Page 1

Dual Fuel Ranges

1

Page 2

CONTENTS

Installation Guide

IMPORTANT SAFETY INSTRUCTIONS 1

WARRANTY AND SERVICE 3

BEFORE INSTALLATION 5

INSTALLING THE LEGS 7

INSTALLATION REQUIREMENTS & 8

POWER RATING & ELECTRICAL CONNECTION 10

WIRING SCHEMATICS 11

GAS CONNECTION 13

GAS CONVERSION PROCEDURE 16

INSTALLATION CHECKLIST 22

FINAL PREPARATION 22

Page 3

CONTENTS

Users Manual

ROOM VENTILATION 24

SURFACE BURNER LAYOUT 24

OVEN COOKING 25

USING THE OVEN 26

MAINTAINING YOUR RANGE 31

TROUBLESHOOTING 32

Page 4

Thank You

We want to thank you for choosing one of our beautiful professional ranges. We

know that you have many brands to choose from and we are thrilled that you have

decided to place one of our products in your home.

Our appliances are designed according to the strictest safety and performance

standards for the North American market. We follow the most advanced

manufacturing process. Each appliance leaves the factory after thorough quality

inspection and testing. Our distributors and our service partners are ready to answer

any questions you may have regarding installation of your ZLINE product.

This manual will help you learn to use the product in the safest, most efficient manner,

and care for it so that it may give you the highest satisfaction for years to come.

This manual also includes directions for the professional installer that will install the

product in your home. We recommend professional installation by trained personnel.

Please keep this manual for future use.

We may have a more up to date manual!

Scan this QR code for a digital copy of the

most recent manual for this appliance.

Page 5

Location of Applicance Tags

The rating tag shows the model and serial number of your range. The tag is located

under the front edge of the range cooktop. The tag is visible when the oven door is

open.

Appliance Tag Here

Important Appliance Information

Dealer

Model

Date Installed

Installer

Range Installation Video

Page 6

Important Safety Instructions

An air curtain or other overhead range, range, cooktop hood which

WARNING

The manufacturer will not be responsible for any damage to property or to persons

caused by incorrect installation or improper use of the appliance.

The manufacturer reserves the right to make changes to its products when considered

necessary and useful, without affecting the essential safety and operating

characteristics.

This appliance has been designed for non-professional, domestic use only. Do not

place any pot or pan on the open oven door, the door is made of glass and can

break under the weight.

Before beginning installation, please read these instructions completely and carefully.

Do not remove permanently affixed labels, warnings, or plates from the product.

This may void the warranty. Please observe all local, state and national codes and

ordinances. Please ensure the range is properly grounded. The installer should leave

these instructions with the consumer who should retain for local inspectors use and

for future reference. The plug should always be accessible. Installation must conform

with local codes or in the absence of codes, the National Fuel Gas Code NSIZ223.

1/NFPA54. Electrical installation must be in accordance with the National electrical

code ANSI/NPA70-latest edition and/or local codes. In Canada: Installation must

be in accordance with the current CAN/CGA-fe 149.1 National gas installation

code or CAN/CGA-B 149.2, Propane installation code and/or local codes.

Electrical installation must be in accordance with the current CSA C22.1 Canadian

electrical codes Part 1 and/or local codes.

Installation of any gas-fired equipment should be made by a licensed plumber. A

manual gas shut-off valve must be installed in the gas supply line ahead of the oven

in the gas flow for safety and ease of service.

operates by blowing downward airflow onto the range, shall not be

used/installed in conjunction with this gas range.

1

Page 7

Important Safety Instructions

Important Safety Information

Please read and follow these important instructions for the safety of your home and

the people living in it.

If the information in this manual is not followed exactly, a fire or

WARNING

Do not store or use gasoline or any other flammable substances in the vicinity of this

or any other appliance.

WARNING

What To Do If You Smell Gas

DO NOT light any appliance.

DO NOT touch any electrical switch.

DO NOT use any phone in your building.

Immediately call your gas supplier from a neighbor’s phone, follow the gas supplier’s

instructions.

In the case you cannot reach the gas supplier, call the fire department.

Installation and service must be conducted by a qualified installer, service agency, or

the gas supplier.

explosion may result causing property damage, personal injury, or

death.

Never use this appliance as a space heater to heat or warm the

room. Doing so may result in carbon monoxide poisoning and

overheating of the oven.

2

Page 8

Warranty and Service

Warranty and Service

All range products carry a one year parts warranty. Service on all products shall be

carried out by factory-trained professionals only. For warranty service, please call

customer service.

Replacement Parts

Only authorized replacement parts may be used in performing service on this appli-

ance.

Replacement parts are available from ZLINE. Call 1-614-777-5004.

