by a distinct logic level instead by the data that was sent by the master. The distinct output data is stored in the

E²PROM and can be set during final module configuration. Thus it is possible to signal the actual IC profile to

some external circuitry and to allow reuse of certain board designs for different product applications.

See chapter 3.7.3 Fixed Output Data Driving on page 32 for further details.

2.3.8 Synchronous Data I/O Mode

AS-i Complete Specification V3.0 newly defines a synchronous data I/O feature, that allows a number of slaves

in the network to switch their outputs at the same time and to have their inputs sampled jointly. This feature is

especially useful if more than 4-bit wide data is to be provided synchronously to an application.

The synchronization point was defined to the data exchange event of the slave with the lowest address in the

network. This definition relies on the cyclical slave polling with increasing slave addresses per cycle that is one

of the basic communication principles of AS-i. The IC always monitors the data communication and detects the

change from a higher to a lower slave address. If such a change was recognized, the IC assumes that the slave

with the lower address has the lowest address in the network.

There are some special procedures that become active during the start of synchronous I/O mode operation and

if more than three consecutive telegrams were sent to the same slave address. This is described in more detail

in chapter 3.7.4 Synchronous Data I/O Mode on page 32.

2.3.9 4 Input / 4 Output processing in Extended Address Mode

A new feature of AS-i Complete Specification v3.0 is also support of 4-bit wide output data in Extended Address

Mode. In Extended Address Mode it was, up to Complete Specification v2.11, only possible to send three data

output bits from the master to the slave because telegram bit I3 is used to select between A- and B- slave type

for extended slave addressing (up to 62 slaves per network). In normal address mode I3 carries output data for

pin D3.

The new definition introduces a multiplexed data transfer, so that all 4-bits of the data output port can be used

again. A first AS-i cycle transfers the data for a 2-bit output nibble only, while the second AS-i cycle transfers the

data for the contrary 2-bit nibble. Nibble selection is done by the remaining third bit. To ensure continuous alternation of bit information I2 and thus continued data transfer to both nibbles, a special watchdog was implemented that observes the state of I2 bit. The watchdog can be activated or deactivated by E²RPOM setting. It

provides a watchdog filter time of about 327ms.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adap ted, merged, translated, stored, or used without the prior written consent of the copyright owner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

13/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

The multiplexed transfer of course increases the refresh time per output by a factor of two, however, some applications can tolerate this increase for the benefit of less external circuitry and better slave address efficiency.

The sampling cycle of the data inputs remains unchanged since the meaning of I3 bit was not changed in the

slave response with the definition of the Extended Address Mode.

More detailed information is described in chapter 3.7.5 Support of 4I/4O processing in Extended Address Mode,

Profile 7.A.x.E on page 34.

2.3.10 AS-i Safety Mode

The enhanced data input features described above require additional registers in the data input path that store

the input values for a certain time before they hand them over to the AS-i transmitter. This causes a time delay

in the input path that could lead to a delayed “turn off” event, if the registers were activated by intention or by

accident in AS-i Safety Applications.

To safely exclude an activation of the enhanced data I/O features in Safety Applications, the IC provides a special Safety Mode that is strongly recommended to be used for AS-i Safety communication purposes. See chapter 3.7.6 Safety Mode Operation on page 34 for further details.

2.3.11 Enhanced LED Status Indication

ASI4U newly supports enhanced status indication by two LED outputs. A special mode for direct application of

Dual-LEDs and the respective different signaling modes is also implemented. Compared to the A²SI, the former

U5RD pin was reassigned as LED2 pin. Thus, compatibility to existing A²SI board layouts is still guaranteed.

However, it will require to keep LED2 pin disabled (default state at delivery) in order to avoid short-circuiting of

U5R to ground. More detailed information on the different signaling schemes and their activation can be found in

chapter 3.9 LED outputs on page 40.

2.3.12 Communication Monitor/Watchdog

Data and Parameter communication are continuously observed by a communication monitor. If neither

Data_Exchange nor Write_Parameter calls were addressed to and received by the IC within a time frame of

about 41ms, a so called No Data/Parameter Exchange status is detected and signaled at LED1.

