Page 1

PRODUCTS MANUAL

R2W SERIES

High Density Redundant Power Supply

For 2U Chassis

Rev.:A1

P/N:702-10041

Page 2

INDEX

1.1 Introduction page 2

1.2 Packing page 3

1.3 Model Designation page 3

1.4 Features page 4

1.5 Pre-Installation page 4

1.6 Drawing page 5 ~ 6

1.7 Specification page 7 ~ 9

1.8 Installation & Testing page 10 ~ 11

1.9 Hot-Swap Procedures page 11 ~ 12

1.10 Pin-outs and function of connectors page 12 ~ 13

1.11 Trouble shooting page 13

1

Page 3

1.1 INTRODUCTION

First of all, thank you for purchasing R2W Series – High-Density Redundant

power supply for 2U chassis.

The R2W is a 1+1, Hot-swappable/Hot-pluggable, High-Density Redundant

power supply set, it consists of:

(1) complete metal frame (nickel-plated)

(2) compact size (smaller than PSII form factor) 1+1 power modules

(3) backplane board

The R2W Series of hot swappable high-density redundant power supply offer a

maximum 400/460 watts of output power. The R2W series provide Active

Power Factor correction (PFC) at full range AC Input complies with

IEC 1000-3-2/3 for critical applications.

The power unit’s size is compact which smaller than PS II form factor and both

power modules built two interior 38X28 m/m ball bearing DC fans. Each power

module has designed with 6 outputs including +3.3V, +5V, +12V, -12V, -5V &

5VSB circuits and higher current availability based on Intel ATX12V / EPS12V

standards. All you can see on the backplane board is just passive components and

this is the key point to a greater Power Supply MTBF.

The unit features a warning sub-system, including LED display, buzzer alarm,

TTL signal, etc., at the same time, it guides user the fast way to find out the

power supply and DC fan Good or Fail optional conditions.

When all the power modules are at normal condition, it balances the load share

through its parallel design and results the power system increase reliability.

To really discover the power and ease in using these products, we recommend

that you read through this manual carefully.

2

Page 4

1.2 PACKING

Your R2W box package should consist of the following:

(A) R2W *1

(B) Accessory pack (included 1 holding bracket for shipment)*1

(C) Products’ manual *1

1.3 MODEL DESIGNATION

Model number identification:

R2W – 6ZZZP

R --- Redundant (AC Input)

2W --- suit for 2U chassis (1U = 44.4 m/m)

6 --- for 6 DC outputs (5V/12V/-5V/-12V/3.3V/5VSB) for

ATX12V / EPS12V Spec.

ZZZ --- total output power, ZZZ- 400,460 etc. (unit: watt)

P --- with PFC built in (full range).

