Zip HT1790Z3-91295, HT1783Z2-91295, HT1790Z1-91295, HT1783Z3-91295, HT3783Z6-91295 Installation Guide

...Page 1

Installation Instructions

®

Zip HydroTap G4

Filtered Boiling, Chilled and Sparkling drinking water for Residential kitchens and tea rooms.

BCS Residential

Affix Model Number Label

Here

802005

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 1 of 28

Page 2

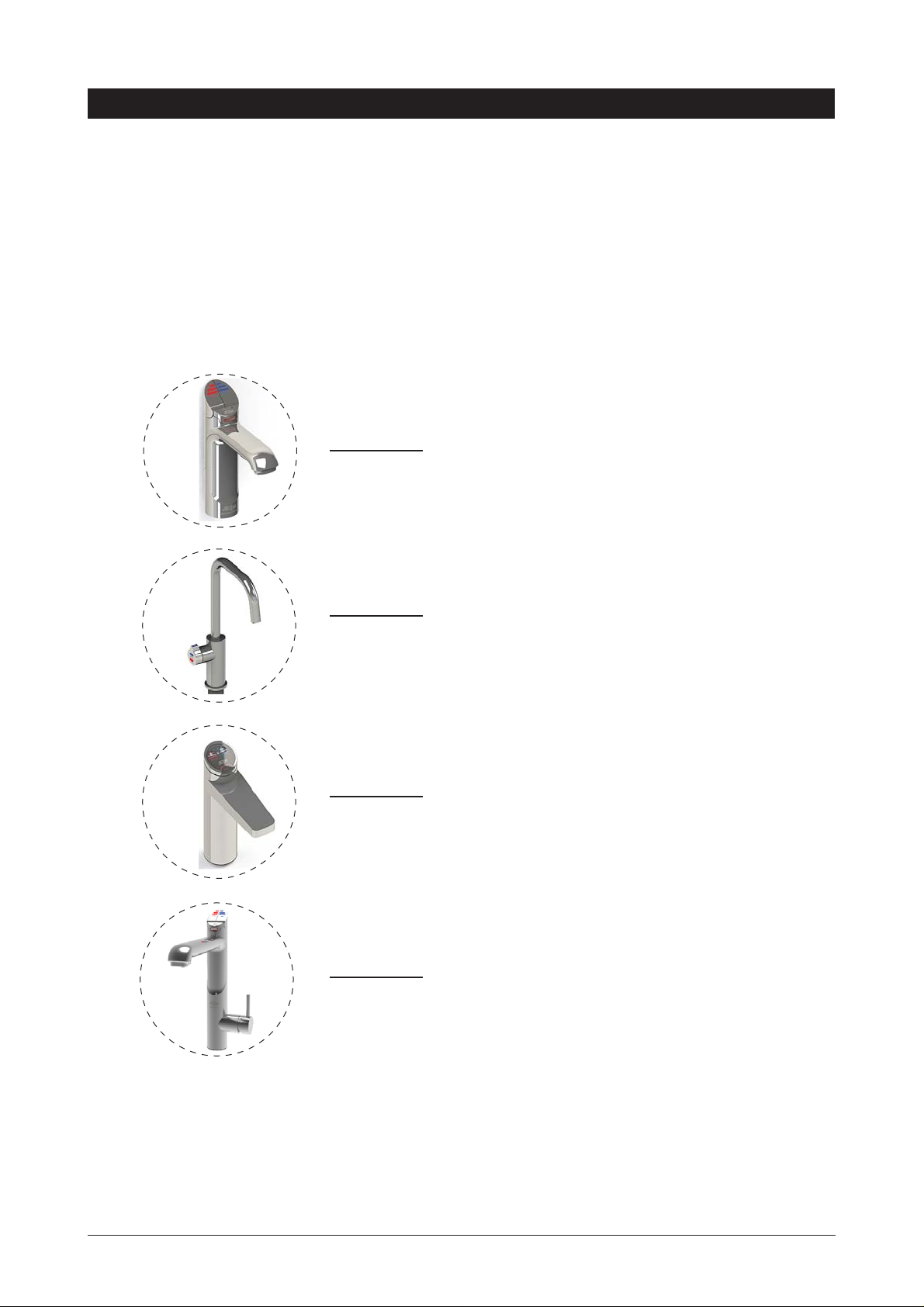

Tap options

The HydroTap applaince series offers a range of interchangeable taps to suit the customer’s needs (See

options below). For ease of installation, it is recommended to fit the tap before installing the undersink unit.

The installation procedure for each of the taps is detailed in a separate tap installation instruction book No.

803341, supplied with the tap.

For all operational features of the HydroTap, please refer to the BCS User manual No.802006.

Classic Tap

Arc / Cube Tap

Elite Tap

All-In-One Tap

Page 2 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 3

Index

HydroTap Specifications

Installation check list ....................................................................................................................4

General Product Features ............................................................................................................5

Important Safety Instructions .......................................................................................................6

Warnings and Regulatory Information ..........................................................................................7

Major components and Accessories ............................................................................................8

Technical Specification ................................................................................................................9

Before Installation and site requirements .....................................................................................10

Installation procedure:

STEP 1 -

(Refer to the Tap installation instruction book 803341)

STEP 2 - Check for adequate ventilation

Section 2 - Ventilation

STEP 3

Section 3 - Booster heater Installation

STEP 4 -

STEP 5

Section 5 - Undersink unit installation

STEP 6

Section 6 - Commissioning

Fit the tap to the benchtop or sink, before installing the undersink unit.

2.1 - Cut out details ..........................................................................................................11-13

- Install the Booster Heater (if required)

3.1 - Booster Heater specifications and Installation ..........................................................14-16

Fit the CO2 Gas cylinder

Section 4 - CO

4.1 - Connect and secure the 2.64kg CO

4.5 - Leak Test ..................................................................................................................18

- Install the undersink unit

5.1 - Check the external bypass valve setting ...................................................................19

5.2 - Mains water supply hose ..........................................................................................19

5.3 - Model BCS ................................................................................................................20

5.4 - Model BCSHA - AIO Mains .......................................................................................21

5.5 - Model BCSHAV - AIO Vented ...................................................................................22

- Commission the HydroTap

6.1 - CO

6.2 - Filter Flush ...........................................................................................................................23

6.3 - Boiling Calibration .....................................................................................................24

6.4 - Booster activation .....................................................................................................24-25

6.5 - Sensor calibration .....................................................................................................25

Cylinder

2

gas cylinder ....................................................17-18

2

Purge .................................................................................................................23

2

Trouble Shooting

Trouble Shooting Table ................................................................................................................26

End of life disposal .......................................................................................................................26

Notes ............................................................................................................................................27

Contact details .............................................................................................................................28

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 3 of 28

Page 4

Installation checklist

Thank you for purchasing a Zip HydroTap. Please read and follow these instructions carefully to ensure safe

and trouble free service. If service is required, please call 1800 638 633

Before Installation:

A. Read the instructions and check if there is adequate space to mount all of the components.

B. Note: Not all fittings are supplied with the appliance kit. Isolation valves and special tools are

not supplied (See Technical Specifications for details).

C. Check the mains water pressure is between 250 - 700kPa

D. Check the water quality to determine if extra filtration will be required.

Note: This product must be fitted to a potable water supply.

E. Check the appliance rating plate and ensure correct power is available for the appliance.

F. Check the under counter cupboard supporting the appliance is adequate for

the total weight of the appliance, when full of water.

