Zip HT1792Z3, HT2764, HT2764Z7, HT2784Z1, HT2784Z5 Quick Guide

...

QUICK START GUIDE

Note: This quick start guide must be read in conjunction with the main installation and user instructions

•Before proceeding, read the installation and user instructions

•Check all the components are present and correct.

•Check that you have all the necessary tools

•Ensure the underbench can support the product weight when full of water, (Check the specifications in the main book and allow an extra 2-4kg when full. )

Before installing ensure the following have been provided at the installation site:

•Sufficient space in the cupboard to install all of the undersink units in accordance with these Installation Instructions. Refer to technical specification for dimensions. If required, make allowance for a booster heater. (Refer to the main book, for detailed installation instructions).

•A potable water supply connection with isolating valve inside the cupboard within reach of the flexible braided hose and positioned so that the connection point and the stop cock will not be obstructed when all the undersink units are installed.

•For Zip BC & BCHA-A HydroTap models, a 220-240Vac, 10A GPO will be required. For Zip BCHA & BCHA-AV HydroTap models, two 220-240Vac, 10A GPOs will be required. (One GPO is for the Zip HydroTap and the other for the Booster heater).

NOTE: Check the cable lengths and outlet positions before proceeding.

•A potable cold water supply with a minimum working pressure of 172kPa and a maximum working pressure of 700kPa connected via an isolation valve.

•For the mains pressure BCHA-A model, both a hot and cold water supply will be required.

•The undersink appliances must be mounted in upright positions as shown in the diagrams.

IMPORTANT! Do not proceed with the installation if these requirements are not met.

