Zk software C3-100 Installation Instructions And Connection Manual

Key hole

Thread hole

Thread hole

3.Get through the thread hole

Get through the thread hole

Fixed case

1

2

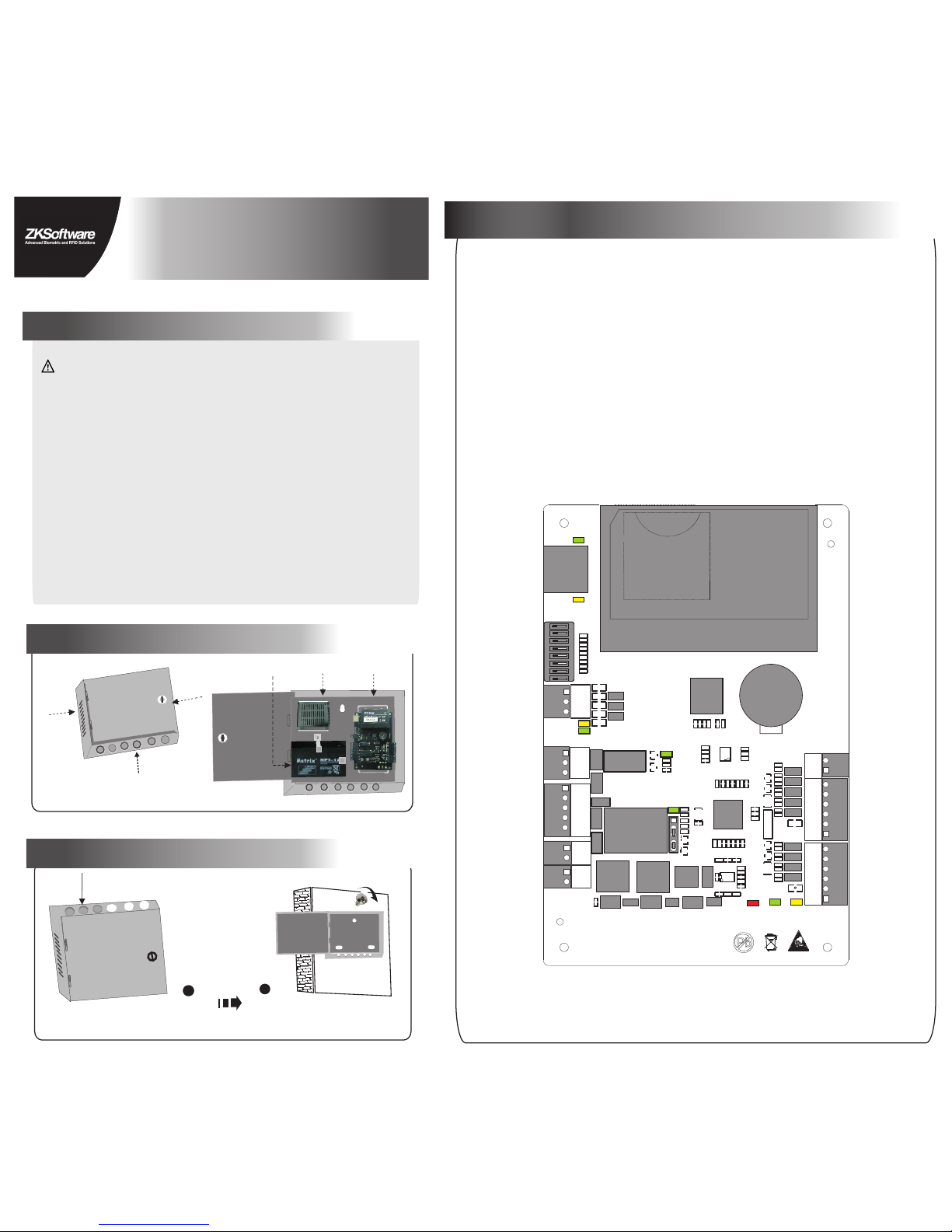

4.LED indicators, Wires, Auxiliary Input and Output

Appearance of case

Notes:

C3- 1 0 0 Installation Instructions and Connection Guide

1.Cautions

Ple ase not e the fol lowin g cauti ons.M is-op erati on may le ad to per sonal i njury o r equip ment fa ilure :

1) Do no t energ ize the sy stem be fore in stall ation i s compl ete; ne ver car ry out in stall ation a ctivi ties wh en

Visi on: 1. 0. 1

Dat e:Oc t. 2010

2) All p eriph eral de vices m ust be gr ounde d.