Before Commissioning:

1. Check the unit has been installed correctly.

2. Flush the supply line before connecting to the undersink unit.

3. Check all plumbing fittings have been tightened.

4. Ensure the outlet and vent pipes are positioned to drain correctly.

5. Ensure there is adequate ventilation.

6. Check all tubes from the underbench unit to the tap, have a constant rise and there are no

sags or kinks in the hoses.

7. Check all electrical connections are correct and there are no loose wires.

Commission: (See section 5)

8. Turn on the gas and water and check for leaks.

9. Turn on the power.

10. Purge the CO

11. Flush the filter.

12. Where applicable, programme the unit to suit the customer’s requirements.

Page 4 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

2.

Page 5

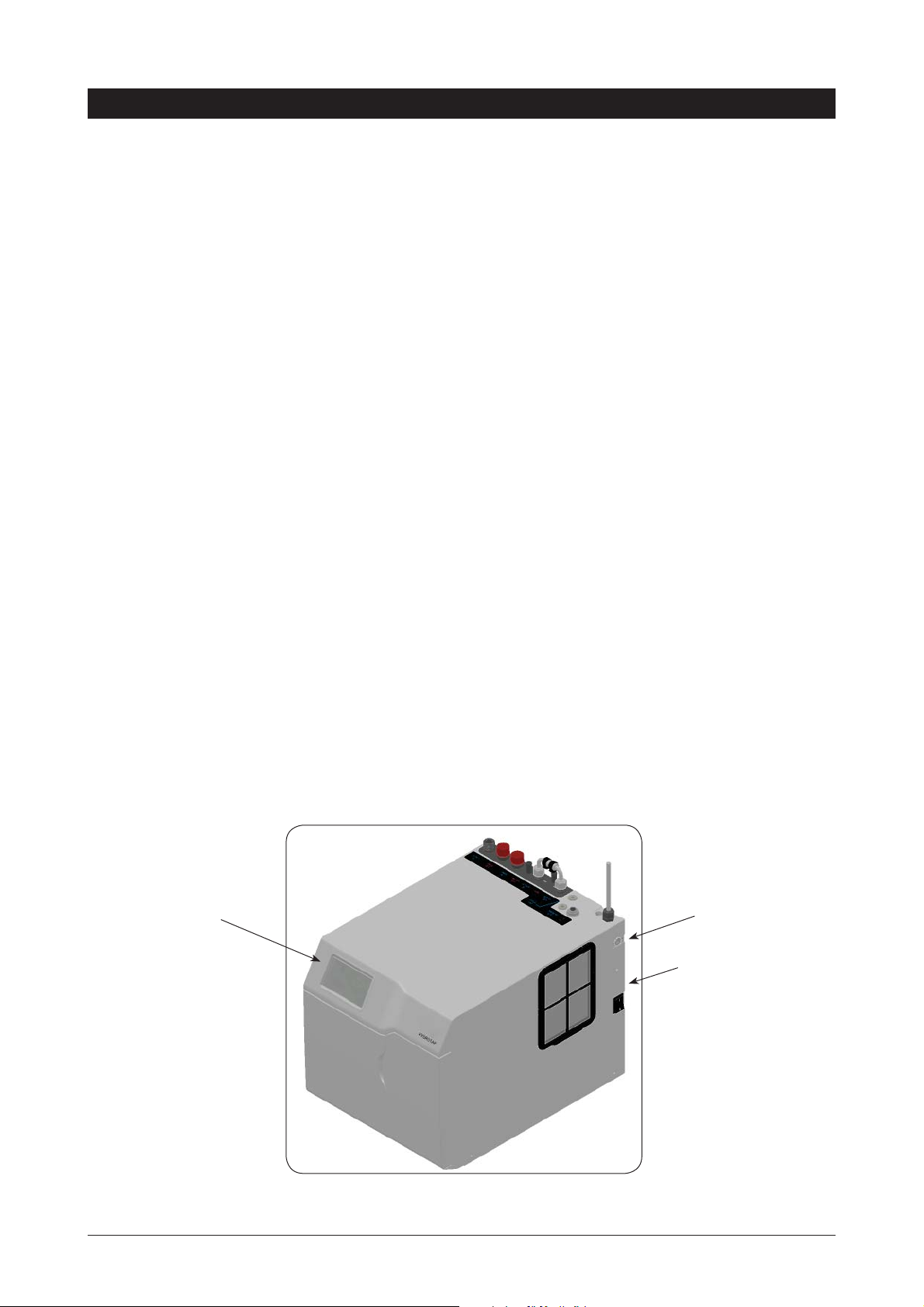

General Product Features

What is the Zip HydroTap ?

The Zip HydroTaps are electronically controlled, filtered, Boiling, Chilled and Sparkling water, drinking

systems for kitchens and tea rooms. The HydroTap units are under bench drinking water appliances with

a dispensing tap mounted on a sink or bench, which may be used for residential applications. These units

utilise a conventional refrigerant compressor to chill the water and (for BCS) an immersion heating element to

boil the water and all utilise a CO

units will dispense boiling water (factory set to 98°C) chilled water (factory set to 5-10°C) These units are

NOT designed to be used for sanitary fixtures.

The boiling water units are fitted with a tap mounted, child safety lock. In addition, there are various energy

saving options accessible via the main menu. Each boiling unit is equipped with a self-calibrating program

which caters for altitude adjustment. The 2kg CO

require periodic replacement and are covered by a limited OEM warranty.

It is important that the Installation be done safely, correctly and completely, in order to utilise all the benefits

the HydroTap can provide. Each Classic and AIO HydroTap can be ordered with the Tap Head Assembly for

Disabled use. The disabled levers are supplied with Braille caps for the visually impaired.

gas cylinder to carbonate the chilled water. Depending on the model, these

2

bottle and the water filter are disposable items. Both will

2

Usage:

The Zip HydroTap is intended for use in residential household and similar applications such as, Rural and

urban residential Kitchens, Hotels, Motels, Bed and Breakfast and other residential type environments

HydroTap BCS

Din plug

Command centre

(for accessories)

ON-OFF Switch

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 5 of 28

Page 6

Important Safety Instructions

This manual contains important safety, Installation instructions for the Zip HydroTap G4.

Safety

This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been

given supervision or instruction concerning use of the appliance by a person responsible for

their safety. Children should be supervised to ensure that they do not play with the appliance.

For products sold in Europe, this appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance. Cleaning and user maintenance shall not be

made by children without supervision.

Refrigerant

The Zip HydroTap unit contains R134A refrigerant under pressure. Maintenance of the refrigeration unit must

be carried out by an accredited service provider or qualified refrigeration technician.

Qualifications

If the power cable is damaged it must be repaired only by a qualified technician. To avoid hazards, all

Installation procedures must be carried out by a suitably qualified tradesperson. The power cable and power

outlet must be in a safe visible position for connection.

Venting

Ensure the tap body is located so the tap outlet safely dispenses into the sink bowl area.

Lifting

Take care when lifting the Zip HydroTap unit. Some units may exceed safe lifting limits. If you feel this is

beyond your personal capabilities, please seek assistance with the lift. The weights of the units are marked

on the packaging. Do not lift the unit by the front cover or any connections at the top rear of the unit. Refer to

the technical specifications for the weight of your product.

Airflow

The ambient operating temperatures, when installed in a cupboard, must be between 5ºC - 35ºC. The

system will operate satisfactorily only if proper air ventilation is provided and only if the recommended air

gaps of 50mm on each side are provided. See section 2 for correct ventilation details.

