Installation instructions

®

Zip HydroTap G4

Filtered boiling and chilled drinking water for commercial kitchens and tea rooms.

VENTILATION IS

ESSENTIAL

Affix model number label

here

!

READ

SECTION 2 'VENTILATION'

READ BEFORE YOU START

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 1 of 28

801314UK

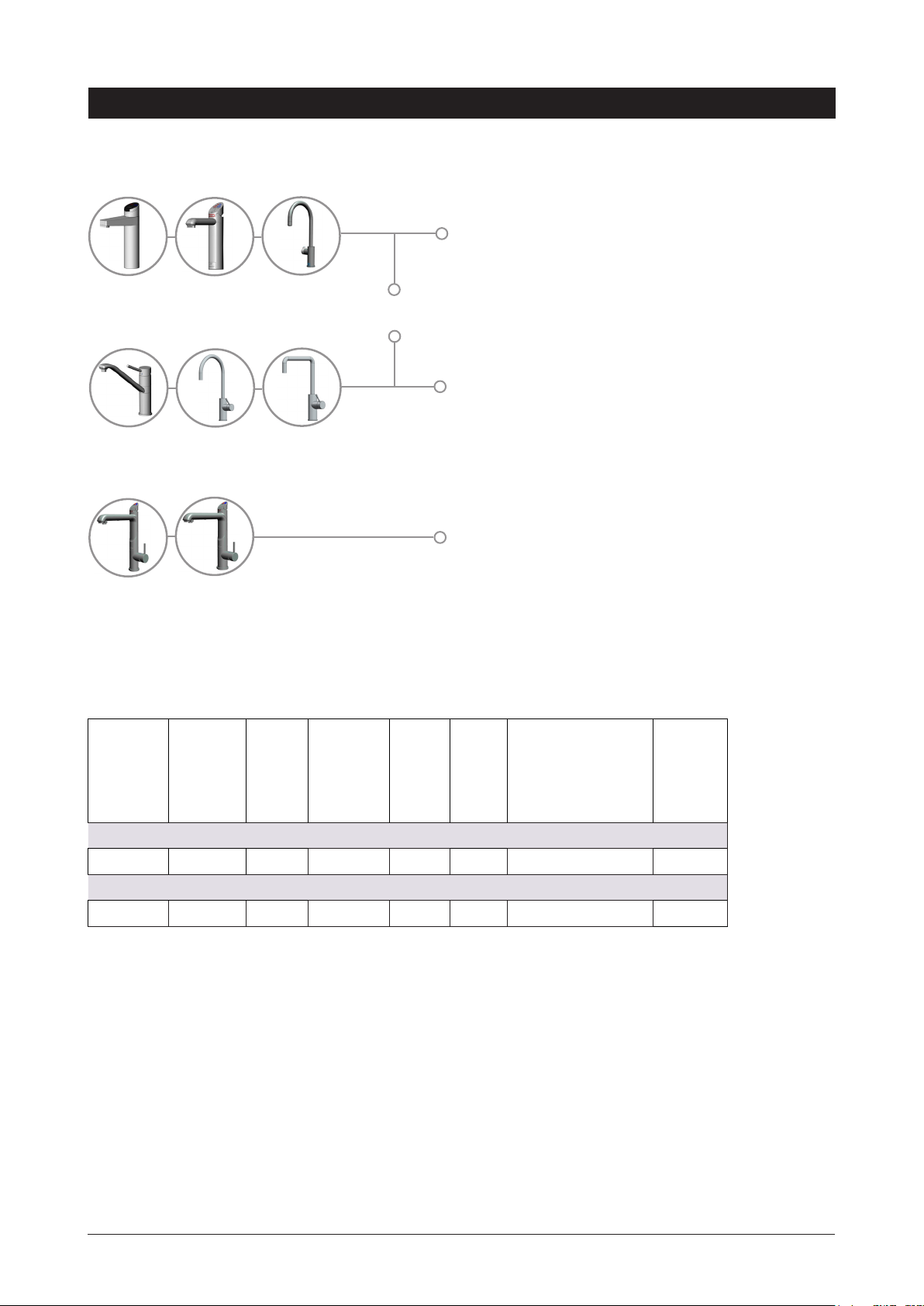

Tap options

The G4 series offers a range of interchangeable taps to suit the customer's needs

Classic HydroTap®G4 range

These standalone taps are directly compatible with

the G4 Command-CentreTM.

Arc / Cube range

Elite range

Mixer range

The mixer tap range may be used in conjunction with

any of the above to provide mixed hot and cold water

for sanitary use.

The All-in-One tap may be used as alternatives to

any of the above combinations.

All-in-One range

Page 2 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Index

HydroTap®G4 specifications

Installation check list .................................................................................................................... 4

General product features ............................................................................................................. 5

Important safety instructions ........................................................................................................ 6

Warnings and regulatory information ........................................................................................... 7

Major components and accessories ............................................................................................. 8

Technical specifications ............................................................................................................... 9

Before installation and site requirements ..................................................................................... 10

Installation instructions

Step 1 -

instructions supplied with the tap head.

Step 2

Section 1- Ventilation.

1.1- Ventilation for all models ............................................................................................11-12

Step 3

Section 2- Booster installation.

Step 4

Section 4 - Command-CentreTM installation.

Step 5

Section 5 - Commissioning.

Measure and cut all the tap holes, fit the taps : Refer to 803341UK Tap installation

- Check for adequate ventilation.

- Install the booster and / or filter / softener (if required).

2.1- Booster specifications and descriptions ..................................................................... 13

2.2- Installation procedure ................................................................................................. 14

2.3- Booster installation ..................................................................................................... 14

2.4- Braided hose connections .......................................................................................... 15

Section 3- Filter / softener installation.

3.1- Filter / softener installation ......................................................................................... 16

- Install the Command-CentreTM.

4.1- Check the external bypass valve setting ................................................................... 17

4.2- Fit the mains water supply hose ................................................................................ 17

4.3- HydroTap®G4 models ................................................................................................ 18

4.4- HydroTap®G4 and mixer tap combinations................................................................ 19

4.5- All-in-One 'Mains' tap ................................................................................................. 20

4.6- All-in-One 'Vented' tap ............................................................................................... 21

- Commission the HydroTap®G4.

