Zip AquaFlo II AF3210, AquaFlo II AF3120, AquaFlo II AF3150, AquaFlo II AF3180, AquaFlo II AF3250 Installation, Maintenance And User Instructions

...

AquaFlo II

Unvented Water Heaters

Issued October 2012

Installation, Maintenance and User Instructions

Please read these instructions carefully before commencing installation.

Please leave these instructions with the end user after installation.

Zip Heaters (UK) Ltd.

14 Bertie Ward Way

Dereham

Norfolk

NR19 1TE

Telephone: 0845 6024533

Fax: 01362 692448

Web: www.zipindustries.co.uk

The terms ‘Zip’ and ‘InLine’

are registered trademarks

Front cover A5_BookletBack cover

Inside Back cover Inside Front cover

AquaFlo Installation, Maintenance and User Instructions Page 1 of 24 V 2.01 - October / 2012

Contents 1

Description 2

Approvals 2

Safety Information 3

Technical data 4 / 12

Parts List 13

Installation 14

Requirements 14

Installation Site 15

Installing the appliance 15

Electrical connection / circuit diagram 20 / 21

Commissioning 22

Annual servicing 23

Warranty 24

Please read these instructions carefully before commencing installation of the AquaFlo

unvented Water Heater.

Please leave these instructions with the end user after installation.

To ensure you have the latest revision of this instruction manual, please visit

www.zipindustries.co.uk to download the latest copy.

In order to preserve our environment we ask that you dispose of this product correctly.

Please contact Zip Customer Service for advice on 0845 602 4533.

AquaFlo Installation, Maintenance and User Instructions Page 2 of 24 V 2.01 - October / 2012