3

Page 9

Product Dimensions

Internal Dimensions

48” Model: 26.5” W/12.5”W x 18.5”D x 14”H

36” Model: 30.5”W x 18.5”D x 14”H

30” Model: 26.5” W x 18.5”D x 14”H

4

Page 10

Before Installation

This appliance shall only be installed by an authorized professional.

The appliance shall be installed in accordance with the standards of the country

where it will be installed. The installation of this appliance must conform to local

codes and ordinances. In the absence of local codes installation must conform to

American National Standards, National fuel Gas code ANSI Z223.1-Latest edition/

NFPA 54 or B 149.1.

The appliance, when installed, must be electrically grounded in accordance with

local codes or, in the absence of local codes, with the National Electrical code,

ANSI/NFPA 70.

If local codes permit, a flexible metal appliance con-nections with the new AGA

or CGA certified design, max 5 feet (1,5m) long, 34˝ I.D. is recommended for

connecting this appliance to the gas supply line. DO NOT bend or damage the

flexible connector when moving the appliance.

This appliance must be used with the pressure regulator provided. The regulator must

be properly installed in order to be accessible when the appliance is installed in

its final location. The pressure regulator must be set for the type of gas to be used.

The pressure regulator has 34˝ female pipe thread. The appropriate fitting must be

determined based on the size of your gas supply line, the flexible metal connector

and the shut-off valve.

The appliance must be isolated from the gas supply piping system by closing its

individual manual shut-off valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 34 PSI(13,8w.cpr 3,5kPA).

All opening holes in the wall and floor, back and under the appliance shall be sealed

before installation of the appliance.

A manual valve shall be installed in an accessible location in the gas line external to

the appliance for the purpose of turning on and shutting off the gas to the appliance.

Do not use aerosol sprays in the vicinity of this appliance while it is

WARNING

in operation.

5

Page 11

Before Installation

Room Ventilation

An exhaust fan may be used with the appliance; in each case it shall be installed

in conformity with the appropriate national and local standards. Exhaust hood

operation may affect other vented appliances; in each case it shall be installed in

conformity with the appropriate national and local standards.

Type of Gas

This appliance is shipped from the factory for use with natural gas. For use with

propane LP gas, please follow the conversion procedure described on pg. 18. A step

by step conversion procedure is also included with each set of LP gas nozzles.

Gas Pressure

The maximum inlet gas supply pressure incoming to the gas appliance pressure

regulator is 34PSI (13,8w. cpr 3,5kPA).

The minimum gas supply pressure for checking the regulator setting shall be at least

1˝ w.c (249 Pa) above the inlet specified manifold pressure to the ap-pliance (This

operating pressure is 4˝ w.c. (1.00kPa) for Natural gas and 11˝ w.c. (2.75 kPa) for

LP gas.

Gas cooktop requires 1”- 6”side wall spacing above the counter height for

proper combustion. Please review specific model installation instructions for

required dimensions. 30 inches between the cooktop and bottom of the cabinet

above. 0.25 inches for sides below countertop height.

NOTE: Please consult your local building codes for variations with installation.

