Page 1

HydroTap Taps Installation

For new installations, It is recommended to fit the tap prior to installing the undersink unit.

Note: This book must be read in conjunction with the undersink installation manual and the user manual

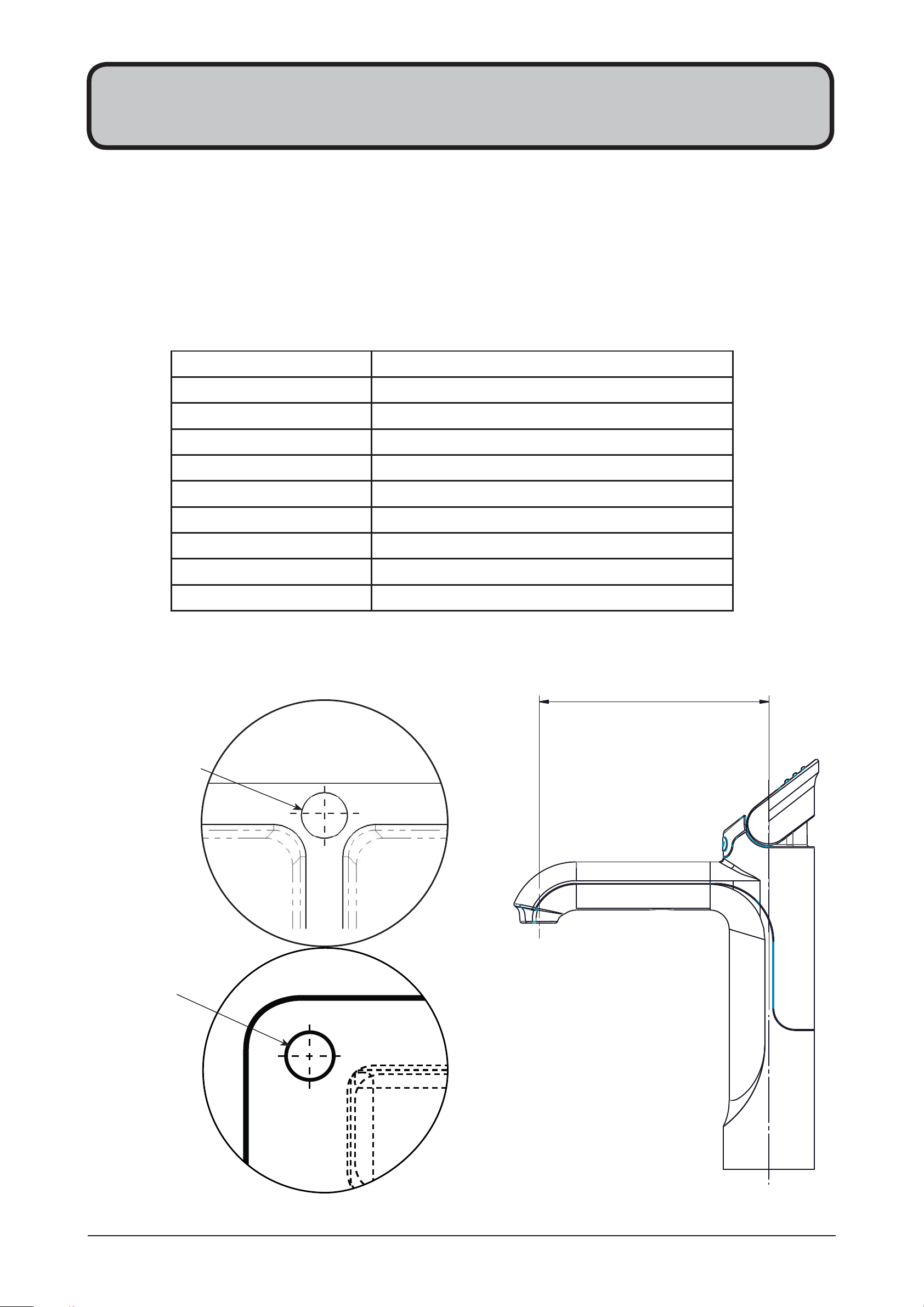

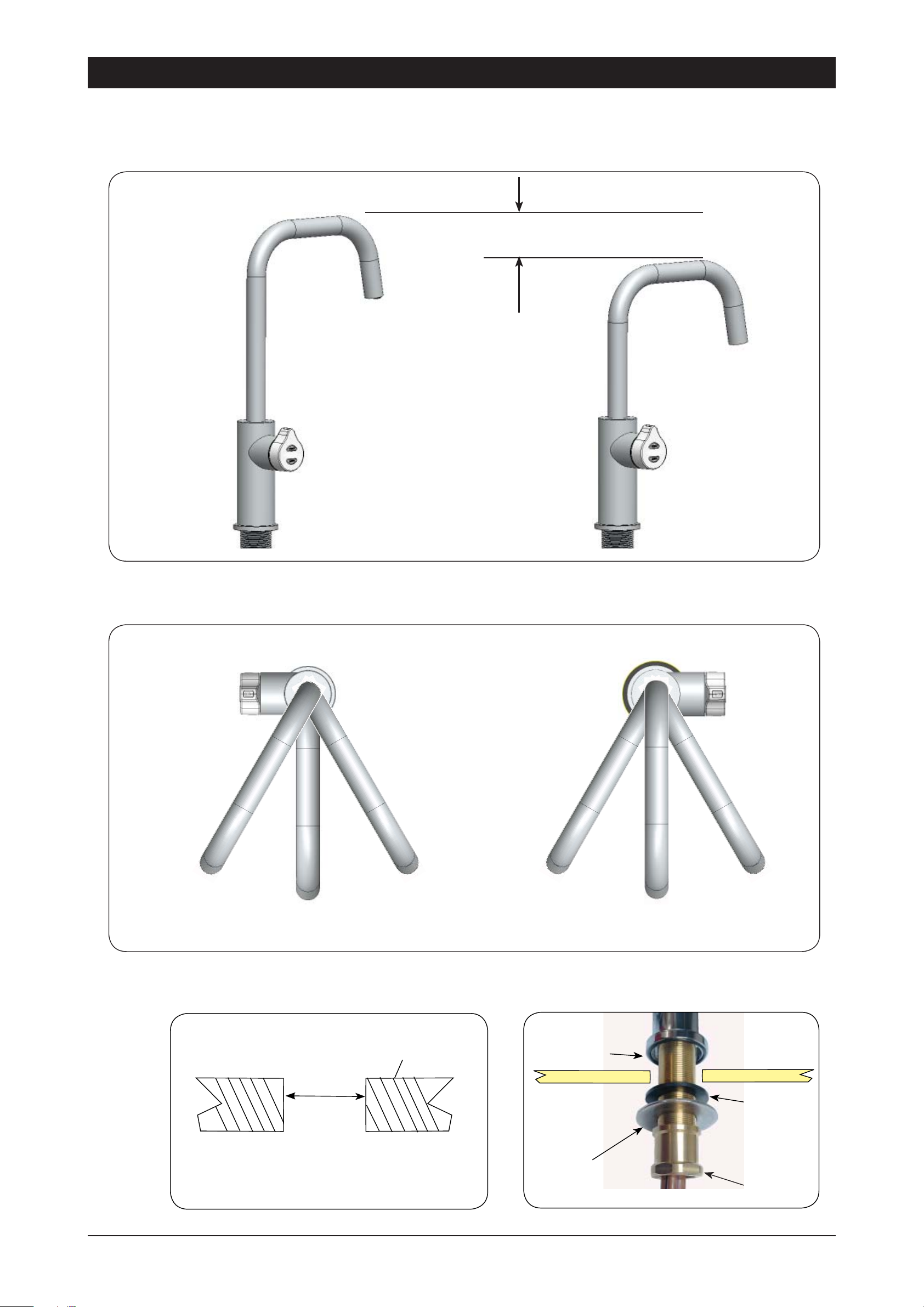

Hole positioning:

Position the tap such that it dispenses into the sink bowl with ample clearance for a cup or tea pot.

Alternatively, the tap could be mounted away from the sink using a font, available as an accessory.

Elite 116 mm

HydroTap Classic 116 mm

HydroTap Arc/Cube 171 - 174 mm (Extended)