5.1- Select language ........................................................................................................ 22

5.2- Filter flush ................................................................................................................. 22

5.3- Flow calibration .......................................................................................................... 22

5.4- Boiling calibration ....................................................................................................... 23

5.5- Booster activation ...................................................................................................... 23

5.6- Safety sensor calibration ............................................................................................ 23

Trouble shooting

Trouble shooting table .................................................................................................................. 24

End of life disposal ....................................................................................................................... 25

Warranty ....................................................................................................................................... 25

Contact details ............................................................................................................................. 28

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 3 of 28

Installation checklist

Before installation

• Read the instructions and check if there is adequate space to install all of the components.

• Note Not all fittings are supplied with the appliance kit. Isolation valves are not supplied.

• Check the mains water pressure is within min / max requirements (see page 9).

• Check the water quality to determine if extra filtration will be required.

• Note This product must be fitted to a potable water supply.

• Check the Command-CentreTM rating plate and ensure correct power is available.

• Check the under counter cupboard floor supporting the Command-CentreTM is adequate for its

total weight, when full of water.

Before commissioning

• Check the system has been installed correctly.

• Check all plumbing fittings have been tightened.

• Ensure the outlet and vent pipes are positioned to drain correctly.

• Ensure there is adequate ventilation.

• Check all tubes and pipes from the Command-CentreTM to the tap have a constant rise and there

are no sags or kinks in the hoses.

• Check all electrical connections are correct and there are no loose wires.

Commission (see section 5)

• Flush the supply line before connecting.

• Turn on the water and check for leaks.

• Flush the filter(s).

• Activate / enable the booster (if fitted).

• Calibrate the safety sensor for boiling models.

• Where applicable, programme the Command-CentreTM to suit the customer’s requirements.

Page 4 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

General product features

Thank you for purchasing a Zip HydroTap®G4. Please read and follow these instructions carefully to ensure

safe and trouble free operation. If help and advice is required, please call 0345 6 005 005.

What is the Zip HydroTap®G4 ?

This Zip HydroTap®G4

is an electronically controlled, filtered, boiling and chilled water drinking system for

the kitchen. The HydroTap®G4 systems are under counter drinking water appliances with a dispensing tap

mounted on a sink or worktop, which has been designed for commercial applications. The HydroTap®G4

utilises a conventional refrigerant compressor to chill the water and an immersion heating element to boil the

water. The boiling and chilled models will dispense boiling water (factory set to 98°C) chilled water (factory

set to 5-9°C). These units are NOT designed to be used as sanitary fixtures.

The Zip HydroTap®G4

models which dispense boiling water are fitted with a tap mounted safety lock. In

addition, there are various energy saving options accessible via the main menu. The system is equipped with

a self-calibrating program which caters for altitude adjustment. The water filter is a disposable item which will

require periodic replacement and is covered by a limited OEM warranty.

It is important that the installation be undertaken safely, correctly and completely in order to utilise all the

benefits that the HydroTap®G4

can provide. HydroTap®G4

Classic taps can be ordered with the tap head

assembly for disabled use. The disabled levers are supplied with Braille caps for the visually impaired.

Command-Centre

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 5 of 28

TM

Important safety instructions

This manual contains important safety and installation instructions for the Zip HydroTap®G4.

Please read all warnings, installation requirements and installation instructions before installing any Zip

HydroTap®G4. This system must be installed in accordance with water supply byelaws,

current IEE regulations and relevant local authority byelaws.

Safety

This appliance is not intended for use by children under 8 years or persons (including

children under 8 years) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or instruction concerning the use of the

appliance by a person responsible for their safety. Children should be supervised to ensure that they do not

play with the appliance. Cleaning and user maintenance shall not be made by children without supervision.

Refrigerant

The Zip HydroTap®G4 Command-CentreTM contains R134A refrigerant under pressure. Maintenance of the

refrigeration unit must be carried out by an accredited service provider or qualified refrigeration technician.

Qualifications

If the power cable is damaged it must be repaired only by a qualified technician. To avoid hazards, all

installation procedures must be carried out by a suitably qualified tradesperson. The power cable and power

outlet must be in a safe visible position for connection.

Venting

Sometimes steam and / or boiling water droplets may discharge through a vent outlet on the tap. If the tap

is not installed using the font, ensure the tap body is located so the tap outlet safely dispenses into the sink

bowl area.

Lifting

Take care when lifting. The Command-CentreTM may exceed safe lifting limits. If you feel this is beyond your

personal capabilities, please seek assistance with the lift. The weights of the Command-CentreTM is marked

on the packaging. Do not lift the Command-CentreTM by the front cover or any of its connections. Refer to the

technical specification, see page 9, for the weight of the product.

Airflow

The Zip HydroTap®G4 operates within the ambient temperature range 5ºC - 35ºC. Proper air circulation

must be provided. The system will operate satisfactorily only if the recommended air gaps are provided. See

Section 1 'Ventilation', page 11, for correct installation to prevent overheating. The vent kit supplied must be

fitted.

Altitude

Water boils at varying temperatures at different altitudes. The HydroTap®G4 adjusts for this during startup

calibration and will recalibrate itself on a regular basis.

Frost protection

If the HydroTap®G4 is located where the ambient air temperature could fall below 5ºC when the heater is

not in use, do not turn off the appliance electrically. This safeguard does not offer the same protection to the

connecting pipework and fittings.o

Positioning

It is important to ensure the Command-CentreTM is positioned in an accessible area close to the floor level.

The Command-Centre

up. The tap must be located above the Command-CentreTM. See Section 4, Command-CentreTM installation.

Page 6 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

TM

must have it’s base mounted in a horizontal position with all inlets and outlets facing

Warnings and regulatory information

Warnings

• The Zip HydroTap®G4 must be earthed. The resistance of the earth

connection from each exposed metal part must be less than 1Ω.

• All installation and service work must be completed by trained and

suitably qualified tradespeople. Faulty operation due to unqualified

persons working on this product, or any other Zip product may void

warranty coverage.

