Page 1

®

Zip ChillTap Sparkling

Residential - Filtered chilled still and chilled sparkling water

Affix Model Number Label Here

804721

804721 09.16 v1.0

Page 2

Contents

Pre-Installation Notes . . . . . . . . . . . . . . . . . . . . . . . . . 3

Read These Warnings First . . . . . . . . . . . . . . . . . . . . 4

Product Specifications. . . . . . . . . . . . . . . . . . . . . . . . . 4

Section 1 - Tap Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 - Installing the Tap . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 2 - Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 - Ventilation (all models) . . . . . . . . . . . . . . . . . . . . 6

2.2 - Extra ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Section 3 - CO2 Cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 - Secure the cylinder mounting . . . . . . . . . . . . . . . 9

3.2 - Connect the regulator . . . . . . . . . . . . . . . . . . . . . 9

3.3 - Connect the gas hose . . . . . . . . . . . . . . . . . . . . . 9

3.4 - Test for gas leaks . . . . . . . . . . . . . . . . . . . . . . . . 9

Section 4 - Undersink unit installation . . . . . . . . . . . . . . . . . . . 10

John Guest (J.G.) fittings . . . . . . . . . . . . . . . . . . 10

4.1 - Chiller Installation . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 - Hose and Tube connections . . . . . . . . . . . . . . . . 11

4.3 - Mains Connection . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 - Chilled Still Connection . . . . . . . . . . . . . . . . . . . . 12

4.5 - Chilled Sparkling /

Carbonation Valve Connection . . . . . . . . . . . . . . . . . . 12

Section 5 - Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.1 - Test and Commission . . . . . . . . . . . . . . . . . . . . . 14

5.2 - Adjusting the flow rate. . . . . . . . . . . . . . . . . . . . . 15

Section 6 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 - Water Filter Replacement . . . . . . . . . . . . . . . . . . 16

6.2 - Air Filter Change . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 - Gas Bottle Replacement . . . . . . . . . . . . . . . . . . . 17

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

End of Life Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Contact Details. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 2 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 3

Pre-Installation Notes

A. Read the instructions.

B. Note: All fittings are supplied with the appliance kit except an isolation valve.

C. Check the water quality to determine if extra filtration will be required.

D. Check the appliance rating plate and ensure correct power is available for the

appliance.

E. Check the underbench cupboard supporting the appliance is adequate for

the total weight of the appliance.

F. Ensure a potable water supply connection with isolating valve inside the cupboard

is within reach of the braided hoses and positioned so that the connection point

and the stop cock will not be obstructed when the undersink units are installed.

Note:

All plumbing must comply with AS/NZS 3500.4.1 & AS/NZS 3500.4.2

All electrical must comply with AS/NZS 3000 wiring rules

All refrigeration must comply with AS/NZS 3350.2.24

Precautions

The plumbing installation must be done in accordance with local Water Authority

regulations and these Installation Instructions.

As the installer, it is your responsibility to supply (if necessary) and install all valves

as required by local regulations and relevant standards.

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 3 of 20

Page 4

Read These Warnings First

1. Please read all Precautions, Installation Requirements, Installation Instructions before installing any Zip ChillTap.

2. Never attempt to install any Zip ChillTap without reading all of the applicable instructions.

3. All electrical connections must comply with current wiring rules.

4. This appliance is not designed for use by young children or infirm people without supervision.

5. Young children should be prevented from having access to ensure they are not able to use or play with the chiller.

6. This appliance must be earthed.

7. If the power supply cord is damaged it must be replaced by a Zip Service Provider or a qualified electrician.

8. The power cord and general power outlet must be in a safe and accessible position after installation.

9. Do not remove the cover of the appliance under any circumstances without first isolating the appliance from the power

supply.

10. This unit is designed for indoor use and must not be installed outdoors or exposed to the elements of nature.

11. This unit must not be positioned in an area that may be cleaned by a water jet.

12. This unit must not be cleaned by a water jet.

13. This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilitie s,

or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety. For products sold in Europe, this appliance can be used by children

aged from 8 years and above and persons with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children should be supervised to ensure that they do not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

14. This appliance is intended to be used in household and similar applications such as

Staff kitchen areas in shops, offices and other working environments;

Farm houses and by clients in hotels, motels and other residential type environments;

Bed and breakfast type environments;

Catering and similar non-retail applications.

