Page 1

THUNDERJET INSTALLATION FIXTURE

For S&S CARBURETORS # 713-910

NOTE: This fixture is intended for use on vertical mills only.

• This guide is to be used in conjunction with the ThunderJet installation

instructions. All additional details are found there.

• The fixture is designed to be secured to the mill table using 3/8” or ½” hardware

through the holes provided in the base.

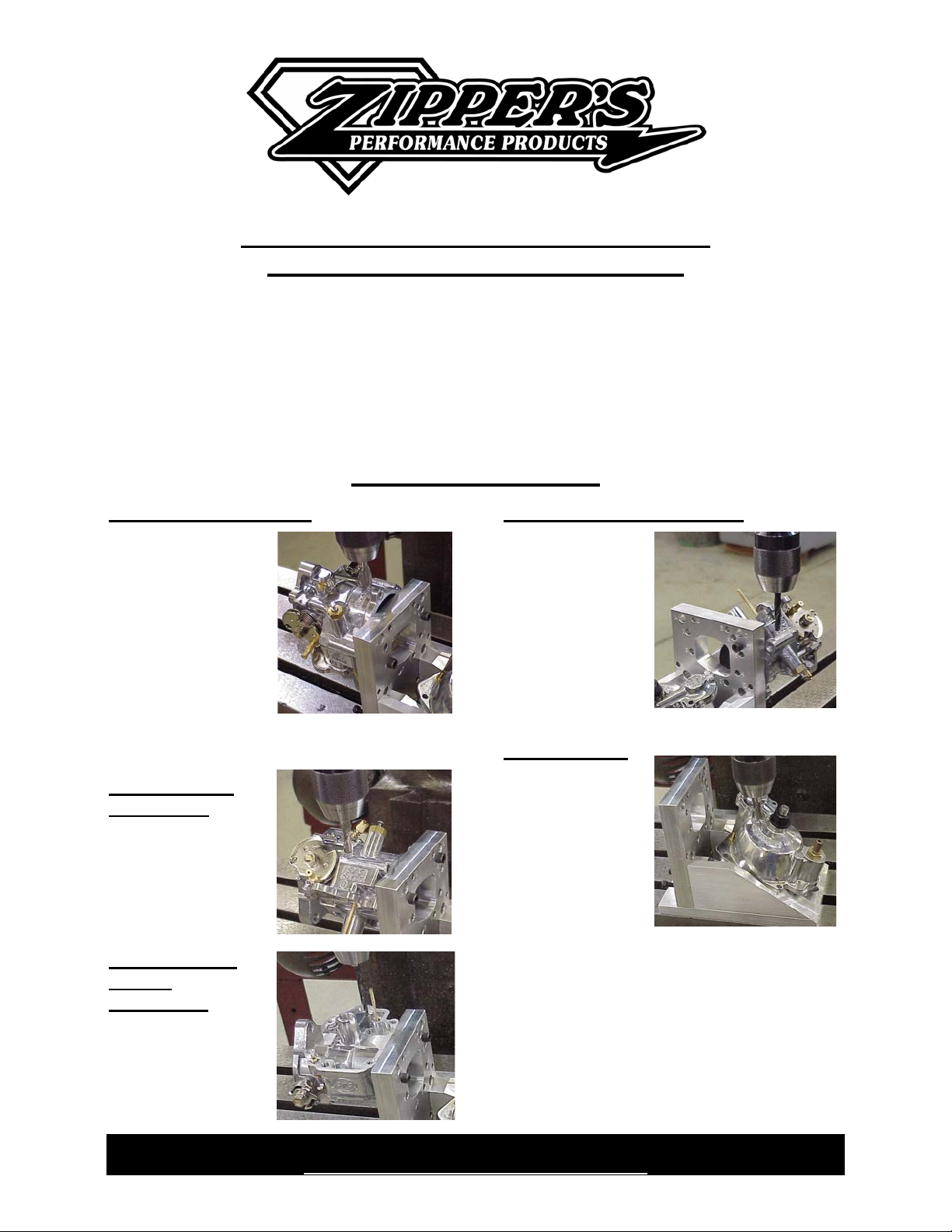

S&S ‘E’ & ‘G’ CARBS

FUEL DELIVERY TUBE

Using the two ¼”20 cap screws

provided, secure t

carb body at air

cleaner surface to

fixture through h

# 2 & 5. NOTE:

Holes # 2 & 6 may

be used to angle th

ThunderJe

clearance is needed below the fuel tank.

t farther forward if additional

he

oles

e

ADJUSTABLE

AIR BLEED

Secure Carb to

fixture using ho

& 8. 1

les #

RIGINAL AIR

O

LEED B

BLOCKING

Secure C

fixture using ho

1

& 6.

arb to

les #

BOWL VENT RELOCATION

Secure Carb to

fixture using

holes # 6 & 7.

FLOAT BOWL

Secure float bowl

to fixture using

the 3/8”- 16

flange nut and

threaded rod

provided using

the 20 degree

slope.