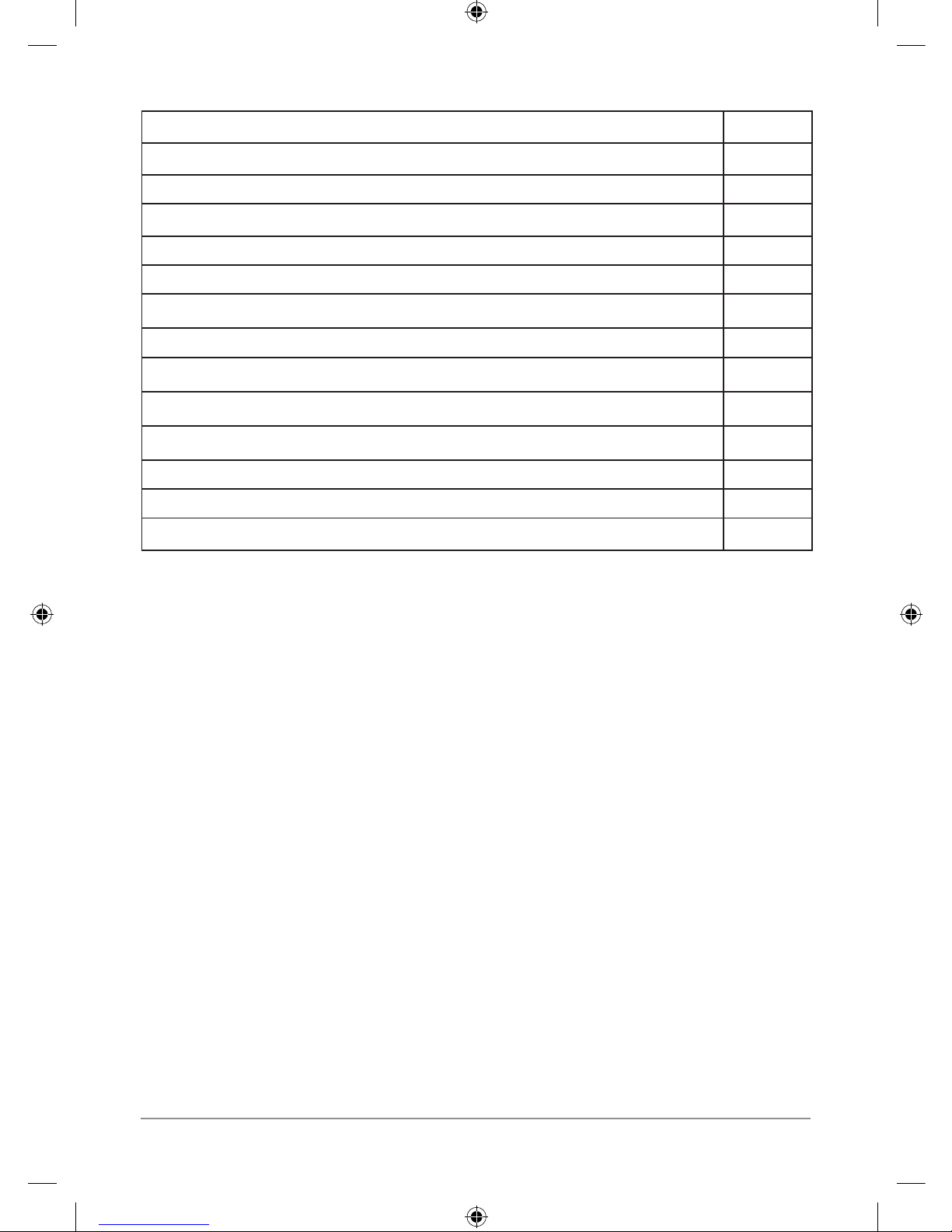

Equipment Supplied with Cylinder Direct Indirect

Solar Twin

Coil

Solar

Direct

Dual Control Thermostat (Indirect Models Only)

û

û

Thermostat (High Limit)

û û

Two Port Zone Valve (Indirect Models Only)

û

û

Cold Water Inlet Set

15 x 22 mm Tundish

Temperature & Pressure Relief Valve

Expansion Vessel

Expansion Vessel Bracket

¾” BSP Female X 22 mm Connection for Expansion Tank

Immersion Heater(s) - Dependant on size and conguration

Grommet for Solar Sensor

û û

Instruction Manual

DESCRIPTION

The corrosion resistant Zip AquaFlo Unvented cylinder is made from Duplex Stainless Steel. It is

highly insulated with environmentally friendly foam enclosed in a rust resistant white steel case.

It is available in Direct and Indirect versions in a family of 7 sizes from 90 – 300 litres. Triple

element options are available on Direct 210 – 300 litre units. Twin Coil and Solar Direct units are

available in 5 sizes from 150 - 300 litres.

To help ensure compliance with the relevant Water and Building Regulations all AquaFlo units

are supplied complete with the necessary safety and control devices needed to connect to the

cold water mains. In order to ensure high ow-rate performance with minimum pressure drop even

in lower pressure areas, pre-adjusted, high quality controls have been selected.

APPROVALS

KIWA approved to UK Water Regulations and UK Building Regulations Part G3 and Part L.

Immersion element / thermostat BEAB / NEMKO approved and CE endorsed.

Storage prior to installation

Zip AquaFlo should be stored upright in a dry area and kept in its original packaging until

immediately prior to installation.

