Page 1

TWIN CAM® INSTALLATION GUIDE

Thank you for purchasing a set of Red Shift Performance Cams! Red Shift Cams are developed and manufactured to the highest

standards by Zipper’s Performance Products. We grind each cam on custom designed Berco® machines that are the most advanced

in the industry. We control the design, manufacturing and testing processes on site, to provide you with excellent quality control and

batch consistency for a better finished product.

Although the process to make a set of Red Shift Cams is time consuming and painstakingly difficult, no expense is spared in creating

the most accurate and dynamically stable camshafts on the market today. Red Shift Cams will make you smile every time you reach

for the throttle. Red Shift Cams are produced by a team with decades of experience in racing, street riding, and manufacturing

experience. No matter what your application is, Red Shift Cams can help you meet or exceed your performance goals.

The information in this document is meant to share our own engine development discoveries with our customers. These “best

practices" we perform on our engines yield outstanding results in enhancing and strengthening the durability of the Twin Cam®

engine, in any high performance application.

To successfully install a new set of Red Shift Camshafts, the following inspection procedures must be performed to ensure proper

operation of your valve train. The oiling system must be operating correctly for proper valve train control, component reliability, and

the final power output. If you do not have the correct factory Service Manual, obtain one before starting this installation. Be sure to

follow all tear down and assembly instructions, and heed all cautions and warnings presented.

Before beginning the teardown, make sure that you’ve got the proper tools and parts ready to complete the installation.

Recommended Parts to Install: Recommended Specialty Tools:

Installation Introduction:

1.) Red Shift Cams 1.) Cam Plate Pressure Tester #772-910

2.) Red Shift Dual Piston Chain Tensioners (07-UP) #413-901 2.) Crankshaft Run-out Checker #772-015

3.) Complete Gasket Kit 3.) Inner Bearing Removal Tool #758-279 (99-06)

4.) High Quality Lifters #758-993 (07-UP)

5.) High Quality Adjustable Pushrods (if required) 4.) Inner Bearing Install Tool #758-787 (ALL TC)

6.) Full Compliment Inner Cam Bearings 5.) Cam Sprocket Lock Tool #758-285 (99-06)

99-06 – Inner / Outer Bearing Kit - Chain Drive #417-450 #758-994 (07-UP)

- Gear Drive #417-455

07-UP – Inner Bearing Kit – Chain & Gear Drive #417-460

6.) 99-06 Spring Release Tool #758-283

7.) 99-06 Zipper’s TC Cam Relief Tool #713-905 (Single)

7.) Precision Ground Oil Pressure Relief Valve #626-010 #713-906 (Dual)

8.) 07-UP – Gear Drive Cams Only – Block-off Plates #672-816

Teardown Procedure:

1.) Read the factory Service Manual’s Cam Compartment Service procedure; and the associated section on Stripping the

Motorcycle for Service.

2.) Following the factory Service Manual’s procedure, remove all components from the motorcycle that will interfere with the

rocker box and cam chest disassembly. This includes the fuel tank, exhaust system, and the floorboard, for example.

3.) Remove the entire Rocker Arm / Stand Assemblies, and set them aside for further inspection.

4.) Remove the Cam Support Plate subassembly & associated parts, including the oil pump.

5.) Disassemble the Cam Support Plate subassembly; removing the camshafts, tensioners, and oil pump from the support plate. On

’99-’06 engines, you will need a special tool to release the spring pressure on the cam chain tensioners. Be sure to install the

retaining lock pins if you are reusing the spring style cam chain tensioners on ’99-’06 engines.

Document V.20130226

Page 2

Inspection Guide:

1.) Crankshaft Run-out – The first thing to check is the run out of the crankshaft pinion shaft. Gear Drive cams cannot be used

with more than 0.003” of run out on the pinion shaft. If the crankshaft run-out is deemed excessive, further disassembly and

repairs will be required. It is highly recommended that anytime the camshaft cover is removed, crankshaft run-out is checked.

2.) Oil Pump - Disassemble the oil pump, and draw a line across the inner / outer gerotors with a permanent marker, so they can

be reinstalled exactly as they were removed. Inspect the gerotors and pump body for damage due to foreign material being

pumped through the system. Follow the factory Service Manual for gerotor tip clearances and the overall stack height tolerance.

