Zip Heaters P4/52, P4/52UB, P4/102, P4/102UB, C2/50 Installation, Maintenance And User Instructions

...

Zip Tudor II & Contract II

Point of use Water Heaters

Models: P4/52, P4/52UB, P4/102,

P4/102UB. C2/50, C2/100, C3/50.

Installation, Maintenance and User Instructions

Please read these instructions carefully before commencing installation of the water heater.

Please leave these instructions with the end user after installation.

Zip Heaters (UK) Ltd

14 Bertie Ward Way

Dereham

Norfolk

NR19 1TE

Telephone: 0845 6 005 005

Fax: 01362 692448

Web: www.zipheaters.co.uk

The term ‘Zip’

is a registered trademark

Issued JUNE 2013 V1.01

Instructions. V1.01 Page 1 JUNE / 2013

Contents 1

Approvals 1

Description 2

WARNINGS

3

CAUTIONS

4

Packed Contents 4

Accessories 4

Technical Data 5

Spare Parts 6

Installation 7

Requirements 7

Wall Mounting 7

Overbasin Installation 8

Underbasin Installation 8

Electrical Installation 9

Cable installation/replacement 9

Safety Cut Out 10

Commissioning & Operation 11

Warranty 12

Please read these instructions carefully before commencing installation of the Point of Use

Water Heater.

Please leave these instructions with the end user after installation. To ensure you have a copy

of the latest instructions visit www.zipheaters.co.uk

Approvals

The Zip Tudor II and Contract II models are approved to the LVD and EMC directives and CE

endorsed.

The Zip Tudor II and Contract II models have been examined, tested and found when correctly

tted to comply with the requirements of the United Kingdom Water Regulations / Byelaws

(Scotland). The products are listed under the WRAS (Water Regulations Advisory Scheme)

Water Fittings and Materials Directory.

Instructions. V1.01 Page 2 JUNE / 2013

These instructions refer to the following models:

TUDOR II LOADING INSTALLATION

5 LITRE MODELS: P4/52, P4/52UB 1.8kW/230V Overbasin/Underbasin

10 LITRE MODEL : P4/102, P4/102UB 1.8kW/230V Overbasin/Underbasin

CONTRACT II

5 LITRE MODELS: C2/50, C3/50 1.8kW/230V Overbasin

10 LITRE MODEL : C2/100 1.8kW/230V Overbasin

Description

The Zip Tudor II and Contract II models are SINGLE point-of-use open outlet water heaters.

Being displacement type water heaters the hot water ow is controlled by the rate at which

cold water enters the vessel.

They can be connected either to the cold water main or fed from an overhead cold water

cistern (minimum head 3 metres).

Being fully automatic the Tudor II and Contract II may be left switched on under the control

of the thermostat, however WARNING This means that the unit remains potentially ‘LIVE’

when the selector is set to ‘0’. The unit can only be switched off (isolated) by operating the

double pole isolating switch to isolate the heater unit from the power supply.

The stored hot water is delivered from an open outlet spout (supplied with overbasin models)

or a Zip approved open outlet vented tap. This type of tting is permanently open to the

atmosphere which allows the expansion of water, that occurs during the heating cycle, to be

safely discharged.

During the heating cycle, drips will form and fall from the delivery spout or tap and these will

cease when the cycle has been completed and the stored water temperature has reached the

level set by the user. The higher the temperature selected the greater the rate of expansion.

Overtightening of the inlet water control valve or tap will not prevent the drips that occur, but

may cause damage to the valve or tap.

Temperature Control

The operating temperature range is 35-80°C. To protect the water heater against frost the

temperature control setting may be positioned at ‘ ‘ when a stored water temperature

of 5°C will be maintained. NOTE -the protection does not extend to connecting pipework or

ttings.

The economy setting ‘E’ will maintain the stored water temperature at approximately 60°C.

At the ‘E’ setting the temperature control locates into a set position and slight resistance will

be felt when rotating the temperature control beyond this setting. This is a safety measure to

ensure that higher temperatures are deliberately selected.