15. The appliance has to be placed in a upright position.

Product Specifications

Model

CS 0.3 134A (100g) 335 442 280 25 26

Power Rating

Refrigerant

(kW)

Height mmDepth mm

Installation Requirements

• Power supply 220-240V AC 50Hz for connection via a 10amp G.P.O.

• Operating temperatures 5ºC - 35ºC.

• External water pressure 250kPa - 700kPa (2.5 bar -7 bar)

• Internal Pressure Limiting Valve: 500kPa

(including fittings)

Frost Protection

If this appliance is located where the ambient air

temperature could fall below

in use, do not turn off the appliiance electrically. This safeguard does not offer the same protection to the connecting

pipework and fittings.

Width mmWeight empty

kg’s

5ºC when the heater is not

Weight full

kg’s

Note: For best results we recommend a minimum static mains water pressure of 250kPa (2.5 bar).

Page 4 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 5

Section 1

Tap Installation

Special Tools

In addition to common tools, the following will be required:

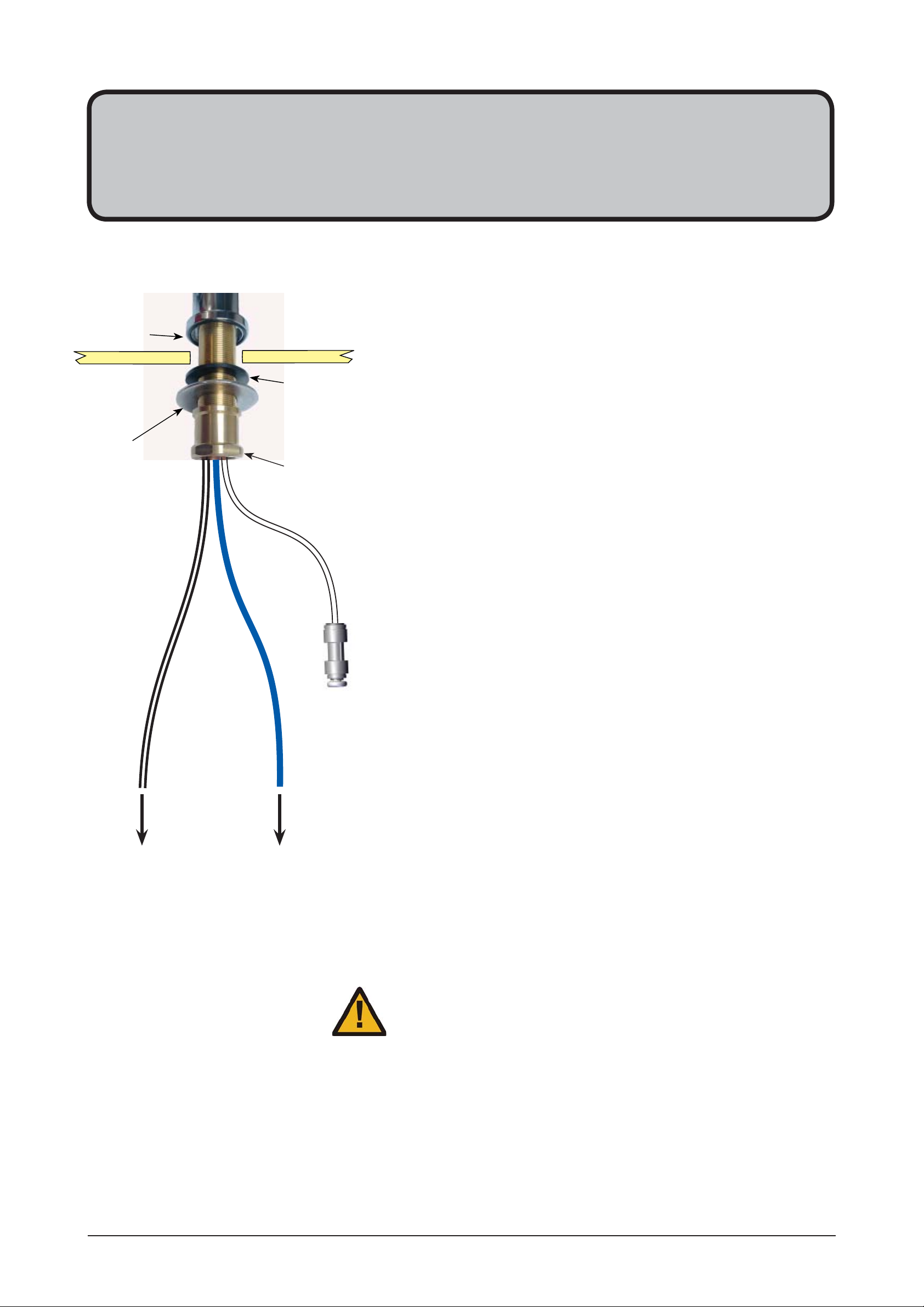

O-RING

WASHER

LOWER

RUBBER

WASHER

NUT

• 25mm diameter sheet metal hole punch for sink tops. (Not supplied)

• 25mm diameter hole saw for timber bench tops. (Not supplied)

Installing the Tap

Position and install the carafe filler at the back of the sink or on the Font,

where there is a minimum 52mm wide flat area within the draining area

