Page 1

QUICK START GUIDE

CS and CSHA Commercial models

Note: This quick start guide must be read in conjunction with

the main installation and user manuals

• Before proceeding, read the installation and user instructions

• Check all the components are present and correct.

• Check that you have all the necessary tools

• Ensure the underbench can support the product weight when full of water,

(Check the specifications in the main book and allow an extra 4-5kg when full. )

Before installing ensure the following have been provided at

the installation site:

• Sufficient space in the cupboard to install all of the undersink units in accordance

with these Installation Instructions. Refer to technical specification for dimensions. If

required, make allowance for a booster heater. (Refer to the main book, for detailed

installation instructions).

• A potable water supply connection with isolating valve inside the cupboard within

reach of the flexible braided hose and positioned so that the connection point and the

stop cock will not be obstructed when all the undersink units are installed.

• For Zip HydroTap CS & CSHA models, a 220-240Vac, 10A GPO will be required.

NOTE: Check the cable lengths and outlet positions before proceeding.

• A potable cold water supply of between 250 - 700kPa

• Isolation valves for Hot and Cold water.

• For the CSHA model, both a hot and cold water supply will be required.

• The undersink appliances must be mounted in upright positions, with their bases

mounted horizontally, as shown in the diagrams.

IMPORTANT!

Do not proceed with the installation if these

requirements are not met.

Hole positioning: Position the tap such that it dispenses into

the sink bowl with ample clearance for a cup or tea pot. Alternatively,

the tap could be mounted away from the sink using a Zip Font,

available as an accessory.

The HydroTap Arc/Cube has a spout that may be fixed in one of 6 angular positions

(depending on the position of the rotary control) and fixed in one of two height positions.

The spout is fixed and does not swivel.

NOTE: The tube kit must be fitted after the HydroTap has been mounted on the benchtop

or sink. Refer to the tube kit assembly instructions, supplied with the tap kit.

NOTE: The plastic spring clip has two internal dimples that may be positioned in

the 6 upper or 6 lower, pre drilled holes in the spout (see diags. below )

NOTE: When determining which of the 6 holes are required for the new spout

height and orientation, check the new plastic clip position will clear the

undercut and that the wiring loom will not be pinched, when assembled.

NOTE: The clip will not fit correctly if one dimple engages before the other. Both

dimples must engage at the same time.