6

Page 12

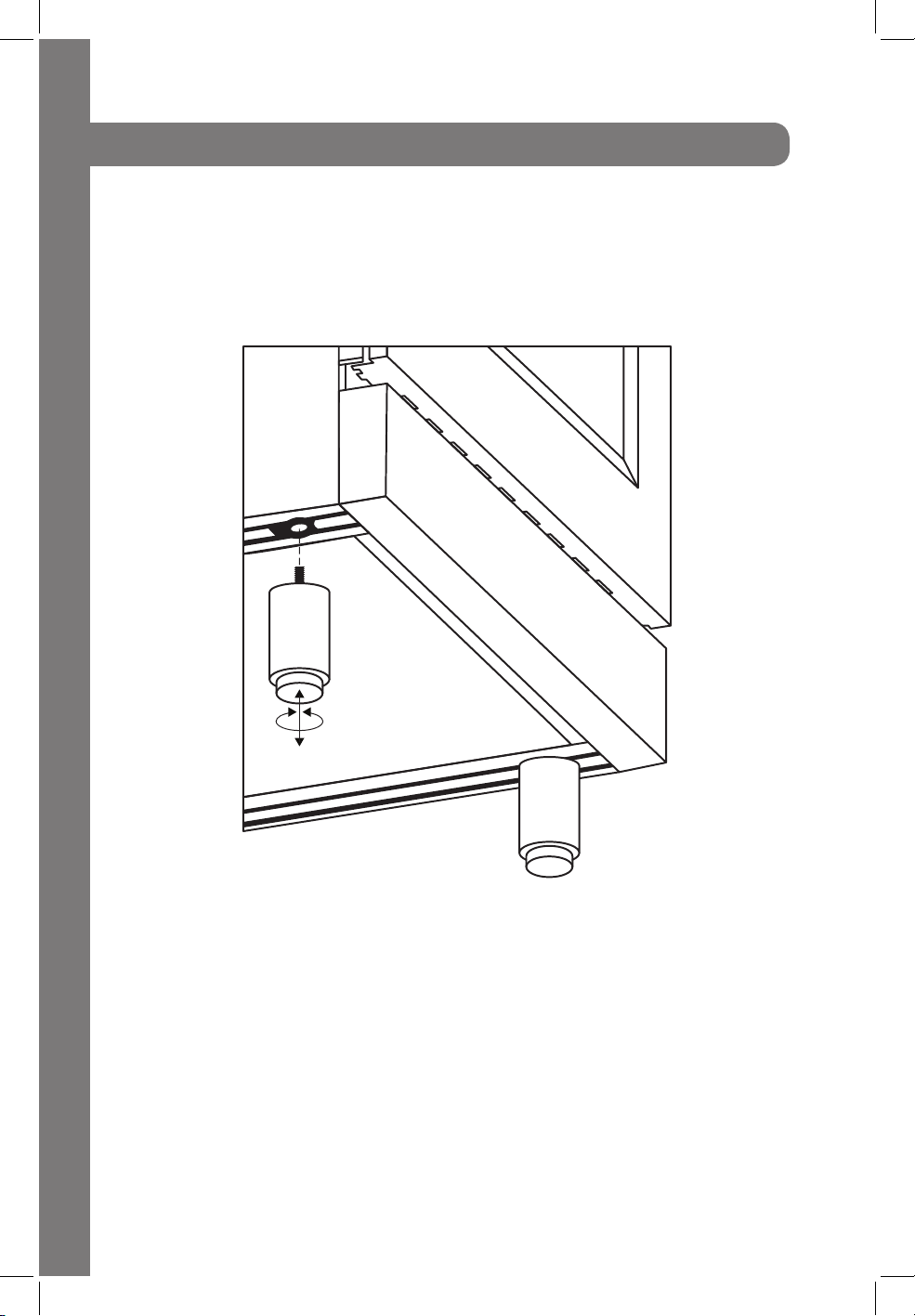

Installing the Legs

Installing the Legs

The ranges must be used with the legs properly installed. Four height-adjustable legs

are shipped with the range, in a foam container above the range.

1. Before installing the legs, position the appliance near its final location as the legs

are not suitable for moving the appliance over long distances.

2. After unpacking the range, raise it enough to insert the legs in the appropriate

receptacles situated on the lower part of the appliance. Lower the range gently to

keep any undue strain from legs and mounting hardware.

3. Adjust leg height to the desired level by twisting the inside portion of the leg

as-sembly until the proper height is reached. Check with a level that the cooktop is

perfectly level.

7

Page 13

Installation Requirements

A properly grounded and horizontally-mounted electrical receptacle type NEMA 14-

50R should be installed no higher than 3” above the floor, no less than 2” and not

more than 8” from the left side (facing product); refer to electrical connection section.

Gas

An agency-approved, properly-sized manual shut-off valve should be installed no

higher than 3” aboce the floor and no less than 2” and no more than 8” from the

right side (facing product).

To connect gas between shut-off valve and regulator, use agency-approved,

properly sized flexible or rigid pipe. Check all local code requirements.

Installation Adjacent to Kitchen Cabinets

The range may be installed directly adjacent to existing coutertop height cabinets

(36”) from the floor.

For the best look, the worktop should be level with the cabinet countertop. This can be

accomplished by raising the unit using the adjustment spindles on the legs.

ATTENTION: the range CANNOT be installed directly adjacent to kitchen walls, tall

cabinets, tall appliances, or other vertical surfaces above 36˝ high. The minimum

side clearance in such cases is 6”.

Wall cabinets with minimum side clearance must be installed 30˝ above the

countertop with coun-tertop height between 35.5” and 37.25”. The maximum depth

of wall cabinets above the range shall be 13”.

8

Page 14

Cooking Range

Installation Requirements

Side View

13 ”

27 ¹/₂”

location of gas

and electrical

extends on floor

2 ³/₄”

36-38”

to cooking

surface

30”

6”

18

Front View

opening width

3.23”

3.23”

5 ³/₄”

2”

9 ³/₄”

30” to 36”

to bottom of

ventilation hood

W

Opening Width

30” Model 30”

36” Model 36”

48” Model 48”

gas

12”

gas

5”

9

Page 15

Oven Circ. Element: 3200 Watts

Power Rating & Electrical Connection

The appliance shall be connected to a single phase electric line rated at 120Vac and

60Hz frequency.