of the sink.

Ensure the distance between the tap and the command centre does not

exceed the length of the supplied tubing.

NOTE: Hoses are maximum 1000mm in length.

Make sure the selected position allows the carafe filler spout to overhang

the sink bowl.

WHITE tube

to

Sparkling Outlet

BLUE tube

to

Still Outlet

CLEAR tube

blocked with

JG fi tting

Make sure the selected position allows the carafe filler spout to overhang

the sink bowl.

Use a 25mm sheet metal punch to create a neat hole without burrs.

Remove the large nut with the stainless steel and rubber washers from

the base of the carafe filler, leaving the rubber-sealing ring (O-ring) in

place.

Fit the carafe filler and seal to the sink, oriented so both the operating

levers are easily accessible.

Slide first, the rubber washer and then the brass washer, followed by the

nut, over the tubes from under the sink, and tighten the nut to secure the

carafe filler firmly into place.

NOTE: The Clear tube must be trimmed to length and blocked with

the JG fitting supplied.

Warning - Do not reuse the old hose-sets. The unit

shall be installed with the new hose-sets supplied.

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 5 of 20

Page 6

Section 2

Ventilation

•

When installing air flow ducts, the following tools will be required:

•

Jigsaw and 12mm Drill

•

Keyhole or Wall Board saw.