Parts Supplied |

Description |

Parts Supplied |

Description |

|

|

|

Vent kit |

|

1 off |

|

1 x Kickboard |

|

Hydrotap Tap |

|

louvre |

|

and hoses |

|

2 x Door vent |

|

|

|

louvre |

|

|

|

1 x front vent grill |

|

|

|

1 off |

|

1 off |

|

HydroTap |

|

Undersink Unit |

|

Booster heater |

|

with air and water- |

|

and hoses |

|

filter |

|

(Supplied with |

|

|

|

BCHAV model) |

1 x Restrictaflow valve and Tee piece for Mixer Taps and select models

1 off Mains water connection hose

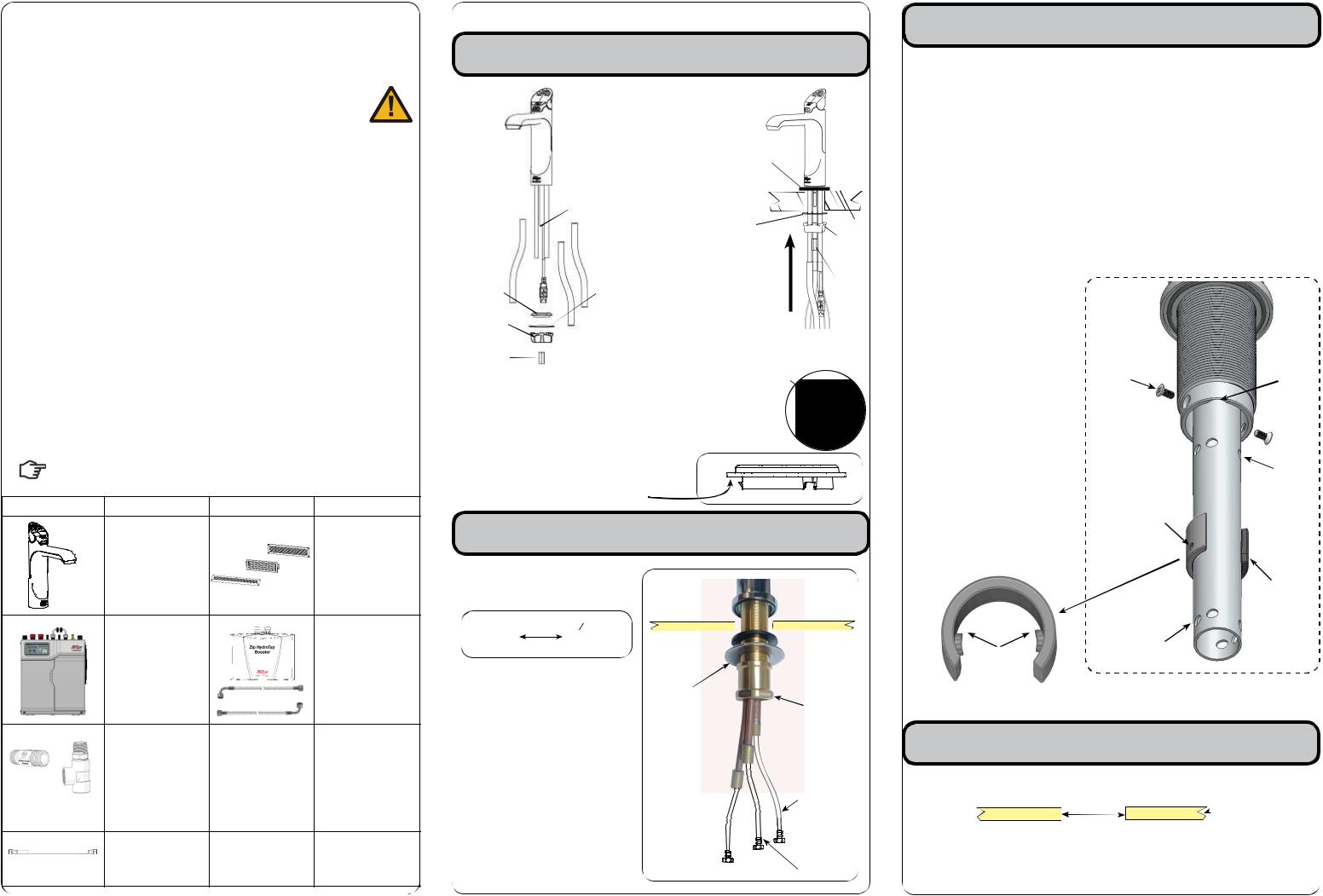

STEP 1- Prepare and fit the Taps

|

|

Black plastic |

|

|

|

|

spacer |

|

|

|

ALL THREAD |

Stainless |

|

|

|

ROD |

|

||

|

washer |

|

||

|

|

|

||

|

|

|

SPIDER |

|

|

STAINLESS |

Fit the |

CLAMP |

|

BLACK |

STAINLESS STEEL |

|

||

STEEL |

|

|||

PLASTIC |

WASHER, |

6mm |

||

WASHER |

||||

SPACER |

SPIDER CLAMP, |

|||

NUT |

||||

|

||||

|

|

AND 6mm NUT. |

||

|

|

|

||

SPIDER |

|

|

|

|

CLAMP |

|

NOTE: feed each of the three tubes and |

||

|

|

|||

NUT |

|

electrical cable evenly in between the legs of |

||

|

the SPIDER CLAMP when installing. |

|||

|

|

|||

|

|

35mm dia hole |

|

|

Hole positioning: Position the tap such that it dispenses into |

|

|||

the sink bowl with ample clearance for a cup or tea pot. Alternatively, |

|

|||

the tap could be mounted away from the sink using a Zip Font, |

Sink |

|||

available as an accessory. |

|

|||

|

|

|||

Apply a light smearing of silicon sealant |

|

|

||

on the underside of the upper spacer to |

|

|

||

ensure a watertight fi t. |

|

|

||

For HydroTap & Mixer taps

cut a 35mm hole in the bench or sink top.

BENCH TOP

Ø35mm

Ø35mm

•Fit the O-ring into the recess on the underside of the Mixer tap. (Note: If mounting on an uneven surface, a light smear of silicone on the seal ring will ensure a water tight seal)

•Affix the three hoses to the tap, noting their colour coding.

•Pass all hoses through the 35mm hole and position the tap so that it discharges into the sink.

•Fit the lower rubber seal to the threaded extension.

•Secure the tap in position with the metal washer and Nut.

O-RING

LOWER

LOWER

RUBBER

WASHER

WASHER

NUT

Red band

Mixer Out

White Hose

External

Mains

Blue band

Mixer IN

Arc/Cube (If required)

1.Remove the 2 x spout locating screws and lower the spout to expose the plastic spring clip

NOTE: The plastic spring clip has two internal dimples that may be positioned in the 6 upper or 6 lower, pre drilled holes in the spout (see diags. below )

2.To reposition the spout, gently spread the plastic spring clip to release the dimples from the spout holes. When released, slide the clip on the spout so that it ends up between the two rows of holes.

3.Rotate the plastic clip on the spout to orient the dimples, so they are in line with the newly selected holes.

NOTE: When determining which of the 6 holes are required for the new spout height and orientation, check the new plastic clip position will clear the undercut and that the wiring loom will not be pinched, when assembled.

4.Slide the plastic clip up/down to engage with the selected holes, making sure the two dimples engage simultaneously with the two selected holes.

NOTE: The clip will not fit correctly if one dimple engages before the other. Both dimples must engage at the same time.

5.With the clip fitted to the newly selected holes, carefully raise the spout (ensure the wiring loom is a neat fit in the undercut and is located between the open ends of the clip) until the clip locating holes are in line with the spout locating screws.

6.Replace the 2 x locating screws.

7.If mounting on a rough or uneven surface, apply a light smearing of silicon sealant on the O ring to ensure a watertight fit.

8.Pass the assembly through the 35mm hole and position the tap so it discharges into the sink.

9.Fit the lower rubber seal to the threaded extension.

10.Secure the tap in position with the metal washer and nut.

Plastic spring clip

Spout locating screws (2)

Clip locating holes (2)

Upper locating positions

Dimples

Undercut for loom

Lower locating positions

Plastic spring clip

All-In-One Tap (If required)

For All-In-One taps cut a 50mm hole in the bench or sink top.

Bench top

Bench top

50mm

Note: make sure the tap location will allow the nozzle to drain into the sink.

802255 - Zip BC, BCHA, AIO, Quick Start Guide - June 2015 - V2.00

Loading...

Loading...