• As the installer, it is your responsibility to supply (if necessary)

and install all valves as required by local regulations and relevant

standards.

• The HydroTap®G4 is rated for 230V 50Hz AC operation.

• Do not remove the cover of the appliance under any circumstances

without first isolating the appliance from the power supply.

• Never locate the Command-CentreTM near, or clean with water jets.

• Do not expose the Zip HydroTap®G4 to the elements of nature.

• Due to the process of continuous improvement, Zip reserves the right

to change details mentioned in this manual, without notice.

• Visit www.zipwater.com/uk to ensure you have the latest copy of this

document.

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 7 of 28

Major components and accessories

801599 - HydroTap User Guide - Nov 2013 UK - V1.05 Page 1 of 20

801600 - Zip Quick Start Guide - October 2013 - V1.06

QUICK START GUIDE

Note: This quick start guide must be read in conjunction with

the main installation and user instructions

•

•

•

• Ensure the underbench can support the product weight when full of water,

Before installing ensure the following have been provided at

the installation site:

•

•

•

required. (One GPO is for the Zip HydroTap and the other for the Booster heater).

•

•

•

STEP 1-

Prepare and fit the Taps

Hole positioning: Position the tap such that it dispenses into

the sink bowl with ample clearance for a cup or tea pot. Alternatively,

the tap could be mounted away from the sink using a Zip Font, avail-

able as an accessory.

Apply a light smearing of silicon sealant

on the underside of the upper spacer to

ensure a watertight fi t.

For HydroTap and Mixer taps

cut a 35mm hole in the bench / sink top.

BENCH TOP

Ø35mm

HydroTap Tap

Mixer Tap

4-in-1

(If required)

NUT

LOWER RUBBER

WASHER

UPPER

RUBBER

WASHER

WASHER

BRAIDED

HOSE x 3

UPPER RUB-

BER WASHER

LOWER RUB-

BER WASHER

WASHER

NUT

White Hose

Ext. Mains

Blue band

Mixer IN

Red band

Mixer Out

O-RING

BASE

BLOCK

SPIDER

BASE

BLOCK

NUT

USB

CABLE

ALL

THREAD

ROD

NOTE: feed each of

the tubes and elec-

trical cable evenly in

between the legs of

the BASE BLOCK

SPIDER.

All-In-One Tap

(If required)

For AIO mains and vented Taps

Cut a 50mm hole in the bench / sink top.

NOTE: make sure the tap location will allow the nozzle to drain into the sink.

SINK TOP

50mm

ALL THREAD

ROD

STAINLESS

STEEL

WASHER

SPIDER

CLAMP

NUT

BLACK

PLASTIC

SPACER

NOTE: feed each of the three tubes and

electrical cable evenly in between the legs of

the SPIDER CLAMP when installing.

Fit the

STAINLESS STEEL

WASHER,

SPIDER CLAMP,

AND 6mm NUT.

6mm

NUT

SPIDER

CLAMP

Stainless

washer

Black plastic

spacer

35mm dia hole

Sink

O-RING

SINK TOP

Fit the O-ring to the underside of the AIO tap

then pass all hoses through the 50mm hole.

Chiller

connection

BLUE

From Mixer OUT to Tap - Vented version only

Boiler

connection

RED

Blue ring on

RHS mains IN to

Mixer IN

White ring

on LHS to

Mains in

Tap

O ring Base

Clear tube to Vent

Parts supplied Description

Tap options

1 x HydroTap®G4

Classic

Elite or #Arc / Cube

#

(inc. Tube kit)

1 x All-in-One

HydroTap®G4

Mains or Vented

1 x Mixer tap

Classic, Arc or Cube

Command-CentreTM and components

Duct kit

1 x Exhaust duct

1 x Mounting plate

2 x Outlet vent

1 x Inlet vent

Accessories Description

Booster

(inc. connection

hoses)

ZT011

Scale filter

installation kit

*ZT200G4

**ZT300G4

Filter not included.

Font Arc / Cube,

93441UK***

Font Classic / Elite

90915UK***

Replacement

internal 0.2 micron

filter

ZT402

Before proceeding, read the installation and user instructions

Check all the components are present and correct.

Check that you have all the necessary tools

(Check the specifications in the main book and allow an extra 5-8kg when full. )

Sufficient space in the cupboard to install all of the undersink units in accordance

with these Installation Instructions. Refer to technical specification for dimensions. If

required, make allowance for a booster heater. (Refer to the main book, for detailed

installation instructions).

A potable water supply connection with isolating valve inside the cupboard within

reach of the flexible braided hose and positioned so that the connection point and the

stop cock will not be obstructed when all the undersink units are installed.

For Zip HydroTap 160/125 &160/175 models, a 220-240Vac, 10A GPO will be

required. For Zip HydroTap 240/175 models, two 220-240Vac, 10A GPOs will be

NOTE: Check the cable lengths and outlet positions before proceeding.

A potable cold water supply with a minimum working pressure of 172kPa and a

maximum working pressure of 700kPa connected via an isolation valve.

For the mains pressure All-IN-ONE, both a hot and cold water supply will be required.

The undersink appliances must be mounted in upright positions as shown in the

diagrams.

IMPORTANT!

Do not proceed with the installation if these

requirements are not met.

Parts Supplied Description Parts Supplied Description

1 off

Hydrotap Tap

and hoses

1 off

Undersink Unit

with air and water-

filter

1 x Restrictaflow

valve and Tee

piece for Mixer

Taps

1 off Mains water

connection hose

1 x

Command-CentreTM

with air and water

filters

1 x Mains water

connection hose

Disabled lever kit

SP91560

(Classic HydroTap®)

Mixer upgrade***

SP91546 Classic

SP93413 Arc

1 x Booster inc.

connection hoses

(supplied with

240 models)

SP93414 Cube

All-in-One

upgrade***

SP93332 (vented)

SP93331 (mains)

1 x Installation

fittings (supplied

with vented mixer

tap models)

®

ZIP HydroTap

User Guide

•

Tap Operation...................(Pages 2-5)

•

LCD Screen & Menu .......(Pages 6-18)

•

Maintenance.................... (Pages 18-20)

•

Duct kit

1x Air Duct

1 x Mounting

plate

Vent kit

1 x Kickboard

louvre

1 x Door vent

louvre

1 x front vent grill

1 off

HydroTap

Booster heater

and hoses

(Supplied with

240/175 models)

Date of Installation.........