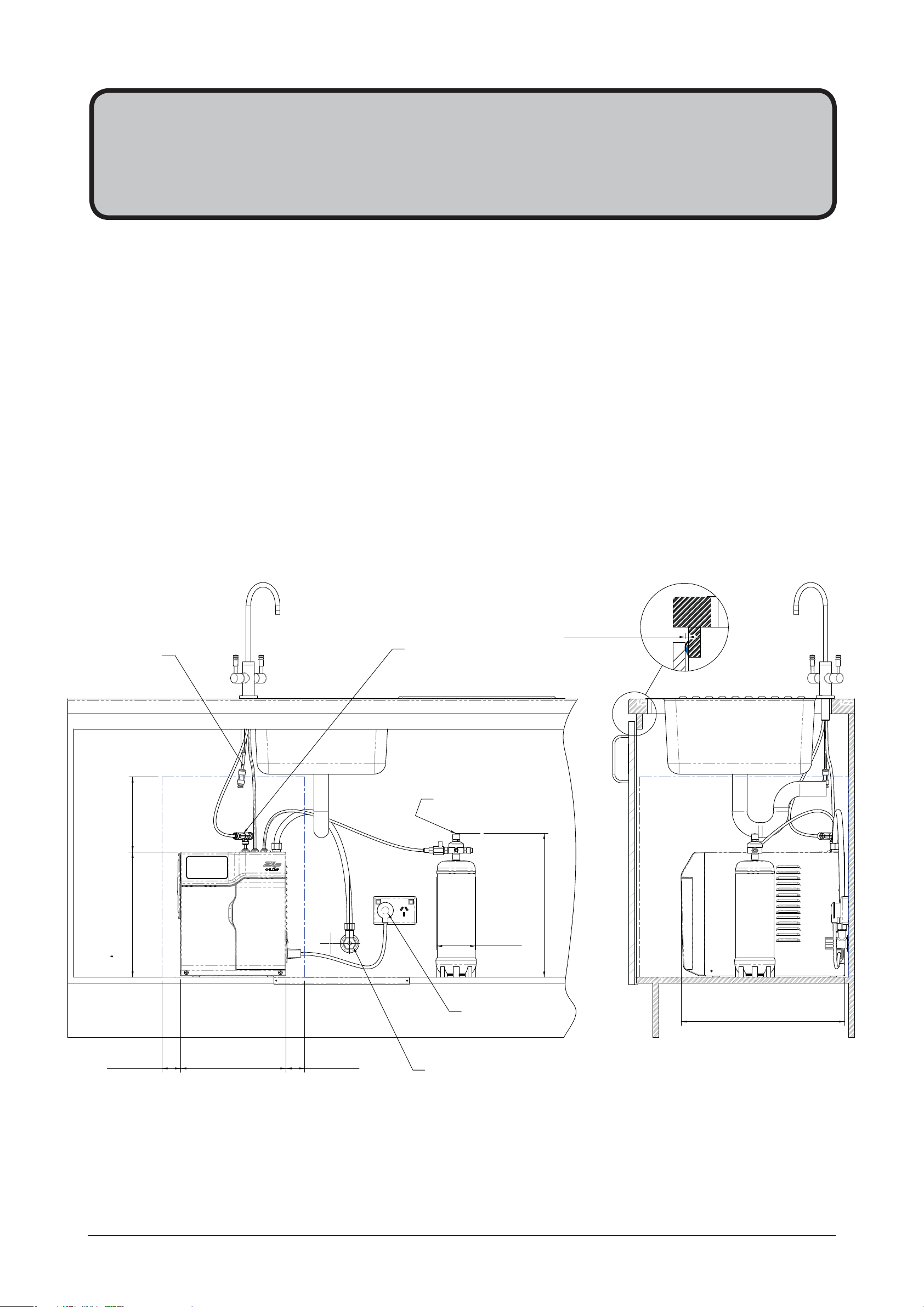

2.1 - Ventilation

Proper air circulation must be provided for all Chilled models. The system will operate correctly only if the recommended air

gaps are achieved during Installation. The minimum requirement is for a 50mm air gap either side and 300mm above of the

undersink unit.

It is important that the 4mm door buffers (For all installations ) are fitted to the inside edge of the cupboard door to allow

sufficient air circulation inside the cupboard. (See the diagram below).

4

min,

Bufer Pad

Clear Gap

Clearance

Envelope

Vent pipe

(Blocked o)

min.

Clearance

Envelope

Carbonation

adjustable

ow valve

2

CO

cylinder with

xed 300kPa reguator

50

200

333

min.

280

Inlet Vent

50

min.

Ø 105

240 - 230V,

50Hz GPO

Mains Cold water

isolation valve

382

435

Page 6 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 7

Ventilation

g

p

2.2

- The following instructions are critical if there is insufficient cupboard air

circulation.

If the air flow, using the silicon door buffers, is insufficient, it will be necessary to fit a standard ChillTap vent kit, which ensures heat

dissipation through natural convection via installed vents.

For high use applications, where the cupboard space temperature is near 35°C, or higher, the inlet vent (See Item B below) and

silicon buffers, need to be fitted.

If the airflow is still insufficient to maintain normal operating temperatures then the inlet vent and door outlet vent (See item D

below) will need to be fitted.

Note: The vent kit has to be installed in a way that allows air to be drawn in from the bottom of the cupboard and expelled

through the top of the cupboard. Therefore placement of the outlet vent should be towards the top of the door or on the side of the

cupboard.

Door outlet vent

Airflow through the cupboard

Warm air

OUT

D

Cutout details

1. Drill four pilot holes 12mm

dia.

2. Finish the cutout using a

jig saw and keyhole or Wall

Board saw

Air inlet vent position

Cool air IN

B

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 7 of 20

Page 8

Ventilation

Typical Cut out procedure for

1. Mark out and cut the air inlet and door outlet holes as shown

2. Ensure the air inlet vent and air outlet vent are positioned at opposite ends of the same

cupboard space.