Replace or repair as needed. If excessive material has gone through the scavenge side of your pump, the oil tank and oil lines

must be cleaned out now as well. Certain models will require the oil pan to be removed for cleaning, while other models require

the entire oil tank to be flushed out with kerosene.

3.) Cam Chain Tensioners - While apart, it’s a good time to evaluate the operation of your cam chain tensioners. Look for uneven

wear patterns in the shoe especially. Replace or repair as needed. Red Shift Dual Piston Cam Chain Tensioners are highly

recommended on ‘07-Up engines.

4.) Cam Chains - Check the outside of both the inner and outer cam chains for any burrs or inconsistencies. Some wear may be

present, but any physical damage to the chain will transfer directly into replacement cam chain tensioners.

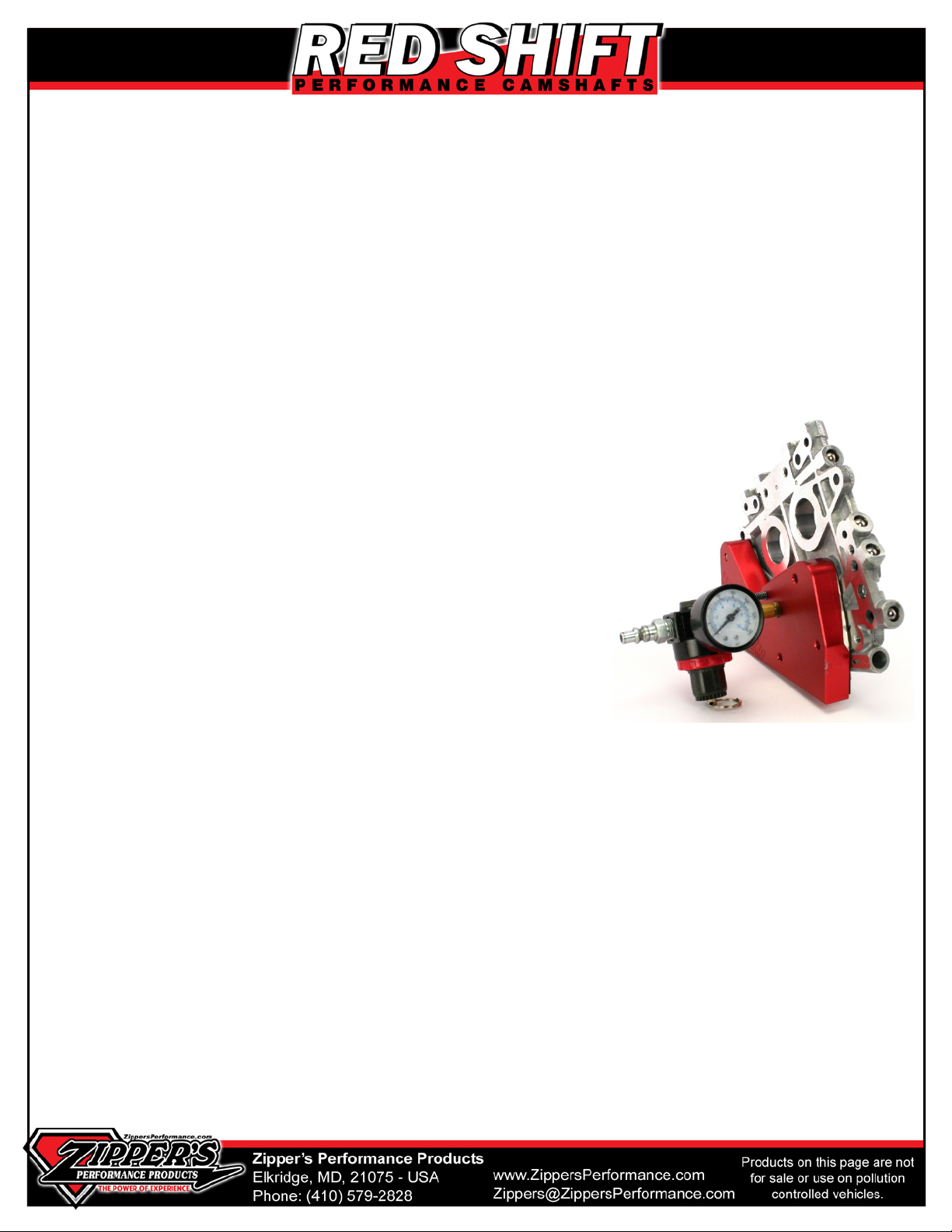

5.) Cam Support Plate – Oil Pressure Relief Valve - We strongly recommend

using the Fueling Cam Support Plate Pressure Tool to check the cam support

plate for leaks at the Oil Pressure Relief Valve. This is an extremely critical step

that is completely bypassed in the standard circle of service technician

training. Our testing of hundreds of O.E. cam support plates have resulted in the

discovery of a complete failure of the proper operation of the bypass valve on a

large percentage of cam support plates.