3

Page 5

1.4 FEATURES

R2W Series --- High-Density Redundant power supply with Active Power Factor

correction

1+1, Hot swappable, Hot pluggable, AC Input for 2U chassis

Easy fit into 2U , 400/460W +400/460W, ATX12V / EPS12V outputs

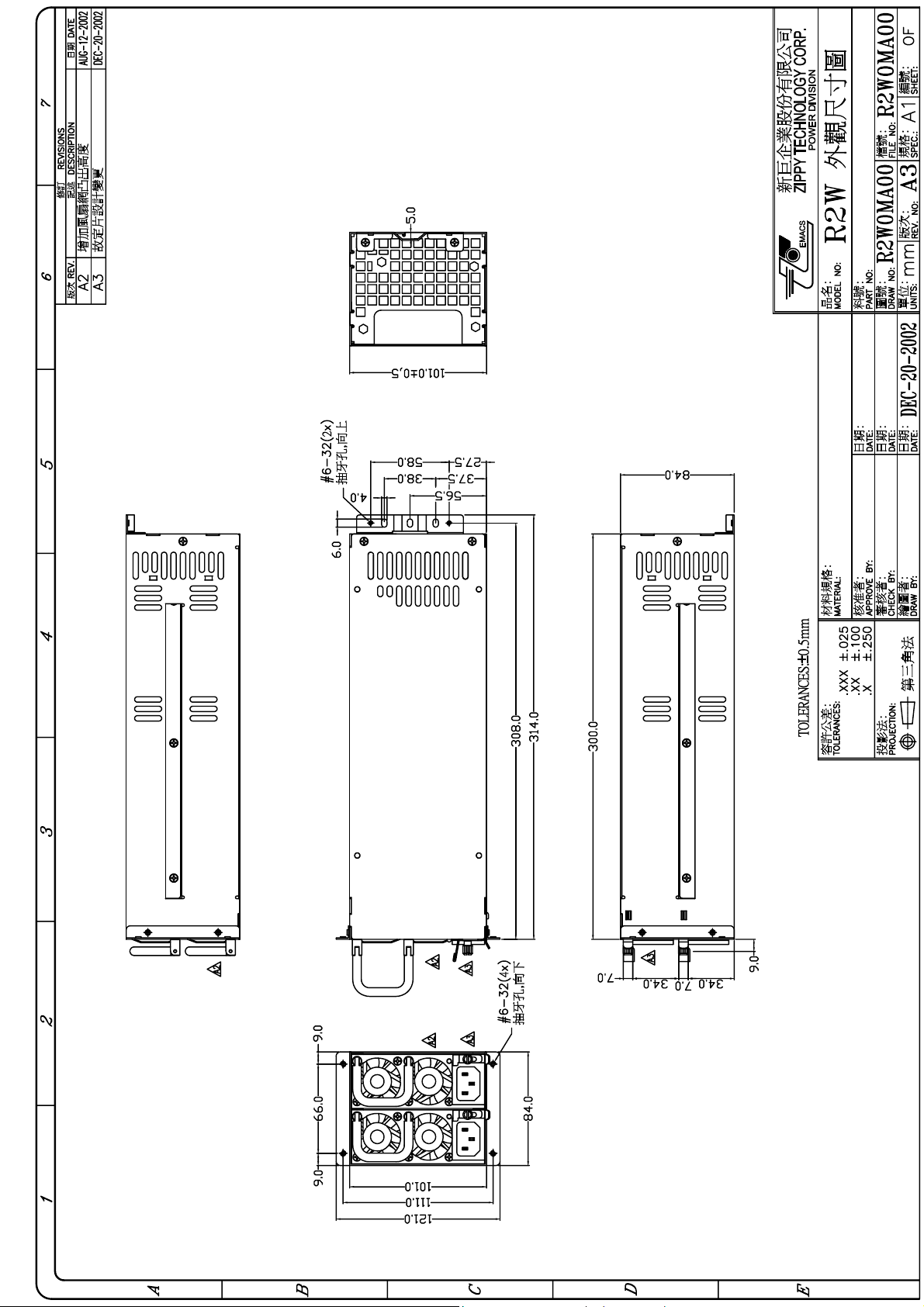

Dimension : 84 (H) x 101 (W) x 300 (D) m/m True Redundant design (Passive backplane) All circuit been designed in the power module Hot swap, Hot plug ability Full range 90V~264VAC input Active Power Factor Correction (PFC) built in ATX 400/460W + 400/460W output power Remote sensing design Meet FCC, CISPR EMI regulation Compact size for 2U chassis Space save design Dual EMI Line Filter inlets design Two 38X28 m/m ball bearing DC fan on power module design High-Density 7.1W/in³ (for 460W module)

1.5 PRE-INSTALLATION

Before installing the R2W unit into the system chassis, please review the

following drawings page 4 ~ 13 and find out the best way to match them.

