Page 1

INSTALLATION AND

OPERATING INSTRUCTIONS

Handling

technology

GPP/GPD5000IL series

"The Hybrid"

THE KNOW-HOW FACTORY

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

Link

IO-

www.IO-Link.com

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

Content:

1. Supporting documents 3

2. Proper use 3

3. Personnel qualication 3

4. Safety notes 3

5. Product description 4

5.1 GPP5000IL function (NO/NC) 4

5.2 GPD5000IL function (NO/NC) 5

5.3 GPP/GPD5000IL function (N) 5

6. Installation 5

6.1 Safety notes 5

6.2 Installing the gripper 5

6.3 Installing the gripper ngers 6

6.4 Static charge 6

6.5 Inuencing the position sensor 6

6.6 Pneumatic connection 6

7. Commissioning 6

7.1 IO-Link commissioning 6

7.2 Control 7

7.3 LED display 8

7.4 Process data 8

7.5 Control with cyclical process data 9

7.5.1 Procedure for data transfer 9

7.5.2 "ControlWord" parameter 10

7.5.3 "DeviceMode" parameter 11

7.5.4 "WorkpieceNo." parameter 11

7.5.5 "TeachPosition" parameter 12

7.5.6 "PositionTolerance" parameter 12

7.5.7 "StatusWord" parameter 13

7.5.8 "Diagnosis" parameter 13

7.5.9 "ActualPosition" parameter 14

7.6 Sensing of end positions 14

7.7 Service parameters 14

7.7.1 StatusWord 0x40 14

7.7.2 Diagnostics 0x41 14

7.7.3 Cycle counter 0x42 15

7.7.4 System temperature 0x43 15

7.7.5 ControlWord 0x44 15

7.7.6 Error code 0x45 15

7.7.7 Error code 0x46 15

7.7.8 Operating seconds counter 0x47 15

7.7.9 ActualPosition 0x100 16

7.7.10 TeachPosition 0x101 16

7.7.11 WorkpieceNo. 0x102 16

7.7.12 DeviceMode 0x103 16

7.7.13 PositionTolerance 0x104 16

7.7.14 Current operating pressure 0x110 16

7.7.15 Pressure switch bottom 0x111 17

7.7.16 Pressure switch top 0x112 17

7.7.17 Pressure hysteresis 0x113 17

7.7.18 Base/Work position switching thresholds 0x114 17

7.7.19 Movement detection 0x115 17

8. Error diagnostics 18

9. Accessories 19

10. Glossary 20

11. Maintenance 21

12. Fault exclusion 21

13. Installer's Declaration (in accordance with the Machinery Directive) 22

14. Declaration of Conformity (in accordance with the EMC Directive) 23

15. Your notes 24

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

2

Page 3

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

1. Supporting documents

Note:

The following documents are available for download on our website.

Only the documents currently available on the website are valid.

• Catalog

• Drawings, performance data, information about accessory parts, etc.

• General terms and conditions, including warranty information

2. Proper use

Note:

The gripper should only be used in its original state with its original accessories, without any unauthorized

changesandwithinthescopeofitsdenedparametersforuse.

Zimmer GmbH shall accept no liability for any damage caused by improper use.

The gripper is designed exclusively for operation using a 24 V DC power supply.

The operating pressure is in the range of 3-8 bar for standard grippers and 4-7 bar for the respective NC/NO versions.

The gripper is used as dened under "Proper use" in enclosed rooms to temporarily grip, handle and hold parts.

The gripper is not suitable for clamping workpieces during a machining process.

Direct contact with perishable goods/food is not permitted.

3. Personnel qualications

Installation, commissioning and operation may be undertaken by trained specialists only. They must have read and understood the

installation and operating instructions in full.

4. Safety notes

1. Installation, commissioning, maintenance and repairs may only be performed by qualied experts in accordance with

these installation and operating instructions.

2. The gripper is state-of-the-art. It is tted to industrial machines and is used to hold workpieces. The following are ex-

amples of situations in which the gripper may cause a hazard:

- the gripper is not properly tted, used or maintained

- the gripper is not used for its intended purpose

- failure to observe the local regulations (legislation, guidelines, directives), such as the EC Machinery

Directive,

- the Accident Prevention Regulations (UVV) and the assembly and operating instructions

are not observed.

3. The gripper may be used only in accordance with its proper use and technical data.

ZIMMER GmbH shall accept no liability for any damage caused by improper use.

4. Any use other than the proper use requires written approval from Zimmer GmbH

5. Make sure that the energy supply is disconnected and before you install, retool, maintain or repair the gripper.

6. In case of maintenance, renovation or expansion work, remove the gripper from the machine and carry out the work

outside the danger zone.

7. When commissioning or testing, make sure that the gripper cannot be actuated by mistake.

8. Modications to the gripper, such as adding drill holes or threads, may be made only with prior approval from Zimmer

GmbH.

9. The specied maintenance intervals and compressed air quality specications are to be observed; also refer to the

Maintenance section. When using the gripper under extreme conditions (see Item 11), the maintenance interval must

be adapted depending on the extent of the contamination. Please contact our hotline for this purpose.

10. Use of the gripper under extreme conditions, such as aggressive liquids and abrasive dust, is subject to prior approval

from Zimmer GmbH

11. When disassembling grippers with integrated springs, exercise increased caution because spring tension is always

present.