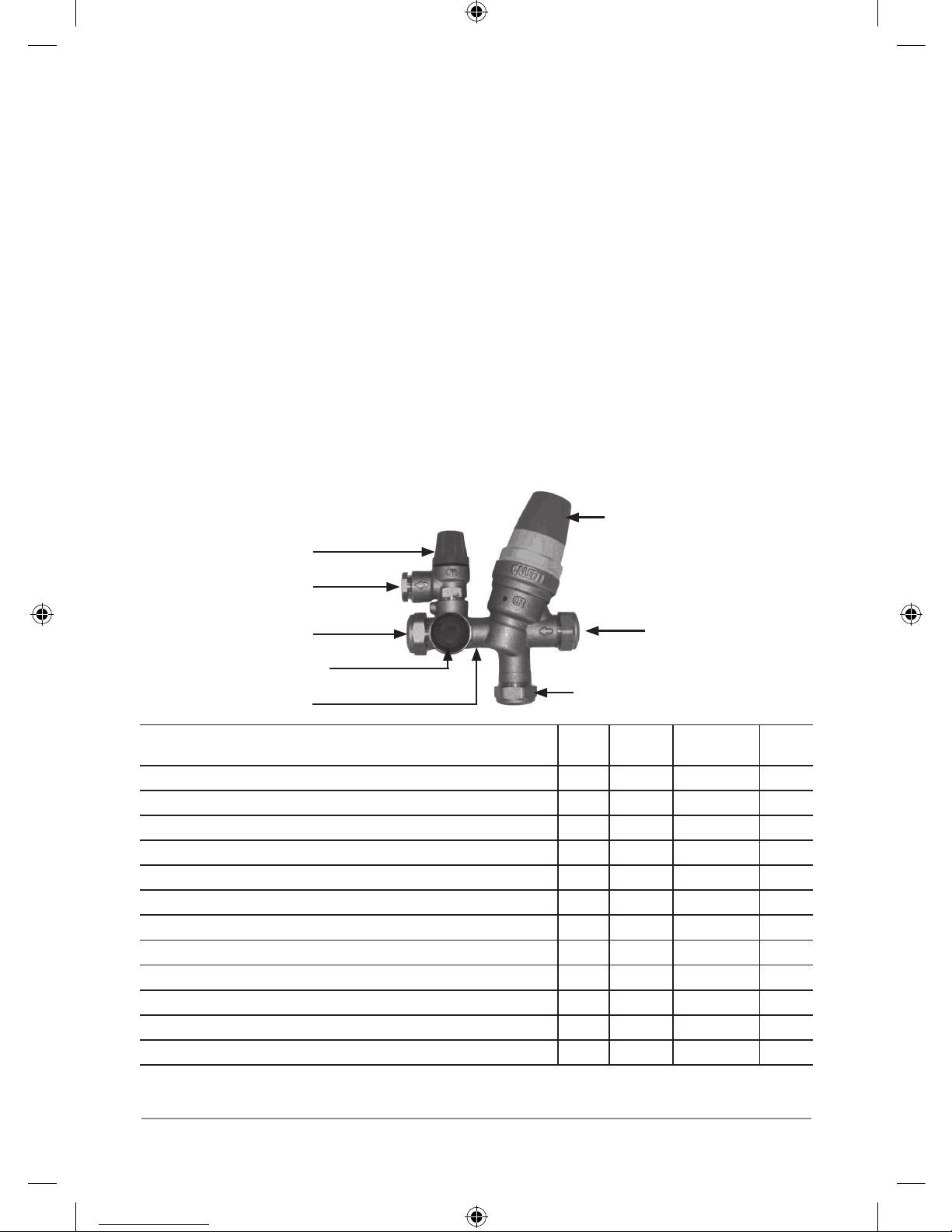

Cold Inlet Set - Connections

Cold Mains In

Balanced Cold Take Off

Cold Supply To Cylinder

Internal Check Valve

Expansion Vessel Take Off

Discharge To Tundish

Expansion Relief Valve

Pressure Reducing Valve (inc.

Line Strainer)

Additional items required (not supplied): Drain for the cold inlet. Isolating valve for the cold feed

supply.

AquaFlo Installation, Maintenance and User Instructions Page 3 of 24 V 2.01 - October / 2012

SAFETY INFORMATION

WARNING

• Installation, commissioning and maintenance of this appliance must only be carried

outbyacompetentinstallerholdingtheirG3unventedqualication, who will then be

responsible for adhering to all relevant standards and regulations.

• The appliance must be wired to a suitably rated double pole fused spur.

• Electrical installation must comply with IEE regulations.

• Isolate appliance at the main electric supply before opening the heating element cover.

• The connection cable must be 2.5mm2 heat resistant (85°C HOFR) sheathed ex complying

to BS 6141:1981.

• This appliance must be earthed at all times.

• The connecting cable must be adequately secured.

• Check that the power supply is switched off prior to electrical connection.

• The appliance, its wiring and piping must not be modied in any way.

• The appliance must only be used when correctly installed and in perfect working order.