If the respective flags are set in the E²PROM the communication monitor can also act as communication watchdog, that initiates a complete IC reset after expiring of the watchdog timer. The watchdog mode can also be

activated and deactivated by a signal at parameter port pin P0. For more detailed information see chapter 3.14

Communication Monitor/Watchdog on page 47.

2.3.13 Write protection of ID_Code_Extension_1

As defined in AS-i Complete Specification v3.0 the ASI4U also supports write protection for ID_Code_Extension_1. The feature allows the activation of new manufacturer protected slave profiles and is enabled by

E²PROM setting. It is described in more detail in chapter 3.16 Write Protection of ID_Code_Extension_1 on

page 47

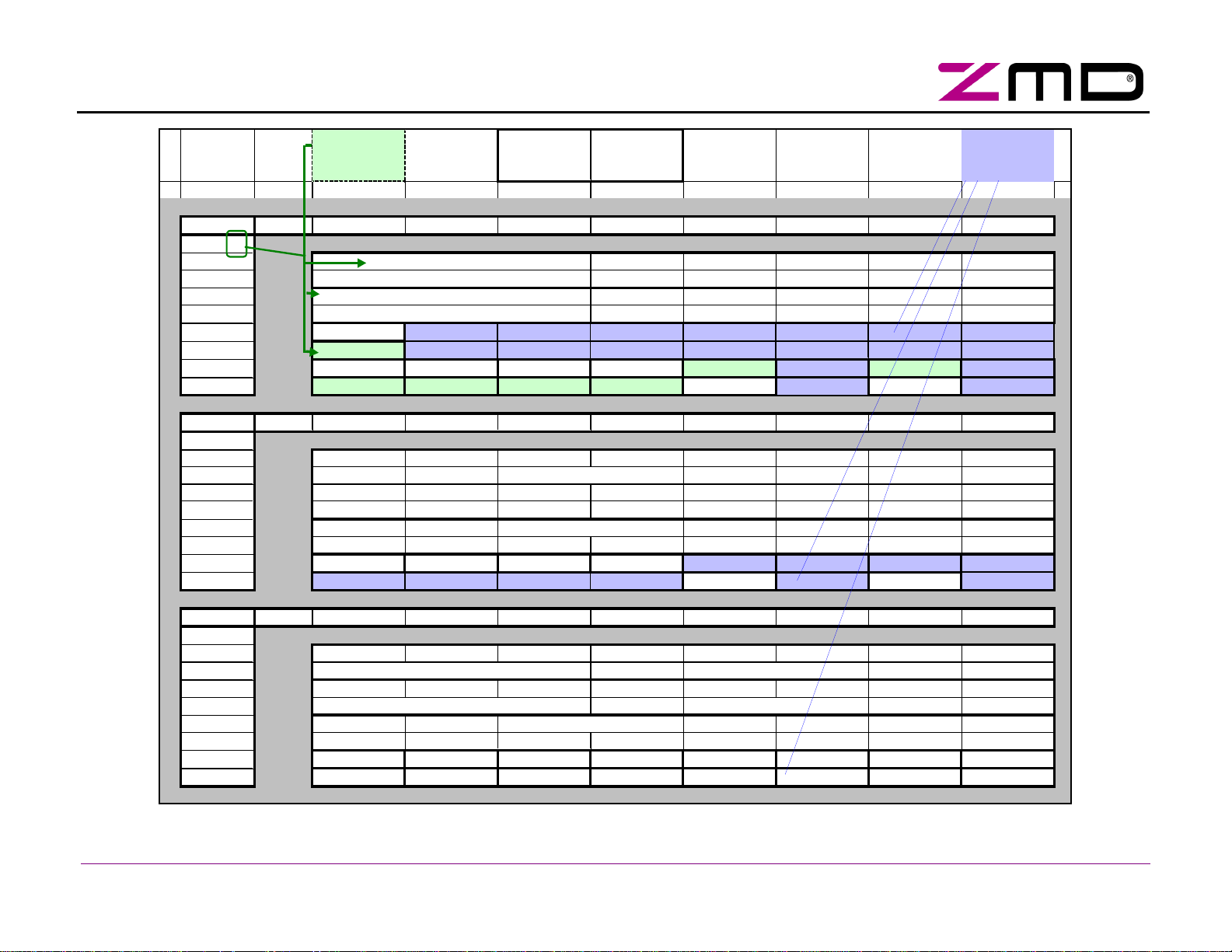

2.3.14 Summary of Master Calls

Table 6 on page 15 and the diagram at the following page show the complete set of Master Calls that are decoded by the ASI4U in Slave Mode. The "Enter Program Mode" call is intended for programming of the IC by

the slave manufacturer only. It becomes deactivated as soon as the Program_Mode_Disable flag is set in the

Firmware Area of the E²PROM.

AS-i Complete Specification compliance note:

In order to achieve full compliance to the AS-i Complete Specification, the Program_Mode_Disable flag must be

set by the manufacturer of AS-i slave modules during the final manufacturing and configuration process and

before an AS-i slave device is delivered to field application users.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. T he

Information furnished in this publication is preliminary and subject to changes without notice.