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

3

Page 4

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

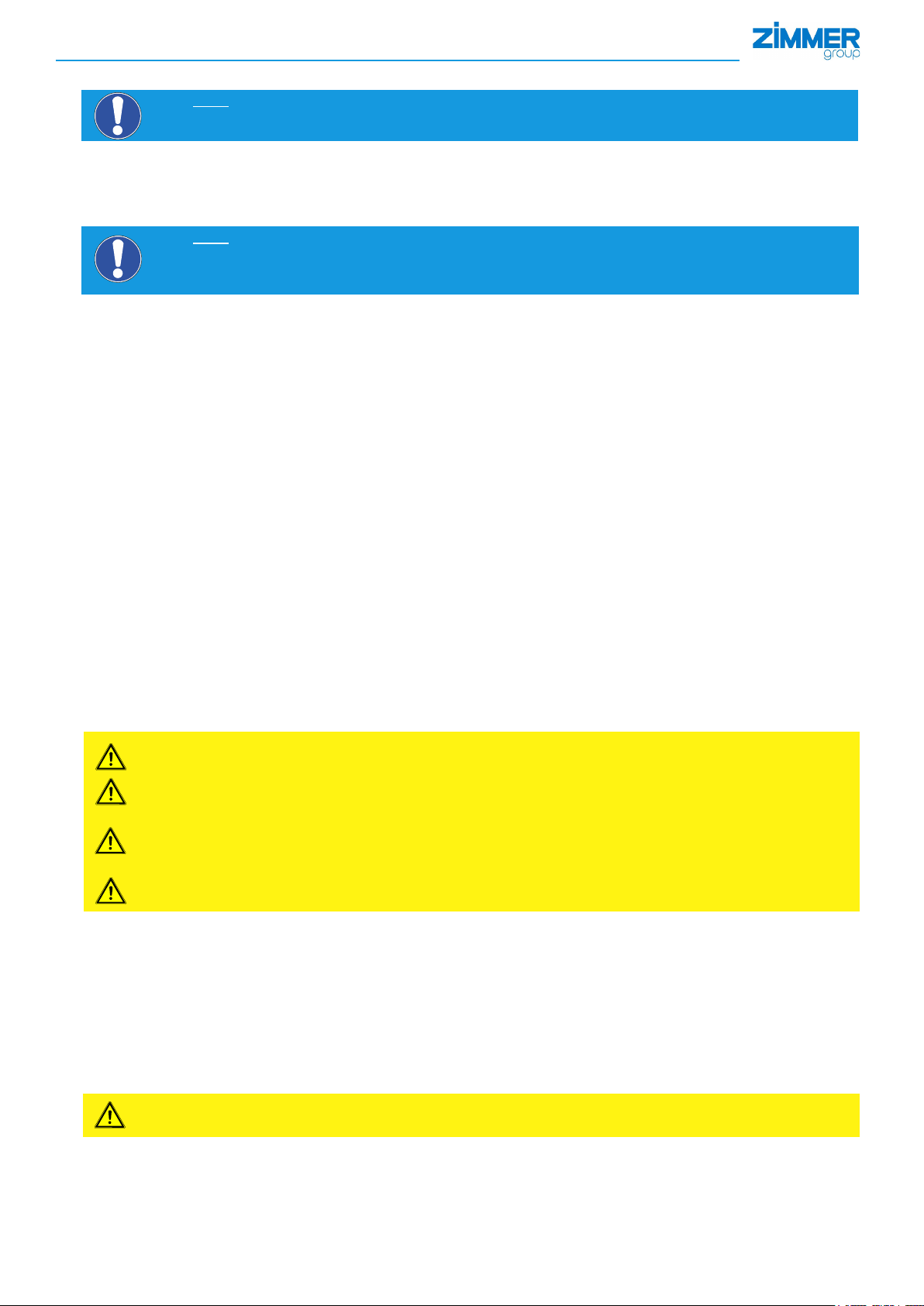

5. Product description

• Alternating ventilation moves the internal pneumatic piston 1

up and down.

• The power generated in this process is transferred 2 to

the gripper jaws 3 via a kinematic system to produce the

gripping force.

• The double-lip seal 5 reliably prevents lubricant from

escaping and guarantees protection with IP 64 from the

exterior.

• Integrated gripping force safety device 4 (only for NC / NO)

Spring inserted in the cylinder chamber used for energy

storage

• The pneumatic piston is controlled by integrated

3/2 NC 24 V DC directional valves. 6

• Communication is carried out over an IO-Link interface 7.

3

2

5

4

1

6

7

The 3-jaw concentric grippers from the GPD5000IL series

operate according to the same principle.

3

2

5

4

1

7

6

INFORMATION:

Useofltered,compressedair,oil-free,inaccordancewithENISO8573-1,Class3.4.3

Note:

The gripping force safety device with an integrated spring as an energy storage unit is only available

fortheNCandNOversions.TheNversionhasno gripping force safety device in either gripping direction.

5.1 GPP5000IL function (NO/NC)

The gripper ngers of the parallel gripper are arranged successively on two shared

steel guide rails and can be moved alongside each other.

Compressed air that moves a piston is used to supply power.

The stroke movement of the piston is diverted to both gripper jaws via a connecting rod.

This generates the movement of the gripper jaws.

An internal spring is used to retain the gripping force when there is a drop in pressure.

The gripper is suitable for outward gripping. (NO = normally open)

The gripper is suitable for inward gripping. (NC = normally closed)

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

NO NC

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

4

Page 5

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

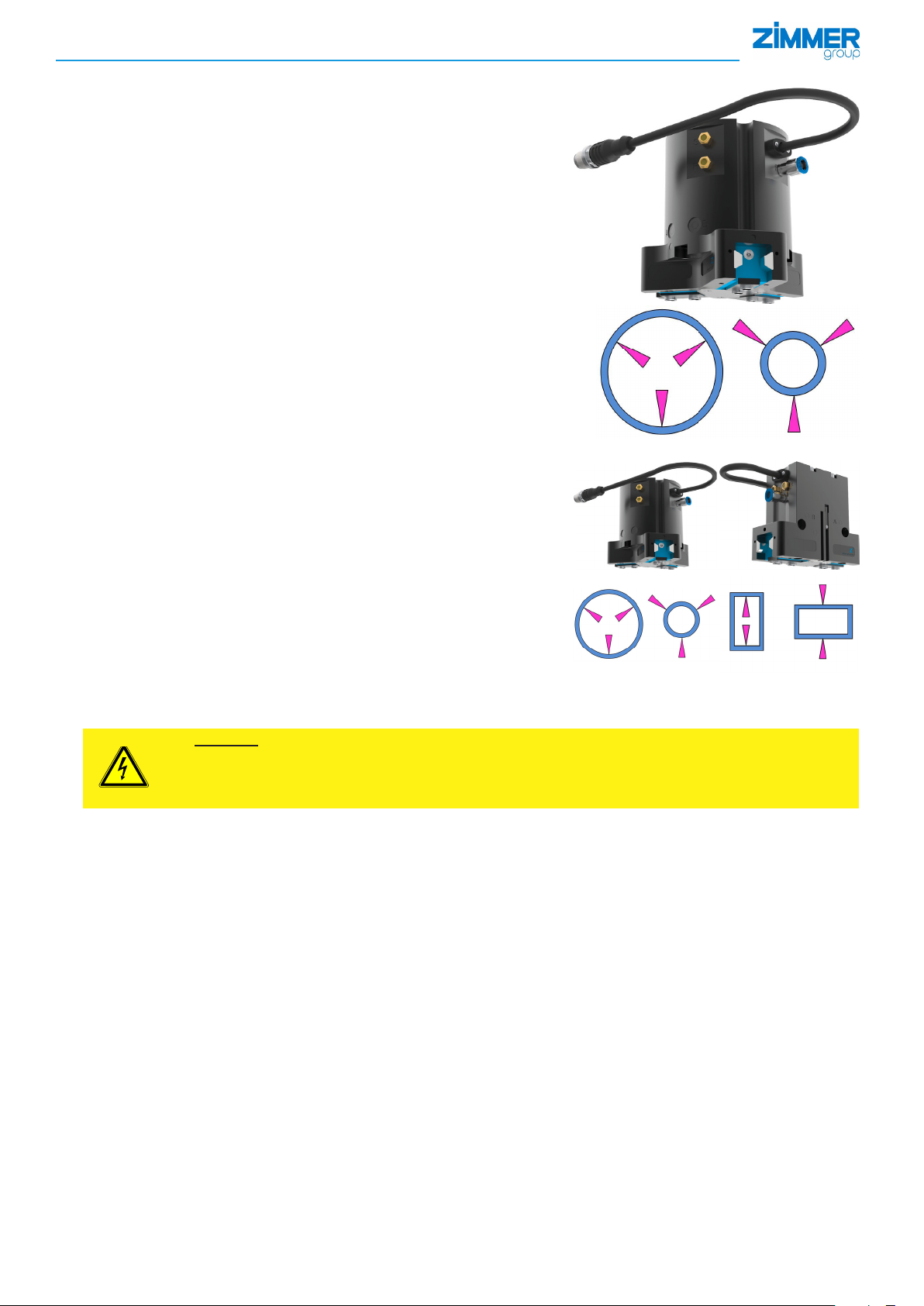

5.2 GPD5000IL function (NO/NC)

The gripper ngers of the three-jaw gripper are each positioned between two

steel guide rails.

Compressed air that moves a piston is used to supply power.

The stroke movement of the piston is diverted to both gripper jaws via a

connecting rod.

This generates the movement of the gripper jaws

An internal spring is used to retain the gripping force when there is a drop in

pressure.

The gripper is suitable for outward gripping. (NO = normally open)

The gripper is suitable for inward gripping. (NC = normally closed)

NO

5.3 GPP/ GPD5000IL function (N)

The gripper ngers of the three-jaw gripper are each positioned between two

steel guide rails.

Compressed air that moves a piston is used to supply power.

The stroke movement of the piston is diverted to both gripper jaws via a

connecting rod.