• Maximum water supply pressure

1.0 MPa (10 bar)

.

• Explosion hazard. Safety ttings such as the temperature & pressure relief valve must not

be modied.

• The appliance must not be used for any purpose other than that for which it was designed.

• When the appliance has been in use for some time, the ttings may be very hot.

• This appliance must not be used by any person (inclu ding children) with limited physical,

sensorial or mental abilities or failing experience and/or knowledge unless they are

supervised by a person responsible for their safety or received instructions about how to

use the appliance. Children should be supervised in order to make sure that they do not play

with the appliance.

• Take care when lifting the Zip AquaFlo. Some units may exceed safe lifting limits. Do not

lift without assistance. The weights of the units are given in the specifications table (see

specications on page 10 to 12)

WARNING:

Indicates a potentially hazardous situation, which, if

not avoided, could result in death and/or serious injury

and/or property damage.

CAUTION:

Indicates a potentially hazardous situation, which, if not avoided,

may result in property damage.

IMPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY.

NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY

AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE

USE.

AquaFlo Installation, Maintenance and User Instructions Page 4 of 24 V 2.01 - October / 2012

CAUTION!

• In case of malfunction isolate the power supply immediately. In case of leaks also isolate the

water supply. Repairs must only be carried out by Zip Heaters (UK) Ltd or an authorised Zip

service engineer.

• If siting outside the heating envelope of the dwelling such as a garage or outbuilding then

frost protection should be provided and exposed pipework should be insulated.

• The appliance must be completely lled with water before being switched on.

• The appliance must only be used for heating wholesome water.

• Minimum water supply 0.15 MPa (1.5 bar), 20 l/min.

• The Zip AquaFlo is intended for connection to mains supply only. In any other case please

contact Zip on 0845 602 4533 for advice.

Zip Heaters (UK) Ltd. cannot be held liable for any damages caused by failure to observe

these instructions.

TECHNICAL DATA / SPECIFICATION

Maximum water supply pressure to pressure reducing valve ...................1.0 MPa (10 bar)

Note!

If supply is above 1.0 MPa (10 bar) a pressure control valve must be used to bring

the pressure under 1.0 MPa (10 bar) before connection to the pressure reducing valve.

Operating pressure .................................................................................... 0.3 MPa (3 bar)

Maximum primary pressure (indirects only) ...............................................0.3 MPa (3 bar)

Immersion Elements: Incology construction 1¾” thread, 14” long, loading 3kW @ 240V.

Note! Titanium elements are also available for areas where aggressive water, constant cycling

and high usage are factors. (See parts on page 13).

Heat Exchanger: 22mm low prole, high efciency stainless steel coil-in-coil.

Controls:

• Thermostat adjustable up to 65°C.

• Over temperature safety cut-out. Manually re-settable. Operates at 85°C.

• Expansion relief valve -

0.6 MPa (6 bar)

.

• Temperature and pressure relief valve - 90°C and 0.7 MPa (7 bar).

• Pressure reducing valve - 0.3 MPa (3 bar).

• Expansion vessel - pre-charged

0.3 MPa (3 bar)

.

• 90 - 150 Ltr units: 12 Ltr vessel.

• 180 - 250 Ltr units: 18 Ltr vessel.

• 300 Ltr units: 24 Ltr vessel.

AquaFlo Installation, Maintenance and User Instructions Page 5 of 24 V 2.01 - October / 2012

