Page 1

INSTALLATION AND

OPERATING INSTRUCTIONS

Handling

technology

HM1000 series

magnetic gripper

THE KNOW-HOW FACTORY

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS: HM1000 series magnetic gripper

1. Supporting documents

NOTE:

The following documents are available for download on our website. Only the documents currently available on

the website are valid.

• Catalog

• Drawings, performance data, information about accessory parts, etc.

• Technical data (data sheets)

• General terms and conditions, including warranty information

2. Proper use

NOTE:

The magnetic grippers of the HM1000 series may only be used in their original state, with original accessories,

without any unauthorized changes and within the scope of their dened parameters for use.

Zimmer GmbH accepts no liability for any damage caused by improper use

The magnetic grippers of the HM1000 series are based on the eect of a permanent magnet. This gripper may only be used to

handle workpieces made of ferromagnetic materials. Handling workpieces that generate their own active electromagnetic eld or

themselves act as a permanent magnet may lead to malfunctions and therefore is regarded as improper use.

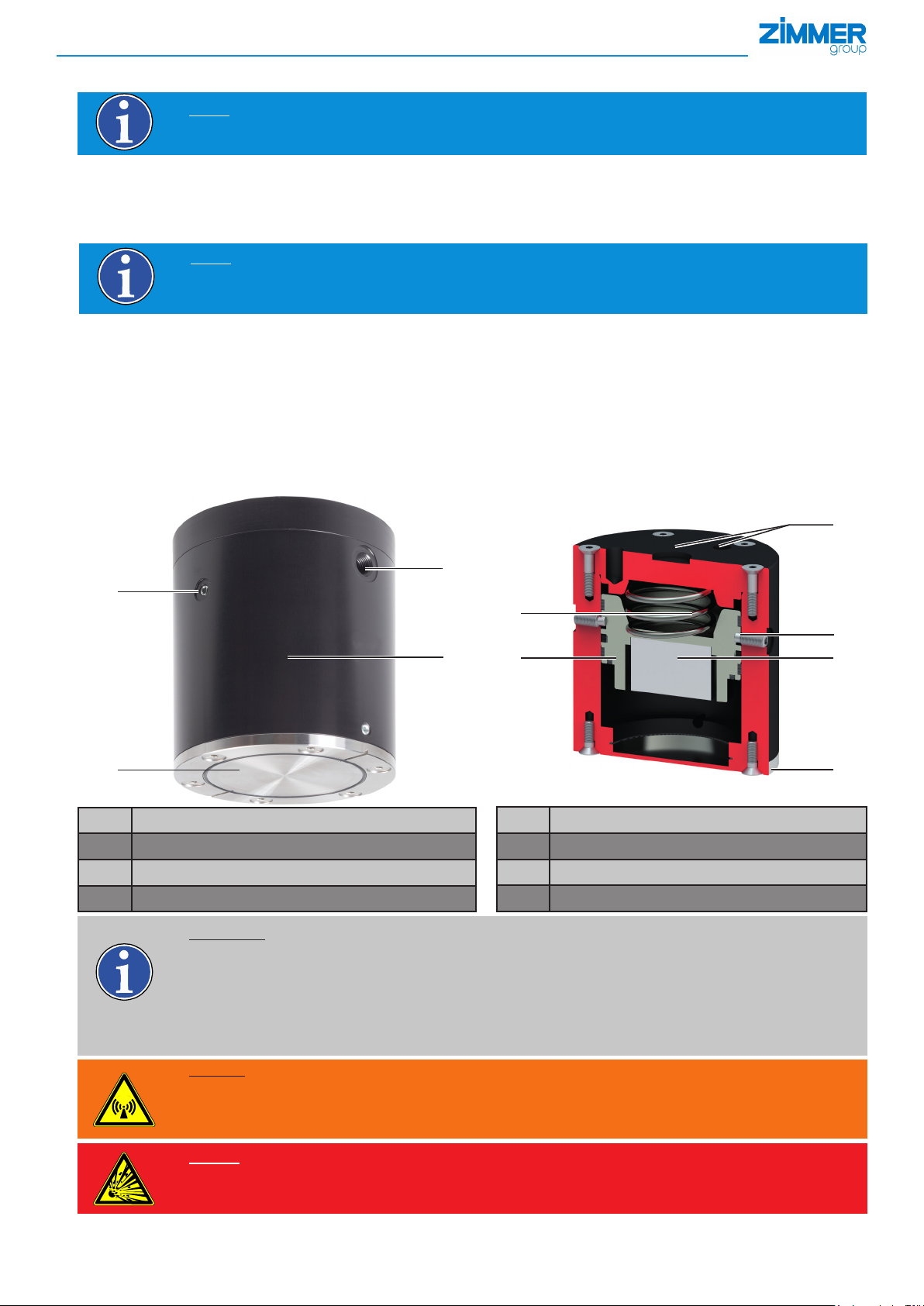

3. Function

The magnetic grippers of the HM1000 series generate the gripping force, referred to here as the adhesive force, by means of a

permanent magnet.

A demagnetized contact plate provides for process-reliable depositing of the workpieces. The residual holding force is less than 1 N.

A spring holds the permanent magnet in the working position. A single-acting pneumatic cylinder moves the permanent magnet into the

detachment position only to deposit the workpiece. This means that only one pneumatic power supply line is needed for the gripper.

8

4

2

5

6

7

Mounting and positioning

1

Spring accumulator

2

Permanent magnet

3

Transport lock

4

Housing, hard-coated aluminum

5

Single-acting pneumatic cylinder

6

Demagnetized contact plate

7

Pneumatic connection

8

Information:

The adhesive forces depend on the surface quality and material thickness of the workpieces to be handled.

