Page 1

Type:

MK/MKS/MKR/MKRS

Version 1.8 / 07.05.2014

Clamping Elements

ZIMMER GmbH, Salmenkopf 5; D-77866 Rheinau-Freistett; TEL.: 0049/7844/9138-0; FAX: -80

Assembly_Instructions_MK_MKR_v18.doc

1/2

Installation and Operating Instructions

1. Security Advice:

Caution:

Please read the complete documentation carefully before starting the set-up operation!

1.1. Depending on the type of application danger will be caused by:

- Contusion during installation caused by unsecured connecting construction

- Improper pneumatic connections

- Malfunction of pneumatic supply caused by pressure fluctuations or excessive heating

- Loose pneumatic connection

- Loose attachment screws

- removal of the spring cap

- Not turning off the operating instrument during installation or repair works at the clamping element

- Human malpractice

- Non-observance of the information and warning facilities during installation and the set-up operation

Installation instructions have to be followed and the necessary equipment and supplies have to b e used during installation,

modifications, maintenance and repair. Throughout every working process on the clamping elements t he appropriate

accident prevention regulations, VDE security and installation instructions have to be followed.

1.2. The application of the clamping elements – in accordance with regulations – implies that t his technology will be utilized

exclusively in consideration of the realm of possibilities defined by technical specification. All different ways of use exclude

further liability of the Zimmer GmbH.

2. Model MK/MKR (without spring storage), MKS/MKRS (inc. spring storage)

The clamping element is preset to the appropriate track gauge ex factory. The contact sections are pressed onto t he nonattached areas of the track guide. Therefore, the process of clamping does not influence the precision and the economic

lifetime of the track.

2.1. Operational Area:

The MK/MKS models are designed for s tatic use. The additional pressurizing on the side of the piston rod, termed as PLUSconnection from now on, can increase the clamping power significantly (see 3.).

-

max. surrounding temperature 70°C

-

pneumatic operating pressure min. 5.5 bar, max. 8 bar

-

check-up of all pneumatic connections in regular intervals

Caution:

Clamping processes during operation may cause damage of the clamping element as well as the linear guide.