14/57

Code_1

1

Configuration

0

0

0

0

1

Datasheet

Instruction MNE ST CB A4 A3 A2 A1 A0 I4 I3 I2 I1 I0 PB EB SB I3 I2 I1 I0 PB EB

Data Exchange

Write Parameter

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

Table 6: ASI4U Master Calls and Related Slave Responses

Master Request Slave Response

DEXG 0 0 A4 A3 A2 A1 A0 0

WPAR 0 0 A4 A3 A2 A1 A0 1

D3

D2 D1 D0 PB 1 0

~Sel

P3

P2 P1 P0 PB 1 0

~Sel

D3 E3D2 E2D1 E1D0

E0

P3 I3P2 I2P1 I1P0

I0

PB 1

PB 1

Address Assignment

Write Extented ID

Delete Address

Reset Slave

Read IO

Read ID Code

Read ID Code_1

Read ID Code_2

Read Status

Broadcast (Reset)

Enter Program Mode

ADRA 0 0 0 0 0 0 0 A4 A3 A2 A1 A0 PB 1 0 0 1 1 0 0 1

WID1 0 1 0 0 0 0 0 0 ID3 ID2 ID1 ID0 PB 1 0 0 0 0 0 0 1

DELA 0 1 A4 A3 A2 A1 A0 0 0 Sel 0 0 0 PB 1 0 0 0 0 0 0 1

RES 0 1 A4 A3 A2 A1 A0 1

RDIO 0 1 A4 A3 A2 A1 A0 1

RDID 0 1 A4 A3 A2 A1 A0 1

RID1 0 1 A4 A3 A2 A1 A0 1

RID2 0 1 A4 A3 A2 A1 A0 1

RDST 0 1 A4 A3 A2 A1 A0 1

~Sel

~Sel

1 0 0 PB 1 0 0 1 1 0 0 1

0 0 0 PB 1 0 IO3 IO2 IO1 IO0 PB 1

Sel

0 0 1 PB 1 0 ID3 ID2 ID1 ID0 PB 1

Sel

0 1 0 PB 1 0 ID3 ID2 ID1 ID0 PB 1

Sel

0 1 1 PB 1 0 ID3 ID2 ID1 ID0 PB 1

Sel

1 1 0 PB 1 0 S3 S2 S1 S0 PB 1

BR01 0 1 1 1 1 1 1 1 0 1 0 1 1 1 --- no slave response ---

PRGM 0 1 0 0 0 0 0 1 1 1 0 1 1 1 --- no slave response ---

Note: In Extended Address Mode the "Select Bit" defines whether the A-Slave or B-Slave is being addressed. Depending on the type of master call bit I3 carries the

select bit information (Sel = A-Slave) or the inverted select bit information (~Sel = B-Slave).