Classic All-In-One 211 mm

Celsius All-In-One 242 - 250 mm

Celsius Arc/Cube 220 mm

Mixer - Arc neck 220 mm

Mixer - Classic 270 mm

TAP Recommended dispensing distance **

Mixer - Cube neck 220 mm

For

A-I-O 50mm and

Mixer taps 35mm

hole

116

Double Bowl

For

Elite,Classic

and Arc/Cube

35mm hole

BC HydroTap Classic

Single

Bowl

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 1 of 20

Page 2

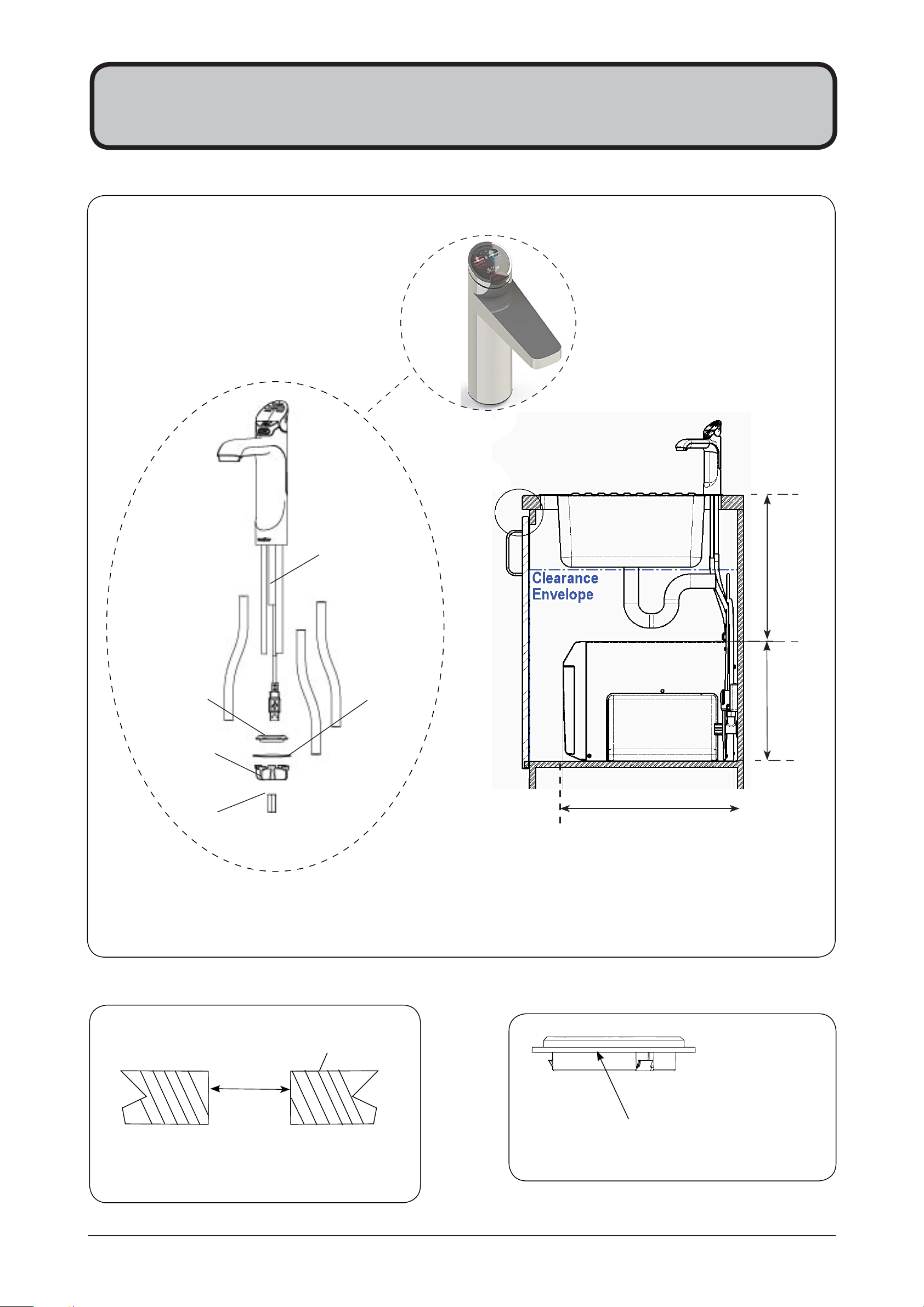

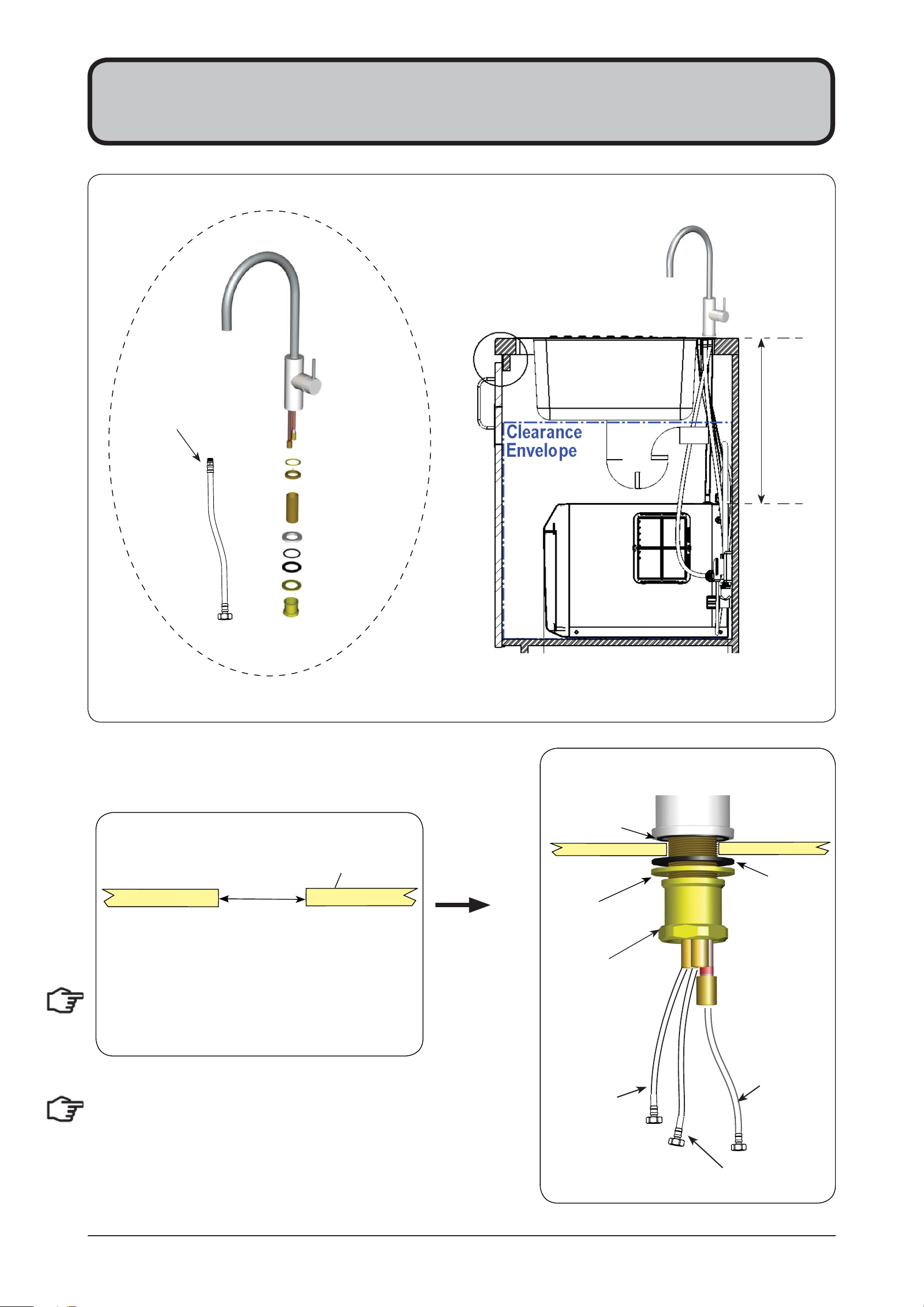

1 - HydroTap Classic & Elite

EliteTap

HydroTap Classic

BLACK PLASTIC

SPACER

SPIDER

CLAMP

NUT

ALL THREAD

ROD

Min 300mm

STAINLESS

STEEL

SPACER

335mm

470mm

Tap assembly exploded view and kitchen layout side view.

1.1

BENCH TOP

Ø35mm

Cut a 35mm hole in the bench / sink top.

1.2

Apply a light smearing of silicon sealant on the

underside of the spacer to ensure a watertight fit.

Page 2 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Page 3

Installation Instructions

Note

Note:

All

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

1.3

BLACK

PLASTIC

SPACER

35mm hole

Fit the

STAINLESS STEEL

WASHER,

SPIDER CLAMP,

AND 6mm NUT.

1.4

STAINLESS

STEEL WASHER

SPIDER CLAMP

6mm NUT

Pass all the hoses, tubes and USB lead

through the 35mm hole.

1.5

Red hose to boiling

water outlet

Blue hose

to chilled

water outlet

Note: feed each of the three tubes and

electrical cable evenly in between the legs of

the SPIDER CLAMP when installing.

Typical HydroTap Installation (see section 5)

Note:

- Mains hose

Clear hose to

Vent

length is 750mm

- Plug and Cord

length is 1800mm

Note:

silicon tubes

must be cut to

All

Incoming water

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

size. They must

have a constant

fall back to the

unit.