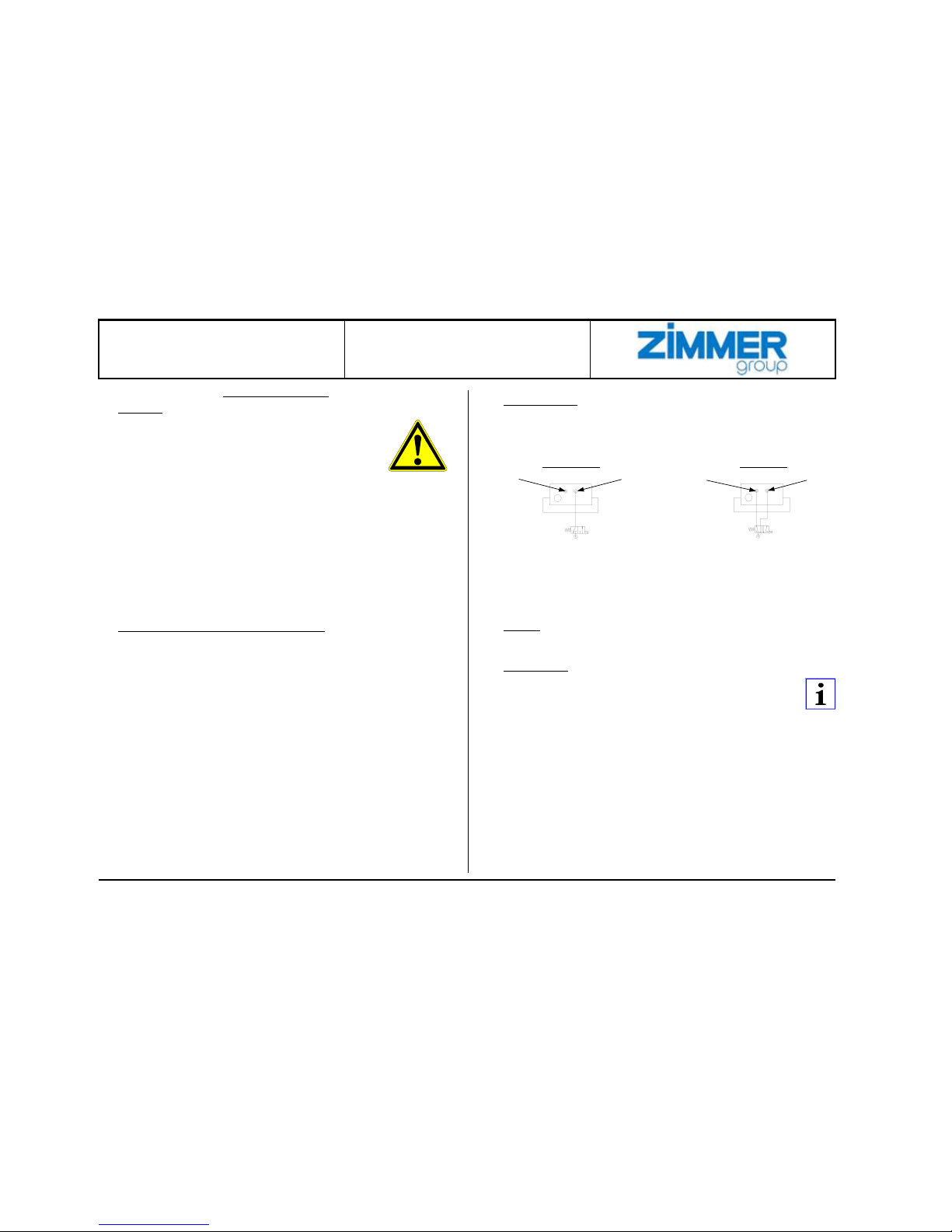

3. MKS and MKS-Plus-Version

The model MKS can be operated as a plain spring storage element or as a pressure supported spring repository element

(PLUS-connection). The clamping power can be increased significantly by the pressure supported spring storage.

Fig. 1 Diagram of Connection

3.1. For a transportation lock, the spring energy storage is pre-stressed by a spacer between the contact sections.

Caution:

It is permitted to remove the transportation lock, only if the air connection is pneumatically pressurized to at least 5.5

bar according to instructions.

It is permitted to release pressure from the clamping element, only if an associated guide rail or a transportation lock

exists!

4. PLUS-Version

The application of the PLUS-Version strictly requires the removal of the air filter. The connection has to be replaced with a

pneumatic connection.

5. Installation Instructions

5.1. General:

For mounting the clamping elements, used screws have to comply with the category of solidity of min. 8.8.

Attachment screws have to be tightened with the required moment. (Tab.1)

The maximum holding load is reached only by a rigid connection construction which must cover the complete

connection surface of the clamping element.

Caution: The cap of the security clamping must not be removed, spring storage!

5.2. Installation / Uninstalling:

-

Removal of the plastic blanking plug

-

Attachment of M5 pneumatic connections, possibly attachment of PLUS-connection

-

pressurize air connection to open the clamping element

-

Set clamping element onto linear guide

-

In case of using an adapter plate PMK, place this adapter plate between the clamping element and the connecting

construction as a device of leveling

-

Turn the screws loosely into the screw threads

-

Clamp model MKS by depressurizing

-

Clamp model MK by pressurizing

-

Tighten attachment screws with the required moment (Tab.1)

-

For uninstalling perform in reverse order

Standard -Connection

Air Connection

Air Filter

PLUS -Connection

PLUS-Connection Air Connection

Page 2

Type:

MK/MKS/MKR/MKRS

Version 1.8 / 07.05.2014

Clamping Elements

ZIMMER GmbH, Salmenkopf 5; D-77866 Rheinau-Freistett; TEL.: 0049/7844/9138-0; FAX: -80

