ZKTeco C5S120, C5S110, C5S140 User Manual

USER MANUAL

C5S110&120&140

Version: 1.1

Date: Apr., 2018

About This Manual

This manual introduces C5S110/120/140 access control panel installation connection and user instructions.

Contents

1 Safety Instructions ............................................................................................................................................................................................... 1

1.1 Important Security Instructions .......................................................................................................................................................... 1

1.2 Installation Cautions ............................................................................................................................................................................... 3

2 System Introduction ............................................................................................................................................................................................ 4

2.1 System Function Parameters ................................................................................................................................................................ 4

2.2 Product Technical Parameters.............................................................................................................................................................. 4

2.3 Control Panel Indicators ........................................................................................................................................................................ 4

3 Installation and Connection .............................................................................................................................................................................. 6

3.1 Chassis Installation .................................................................................................................................................................................. 6

3.2 Installation of Access Control Panel Wires........................................................................................................................................ 7

3.3 Control Panel System Installation ....................................................................................................................................................... 8

3.4 Control Panel Connection Terminals ................................................................................................................................................. 9

3.5 Connection with Door Sensors, Exit Switches, and Auxiliary Input Devices ....................................................................... 12

3.6 Connection with Readers .................................................................................................................................................................... 13

3.7 Relay Output Connection.................................................................................................................................................................... 15

3.8 Access Control Panel System Power Supply Structure ............................................................................................................... 17

4 Equipment Communication ........................................................................................................................................................................... 19

4.1 Access Control Networking Wires and Wiring .............................................................................................................................. 19

4.2 TCP/IP Communication ........................................................................................................................................................................ 20

4.3 RS485 Communication ........................................................................................................................................................................ 20

4.4 Wireless Communication..................................................................................................................................................................... 20

4.5 DIP Switch Settings ............................................................................................................................................................................... 23

4.6 USB Upgrade ........................................................................................................................................................................................... 23

Contents I

1 Safety Instructions

1.1 Important Security Instructions

1) Read, follow and keep instructions: Before operating the equipment, read and follow strictly all security and

operation instructions. Please keep the instructions in good condition for future reference.

2) Accessories: Please use the accessories recommended by the manufacturer or delivered with the product. Any

other related product is not recommended as the major alarming or monitoring system. The major alarming

or monitoring system should comply with the local applicable fire-prevention and security standards.

3) Installation cautions: Do not place this equipment on any unstable table, tripod mount, support or base, lest

the equipment should fall and get damaged, and more undesirably cause severe personal injuries. Therefore,

it is important to install the equipment as instructed by the manufacturer.

4) All peripheral devices must be grounded.

5) No external connection wires can be exposed. All connections and idle wire ends must be wrapped with

insulating tapes to prevent accidental contact with exposed wires from damaging the equipment.

6) Repair: Do not attempt unauthorized repair of the equipment. Disassembly or detachment is likely to cause

shock or other risks. All repair jobs should be done by qualified repair personnel.

7) Damages in need of repair: In any of the following cases, first disconnect the power supply from the

equipment and notify qualified repair personnel for repairs:

The power cord or connector is damaged;

There is entry of liquid or any other foreign object into the equipment;

The equipment is wetted or exposed to bad weather (rain, snow, etc.);

If the equipment cannot work normally even though operated as instructed, please be sure to adjust

only the control components specified in the operation instructions. Incorrect adjustment of other

control components may cause damage to the equipment, and even the equipment may not be

recovered;

The equipment falls down or its performance changes obviously.

8) Replacing components: If it is necessary to replace a component, the repair personnel must use only the

substitutes specified by the manufacturer.

9) Security inspection: After the equipment is repaired, the repair personnel are supposed to conduct security

inspection to ensure the equipment can work normally.

10) Power supply: Operate the equipment with only the type of power supply indicated on the label. Contact the

operator for any uncertainty about the type of power supply.

Safety Instructions 1

Violation of any of the following cautions is likely to lead to personal injury or equipment failure, We will not

be responsible for the damages or injuries caused thereby.

Before installation, switch off the external circuit (that supplies power to the system), including locks.

Before connecting the equipment to power supply, ensure the output voltage is within the specified range.

Never connect power before completion of installation.