This generates the movement of the gripper jaws.

There is no gripping force retention in the event of a pressure or voltage loss.

The gripper is suitable for outward or inward gripping.

NC

6. Installation

6.1 Safety notes

CAUTION:

Bleed the pressure supply and switch o the power supply for the electronics before any assembly, installation

or maintenance work.

► Risk of injury

6.2 Installing the gripper

The gripper can be installed from several sides on a mounting surface that meets the specications for evenness.

If the length of the mounting surface is <100 mm, the permitted unevenness is <0.02 mm.

If the length of the mounting surface is >100 mm, the permitted unevenness is <0.05 mm.

The following work steps are to be carried out to install the gripper:

► Insert centering sleeves/alignment pins into the provided matching parts on the gripper.

► Position the gripper on the intended mounting surface using the centering sleeves/alignment pins.

► Secure the gripper with cylinder screws of strength class 8.8.

► Connect the M12 5-pin supply cable for the IO-Link Port Class B.

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

5

Page 6

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

6.3 Installing the gripper ngers

Before installing the gripper ngers, make sure they are of a suitable length for the selected gripper variant.

The following work steps should be performed to install the gripper ngers:

► Insert centering sleeves into the provided matching parts on the gripper jaws

► Position the gripper ngers on the gripper jaws using the centering sleeves

► Secure the gripper ngers using cylinder screws with strength class of at least 8.8

NOTE:

For details on the tightening torque, screw diameter and maximum weight and length of the gripper ngers, refer to

the product data sheet.

6.4 Static charge

Many dierent non-conductive parts move around in the gripper. As a consequence, high voltages can arise as a result of

electrostatic charges, which can also discharge to the component. If this is not desired, it must be ensured that the gripper can be

discharged of electrostatic charges via its mounting surface.

NOTE:

Grounding the gripper attachment is recommended if parts sensitive to electrostatic discharge come into contact

with the gripper.

6.5 Inuencing the position sensor

In the adjacent gure, an area in which no magnets or components with

ferromagnetic properties may be fastened is marked.

This can have a signicant inuence on accuracy of the position sensor and/

or result in a malfunction of the position sensor.

NOTE:

The position sensor itself must never be covered up by fer-

romagnetic attachment or design elements.

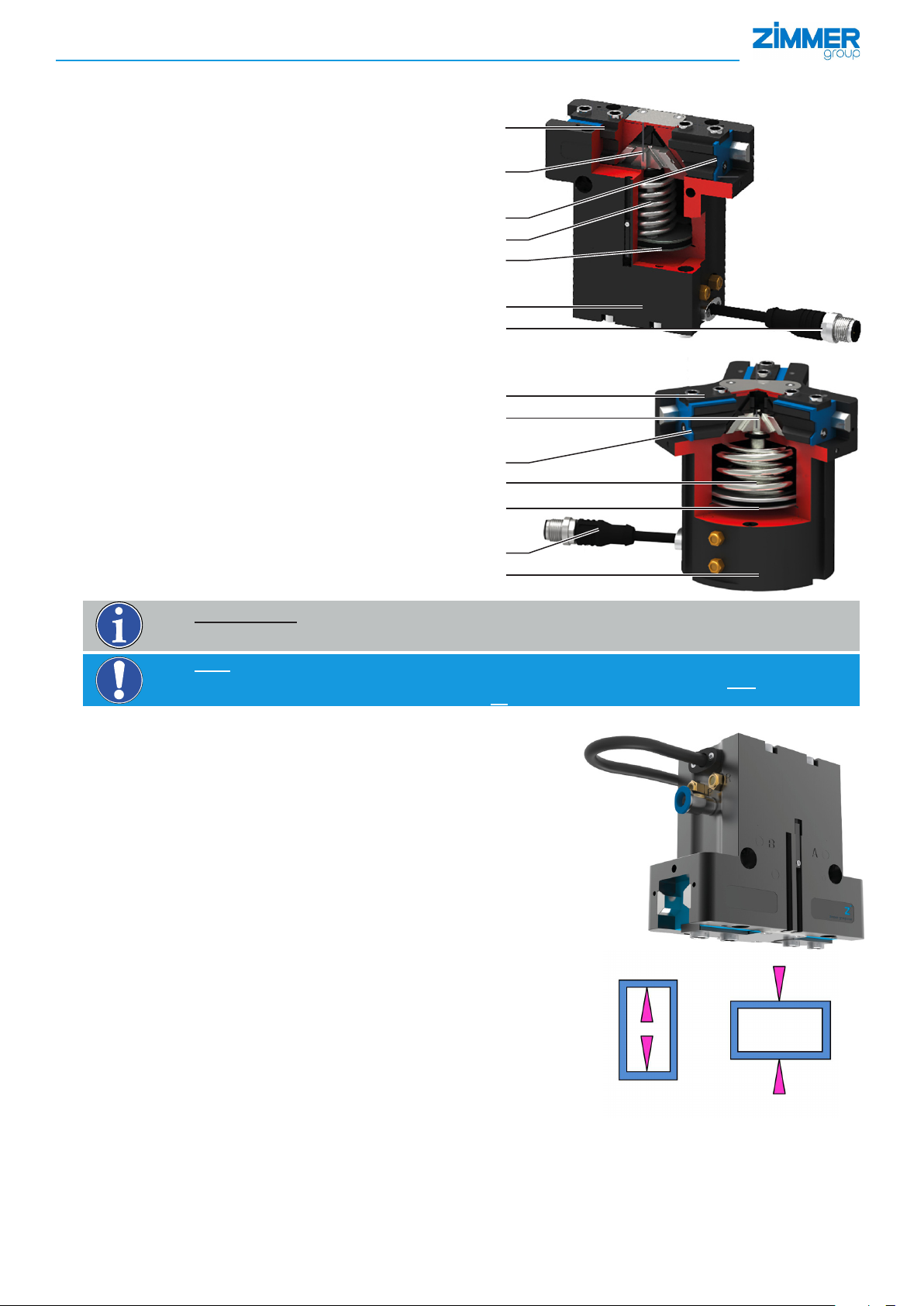

6.6 Pneumatic connection

7 Connection "R": Exhaust air with

mounted silencer

8 Connection "S": Exhaust air with

mounted silencer

9 Connection "P": Compressed air

8

9

7

INFORMATION:

The pneumatic connections A and B right on the gripper are not used and are closed.

For applications with an IP64 protection class, we recommend installing hoses on the "R" and "S" connections

for diverting the exhaust air to prevent the condensate from damaging the silencers.

7. Commissioning

7.1 IO-LINK commissioning

► Connecting the gripper to the IO-Link master

► Ensuring the supply voltage (for Port Class A additional supply via Y-cable)