3) It is p refer red tha t all wir es run th rough P VC or gal vaniz ed pipe s.

5) It is r ecomm ended t hat car d reade rs and bu ttons s hould b e insta lled at h eight o f 1.4m- 1.5m ab ove gro und.

6) It is r ecomm ended t o use the p ower su pply in c ase for c ontro l panel , and ext ernal p ower su pply fo r each

4) It is s trong ly reco mmend ed that t he leng th of exp osed pa rt of any c onnec tion ca ble sho uld not b e longe r

Pro fessi onal cl ampin g tools m ay be use d to avoi d unint entio nal con tact of e xpose d wires t o tha n 4 mm.

the s ystem i s energi zed.

sho rt-ci rcuit o r commu nicat ion fai lure. avo id

Des cript ion of no rmal wo rking s tate:

Con nect th e syste m to the po wer sup ply.If t he syst em work s prope rly,the P OWER in dicat or(re d) is lit

con stant ly and th e RUN ind icato r(gre en) fla shes.

Hea t

dis sipat ion

hol e

2.Components

Power supply

Backup battery

Control panel

1)Meaning of LED indicators:

LINK indicator(green): always(green) indicates TCP/IP

ACT indicator(yellow):its flashing indicates data is in transmitting

TX indicator(yellow):its flashing indicates it is sending data through

RX indicator(green):its flashing indicates it is receiving data through

Auxiliary output indicator(green):always(green) indicates it is in use.

Lock indicator(green):always(green) indicates lock is open.

POWER indicator(red): always(red) indicates control panel is power

RUN indicator(green):its flashing indicates the system works normally.

CARD indicator(yellow):its flashing indicates card is punched on reader.

A Use 2-conducotor power cord

2)Recommended use of wires:

3)The auxiliary input may be connnected to infrared body detectors,

4)The auxiliary output may be connected to door bells,alarms,etc.

B Use 6-conductor wire between wiegand reader and control panal

C Use 4-conducotor lock power cord (RVV 4*0.75mm)

D Use 2-conducotor switch power cord(RVV 2*0.5mm)

communication is proper;

on.

alam switches,etc.

Ethernet interface

Dip switch

RS485 interface

Auxiliary output1

Door1

Power of lock

Power of control panel

A

A

C

D

D

B

B

{

{

{

{

{

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD card

Advanced Access Control

loc k.

through TCP/IP communication.

RS485 communication.

RS485 communication.

(RVVP 6*0.5mm) (To choose the proper cord according to the

interface you connect, such as 6,8,10 cord.)

1# Door Button

1# Door

wiegand reader

1# Door

wiegand reader

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

1 2 3 4

1 2 3 4

ON

ON

5 6 7 8

5 6 7 8

Dia gram of p laces o f DIP swit ch.

1

2

4

8

16

32

Res tore

fac tory se tting .

RS4 85

ter minal

res istan ce.

fig ure( 5- 1)