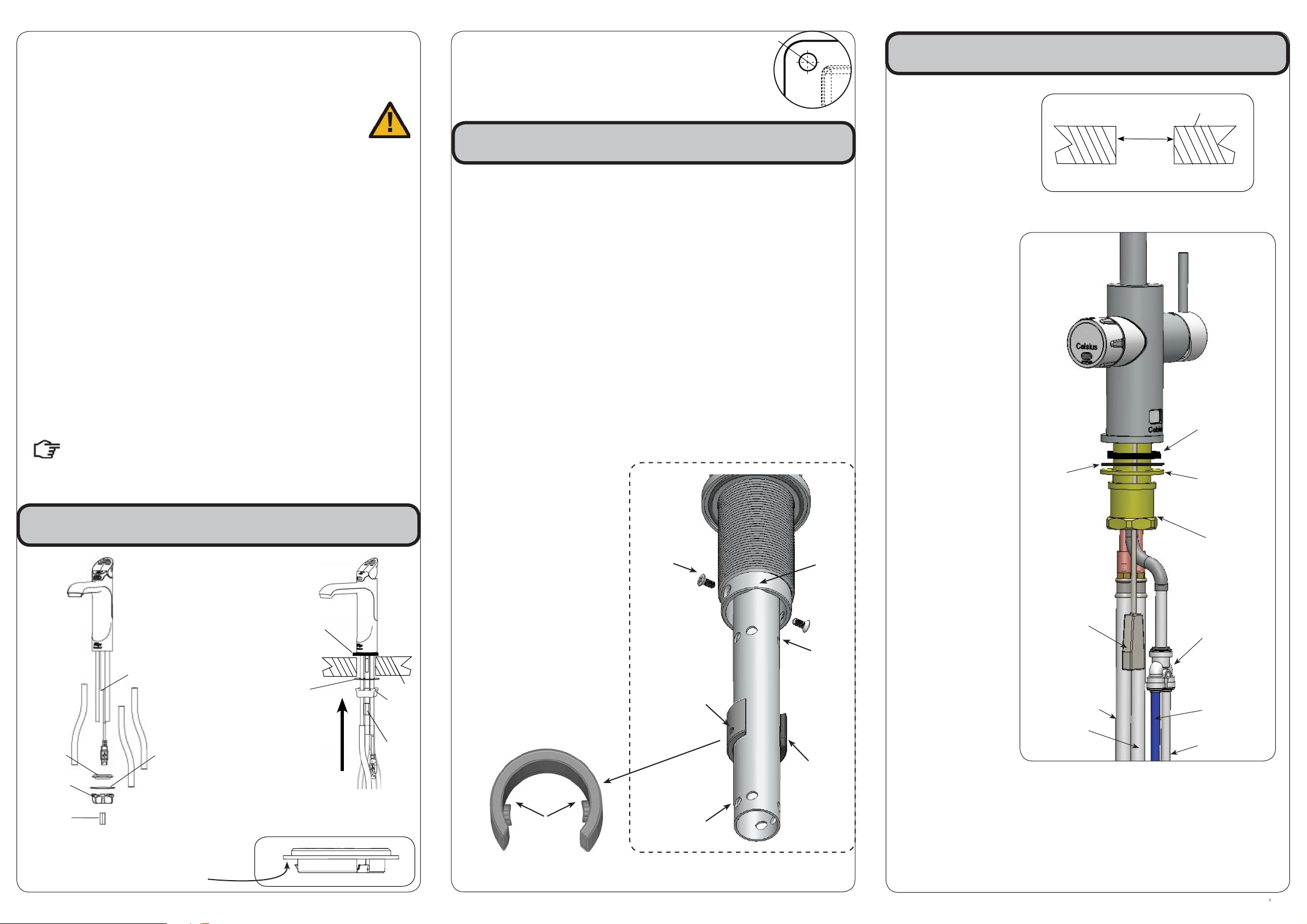

1 - HydroTap and Elite Tap

Black plastic

spacer

BLACK

PLASTIC

SPACER

SPIDER

CLAMP

NUT

ALL THREAD

ROD

STAINLESS

STEEL

WASHER

NOTE: feed each of the three tubes and

electrical cable evenly in between the legs of

the SPIDER CLAMP when installing.

Stainless

washer

Fit the

STAINLESS STEEL

WASHER,

SPIDER CLAMP,

AND 6mm NUT.

SPIDER

CLAMP

6mm

NUT

35mm dia hole

Sink

2 - HydroTap Arc/Cube

1.

Remove the 2 x spout locating screws and lower the spout to expose the plastic

spring clip

2.

To reposition the spout, gently spread the plastic spring clip to release the dimples

from the spout holes. When released, slide the clip on the spout so that it ends up

between the two rows of holes.

3.

Rotate the plastic clip on the spout to orient the dimples, so they are in line with the

newly selected holes.

4.

Slide the plastic clip up/down to engage with the selected holes, making sure the

two dimples engage simultaneously with the two selected holes.

5.

With the clip fitted to the newly

selected holes, carefully raise

the spout (ensure the wiring

loom is a neat fit in the undercut

and is located between the open

ends of the clip) until the clip

locating holes are in line with

the spout locating screws.

6.

Replace the 2 x locating screws.

7.

If mounting on an uneven

surface, apply a light smearing

of silicon sealant on the O ring

to ensure a watertight fit.

8.

Pass the assembly through the

35mm hole and position the tap

so it discharges into the sink.

9.

Fit the lower rubber seal to the

threaded extension.

10.

Secure the tap in position with

the metal washer and nut.

11.

Fit the tube kit, as supplied

Plastic spring clip

Dimples

Spout locating

screws (2)

Clip locating

holes (2)

Upper locating

positions

Undercut

for loom

Lower locating

positions

Plastic spring

clip

3 - Celsius Arc/Cube

Pass all the

•

hoses, tubes and

USB lead through

the 35mm hole.

• Ensure the

black rubber

seal is correctly

positioned to give

a water tight seal

• Secure the rubber

& brass washers

and large nut

from inside the

cupboard space,

as shown.

• Connect the

Hot and Cold

braided hoses

to the external

mains and hot

water supply

respectively.