This Oil Pressure Relief bypass valve has been found in many cases to be

leaking 50% or more pressure at idle. These leaks cause a dramatic reduction in

the amount of lubrication on all of the key parts of the engine, especially high

contact pressure valve train parts. Another key issue is in maintaining oil

pressure when the engine is at its lowest rpm, which is hot idle. A precision

ground Oil Pressure Relief Valve may be required to properly seal this bypass

valve. Any losses at this point will systematically reduce oil pressure to the entire

engine, specifically shortening the normal lifespan of the high pressure

components in the valve train and other key areas of the engine. Call your

Zipper’s Sale Rep for more information on this issue and the various solutions

available for you.

6.) Take-Out Camshafts - Although these are the key items being replaced, it’s the right time to take a moment to inspect the

wear on the lobes and bearing journals. Finding issues on the parts that are being removed will aide you in setting up your new

Red Shift Cams for a long reliable lifespan.

7.) Lifters - Inspect the lifters’ roller surfaces, the bearing condition, and the outer diameter of the lifter bodies. We recommend

that higher quality lifters be installed when upgrading your camshafts, but studying the condition of the take-out parts will help

you identify previous oiling and control issues. The latest factory lifters referred to as “-99C” should be removed regardless of

mileage, and replaced with a higher quality aftermarket replacement. The newest lifters do not appear to be made to the same

quality standards as the earlier lifters.

8.) Pushrods - Check the pushrods for unusual wear on the tips, blockage through the body, and any rubbing or interference

marks from hitting the pushrods tubes. You may be reusing these non-adjustable pushrods, if you’ve purchased a Red Shift Cam

that was designed for use with these pushrods. In many cases these will be replaced with a high quality adjustable pushrod.

Many options are available; please call your Zipper’s Sales rep for a rundown on available pushrods for your application.