2 C5S110&120&140 User Manual

1.2 Installation Cautions

1) The conduits of wires under relay must be matched with metaled conduits, other wires can use PVC conduits,

to prevent failure caused by rodent damage. Although a control panel is designed with good antistatic,

lightning-proof, and leakage-proof functions, ensure its chassis and the AC ground wire are connected

properly and the AC ground wire is grounded physically.

2) It is recommended not to plug/unplug connection terminals frequently when the system is energized. Be sure

to unplug the connection terminals before starting any relevant welding job.

3) Do not detach or replace any control panel chip without permission, because unprofessional operation may

cause damage to the control panel.

4) It is recommended not to connect any other auxiliary devices without permission. All non-routine operations

must be communicated to our engineers in advance.

5) A control panel should not share one power socket with any other large-current device.

6) It is preferable to install card readers and buttons at heights of 1.4-1.5m above the ground, but the heights

are subject to proper adjustment according to customers’ usual practice.

7) It is advised to install control panels at places easy of maintenance, like a weak electric well.

8) It is strongly recommended that the exposed part of any connection terminal should not be longer than

4mm, and specialized clamping tools may be used to avoid short-circuit or communication failure resulting

from accidental contact with excessive exposed wires.

9) To save access control event records, export data periodically from control panels.

10) Get prepared countermeasures according to application scenarios for unexpected power failure, like

selecting power supply with UPS.

11) If RS485 reader is connected externally and shares the power supply for the device (The control panel does

not support fingerprint verification of RS485 reader), it is recommended that the connection between the EXT

RS485 port and the reader be no longer than 100m. Otherwise, it is recommended that the reader use a

separate power supply.

12) The connection between a PC and a control panel should be shorter than 1200m for RS485 communications.

A length within 800m is recommended to make communications more stable.

13) To protect the access control system against the self-induced electromotive force generated by an electronic

lock at the instant of switching off/on, it is necessary to connect a diode in parallel (please use the FR107

delivered with the system) with the electronic lock to release the self-induced electromotive force during

onsite connection for application of the access control system.

14) It is recommended that an electronic lock and a control panel should use respective power supplies.

15) It is recommended to use the power supply delivered with the system as the control panel power supply.

16) In a place with strong magnetic interference, galvanized steel pipes or shielded cables are recommended, and

proper grounding is required.

Safety Instructions 3

2 System Introduction

The access control management system is a new modernized security management system, which is an effective

measure for security and protection management. It is mainly used to manage entrances and exits of important

places, such as banks, hotels, equipment rooms, offices, smart communities, and factories.

2.1 System Function Parameters

High-speed 32-bit 1.2GHz CPU, 128M RAM, and 256M Flash.

Embedded LINUX operating system.

The C5S110 for one-door one-way/two-way, C5S120 for two-door one-way/two-way, and C5S140 for

two-door two-way or four door one-way/two-way

A maximum of 100,000 card holders and 200,000 offline event records.

Support of multiple Wiegand card formats and a password keypad, compatible with various types of cards.

Use of dual communication technologies: the Ethernet plus the RS485 industrial bus, for reliable

communications.

With a watchdog (hardware) built in the control panel to prevent crash.

Over-current, over-voltage, and inverse-voltage protection for input of power supply to the control panel.

Over-current protection for the power supply to card readers.

Instant over-voltage protection for all input/output ports.

Instant over-voltage protection for communication ports.

2.2 Product Technical Parameters

Working power supply: Rated voltage 12V (±20%) DC, rated current ≥ 3A (rated current for C5S140 ≥ 5A)

Working environment: Temperature -10°C~50°C; humidity 20%~80%.

Electronic lock relay output: The maximum switching voltage: 36V(DC); The maximum switching current: 5A

Auxiliary relay output: The maximum switching voltage: 36V(DC); The maximum switching current: 2A

With detachable connection terminals made of alloy-steel non-magnetic flange materials.