• The blue and

white tubes are

connected to

the top of the

undersink unit.

(See step 6)

BENCH TOP

Ø35mm

Cut a 35mm hole in the bench / sink top.

BLACK RUBBER

BRASS

RUBBER

Washer

USB

PLUG

HOT & COLD

BRAIDED

HOSES

WASHER

BRASS

Y-PIECE

CHILLED

TUBE

SPARKLING

TUBE

Seal

NUT

JG

Apply a light smearing of silicon sealant on

the underside of the upper spacer to ensure a

watertight fi t.

804053 - CS & CSHA. Residential Quick Start Guide - Sept 2016 - v3.01

Page 2

4 - 1.0 KG CO2 Cyl.

This cylinder must be installed in an open plan area or in an enclosed room, with a

volume no less than 20 m

a complete list of warnings.

1.

Secure the gas bottle supplied to a suitable wall, within 1 metre of the unit,

in an upright position. This is done by screwing the metal plate holding the

hook-and-loop strap to a cupboard wall, 200mm above the floor or base of the

cupboard. Make sure the gas bottle can stand before securing to the wall. Due

to regulatory requirements the gas bottle must be stored securely and in an

upright position.

2.

Make sure the regulator knob is turned fully anti-clockwise to the end-stop

before fitting. Remove the gas bottle from the wall to fit the regulator. Be aware

that some CO

avoid excess gas leakage, promptly screw the regulator on to the bottle.

3.

Connect the braided gas hose to the top of the undersink unit via the John

Guest fitting marked ‘Gas IN’ Then connect the threaded end to the regulator,

taking care not to lose the plastic olive located inside the threaded nut. When

commissioning, turn the gas ON by rotating the regulator knob clockwise and

adjust to 2.7-3.0 bar (270-300kPa). The arrow should sit in the green section of

the regulator gauge; it should not fall in the red or yellow sections.

4.

When commissioning, use soapy water to perform a leak test. Apply the soapy

water to the gas connections using a sponge. If any bubbles appear and grow,

there is a gas leak at the connection. Clean away the soapy residue and tighten

or refit the leaking connection. Make sure the regulator is turned off when

tightening or refitting the leaking connection.

5.

Refit the gas bottle to the Hook-and-loop strap and secure the bottle in an

upright position.

NOTE:

and in no cases should the normal operating pressure of 2.7-3.0 bar (270-300kPa)

be exceeded.