Affix Model Number Label

1 x User guide and

BC160/125G4

BC240/175G4

BCH160/125G4

BCH240/175G4

AV160/125G4

AN160/125G4

AV240/175G4

AN240/175G4

Here

801599

1 x Quick start

1 x Installation

guide

instruction

*ZT200G4 kit to fit filters

FL2300 (Light commercial use)

FL3600 (Normal commercial use)

**ZT300G4 kit to fit filters

FL6000 Plus (Heavy commercial use)

Recommended

water block

HE45004

*** Chrome finish part numbers are shown,

alternative finishes are available.

Page 8 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Technical specifications

Commercial Boiling Chilled HydroTap®G4 range

HydroTap®s

Boiling, chilled and filtered.

Elite

Classic

Mixer taps

Classic

Arc

All-in-One taps

Vented

Mains

Specifications

Capacity

Boiling

(cups

167ml/hr)

Capacity

Chilled

(glasses

200ml/hr)

Boost

(10A)

Arc / Cube

Cube

13A

sockets

required

+

Power

Rating

(kW)

230V

Boiling, chilled and filtered and mixed hot & cold.

Boiling, chilled and filtered and mixed hot & cold.

Boost

Rating

(kW)

230V

Unit Dimensions

W x D x H (mm)

with air duct

**Dry

Weight

(kg)

Boiling, chilled and filtered, without booster

160 175 no 1x13A 2.20 N/A 450 x 470 x 335 28

Boiling, chilled and filtered, with booster

240 175 yes 2x13A 2.20 2.20 450 x 470 x 335 28

Note

Chilled water will continue to be dispensed after the rated capacity has been used, although this may

affect the dispense temperature.

**Add an extra 5-8 kg when full of water.

Min / Max water supply pressure

HydroTaps and Mains All-in-One taps..............................0.17 MPa (1.7 bar) - 0.7 MPa (7 bar)

Mixer taps and Vented All-in-One taps.............................0.2 MPa (2 bar) - 0.7 MPa (7 bar)

Booster and scale filtration...............................................0.2 MPa (2 bar) - 0.7 MPa (7 bar)

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 9 of 28

Before installation

Before installation ensure that the following have been

provided at the installation site

•

Review of all the technical specifications.

•

Ensure the under counter cupboard floor can support the product weight

when full of water (allow an extra 5-8kg when full).

•

Sufficient space in the cupboard to install the Command-CentreTM and

other components in accordance with these installation instructions. See

Technical specification, page 9 for dimensions. Make allowance for a

booster if required. See sections 2 to 4, pages 13 to 21 for installation

instructions.

•

For Zip HydroTap®G4 models without booster, 1 x 220-240V AC 13A socket

will be required.

For Zip HydroTap®G4 models with booster, 2 x 220-240V AC 13A sockets will

be required.

(One socket is for the Command-CentreTM and the other for the booster).

•

Both the Command-CentreTM and booster must be installed in accordance

with IEE regulations, See Technical specification, page 9 for power

ratings.

Note Check all cable and hose lengths against inlet /outlet positions before

proceeding (see sections 2 to 4, pages 13 to 21 for general layout).

•

A potable water supply connection with isolating valve inside the

cupboard within reach of the braided hoses and positioned so that the

connection point and the stop cock will not be obstructed when the

Command-CentreTM is installed.

•

For the All-in-One 'Mains' models an external hot and cold water supply is

required.

•

If an external filtration or water softening device is required, then it is

important to allow extra space for these items.

•

A potable cold water supply with a minimum working pressure of:

(see page 9 min. / max. water supply pressure).

•

If pressure is likely to exceed 0.7 MPa (7 bar), install a 0.35 MPa (3.5

bar) pressure limiting valve.

•

The appliance must be placed with its base in a horizontal position.

IMPORTANT!

not met.

Page 10 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Do not proceed with the installation if these requirements are

Section 1

Ventilation

When installing air flow vents, the following tools will be required

•

Jigsaw and drill.

•

Keyhole or wall board saw.

1.1 Preferred ventilation arrangement shown below.

The ducted vent kit supplied with the Command-CentreTM exhausting through the kick-space should be used,

to provide adequate ventilation in all conditions. (Ancillary components are not shown in these diagrams).

Vent cut-out details

A Air outlet vent

Cupboard back must be

fully closed to prevent

recirculation into

cupboard from

kick space.

Inlet grille

100mm

min.

Inlet grille should be

fitted in baseboard

Position vent grille on

either the kick board or the

cupboard ends

Important See section 4 Command-Centre

pages 17 to 21.

TM

installation,

B Air inlet vent

C Ducted vent

B

C

A

A

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 11 of 28

Ventilation

1.2 Alternative arrangement (Dual fan kit)

In situations where the preferred arrangement cannot be used or will not work effectively e.g.

• Single cupboard where the 100mm grille spacing cannot be achieved.

• Where there are openings in the back of the cupboard allowing exhaust air to recirculate into the cupboard

space.

An SP93156 Dual exhaust fan kit* must be fitted in either arrangement A or B shown below and connected to

the DIN socket on the Command-Centre

TM

.

A Fan kit fitted to kick board and with kick space duct fitted to the Command-CentreTM.

B Fan kit fitted to cupboard door (position B1) or side (position B2) and without kick space duct fitted to the

Command-CentreTM.

*

For dual exhaust fan cut-out dimensions see the instructions provided with the kit.

BA

B1

B2

1.3 Alternative arrangement (Vent tray)

In situations where cupboard width is 1000mm or greater, without central pillar and where vent grilles cannot

be fitted in the kick board (e.g. hospitals).

• Use the Vent tray kit.