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 3 of 20

lengths supplied

Page 4

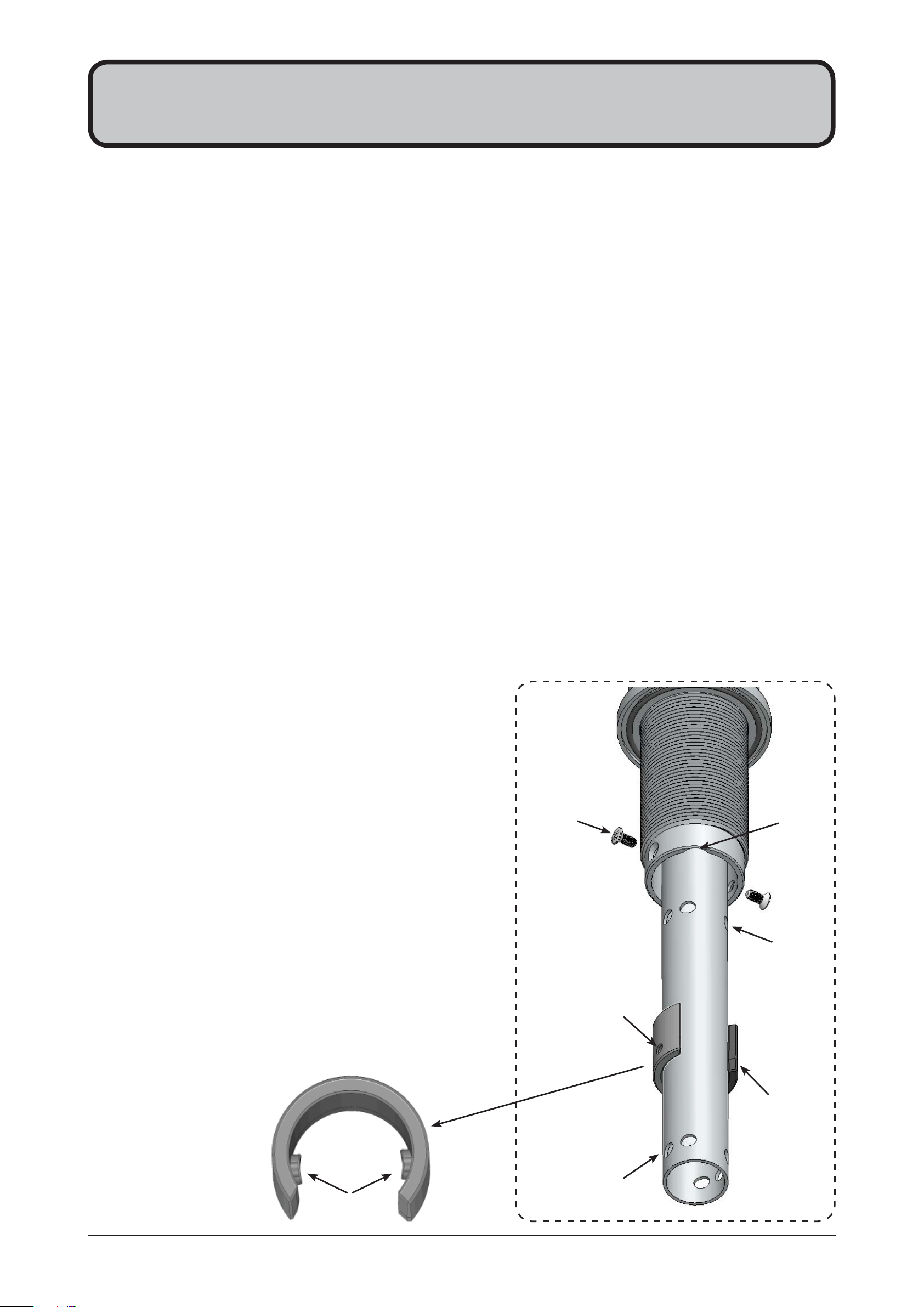

2 - HydroTap Arc/Cube

The HydroTap Arc/Cube has a spout that may be fixed in one of 6 angular positions (depending on the

position of the rotary control) and fixed in one of two height positions. The spout is fixed and does not swivel.

NOTE: The tube kit must be fitted after the HydroTap has been mounted on the benchtop or sink.

Refer to the tube kit assembly instructions, supplied with the tap kit.

To reduce the risk of scalding, Position A should not

be selected with any of the Boiling water units.

2.1

1.

NOTE: The plastic spring clip has two internal dimples that may be positioned in the 6 upper or 6 lower,

2.

3.

NOTE: When determining which of the 6 holes are required for the new spout height and orientation,

To change the spout position

Remove the 2 x spout locating screws and lower the spout to expose the plastic spring clip

pre drilled holes in the spout (see diags. below & Figs. 1.7 & 1.8)

To reposition the spout, gently spread the plastic spring clip to release the dimples from the spout

holes. When released, slide the clip on the spout so that it ends up between the two rows of holes.

Rotate the plastic clip on the spout to orient the dimples, so they are in line with the newly selected

holes.

check the new plastic clip position will clear the undercut and that the wiring loom will not be pinched,

when assembled.

(See fig. 1.8)

4.

Slide the plastic clip up/down to engage with the selected holes, making sure the two dimples engage

simultaneously with the two selected holes.

NOTE: The clip will not fit correctly if one dimple engages before the other. Both dimples must engage at

the same time.

5.

With the clip fitted to the newly selected holes,

carefully raise the spout (ensure the wiring loom is

a neat fit in the undercut and is located between the

open ends of the clip) until the clip locating holes are

in line with the spout locating screws.

6.

Replace the 2 x locating screws.

7.

If mounting on an uneven surface, apply a light

smearing of silicon sealant on the O ring to ensure a

watertight fit. (See fig. 1.9)

8.

Pass the assembly through the 35mm hole and

Spout locating

screws (2)

Undercut

for loom

position the tap so it discharges into the sink.

9.

Fit the lower rubber seal to the threaded extension.

10.

Secure the tap in position with the metal washer and

nut.

11.

Fit the tube kit, as supplied.

Plastic spring clip

Dimples

Page 4 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Clip locating

holes (2)

Upper locating

positions

Lower locating

positions

Plastic spring

clip

Page 5

Installation Instructions

2.2

Height adjustment (Fixed position options)

50mm

2.3

Left Hand Control Right Hand Control

Angular adjustment (Fixed position options)

NOTE: Position A is

not recommended with

Boiling water units

AA

C

C

B

B

2.4

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 5 of 20

Mounting (See table on Page 11 )

BENCH TOP

Ø35mm

Cut a 35mm hole in the bench / sink top.