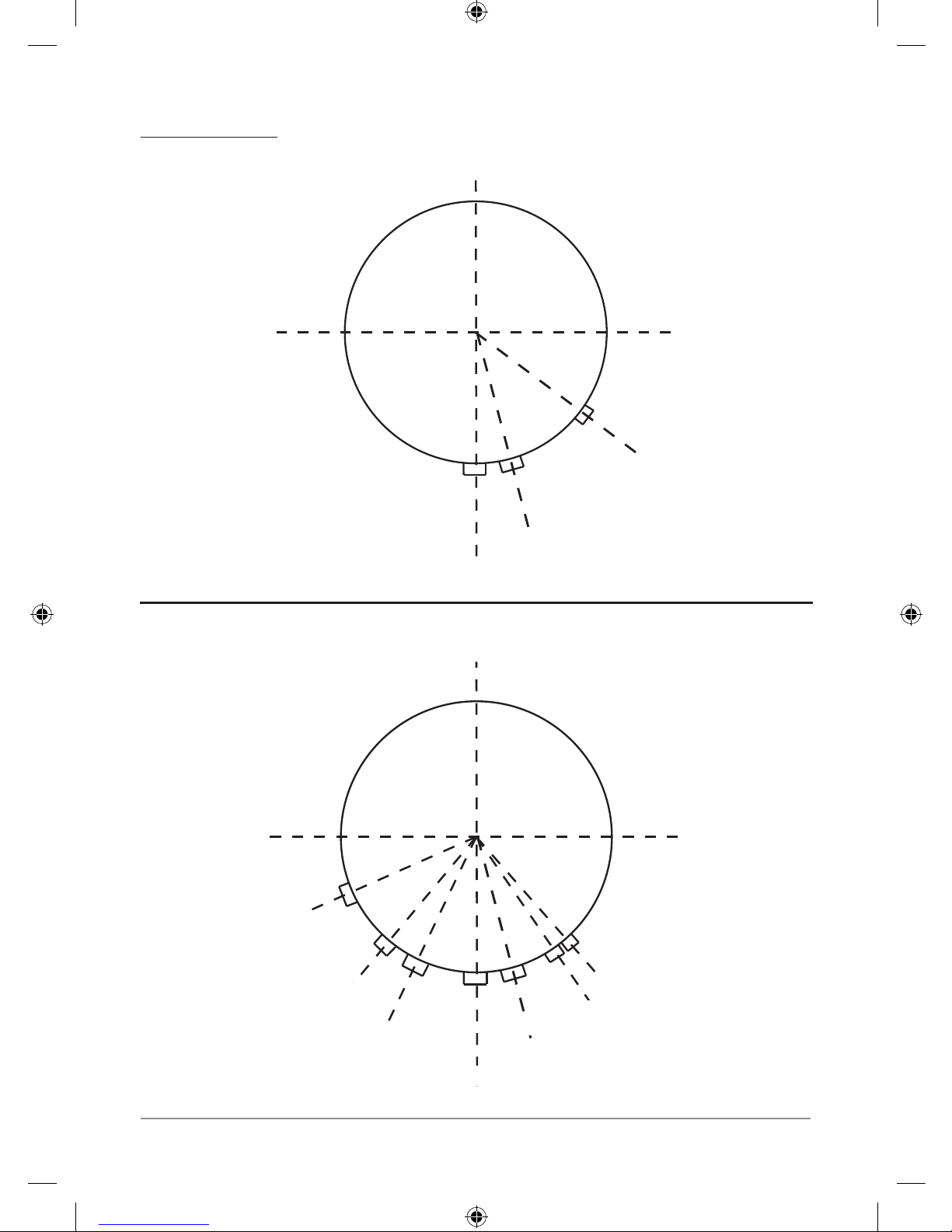

Connection Points

AquaFlo Indirect and Solar Compatible

Immersion

Cold Inlet

Primary Coil

T&P Valve

Stat Pocket

Sec Return

Primary Coil

38°

35°

25°

40°

66°

15°

Immersion

T&P Valve

Cold Inlet

AquaFlo Direct

45°

15°

AquaFlo Installation, Maintenance and User Instructions Page 6 of 24 V 2.01 - October / 2012