3. Fit the inlet vent, as shown and secure with 5 screws

4. If required, fit the outlet vent, as shown in the hottest part (top) of the cupboard and

secure with 4 screws

B

D

Cutout details

B

Air inlet vent

Page 8 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 9

Section 3

CO

2

WARNING:

This cylinder must be installed in an open plan area or in an enclosed room,

with a volume no less than 20m3. If more than 1 gas cylinder containing CO2 is

present within the same location, the recommended ventilated area should be in

proportion to the number of gas cylinders stored in that location.

A ventilated area is a non-enclosed area which could include the kitchen, living

room etc.

See gas bottle and MSDS sheet for a complete list of warnings.

(See: www.zipindustries.com)

Cylinder

Turn the knob fully clockwise

before fitting the regulator

CLOSED

Rotate the knob fully anticlockwise to turn the gas on.

3.1

Secure the gas bottle supplied to a suitable wall, within 1 metre of the unit,

in an upright position. This is done by screwing the metal plate holding the

hook-and-loop strap to a cupboard wall, 200mm above the floor or base of the

cupboard. Make sure the gas bottle can stand before securing to the wall.

Due to regulatory requirements the gas bottle must be stored

securely and in an upright position.

3.2

Make sure the regulator knob is turned fully clockwise to the end-stop before

fitting see fig.1. Fit the regulator to the gas bottle. Be aware that some CO2 may

be discharged from the connection to the regulator as the bottle and the regulator

are be assembled together. Any CO2 released will be cold. Continue to screw on

the regulator to stop this leakage.

Secure the cylinder mounting:

Connect the regulator:

OPEN

Note: The regulator comes pre-set fixed pressure at 300kPa.

3.3

Connect the braided gas hose to the top of the undersink unit via the John Guest

fitting marked ‘CO2 IN’ Then connect the threaded end to the regulator, taking

care not to lose the plastic olive located inside the threaded nut. To turn the gas

ON, rotate the regulator knob anti-clockwise to the end-stop.

Connect the gas hose:

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 9 of 20

Page 10

CO2 Cylinder

3.4

Using soapy water perform a leak test. Turn the gas OFF. Apply the soapy water

to the gas connections using a sponge or brush. Cover all of the gas joints with a

liberal amount of suds.

Turn ON the gas. Inspect the joint for leaks. If any bubbles appear and grow, there

is a gas leak at the connection. The joint will need to be resealed and tested again.

Clean away the soapy residue and tighten or refit the leaking connection. Make sure

the regulator is turned off when tightening or refitting the leaking connection.

Refit the gas bottle to the hook-and-loop strap and secure the bottle in an upright

position.

NOTE:

Test for gas leaks:

Care must be taken when working with high pressure carbon dioxide.

Test for leaks at these two poitns

IMPORTANT:

After replacing a bottle or after making a gas connection, check for gas leaks between regulator and

bottle, and between regulator and braided hose.

Page 10 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 11

Undersink Unit Installation

If caps are removed to allow lifting

handles to be installed during

installation of the unit, ensure they

are refi tted when unit is in position.

Section 4

General instructions for

John Guest connections

On / Off Switch

John Guest (JG) fittings

NOTE: Ensure all John Guest

tube ends are cut clean and

square.

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 11 of 20

Page 12

Undersink Unit Installation

Note: To avoid water leaks,

take care when bending rigid

plastic tubing. The tube must not

be kinked or crushed around a

bend, as the tube may containing

water under pressure. Therefore

be careful not to nick, scratch

or damage the tube during

installation.

4.1 - Chiller Installation

Place the chiller unit into the cupboard with the proposed outlet tap position as close

as possible, to minimise the length of tubing exposed between the chiller unit and the

outlet tap. (The tubing length is limited to 1000mm)

Allow at least 50mm around the chiller unit to permit free airflow. Both the top and

the front of the chiller must remain accessible for servicing purposes.

4.2 - Hose and Tube connections:

NOTE: You must separately supply and install an isolation valve (not supplied) in

the water supply line before the connection to the product.

Connect the braided hose to the isolation valve. For best results we recommend a

minimum static pressure of 250kPa (2.5 bar).

water fl ow

4.3 Mains Connection (with chiller inlet):

Connect the braided hose from the isolation valve to the top of the undersink unit,

marked MAINS IN.