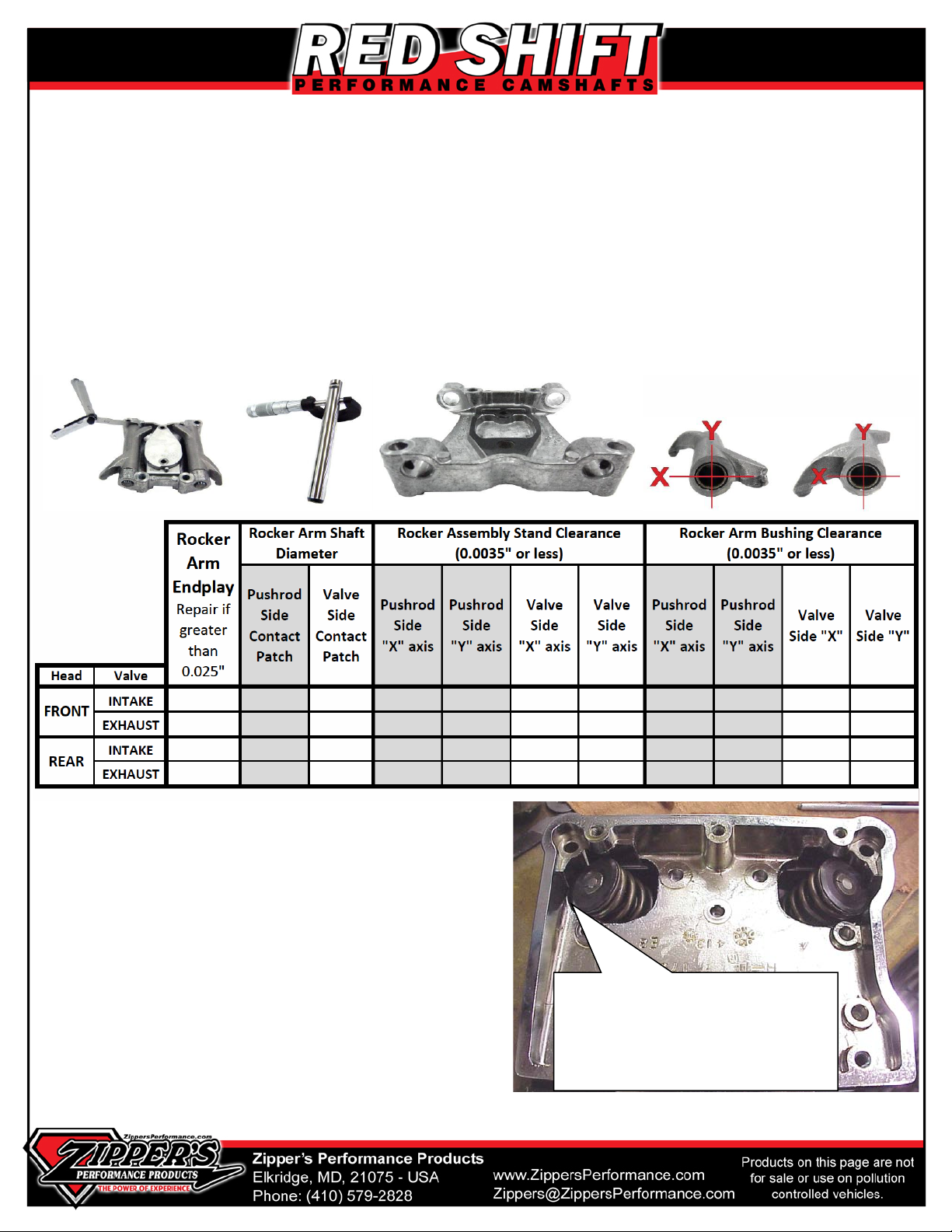

9.) Rocker Arm Assemblies - Checking the Rocker Arm Assemblies is commonly overlooked during a cam installation. The rocker

arms are inexpensive to replace, and typically one of the first items to show accelerated wear when operating in a low oil

pressure environment. Do a complete inspection on the rocker arms & assemblies before performing repair work to any of the

parts. You may find that it’s cheaper to purchase a new factory rocker arm than repairing multiple issues. If both bushings need

replacement, the repair cost will be near the replacement cost. A worksheet is provided at the end of this section to aide in the

inspection process.

Page 3

Check for clearance between the spring

clearance AFTER assembly.

a. Rocker Arm Pushrod Cups - Visually inspect each rocker arm pushrod cup for a proper 360

only see a wear pattern that’s 2/3 of a circle, you’ll need to either replace, or lap the pushrod cup until a full circular sealing

ring is present. All oil to the top end travels through the pushrod and into the rocker arm at this point, so a leak here will

diminish the oil pressure to the top end.

b. Rocker Arm Valve Tip Pads - Look for damage on both the rocker arm Valve Tip Pad, and then the associated valve tip itself.

With the right tools, it is possible to resurface the tip, if the damage is minimal. Repair or replace as necessary for your

situation.

c. Rocker Arm Endplay - Follow the factory Service Manual’s procedure and tolerances. Repair or replace as necessary.

d. Rocker Arm Shaft Diameter - Follow the factory Service Manual’s procedure and tolerances. Repair or replace as necessary.

e. Rocker Arm Bushing Clearance - The pushrod side bushing takes a beating if not properly lubricated. Follow the factory

service manual for the proper inspection procedure, and use the factory tolerances as your guideline. Repair or replace as

necessary.

f. Rocker Stand Clearance - Follow the factory Service Manual’s procedure and tolerances. Repair or replace as necessary.

o

pushrod tip sealing ring. If you

10.) Rocker Box to Valve Spring Clearance – If using late model

96 / 103 style heads with factory-equipped beehive springs;

rocker box clearance will not be a problem. Any dual or triple

spring pack must be checked, as they commonly hit the lower

rocker box, and potentially the top lid. If an aftermarket rocker

box is being used, always check for spring clearance, including

the top lid. A minimum of 0.060” clearance must be present

around the top of the spring pack.