• The flat vent grille, supplied should be used as an

inlet vent and fitted to the cabinet side (adjacent

to the Command-Centre air inlet) or angled inlet

grille fitted in baseboard, if 100 mm separation

from Vent tray

exhaust can be

achieved.

Position a vent

grille in the

cupboard end or

inlet grille on the baseboard

100mm min.

Vent tray

Inlet grille should be

100mm

min.

Inlet grille

fitted on baseboard

Page 12 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Section 2

Booster system

2.1 Product description

The booster system is a compact electronically

controlled auxiliary water heater. It is intended to

provide pre-heating of water before it enters the Zip

HydroTap®G4 boiling tank. If the booster is used the

boiling water output will increase from 160 to 240

167ml cups/hour.

Note 1 Water connection

blue cap - water in

red cap - water out.

The braided hoses cannot be

lengthened.

Note 2 The electrical cable

length is 0.6m.

Note 3 Position the booster

within reach of the fixed hose

lengths, keeping the booster

as close as possible to the

Command-CentreTM inlet /

outlet connections.

Note 4 Ensure the booster

is mounted in an

upright position (as shown)

with a horizontal base.

Note 5

external water filter / softener is required, the external bypass valve must be set correctly, see page 17.

Booster specifications

Nominal power rating 2.2 kW

Nominal current 10 A

Electricity supply 50Hz AC 230 V

Electricalex,white-0.6mnom.length 13 A

Fixedowrate 1.2 L/min

Before you install a booster, determine whether an external water filter / softener is required. If an

Rating Unit

Mount base

horizontally

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 13 of 28

Booster installation

2.2 Installation procedure

Site requirements

•

Booster must only be installed in a frost-free area. Never expose booster to frost.

•

The booster is designed for wall mounted installation and must be installed with water connectors

facing upwards.

•

The booster is protected against water ingress to class IP 25.

•

The 500mm braided hoses supplied with the booster cannot be lengthened.

•

The 90° elbow hose ends should be fitted to the inlet and outlet connections on top of the booster.

•

The hot water outlet hose must be thermally insulated with the insulation provided.

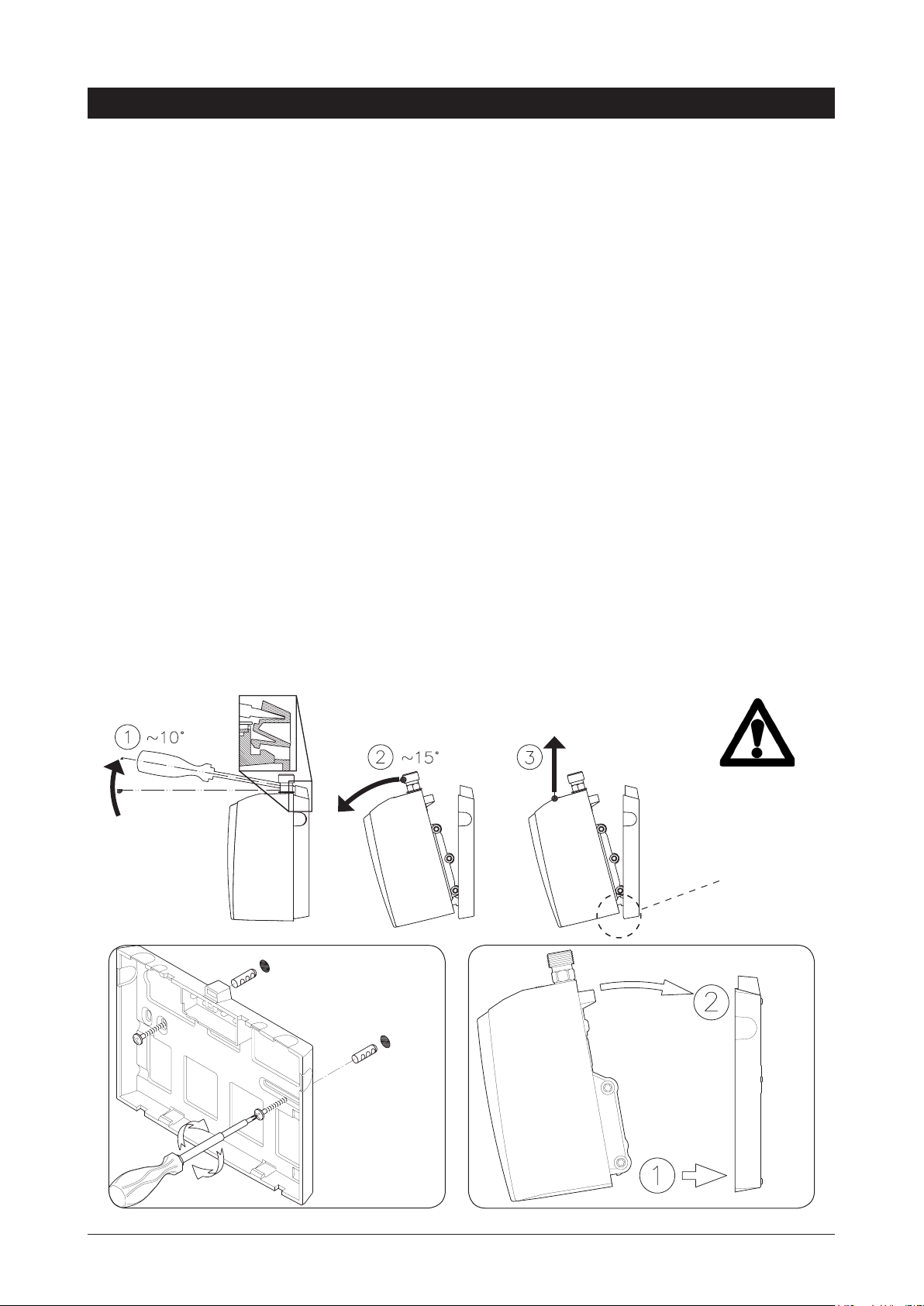

2.3 Booster installation see diagrams below

• To remove the mounting chassis, insert a flat blade screwdriver all the way into the lock.

• Gently angle the screwdriver upwards by approximately 10°.

• Pull the booster forwards by approximately 15°.