Positioning

It is important to ensure the underbench unit is positioned in an accessible area close to the floor level. The

unit must have it’s base mounted in a horizontal position with all inlets and outlets facing up. The Tap must be

located above the underbench unit. See section 4 for details.

Page 6 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 7

Important Safety Instructions

WARNINGS

1.

The Zip HydroTap unit must be earthed. The resistance of the earth

connection from each exposed metal part must be less than 1 ohm.

2.

All Installation and service work must be completed by trained and

suitably qualified Tradespeople. Faulty operation due to unqualified

persons working on this product, or any other Zip product may void

warranty coverage.

3.

All Plumbing must comply with AS/NZS3500.

4.

All Electrical must comply with AS/NZS3000

5.

All Plumbing and Electrical connections must be made in accordance

with local regulations.

6.

This HydroTap product is rated for 230V 50Hz AC operation.

7.

Underbench units must never be located near, or cleaned with water

jets.

8.

Zip HydroTaps are not to be exposed to the elements of nature

9.

Due to the process of continuous improvement, Zip Heaters reserves

the right to change details mentioned in this manual, without notice.

CO2 Cylinder Warnings:

•

Pressurised container.

•

Protect from sunlight.

•

Contains gas under pressure, may explode if heated.

•

Do not expose to temperatures exceeding 50˚C.

•

Do not pierce or burn, even after use.

•

Do not refill – non rechargeable

•

Ensure cylinder is empty before disposal.

•

Do not expose to naked flame or any incandescent material.

•

Keep out of reach of children.

•

High concentration of gas may cause asphyxiation.

•

Use only in ventilated areas.

•

Unless well ventilated, store the cylinder in an area no less than

20 cubic meters for each kg of gas. (See section 4)

•

Use only in an upright position.

•

This bottle must be used with the approved pressure regulator.

•

Avoid shock.

•

Use according to MSDS. (Material Safety Data Sheet).

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 7 of 28

Page 8

Major components and accessories

Parts supplied Description

1 off 4

HydroTaps

with hoses

(Classic tap shown)

1 off

HydroTap

Undersink Unit with

air and water filters

1 off

Mains water

connection hose

Vent Kit

1 x Inlet vent

1 x Outlet vent

9 x Screws

Accessories Description

Softener

and head assembly

Font Kit for

Arc & Cube Models

Font Kit for Classic &

Elite Models

Replacement Filter

User

Manual

Quick

start guide

1 x User guide and

1 x Quick start guide

1 off

CO

gas cylinder &

2

regulator assy.

HydroTap Booster

Water System with

connection hoses.

(Model BCSHAV)

1 x Restrictaflow

valve and Tee piece

for BCSHAV and

select models

Disabled lever Kit

Page 8 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 9

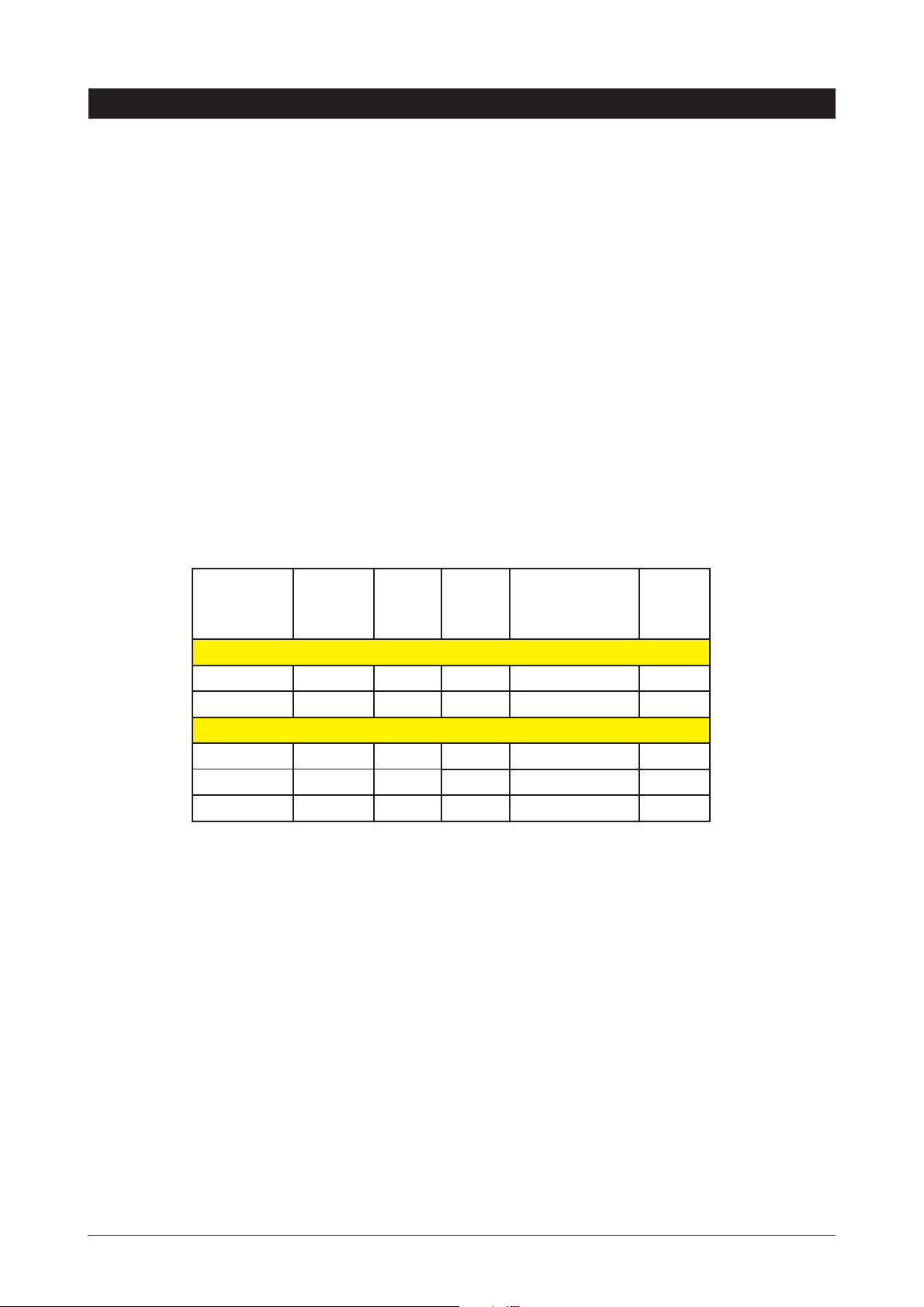

Technical Specifications

Product covered by these instructions:

BCS = Boiling Chilled Sparkling, Filtered

BCSHA = Boiling Chilled Sparkling, Hot & Ambient (Mains)

BCSHAV = Boiling Chilled Sparkling, Hot & Ambient (Vented)

D = Disabled lever controls, (Order as an option)

NOTE:

this may be at slightly higher temperature.

chilled water will continue to be dispensed after the rated capacity has been used, although

GPO's

Required

Boiling Chilled Sparkling

BCS 1x10A 1700 N/A 339 x 460 x 335 30

All-In-One

BCSHA 1x10A 1700 N/A 339 x 460 x 335 30

BCSHAV 2 x 10A 1700 2200 339 x 460 x 335 30

Power

Rating

(W)

Booster

Rating

(W)

Unit Dimensions

W x D x H

(mm)

**Dry

Weight

(Kg)

** Add an extra 5 kg when full of water

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 9 of 28

Page 10

Before Installation

Note

Before installing ensure that the following have been provided at the

Installation site:

•

Review all the technical specifications.