Neon Lamp (Tudor II and C3/50 models)

The Neon lamp will glow while the elements are in operation but will extinguish when the

chosen temperature has been reached. CAUTION: The unit will remain ‘LIVE’ when the

neon lamp does not glow.

Once installed DO NOT remove the cover under any circumstances without rst isolating the

electrical supply to the heater.

Instructions. V1.01 Page 3 JUNE / 2013

WARNINGS

• Installation, commissioning and maintenance of this appliance must only be carried

out by a competent installer who will then be responsible for adhering to all relevant

standards and regulations.

• The appliance must be disconnected from mains power supply before carrying out

any work involving live circuits.

• The appliance must be permanently connected to the supply through an isolating switch

with a contact separation of at least 3mm in all poles and be protected by a suitably rated

RCD.

• To protect the appliance, an MCB (miniature circuit breaker) or cartridge fuse must be

tted with a rating suitable for the nomi nal current of the appliance.

• The cross sectional area of the connection cable must be appropriate for the power rating

and location of the appliance. See Technical Data.

• The connecting cable must be adequately secured.

• This appliance must be earthed at all times.

• Check that the power supply is switched off prior to electrical connection.

• The appliance, its wiring and piping must not be modied in any way.

• In case of malfunction isolate the power supply immediately. In case of leaks also isolate

the water supply. Repairs must only be carried out by Zip Heaters (UK) Ltd or an authorised

Zip service engineer.

• Temperatures in excess of approximately 43°C are perceived as hot, especially by children,

and may cause a feeling of burning.

• This appliance must not be used by any person (inclu ding children) with limited physical,

sensorial or mental abilities or failing experience and/or knowledge unless they are

supervised by a person responsible for their safety or have received instructions about

how to use the appliance.

WARNING: Situations that could cause injury to yourself or others.

CAUTION: Situations that could cause damage to your appliance or other equipment.

NOTE: Notes, usage tips or additional information.

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY.

NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT

CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO

SO MAY CAUSE DAMAGE AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY.

RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

Possible New Statement

Instructions. V1.01 Page 4 JUNE / 2013

CAUTIONS

• Children should be supervised in order to make sure that they do not play with the appliance.

• The water vessel is intended for an open outlet and should never be subject to greater

than atmospheric pressure.

• The inlet control valve should not be subject to pressure exceeding 0.35 MPa (3.5bar).

• The appliance must only be used when correctly installed and in perfect working order.

• The appliance must be installed in a frost-free room and must never be exposed to frost.

• The appliance must be completely lled with water before being switched on.

• THE HOT WATER SHOULD BE DELIVERED FROM THE OPEN OUTLET SPOUT SUPPLIED OR A

ZIP APPROVED OPEN OUTLET TAP FITTING THAT REMAINS PERMANENTLY OPEN TO ALLOW

FOR EXPANSION THAT OCCURS DURING THE HEATING CYCLE. UNDER NO CIRCUMSTANCES

SHOULD THE SPOUT OR OUTLET BE CONNECTED TO A TAP WHICH IS CAPABLE OF BEING

CLOSED.

• The Zip Tudor II and Contract II is intended for connection to mains supply only. In any other

case please contact Zip on 0845 6 005 005 for advice.

• Zip Heaters (UK) Ltd cannot be held liable for any damages caused by failure to

observe these instructions.

• It is recommended that an HE45004 Water Block is tted in the water supply line to

minimise the potential damage in the event of any leakage.

Packed Contents:

Please check that the items below have been supplied in the Heater Unit package.

Outlet Spout x1(except UB models)

Wall Bracket x1

Control Valve x1 (except UB models)

Fixing Screws x2

Rawlplugs x2

Accessories:

Only Zip approved open outlet accessories should be used, the following are available.

HE45004 Water Block (for both overbasin and underbasin models)

Overbasin TS/1 Telescopic Spout 350-600mm.

Underbasin UB/1 Monobloc Mixer Tap.

UB/6 Single Lever Basin Tap.