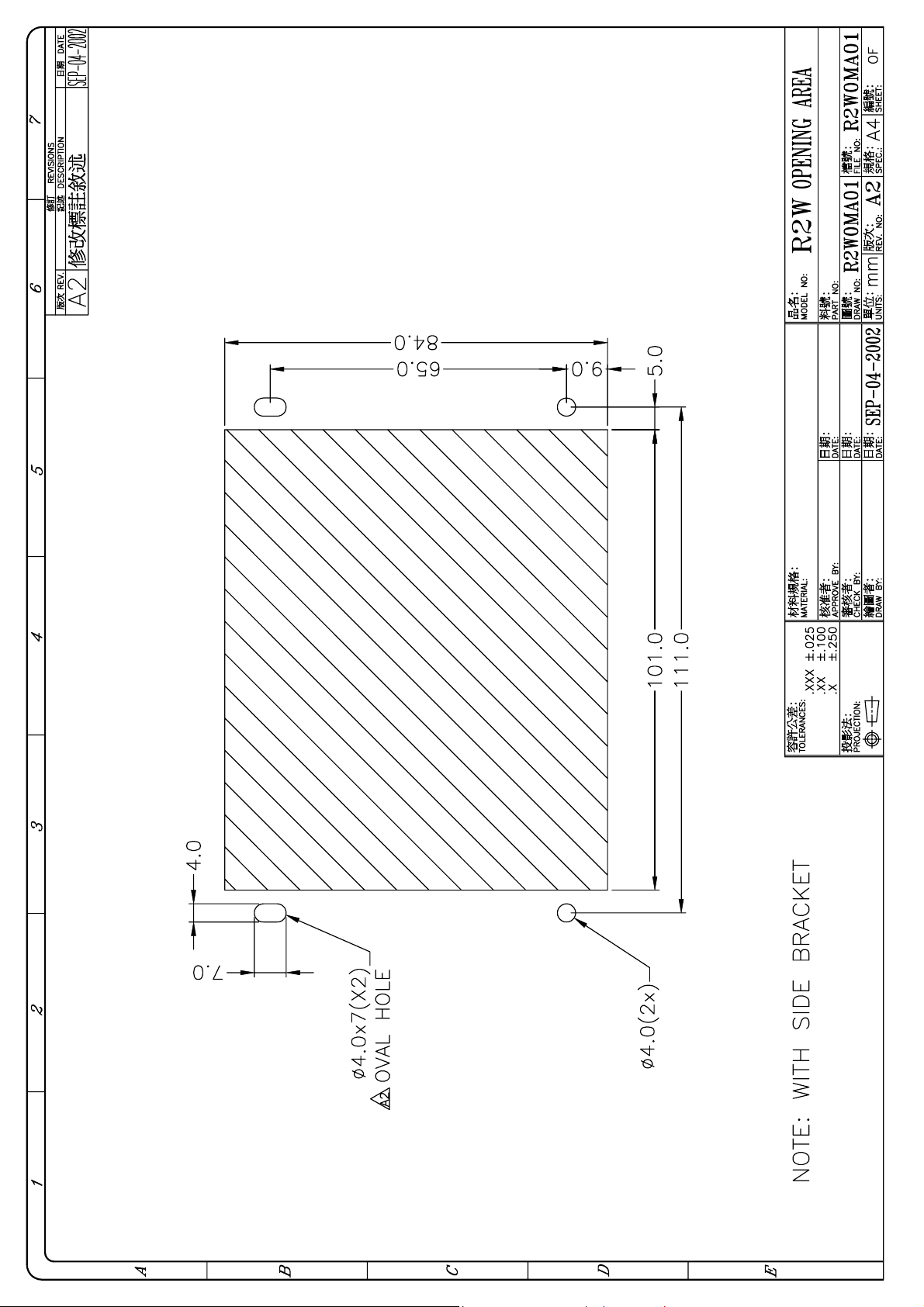

1.6 DRAWING (page 5 ~ 6)

1.7 SPECIFICATIONS (page 7 ~ 9)

4

Page 6

Page 7

Page 8

INPUT CHARACTERISTICS: R2W-6400P

VOLTAGE: 90 ~ 264 VAC FULL RANGE

FREQUENCY : 47 ~ 63 Hz

INPUT CURRENT: 8.0 / 4.0 A FOR 115 / 230 VAC

INRUSH CURRENT: 60A / 80A MAX. FOR 115 / 230 VAC PER POWER MODULE

OUTPUT CHARACTERISTICS:

OUTPUT

VOLTAGE

5V 3.5 26

12V 2 28

-5V 0.05 0.7 +5/-10%

-12V 0.05 0.7 +5/-10%

3.3V 1.0 24

+5VSB 0.1 2.0 + 6%

OUTPUT CURRENT REGULATION OUTPUT

MIN.[A] MAX.[A] PEAK(A) LOAD LINE

±

±

±

5%

6%

5%

±

±

±

±

±

±

1%

1%

1%

1%

1%

1%

RIPPLE & NOISE

MAX. [P-P]

50mV

120mV

120mV

150mV

50mV

50mV

REMARKS: TOTAL CURRENT OF +5V AND + 3.3V NOT EXCEED 43 A;

Total output power not exceed 400w

. TEMPERATURE RANGE : OPERATING 0

HOLD UP TIME: 16 ms MINIMUM AT FULL LOAD & 90 VAC INPUT VOLTAGE

DIELECTRIC WITHSTAND: INPUT / OUTPUT 1500 VAC FOR 1 MINUTE

INPUT TO FRAME GROUND 1500 VAC FOR 1 MINUTE

EFFICIENCY: 68% TYPICAL, AT FULL LOAD 115V

POWER GOOD SIGNAL: ON DELAY 100 ms TO 500 ms, OFF DELAY 1 ms

OVER LOAD PROTECTION: 110 ~ 160% MAX.