•

Ensure the underbench can support the product weight when full of water,

(allow an extra 5kg when full. )

•

Sufficient space in the cupboard to install all of the undersink units in accordance with these

Installation Instructions. Refer to technical specification for dimensions. Make allowance for a booster

heater and / or water softener if required. Refer to section 3 & 4, for Installation instructions.

•

For Zip HydroTap BCS models, a 220-240Vac, 10A GPO will be required. For Zip HydroTap

BCSHAV model, a double 220-240Vac, 10A GPO will be required. (One outlet is for the Zip HydroTap

and the other for the Booster heater).

Note: Check all cable and hose lengths against inlet /outlet positions before proceeding (See section 5 for general layout).

•

A potable water supply connection with isolating valve inside the cupboard within reach of the braided

hoses and positioned so that the connection point and the stop cock will not be obstructed when the

undersink units are installed.

•

For the mains pressure All-IN-ONE, an external hot and cold water supply will be required.

•

If an external filtration or water softening device is required, then it is important to allow extra space

for these items.

•

A cold water supply with a minimum working pressure of 250kPa and a maximum working pressure

of 700kPa connected via an isolation valve.

•

The fitting of an air flow duct, attached to the right hand side of the unit, requires a rectangular cut

size of 284mm x 45mm, to provide adequate warm air displacement. See section 2.

•

The appliance must be placed with it’s base in a horizontal position.

IMPORTANT!

Do not proceed with the Installation if these requirements are not met.

Special Tools Required:

In addition to normal tools, the following will be required:

For the standard and Mixer taps:

•

35mm diameter sheet metal hole punch for sink tops. (Not supplied)

•

35mm diameter hole saw for timber bench tops. (Not supplied)

•

Nut runner tube spanner (supplied) for fixing tap assembly.

For the All-In-One tap:

•

50mm diameter sheet metal hole punch for sink tops. (Not supplied)

•

50mm diameter hole saw for timber bench tops. (Not supplied)

•

Nut runner tube spanner (supplied) for fixing tap assembly.

Page 10 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 11

Section 2

Ventilation

When installing air flow ducts, the following tools will be required:

•

Jigsaw and 12mm Drill

•

Keyhole or Wall Board saw.

2.1

Ventilation for All Models

Proper air circulation must be provided for all Boiling and Chilled models. The system will operate correctly

only if the recommended air gaps are achieved during Installation. The minimum requirement is for a 50mm air

gap either side and 300mm above of the undersink unit.

It is important that the 4mm door buffers (For all installations ) are fitted to the inside edge of the cupboard

door to allow suficient air circulation inside the cupboard. (See the diagram below).

IMPORTANT:

See section 4 for clearances.

4 min.

Buffer Pad

Clear Gap

Min 300mm

460mm

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 11 of 28

Page 12

Ventilation

2.2

The following instructions are critical if there is insufficient cupboard air

circulation.

If the air flow, using the silicon door buffers, is insufficient, it will be necessary to fit a standard HydroTap vent

kit, which ensures heat dissipation through natural convection via installed vents.

For high use applications, where the cupboard space temperature is near 35°C, or higher, the inlet vent

(See Item B below) and silicon buffers, need to be fitted. If the airflow is still insufficient to maintain normal

operating temperatures then the inlet vent and door outlet vent (See item D below) will need to be fitted.

Alternatively a fan kit may be installed, using the AUX din plug of the right hand side of the appliance

(Contact your local service centre for availability).

Note: The vent kit has to be installed in a way that allows air to be drawn in from the bottom of the cupboard

and expelled through the top of the cupboard. Therefore placement of the outlet vent should be towards the

top of the door or on the side of the cupboard.

Airflow through the cupboard

Warm air

OUT

Door outlet vent

Cutout details

1.

Drill four pilot holes

12mm dia.

2.

Finish the cutout using

a jig saw and keyhole

or Wall Board saw

D

Air inlet vent position

Cool air IN

B

Page 12 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 13

Ventilation

Typical Cut out procedure for

1.

Mark out and cut the air inlet and door outlet holes as shown

2.

Ensure the air inlet vent and air outlet vent are positioned at opposite ends

of the same cupboard space.

3.

Fit the inlet vent, as shown and secure with 5 screws

4.

If required, fit the outlet vent, as shown in the hottest part (top) of the

cupboard and secure with 4 screws

B

D

B

Air inlet vent

Cutout deatils

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 13 of 28

Page 14

Section 3

Booster Heater

3.1

The boost unit is a compact electronically

controlled auxillary water heater. It is intended

to provide pre heating of water before it enters

the Zip HydroTap G4 boiling tank. The Booster

is supplied with the BCSHAV model. However,

it may be later installed, as an accessory for the

BCS model, to increase its delivery.

Note1: water connection

:Blue marking - water in

:Red marking - water out.

The braided hoses cannot be

lengthened.

Note2: The electrical cable

length is 1.0 metre.

Note3: Position the Booster

within reach of the fixed hose

lengths, keeping the Booster

as close as possible to the

undersink unit inlet/ outlet

fittings.

Note4: Ensure the Booster

heater is mounted in an

upright position (as shown)

with a horizontal base

Product Description

Mount base

Horizontally

339 mm

Booster Specifications:

Nominal Power Rating 2.2 kW

Nominal Current 10 A

Electric Supply 50Hz AC 230 V

Elect fl ex and plug (black) - 1 meter length (with 90º Aus-

tralian plug)

Fixed Flow Rate 1.2 L/min

Minimum water pressure 200 kPa

Page 14 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Rating Unit

10 A

Page 15

Booster Installation

3.2

Installation Procedure

Site requirements

•

Appliance must only be installed in a frost-free area. Never expose appliance to frost.

•

The Appliance is designed for wall mounted Installation and must to be installed with water connectors

facing upwards.

•

The appliance complies with protection class IP 25.

•

The 300mm braided hoses supplied with the unit cannot be lengthened.

•

The 90° elbow hose ends, should be fitted to the inlet and outlet connections on top of the Booster.

•

The hot water outlet hose must be thermally insulated with the insulation provided.

3.3

To Remove / Install the appliance

1.

Insert a flat head screwdriver all the way into the lock.

2.

Gently angle the screwdriver upwards by approximately 10° as shown in the image below.

3.

Pull the appliance forwards by approximately 15° as shown.

4.

Carefully pull the appliance upwards to complete the removal process. Taking care not to break the

lower clips.

5.

To install; Place the appliance on the wall bracket and snap into position (See installation below).

NOTE: Remove the backing plate for wall mounting

Tilt Forward Lift UP

Release

Installation

Take care

not to break

the lower

clips when

removing or

installing the

Booster

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 15 of 28

Page 16

Booster System

NOTE1: This appliance is intended for use with the Zip HydroTap under sink unit.

NOTE2: Water connections must be pointing vertically upwards.

NOTE3: The booster unit should be installed as close as possible to the Zip

HydroTap Unit as the 400mm connection hoses cannot be lengthened.

3.4

Braided hose connection

1.

The cold water inlet (blue) and hot water outlet (red) are marked on the rating plate. Connect the

braided hoses from the ‘Bypass Out’ fitting to the water inlet of the booster unit (Marked Blue) and

from the outlet of the booster unit (Marked Red) to the ‘Bypass IN’ fitting on the Zip HydroTap unit.