UB/7 Single Lever Sink Tap.

Instructions. V1.01 Page 5 JUNE / 2013

Technical data

Model Tudor II and Contract II models

Nominal supply voltage 1/N/PE 230V~

Power rating (kW) 1.8

Rated Current (A) 7.8

Element type Embedded Rod

Maximum supply pressure 0.35MPa (3.5 bar)*

Temp. Adjustment range 35°C~80°C

Capacity 5 Litre 10 Litre

Dimensions H x W x D (mm) 390x255x215 440x310x265

Minimum weight (kg) (Empty) 3.5 4.0

Maximum weight (kg) (Full)) 8.5 14.0

Rated volume (litres) 5 10

Water connections (BSP) 1/2”

Protection class IP24

All data quoted at nominal supply voltage.

For higher supply pressures it is recommended that a Zip AQ3 (set at 3.5 bar) pressure reducing

valve is used.

ZIP Tudor II

ZIP

CONTRACT

W

D

H

D

W

H

C3/50Tudor II, C2/50 and C2/100

NOTE:

Overbasin and underbasin models are NOT interchangeable. For underbasin applications use

models designated ‘UB’ and use only Zip approved vented tap accessories.

Instructions. V1.01 Page 6 JUNE / 2013

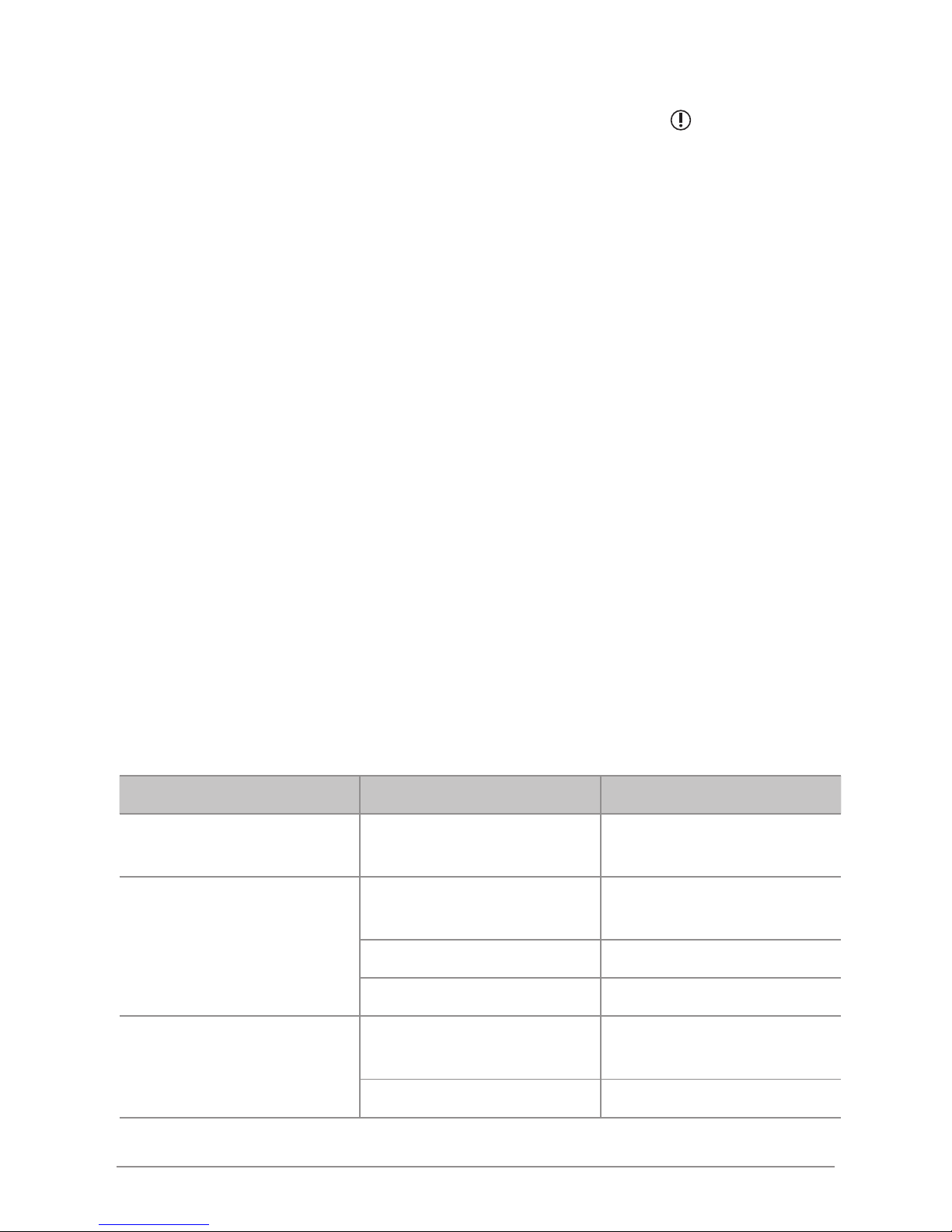

ITEM Description PART No. P4 MODELS C2 MODELS C3 MODEL

1 Heating element CTO111/4 X X X

2 Element gasket CTO116/4 X X X

3 Fascia CT0130 X

3 Fascia (OB) CT0107/3 X

3 Fascia (UB) CT0108/3 X

4 Thermostat CT0119/4 X X X

5 Re-settable cut-out CT0121/4 X

5 Re-settable cut-out CT0122 X

5a Thermal fuse CT0120 X

6 Neon light indicator CT0129/4 X X

7 Retaining nut CT0115/4 X X X

8 Front cover (5L) CT0103/3 X

8 Front cover. OB (5L) CT0123 X

8 Front cover. UB (5L) CT0124 X

8 Front cover (5L) CT0125 X

9 Back cover (5L) CT0101/3 X X X

8 Front cover (10L) CT0105/4 X X

9 Back cover (10L) CT0102/3 X X

10 Outlet Spout CT0137 X(OB) X X

11 Control valve CT0138 X(OB) X X

12 Control knob with spring CT0106/3 X X X

Spare Parts

9

8

1

5

4

2

7

6

5a

11

10

3

ZIP TUDOR II

12

Instructions. V1.01 Page 7 JUNE / 2013

Installation.

Requirements.

• Before starting installation the WARNINGS (page 3) and CAUTIONS (page 4)