OVER VOLTAGE PROTECTION: +5V 5.7V ~ 6.5V, 3.3V 3.9 ~ 4.3V, 12V 13.3 ~ 14.3V

. OVER CURRENT PROTECTION

EMI NOISE FILTER: FCC CLASS B, CISPR22 CLASS B

SAFETY: UL 1950, CSA 22.2 NO/ 950, TÜV IEC 950

REMOTE ON / OFF CONTROL

FAULTY ALARM METHODS : LED, BUZZER, TTL SIGNAL

HOT-SWAPPABLE / HOT-PLUGGABLE REDUNDANCY FUNCTION

REMOTE SENSING DESIGN

ISOLATION: BUILT-IN IN THE POWER MODULE

MEET IEC-1000-3-2 CLASS D ( ACTIVE PFC )

DIMENSION: 84(H) X 101(W) X 300 (D) mm

COOLING : TWO 38x38x28 mm DC FANS (MODULE)

AC INLET IN EACH MODULE

0

C --- 400C, STORAGE –200C --- 700C

7

Page 9

INPUT CHARACTERISTICS: R2W-6460P

VOLTAGE: 90 ~ 264 VAC FULL RANGE

FREQUENCY : 47 ~ 63 Hz

INPUT CURRENT: 8.0 / 4.0 A FOR 115 / 230 VAC

INRUSH CURRENT: 60A / 80A MAX. FOR 115 / 230 VAC PER POWER MODULE

OUTPUT CHARACTERISTICS:

OUTPUT

VOLTAGE

5V 2.0 30

12V 2 32

-5V 0.05 0.7 +5/-10%

-12V 0.05 0.7 +5/-10%

3.3V 1.0 24

+5VSB 0.1 2.0 + 6/-5%

OUTPUT CURRENT REGULATION OUTPUT

MIN.[A] MAX.[A] PEAK(A) LOAD LINE

±

±

±

5%

5%

5%

±

±

±

±

±

±

1%

1%

1%

1%

1%

1%

RIPPLE & NOISE

MAX. [P-P]

50mV

120mV

120mV

120mV

50mV

50mV

REMARKS: TOTAL CURRENT OF +5V AND + 3.3V NOT EXCEED 43 A; total

output power not exceed 460w

. TEMPERATURE RANGE : OPERATING 0

HOLD UP TIME: 16 ms MINIMUM AT FULL LOAD & 90 VAC INPUT VOLTAGE

DIELECTRIC WITHSTAND: INPUT / OUTPUT 1500 VAC FOR 1 MINUTE

INPUT TO FRAME GROUND 1500 VAC FOR 1 MINUTE

EFFICIENCY: 68% TYPICAL, AT FULL LOAD 115V

POWER GOOD SIGNAL: ON DELAY 100 ms TO 500 ms, OFF DELAY 1 ms

OVER LOAD PROTECTION: 110 ~ 160% MAX.

OVER VOLTAGE PROTECTION:

+5V 5.7V ~ 6.5V, 3.3V 3.9 ~ 4.3V, 12V 13.3 ~ 14.3V

. OVER CURRENT PROTECTION

EMI NOISE FILTER: FCC CLASS B, CISPR22 CLASS B

SAFETY: UL 1950, CSA 22.2 NO/ 950, TÜV IEC 950

REMOTE ON / OFF CONTROL

FAULTY ALARM METHODS : LED, BUZZER, TTL SIGNAL

HOT-SWAPPABLE / HOT-PLUGGABLE REDUNDANCY FUNCTION

REMOTE SENSING DESIGN

ISOLATION: BUILT-IN IN THE POWER MODULE

MEET IEC-1000-3-2 CLASS D ( ACTIVE PFC )

DIMENSION: 84(H) X 101(W) X 300 (D) mm

COOLING : TWO 38x38x28 mm DC FANS (MODULE)

AC INLET IN EACH MODULE

0

C --- 400C, STORAGE –200C --- 700C

8

Page 10

INPUT CHARACTERISTICS: R2W-6500P

VOLTAGE: 105 ~ 264 VAC FULL RANGE

FREQUENCY : 47 ~ 63 Hz

INPUT CURRENT: 8.0 / 4.0 A FOR 115 / 230 VAC

INRUSH CURRENT: 60A / 80A MAX. FOR 115 / 230 VAC PER POWER MODULE

OUTPUT CHARACTERISTICS:

