Page 1

Installation and Operating Instructions

Zip Filter Tap

Cold Water Filtration (unchilled)

Affix Model Number Label Here

801085

Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00 Page 1 of 8

Page 2

R

Please read all Warnings, Installation Requirements and Installation Instructions before installing any

Zip Filter Tap.

These appliances are not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliances by a person responsible for their safety.

Children should be supervised to ensure they do not play with the appliances.

The units are for indoor use only and must not be exposed to the elements of nature.

These units must not be positioned in an area that may be cleaned by a water jet. These units must not be cleaned by a

water jet.

WARNING: For correct operation of this appliance it is essential to observe the manufacturer’s instructions.

Read These Warnings First

Precautions

The plumbing installation must be done in accordance with local Water Authority regulations and these Installation

Instructions.

As the installer, it is your responsibility to supply (if necessary) and install all valves as required by local regulations and

relevant standards.

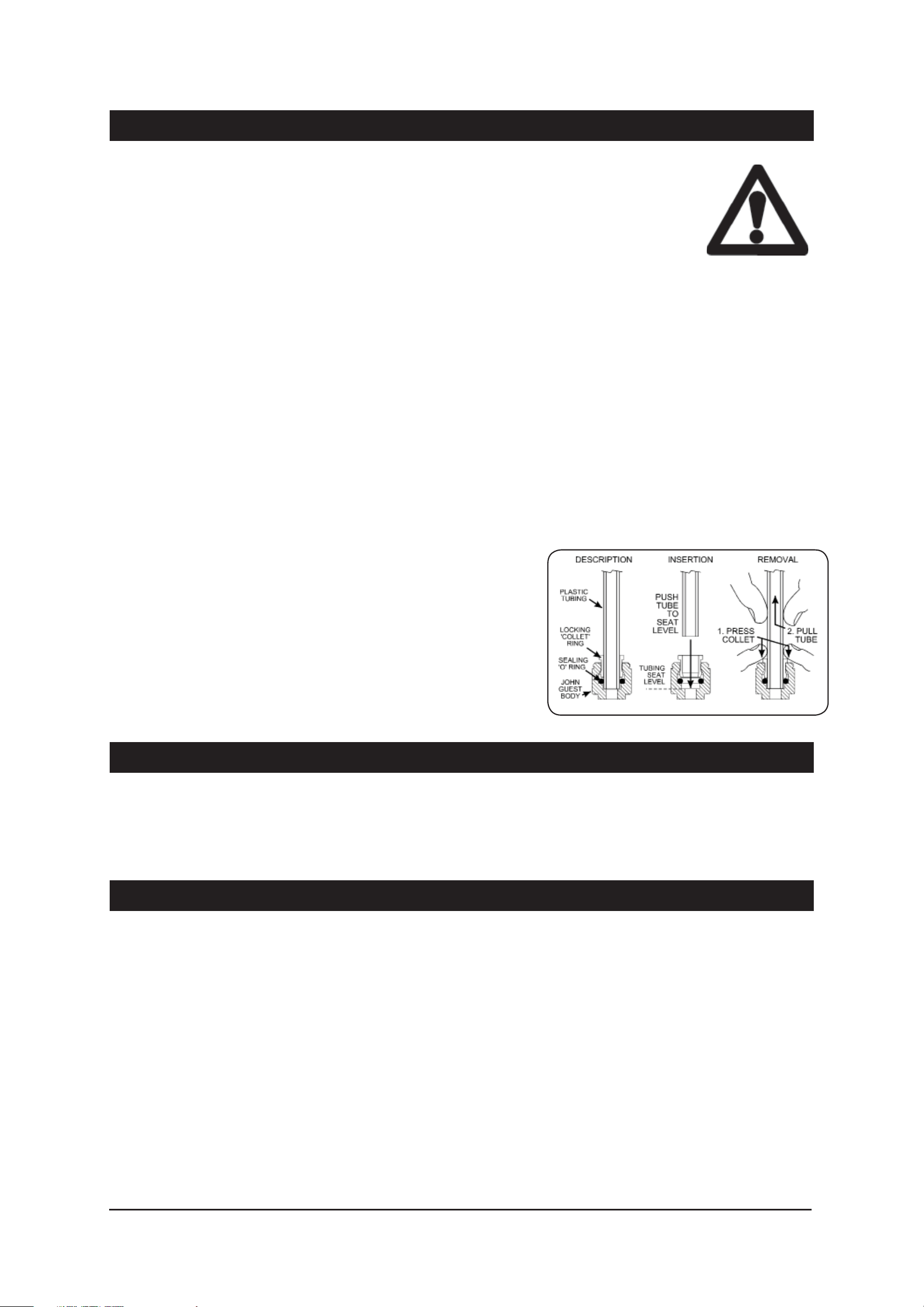

Correct Use of JG Quick Connect Fittings

John Guest quick connect fittings and hoses are used in Zip products.

Note insertion and removal details for JG fittings using plastic tubing as

seen in the adjacent diagram.