should be read and fully understood.

• It is recommended that the piping and water connection is carried out by a qualied

plumber.

• Thoroughly ush the water supply pipes before installation to remove any water borne

debris.

• The electrical installation including earthing and cross bonding should comply with current

IEE regulations and any Local Authority requirements.

• Zip Contract and Tudor water heaters must be installed according to the specication on

the rating plate and the technical specications.

• Take care to protect the wiring from damage during installation and ensure that any

uninsulated wiring is not directly accessible after installation.

• For maintenance work an isolating valve should be installed in the water supply line to

the heater.

• A minimum clearance of 270mm is required underneath the overbasin heater units and

above the underbasin units to allow for the removal of the element plate assembly and for

servicing purposes.

• When considering the location of the heater, consideration should be given to the safe and

visible disposal of any water resulting from leaks and seepage.

Wall Mounting.

The unit will be supported by being hung on a bracket xed to a support wall, using the

xings provided (as shown g.1).

Therefore it is important to ensure that the wall is strong and solid enough to fully support

the unit when full.

It is important to ensure when drilling the wall, that the selected position avoids any

pipework or electrical cabling.

To mount the heater, the bracket ‘hooks’ locate into the slots provided in the back of the

unit, allowing it to hang at against the wall.

IT IS NOT NECESSARY TO REMOVE THE CASING TO MOUNT THE

WATER HEATER ON THE WALL BRACKET.

g. 1

Instructions. V1.01 Page 8 JUNE / 2013

Overbasin Installation.

The inlet control valve supplied incorporates compression ttings suitable for tting

between 15mm copper piping (water supply) and the inlet connection (coloured blue)

situated on the water heater.