As a rule: "The rougher the surface, the lower the residual adhesive forces."

"The lower the material thickness, the lower the holding forces."

1

4

3

7

The holding force depends on the ferromagnetic properties of the workpieces being handled.

Assuming a holding force of 100% for technically pure iron, the following materials may be assumed to have:

St37: 0.94% / St34: 0.82% / St50: 0.75% / St70: 0.7% / 20MnCr5: 0.5% / Cast iron: 0.3%

Warning:

The magnetic gripper contains a permanent magnet. The magnetic eld can pose a health hazard to persons with

electronic implants (such as a pacemaker).

► Health hazard

► Avoid staying within the eective range of the magnetic eld

Danger:

Unintended ignition sources can arise from the magnetic eld. For this reason, use within potentially explosive

environments is not permitted.

► Risk of fatal injury

DDOC00184 deu / 1/21/2019 / 0

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

Page 3

INSTALLATION AND OPERATING INSTRUCTIONS: HM1000 series magnetic gripper

4. Technical data

*1)

HM1030NC HM1046NC HM1078NC HM1097NC

Adhesive force (for 0 mm air gap, high surface quality ) N 27 65 220 450

Min./max. operating pressure bar 3 / 8

Min./max. operating temperature °C +5 / +80

Pneumatic connection M5 M5 G1/8" G1/8"

Cylinder volume per cycle

cm³

3.5 9 75 250

Weight kg 0.06 0.28 1.2 2.2

Ø pitch circle mounting holes Ø - 30 45 60

Mounting screws, quality 8.8 mm - 3 x M5x7 3 x M8x9 3 x M10x15

Permitted tightening torque N - 6.03 24.93 49.45

Ø centering hole for centering disk Ø - 10H7 15H7 20H7

Threaded stem Ø M10 x 13.5 - - -

*1) Please always compare the technical data with the corresponding tables on the Internet at www.zimmer-group.de!

5. Installation

► The dimensions for a particular mounting piece 2 can be taken from the

drawings on the product data sheets.

The product data sheets and CAD data are available on our website,

www.zimmer-group.de, in all common data formats

The drawing to the right shows the HM1078 as an example

The mounting piece 2 shown to the right is a ball joint and is

available as an accessory matching the gripper

► Observe the permitted tightening torque (see Tab. Technical data)

► The gripper is aligned on the mounting piece using a centering disk 3 that

matches the gripper and is also available as an accessory.

► Establish the pneumatic connection (see Tab. Technical data)

1234

5.1 Installation of HM1030

Information:

The HM1030 gripper is unique. Due to its small size, it is mounted and connected

to the pneumatic system by a central, threaded Ø M10 stem, which also contains a

pneumatic ØM5 connection.

DDOC00184 deu / 1/21/2019 / 0

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

Page 4

INSTALLATION AND OPERATING INSTRUCTIONS: HM1000 series magnetic gripper

5.2 Transport lock for HM 1078 and HM1097

A transport lock 4 holds the permanent magnet in the retracted position during

transportation and storage to protect against the escaping magnetic eld.

This transport lock must be removed before the unit is rst put into operation.

► Pressurize the gripper with at least 3 bar

► Unscrew the transport lock 4

► Close the now open hole with the included dummy plug em

4

em

6. Maintenance

► The magnetic grippers of the HM1000 series are maintenance-free for up to 5 million gripping cycles.

Even though the magnetic grippers are, as mentioned, maintenance-free, perform a regular visual inspection to check for

any corrosion, damage and contamination.

Clean the magnetic gripper as needed using a commercially available machine cleaning agent and then apply an anti-

corrosion agent to the housing.

INFORMATION:

Complete disassembly of the magnetic gripper for gasket maintenance is possible after 5 million cycles

only at Zimmer.

7. Declaration of incorporation in terms of the EC Machinery Directive 2006/42/EC on Machinery (Annex II 1 B)

In terms of the EU Machinery Directive 2006/42/EC (Annex II 1 B)

Name and address of the manufacturer: Zimmer GmbH, Im Salmenkopf 5, 77866 Rheinau, Germany

Phone: +49 7844 91380, www.zimmer-group.de

We hereby declare that the incomplete machines described below

Product designation: magnetic gripper

Type designation: HM10

satisfy the following basic requirements of the Machinery Directive 2006/42/EC:

No. 1.1.2., No. 1.1.3., No. 1.1.5., No. 1.3.2., No. 1.3.4., No. 1.3.7., No. 1.5.3., No. 1.5.4., No. 1.5.8., No. 1.6.4., No. 1.7.1., No. 1.7.4.

We also declare that the specic technical documents were produced in accordance with Annex VII Part B of this Directive.

We undertake to provide the market supervisory bodies with electronic versions of special documents for the incomplete machine

through our documentation department, should they have reason to request them.

The incomplete machine may only be commissioned if the machine or system in which the incomplete machine is to be

installed has been determined to satisfy the conditions of the Machinery Directive 2006/42/EC and the EC Declaration of

Conformity has been produced in accordance with Annex II 1 A.

Authorized representative for compiling the relevant technical documents

Kurt Ross See manufacturer's address Rheinau, Germany, 7/25/2013 Martin Zimmer

First name, last name Address (Place and date of issuing) (Legally binding signature)

Managing Director

DDOC00184 deu / 1/21/2019 / 0

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

Loading...

Loading...