8

7

9

Pin Color Function Explanation

1 Brown

2 White

3 Blue

4 Black

5 Gray

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

+24V DC sensor Power supply for IO-Link communication

+24V DC actuator Actuator supply voltage

GND sensor Sensor 0 V DC supply voltage

C/Q IO-Link communication

GND actuator Actuator 0 V DC supply voltage

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

6

Page 7

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

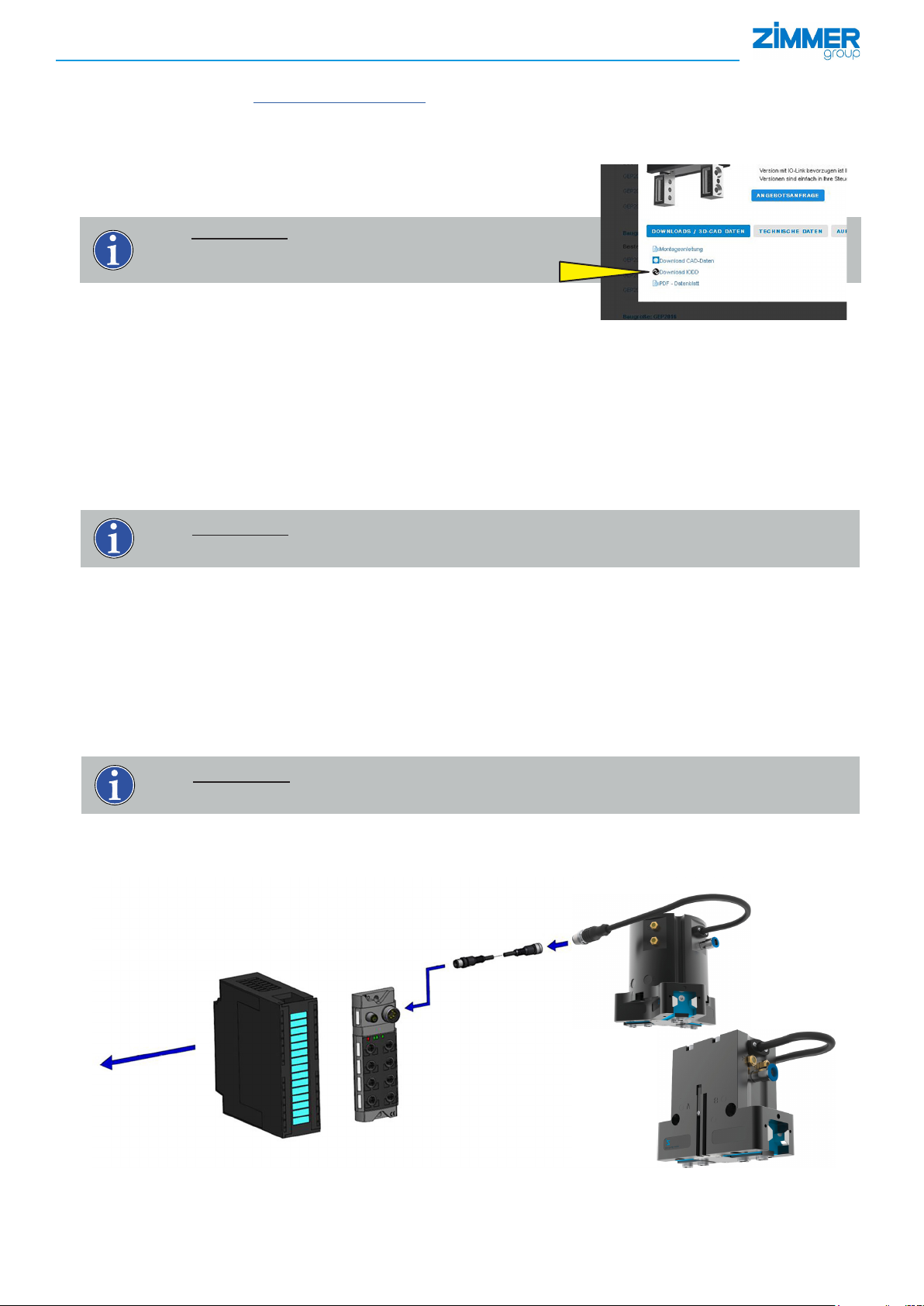

► Importing the IODD (device description) into the control system

Go the website https://ioddnder.io-link.com

Search for "Zimmer Group" in the search window that appears

Select the desired device and download the corresponding *.zip les

The complete content of the zip les is required for importing within the control

INFORMATION:

The IODD le can also be downloaded from

the product datasheet on our website.

Picture shown as example

When the hardware conguration is complete and the IO-Link connection to the gripper is established,

some data must already be visible in the process input data.

Some control systems demand a byte swap to bring this process data into a sequence that makes sense.

► To determine whether a byte swap is necessary, you can check Bit 6 [GripperPLCActive] in the "StatusWord".

► For this purpose, it is necessary to determine whether bit 6 [GripperPLCActive] is active in the rst or second status byte.

This bit must be the only one active in this byte.

If bit 6 in the rst byte is active, a byte swap still has to be applied here.

If bit 6 in the second byte is active, the bytes already have the correct sequence and you can continue with the rest of

the commissioning.

INFORMATION:

It is mandatory to carry out a verication of the process data

The gripper is controlled via IO-Link by means of the cyclical process data and the acyclical service data, with a cycle time of 5 ms.

During a communication cycle the IO-Link master sends 8 bytes to the gripper and receives 6 bytes of process data.

If the gripper is operational, a "1" must be sent in the "ControlWord" during a cold start for safety reasons. This "1" tells the gripper to

accept the current values that have been transmitted in the process data.

The gripper is now ready for operation. The gripper then moves to the proper position after receiving the corresponding command

in the "ControlWord" (decimal 256 or 512).

The gripper features bidirectional behavior. This means that the gripper cannot position itself on intermediate values. Each movement command is executed to the maximum possible position.

INFORMATION:

For more information, refer to the "StatusWord" section

7.2 Control

The gripper is controlled via IO-Link by means of the cyclical process data, with a minimum cycle time of 5 ms. During a communication cycle the IO-Link master sends 8 bytes to the gripper and receives 6 bytes of process data.

Fieldbus or PLC

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

IO-Link master

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

7

Page 8

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

The gripper is connected to the IO-Link master by a 5-pin M12 connector, in accordance with Port Class B. In doing so,

pin 1 (24 VDC) and pin 3 (0 VDC) are for supplying power.

Pin 2 (24 VDC) and pin 5 (0 VDC) are required for auxiliary power supply to the gripper.

Pin 4 is used for IO-Link communication between the gripper and the IO-Link master.

The actuator supply voltage acts on the internal valves. As a result of this voltage being switched-o, the valves will no longer be

able to be switched. In the event of an emergency (switch-o of the actuator voltage), the gripper bleeds the pistons and, depending

on the design of the gripper (N, NC, NO), there is no gripping force safety device present.