Avoid exerting any mechanical pressure on the appliance. This can be achieved by applying a spanner

on the flats of the inlet and outlet connections when tightening the braided hose connectors. Do not

overtighten ! Tighten the braided hoses by hand, then turn an additional 90° - 180° with a spanner

2.

Once the water connections have been made, check for any leaks and rectify as necessary.

s

Typical Installation

Braided Hoses

Strainer

Cold Water

Connection

(inlet, G1/2”)

Hot Water

Connection

(outlet, G1/2”)

Hold the hexagon while

tightening the braided

hose fittings

Page 16 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 17

Section 4

CO

Cylinder

2

WARNING:

This cylinder mus be installed in an open plan area or in an enclosed room, with a volume no less than 20m3.

If more than 1 gas cylinder containing CO

area should be in proportion to the number of gas cylinders stored in that location.

A ventilated area is a non-enclosed area which could include the kitchen, living room etc.

See gas bottle and MSDS sheet for a complete list of warnings. (See: www.zipindustries.com)

4.1

Secure the gas bottle supplied to a suitable wall, within 1 metre of the unit, in an upright position. This is done

by screwing the metal plate holding the Hook-and-loop strap to a cupboard wall, 200mm above the floor or

base of the cupboard. Make sure the gas bottle can stand before securing to the wall.

Due to regulatory requirements the gas bottle must be stored securely and in an

upright position.

Secure the cylinder mounting:

is present within the same location, the recommended ventilated

2

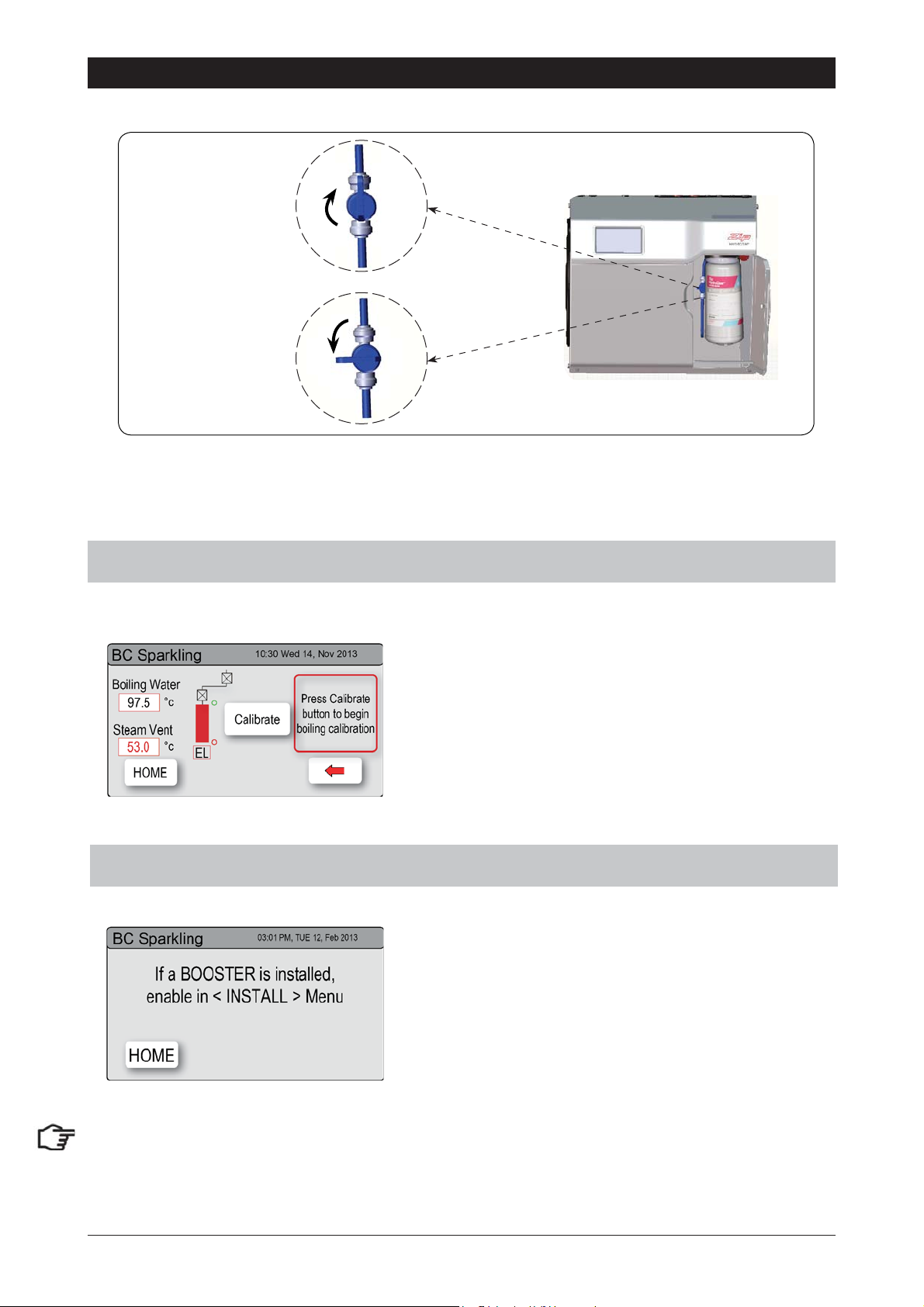

4.2

Connect the regulator:

Make sure the regulator knob is turned fully anticlockwise to the end-stop before fitting. Fit the regulator

to the gas bottle. Be aware that some CO

discharged from the connection to the regulator as the

bottle and the regulator are be assembled together. Any

CO

released will be cold. Continue to screw on the

2

regulator to stop this leakage.

Note: The regulator comes pre-set fixed pressure at 300kPa.

4.3

Connect the gas hose:

Connect the braided gas hose to the top of the

undersink unit via the John Guest fitting marked ‘Gas

IN’ Then connect the threaded end to the regulator,

taking care not to lose the plastic olive located inside

the threaded nut. To turn the gas ON, rotate the

regulator knob clockwise to the end-stop.

may be

2

Turn the knob fully anticlockwise before fitting

CLOSED

OPEN

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 17 of 28

Page 18

CO2 Connections & Leak Testing

4.4

Test for gas leaks:

Using soapy water perform a leak test. Apply the soapy water to the gas connections using a sponge. If any

bubbles appear and grow, there is a gas leak at the connection. Clean away the soapy residue and tighten

or refit the leaking connection. Make sure the regulator is turned off when tightening or refitting the leaking

connection.

Refit the gas bottle to the Hook-and-loop strap and secure the bottle in an upright position.

NOTE:

normal operating pressure of 2.7-3.0 bar (270-300kPa) be exceeded.

Connect the unit to the mains power supply.

Care must be taken when working with high pressure carbon dioxide, and in no cases should the

IMPORTANT:

After replacing a bottle or after making a

gas connection, check for gas leaks:

Stage1:

1.

Turn the gas OFF

2.

Using soapy water applied with a sponge, or with

a brush, cover all of the gas joints with a liberal

amount of suds.

Stage 2:

1.

Turn ON the gas

2.

Inspect the joint for leaks

3.

If any bubbles appear, the joint

will need to be resealed.