O-RING

LOWER

RUBBER

WASHER

WASHER

NUT

Page 6

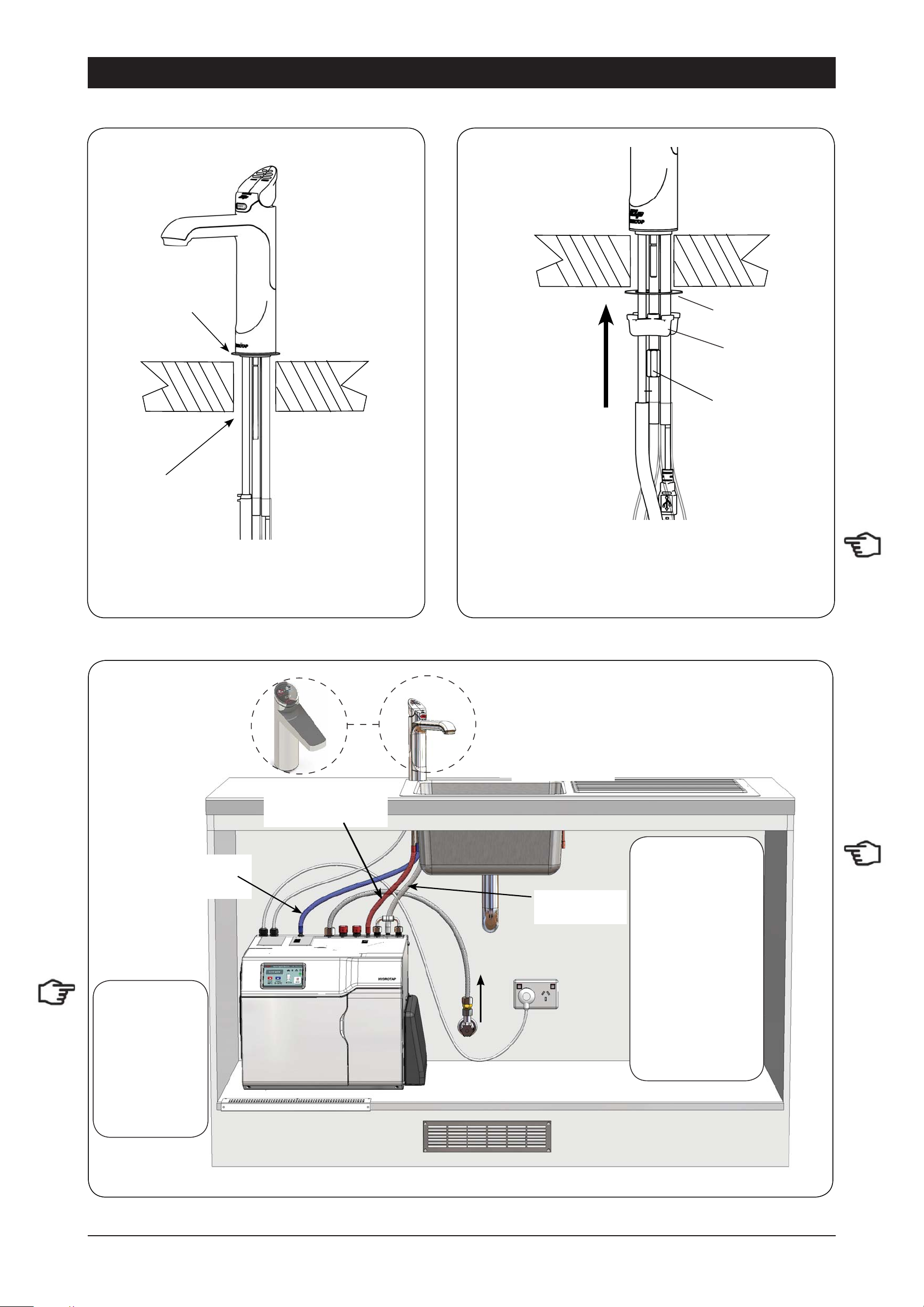

3 - Mixer Tap Installation

Note

BRAIDED

HOSE x 3

Tap assembly exploded view and kitchen layout side view.

Min 300mm

3.2

3.1

SINK TOP

35mm

Cut a 35mm hole in the bench / sink top.

Note: make sure the tap location will allow

the nozzle to drain into the sink.

Note:

The mixer tap requires a Restrictafl ow valve,

O-RING

WASHER

NUT

External

Mains

LOWER

RUBBER

WASHER

Red band

Mixer Out

as supplied, to be fi tted in the cold water sup-

ply line, from the isolation valve tee piece, to

the mixer tap. (See Fig. 1.13)

Page 6 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Blue band

Mixer IN

Page 7

Installation Instructions

3.3

•

Fit the O-ring into the recess on the underside of the Mixer tap. (Note: If mounting on an uneven

surface, a light smear of silicone on the O-ring will ensure a water tight seal)

•

Pass the tap tubes and threaded extension through the 35mm hole and position the tap so that it

discharges into the sink.

•

Fit the lower rubber seal to the threaded extension.

•

Secure the tap in position with the metal washer and Nut.