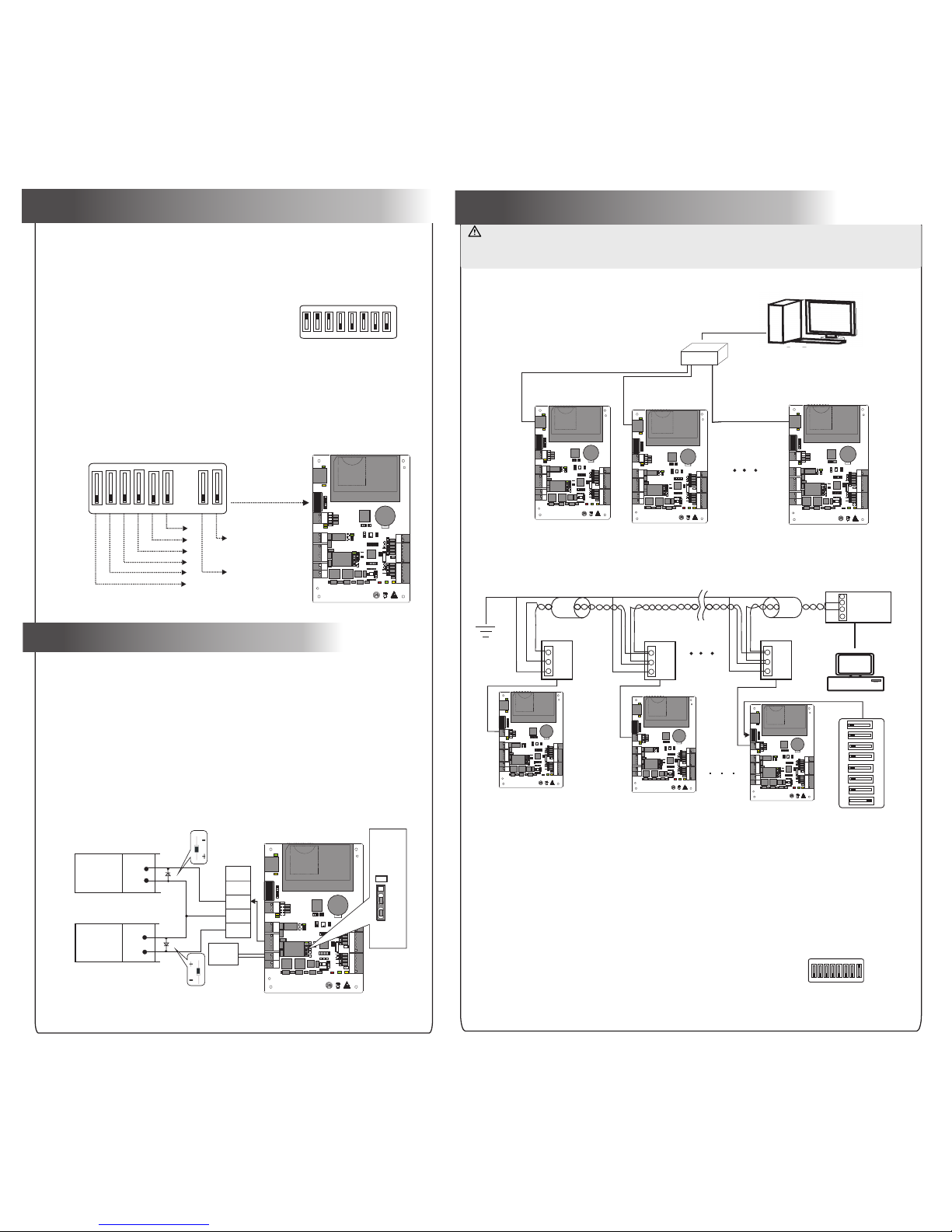

Set R S485 ad dress t hroug h DIP swit ch:

1)Internationally accepted RVSP(shielded twisted-pair) wires should be used for communication to effectively avoid interference.

RS485 communication wires should be connected by means

of bus cascade connection.

2.RS485 Communication

1.TCP/IP Communication

The background PC software is able to communicate with the system according to two protocols(RS485 and TCP/IP) for data

exchange and remote management. The communication cable should be away from high-voltage lines as far as possible. Do

not keep the communication cable in parallel with power cords or bind them together.

3)One RS485 BUS may hold 63 units of control panel, but it is not recommended to connect with more than 32 units.

access control panels.

7.Equipment communication

5.RS485 address setting, Restore factory setting, Terminal resistance setting

NO Lock

NC Lock

+

+

+

-

-

Lock p ower

inpu t

Enla rged di agram

of loc k ports

NC

NO

GND

COM

SEN

Diode

Diode

LOCK

LOCK

+

+

-

-

FR107

FR107

6.Connection of lock

“Wet mode” wiring diagram of lock connecting with external power supply.