4.4 - Chilled Still Connection:

Remove the plug fitted into the connection marked “Still Outlet“ by first depressing

the collet and simultaneously pulling out the plug. Measure and trim the 1/4” blue

tube from the carafe tap to the JG fitting marked “Still Outlet” on the top rear of the

chiller unit. Before making connection, insulate the tube with the loose length of the

foam insulation, trim the insulation to the correct length, which is about 5-10mm

shorter than blue tube. Push the blue tube fully into the John Guest fitting marked

“Still Outlet”. Make sure all connections to John Guest fittings are pushed in past the

“O”ring to full depth.

FIG.1

Carbonation

Valve

4.5 - Chilled Sparkling / Carbonation Valve

Connection:

1. Remove the plug fitted into the connection marked “Sparkling Outlet“ by first

depressing the collet and simultaneously pulling out the plug. Fit the carbonation

valve to the sparkling outlet connection on top of the unit as shown in FIG.1.

2. Measure and trim the 1/4” white tube from the carafe tap.

3. Before making connection, insulate the tube with the loose length of the foam

insulation, trim the insulation to the correct length, which is about 5-10mm shorter

than white tube.

Page 12 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 13

Undersink Unit Installation

4. Connect the white tube to the carbonation valve as shown in FIG.2. Push the white tube fully into the in carbonation valve. Make

sure all connections are pushed in past the “O”ring to full depth.

5. Arranging tubes in the most direct route between tap outlet and unit.

The tap connection is now complete.

IMPORTANT: The Clear tube is non functional. However, it must be trimmed to length and blocked with the JG fitting supplied,

otherwise water will leak from it whenever the tap is operated.

Note: After dispensing sparkling water, a small amount will remain in the carafe filler. If the next drink is to be still water and you

do not wish any trace of sparkling water, the still water should be running for approximately 1 second before filling your glass or

bottle. The same is applicable if still water is dispensed prior to dispensing sparkling water.

Chilled Sparkling /

Carbonation Valve Connection

WHITE tube

Carbonation Valve

CLEAR tube

blocked with

JG fi tting

to

BLUE tube

to

Still Outlet

FIG.2

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 13 of 20

Page 14

Sparkling filtered water

(white)

Commissioning

Chilled filtered water

(blue)

Section 5

5.1 - Test and Commission:

Do NOT turn power or water on to the unit. The carbonator must be purged

first with the CO2 gas. Failure to do so will result in poor tasting water. Turn the

sparkling water lever on (white ringed lever) The CO2 will start to run out of the

tap. Gas will purge or escape from the tap at this point. Let it run for approximately

5 seconds to completely fill the tank. Close the sparkling lever by rotating back to

upright.

Note: Should no CO2 gas be expelled, check if regulator valve is open.

FIG.1

Turn on the still water lever (blue ringed lever) then turn on the water supply to the

unit. First air, then water will flow from the tap. Allow the water to continue to flow

for about 7.5 litres, which is required to activate the filter. Once this has been done

turn off the still water lever.

Connect the unit to the mains power supply and turn ON. Confirm the ON/OFF

switch at the side of the undersink unit is on.

The compressor and fan will start, and the water pump will operate for

approximately 20 seconds to fill the carbonator vessel.

After approximately 5 minutes, the compressor and fan will stop as the chiller has

reached its normal operating temperature.

To achieve an optimal level of carbonation, it is beneficial to purge the carbonation

vessel again by isolating the water and electrical supply, and opening the sparkling

lever on the tap until gas is expelled for approximately 5 seconds. Close the tap

and turn on water and power. Wait 20 seconds and the sparkling water should be

ready for use.

ROTATE

FIG.2

Important: Optimal carbonation levels occur at low water temperatures.

Excessive flow rates of carbonated water will result in poor drink quality and

malfunction of system. It is recommended that the flow rate for carbonated water

should be approximately 1.2-1.6 litres/minute.

The lever on the right (Blue rings) is used for chilled still filtered water and the lever

on the left (White rings) is used for chilled sparkling filtered water.

Chilled water is obtained by rotating the lever on the right, to a horizontal position.

The water is chilled by a refrigeration unit fitted within the cabinet stand, under the

basin.

With the carafe tap, you can obtain chilled water within the rated capacity, for as

long as you leave the lever in the open (horizontal) position. When finished, return

the lever to the OFF (upright) position.

Sparkling water is obtained in the same way as the chilled water, by rotating the

lever on the left hand side of the carafe tap.