Page 18 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 19

%

5RWDWH

RQO\

Section 5

$

5RWDWH

RQO\

Undersink Unit Installation

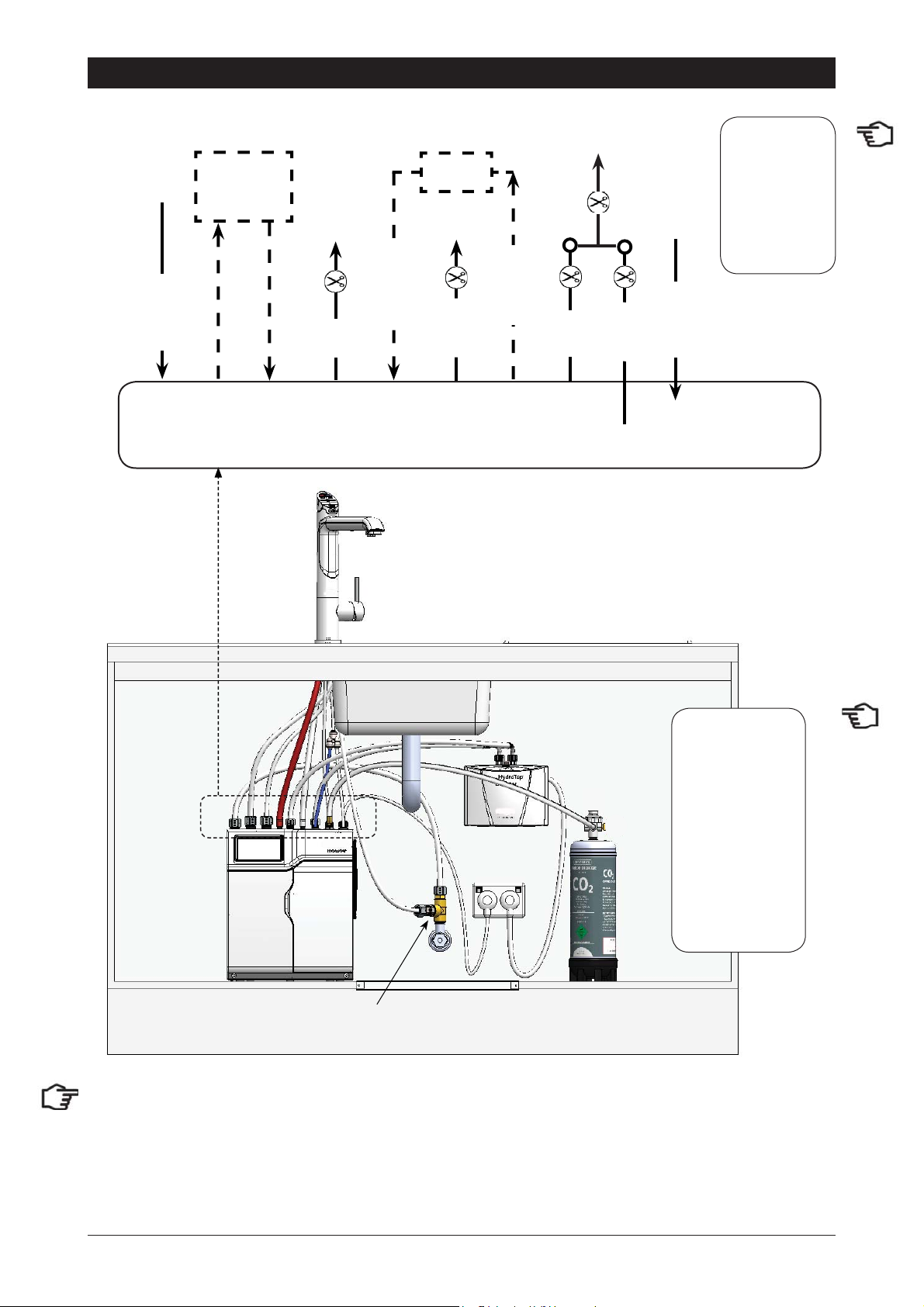

Note:

5.1

Before you install a unit, determine whether a water softener or an external filter is required.

E

xternal Bypass Valve

The diverter bypass valve allows the user to choose to have the boiling feed water bypass the internal filter

and only be filtered by the external filtration. This diverter valve is located at the rear panel of the Zip HydroTap

undersink unit on the filter door side, see the image below.

If no external fi lter is installed, select position A

Check to determine

which filter bypass

position you need

for your product.

If an external filter is installed, select position B

5.2 Hose and tube fitting. (Do not overtighten)

•

Remove all caps from the top of the undersink unit

•

Fit the foam insulation to the Blue and to the White tubes after trimming them to length

•

Install the mains water braided hoses to the undersink unit before locating the unit in place.

John Guest fittings (Insertion and removal)

Be careful when cutting the poly tube so that there are no rough edges and that the tube is not distorted.

1.

Use a sharp knife to ensure the tube has a clean,

straight edge. Do not cut at an angle.

2.

Remove any swarf or unwanted material.

3.

Push the tube into the John Guest fitting making

sure all connections to the John Guest fittings are

pushed in past the “O”ring to full depth, at least

15-16mm.

4.

Check for a good joint by pulling back on the tube.

If the tube comes out, of the fitting, repeat the

above step.

5.

To remove the tube, press the collet into the fitting and at the same time pull back on the tube.

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 19 of 28

Page 20

Installation Instructions

Note:

All

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

5.3

MAINS INMIXER

Model BCS

BRAIDED

MIXER INBOILING

OUT

OUT

RED

BYP ASS INVENT BYPASS

CLEAR

OUT

BLUE

CHILLED

OUTLET

SPARKLING

WHITE

OUTLET

BRAIDED

USB

CO2

IN

Note:

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

All

unit.

POWER

CORD

Min.

50 mm side

Clearance

339 mm

Max.

500mm

Max.

1000mm

Note:

- Mains hose

length is 750mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

Note: The tube lengths are matched to the pumps performance and therefore CANNOT be lengthened

: Not required for standard BCS HydroTap models.

Page 20 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 21

5.4

Note:

All

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

Installation Instructions

Model BCSHA All-In-One (Mains)

Note:

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

All

BRAIDED

MAINS INMIXER

OUT

RED

MIXER INBOILING

OUT

CLEAR

BYP ASS INVENT BYPASS

OUT

BLUE

CHILLED

OUTLET

SPARKLING

WHITE

OUTLET

BRAIDED

CO2

IN

CORD

POWER

USB

Note:

- Mains hose

length is 750mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

External HOT and COLD

isolation valves

(Not Supplied)

Note: The tube lengths are matched to the pumps performance and therefore CANNOT be lengthened

: Not required for standard BCSHA HydroTap models

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 21 of 28

Page 22

Installation Instructions

Note:

All

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

unit.

5.5

MAINS INMIXER

Model BCSHAV All-In-One (Vented)

HydroTap

Mixer

Connections

BRAIDED

OUT

RED

MIXER INBOILING

OUT

BYP ASS INVENT BYPASS

Booster

BRAIDED

CLEAR

BRAIDED

OUT

BLUE

CHILLED

OUTLET

SPARKLING

OUTLET

WHITE

CO2

IN

Note:

silicon tubes

must be cut to

size. They must

have a constant

fall back to the

BRAIDED

POWER

USB

unit.

CORD

All

Note:

- Mains hose

length is 750mm

- Plug and Cord

length is 1800mm

Position the under

sink unit close

to the outlet tap,

within reach of

the hose and cord

lengths supplied

Restrictaflow valve & Tee piece

(Supplied)

Note:

The All-In-One vented taps require a Zip Restrictafl ow valve and Tee piece, as supplied, to be fi tted in

the cold water supply line, from the isolation valve (Not supplied), to the mixer tap. (See diagrams)

Note: Fit the insulation (supplied) to the JG tubes used for Sparkling and for Chilled water

Note: To activate filter, flush at least 10L of water through the filter before connecting to a Booster heater.