NB: Be sure to cut the tube squarely with a sharp knife or tube cutter.

Shake out and remove any swarf or debris.

Installation Requirements

• Operating temperatures 5º C - 35º C.

• Water pressure 172 kPa - 700 kPa (0.172 MPa -0.7 MPa)

It is the installers responsibility to ensure the installation complies with AS/NZS3500.1, AS/NZS3500.2, AS/NZS3500.4.1,

AS/NZS3500.4.2 and local water authority regulations.

Installation Instructions

Installing the Filtration Unit

The filtration unit should be mounted in a convenient position in the cupboard, to allow for ready and easy access during

filter changes.

Usually the side of the cupboard, near the door, is most suitable. However, the length of the tubes from filter to carafe

tap and from water supply to filter need to be considered when selecting a suitable position to mount the filter head.

Using the two screws provided, screw the filter head to the inside of the cupboard, allowing 270 mm minimum clearance

between the underside of the filtration head and any obstructions like shelves, etc.

Write the installation date on the filter cartridge. Fit the cartridge into the housing. The model you have may appear

slightly different to that illustrated, however, operation and function is identical.

Align the tabs of the cartridge with the filter housing and insert it into the socket. Turn the cartridge a quarter turn to the

right until it stops and locks into position.

Check that the direction of flow on the filter head is correct.