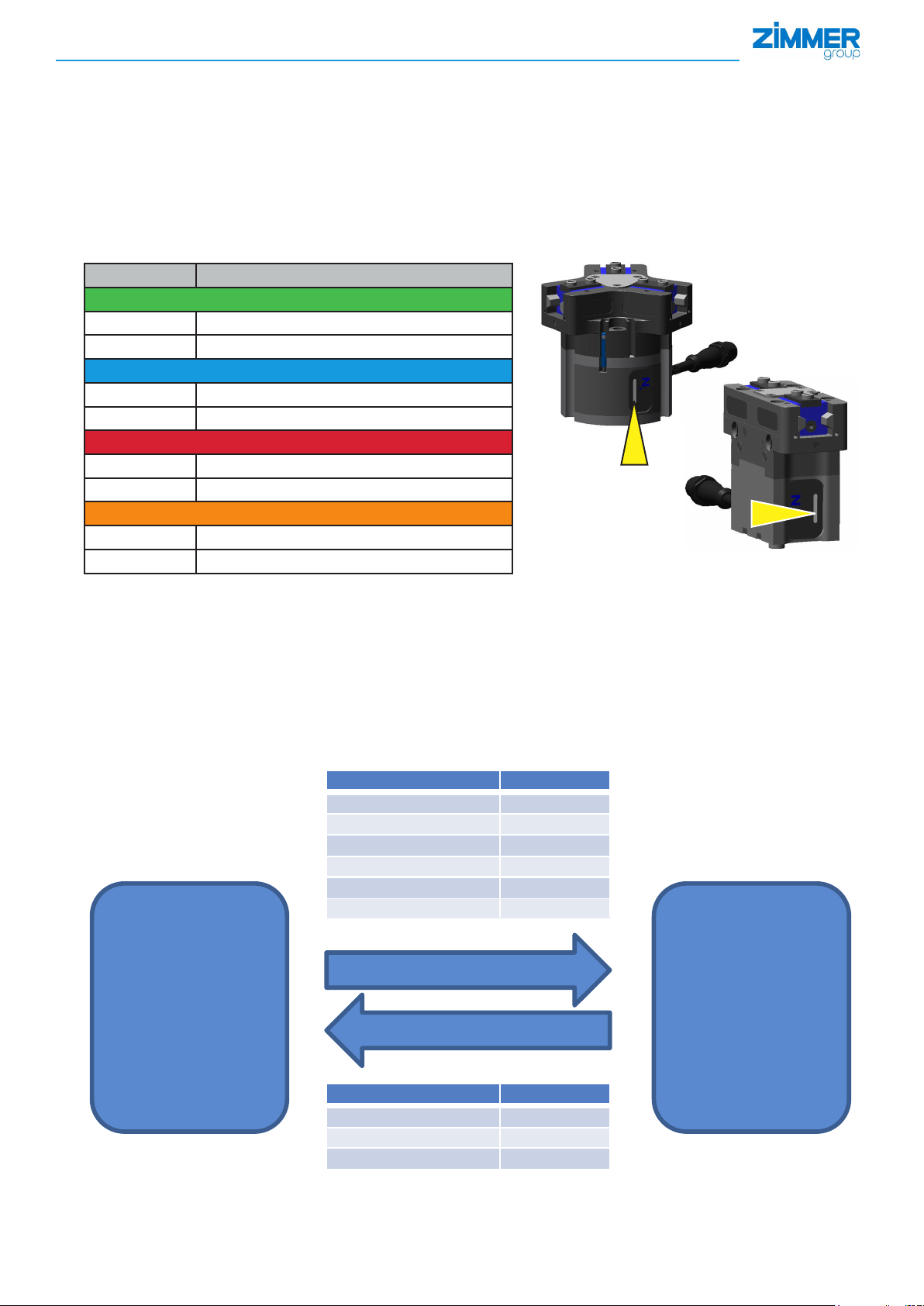

7.3 LED display

The color of the LED reects the status of the gripper.

Status Function

Green

On continuously Teach position

Flashing

Not currently assigned

Blue

On continuously Base position/Work position

Flashing

Not currently assigned

Red

On continuously The gripper has a fault

Flashing No IO-Link connection is available

Orange

On continuously Gripper is in undened position

Flashing

Not currently assigned

7.4. Process data

It is possible to control the gripper solely by the process data transmitted in each IO-Link cycle. To use this method of control,

a "0" must be continuously transmitted in the workpiece number.

As a result, the currently applied process data is used as a process parameter.

Unlike the gripping force and the "TeachPosition," the "ControlWord" and the "WorkpieceNo." are always valid!

If the gripper is controlled via the stored workpiece records, the values entered there are used as the current values. As a result, the

process data words "gripping force" and "TeachPosition" are devalued. The "WorkpieceNo." parameter is to be recognized as being

a selector switch.

Name Data type

ControlWord

DeviceMode.

WorkpieceNo.

TeachPosition

RESERVE

PositionTolerance

Outputs

UINT 16

UINT 8

UINT 8

UINT 16

UINT 8

UINT 8

GPP/GPD5000ILControl system

Inputs

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

Name Data type

Status

Diagnostics

ActualPosition

UINT 16

UINT 16

UINT 16

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

8

Page 9

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

7.5 Control with cyclical process data.

In general, the gripper can be controlled only by the cyclically exchanged process data.

However, this is possible only if a "0" is transmitted in the "WorkPosition" process data word.

Since very dierent gripper jaws exist for the gripper series, the required travel path can be determined directly with the gripper or

specially calculated by hand.

The process is as follows (gripping from the outside to the inside):

Step 1:

Insert the workpiece and set the "MoveToWork" bit (ControlWord = 512/0x200) by means of the "ControlWord" parameter.

This command makes the gripper move toward "WorkPosition" until it touches the workpiece.

Step 2:

If the gripper has been successfully stopped by the workpiece, then the corresponding travel path for this workpiece can be read

o using the actual position.

Step 3:

The travel path can be transferred to the gripper using the "TeachPosition." This allows the gripper to transmit feedback

about whether it has gripped the correct workpiece to the control system using the "Teach" bit in the "StatusWord"

(StatusWord = 512/0x0200). It may be necessary to adjust the position tolerance.

Step 4

To use this method, a "0" must be transmitted to the gripper in the WorkpieceNo." parameter.

Steps 1 and 2 can be repeated for as many workpieces as desired, and this allows dierent workpieces to be gripped securely

using the gripper.

The "StatusWord" parameter always tells the controller whether the gripper has gripped the workpiece.

INFORMATION:

The status of the gripper should be used to check whether a workpiece has been gripped correctly.

The position measurement resolution is 0.01 mm.

The position measurement accuracy is 0.01 mm.

If the "ActualPosition" parameter is used for detecting the workpiece, then uctuations around the exact value

must be taken into consideration during start-up.

7.5.1 Procedure for data transfer

All data that is transmitted to the gripper and is described in subsequent sections must be transmitted using the "handshake"

procedure.

INFORMATION:

This procedure is called "handshake" because it enables a "clean" transmission.

Data transmission takes place from "hand to hand" (between the control system and gripper).

"HANDSHAKE" procedure

The data transmission starts with the transmission of the

Subsequently, the response of the gripper must be tested using the

Data transmission is done by changing the corresponding process data and sending the "acquire" command by the

ControlWord = 0x01

The data transfer is completed with the

The gripper acknowledges this with

ControlWord = 0x00

ControlWord = 0x00

Status bit 12 = False

Status bit 12 = True

and the corresponding response from the gripper by

to the gripper.

.

.

the

"FAULT ACKNOWLEDGMENT" procedure

If the gripper has a fault, the error bit is set in the status word.

This fault can be reset by sending the

Status bit 12 = False

ControlWord = 0x8000

.

NOTE:

Not all faults can be reset. There are faults for which the error message is not reset after acknowledgment. The

user must wait until the gripper resets the fault by itself.

For example: Overtemperature fault case.

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

9

Page 10

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

Outputs: Process data from the IO-Link master to the GEP/GED5000IL

7.5.2 "ControlWord" parameter

Structure of the control word

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

Byte 1

Error

Reset

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

- - - - - "MoveToWork" "MoveToBase"

Byte 0

Note:

In the "ControlWord" parameter, only one single bit may be set at a time.

Only the values listed in the following table are valid.

Bit 0: "Datatransfer":

Setting this bit causes the gripper to take over the data transmitted in the process data ("WorkpieceNo." = 0) or the data

Bit 1: "WritePDU":

Setting this bit tells the gripper that it should write the current process data to the selected

workpiece recipe.

Bit 2: "ResetDirectionFlag":

Setting this bit tells the gripper that the direction ag needs to be reset. This makes it possible to repeatedly move to a

Adjust - - - Teach ResetDirectionFlag- WritePDU Data transfer

Decimal value Hexadecimal value

Data transfer

WritePDU

Teach

Adjust

MoveToWork

MoveToBase

Error Reset

stored in the workpiece data records ("WorkpieceNo." = 1 to 31) as the active data set.

position. This is useful when switching workpiece recipes.

1 0x1

2 0x2

8 0x8

128 0x80

256 0x100

512 0x200

32,768 0x8000

Bit 3: "Teach"

Setting this bit tells the gripper to save the current position as the "TeachPosition" in the selected "WorkpieceNo."

INFORMATION:

This only works if no "0" is transmitted in the workpiece No.!