-

LED

1

2

3

4

5

Jum per

ter minal

Fac tory

def ault

wet m ode

1 2 3 4 5 6 7 8

ON

Not es:

4) When t he bus is l onger t han 300 m, to enh ance th e stabi lity of c ommun icati on, it is n ecess ary to ke ep plac e 8 of DIP

2) Cons ideri ng stab ility o f commu nicat ion, it i s recom mende d the len gth of RS 485 bus i s less th an 600m

As sh own in th e figur e above , place 8 o f the DIP sw itche s of unit s 1# and 8# i s place d at "ON " s tatus .

PC

Swi tch

DIP s witch

1 2 3 4

ON

5 6 7 8

1# co ntrol p anel 2# co ntrol p anel

8# co ntrol p anel

485+

485-

GND

48 5

Con verte r

485+

485+

485+

485-

485-

485-

GND

GND

GND

ser ial lin e

PC

3) Wh en the Ele ctric al Lock i s conne cted to t he Acces s Contr ol Syst em, you n eed to pa ralle l one FR1 07

in th e packa ge) to pr event t he self -indu ctanc e EMF affe cting t he syst em, do no t rever se dio de (equ ipped

the p olari ties.

1# co ntrol p anel

2# co ntrol p anel

n# co ntrol p anel

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

BUTTON1

READER1 READER2

+12V

+12V

GND

GND

WD1

WD1

WD0

WD0

GLED

GLED

BEEP

BEEP

IN

GND

ACT

LINK

1

TX

RX

V+

POWER

PC

NC

COM

NO

COM

NO

NC

LOCK1

GND

SEN

V-

GND

485-

485+

AUXOUT1

LOCK

GND

+12V

1 2 3 4

ON

5 6 7 8

1

POWER

CARD

RUN

LAN

SD卡

Advanced Access Control

1) Pl ace 1-6 o n DIP swit ch are fo r setti ng the nu mber of c ontro l panel w hen com munic ating t hroug h

RS4 85, it is a dopte d for bin ary cod ing, an d littl e endia n, the ad dress r epres ented b y place 1 -6 are

sho wn as fig urue( 5-1).

2) Be fore se tting t he addr ess, pl ease ke ep the sy stem is p ower off , Jump pl ace 1-6 t o desir ed stat us,

and t he addr ess num ber sha ll not be t he same a s anoth er one in t he netw ork. Fo r examp le: to se t the

dev ice num ber as 39 ( 39=1+ 2+4+3 2), the c orres pondi ng RS48 5 code is 111 001, th en Jump p lace 1,

2,3 a nd 6 at “ON ” statu s.

3) Pl ace 7 is fo r resto ring fa ctory d efaul t setti ngs, Ju mp it for t hree ti mes wit hin 10 se conds a nd rest art

the s ystem , then al l infor matio n in RAM of c ontro l panel w ill be cl eared a nd the sy stem re store s facto ry

def ault se tting s.

4) Pl ace 8 is fo r setti ng term inal re sista nce whe n commu nicat ing thr ough RS 485. Ju mp it at “O N” stat us,

the n it is equ ivale nt to hav e a termi nal res istan ce of 120 o hm betw een 485 + and 485 -.

1) Co ntrol p anel pr ovide s lock co ntrol o utput i nterf aces. F or NO loc k ,it is op en when p ower is o n, and

clo sed whe n power i s off, so “ COM and N O” inter faces s hould b e used; F or NC loc k, it is op en when

pow er is off , and clo sed when p ower is o n, so CO M and NC” in terfa ces sho uld be us ed.

2) Co ntrol p anel su pport s “dry mo de” and “ wet mod e” by set ting th e jumpe r, it is “we t mode” w hen

con necti ng “V+ V-” In put int erfac es to sup ply pow er for lo cks, pl ease sh orten 2 -3 and 4- 5. Equi pment

fac tory de fault s ettin g is dry mo de. For s ettin g “dry mo de” and “ wet mod e”, ple ase ref er to <<C 3-100 /

200 /400 ac cess co ntrol p anel in stall ation i nstru ction s>>.

swi tches o f the fir st and th e last co ntrol p anel at “ ON” sta tus.

Loading...

Loading...