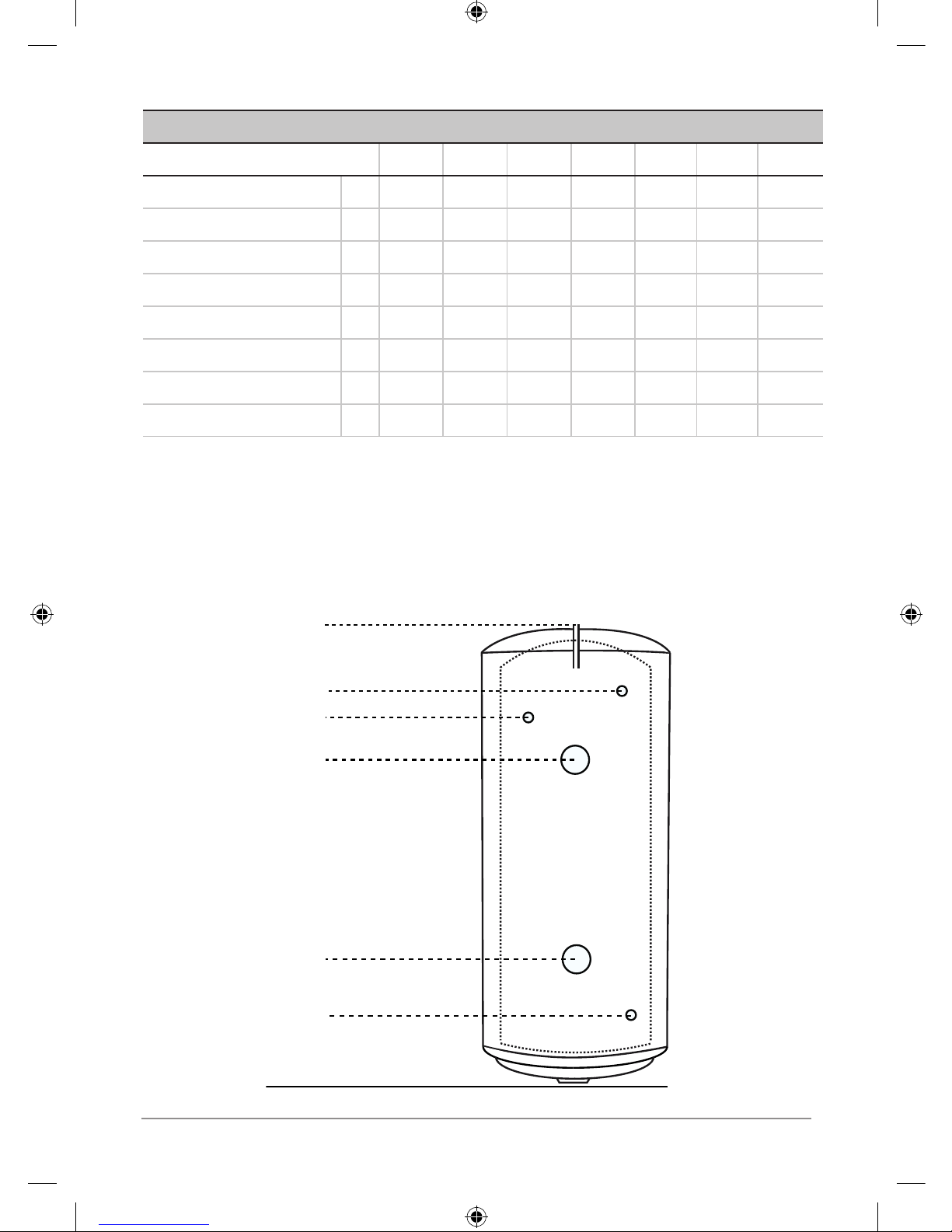

AQUAFLO DIRECT DIMENSIONS

Model AF3090 AF3120 AF3150 AF3180 AF3210 AF3250 AF3300

Nominal Capacity (Litres) 90 120 150 180 210 250 300

Diameter (mm) 545 545 545 545 545 545 545

Height (mm) A 727 915 1102 1290 1478 1728 2041

T & P Valve (mm) B 515 703 890 1078 1266 1516 1829

Sec. Return (mm) C - - - - 1009 1259 1509

Immersion 2 (mm) D - 519 619 719 819 959 1109

Immersion 1 (mm) E 242 242 242 242 242 242 242

Cold Inlet (mm) F 192 192 192 192 192 192 192

A

B

C

D

E

F

Loading...

Loading...