Electric Power Rating

Recommended voltage of 120/240 Vac: 12A Max

If voltage is less than 120/240 then preheat times may vary.

Heating Element Power Rating

Gas Model: Electric Model:

Oven Bake (Gas): 18,000 BTU Oven Bake (Electric): 1500 Watts

Oven Broil (Gas): 13,000 BTU Oven Broil (Electric): 2850 Watts

Install suitable electric power supply receptacle connection type NEMA 14-50R able

to support a load of at least 30 A (Per Line) according to local code requirements.

For four wires power supply connection system (see diagram below).

Four-Wire Connection

Receptacle

NEMA 14-50R

L2 (red)

N (white)

cable from

power supply

G (green)

L1 (black)

L2 (red)

N (white)

G (green)

L1 (black)

Electrical Grounding

Our electric oven (RA30/36/48) is equipped with a four-prong plug and our gas

oven (RG30/36) is equipped with a three-prong plug for your protection against

shock hazard and should be plugged directly into a properly grounded receptacle.

Do not cut or remove the prong from this plug.

Disconnect electrical power at the circuit breaker box or fuse box

before installing the appliance.

WARNING

Provide appropriate ground for the appliance. Use copper

conductors only.

10

Page 16

Model: RG30

Wiring Schematics

11

Page 17

Model: RA30, RA36

Green

Model: RA48

Left Oven Fan

Indicator

Light

Indicator

Light

L1 N L2 G

Wire

Connector

Switch for

Thermostat

Switch for Thermostat

Ignition

Allumage

43125

P2

P1

P3

Switch for Oven

Snap Thermostat Switch

Snap Thermostat

Switch

Inside 1800/2395 W,

Outside 650/865 W

Heat Pipes - Up

Heat Pipes - Up

1300/1730 W

Heat Pipes - Down

1300/1730 W

Heat Pipes - Down

2000/2670W

Case Fan

Case Fan Left Lamp Right Lamp

Right Lamp

D

C

B

A

432

1

Switch for

Electric Oven

Switch for Lamp

Switch for Lamp

Right Oven Fan

Microswitch 1

Microswitch 2

Microswitch 3

Microswitch 4

Microswitch 5

Microswitch 6

L1

N

L2

G

Red White Black Yellow

and

Green

CAUTION: Connect the red wire to

the L1 tab (left), the black wire to the

L2 tab (right), the white wire to the N

tab (central), and the yellow and

green wire to the ground screw. DO

NOT SWAP CONNECTIONS.

120/208 V Ac 60Hz

120/240 V Ac 60Hz

Red

White

Black

Green

Model: RG36

Black

White

Red

120/208 V Ac 60Hz

120/240 V Ac 60Hz

Wire

Connector

L1 N L2 G

Wiring Schematics

Ignition

Light

Indicator

Allumage

Switch for Thermostat

P2

P1

43125

Microswitch 1

P3

Switch for Oven Snap Thermostat Switch

Microswitch 2

Microswitch 3

Microswitch 4

Microswitch 5

Microswitch 6

Case Fan Left Lamp Right Lamp Switch for Lamp

CAUTION: Connect the red wire to

the L1 tab (left), the black wire to the

L2 tab (right), the white wire to the N

tab (central), and the yellow and

green wire to the ground screw. DO

NOT SWAP CONNECTIONS.

G

and

Green

L2

N

Left Oven Fan Right Oven Fan

Heat Pipes - Up

Inside 1800/2395 W,

Outside 650/865 W

Heat Pipes - Down

2000/2670W

L1

Red White Black Yellow

12

Page 18

Gas Connection

All gas connections must comply with national and local codes. The gas supply

line (service) must be the same size or greater than the inlet line of the appliance.

This range uses a ½˝ NPT inlet. Use appropriate sealant on all pipe joints that are

resistant to gas.

This range can be used with Natural or LP/propane gas. The range is shipped from

the factory for use with natural gas.

For LP/Propane household installation, the appliance must be converted by the

dealer, factory-trained professional, or qualified licensed plumber or gas service

company.

Gas conversion is important for safe and effective use of the appliance. It is the

responsibility of the dealer and the owner of the range to perform the appropriate

gas conversion following the directions of the manufacturer.

The gas conversion procedure is described in this manual and in the package

containing the conversion nozzles shipped with every range.

Please provide the service person with this manual before work is started on the

range.

DO NOT use an open flame when checking for leaks.

WARNING

Leak testing of the appliance shall be conducted according to the manufacturer’s

instructions. Before placing the oven into operation, always check for leaks with

soapy water solution or other acceptable method. Check for gas leakage with soapy

water solutions on all gas connections between inlet gas pipes of the appliance, the

gas regulator and, the manual shut-off valve. Bubbles will form with a soapy water

solution if there is a leak.