Bit 7: "Adjust":

If no other bit is set in the control word, the "adjust" bit can be used to readjust the end position of the ngers. The "adjust"

bit has to be set briey. Afterwards, the gripper runs through an automated routine, which runs through a gripping cycle in

order to learn the end positions.

INFORMATION:

For more information on the dierent data sets of the "Adjust" parameter, refer to the "End positions" section.

Bit 8: "MoveToBase"

Setting this bit tells the gripper that it should move to the "BasePosition."

Bit 9: "MoveToWork"

Setting this bit tells the gripper that it should move to the "WorkPosition."

Bit 15: This bit can be used to acknowledge all errors that can be reset and thus reset them.

You can nd out whether an error is present from the error list.

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

10

Page 11

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

Details

Name ControlWord

Data type UINT 16

Permission Write

Transmission Cyclical

Value range 0–65535

7.5.3 "DeviceMode" parameter

This parameter is used to transmit the desired operating mode to the gripper.

Mode number Function

2 Switches valves o

100 Universal operation, internal and external gripping (N)

Details

Name DeviceMode

Data type UINT 8

Permission Write

Transmission Cyclical

Value range 0–255

INFORMATION:

All transmitted process data must be acquired using the "ControlWord" = 0x01 "Data transfer."

7.5.4 "WorkpieceNo." parameter

If a "0" is transmitted, the "TeachPosition" transmitted in the process data is considered valid for the gripper.

This parameter is used both for selecting the already stored workpiece data and for selecting the workpiece number record in order

to store it in the current process data.

Example: To use the data stored in workpiece record 3 ("PositionTolerance," "TeachPosition" and "DeviceMode"), a 3 (workpiece

number = 3) must be transmitted in the workpiece number of the process data.

Details

Name WorkpieceNo.

Data type UINT 8

Permission Write

Transmission Cyclical

Value range 0 - 32

INFORMATION:

For more information on the use of dierent data records of the parameter

"WorkpieceNo." refers to the "Work with workpiece numbers" section.

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

11

Page 12

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

7.5.5 "TeachPosition" parameter

The "TeachPosition" process data byte is only valid if, at the same time, the workpiece number is "0".

The "TeachPosition" tells the gripper the position at which the workpiece is expected. The "PositionTolerance" parameter can be

used to set a tolerance range around this position. Thus the gripper can distinguish whether a correct or incorrect workpiece has

been gripped. Conrmation that the correct workpiece has been gripped is communicated to the controller via the "StatusWord"

(input). If the detection is correct, the "teach" bit is set in this status word, thereby giving the user the option to monitor this work

step.

The stroke measurement system has a resolution of the position of 1/100 mm.

Product Stroke per gripper jaw Maximum "TeachPosition" (approx.)

GPP/GPD5006IL 6 mm 1200

GPP/GPD5008IL 8 mm 1600

GPP/GPD5010IL 10 mm 2000

Example: Explanation of the values using GPP5006IL

Full stroke of 6mm per gripper jaw:

"BasePosition" = 0

"WorkPosition" = 1200 (2*6*100 => 2 gripper jaws * 6 mm stroke per gripper jaw * Resolution at 1/100 mm)

The "TeachPosition" can acquire values from 0 to 1200

Details:

Name TeachPosition

Data type UINT 16

Permission Write

Transmission Cyclical

Value range 0–max. jaw stroke of the gripper

7.5.6. "PositionTolerance" parameter

This parameter can be used to transmit the current desired position detection tolerance for the workpiece to the gripper. Also see

Section 6.3.4

This can be input in mm/100 and always functions equally well in both the "+" direction and the "-" direction.

Details

Name Position tolerance

Data type UINT 8

Permission Write

Transmission Cyclical

Value range 0–255

INFORMATION:

All transmitted process data must be acquired using the "ControlWord" = 0x01 "Data transfer."

Refer to "HANDSHAKE" procedure

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

12

Page 13

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

Inputs: Process data from the IO-Link master to the GEP/GED5000IL

7.5.7. "StatusWord" parameter

Structure of the status word

Bit 15 Bit 14 Bit 13 Bit 12 Bit 11 Bit 10 Bit 9 Bit 8

Byte 1

Error

ControlWord

0x200

ControlWord

0x100

Data transfer

ok

undenedPosition WorkPosition TeachPosition BasePosition

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Byte 0

Active

- - - - - -

GripperPLC

Bit 6: This bit is active as soon as the gripper has booted up after the cold start. This bit can be used to

verify a byte swap.

Bit 8: Active if the gripper is set to "BasePosition"

Bit 9: Active if the gripper is set to "TeachPosition"

Bit 10: Active if the gripper is set to "WorkPosition"

Bit 11: Active if the gripper is not set to any Teach Position

Bit 12: This bit is used for data transmission with the handshake.

This bit is active as soon as data has been taken over by the gripper by the parameter "ControlWord"=1 (DEZ)

Bit 13: This bit is a direction ag and is active when the last movement order was in the "BasePosition" direction

Bit 14: This bit is a direction ag and is active when the last movement order was in the "WorkPosition" direction

Bit 15: Error in the gripper. If this bit is active, the error message can be dened using the "Diagnostics" parameter.

INFORMATION:

For checking the correct gripping of the workpiece, the use of the "StatusWord" is

recommended.

The "TeachPosition" tolerance can be adjusted in another process parameter.

If the actual position is used to sense the correct position, the tolerances and uctuations of the value must be

observed during programming!

Details

Name StatusWord

Data type UINT 16

Permission Write

Transmission Cyclical

Value range 0–65535

7.5.8 "Diagnosis" parameter

The value returned in the "Diagnostics" parameter corresponds to the "Diagnostics code."

► refer to the "Error diagnostics" section

Details:

Name: Diagnostics

Data format: UINT16

Permission: Read

Transmission: Cyclical

Value range: 0 to 65535

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

13

Page 14

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

7.5.9 "ActualPosition" parameter

The "ActualPosition" parameter corresponds to the current position of the gripper jaws with respect to the full stroke of the gripper

and scaled to 0.01 mm.

Example: For a GPP5006IL gripper:

Depiction of the left gripper ngers:

Depiction of right gripper ngers:

Depiction of workpiece:

"Actual position" = "0" corresponds to the "Gripper to BasePosition" status (open): ...............

"Actual position" = "800" corresponds to the "Gripper to TeachPosition" status (workpiece gripped):

"Actual position" = "1200" corresponds to the "Gripper to WorkPosition" status (closed):

Details:

Name: ActualPosition

Data format: UINT16

Permission: Read

Transmission: Cyclical

Value range: 0 to max. jaw stroke of the gripper

7.6 Sensing of end positions

Two bits in the "status" parameter give feedback about the end positions.

The "BasePosition" bit (status = 768) is set when the base position is reached.

Accordingly, the "WorkPosition" bit (status = 1024) is set when the "WorkPosition" is reached.

The gripper is preset at the factory to have its end positions sensed at the maximum potential stroke of the gripper.

For special gripper jaws, if necessary, the end positions can be reset using an automated traversing routine. This means that the

"WorkPosition" or "BasePosition" will reference itself again accordingly.

► To this end, the "adjust" bit must be set in the "ControlWord" = 2048 for at least 2 seconds

The requirement here is that no additional bit is set in the "ControlWord"

If this bit is canceled before the end of the traversing routine, the procedure must be repeated because in this case the end

positions have not been correctly determined.

Warning:

At the gripper, a movement is triggered immediately when the bit is set!

► Risk of injury

► Before setting the bit, check whether the movement range of the gripper is clear.

7.7 Service parameters

Service data is not exchanged cyclically in each communication cycle. This data is exchanged only acyclically upon request of the

IO-Link master. Transmission of this acyclical data occurs over multiple communication cycles.