•

Affix the three hoses to the tap. Match the hose colours to the coloured bands on the copper extension

tubes. (See diag. 1.11)

Installing the Mixer Tap

(Classic, Arc and Cube)

Arc Mixer Tap

Mixer tap

O-ring

Sink top

Lower seal

Securing nut

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 7 of 20

Washer

Page 8

3.4

Note:

All

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

Installation Instructions

Typical HydroTap 4-in-1 Installation (see section 5)

HydroTap

Note:

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

POWER

CORD

unit.

All

USB

BLUE

CHILLED

OUTLET

WHITE

MAINS

IN

Mixer

Connections

MIXER

OUT

MIXER

IN

RED

BOILING

OUT

CLEAR

BYPASS INVENT

BYPASS

OUT

Note:

- Mains hose

length is 750mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

Restrictafl ow valve

(Supplied)

Tee piece

(Supplied)

Note:

Page 8 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

The tube lengths are matched to the pumps performance and therefore CANNOT be lengthened

COLD isolation valve

(Not supplied)

Page 9

4.1

Note

4 - Classic All-In-One Tap

Installation

4.2

Min 300mm335mm

470mm

SINK TOP

50mm

Cut a 50mm hole in the bench / sink top.

Note: make sure the tap location will allow the

nozzle to drain into the sink. (See Page 11)

Installation Procedure

• Fit the seal ring to the base

sealant to ensure a watertight seal

• Mount the tap on top of the cut out hole after passing the usb cable and tubes through the 50mm hole

• Thread the cable and silicon tubes through the circular clamp block (Check the tube colour alignment with the

coloured dots on the clamp block). (See fig 1.16)

• Clamp the assembly in position using the threaded nut and clamp block

of the tap and If mounting on an uneven surface, apply

a light smear of silicone

• Working from inside the cupboard, attach the braided hoses to the tube extensions (ensure the seals on the end of

the hoses are lubricated). Check the correct position for Hot and Cold connections by matching the colours on the

braided hoses with the coloured markings on the copper extension tubes. (See fig. 1.18)

• Test for leaks after all the connections have been secured.

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 9 of 20

Page 10

Installation Instructions

4.3

WHITE mark

Clamp Block markings and silicon tube positions,

viewed from underneath

R

BLUE mark

SILICON TUBES

B

C

BLUE mark RED mark

R

C

B

AIO Vented assy

4.4

USB CABLE

AIO Mains assy

CLAMP BLOCK O-RING

Mains IN

To Mixer

Mains IN

From Mixer

OUT

BLUE to Chiller

RED to Boiling

connection

R

B

connection

IN

FIXING NUT

CLEAR

to vent

From HWS

connection

R

RED to Boiling

connection

BLUE to Chiller

connection

B

C

Page 10 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Page 11

Installation Instructions

Note:

All silicon tubes must

be cut to size. They must have a

constant fall back to the unit.

4.5

•

Screw the braided hoses

into the extension tubes.

Ensure the o-rings

are lubricated prior to

assembly and that the

braided hoses, with

coloured markings,

are correctly matched

with the colours on the

extension tubes and

on the clamp block (as

indicated).

•

Make sure all tubes and

Typical Vented assembly

CLAMP

BLOCK

Extension

tubes

Braided

hoses

Vented braided hose positions

WHITE

Mains IN

RED from

Mixer OUT

BLUE to

Mixer IN

Mains braided hose positions

BLUE

Mains IN

hoses are firmly secured.

4.6

RED

HOT IN

Underside view

Typical All-in-1 Mains Installation (see section 5)

Note:

be cut to size. They must have a

constant fall back to the unit.

All silicon tubes must

from HWS

BLUE Chilled

RED Hot

Note:

- Mains hose

length is 750mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

External HOT & COLD

isolation valves

(Not supplied)

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 11 of 20

Tee piece

(Supplied)

Page 12

4.7

Note:

All

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

Installation Instructions

Typical All-In-One Vented assembly with Booster heater (See section 5)

Note:

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

All

BC Unit

A-I-O Tap

Booster

Note:

- Mains hose

length is 750mm

335mm

400mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

Restrictaflow valve & Tee piece

(Supplied)

Restrictaflow valve

Note:

cold water supply line, from the isolation valve (Not supplied), to the mixer tap. (See diagrams)

Page 12 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

The All-In-One vented taps require a Restrictafl ow valve and Tee piece, as supplied, to be fi tted in the

Page 13

5 - Celsius All-In-One Tap

Installation

5.1

Special Tools Required:

In addition to normal tools, the following will be

required:

•

50mm diameter sheet metal hole punch for

sink tops. (Not supplied)

•

50mm diameter hole saw for timber bench

tops. (Not supplied)

•

54mm AF tube spanner or wrench (Not

supplied) for fixing tap assembly.

Clearance

Min 300mm335mm

464

5.2

BENCH TOP

Ø 50mm

Cut a 50mm hole in the bench / sink top. Note:

make sure the tap location will allow the nozzle

to drain into the sink

•

Pass all the hoses, tubes and USB lead through

the 50mm hole.

•

Ensure the black rubber seal is correctly

positioned to give a water tight seal

5.3

•

Secure the rubber & steel washers and large nut

from inside the cupboard space, as shown.