13

Page 19

Gas Connection

Manual Shut-Off Valve

This valve is not shipped with the appliance and must be provided by the installer.

The manual shut-off valve must be installed in the gas service line between the gas

hook-up on the wall and the appliance inlet, in position where it can be reached

quickly in the event of an emergency.

In Massachusetts: A T handle type manual gas shut-off valve must be installed in the

gas supply line to this appliance.

Flexible Connections

In case of installation with flexible couplings and/or quick-disconnect fittings, the

installer must use a heavy duty, AGA design-certified commercial flexible connector

of at least ½˝ (1.3cm) IF NPT (with a suitable strain relief in compliance with ANSI

Z21.41 and Z21.69 standards.

In Massachusetts: The unit must be installed with a 36˝ (3 foot long) flexible gas

connector.

In Canada: Use CAN 1-6. 10-88 metal connectors for gas appliances and CAN

1-6.9 M79 quick disconnect device for use with gas fuel.

Pressure Test Point Stopper Valve

To avoid gas leaks, the pressure test-point stopper valve and gasket supplied with the

range must be installed on the gas fitting at the back of the range according to the

diagram below.

Gas pipe

Gasket

Gas connection adaptor 1/2” NPT with

pressure test point 1/8” NPT (to be fixed

toward external side of the appliance)

Pressure test-point stopper

14

Page 20

Gas Connection

Pressure Regulator

Since service pressure may fluctuate with local demand, every gas cooking

appliance must be equipped with a pressure regulator on the incoming service line

for safe and efficient operation.

Pressure Regulator

The pressure regulator shipped with the appliance has two female threads 34”NPT.

The regulator shall be installed properly in order to be accessible when the appliance

is installed in its final position.

Manifold pressure should be checked with a manom-eter and comply with the values

indicated below.

Natural Gas->4.0”W.c.P

L P/Propane-> 10.0” W.c.P

Incoming line pressure upstream from the regulator must be 1˝ W.C.P. higher than the

manifold pressure in order to check the regulator.

The regulator used on this range can withstand a maximum input pressure of ½

PSI (13.8˝ W.C or 3.5kPa) If the line pressure exceeds that amount, a step down

regulator is required.

The appliance, its individual shut-off valve, and the pressure regulator must be

disconnected from the gas line during any pressure testing of that system at pressures

in excess of ½ PSI (13.8˝ W.c or 3.5kPa).

15

WARNING

Before carrying out this operation, disconnect the appliance from

gas and electricity.

Gas conversion shall be conducted by a factory-trained

professional.

Page 21

Gas Conversion Procedure

The gas conversion procedure for this range includes:

1. Pressure Regulator

2. Surface Burners

3. Flame Adjustment

The conversion is not finished if all steps are not completed.

Before performing the gas conversion, locate the package containing the

replacement nozzles, which has a number indicating its flow diamerter printed on the

body. Consult the table below for matching nozzles to burners.

Save the nozzles removed from the range for future use.

Propane Conversion Video

LPG: Liquid Propane Gas NG: Natural Gas

The Oven Upper Burner is:

LPG: 1.08 - L15 NG: 1.79 - N15

The Oven Bottom Burner is:

LPG: 1.27 - L20 NG: 2.38 - N 21

16

Page 22

Gas Conversion Procedure

screw and spring.

Step 1: Pressure Regulator

The pressure regulator supplied with the appliance is a convertible type pressure

regulator for use with Natural Gas at a nominal outlet pressure of 4˝ w.c. or LP gas

at a nominal outlet pressure of 11” w.c. and it is pre-assembled from the factory

to operate with one of these gas pressure as indicated in the labels affixed on the

appliance, package and instruction booklet.

To convert the regulator for use with other liquid propane LP gas:

1. Unscrew the upper cap of the regulator, reverse its direction, and screw it in firmly

against the cap.

2. Screw the metal cap, by hand, in the original position on the regulator.

Gas Conversion Procedure

17

5/8

Reverse regulator

Page 23

Gas Conversion Procedure

Step 2: Surface Burners

To replace the nozzles of the surface burners, lift up the burners and unscrew the

nozzles shipped with the range using a 7 mm (socket wrench).

Replace nozzles using the conversion set supplied with the range. Each nozzle has a

number indicating its flow diameter printed on the body. Consult the table on page

18 for matching nozzles to burners.

Step1

Step 2

Step 4

9/32

NG LPG

Step 3

Step 5

9/32

NG = Natural Gas

LPG = Liquid Propane Gas

18

Page 24

Gas Oven Conversion Procedure

Step 1:

Open the oven door

and remove the tray and

racks.