7.7.1 Status 0x40

This parameter can be used to read out the "StatusWord" of the gripper.

Details:

Name: StatusWord

Data format: UINT16

Permission: Read

Transmission: Acyclical

7.7.2 Diagnostics 0x41

This parameter can be used to read out the "DiagnosisWord" of the gripper.

Note: Corresponds to the process data eld

Details:

Name: Diagnostics

Data format: UINT16

Permission: Read

Transmission: Acyclical

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

14

Page 15

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

7.7.3 Cycle counter 0x42

This parameter can be used to read out the total number of cycles of the gripper.

During each gripping cycle, this parameter is incremented.

Details:

Name: Cycle counter

Data format: UINT32

Permission: Read

Transmission: Acyclical

7.7.4 System temperature 0x43

This parameter can be used to read out the current temperature of the electronics of the gripper.

Details:

Name: System temperature

Data format: INT16

Permission: Read

Transmission: Acyclical

7.7.5 ControlWord 0x44

This parameter can be used to read out the current ControlWord of the electronics of the gripper.

Details:

Name: ControlWord

Data format: UINT16

Permission: Read

Transmission: Acyclical

7.7.6 Error code 0x45

This parameter can be used to read out the fault status as a string.

Details:

Name: ErrorcodeDataformat STRING

Data format: UINT16

Permission: Read

Transmission: Acyclical

7.7.7 Error code 0x46

Returns the number of the faults that have occurred since the last restart.

Details:

Name: Error counter

Data format: UINT32

Permission: Read

Transmission: Acyclical

7.7.8 Operating seconds counter 0x47

This parameter can be used to read out the current operating time of the electronics of the gripper within seconds.

Details:

Name: Operating seconds counter

Data format: UINT32

Permission: Read

Transmission: Acyclical

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

15

Page 16

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

7.7.9 ActualPosition 0x100

The "ActualPosition" corresponds to the current position of the gripper jaws with respect to the full stroke of the gripper, scaled to

1/100 mm.

Details:

Name: ActualPosition

Data format: UINT16

Permission: Read

Transmission: Acyclical

Value range: 0–max. jaw stroke of the gripper

7.7.10 TeachPosition 0x101

This parameter can be used to read out the "TeachPosition" of the gripper that is currently being transmitted.

Details:

Name: TeachPosition

Data format: UINT16

Permission: Read

Transmission: Acyclical

7.7.11 WorkpieceNo. 0x102

This parameter can be used to read out the workpiece number of the gripper that is currently being transmitted.

Details:

Name: WorkpieceNo.

Data format: UINT8

Permission: Read

Transmission: Acyclical

7.7.12 DeviceMode 0x103

This parameter can be used to read out the driving mode of the gripper that is currently being transmitted.

Details:

Name: DeviceMode

Data format: UINT8

Permission: Read

Transmission: Acyclical

7.7.13 PositionTolerance 0x104

This parameter can be used to read out the tolerance of the "TeachPosition" of the gripper that is currently being transmitted.

Details:

Name: PositionTolerance

Data format: UINT8

Permission: Read

Transmission: Acyclical

7.7.14 Current operating pressure 0x110 -

This parameter can be used to read out the current operating pressure of the gripper. [in 1/10 bar]

Details:

Name: ActualPressure

Data format: UINT8

Permission: Read

Transmission: Acyclical

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

16

Page 17

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

7.7.15 Pressure switch bottom 0x111

This can be used to dene the minimum operating pressure (in increments of 0,1 bar) of the gripper, below which a diagnostic message is output.

Details:

Name: Low Pressure Error Threshold

Data format: UINT8

Permission: Read/write

Transmission: Acyclical

7.7.16 Pressure switch top 0x112

This can be used to dene the maximum operating pressure (in increments of 0,1 bar) of the gripper, above which a diagnostic

message is output.

Details:

Name: Pressure switch high

Data format: UINT16

Permission: Read

Transmission: Acyclical

7.7.17 Pressure hysteresis 0x113

This parameter can be used to specify the hysteresis-range of the pressure switch [in increments of 0,01 bar].

Details:

Name: PressureHysteresis

Data format: UINT8

Permission: Read/write

Transmission: Acyclical

7.7.18 Base/Work position switching thresholds 0x114

This parameter can be used to change the position switching thresholds for the Base- and WorkPosition.

Details:

Subindex 1: From the BasePosition to the outside

Subindex 2: From the BasePosition to the inside

Subindex 3: From the WorkPosition to the inside

Subindex 4: From the WorkPosition to the outside

Subindex 0: All 4 values at once

Name: Base/WorkPosition switching thresholds

Data format: UINT16 or UINT16[4]

Permission: Read/write

Transmission: Acyclical

7.7.19 Movement detection 0x115

With this, the threshold of the movement detection can be adjusted.

Details:

Name: Movement Threshold

Data format: UINT16

Permission: Read/write

Transmission: Acyclical

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

17

Page 18

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

8. Error diagnostics

Diagnostics

message

0x0 No error - -

0x100

0x101

0x102

The actuator power supply is not

available

Max. permitted temperature

exceeded

Temperature below min.

permitted temperature

0x104 Operating pressure too high

0x105 Operating pressure too low

0x300

0x301

0x304

0x305

0x306

0x307

The congured "ControlWord" is

implausible

The congured teach position is

outside the permitted range

The congured tolerance value

is outside the permitted range

The device has an incorrect

reference position

The congured "DeviceMode" is

not plausible

Movement order cannot be

carried out

0x308 "WorkpieceNo." not available

Error Possible causes Measures

• Actuator power supply not

connected

• Cable break

• Actuator power supply not

► Test of the actuator power supply

voltage

sucient

• Ambient temperature too high

• Gripper is overloaded

► Provide sucient ventilation/cooling

► Check the object to be gripped or the

gripper jaw

• Ambient temperature too low ► Provide a sucient operating

temperature

► Install the pressure control valve to

• Pressure in pressure supply set

too high

reduce the operating pressure

N: max. 8 bar

NC/NO: max. 7 bar

• Pressure supply not connected

• Line break

• Pressure in pressure supply set

► Check the pressure supply

(at least 2 bar)

too low

• Multiple bits are set in the

"ControlWord."

► Only one bit may be active on the

"ControlWord."

• Wrong value on the "TeachPosition" ► Test of the "TeachPosition"

parameters

Permissible range, depending on

design size.

Max. position value corresponds to

the back jaw stroke x 200

e.g.:

HRC with approx. 12 mm

Jaw stroke:

0 ≤ "TeachPosition" ≤ 1200

• Wrong value on the

"PositionTolerance" parameter

► Test of the "PositionTolerance"

parameters

Permitted range:

0 < "PositionTolerance" ≤ 255

• Gripper does not have any

reference position

• Wrong value on the "DeviceMode"

parameter

• Modied process data were not

taken over

Zimmer Group Service

► Adjusting the "DeviceModes"

Universal = 100

Grip workpiece outside = 60

Grip workpiece inside = 70

• Multiple move commands to the

same direction

• Move command transmitted

► Reset direction ag and resend move

command.

despite existing error

• Transmitted workpiece number is

outside the permitted range 0 to 32

• Modied process data were not

taken over

► Check the values of the

"WorkpieceNo." parameter

► Take over the process data with a

"Handshake"

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

18

Page 19

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

Diagnostics

message

Error Possible causes Measures

"TeachPosition" does not

0x309

correspond to the active value in

the gripper

Teach position tolerance does

0x30F

0x310

not correspond to the active

value in the gripper

"DeviceMode" sent by the

master does not correspond to

• Process data sent by the master

has been changed

the active value in the gripper

"WorkpieceNo." sent by the

0x311

master does not correspond to

the active value in the gripper

0x312

Initial status after a gripper

restart

• After a restart, a one-time data

takeover through "ControlWord"

= 1 must be carried out

0x404 Error of the position sensor

• Fault of the integrated position

sensor

0x406 System error • Internal system error

► Conrming the newly transmitted

process data with a "Handshake"

"ControlWord" = 0x1

► Conrming the current process data

with a "Handshake" "ControlWord" = 0x1

► Check whether the integrated position

sensor is influenced by an external

magnetic field

► Ensure the necessary distance between

the sensor and ferromagnetic materials

Zimmer Group Service

Zimmer Group Service

9. Accessories

If any accessories not sold or authorized by Zimmer Group are used, the function of the gripper cannot be guaranteed.