Care must be taken when working with high pressure carbon dioxide,

may be discharged from the connection during assembly. To

2

3

. See details on the gas bottle and in the MSDS sheet for

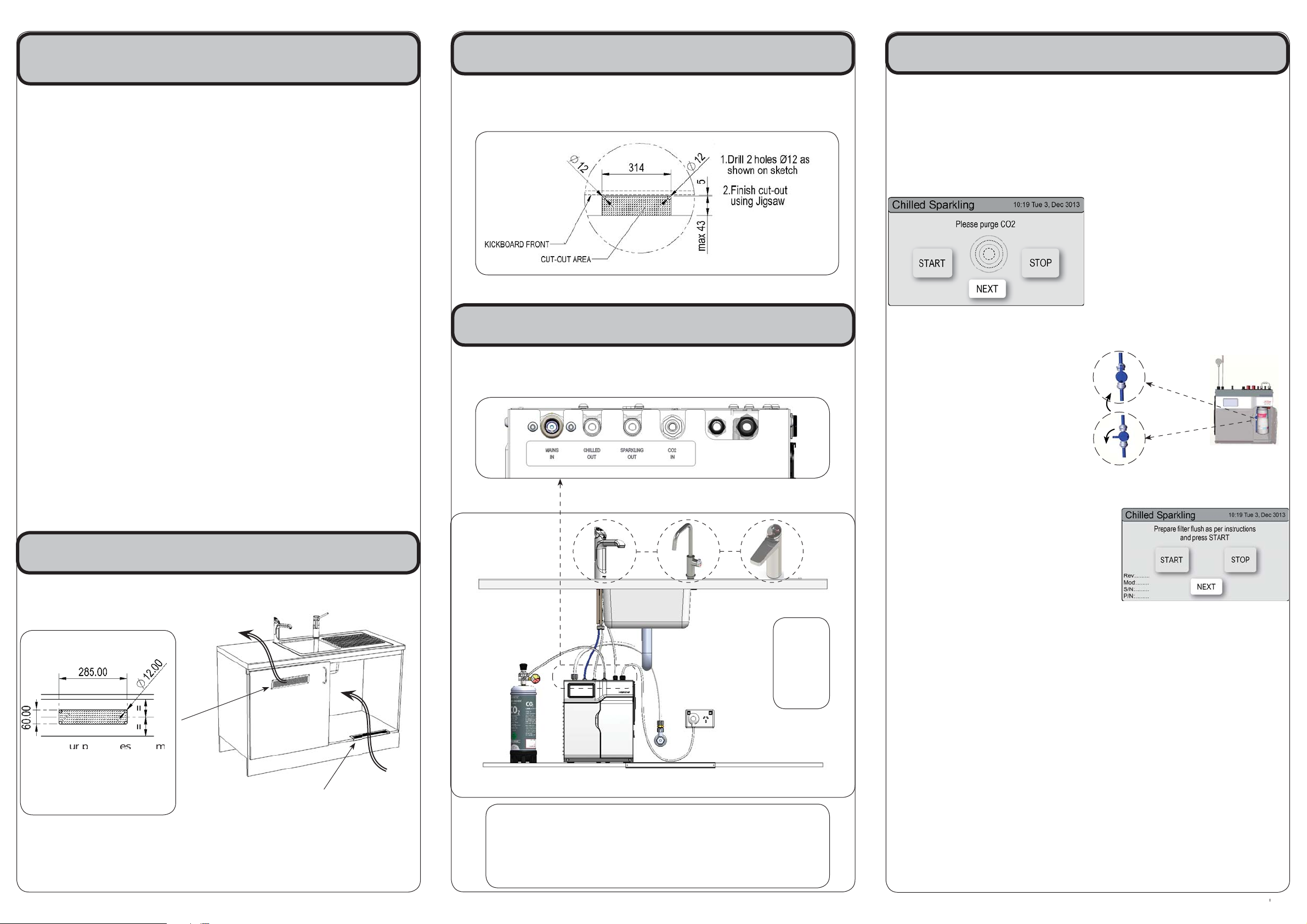

5 - Ventilation

5 - Ventilation

Air inlet vent cutout details

6 - HydroTap Unit

Note: Remove all caps from the top of the undersink unit and Install the mains water

braided hoses to the undersink unit before locating the unit in place..

CS Models

7 - Commissioning

Commissioning the HydroTap

Turn on the water and gas to check for any leaks before turning on the power.

The system will promp you to select a language before continuing with the filter flush

procedure

CO2 Purge:

1.

Press the [START] button to

commence the purging process.

2.

Purge for 5 seconds and ensure all

water has stopped flowing through

Filter Flush:

Have a 10L bucket or similar container (not

supplied) at the ready to hold a quantity of

water that will be ejected while the Filter

Flush Mode is in operation. Open the filter

access door on the front of the HydroTap

and the filter cartridge will be exposed.

Located to the rear RHS of the cartridge is a

flush line, approx 600mm long and the flush

line stop cock. Place the valve end of the

flush line into the 10L bucket or container.

1.

Turn the stop cock ON

2.

Press [Start] button to start filter flush.

3.

Allow at least 10 litres of water to flush through

the filter.

4.

Once the filter flush is finished, Turn the stop

cock OFF then press [Stop] to end filter flush

mode.

the tap. (You will hear the CO

escaping from the tap).

3.

Press the [Stop] button.

4.

Press [Next] for the filter flush screen

OPEN Position

ON

Stop cock

operation

OFF

CLOSED Position

gas

2

Warm air

OUT

Cutout details

1.

Drill four pilot holes 12mm

dia.

2.

Finish the cutout using

a jig saw and keyhole or

Wall Board saw

Air inlet vent position

Note: For alternative options, refer to section 2 of the main instructions

804053 - CS & CSHA. Residential Quick Start Guide - Sept 2016 - v3.01

Note:

Insulate the

Blue and

the White

tubes after

Trimming to

length

Cool air IN

Note:

- Mains hose length is 750mm

- Plug and Cord length is 1800mm

Position the under sink unit close to the outlet tap, within reach of the

hose and cord lengths supplied

Loading...

Loading...