Step 2:

Remove the upper burner

screw.

Step 3:

Remove the burner from

its connection against the

back wall of the oven. Be

careful not to scratch or

damage the connection

wire that will remain

connected throughout this

procedure.

Step 4:

Using a 7mm (9/32) tap

or socket wrench, remove

the nozzle, screwing

counter clockwise.

19

Page 25

Gas Oven Conversion Procedure

Burner Vent

AR3

Nozzle

Step 5:

Set the natural gas nozzle

aside and replace with

the propane nozzle.

Screw in and tighten the

new nozzle; clockwise.

Step 6:

Place the burner vent

back into position over

the new nozzle in the

AR3 slot.

Step 7:

Secure the burner back in

place with the mounting

screw that was removed

in step 2.

Step 8:

Follow steps 2 through 7

with the bottom burner.

Ensure the nozzles and

burners are secured

properly.

20

Page 26

Flame Adjustment Procedure

2.0 x 50 mm

1. Light one burner at a time and set it to the MINIMUM position (small flame).

2. Remove the knob.

3. The range is equipped with a safety valve. Using a small-size slotted screwdriver,

locate the choke screw (see diagram below) and turn to the right or left until the

burner flame is adjusted to desired minimum.

4. Make sure that the flame does not go out when switching quickly from the

MAXIMUM TO THE MINIMUM position.

Flame Adjustment

21

2.0 x 50 mm

Page 27

Installation Checklist

1. Is the range mounted on its legs?

2. Is the back guard securely connected?

3. Has the anti-tip device been properly installed?

4. Does the clearance from the side cabinets comply with the manufacturers’

direction?

5. Is the electricity properly grounded?

6. Is the gas service line connected following the directions of the manufacturer?

7. Have all the proper valves, stoppers, and gaskets been installed between the

range and the service line?

8. Has the gas connection been checked for leaks?

9. Has the range been setup for the type of gas available in the household? (LP,

propane, or natural gas)

10. Does the flame appear sharp blue with no yellow tipping?

11. Has the minimum setting for all burners been adjusted?

Final Preparation

All stainless steel body parts should be wiped with hot, soapy water and with a

stainless steel cleanser.

If build-up occurs, do not use steel wool, abrasive cloths, cleaners, or powders. If it is

necessary to scrape stainless steel to remove encrusted materials, soak with hot, wet

cloths to loosen the material, and then use a wood or nylon scraper. DO NOT use

a metal knife, or any other metal tool to scrape stainless steel! Scratches are almost

impossible to remove.

Before using the oven for food preparation, clean thoroughly with a warm soap and

water solution to remove film residues and any dust or debris from installation, then

rinse and wipe dry.

22

Page 28

Users Manual

23

Page 29

Room Ventilation

Surface Burner Layout

Any child or adult can tip the range, verify the anti-tip device has

been properly installed and engaged.

Ensure the anti-tip device is re-engaged when the range is moved.

WARNING

Do not operate the range without the anti-tip device in place and

engaged. Failure to do so can result in serious injury or serious burns

to children or adults.

The use of a gas cooking appliance generates heat and humidity in the room where

it is installed. Prop-er ventilation in the room is needed. Make sure the kitchen is

equipped with a range hood of appropriate power (400 CFM minimum). Activate

the exhaust fan/range hood when possible. Intensive and con-tinuous use of the

appliance may require additional ventilation, for example by opening a window.

Surface Burner Layout

Surface Burner Layout

Small Burner Medium Burner

Small Burner Medium Burner

Rapid BurnerDual Power Burner

Rapid BurnerDual Power Burner

Rapid Burner

Medium Burner

Small Burner

Rapid BurnerDual Power Burner

Medium Burner

24

Page 30

Oven Cooking

Be sure to set all worktop/oven/broiler burner controls to the OFF position after each

use of the appliance.

OFF

Maximum temperature setting/recommended control knob position for burner

ignition.

Minimum Temperature Setting

Appliance with Worktop Gas Valves

Alternative Type

Note: When igniting a burner, all burners will spark, but only

the burner’s knob you are using will ignite the flame.

25

Page 31

Using the Oven

A

B

A

B

Correct

Incorrect

A

B

A

B

A

B

Correct

Incorrect

A

B

Surface Burner Operation - Electric Ignition

To activate the electric ignition, simply turn the control knob counter-clockwise to

maximum power (*position*), then press the knob in to start the flow of gas and

the ignition spark. The spark will be re-leased at the metal tip of the white ceramic

pin located on the side of the burner. Once the flame is on, release the control knob

gently. If the flame turns off, simply repeat the above procedure.