OUTPUT

VOLTAGE

5V 2.0 30

12V 2 32

-5V 0.05 0.7 +5/-10%

-12V 0.05 0.7 +5/-10%

3.3V 1.0 24

+5VSB 0.1 2.0 + 6/-5%

OUTPUT CURRENT REGULATION OUTPUT

MIN.[A] MAX.[A] PEAK(A) LOAD LINE

±

±

±

5%

5%

5%

±

±

±

±

±

±

1%

1%

1%

1%

1%

1%

RIPPLE & NOISE

MAX. [P-P]

50mV

120mV

120mV

120mV

50mV

50mV

REMARKS: TOTAL CURRENT OF +5V AND + 3.3V NOT EXCEED 43 A; total

output power not exceed 500w

. TEMPERATURE RANGE : OPERATING 0

HOLD UP TIME: 16 ms MINIMUM AT FULL LOAD & 90 VAC INPUT VOLTAGE

DIELECTRIC WITHSTAND: INPUT / OUTPUT 1500 VAC FOR 1 MINUTE

INPUT TO FRAME GROUND 1500 VAC FOR 1 MINUTE

EFFICIENCY: 68% TYPICAL, AT FULL LOAD 115V

POWER GOOD SIGNAL: ON DELAY 100 ms TO 500 ms, OFF DELAY 1 ms

OVER LOAD PROTECTION: 110 ~ 160% MAX.

OVER VOLTAGE PROTECTION:

+5V 5.7V ~ 6.5V, 3.3V 3.9 ~ 4.3V, 12V 13.3 ~ 14.3V

. OVER CURRENT PROTECTION

EMI NOISE FILTER: FCC CLASS B, CISPR22 CLASS B

SAFETY: UL 1950, CSA 22.2 NO/ 950, TÜV IEC 950

REMOTE ON / OFF CONTROL

FAULTY ALARM METHODS : LED, BUZZER, TTL SIGNAL

HOT-SWAPPABLE / HOT-PLUGGABLE REDUNDANCY FUNCTION

REMOTE SENSING DESIGN

ISOLATION: BUILT-IN IN THE POWER MODULE

MEET IEC-1000-3-2 CLASS D ( ACTIVE PFC )

DIMENSION: 84(H) X 101(W) X 300 (D) mm

COOLING : TWO 38x38x28 mm DC FANS (MODULE)

AC INLET IN EACH MODULE

0

C --- 400C, STORAGE –200C --- 700C

9

Page 11

1.8 INSTALLATION & TESTING

Turn off (Remote off) the on/off switch.

Mount the power supply in the system chassis using the proper mounting tool,

the mounting holes in the power supply should match those in the case. Attach

the connectors to the M/B by following the M/B instructions, there are various

connectors / pin-outs on both power supply and M/B. They should match each

other; otherwise the connection will cause undetectable harms.

Attach all the remaining power supply connections to the various peripherals as

needed. These connectors are “keyed”, so there will be only one possible way to

connect them.

Before applying power to the system, make sure there are no loose or incorrect

connectors. You do not need to worry about the setting of AC Input because of

the units’ full range features. Double check that all connections to the M/B are

matched properly. Maybe you would like to test the redundancy function before

you put back the cover of your system chassis. Remote on the on/off switch, you

will notice that if the power unit is operating properly, the individual LEDs and

external warning LEDs (please refer to Sec. 1.10 for detail explanation) are lit

Green. Now remove one of the power modules, the warning buzzer in the power

system will sound and the external warning LED which displays the status of the

total power supply system will change color to Red, the individual LEDs (on the

front of power module) indicating the power supply’s status will not light.

Meanwhile, the power supply will continue to backup the power output without

affecting the computer system’s operation.

When the warning buzzer sounds, the user can reset the warning buzzer by

pressing the buzzer reset or use the reset switch of the system chassis. The reset

switch can be connected by wires lead provided from the power supply system

(please refer to Sec. 1.10). Insert the power module which is removed for testing

earlier, the sound of the warning buzzer will disappear, the external warning LED

will turn Green again. The LED indicating the status of the power supply will

light again when testing another power supply by performing the similar

procedure.

10

Page 12

If everything works out fine, then turn off (remote off) the power system. Now

put back the cover of the case and tighten with the screws that you have retained

earlier. Now you have completed the installation of the R2W redundant power

supply system.