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

15/57

B-Slave with

ASI Master

ASI Slave

Response (blue

ADR != 0

I2 I1 I0

000

001

010

011

100

101

110

111

CB I4

I3

I3=Sel

(Slave Address != 0) AND (Progam Mode not activated)

001

Sel=1

101

Sel=1

110

Sel=0

Broadcast

111

Sel=1

ADR == 0

I2 I1 I0

000

001

010

011

100

101

110

111

CB I4 I3

(Slave Address == 0) AND (Progam Mode not activated)

011

101

110

Broadcast

111

I2 I1 I0

000

001

010

011

100

101

110

111

CB I4 I3

Progam Mode activated

001

011

16/57

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

No Slave

Profile 0.A

(green shaded)

Request

(black/green)

Response

(blue)

shaded)

000 Sel=0

010 Sel=0

011 Sel=1

100 Sel=0

000

001

010

100

000

010

100

101

110

111

Data_Exchange /Sel D2 D1 D0

Data_Exchange D3 D2 D1 D0 D3 D2 D1 D0

Write_Parameter /Sel P2 P1 P0

Write_Parameter P3 P2 P1 P0 P3 P2 P1 P0

Delete_Addr x0

Delete_Addr x0

Rd_IO_Cfg <I3:I0> Read_ID <I3:I0> Read_ID_1<I3:I0> Read_ID_2 <I3:I0> Reset_Slave 0x6

Rd_IO_Cfg <I3:I0> Read_ID <I3:I0> Read_ID_1<I3:I0> Read_ID_2 <I3:I0> Reset_Slave 0x6 Rd_Status

Address_Assignment A4 A3 A2 A1 A0

0x6

Write_Var_Ext_Code1 ID3 ID2 ID1 ID0

0x0

Rd_IO_Cfg <I3:I0> Read_ID <I3:I0> Read_ID_1<I3:I0> Read_ID_2 <I3:I0>

Reset_Slave 0x6

Data_Exchange - - - - I3 I2 I1 I0 (EEPROM READ ACCESS)

Write_Parameter I3 I2 I1 I0 I3 I2 I1 I0 (EEPROM WRITE ACCESS)

Write_Var_ID_Code ID3 ID2 ID1 ID0

0x0

Rd_IO_Cfg <I3:I0> Read_ID <I3:I0> Read_ID_1<I3:I0> Read_ID_2 <I3:I0> Reset_Slave 0x6

Rd_IO_Cfg <I3:I0> Read_ID <I3:I0> Read_ID_1<I3:I0> Read_ID_2 <I3:I0> Reset_Slave 0x6

EnterPmode

Broadcast

EnterPmode

Rd_Status

Rd_Status

Rd_Status

Rd_Status

<S3:S0>

<S3:S0>

<S3:S0>

<S3:S0>

<S3:S0>

reserved

reserved

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be reproduced, adapted, merged, translated, stored, or used without the prior written consent of the copyright owner. The Information furnished in this publication is preliminary and subject to changes without notice.

ASI+

ASI

-

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

2.4 Master Mode

Master Mode and the related Repeater- and Monitor-Modes differ completely in their functional properties from

the Slave Mode. While the IC can autonomously perform different tasks in Slave Mode, it will only act as physical layer transceiver in Master-, Repeater- and Monitor-Mode. The basic property of these modes is a modulation / demodulation of AS-i signals to Manchester-II-code and vice versa. The following figure shows the different data path configurations.

Master Mode Slave Mode, ASI-Channel Slave Mode, IRD Addressing Channel

ASI- Receiver

UART

ASI- Transmitter

Figure 6:

Data path in Master-, Repeater- and Monitor-Mode

Master-Mode, Repeater-Mode and Monitor-Mode differ from each other in the kind of signals that are available

at the data I/O and parameter port pins of the IC. Following signal assignments are provided:

IRD CMOS

Input

LED Output

IRD

(TX)

LED1

(RX)

Pin Master Mode Repeater Mode Monitor Mode

P0 Receive Clock Hi-Z Receive Clock

P1 Power Fail Hi-Z Power Fail

P2 Receive Strobe – Slave Telegram Hi-Z Receive Strobe – Slave Telegram

P3 Hi-Z Hi-Z Receive Strobe – Master Telegram

DI0

DI1

DI2

DI3

Inverting of IRD input signal. If both inputs are on different level, the IRD input signal is inverted

before further processing, otherwise it is directly forwarded to the UART.