Assembly_Instructions_MK_MKR_v18.doc

2/2

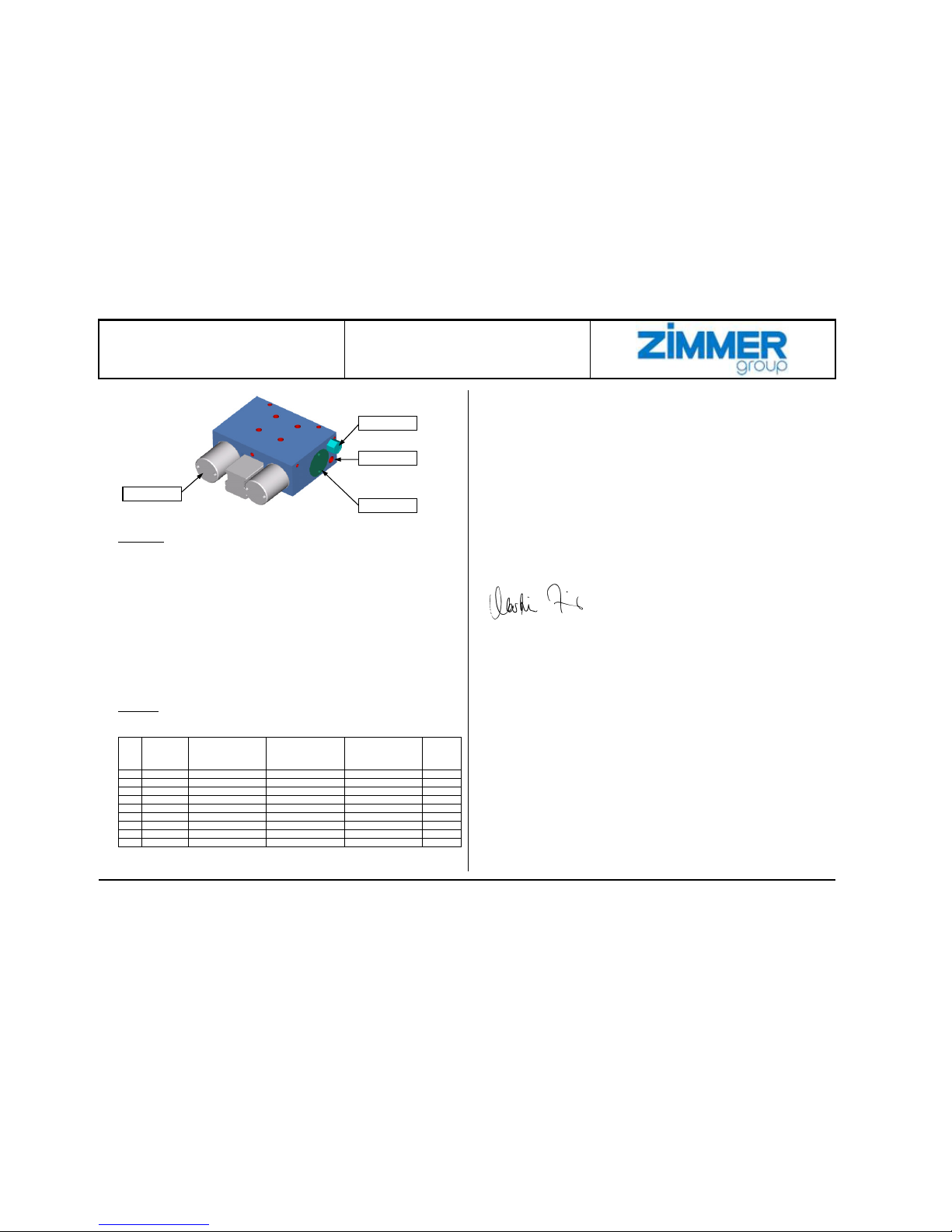

6. Operational Test

6.1. After the appropriate installation of the clamping element the operating readiness has to be tested

The mobility has to be tested by manually moving the slide.

The process of clamping has to be tested by manually moving the connecting construction.

The appropriate mounting of the fixed and flexible pneumatic pipe installation has to be tested by visual control.

All pneumatic connections at the pressurized element have to be visually checked for leakage.

All attachment screws have to be checked for their required moment (Tab.1).

6.2. Readjusting

After appropriate installation, readjusting will not be necessary because the contact sections are preset ex factory.

Open the clamping element

Tighten adjustment screws clockwise until the contact section suits. (supplies, adapter)

Caution: Both adjustment screws have to be screwed in identically and subsequently have to be screwed back to an angle

of 15°.

Start operational test.

For further information, please contact our technical service: 0049/7844/9138-0

7. Technical Data

Table 1

Size Connection

estimated Consumption

per Cycle at 6bar

[cm³]

estimated PLUS-

Consumption

per Cycle at 6bar

[cm³]

Attachment Screw

Category of Solidity

8.8

tightening

Torque

[ Nm ]

12 M5 7 20 M4 2,8

15 M5 11 35 M4 2,8

20 M5 19 63 M5 5,5

25 M5 21 68 M6 9,5

30 M5 31 121 M8 23,0

35 M5 31 129 M8 23,0

45 M5 41 175 M10 46,0

55 M5 41 175 M10 46,0

65 M5 41 175 M10 46,0

Data concerning air consumption is approximate.

Technical modifications reserved.

Manufacturer's Statement

_____________________________________________________________________________________________

in terms of the EC – Machinery Directive 98/37/EG, Appendix II B

Herewith we certify that the type of construction

Product's Name: Clamping Elements

Part Number: MK / MKS

is – in its delivered version - intended to be installed into a machine or for the assembly with other machines in order to create a

new machine, and that its start-up is prohibited until it is proved that the machine, in which t he above-named machine shall be

integrated, corresponds to the EC – Machinery Directive 98/37/EG.

....................... ............................ ............................. ..........

Legally binding signature (business management)

Air Filter

Adjusment Screw

Spring Storage

Air Connection

Loading...

Loading...