1.9 HOT-SWAP PROCEDURES

Please refer to the following when either power module or the fan found

defective.

A) Locate the defective power module by examining the individual LED (if LED

without light, it indicates the power module is defective).

***WARNING:

Please perform the above step carefully otherwise it may cause shut down the

whole system.

***WARNING:

Please do not remove the defective power module until you have worn gloves to

keep from be burned. This is due to the cover of the power module is used as heat

sink for cooling, usually the temperature is around 50 ~ 60 degree Celsius under

full load condition.

B) Loosen the bracket screws of the power module

C) Remove the defective power module by pulling out method

***WARNING:

Please put aside the power module await for cooling down. Keep from other

people tough it until it is cool.

11

Page 13

D) Replace a new Good power module, insert the power module into the power

system to the end.

E) Check the LED of the power module light Green.

F) Check the LED indicating the total power system status. It should be from

twinkle to Green.

G) Tighten the screws of the power module to fix it.

H) If you want to test this new power module in simulating defective situation.

Please refer to the Section 1.8 Installation & Testing Section.

Remarks: If the DC fan of the power module fail, you have to replace the power

module. Please follow with the Hot-Swap procedures of the power module.

1.10 PINOUTS AND FUNCTION OF THE CONNECTORS

*** Please be aware of the polarity***

THE POWER SIGNAL CONNECTOR OF TOTAL POWER

PIN# COLOR CONDITION

1 RED POWER FAIL

2 BLACK GND

3 GREEN POWER OK

THE BUZZER RESET SWITCH CONNECTOR

PIN# COLOR LEVEL

1 YELLOW +5VSB(PULL HIGH)

2 BLACK GND

THE SIGNAL CONNECTOR OF POWER RESET

PIN# COLOR VOLTAGE

1 RED TTL SIGNAL

(OPEN COLLECTOR)

2 BLACK GND

12

Page 14

TTL signal :

Sink current max. 5mA

Source current max. 50uA

Low Active --- Defective

High --- Normal

1.11 TROUBLE SHOOTING

If you have followed these directions correctly, there should be no problem

occurred. Some common symptoms are: the system doesn’t work, buzzer sounds,

work for a very short period, etc., please try the following steps to verify and

correct it:

1. Check all the connections (correct pinouts, loose connections, wrong direction,

etc).

2. Check for short-circuits or defective peripherals by unhooking each peripheral

once at a time. When the systems functions again, you have solved the

problem.

3. Once you hear the buzzer sound or see the LED with RED light, please be

aware of :

a. If the load is under the minimum / over the maximum

(please refer the Sec. 1.7 specification)?

b. If each power cord been well plugged into the inlet?

Suppose the above conditions happen, please unplug the power cords, wait for 2

~ 3 minutes for releasing the protection state, then test it again.

c. If buzzer still sounds or the LED shows power module is defective, please

locate the defective power module, perform hot-swap procedure (please refer

load of each channel

to the Sec. 1.9 Hot-swap procedures), sent the defective power module to your

vendor for RMA operation.

d. If you can not fix the problem, please contact with your vendor for supporting.

13

Page 15

The “RELIABILITY “ solution to E-application

新巨企業股份有限公司

ZIPPY TECHNOLOGY CORP.

POWER DIVISION

HEADQUARTERS

10F, NO. 50, MIN CHYUAN RD., SHIN-TIEN CITY,

TAIPEI HSIEN, TAIWAN, R.O.C.

TEL: 886-2-29188512 FAX: 886-2-29134969

WEB SITE: http://www.zippy.com.tw E-mail:power@zippy.com.tw

USA OFFICE

U.S. East (Atlantic)

11 Melanie Lane, Unit 1B East Hanover, NJ 07936

TEL:1-973-463-9499 FAX:1-973-453-8014

E-mail:edward@zippy.com

U.S. W est (Pacific)

961 CALLE NEGOCIO, SAN CLEMENTE CA 92673, USA

TEL: 1-949 366 9525 FAX: 1- 949 366 9526

EMAIL: powerusa@zippy.com

CANADA OFFICE

ZIPPY TECHNOLOGY CANADA INC.

Unit3-3671 Viking Way Richmond, B.C V6V 2J5 Canada

TEL:1-604-278-6615 FAX:1-604-278-6624

CELL: 1-778-288-9622 E-mail:ian@zippy.com

Note:

*The description stated herein is subject to change without prior notice.

*All brand names and trademarks are the property of their respective owners

Loading...

Loading...