S

ee Reverse side for S&S ‘B’ & ‘D’

instructions.

66665555--AA AAmmbbeer

rton Drive, Elkridgee,, MMDD 2211007755 441100--557799--22882288

ton Drive, Elkridg

www.ZippersPerformance.com

Page 2

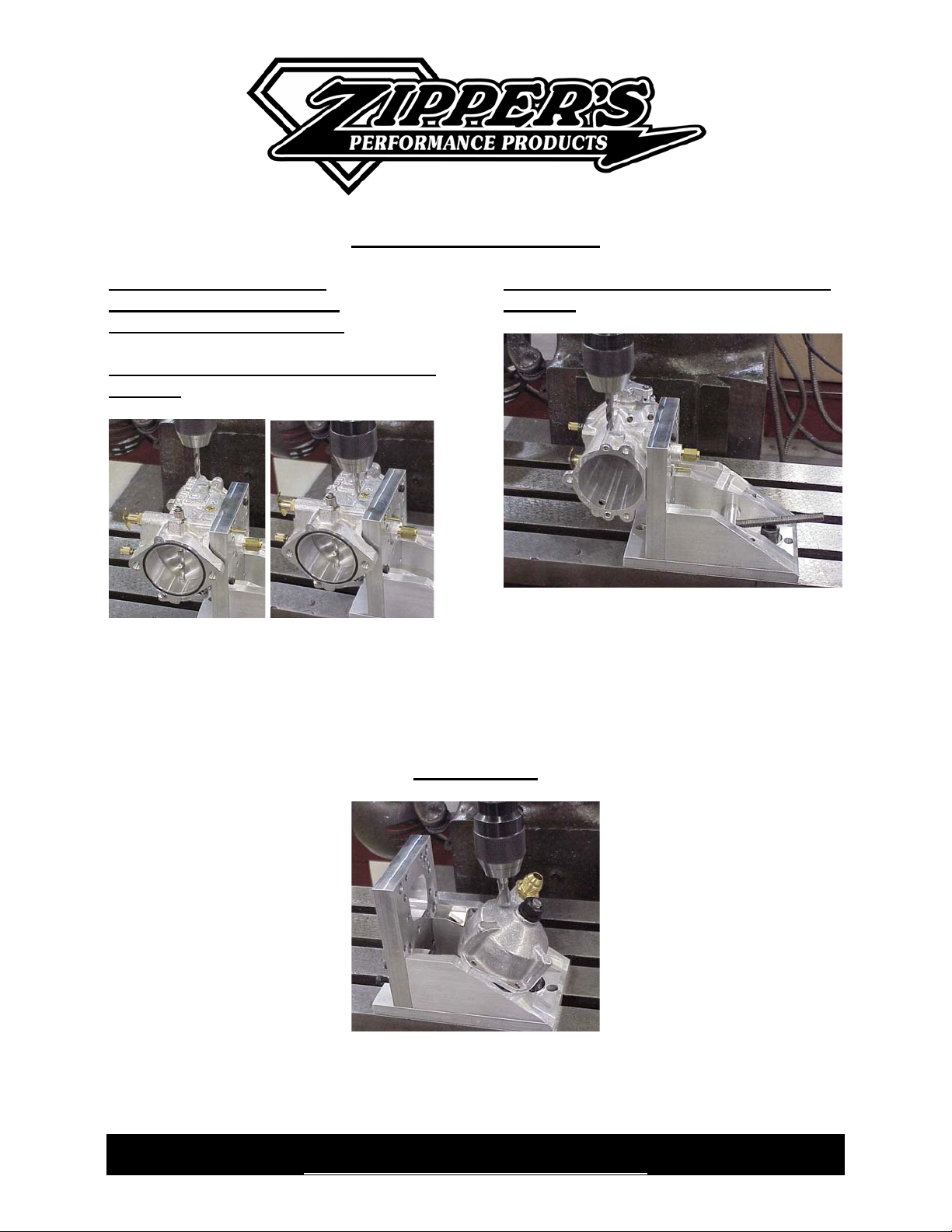

S&S ‘B’ & ‘D’ CARBS

EXTERNAL BOWL VENT

ADJUSTABLE AIR BLEED

THUNDERJET FUEL TUBE

:00 position, viewed facing air filter

(9

surface)

U

sing the two #10-24 cap screws provided,

secure the Carb body at bowl surface to

fixture through the two holes marked ‘B’.

FLOAT BOWL

:00 position, viewed facing air filter

(3

surface)

Using the two #10-24 cap screws provided,

secure the Carb body at bowl surface to

fixture through the two holes marked ‘D’.

ecure float bowl to fixture using the 3/8”- 16 flange nut and threaded rod provided using the 35 S

degree slope. Clock (rotate) bowl as needed.

66665555--AA AAmmbbeerrttoonn DDrriivvee,, EEllkkrriiddggee,, MMDD 2211007755 441100--557799--22882288

www.ZippersPerformance.com

Loading...

Loading...