To ensure proper alignment of the lower rocker box

when checking for clearance, use 2-3 tapered (alignment)

screws to hold the lower box in place. Using a standard zip-tie,

make a 2” loop, and make sure it fits around the top spring

collar. If the zip-tie doesn’t fit between the spring pack and the

rocker box, then remove the rocker box and cut material away

until it fits.

retainer and the lower frame boss above

intake and exhaust springs. Clearance as

needed. Verify you have at least .060”

Page 4

1999-2006

Model Year Specific Installation Warnings:

1.) Camshaft to Case Clearance –

significantly more material in the bottom end castings, resulting in

interference issues with even the smallest bolt-in camshafts.

Zipper’s developed a cam relief tool in early 2000 to properly machine

clearance into the engine case, when it was apparent that higher lift cams

would not bolt right in. The nice thing about the Zipper’s tool is the machined

chip size, since the system uses a carbide tool bit, all of the cleanup is generally

larger chips of material. Although a die-grinder will create the proper

clearance, any grinding tool will produce extremely fine debris and grit as it

cuts. Fine grit is more difficult to clean up, and is more likely to embed itself

into the powder coat inside the cam chest, because of the heat the particles of

grit carry. Some of this grit will not release from the powder coat until the

engine is running at full operating temperature.

Early Twin Cam engines were produced with

2.) 1999-2000 Spline Drive System - If you have an early 2000 or earlier model engine and wish to retain the stock

keyed type drive cam, we strongly urge you to purchase an aftermarket drive gear. Stock drive gears use a narrow key

channel, which has known to fail and spin on the camshaft when used with performance cams. This can cause

extensive damage to the top end components if this failure occurs with the valves open. Drive gears with a longer key

channel can be purchased through the Zippers Sales Department.

3.) 1999-2006 Rear Camshaft Endplay - If you are installing an updated rear cam roller bearing from H-D®, be sure to

check cam endplay spacing as per the factory Service Manual. This bearing was designed specifically for the splined

type camshafts, but can be installed on keyed type camshafts by installing an additional hardened spacer washer (H-D

P/N 8986) on the cam sprocket side of the bearing.

1999-2008

1.) Cam Cover Clearance –

When installing either a gear drive system, or Red Shift Dual Piston Cam Chain Tensioners,

you must create clearance on one of the casting ribs inside the cam chest cover. Simply remove one support fin with a

die-grinder, taking it down flush with the inside of the cover.

Starting in 2009, the cam chest cover no longer is produced with support ribs, and no additional clearance is required.

Page 5

Recommended Upgrades & Modification Tips:

Although some of the following topics are model year specific, perform these necessary tasks before you begin the actual reassembly process. Having all of the machine work completed, with the subassemblies ready to go will make the installation go

easier.

1.) Inner Cam Bearings

With the cam chest open, upgrade and replace the factory installed inner cam bearings. The highest quality, fullcomplement Torrington® brand needle bearing is available for direct replacement. It is highly recommended that the

proper tools are used for damage-free bearing removal and installation.

2.) Test & Repair Cam Support Plate

The Cam Support Plate performs an array of functions, so it’s easy to overlook the Oil Pressure Relief Valve. Always

check for leaks at the Oil Pressure Relief valve if you have the cam support plate out of the engine. Even new in the box

plates must be checked before installing, many times new does not mean sealed.

3.) Blueprint & Repair Rocker Arms, Shafts, and Rocker Stand Supports.

Using the provided worksheet, inspect and determine the status of your rocker arm assemblies. Since these are

high pressure points of contact, it is critical that the tolerances are held within factory specs. Low oil pressure or a loss of

valve train control will immediately affect the condition of the rocker arm bushings.

Please research your options when repairing an out of spec rocker arm bushing. If you find more than one problem

on a single rocker arm, it may be cheaper to replace the entire rocker arm than repair it. A new rocker arm from the factory

comes with new bushings installed, sized for a standard rocker arm shaft, and is inexpensive. Although replacement

bushings alone are very inexpensive, if you have to replace both the pushrod and valve side bushings, the labor costs to

replace the bushings will exceed the price of a new rocker arm.

Once complete, wash all of the pieces of the rocker arm assemblies. Coat the rocker arm shafts with a high quality

assembly lubricant, and reassemble the rocker arm assemblies.