DO NOT ignite the burners if the black burner cap is not installed or

WARNING

Manual Ignition

Manual ignition is always possible even when the power is cut off, or in the event of

a power failure. Turn the control knob counter-clockwise to the MAXIMUM position;

light the flame with a kitchen lighter or with a match.

Using the Burners Correctly

Keep children at a safe distance from the appliance during

WARNING

operation. DO NOT allow children to operate the appliance!

not centered, the flame will be irregular.

1. Always check that the burner caps are properly installed before operation:

A

A

B

B

Correct

A

B

Incorrect

2. Verify that the flame of the worktop burners is completely blue and with a regular

aspect as shown below:

3. Always adjust the burner flame so it does not extend beyond the edge of the pan.

Correct Incorrect

26

Page 32

Using the Oven

Using Pans Correctly

1. Always ensure that the bottom and handles of pans do not protrude over the

worktop.

2. When cooking with flammable fat, such as oil, do not leave the range unattended.

3. Use pots of the appropriate size on each burner following the indication of the

diagram below.

4. To avoid overflow when boiling liquids; turn knob to the minimum heat.

5. Always use pots with matching lids.

6. Dry the bottoms of pans before operation.

7. Wok Cooking: Always use the wok adapter supplied with the range. The wok

pan’s external diameter shall not be smaller than 10” and larger than 16”.

Oven Cooking

1. Use care when opening door. Let hot air or steam escape before removing or

placing food.

2. DO NOT heat unopened food containers. Pressure build-up may cause container

to burst and result in injury.

3. Keep oven vent ducts unobstructed.

Placement of Oven Racks

1. Always place oven racks in desired location while oven is cool. If rack must be

moved while oven is hot, DO NOT let potholder make contact with heating element

in oven.

2. DO NOT CLEAN DOOR GASKETS. The door gasket is essential for a good seal.

Care should be taken not to rub, damage, or move the gasket.

3. DO NOT USE ABRASIVE OVEN CLEANERS. No commercial oven cleaner or

oven liner protective coating of and kind should be used in or around any part of the

oven.

Clean only the parts listed in the manual, before cleaning the oven, remove broiler

pan and other utensils.

4. In case of electric power failure reset oven/broiler controls to the OFF position, do

not attempt to use oven/ broiler until the power has been restored.

27

Page 33

Using the Oven

Placement of Oven Racks Continued

5. DO NOT TOUCH HEATING ELEMENTS OR INTERIOR SURFACE OF OVEN.

Heating elements may be hot even though they are dark in color. Interior surfaces of

an oven become hot enough to cause burns. During and after use, do not touch, or

let clothing or other flammable materials come into contact with the heating elements

or interior surfaces of the oven until they have had suf-ficient time to cool. Other

surfaces of the appliance may become hot enough to cause burns, for example,

oven vent openings and surfaces near these openings, oven doors, and oven glass

window.

6. Take care to reset all worktop/oven/broiler burner controls to the OFF position

after use of the appliance.

Symbols:

Oven Functions Selector

WARNING

OFF

Max

250

450

400

To reduce the risk of tipping of the appliance, it must be secured with

a properly installed anti-tip device. To check if the device is installed

properly, remove the appliance from the wall and verify that the

anti-tip device is engaged.

350

300

28

Page 34

Using the Oven

Oven Racks

The ranges are equipped with commercial grade shelves and an enamel cooking

tray. Shelves are mounted on the appropriate guides situated on the sides of the

oven compartment. Insert the shelf between the top and bottom guide in any of the 5

positions available.

To keep the oven as clean as possible, cook on the tray.

When available, always follow recipe book directions. Personal experience will

help to determine any variation in the values reported in the table. In any case, it is

recommended to follow the instructions of the specific recipe being used.

When using the oven for the first time it should be operated for

15-30 minutes at a temperature of about 500°F/260°C without

WARNING

Note: if you have a griddle, you may want to clean it but it does not need to be

seasoned before use.

cooking anything inside in order to eliminate any moisture and

odors from the internal insulation.

29

Page 35

Using the Oven

High Bake/Preheat: This setting is the optimum setting for raosting and baking,

suggested use if for baking at temperatures 300-525 degrees. High Bake will use

both the bottom element and the top element for even cooking and optimal oven

temperatures. Use this setting for preheating the oven- High Bake is designed to

get the oven to optimal temperature as quickly as possible. After the oven reaches

desired temperature, you can leave on this setting for optimal heat, or adjust

accordingly to convection bake, bake, convection broil, or broil.

Bake/ Low Bake: Utilizing only the bottom element, this setting is designed for low

heat settings under 375 degrees for optimal results.

Convection Bake: Utilizing both the bottom heating element and convection fan this

setting is recommended for all temperatures up to 450 degrees. For most baking

applications and recipes, this setting is recommended for a faster and more even

cooking experience.