Page 2 of 8 Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00

Page 3

# Installation Instructions

1

1

2

Filter cartridge removal

2

Filter cartridge insertion

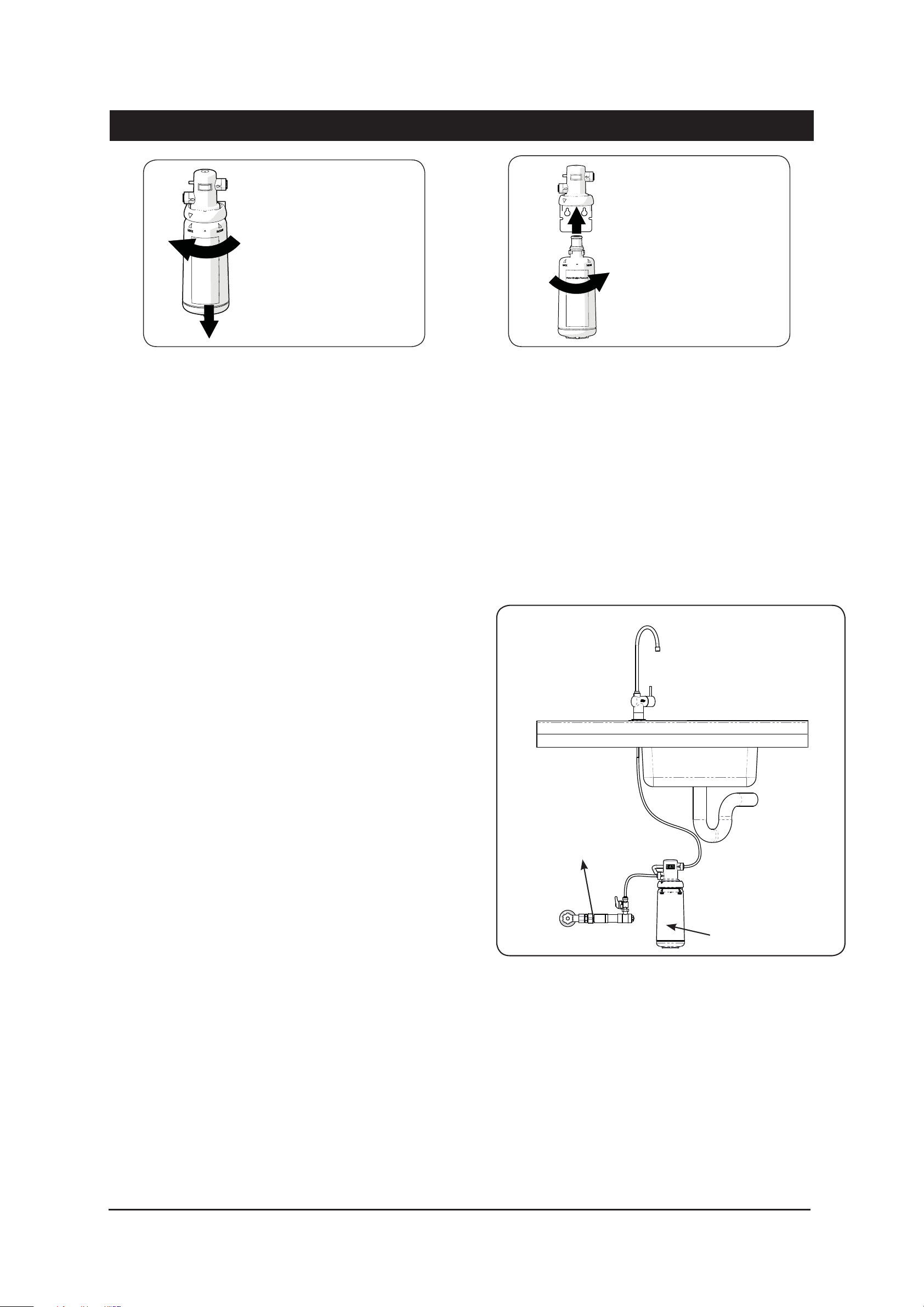

Installing the Filter Tap

Position the Filter Tap at the back of the sink where there is a 45 mm wide flat area within the draining areas of the

sink. The recommended position is over one corner of the bowl. Make sure the selected position allows the spout to

overhang the sink bowl.

The cutout size is 25 mm. Mark the centre of the new Filter Tap position on the sink with a centre punch. Drill out the

centre of the hole to allow the screw of a sheet metal punch to pass through the sink. Use a 25 mm sheet metal punch

to neatly cut the hole.

Remove the nut and washer from the base of the Filter Tap, and pass the tubing through the sink until the Filter Tap sits

upright within the hole you just created in the sink surround.

Orientate the Filter Tap so that the activating lever is away from

the sink bowl. Slide on the washer and nut from beneath the sink,

Installation Diagram

and tighten the nut to secure the Filter Tap firmly into place.

Take care, when bending plastic tubing, to prevent it from kinking

or crushing on a bend.

Do not connect the tubes in any other arrangement than that

described here. The filter cartridge and the Filter Tap have

directional flow connections that will not work if connected

incorrectly. Incorrect installation will void any product warranty.

Note that the flow direction of the filter housing is indicated on

the filter housing.

Double Non Return - DNR

and pressure limiting Valve

Measure and cut the tube from the Filter Tap to length so that

it runs around the back of the cupboard to the outlet side of the

filter housing. Use a tube cutter to cut the end off the tubing neat

and square, so that there are no dags or rough edges. Shake the

tube vertically to allow any debris to fall out of the tube before

Filter

inserting it into the filter head.

Push this end of the blue tube firmly into the John Guest socket on the outlet side of the filter head.

It must push in at least 10 mm. Test the connection by trying to pull the tube out. If it comes out, re-insert it so that it

won’t come out when pulled against.

Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00 Page 3 of 8

Page 4

#

Installation Instructions

Installing the DNR Multifunction Valve

The DNR valve must be inserted into the tube between the main isolation valve

and the filter cartridge. Ensure the flow is in the correct direction.

The DNR valve must be connected downstream of an accessible isolation tap.

The 3/4”F- BSP threaded section on the inlet end of the DNR valve may be

connected directly to an isolation tap.

NOTE: The centre of the 3/4” fitting may be removed with an 8mm allen key to

allow for direct connection to a 1/2” BSP Tap. Remember to re-fit the strainer

and sealing washer.

Alternatively, the DNR valve may be positioned so that it can be seated into a

retaining clip screwed to the cupboard wall.

Take the one metre tube from the filter kit.

Meaure and cut the tube from the DNR valve to length so that it runs around the back of the cupboard to the inlet side of

the filter housing. Leaving a little extra slack in this line for the connection of the DNR valve.

3/4” FBSP

Water Inlet

1/2” FBSP

Black sealing plug

Strainer and

sealing washer

Pos.B ( Alternative outlet )

Service valve

To filter

Pos. A

Insert the tube end into the (JG) fitting on the side of the DNR valve.

Insert the other end of tube into the (JG) fitting on the Inlet side of the filter head. Note the directional arrows on the body

of the Valve. It must end up connected so that they point in the direction of the Flow. (see Installation Diagram on Pg 3.)

The valve may be positioned vertically or horizontally.

When mounted horizontally the service tap may be fitted to one of two outlet port positions i.e axially in line (Pos A) or at

90 degrees (Pos B). When changing the outlet position remember to refit the black sealing plug to the un-used port.

Filling the system

Turn ‘on’ the water supply. Check the connections for leaks. Repair any found.

The filter and tubing are full of air until purged, and the filter cartridge requires activation when first installed. Flip up the

operating lever on the Zip Filter Tap for a minimum of five minutes until all of the air has been purged from the system,

and the cartridge has time to become fully activated.

Every time the filter cartridge is replaced, repeat this procedure of a five minute flush to activate the new cartridge

properly.

Page 4 of 8 Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00

Page 5

#

NOTE: When flushing the system, some black particles may be released into the water. This is normal. The water will

become clear after the first few litres.

Complete the installation and leave these instructions with client.

Installation Instructions

Service

All service work must only be carried out by a suitably qualified and experienced service person.

Before calling for service, check the water supply is turned ‘ON’ and OK.

Call Zip in Australia on 1800-638-633 for assistance, service, spare parts, or enquiries.

# Filter Replacement

Not changing cartridges when required may cause the water to become biologically unsafe.

Thoroughly flush the water through if the filter tap has not been used for more than 12 hours. For safe operation, the

filter cartridge should be replaced at least every 6-12 months, or earlier if you notice a persistent reduction in water

pressure from the Filter Tap, or an unpleasant taste or odour in the water.

Use only a Zip filter cartridge to match that of your Filter Tap. Replacement cartridges can be obtained through plumbing

suppliers or directly from Zip.

When replacing your Zip filter cartridge, replacement instruction will be provided with your replacement cartridge kit.

# Operating Procedures

Operating

You can obtain filtered water within the rated capacity for as long as you rotate the

lever. In the upright position the tap is off, when the lever is rotated anticlockwise

water will flow. Water will continue to flow until the lever is returned to the upright

position.

Cleaning

ROTATE

Never use strong, corrosive or abrasive cleaning materials on the Zip Filter Tap. Wipe

the outer surfaces clean with a sponge or a soft cloth using a mild soap and water.

Troubleshooting

Problem Cause Remedy

No water at outlets Water not connected Connect and turn on water

Poor flow at outlet Blocked filter Replace filter

Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00 Page 5 of 8

Page 6

Performance Data Part Number 91289

Performance Data Sheet

Use Replacement Catridge 91289

The concentration of the indicated substances in water entering the system was reduced to a concentration less than or equal to the

permissible limit for water leaving the system as specified in NSF/ANSI Standard 42 and NSF/ANSI Standard 53.