Page 22 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 23

Section 6

Commissioning

The HydroTap is now ready to be commissioned.

•

Turn ON the water and gas and check for any leaks.

•

Turn the power ON at the GPO and at the side of the undersink unit

•

If fitted, ensure the Booster is turned OFF. (The Booster is commissioned, later, at section 7.4)

•

Familiarise yourself with the operation of the Tap, in preparation for use (See User Guide)

•

Follow the Installation instructions below (and review Section C of the User Guide).

•

Initially you will be prompted to select a language

•

After commissioning, the system may be customised by selecting further options in

Section G - Settings, within the User Guide.

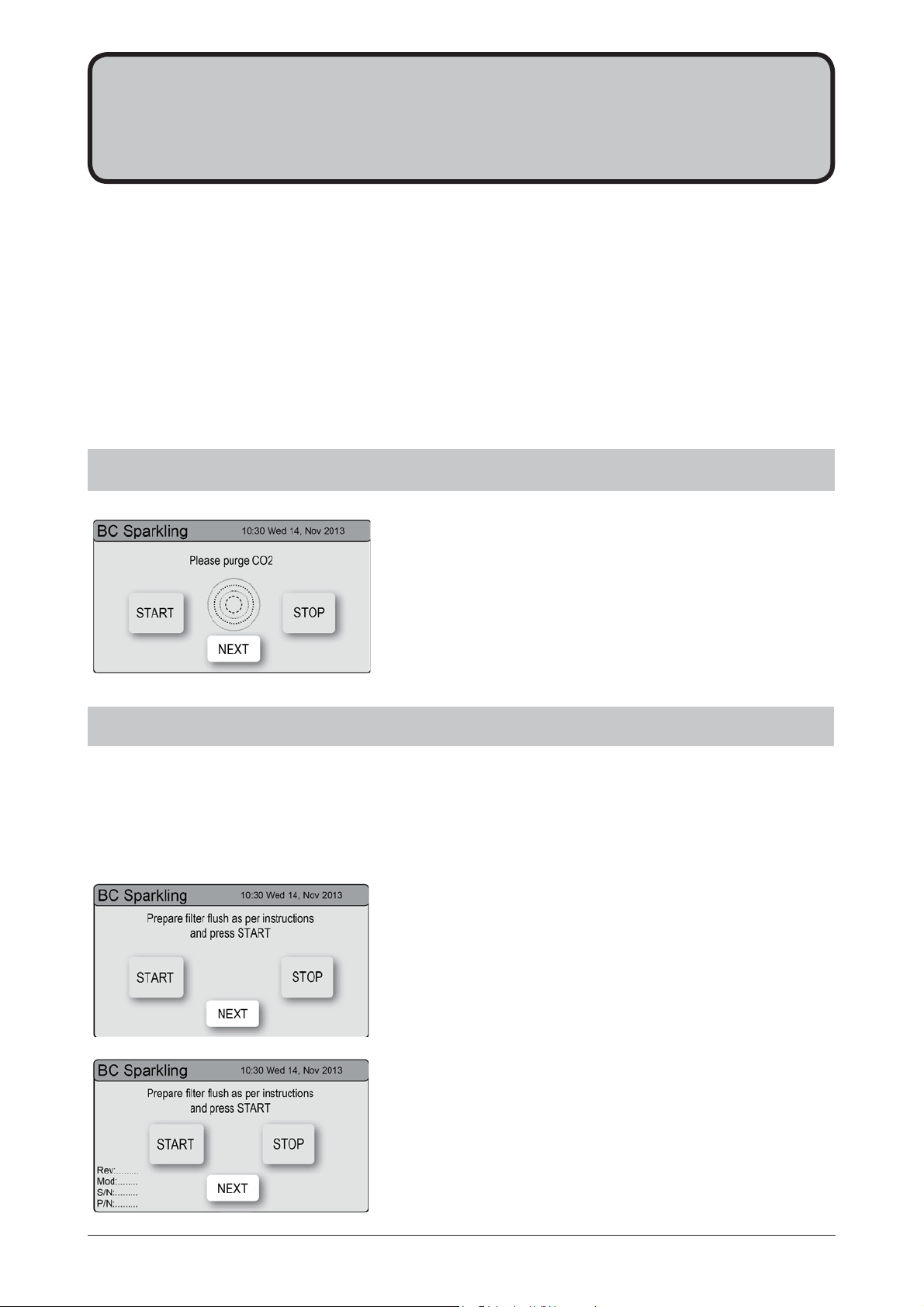

6.1 - CO

Purge

2

1.

Press the [START] button to commence the purging

process.

2.

Purge for 10 seconds and ensure all water has stopped

flowing through the tap. (You will hear the CO

escaping from the tap).

3.

Press the [Stop] button.

4.

Press [Next] for the filter flush screen

2

gas

6.2 - Filter Flush

Have a 10L bucket or similar container (not supplied) at the ready to hold a quantity of water that will be

ejected while the Filter Flush Mode is in operation. Open the filter access door on the front of the HydroTap

and the filter cartridge will be exposed. Located to the rear RHS of the cartridge is a flush line, approx 600mm

long and the flush line stop cock. Place the valve end of the flush line into the 10L bucket or container.

1.

Press [Start] [Stop] buttons to start and stop the filter

flush.

2.

Turn the flush line stop cock ON (See diagram).

3.

Press [Start] and allow at least 10 litres of water to flush

through the filter.

4.

The product details will be displayed in the screen.

5.

Once the filter flush is finished, Turn the stop cock OFF

then press [Stop] to end filter flush mode.

6.

Press [Next] for the Boiling Calibration screen.

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 23 of 28

Page 24

Commissioning

OPEN Position

ON

Stop cock

operation

CLOSED Position

OFF

6.3 - Boiling Calibration (Boiling models)

6.4 - Booster

•

Press the calibration button and the system will

commence the Boiling calibration procedure. This

will take approx 5-6 minutes.

•

Upon completion, a Booster reminder screen will

appear and allow you to return home by pressing

the [Home] button.

•

Check the Date and Time settings (See Note

below)

NOTE: failing to make the correct selection for the “Booster”, will affect product performance.

NOTE: Depending on your location you may need to re-set the internal clock. See section G of the user

guide to check and if necessary, reset the Date and Time for your time zone.