• Carefully pull the booster upwards to complete the removal process. Take care not to break the lower

clips.

• Attach the mounting chassis horizontally to the wall / cupboard wall.

• To install, clip the booster into the on the mounting chassis and snap into position (see installation

below).

Note Remove the wall mounting chassis from the rear of the booster for wall mounting.

Tilt forward Lift up

Take care not

Release

Attach

to break the

lower clips

when removing

or installing the

booster.

Install

Page 14 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Booster system

Note 1 This appliance is intended for use with the Zip HydroTap®G4 Command-CentreTM

Note 2 Water connections must be pointing vertically upwards.

Note 3 The booster unit should be installed as close as possible to the Zip HydroTap®G4 as the 500mm

connection hoses cannot be lengthened.

2.4 Braided hose connection

• The cold water inlet (blue cap) and hot water outlet (red cap) are marked on the rating plate. Connect

the braided hoses from the ‘BYPASS OUT’ fitting on the Command-CentreTM to the water inlet of

the booster (blue cap) and from the outlet of the booster (red cap) to the ‘BYPASS IN’ fitting on the

Command-CentreTM. Avoid exerting mechanical force on the booster. This can be achieved by using a

spanner on the flats of the inlet and outlet connections when tightening the braided hose connectors.

Do not over-tighten ! Tighten the braided hoses by hand, then turn a further 90O to 180O with a spanner.

• Once the water connections have been made, check for any leaks and rectify as necessary.

Typical installation

s

Braided hoses

Strainer

Cold water connection

(inlet, 3/8” BSP)

Hot water connection

(outlet, 3/8” BSP)

Hold the hexagon while

tightening the braided

hose fittings

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 15 of 28

Section 3 Filter / softener installation

An external filter / softener may be fitted to reduce the incidence of scale build up in the hot tank or may be

supplied at the customer’s request. (Scale filter head fitting kit order code ZT200G4 or ZT300G4).

3.1 Mounting the filter head

•

Choose a suitable location, (cupboard back or side wall) within

the reach of the braided hoses.

•

Mount the filter head bracket in an upright position, using the

screws supplied in the ZT200G4 or ZT300G4 kit.

•

Ensure there is enough headroom for the filter cartridge to be

easily fitted and removed. *Allow a min. 80mm base clearance.

•

Attach the hoses as adjacent diagram, noting the flow

directions as marked on the filter head.

3.2 Cartridge installation and flush.

• Remove the sanitary cap from the new cartridge and make

sure the o-rings are correctly positioned.

Inlet

Filter Label

Outlet

• Moisten o-rings with water. Do not use any petroleum products

to lubricate the o-rings.

• Install cartridge with a quarter turn anticlockwise until cartridge

comes to a complete stop.

• Cartridge installation is complete

• Note The following instructions to flush the filter must

be undertaken AFTER commissioning of the complete

HydroTap®G4 system, see section 5, Commissioning, page 22.

• Disconnect the braided hose from the filter outlet on the filter

head (out arrow) & insert the filter flush pipe (plastic pipe).

Direct the pipe into a container of greater than 10 litre capacity.

• Turn the mains water supply on.

• Use the HydroTap®G4 to dispense boiling water. After a short

time water will flush through the filter into the container.

• Allow 10 litres of water to flush through.

• Turn the mains water supply off.

• Remove the filter flush pipe (plastic pipe) from the filter outlet,

and refit the braided hose from the Command-Centre

TM.

.

*Min. 80mm

Clearance to cabinet

oor.

Page 16 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

• Turn the mains water supply on.

• If a booster is fitted, turn the power to the booster off and

use the HydroTap®G4 boiling lever to dispense water for 30

seconds, allow the tank to refill.

• Turn the power to the booster on and dispense boiling water for

a further 30 seconds. The filter / softener flush is complete

.

B

Rotate 90°

only

1

2

3

4

Section 4

A

Rotate 90°

only

1

2

3

4

Command-Centre

TM

installation

4.1 External bypass valve

The diverter bypass valve allows the user to choose to have the boiling feed water bypass the internal

filter and only be filtered by the external filtration. This diverter valve is located at the rear panel of the

Command-CentreTM, see the diagram below.

Check the table below to determine which filter bypass position you need for your product.

Ifnoexternallterisinstalled,selectpositionA

If an external filter is installed, select position B

Leave in position A until after commissioning (section 4). Select position B if scale filter is fitted, before

flushing the scale filter as described on page 16.

4.2 Braided hose fitting

Install the mains water braided hoses to the Command-CentreTM before locating in place.

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 17 of 28

Installation instructions

4.3 HydroTap®G4 models

Refer to 803341UK Tap installation instructions (for Arc / Cube also refer to

the tube kit assembly instructions) supplied with the tap.

Elite Classic

Arc / Cube

Note All silicon tubes /

plastic pipes must be cut

to size. They must have a

constant fall back to the

Command-Centre

POWER

CABLE

USB

TM

BLUE

CHILLED

OUTLET

BRAIDED

MAINS INMIXER

OUT

MIXER

IN

RED

BOILING

OUT

Options

BYPASS INVENT

CLEAR

BYPASS

OUT

Clearance envelope

535mm

535mm

Booster option.

COLD isolation valve

Note Ambient mains

water braided hose length

is 750mm.

Electrical power cable

length is 3m nom.

Position the Command-

TM

Centre

according to the

hose and cable lengths

supplied.

(notsupplied)

Note The braided hoses and connection tubes supplied with the tap head assembly and cold inlet CANNOT

be lengthened. Also ensure that the (factory fitted) bypass tube assembly is fitted in place if the booster

and / or external filter are not used.

Not required for HydroTap®G4 models.

Page 18 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Installation instructions

4.4 HydroTap®G4 and mixer tap combinations

Refer to 803341UK Tap installation instructions

(for Arc / Cube also refer to the tube kit assembly instructions) supplied with the tap.