Fit the control valve to the cold water supply ensuring that the water will ow in the

direction of the arrow indicated on the side of the control valve (g.2a).

Do not over tighten the compression joints but ensure that these are leak free.

WATER

SUPPLY

ZIP Tudor II

g. 2

g. 2a

MAINS

Supply

ZIP

Tudor II

Cold (Supply In)

Hot to Tap

ZIP Approved

Vented Tap

Underbasin Installation.

In all underbasin installations the outlet must be connected to an open outlet type

fitting approved by Zip heaters.

The diagram below (fig 3) shows a typical installation of a monobloc mixer tap

assembly, product ref. UB1. Alternative Zip approved products are product ref. UB6

and UB7.

NOTE:

When installing underbasin models it is recommended that bre washers are used on

both inlet and outlet connections to ensure a watertight seal.

Connect mains supply to the ‘blue’ tag tail (arrow pointing UPWARD). The inlet ‘blue’

connection on the heater is connected to the ‘blue’ tag tail (arrow pointing DOWNWARD).

The outlet connection of the heater ‘red’ is connected to the ‘red’ tag tail (arrow pointing

UPWARD).

g.3

Instructions. V1.01 Page 9 JUNE / 2013

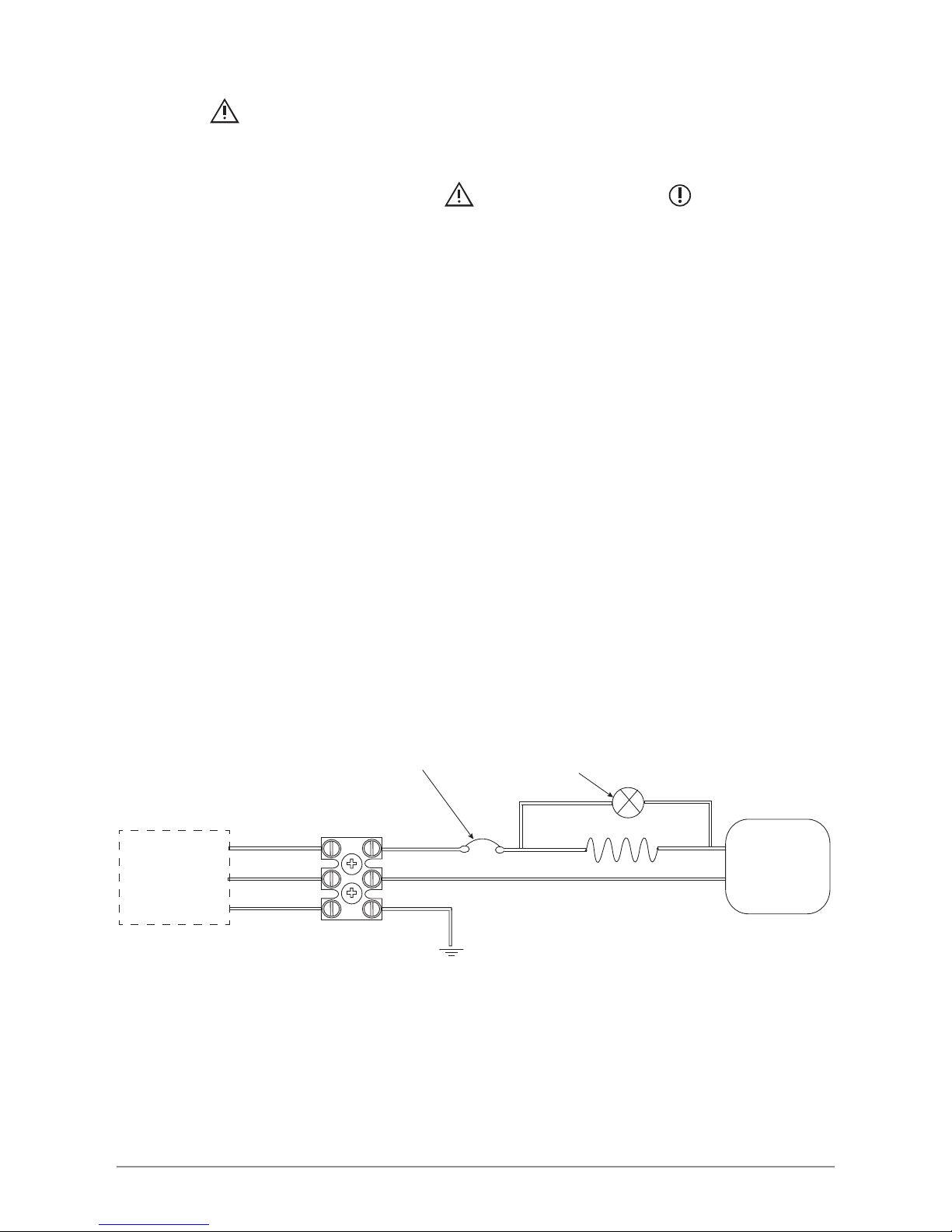

BROWN

BLUE

GREEN/YELLOW

RED

BLACK

HEATING ELEMENT

THERMOSTAT

NEON

INDICATOR BULB

EARTH

Supply through a

Fused doublepole

switch or fused

spur.

Tudor II and C3/50 models.

OVER TEMPERATURE

SAFETY CUT OUT

Electrical Installation.

WARNING: SWITCH OFF THE MAINS ELECTRICAL SUPPLY BEFORE CARRYING OUT

ANY WORK INVOLVING A LIVE CIRCUIT. 230v AC SUPPLY ONLY, THIS APPLIANCE MUST BE

EARTHED.

Before starting installation the WARNINGS (page 3) and CAUTIONS (page 4) should be

read and fully understood.

It is recommended that the electrical installation is carried out by a qualied electrician.

g.4

NB. Tudor II .

The Tudor models all come pre-wired with a 1 metre length of cable.

If in the lifetime of the unit the cable is damaged or a greater length of cable is required then

to replace the supply cable, refer to the following ‘Cable installation/replacement’

instructions.

Cable installation/replacement ( Tudor II and Contract II ).