Capacity: 3,785 litres Contaminant Reduction Determined by NSF testing.

Test Conditions: pH7.5, Pressure: 415 kPa, Flow Rate: 1.9L/min

Substance

Reduction

Chlorine Taste

and Odor

Cyst* 140,000

Lead pH @6.5 0.150

Lead pH @8.5 0.150

* Based on the use of Cryptosporidium parvum oocysts

Average

Infl uent

2.0 mg/L 2.0 mg/L ±10% 97.3% 0.05 mg/L N/A 5.0 mg/L 50% J-00109688

cysts/L

mg/L

mg/L

NSF/ANSI specifi ed

Challenge Concentration

Minimum 50,000 cysts/L >99.99% 3 cyst/L N/A 1 cyst/100 L 99.95% J-00109693

0.15 mg/L ± 10% >99.3% 0.001 mg/L 0.010 mg/L 0.01 mg/L N/A J-00109691

0.15 mg/L ± 10% 99.3% 0.001 mg/L 0.010 mg/L 0.01 mg/L N/A J-00109692

Application Guidelines/ Water Supply Parameters

Service Flow 1.9 Ipm

Water Supply Potable Water

Water Pressure 172 - 862 kPa

Water Temperature 4.4ºC - 38ºC

Avg %

Reduction

Average

Product

Water

Concentration

NSF Max

Permissible

Product Water

Concentration

Australian/ New Zealand

(AS/NZS Standard 3497)

Max Permissible Prod-

uct Water Concentration

NSF

Reduction

Require-

ments

System tested and certifed by NSF

International against NSF/ANSI Standard

42 and Standard 53 for the reduction of

substances as listed below according to

Standard 42 and Standard 53.

NSF Test

Report

It is essential that the manufacture’s recommended installation, maintenance and filter replacement requirements be carried out for the

product to perform as advertised. See installation Manual for details.

Note: While the testing was performed under standard laboratory conditions, actual performance may vary.

WARNING

To reduce the risk associated with ingestion of contaminants:

Do not use with water that is microbiologically unsafe or of unknown quality without adequate disinfection before and after the system.

Systems certifi ed for cyst reduction may be used on disinfected water that may contain fi lterable cysts.

EPA Establishment Number 070595-MEX-001

CAUTION

To reduce the risk associated with property damage due to water leakage:

• Read and follow Use Instructions before installation and use of this system.

• Installation and use MUST comply with all state and local plumbing codes.

• Do not install if water pressure exceeds 862 kPa. If your water pressure exceeds 551.68 kPa, you must install a pressure limiting

valve. Contact a plumbing professional if you are uncertain how to check your water pressure.

• Do not install where water hammer conditions may occur. If water hammer conditions exist you must install a water hammer

arrester. Contact a plumbing professional if you uncertain how to check for this condition.

• Do not install on hot water supply lines. The maximum operating water temperature of this filter system is 38ºC.

• Protect filter from freezing. Drain filter when temperatures drop below 4.4ºC.

• The disposable filter cartridge must be replaced every 12 months or at the specified service cycle, or sooner, if a noticeale reduction

in flow rate occurs.

Page 6 of 8 Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00

Page 7

Notes

Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00 Page 7 of 8

Page 8

Contact Details

Head Office

Zip Heaters (Aust) Pty. Ltd.

ABN: 46 000 578 727

67 Allingham Street

Condell Park NSW 2200

Postal: Locked Bag 80

Bankstown 1885 Australia

Website: www.zipheaters.com

Facsimile: (02) 9796 3858

Telephone: (02) 9796 3100

Free Call: 1 800 638 633

As Zip policy is one of continuous product improvement, changes to

specifications may be made without prior notice. Images in this booklet have

been modified and may not be true representations of the finished goods.

WMKA25287

AS/NZS 3497

The term “Zip” is a registered trade mark of Zip Heaters (Aust) Pty Ltd.

Zip Filter Tap - Installation & Operating Instructions - 801085 - November 2012 v1.00 Page 8 of 8

Loading...

Loading...