4.) Higher Quality Lifters Replace your hydraulic lifters now!! Red Shift recommends that lifters be replaced with any new

cam installation; we strongly suggest lifters are removed for a full inspection of the rollers at or before 20,000 miles of use,

regardless of the brand of lifter or camshaft. Many skilled engine builders replace lifters at this mileage threshold because

they view the rollers as wear items; they are fully aware that waiting until failure will be extremely costly for your

engine. Any material shedding from the lifter roller or roller bearings can be a sign of a lubrication problem, which will

cause significant damage throughout the entire engine. Don’t let a part that’s inexpensive and easy to replace ruin your

engine internals!!

5.) Higher Quality Pushrods

The majority of Red Shift cams are designed to be used with adjustable pushrods. Red Shift always recommends

stiffness over weight when discussing pushrods. Zipper’s sells a well proven “Pro-Taper” pushrod that is significantly stiffer

than a factory pushrod. Many new options are available, including heavy walled 3/8” straight pushrods that work extremely

well with factory installed springs, and have plenty of clearance between the pushrod and the pushrod tube.

6.) Red Shift Dual Piston Cam Chain Tensioners

The revolutionary new dual-piston design is so simple

and effective; it’s easy to see why it works. When the Twin Cam®

engine is running, the power pulses rock the tensioner shoe back

and forth. On a single piston tensioner design, the natural shoe

movement causes the hydraulic piston to momentarily unseat at

the base, which interrupts the pressurized oil stream and

introduces air into the hydraulic tensioner. Air will diminish or

eliminate the pressure that the tensioner shoe places on the cam

drive chains, allowing loss of valve train control - leading to

“bounced” components including valves, spring collars, rocker

arms, pushrods, lifters and camshafts.

Red Shift® Dual Piston Cam Chain Tensioners are designed with shoe and hydraulic

stability in mind, eliminating harmful air leaks in the cam chain tensioning system while

dramatically improving overall valve train control and durability.

Page 6

Assembly Instructions:

Red Shift Cams produces a wide range of performance camshafts, from bolt-in cams for factory engines, to high-lift cams for

dedicated racing engines. It is important to know that as the performance level increases, the number of steps increase accordingly

to ensure that your installation is successful. Red Shift bolt-in cams are extensively tested in factory-built engines to ensure proper

valve-to-valve and valve-to-piston clearancing on unmodified engines. However, if you’re building a customized performance engine,

the task is up to the engine builder to determine if the desired cam will physically work or not. Changing the pistons, decking the

head gasket surface, and altering the valve sizes significantly alter the available clearances. It is critical to know that the cam has

enough clearance before installing it and finding out that there’s interference the hard way.

On All models:

Read the re-assembly procedure in your factory service manual, and mark the page with the hardware torque values.

1.)

2.) Thoroughly wash and clean all of the parts that you’re about to reinstall in your engine.

3.) Re-assemble the oil pump, and install it on the crankshaft. Pay careful attention to the installation, if the o-ring on the end

of the pump is damaged, the engine will be unable to scavenge properly, and will wet-sump.

4.) Read the appropriate section for your model year motorcycle.

’07-UP Chain Drive

5.) Coat the camshaft lobes, bearing journals, and chain sprockets with assembly lubricant.

6.) Install the inner Cam Chain onto the cams, making certain that the timing marks are pointed at each other.

7.) Insert the cams into the cam support plate.

8.) Install the thrust washer on the front cylinder’s camshaft, and install a new c-clip onto the end of the camshaft. This will

lock the cam set into the Cam Support plate.

9.) Install the Inner Cam Chain Tensioner.

10.) Install the cam support plate assembly into the engine, and torque the assembly in place.

11.) The oil pump should be fastened to the cam support plate, and torqued in place.

12.) Reinstall the factory spacer on the rear cylinder’s camshaft for a mock up.

13.) Mock up the drive sprockets first, leaving the chain on your workbench. Check the alignment of the two drive sprockets,

as the factory service manual describes. A different spacer may need to be sourced to correct any misalignments between

the rear camshaft and the crankshaft. Factory spacers are available in 0.010” thickness increments.

14.) Once the sprocket alignment has been set, install the outer drive chain onto the two sprockets, lining up the timing marks.

Install all 3 pieces onto the engine at the same time, and install the appropriate bolts for each sprocket. Always use blue

Loctite on the threads, and torque the bolts in place. The special sprocket locking tool makes torqueing these bolts a cinch.

15.) Install the outer Cam Chain Tensioner.

16.) Install the outer Cam cover, following the factory torque spec and torque pattern.

‘99-06 Chain Drive

Install the new Outer bearings onto the camshafts.