Page 24 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 25

Commissioning

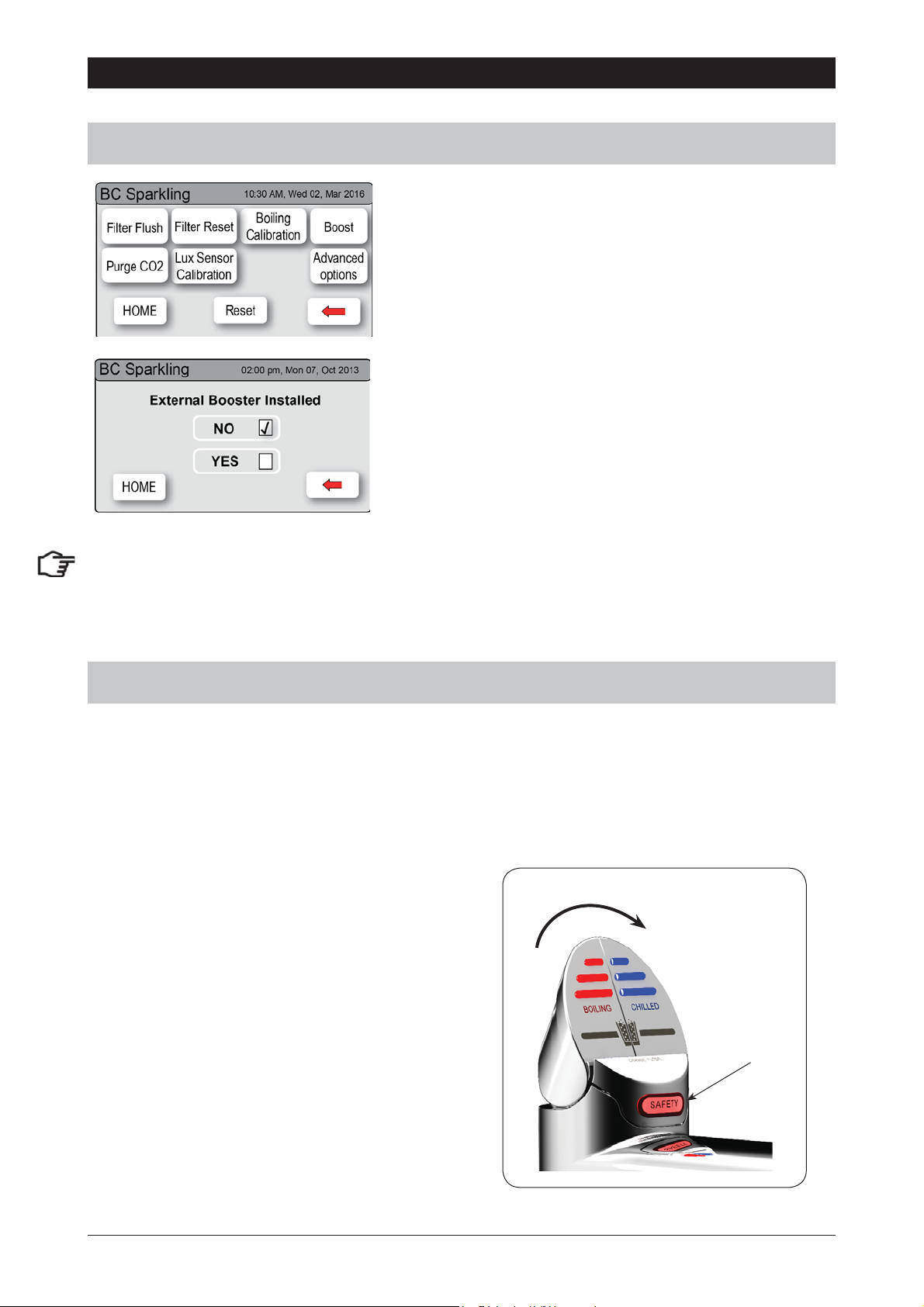

To enabled when a Booster unit is installed.

1. Press the [MENU] button for main menu.

2. Press the [Install] button.

3. Press the [Booster] button.

4. In the next screen, select YES to enable the Booster.

5. Water must be run through the Booster for a min of 30

seconds, before the heater will activate.

6. Dispense boiling water for 30secs and check the Booster outlet hose is warm when the boiling water tank is

replenishing.

NOTE: For any subsequent fi lter changes or any operational procedures, please refer to the HydroTap user

guide, located inside the fi lter housing access door.

6.5- Safety Sensor Calibration (Classic and All-In-One models)

Light intensity varies from site to site, therefore it is recommended that a re-calibration be performed at the

time of the installation. All direct natural sun light must be shaded from the HydroTap, during the calibration.

This can be achieved by closing any nearby curtains, blinds, or by shielding the HydroTap with a dark cloth.

1.

With the unit in Normal operating mode and with

the safety enabled

2.

Turn the power OFF

3.

Pull both tap levers to the forward position

4.

Turn ON the power

Pull both levers

forward

5.

The unit will calibrate the safety switch

6.

Return the levers to the neutral position.

7.

To check the calibration, dispense Boiling water,

Safety

sensor

in normal light conditions with the safety enabled.

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 25 of 28

Page 26

Trouble Shooting

System Fault

Possible Cause Solutions

Message

Power board fault Electrical disruption Check power supply and all fuses

Interface fault Internal fault Call Zip Service

Level board fault Internal fault Call Zip Service

Condenser screen blocked Blocked Air filter Remove blockage / Clean filter / check user guide

Water leak, Isolate mains Water leak Turn off mains water supply / Call for service

Compressor over-run Compressor too Hot Check ventilation

Water supply failed No water Check water supply is turned ON

Hot sensor Open Internal fault Call Zip Service

Hot sensor Closed Internal fault Call Zip Service

Cold sensor Open Internal fault Call Zip Service

Cold sensor Closed Internal fault Call Zip Service

Flood sensor Open Internal fault Call Zip Service

Condenser sensor Closed Internal fault Check Ventilation / Call Zip Service

Condenser sensor Open Internal fault Check ventilation / Call Zip service

Heater fuse / driver fault Internal fault Call Zip Service

Heater driver fault No hot water Call Zip Service

Compressor driver fault No chilled water Call Zip Service

Hot sensor degraded Internal fault Call Zip Service

Condenser overtemp. Blocked air filter Remove blockage / Clean filter / check user guide

A DC Pump is faulty Internal fault Call Zip Service

Steam is too cool Internal fault Call Zip Service

Steam sensor Open Internal fault Call Zip Service

Steam sensor Closed Internal fault Call Zip Service

Over Steamed Internal fault Call Zip Service

Hot tank overfilled Internal fault Call Zip Service

Comp Fuse/Driver Fault Internal fault Call Zip Service

Hot tank under filled Low water pressure Check water supply

Boil dry protection Safety activated Turn OFF / On power to reset

Flash Mem corrupted Internal fault Call Zip Service

Flow Sensor Fault Internal fault Call Zip Service

Call an electrician, a plumber, or Zip for a free call in Australia on 1800-638-633 for assistance, service, spare

parts or enquiries.

End of Life Disposal

In order to help preserve our environment we ask that you dispose of this product correctly. Please contact

your local city council for collection centre details.

Page 26 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Page 27

Notes

802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01 Page 27 of 28

Page 28

Contact Details

Head Office

Zip Heaters (Aust) Pty. Ltd.

ABN: 46 000 578 727

67 Allingham Street

Condell Park NSW 2200

Postal: Locked Bag 80

Bankstown 1885 Australia

Website: www.zipwater.com

Facsimile: (02) 9796 3858

Telephone: (02) 9796 3100

Free Call: 1 800 638 633

As Zip policy is one of continuous product improvement, changes to

specifications may be made without prior notice. Images in this booklet have

been modified and may not be true representations of the finished goods.

The standard cup referred to in this publication is 167 ml (6 fl oz).

The standard glass is 200 ml (7 fl oz).

The terms “Zip” and “HydroTap” are registered trade marks of Zip Heaters

(Aust) Pty Ltd.

Zip products described in this publication are manufactured under one or more

of the following patents: AU675601, AU637412, AU635979, GB0422305,

GB2065848, US4354049, US5103859, US5099825 and SA2006/08043. Other

patents are in force and patent applications are pending.

WMKA00099

AS 3498

Page 28 of 28 802005 - Sparkling HT-BCS Residential- Installation Instructions - 09.2016 - v3.01

Loading...

Loading...