Control panel dimensions: C5S110: 160mm*140mm*31.6mm; C5S120/140: 197mm*171mm*31.6mm

Chassis dimensions: 308.25mm*355.2mm*67.8mm

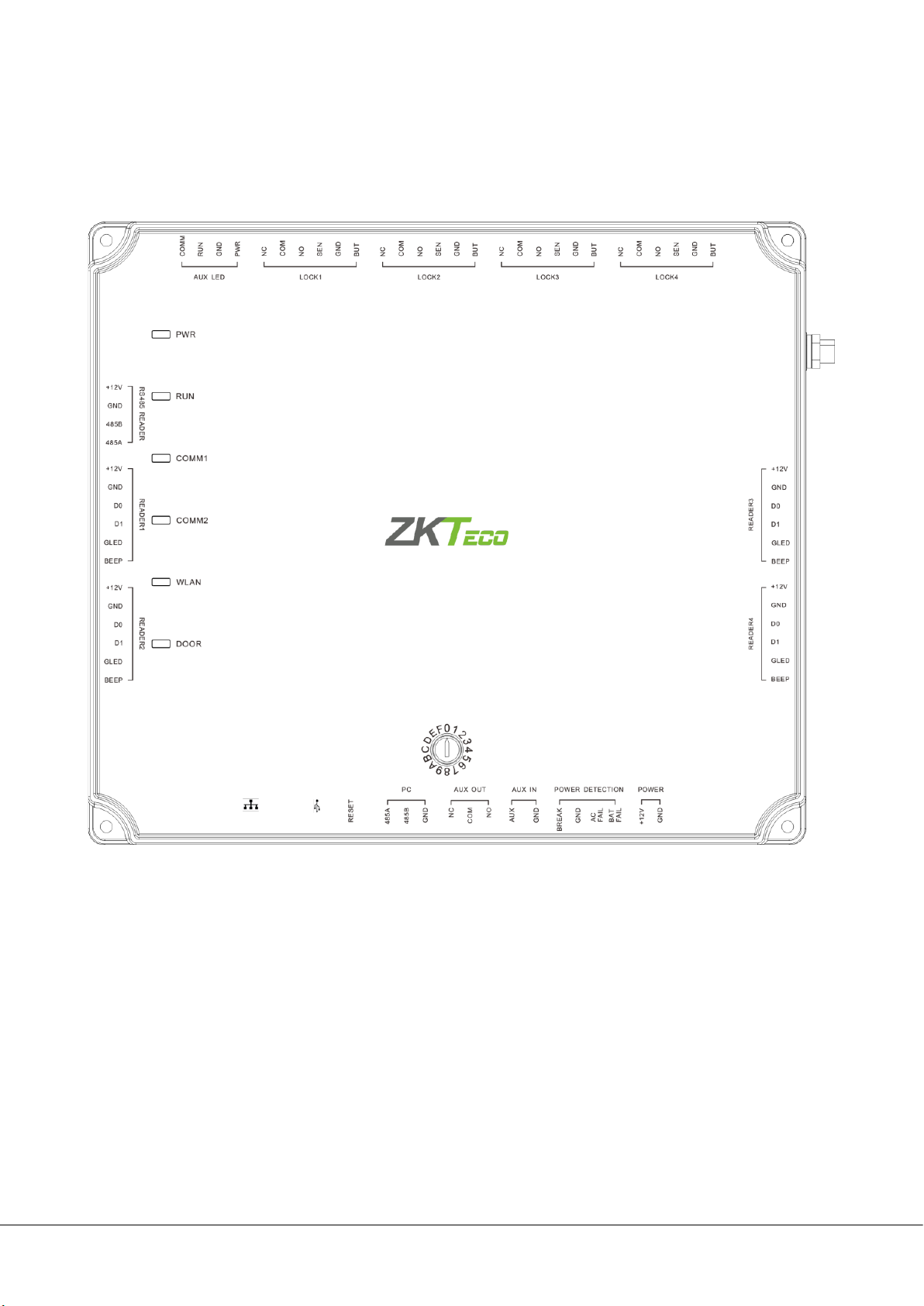

2.3 Control Panel Indicators

When the C5S110/120/140 is powered on, normally the POWER indicator (red) is lit constantly, the RUN indicator

(green) flashes (indicating the system is normal), and other indicators are all off.

However, under the following circumstances:

1) COMM1 indicator (yellow): flashing indicates the system is communicating with upper-level devices (for

example, the PC).

2) COMM2 (yellow): flashing indicates the system is communicating with lower-level devices (for example,

readers).

4 C5S110&120&140 User Manual

3) WLAN indicator (green): flashing indicates the system is communicating in wireless (WIFI) mode.

4) DOOR indicator (green): flashing indicates a door opening signal (a door is opened).

Diagram of C5S140 indicators:

System Introduction 5

Loading...

Loading...