Broil: This setting uses only the top heating element.

Convection Broil: This setting uses both the top heating element and the convection

fan. For most broiling applications and recipes, this setting is recommended for a

faster and more even cooking experience.

Maintaining your Range

Replacing the Oven Bulbs

Disconnect the power before servicing the unit.

WARNING

To replace the oven light bulb, unscrew the protection cap that projects out inside

the oven. Note: Touching the bulb with your fingers may cause the bulb to burn out.

Always use protective gloves or a clean cloth to remove the bulb.

30

Page 36

Maintaining Your Range

Cleaning Your Range

During cleaning operation never move the appliance from its original

installation position. Never use abrasive cleaners! Scratches on the

WARNING

Cleaning after Installation: Use a stainless steel cleaning product or wipe to elimi-

nate the glue residues of the blue protection film after removal.

Cleaning the Worktop: Periodically clean the burner heads, the cast iron pan

supports, and the burner caps using warm water. Remove burner food and fat

residues with a rub-ber spatula.

Cleaning Stainless Steel: For the best results use a stainless steel cleaner product with

a soft sponge or cloth with a warm soap and water solution. Never use abrasive

powders or liquids.

Cleaning the Burner Caps: Lift the burner caps from the burner heads and wash them

in a warm soap and water solution. Dry thoroughly before using them again. Before

reinstalling them on the burner head, check that the gas flow holes are not clogged

with food residues or cleaning products.

Cleaning Enamel: Enameled parts should be cleaned frequently with warm soap

and water solution applied with a soft sponge or wipe. Never use abrasive powders

or liquids! Do not leave acid or alkaline substances on the enameled parts (such

as vinegar, lemon juice, salt, tomato sauce etc.) Use a rubber spatula to remove fat

residues.

Cleaning Glass Door: Clean the glass using a non-abrasive sponge or wipe with a

warm soap and water solution. Use a rubber spatula to remove fat deposits.

stainless steel surfaces are permanent. Do NOT clean the range when hot!

31

Page 37

Troubleshooting

Oven Problem

Range does not function

Broil does not work

Door does not open

Igniter does not work

Igniter sparking taut; No flame ignition

Burner ignites but flame is large,

distorted, or yellow

Oven door is locked and will not

release, even after cooling.

Oven is not heating

Oven light is not working properly

Oven light stays on

Cannot remove lens cover on light

Possible Cause and/or Remedy

Range is not connected to electrical power. Check

power circuit breaker, wiring, and fuses.

Temperature control knob is rotated too far past

broil position (500°F); preheating indicator will

light intermittently.

Oven is still in self-clean mode. Door latch will

release when a safe temperature is reached.

The circuit is tripped, fuse is blown, or range is not

connected to power.

Gas supply valve is in the “OFF” position or gas

supply is interrupted.

Burner ports are clogged or the unit is not set to

the appropriate gas type. Call a technichian to

repair.

Turn the oven off at the circuit breaker and wait 5

minutes. Turn the breaker back on and the oven

will reset itself.

Check the circuit breaker or fuse box to your

house. Make sure ther is proper electrical power

to your oven.

Replace or reinsert the light bulb if loose or

defective.

Check for obstruction in the oven door. Check to

see if hinge is bent.

There may be soil or build up on the lens cover.

Wipe the lens cover with a clean, dry towel prior

to attempting to remove the lens cover.

32

Page 38

MEET THE REST

OF THE FAMILY

Call us for 5% off a ZLINE complementary product

Mention the promo code FAMILY5 when you call in

C.

A.

B.

A. KITCHEN SINKS

Single bowls and double bowls in stainless steel.

Starting at $219.95

B. MICROWAVE DRAWERS

Available in stainless steel that can be installed in a kitchen island, pantry or cabinetry.

Starting at $949.95

C. PROFESSIONAL RANGE HOODS

Available in stainless steel, black stainless steel, snow stainless steel and a variety of

wood finishes in three sizes: 30”, 36”, 42” and 48”.

Starting at $319.95

E.

D.

D. KITCHEN FAUCETS

Pull down and standard faucets available in stainless steel, chrome, oil-rubbed bronze

and matte black.

Starting at $239.99

E. DISHWASHERS

Panel-ready and designer dishwashers available in two sizes: 18” and 24”.

Starting at $699.95

*PRICE SUBJECTED TO CHANGE

www.zlinekitchen.com

1-614-777-5004

33

Page 39

34

Page 40

Kitchen and Bath

Two Locations:

916 Delaware Avenue

Marysville, Ohio 43040

350 Parr Circle

Reno, NV 89512

www.zlinekitchen.com

1-614-777-5004

Loading...

Loading...