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 13 of 20

Page 14

5.4

Note:

Trim all plastic tubes to min-

imise any dead leg of water.

Installation Instructions

6WHDP9HQW

2XWOHW

%RLOLQJ:DWHU

2XWOHW

+RW&ROG

:DWHU2XWOHW

Underside of spout of Celisus AIO tap.

&KLOOHG:DWHU

2XWOHW

439.5

258

255

220mm

(Hot & Cold Outlet)

Swing

42.9

Swing

151

85

5.5

Note:

imise any dead leg of water.

O-RING SEAL

BLACK RUBBER SEAL

STEEL WASHER

Trim all plastic tubes to min-

BRASS NUT

HOT & COLD

BRAIDED HOSES

USB PLUG

Page 14 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Page 15

Installation Instructions

5.6 Plumbing Connection

STEAM

VENT

BOILING

OUTLET

TOP END OF 3-WAY

SILICONE TUBE

3 WAYS MULTI

CHANNEL

BOILING

OUTLET

CHILLED

OUTLET

CHILLED

OUTLET

JG STRAIGHT

CONNECTOR

STEAM

VENT

BOTTOM END OF

3-WAY SILICONE TUBE

USB PLUG

3 STAINLESS

STEEL TUBES

BRAIDED HOSE

FOR MIXED WATER

BRASS NUT

FROM BOILING OUTLET

AT BASE UNIT OR

COMMAND CENTRE

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 15 of 20

FROM STEAM

VENT OUTLET

OF COMMAND

CENTRE

FROM CHILLED OUTLET

AT BASE UNIT OR

COMMAND CENTRE

COLD MAINS HOT MAINS

Page 16

5.7

Note:

All silicon tubes must be

cut to size. They must have a con-

stant fall back to the unit.

Installation Instructions

Typical All-In-One Mains Installation

BLUE Chilled

RED Boiling

Tee piece

(Supplied)

Note:

cut to size. They must have a con-

All silicon tubes must be

stant fall back to the unit.

Note:

- Mains hose

length is 750mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

External HOT & COLD

isolation valves

(Not supplied)

Page 16 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Page 17

6 - Celsius

Tap Installation

Special Tools Required:

In addition to normal tools, the following will be required:

•

35mm diameter sheet metal hole punch for sink tops. (Not supplied)

•

35mm diameter hole saw for timber bench tops. (Not supplied)

•

42mm AF tube spanner or wrench (Not supplied) for fixing tap assembly.

NOTE: Taps are available with ARC or CUBE neck options.

Hole positioning:

Position the tap such that it dispenses

into the sink bowl.

Double Bowl

35mm hole

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 17 of 20

Page 18

CSHA Tap connections

6.1

BENCH TOP

Ø35mm

Cut a 35mm hole in the bench / sink top.

Chilled Sparkling Tap components

6.2

RUBBER

Washer

Note: Trim all plastic

tubes to minimise any

dead leg of water.

BLACK RUBBER

Seal

BRASS

WASHER

BRASS

NUT

USB

PLUG

HOT & COLD

BRAIDED

HOSES

Page 18 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

JG

Y-PIECE

CHILLED

TUBE

SPARKLING

TUBE

Page 19

BHA and CHA Tap connections

6.3

Boiling

model Vent

outlet

BLACK RUBBER

SEAL

RUBBER

Washer

USB

PLUG

BRASS

WASHER

BRASS

NUT

BOILING

or

CHILLED

TUBE

VENT

TUBE

HOT & COLD

BRAIDED

HOSES

803341 - Tap Installation Instructions - 02.17 - v2.02 Page 19 of 20

Page 20

6.4

•

•

Tap Installation

Pass all the hoses, tubes and

USB lead through the 35mm

hole.

Ensure the black rubber seal

is correctly positioned to give

a water tight seal

•

Secure the rubber & brass

washers and large nut from

inside the cupboard space, as

shown.

Boiling

model Vent

outlet

BLACK

RUBBER

SEAL

RUBBER

WASHER

Head Office

Zip Heaters (Aust) Pty. Ltd.

ABN: 46 000 578 727

35mm HOLE

IN BENCH

TOP

FIT THE

RUBBER WASHER,

BRASS WASHER,

AND LARGE NUT

67 Allingham Street

Condell Park NSW 2200

Postal: Locked Bag 80

Bankstown 1885 Australia

Website: www.zipwater.com

Facsimile: (02) 9796 3858

Telephone: (02) 9796 3100

Sales & Service.

Free Call: 1 800 63 86 33

Customer Care.

Free Call: 1 800 42 43 44

NZ Office

Zenith Heaters Limited,

IRD No. 95 640 729

Unit 2/15 Moselle Avenue,

Henderson, Auckland 0610

New Zealand.

Website: www.zenithheaters.co.nz

Int. Phone: +(64 9) 838 8612

Telephone: 0800 558055

Facsimile: 0800 559055

WMKA00099

AS 3498

Page 20 of 20 803341 - Tap Installation Instructions - 02.17 - v2.02

Loading...

Loading...