Inverting of LED output signal. If both inputs are on different level, the LED output signal is inverted after processing, otherwise it is directly forwarded to the LED1 output.

DO0 Hi-Z Hi-Z Pulse Code Error

DO1 Hi-Z Hi-Z No Information Error

DO2 Hi-Z Hi-Z Parity Bit Error

DO3 Hi-Z Hi-Z Manchester-II-Code Error at IRD Input

More detailed signal descriptions can be found in chapters 3.6 Parameter Port and PST, 3.7 Data Port and DSR

as well as 3.12 UART.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. T he material contained herein may not be reprod uced, adapted, merged, translated, stored, or used without the pri or wri tten co nsent of the co pyright owner. The

Information furnished in this publication is preliminary and subject to changes without notice.

17/57

tion

ctional Parameter Port

Watchdog can be activated/deactivated by

Communication watchdog is continuously

Datasheet

ZENTRUM MIKROELEKTRONIK DRESDEN AG

“ASI for you” IC

2.5 E²PROM

The ASI4U provides an on-chip E²PROM with typical write times of 12.5 ms and read times of 110ns. For security reasons the memory area is structured in two independent data blocks and a single bit Security flag.

The data blocks are named User Area and Firmware Area. The Firmware Area contains all manufacturing related configuration data (i.e. selection of operational modes, ID codes, …). It can be protected against undesired

data modification by setting the Program_Mode_Disable flag to ‘1’.

The User Area contains only such data that is relevant for changes at the final application (i.e. field installation

of slave module). The environment, where modifications of the user data may become necessary, can sometimes be rough and unpredictable. In order to ensure a write access cannot result in an undetected corruption of

E²PROM data, additional security is provided when programming the User Area.

Any write access to the User Area (by calls Address_Assignment or Write_ID_Code1) is accompanied by two

write steps to the Security flag, one before and one after the actual modification of user data.

The following procedure is executed when writing to the User Area of the E²PROM:

1. The Security flag is programmed to ‘1’.

2. The content of the Security flag is read back, verifying it was programmed to ‘1’.

3. The user data is modified.

4. A read back of the written data is performed.

5. If the read back has proven successful programming of the user data, the Security flag

is programmed back to ‘0’.

6. The content of the Security flag is read back, verifying it was programmed to ‘0’.

In addition to a read out of the data areas, the Security flag of the E²PROM is also read and evaluated during IC

initialization. In case the value of the Security flag equals ‘1’ (i.e. due to an undesired interruption of a User Area

write access), the entire User Area data is treated as corrupted and the Slave Address is set to 0x0 in the corresponding volatile shadow registers during initialization. Thus the programming of the User Area data can be

repeated.