First remove the temperature adjustment selector switch and release the screw located

beneath.

Unscrew the four cover screws-two on the top and two on the bottom of the unit, this will

then allow the outer cover to be removed.

The supply cable should have a nominal cross section of not less than 1.5mm².

The supply cable enters the casing through a cable clamp located in the rear casing cover

Make the connections in the terminal block provided as indicated in (g.4), then after ensuring

that the cable is rmly clamped, replace the front casing, cover and selector switch.

Instructions. V1.01 Page 10 JUNE / 2013

Models P4/52,P4/52UB, P4/102, P4/102UB

A manually resettable cut out that may be reset by a qualied electrician once the fault has

been corrected

Models C2/50, C2/100

A thermal fuse which should be replaced by a qualied electrician.

Model C3/50

An automatically ressttable cut out, reset by simply switching off the electrical supply to the

unit for at least 2 minutes.

When power is restored the cut out will have reset. However if the fault persists then the unit

should be isolated from the power supply and fault nding be carried out by a qualied

engineer.

Safety Cut Out.

In the event of a malfunction that leads to an over temperature situation, a safety cut out will

automatically cut off the electrical supply to the element (refer g.4).

The cut out and reset operations for the various models are described below.

Instructions. V1.01 Page 11 JUNE / 2013

Commissioning & Operation.

DO NOT SWITCH ON THE HEATER UNTIL IT IS FILLED WITH WATER

Open the inlet control valve or tap to allow the tank to ll with water, the tank will be full

when water begins to run continuously from the spout or tap.

Close the inlet control valve or tap and switch on the electrical supply, adjusting the temperature

control to the required level.

The contents of the water vessel will be heated to the selected temperature.

NB. During the heating cycle expansion will take place and water will drip from the spout

or tap. This will cease when the operating temperature has been reached, (approx 9

mins/+50°C for the 5L models, approx. 18 mins/+ 50°C for the 10L model).