+

Elite Classic

Note All silicon tubes /

plastic pipes must be cut

to size. They must have a

constant fall back to the

Command-Centre

POWER

CABLE

USB

Arc / Cube

TM

CHILLED

OUTLET

BLUE

BRAIDED

MAINS

IN

HydroTap

Mixer

Connections

MIXER

OUT

Classic

MIXER

IN

Arc

RED

BOILING

OUT

BYPASS INVENT

Note Ambient mains water braided

hose length is 750mm.

Electrical power cable length is 3m nom.

Position the Command-Centre

according to the hose and cable

lengths supplied.

Cube

Options

CLEAR

BYPASS

OUT

TM

For detail of vented mixer tap

mains water connections:

See the mixer tap section of

Clearance envelope

803341UK Tap installation

instructions,

supplied with the tap.

535mm

535mm

Note The braided hoses and connection tubes supplied with the tap head assembly and cold inlet CANNOT

be lengthened. Also ensure that the (factory fitted) bypass tube assembly is fitted in place if the booster

and / or external filter are not used.

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 19 of 28

Installation instructions

4.5 All-in-One 'Mains' tap

Refer to 803341UK Tap installation instructions (for Arc / Cube also refer to

the tube kit assembly instructions) supplied with the tap.

BRAIDED

BLUE

POWER

CABLE

USB

CHILLED

OUTLET

MAINS

IN

MIXER

OUT

MIXER

IN

Options

RED

BOILING

OUT

BYPASS INVENT

CLEAR

BYPASS

OUT

Note All silicon tubes / plastic pipes

must be cut to size. They must have a

constant fall back to the

Command-Centre

TM

Note Ambient mains

water braided hose

length is 750mm.

Clearance envelope

Electrical power cable

length is 3m nom.

Position the

TM

Booster option

Command-Centre

according to the hose

and cable lengths

supplied.

535mm

External HOT & COLD isolation valves

535mm

Maletomaleadaptor

toT-piece(notsupplied)

T-pieceand

Restrictaowvalve

(notsupplied)

(notsupplied)

Note The braided hoses and connection tubes supplied with the tap head assembly and cold inlet CANNOT

be lengthened. Also ensure that the (factory fitted) bypass tube assembly is fitted in place if the booster

and / or external filter are not used.

Not required for standard AIO 'Mains' HydroTap®G4 models.

Page 20 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Installation instructions

4.6 All-in-One 'Vented' tap

Refer to 803341UK Tap installation instructions (for Arc / Cube also refer

to the tube kit assembly instructions) supplied with the tap.

HydroTap

AIO Mixer

Connections

Note All silicon tubes

/ plastic pipes must be

cut to size. They must

have a constant fall back

to the

Command-Centre

POWER

CABLE

USB

TM

CHILLED

OUTLET

BLUE

BRAIDED

MAINS INMIXER

OUT

MIXER

IN

Options

RED

BOILING

OUT

BYPASS INVENT

CLEAR

BYPASS

OUT

Note Ambient mains

water braided hose length is 750mm.

Electrical power cable length is 3m nom.

TM

Position the Command-Centre

according to the hose and cable lengths

supplied.

Maletomaleadaptorto

T-piece(supplied)

Clearance envelope

Booster

option

535mm

External

filter option

Restrictaowvalve&T-piece

535mm

COLD isolation valve

(notsupplied)

(supplied)

Note The braided hoses and connection tubes supplied with the tap head assembly and cold inlet CANNOT

be lengthened. Also ensure that the (factory fitted) bypass tube assembly is fitted in place if the booster

and / or external filter are not used.

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 21 of 28

Section 5

Commissioning

The HydroTap®G4 is now ready to be commissioned.

•

Turn the power and water on and check for any leaks.

•

If fitted, ensure the booster is turned off. (The booster is commissioned later, see page 23).

•

Familiarise yourself with the operation of the tap, in preparation for use, see the user guide.

•

Follow the installation instructions below (and read section C of the user guide).

•

After commissioning, the system may be customised by selecting further options in section G - settings

of the user guide.

5.1 Select the language

Initial commissioning screen

5.2Filterush

Have a bucket or similar container (not supplied) at the

ready to hold a quantity of water that will be ejected

while the filter flush mode is in operation. Open the

filter access door on the front of the HydroTap®G4 and

the filter cartridge will be exposed. Located to the rear

right hand side of the cartridge is a flush line, approx

600mm long and the flush line stop cock. Place the free

end of the flush line into the bucket or container (not

supplied).

select the filter flush screen automatically.

Zip

Note

At first commissioning, the system will

Boiling Chilled

Prepare filter flush as per instructions

and press START

03:01 PM, TUE 12, Feb 2013

• Press [START] / [STOP] button to start and stop the filter

flush.

• Turn the flush stop cock on.

Language selection screen

OPEN Position

Stop cock

operation

CLOSED Position

OFF

ON

START

NEXT

STOP

5.3 Flow calibration

Zip

Boiling Chilled

To calibrate, touch START button

Empty / Filling

START

Page 22 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

NEXT

03:01 PM, TUE 12, Feb 2013

Pulses/L (360 - 440)

• Allow at least 10 litres of water to flush through the filter.

• Once the filter flush is finished, Turn the stop cock off

then press [STOP] to end filter flush mode.

• Press [NEXT] for the flow calibration screen.

• Press the [START] button and the tank will first empty then

fill. Upon completion the pulse count will be displayed. Check

the value is within limits.

• Press [NEXT] for the boiling calibration screen.

Note Foranysubsequentlterchangesoranyoperational

procedures, please refer to the HydroTap®G4 user guide, located

insidethelterhousingaccessdoor.

Commissioning

5.4 Boiling calibration (boiling models)

•

Press the [Calibrate] button and the system will

start the boiling calibration procedure. This will

take approx. 5 to 6 minutes.

5.5 To enable a booster, when installed.

• Press the [MENU] button for main menu.

• Press the [Install] button.

• Press the [Boost] button.

• In the next screen, select [YES] to enable the booster.

• Before connecting the power to the booster, water

must be run through for a min. of 30 seconds to purge.

Run the boiling tap for 30 seconds and the allow the

tank to refill.

• Dispense boiling water for 30 seconds and check the

booster outlet hose is warm when the boiling water

tank is replenishing.