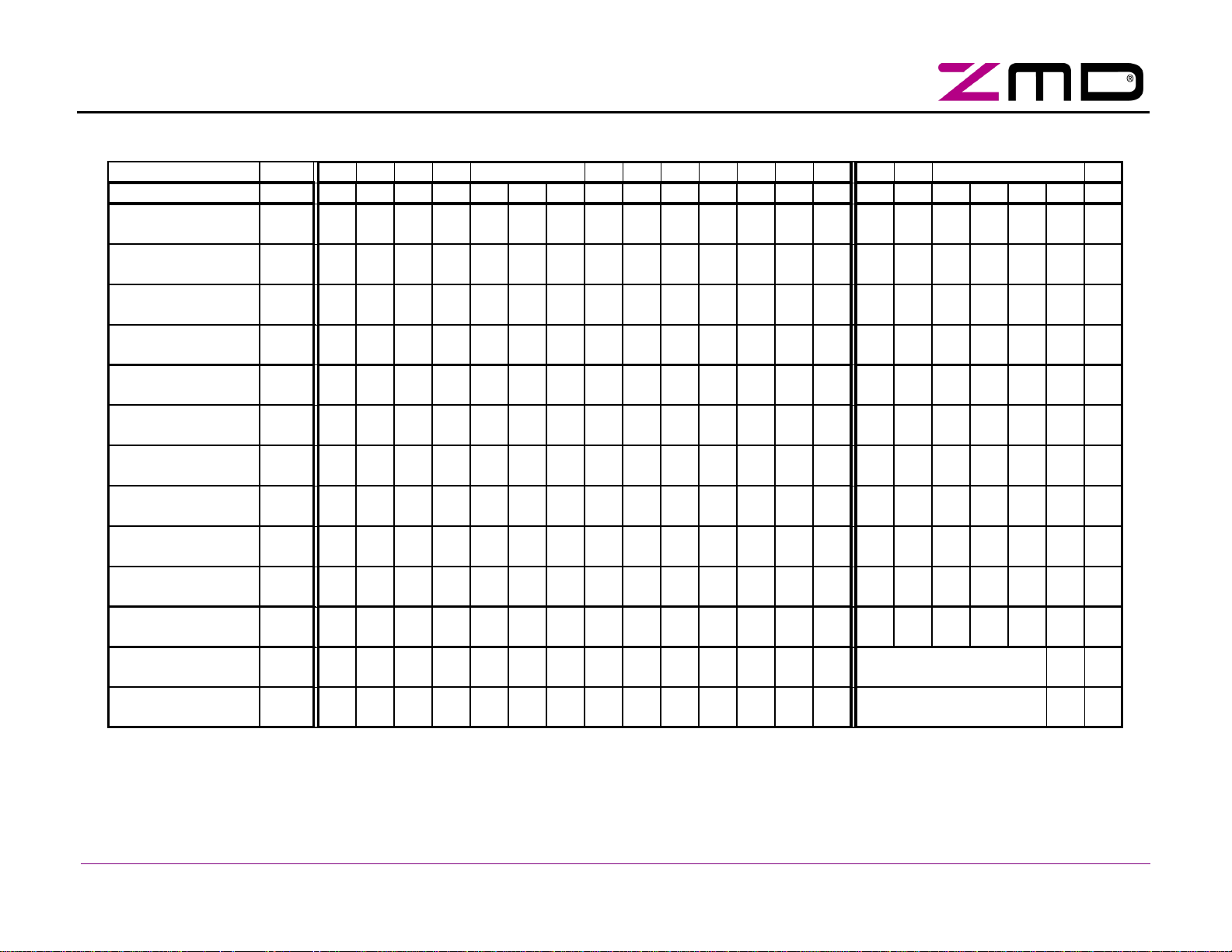

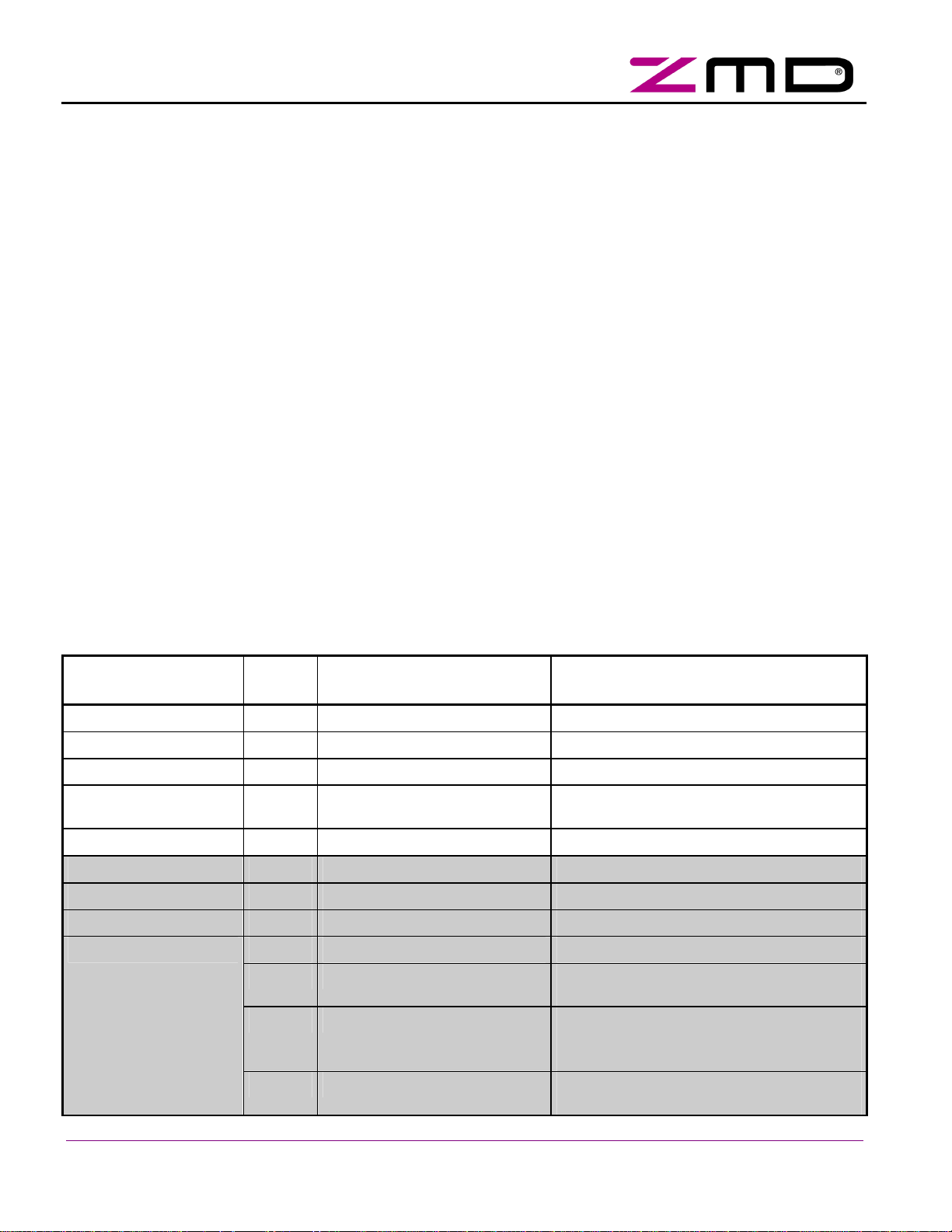

Table 7: E²PROM Content

ASI4U internal

E²PROM Address [hex]

Bit

Position

0 0 … 3

1 0

2 0 … 2

2 3

3 … 7

8 0 … 3

9 0 … 3

A 0 … 3

B

0

1

2

3

EEPROM Cell Content EEPROM Register Content

A0 … A3

A4

Slave address low nibble

Slave address high nibble

ID1_Bit0 … ID1_Bit2 ID_Code_Extension_1

ID1_Bit3 ID_Code_Extension_1, A/B slave selec

in extended address mode

Not implemented

ID_Bit0 … ID_Bit3 ID_Code

ID2_Bit0 … ID2_Bit3 ID_Code_Extension_2

IO_Bit0 … IO_Bit3 IO_Code

Multiplex_Data

Multiplex_Paramter

Multiplexed bi-directional Data Port mode

Multiplexed bi-dire

mode

P0_Watchdog_Activation

the logic value at parameter pin P0.

Watchdog_Active must not be set.

Watchdog_Active

activated.

Copyright © 2006, ZMD AG, Rev.1.6

All rights reserved. The material contained herein may not be repr oduced, ad apted, merged, translated, stored, or used without the prior written consent of the copyright o wner. The

Information furnished in this publication is preliminary and subject to changes without notice.

18/57

Loading...

Loading...