5.)

6.) Coat the camshaft lobes, inner bearing journal, and chain sprockets with assembly lubricant.

7.) Install the inner Cam Chain onto the cams, making certain that the timing marks are pointed at each other.

8.) Press the cams and bearings into the cam support plate, locking the front camshaft in place with a c-clip.

9.) Install the cam support plate assembly into the engine, and torque the assembly in place.

10.) Release the Inner Cam Chain Tensioner.

11.) The oil pump should be fastened to the cam support plate, and torqued in place.

12.) Reinstall the factory spacer on the rear camshaft for a mock up.

13.) Mock up the drive sprockets first, leaving the chain on your workbench. Check the alignment of the two drive sprockets,

as the factory service manual describes. A shim may need to be sourced to correct any misalignments between the rear

camshaft and the crankshaft.

Page 7

Once the sprocket alignment has been set, install the outer drive chain onto the two sprockets, lining up the timing marks.

14.)

Install all 3 pieces onto the engine at the same time, and install the appropriate bolts for each sprocket. Always use blue

Loctite on the threads, and torque the bolts in place. The special sprocket locking tool makes torqueing these bolts a cinch.

15.) Release the outer Cam Chain Tensioner.

16.) Install the outer Cam cover, following the factory torque spec and torque pattern.

ALL Gear Drive Cams

For any gear driven cam, read the instructions and warnings provided with the gear kit.

5.)

6.) Install the inner gears onto the camshafts.

7.) Install the bearings onto the new camshafts (’99-06 only). On an ’07-UP model, coat the outer bearing journals with

assembly lubricant. Install the assembly in the cam support plate.

8.) Install the cam assemblies into the cam support plate. Double check the timing marks once installed, both on the outboard

side of the cams, and the gears themselves.

9.) Coat the lobes and inner bearing journals with assembly lubricant.

10.) Reinstall the cam support plate into the cam chest. Torque in place

11.) The oil pump should be fastened to the cam support plate, and torqued in place.

12.) Install the outer drive cam gears. Check the outer cam gear backlash, and follow the procedures in the gear drive kit.

13.) Torque the cam gear retaining bolts in place, using Blue Loctite.

14.) Install the outer Cam cover, following the factory torque spec and torque pattern.

All Models – Final Setup Tips:

1.) Anti-Rotation Pin –

assembled, install the hydraulic lifters into the engine. Make certain that you

have the oil feed hole in the lifter facing outward. Using a set of feeler gauges,

measure the clearance between the center of the anti-rotation pin, and the

casting, when both lifters are positioned on the base circle of the cam. Do not

measure at each individual lifter.

Red Shift recommends between 0.002”to 0.004” of clearance. Oversized pins

are available in +0.002” and +0.006” sizes. Most will require the use of the

+0.002” pins for proper clearance. Both too much, and too little clearance will

result in operational issues. Not enough clearance can cause the lifters to

stick, and too much clearance will allow the lifter roller to turn and side load

under operation.

Allowable Lifter Rotation – Now that the cam chest is

2.) Pushrod Adjustment Procedure - Only for Adjustable pushrods

a. DRY - Starting with a dry lifter will allow full compression of the lifter, without risk of damaging the valve. Install

the pushrod, and fully extend it in place. Shorten the pushrod by 4 flats (2/3 of a turn), for proper lash. Make sure

to tighten the locknut to keep the pushrod at this length.

b. WET – If your lifters are primed or fully pumped up, you simply have to bleed the oil out of the lifter to find the

bottom. Install the pushrod and extend it fully to zero lash, with no pressure on the valve. Lower the adjuster 22

flats (3 -2/3 Full turns), and stop at this point to allow the lifter to bleed down. Once you can freely spin the

pushrod, adjust the pushrod down another 20 flats (3-1/3 turns). The hydraulics should be at the bottom, but give

it a few minutes to bleed down. If the pushrod turns, slowly lengthen the pushrod until the free movement is

contained. At this point, shorten the pushrod by 4 flats (2/3 of a turn), and tighten the lock nut.

3.) Fuel / Spark Tuning - To optimize the output of your new Red Shift cam, both fuel and spark adjustments need to be

performed. The use of wide band oxygen sensors are highly recommended when tuning.

Page 8

Red Shift Camshaft Application Matrix

Red Shift Twin Cam® Timing Specs

Loading...

Loading...