Note Foranysubsequentlterchangesoranyoperationalprocedures,pleaserefertotheuserguide,

locatedinsidethelterhousingaccessdoor.

Note Depending on your location you may need to reset the internal clock. See section G of the user guide to

reset the date and time.

5.6 Safety sensor calibration (boiling models)

Light intensity varies from site to site, therefore it is recommended that a re-calibration be performed at the

time of the installation.

All direct sunlight must be shaded from the HydroTap®G4, during the calibration. This can be achieved by

closing any nearby curtains, blinds, etc.

Procedure

• Shield the HydroTap®G4 from direct sunlight.

• In normal operating mode. Turn the power off.

• Pull both tap levers to the forward position.

• Turn the power on.

Pull both levers

forward

Safety

sensor

• The safety sensor will calibrate.

• Return the levers to the neutral position.

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 23 of 28

Trouble shooting

System fault

Possible cause Solutions

message

Power Board Fault Electrical disruption Check power supply and all fuses

Interface Fault Internal fault Call Zip Service

Level Board Fault Internal fault Call Zip Service

Condenser Screen Blocked Blocked air filter Remove blockage / clean filter / check user guide

Water leak, Isolate Mains Water leak Turn off mains water supply / call for service

Compressor Over Run Compressor too hot Check ventilation

Water Supply Failure No water Check water supply is turned ON

Hot Sensor Open Internal fault Call Zip Service

Hot Sensor Closed Internal fault Call Zip Service

Cold Sensor Open Internal fault Call Zip Service

Cold Sensor Closed Internal fault Call Zip Service

Flood Sensor Open Internal fault Call Zip Service

Condenser Sensor Closed Internal fault Check ventilation / call Zip Service

Condenser Sensor Open Internal fault Check ventilation / call Zip service

Heater Fuse / Driver Fault Internal fault Call Zip Service

Heater Driver Fault No hot water Call Zip Service

Compressor Driver Fault No chilled water Call Zip Service

Hot Sensor Degraded Internal fault Call Zip Service

Condenser Overtemp Blocked air filter Remove blockage / clean filter / check user guide

A DC Pump is faulty Internal fault Call Zip Service

Steam too Cool Internal fault Call Zip Service

Steam Sensor Open Internal fault Call Zip Service

Steam Sensor Closed Internal fault Call Zip Service

Hot Tank Over filled Internal fault Call Zip Service

Comp Fuse/Driver Fault Internal fault Call Zip Service

Hot Tank Under filled Low water pressure Check water supply

Boil Dry Protection Safety activated Turn OFF/ON power to reset

Flash Memory corrupted Internal fault Call Zip Service

Flow Sensor Fault Internal fault Call Zip Service

Call an electrician, a plumber, or Zip on 0345 6 005 005 for assistance, service, spare parts or enquiries.

Page 24 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

End of life disposal

The use of this crossed out wheeled bin logo indicates that this product needs to be disposed of

separately to any other household waste.

Within each of the European Union member countries, provisions have been made for collection

and recycling of unwanted electrical and electronic equipment. In order to help preserve our

environment we ask that you dispose of this product correctly. Please contact Zip Customer

Service on 0345 6 005 005 for advice.

Warranty

Certain warranties may be implied by law into your contract with Zip. The warranty provided below is

additional to these implied warranties and nothing set out below shall limit your statutory rights or rights at law.

Zip Heaters (UK) warrants that, should the hot tank fail within five years of installation subject to satisfactory

maintenance and registration of the product, or any part fail within two years of installation, the part will be

repaired or replaced free of charge by Zip, its distributor or service provider, (except as set out below),

provided the appliance is installed and used strictly in accordance with the instructions supplied, and that

failure is not due to accident, misuse, abuse, unsuitable water conditions, or to any alteration, modification or

repair by any party not expressly nominated by Zip.

No costs are payable by the customer other than any mileage or travelling-time charges incurred by a Zip

service provider or the cost of removal, cartage and re-installation of any component of the appliance if it

needs to be returned for repair to Zip or its distributor.

This warranty does not cover damage resulting from non-operation of the appliance, the use of non authorised

parts or consequential damage to any other goods, furnishings or property.

No warranty applies to the life of any filtration cartridge installed with the appliance as cartridge life may vary

according to water quality and the rate of water consumption.

Zip does not exclude, restrict or modify any liability that cannot be excluded, restricted or modified or which

cannot, except to a limited extent, be excluded, restricted or modified as between the owner or user and Zip

under the laws applicable.

Furthermore this warranty does not displace any statutory warranty, but, to the extent to which Zip is entitled

to do so, the liability of Zip under any statutory warranty will be limited at Zip’s option to the replacement of the

appliance or supply of equivalent appliance, the payment of the cost of replacing the appliance or acquiring an

equivalent appliance, or the payment of the cost of having the appliance repaired or the repair of the

appliance.

HydroTap®G4 residential models are designed specifically for use in a domestic environment and

inappropriate installations such as in a commercial location will invalidate the warranty.

Registering your purchase.

Registering your Zip installation on the Zip website may help to establish date of installation should it become

necessary to service the appliance under terms of the Zip warranty. To register your installation go to

www.zipwater.com/uk and look under the heading “Warranty”.

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 25 of 28

Notes

Page 26 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Notes

801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04 Page 27 of 28

Contact Details

Head Office

Zip Water UK

14 Bertie Ward Way

Dereham

Norfolk

NR19 1TE

Website: www.zipwater.com/uk

Email: sales@zipindustries.co.uk

Facsimile: 01362 692 448

Telephone: 0345 6 005 005

The standard cup referred to in this publication is 167 ml (6 fl oz).

The standard glass is 200 ml (7 fl oz).

The terms “Zip” and “HydroTap” are registered trade marks of Zip Heaters (Aust) Pty Ltd.

Zip products described in this publication are manufactured under one or more of the following patents: AU675601,

AU637412, AU635979, GB0422305, GB2065848, US4354049, US5103859, US5099825 and SA2006/08043. Other

patents are in force and patent applications are pending.

Page 28 of 28 801314UK - G4 Boiling chilled commercial installation instructions - June 2016 - V2.04

Loading...

Loading...