Therefore always ensure that the spout outlet is positioned over the basin.

Hot water is drawn off by opening the inlet control valve or tap, this allows cold water to

enter the storage vessel as the heated water is displaced and is owing out.

Safety Warning.

Under no circumstances is the water heater to be used if suspected of being frozen.

If water ceases to ow switch off the electrical supply immediately at the isolating switch.

It is then recommended that a qualied Plumber/Electrician checks the unit.

Any water can be drained via the cold inlet connection whilst in the original location.

To remove the outer case, prise off the temperature selector switch and release the screw

located beneath it.

Remove the four front cover securing screws at the top and bottom of the unit, the outer case

can now be lifted off.

Maintenance.

Very little maintenance is required, however it is recommended that the replacement of spare

parts is carried out by a relevant competent person ie. Plumber or Electrician for any more

information please contact the Service Dept. ZIP HEATERS (UK) LTD TEL.0845 6 005 005.

Problem Possible cause Solution

NO WATER

MAINS WATER NOT TURNED

ON

CHECK SUPPLY AND TURN ON

NO HOT WATER

OVER TEMPERATURE CUT

OUT HAS OPERATED

REFER TO INSTRUCTIONS ON

PAGE 10.

FAULTY THERMOSTAT REPLACE THERMOSTAT

FAULTY ELEMENT REPLACE ELEMENT

WATER IS TOO HOT

THERMOSTAT IS SET TOO

HIGH

RESET THERMOSTAT

FAULTY THERMOSTAT REPLACE THERMOSTAT

Instructions. V1.01 Page 12 JUNE / 2013

The Zip appliance you have chosen is precision-built from the nest materials available and

should give many years of trouble free service.

Certain warranties may be implied by law into your contract with Zip.

The

warranty provided below is additional to these implied warranties and

nothing

set out

below shall limit your statutory rights or rights at law.

Zip Heaters (UK) Ltd warrants that, should any part fail within 12

calendar

months of

installation, that part will be repaired or replaced free of charge by

Zip or its Distributor or

Service Provider, except as set out below, provided

the

appliance is installed and used strictly

in accordance with the

instructions

supplied, and that failure is not due to accident, misuse,

abuse,

unsuitable

water conditions, or to any alteration, modication or repair by any party

not

expressly nominated by

Zip.

No costs are payable by the customer other than any mileage or

travelling-time

charges

incurred by a Zip Service Provider or the cost of removal, cartage

and

re-installation of any

component of the appliance if it needs to be returned

for

repair to Zip or its Distributor.

This warranty does not cover damage resulting from non-operation of

the

appliance or

consequential damage to any other goods, furnishings or property.

Zip does not exclude, restrict or modify any liability that cannot be

excluded,

restricted or

modied or which cannot, except to a limited extent, be

excluded,

restricted or modied as

between the owner or user and Zip under the

laws

applicable.

Furthermore, this warranty does not displace any statutory warranty, but, to

the

extent to

which Zip is entitled to do so, the liability of Zip under any

statutory

warranty will be limited

at Zip’s option to the replacement of the appliance

or

supply of equivalent appliance, the

payment of the cost of replacing

the

appliance or acquiring an equivalent appliance, or the

payment of the cost of having the appliance repaired or the repair of the

appliance.

Warranty

NOTE: It is our policy to continually improve products and as such we reserve the right to alter

data, specications and component parts without prior notice.

To ensure you have the latest revision of this instruction manual, please visit www.zipheaters.co.uk

to download the latest copy.

IMPORTANT: No liability is accepted for incorrect use of this product.

The use of this crossed out wheeled bin logo indicates that this product needs

to be disposed of separately to any other household waste.

Within each of the European Union member countries, provisions have been

made for the collection and recycling of unwanted electrical and electronic

equipment.

In order to preserve our environment we ask that you dispose of this product

correctly. Please contact Zip Customer Service for advice on 0845 6 005 005.

Loading...

Loading...