Page 14 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 15

Commissioning

5.2 Adjusting the fl ow rate

Rotate to adjust

water fl ow

FIG.3

The carbonation valve has an adjustable fl ow rate. The optimum setting for the valve

is 1.6 litres per minute. Using a 6mm Allen key or a large fl at blade screw driver, you

can adjust the fl ow on the valve.

1. After product commissioning and CO2 purge, you are now ready to adjust carbonator water fl ow rate.

2. To adjust the fl ow rate, rotate the adjustment screw anti-clockwise to increase the

fl ow and clockwise to decrease the fl ow, see FIG.3. (Use 1/4 or 1/2 turn increments)

3. To measure the fl ow rate you have set, use a measuring cup or jug and run the spar-

kling water for 15 seconds. Multiply the amount of water dispensed in that 15 seconds

by 4 to get your fl ow rate in litres per minute. 1.6 litres per minute is the optimum fl ow

rate.

Warning - T ake care NOT to use excessive force

during adjustment of the carbonation valve.

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 15 of 20

Page 16

Section 6

Maintenance

6.1 Water Filter Replacement

NOTE: For safe operation, the filter cartridge should be replaced every 6-12

months, or earlier if you notice a persistent reduction in water pressure from the

appliance or an unpleasant taste or odour in the water.

REMOVE FILTER

1. ROTATE

2. PULL DOWN

INSERT FILTER

1. INSERT

2. ROTATE

Water Filter Change:

1. Turn off the water and power supply to the unit.

2. Turn the still water lever (blue ringed lever) on, to release any water

pressure in the unit. Once water has stopped running from the tap turn off

the lever.

3. Turn the filter clock wise and gently pull the cartridge down. The cartridge

should release from the filter head. Dispose of the filter cartridge

responsibly. Clean any water that has pooled below the filter head.

4. Fit a new filter by turning filter anticlockwise and gently pushing up. The

filter will click or lock into place.

5. Turn the still water tap on.

6. Turn on the water supply to the unit. Allow 7.5 litres to flow from the

outlet.

7. Turn off the still water lever.

8. Turn on the power supply to the unit.

Warning

Not changing filtration cartridges when required, may cause the water to become

biologically unsafe.

If the Zip ChillTap is switched off for a long period of time (e.g. More than a

weekend), run water through the chilled water outlet for at least 5 minutes before

consumption.

Use only a Zip Filter to match that used with this ChillTap (if fitted). Replacement filter

cartridges can be obtained through plumbing suppliers or directly from Zip.

Replacement instructions come with the filter cartridges.

Before attempting to disconnect or remove the filter cartridge from the housing,

isolate (turn off) the water supply prior to the filter system, and then relieve the

system pressure by operating the chilled water outlet tap until the water ceases to

flow.

Page 16 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 17

Slide to remove

Filter

Maintenance

6.2 Air Filter Change:

The Zip ChillTap air filter is conveniently located on the outside of the condenser. The

filter screen is a sliding fit in the plastic housing on the left hand side of the under sink

unit. The screen may be removed for cleaning, by sliding it forward. This needs to be

inspected at least quarterly, cleaned and replaced if damaged.

Note: For best performance the unit should only be operated with a clean air filter

screen, correctly fitted in place. Maintain, at least, a 50mm air gap in front of the

screen at all times. Take care not to allow cloths or other soft materials to accidentally

block the air inlet.

6.3 Gas Bottle Replacement:

1. Turn off the water and power supply to the chilled sparkling unit.

2. Turn off the regulator on top of the bottle. The regulator has a left hand thread,

to turn off, turn anticlockwise until shut.

3. Remove the CO2 bottle from its mounting and unscrew the bottle from the

regulator. The braided hose may be left connected to the regulator, or, for

convenience, removed and refitted to the regulator and new bottle.

4. Connect the new bottle to the regulator. Be aware that some CO2 may be

discharged from the connection to the regulator when the bottle and the regulator

are assembled together. Any CO2 released will be cold.

5. Ensure the braided hose is correctly fitted to the regulator, with the sealing olive

in place, before turning on the gas.

6. Turn the regulator on

7. Turn the sparkling lever to the on position. Leave it on until all the water has

been purged through the tap. Let the tap run for a further 10 seconds to purge

the CO2 through the tank. Turn off the sparkling lever.