The accessory range of the Zimmer Group is specically tailored to and certied for the individual grippers.

Corresponding optional accessories or those included in the scope of supply can be found in the respective product data sheets at

www.zimmer-group.com.

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

19

Page 20

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

10. Glossary

Term/

abbreviation

"BasePosition"

"WorkPosition"

"TeachPosition"

"ActualPosition"

"ControlWord"

"DeviceMode"

"Workpiece No."

"PositionTolerance"

Base position

Initial position from which the gripper moves

Work position,

Any position of the gripper within the maximum and minimum possible movement range

Teach position,

for conditioning the gripper to the workpiece.

Current position,

Position of the gripper jaws with respect the maximum

possible stroke

Control word,

Parameter for command execution

Process parameter,

Switch that changes between movement proles of the gripper

Workpiece number,

Option for saving multiple recipes

Position tolerance,

referring to the tolerance of the teach position

Description

HRC

Human-Robot-Collaboration

Status Display parameter

Diagnostics

Diagnostics

Display parameter = error number

Oset Value for the subsequent correction of a parameter

"GripForce"

Direction

Gripping force

Value in the data set of the controller

Command/signal from the controller

Specication of the movement direction of the gripper jaws

Normal N The gripper can be used for both external and internal gripping (no gripping force safety device).

normally open

normally closed

NO The gripper is set up for external gripping.

With gripping force safety device

NC The gripper is set up for internal gripping.

With gripping force safety device

GND Ground/power supply 0V

Workpiece No.

Workpiece number

Designation of the data set in the control system

GPD Pneumatic gripper/three-jaw version

GPP Pneumatic gripper/two-parallel-jaw version

Traversing routine

Travel path

Adjust

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

Traversing routine

Dened process for moving the gripper jaws

Travel path

Path on which the gripper jaws travel

adjust

The gripper carries out an adjustment run

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

20

Page 21

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

11. Maintenance

INFORMATION:

B

value: 30.000.000 cycles.

10d

Maintenance-free operation of the gripper is guaranteed for up to 30 million gripping cycles.

The maintenance interval may shorten under the following circumstances:

Operation with compressed air that does not comply with DIN ISO 8573-1 quality class 4

Dirty environment

Improper use and use that does not comply with the performance data

Ambient temperature of more than 50°C; lubricants harden faster!

We recommend using the Zimmer GmbH repair service for maintenance and the replacement of seals.

Dismantling and reassembling the gripper without authorization may result in complications, as special installation equipment is

required in some cases.

12. Fault exclusion

► Inherently safe design engineering

The safety function is implemented using moving parts that are connected to each other through positive locking

No indirect triggering of the safety function caused by coupler elements (sensors, etc.)

► Proven technology

Methods in accordance with ISO 13949-1, Annex C, C.2 "Methods of good engineering practice"

MTTFd value = 150 years

Failure of the spring 4 "on the safe side" – No safety function failure

– Fatigue strength conrmed by the manufacturer

Failure of spring 4 – Fatigue strength conrmed by the manufacturer

Gate broken: Gripper jaw is no longer pulled inwards = force buildup no longer possible

► Wear resistance

Verication in above-mentioned endurance test that any potential wear does not impede the safety function

Use of wear-resistant materials for the safety-relevant components

Material of the gripper nger: 16MnCr5

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

21

Page 22

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

13. Declaration of incorporation

intermsoftheEUMachineryDirective2006/42/EC(AppendixII1B)

Name and address of the manufacturer:

Zimmer GmbH, Im Salmenkopf 5, D-77866 Rheinau, Germany, Phone: +49 7844 91380,

www.zimmer-group.de

We hereby declare that the incomplete machines described below

Product designation: Pneumaticparallelgripper/pneumaticthree-jawgripper

with intelligent control system

Type designation: GPP50��IL-/GPD50��IL-Series

conform to the requirements of the Machinery Directive, 2006/42/EC, Article 2g, Annex VII,b – Annex II,b, in their

design and the version we put on the market.

The following harmonized standards have been used:

• Basichealthandsafetyrequirements:No.1.1.2,No.1.1.3,No.1.1.5,No.1.3.1,No.1.3.2,No.1.3.4,No.1.3.7,No.1.5.1,

No.1.5.3,No.1.5.4,No.1.6.4,No.1.7.1,No.1.7.3.

• DINENISO12100:2011-03 Safetyofmachinery–Generalprinciplesfordesign–Riskassessment

and risk reduction

• DINEN60204-1 Safetyofmachinery–Electricalequipmentofmachines,part1

• DINENISO13849-1/-2 Safetyrelatedpartsofcontrolsystems

• DINENISO4414 Fluidpower–Generalrules–Safetyrequirementsforpneumaticsystems

and their components

Afulllistofappliedstandardsisavailableforviewingatthemanufacturer'sfacilities.

Commissioning of the incomplete machine is prohibited until it has been found that—where applicable—the

machine in which the above-mentioned incomplete machine is to be installed complies with the Machinery Directive

(2006/42/EC).

Authorized representative for compiling the

relevant technical documents

Kurt Ross Seemanufacturer'saddress Rheinau,Germany,2017-09-01 MartinZimmer

First name, last name Address (Placeanddateofissuance) (Legallybindingsignature)

ManagingPartner

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

22

Page 23

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

14. Declaration of conformity

intermsoftheEUDirective2014/30/EConelectromagneticcompatibility

Name and address of the manufacturer:

Zimmer GmbH, Im Salmenkopf 5, D-77866 Rheinau, Germany, Phone: +49 7844 91380,

www.zimmer-group.de

We hereby declare that the products described below

Product designation: Pneumaticparallelgripper/pneumaticthree-jawgripper

with intelligent control system

Type designation: GPP50��IL-/GPD50��IL-Series

conform to the requirements of the Electromagnetic Compatibility Directive 2014/30/EU in their design and the

version we put on the market.

The following harmonized standards have been used:

DINENISO12100:2011-03 Safetyofmachinery–Generalprinciplesfordesign–Riskassessmentand

risk reduction

DINEN61000-6-3 EMCGenericstandard,Emissionstandardforresidential,commercialandlight-industrial

environments

DINEN61000-6-2 EMCGenericstandard,Immunityforindustrialenvironments

DINEN61000-6-4 EMCGenericstandard,Emissionstandardforindustrialenvironments

Afulllistofappliedstandardsisavailableforviewingatthemanufacturer'sfacilities.

Authorized representative for compiling

the relevant technical documents

Kurt Ross Seemanufacturer'saddress Rheinau,Germany,2017-09-01 MartinZimmer

First name, last name Address (Placeanddateofissuance) (Legallybindingsignature)

ManagingPartner

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

23

Page 24

INSTALLATION AND OPERATING INSTRUCTIONS: Pneumatic gripper, intelligent GPP/GPD5000IL series

15. Your notes

DDOC00247 enu / 2018-09-14 / Index a

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

24

Loading...

Loading...