8. Turn on the cold water supply first and then the power supply.

9. Wait 20 seconds and then turn on the sparkling lever and wait for water to

start to come through.

10. Dispense some sparkling water from the tap. Perform a taste test.

Service

There are no user serviceable parts but there are dangerous voltages present

within the unit. All service work must only be carried out by a suitably qualified and

experienced service person.

Before calling for service, check that both the water and electricity supplies are turned

‘ON’ and OK.

Call a licenced electrician, plumber, or Zip for a free call in Australia on 1800638-633, for assistance, service, spare parts, or enquiries.

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 17 of 20

Page 18

Trouble Shooting

Prior to any fault finding, please ensure all water connections to the chiller are sound and that the incoming water supply is

turned on. Also ensure that all electrical connections to the chiller are secure and that the chiller has had adequate time to

cool down.

Symptom Possible Cause Responsibility Solution

No still water

No sparkling water

Mains water not

connected or turned on

Water pressure regulator

failed

Unit frozen up

No CO2 pressure

Internal fault

User or Service

Technician

Service

Technician

Service

Technician

User

Service

Technician

Connect or turn on water supply.

Contact local Zip Service Provider.

Contact local Zip Service Provider.

Check if CO2 regulator valve is open.

Replace empty CO2 gas bottle.

Contact local Zip Service Provider.

Poor levels of

carbonation in drinks

Water temperature high

Air in carbonation can

Residue in carbonation

can

Carbonation can is

overfilled

User

User

Service

Technician

Service

Technician

See warm drinks symptom below, or allow chilled

system time to recover.

Purge system as described on page 15 “Gas Bottle

Replacement”.

Contact local Zip Service Provider.

Contact local Zip Service Provider..

Page 18 of 20 804721- CS_ChillTap Sparkling 09.16 v1.00

Page 19

Trouble Shooting continued

Symptom Possible Cause Responsibility Solution

Warm drinks

No power

Thermostat faulty or out of

calibration.

Insufficient cooling air flow

through the refrigeration

system

Refrigeration failure

Rated chilled water capacity

has be expended

User or Service

Technician

Service

Technician

Service

Technician

Service

Technician

User

Restore power to the unit.

Contact local Zip Service Provider.

Contact local Zip Service Provider.

Contact local Zip Service Provider.

Allow unit sufficient time to recover.

Cleaning

Never use strong, corrosive or abrasive cleaning materials on the Zip ChillTap.

Wipe clean the outer surfaces with a sponge or a soft cloth using a mild soap

and water.

The louvres on the sides of the chiller unit need to be kept free of dust and lint

to permit free flow of air through the vents. They should be checked regularly, at

least monthly, and dusted or vacuumed.

Sanitising the Carbonation unit, may be required when the quality of sparkling

water deteriorates. Please contact your local Zip service provider.

End of Life Disposal

In order to help preserve our environment we ask that you dispose of this

product correctly. Please contact your local city council for collection centre

details.

804721 - CS_ChillTap Sparkling 09.16 v1.00 Page 19 of 20

Page 20

Contact Details

Head Office

Zip Heaters (Aust) Pty. Ltd.

ABN: 46 000 578 727

67 Allingham Street

Condell Park NSW 2200

Postal: Locked Bag 80

Bankstown 1885 Australia

Website: www.zipwater.com

Facsimile: (02) 9796 3858

Telephone: (02) 9796 3100

Sales & Service.

Free Call: 1 800 63 86 33

Customer Care.

Free Call: 1 800 42 43 44

As Zip policy is one of continuous product improvement, changes to specifi cations may be made

without prior notice. Images in this booklet have been modifi ed and may not be true representations

of the fi nished goods.

The standard glass is 200 ml (7 fl oz).

The terms “Zip” and “ChillTap” are registered trade marks of Zip Heaters (Aust) Pty Ltd.

Zip products described in this publication are manufactured under one or more of the following

patents: AU675601, AU637412, AU635979, GB0422305, GB2065848, US4354049, US5103859,

US5099825 and SA2006/08043. Other patents are in force and patent applications are pending.

804721 ChillTap Sparkling 09.16 v1.0

WMKA21821

ATS 5200.105

Loading...

Loading...