Zimmer GEP5006, GED5006, GEP5008, GED5008, GEP5010 Installation And Operating Instructions

...Page 1

INSTALLATION AND OPERATING

INSTRUCTIONS

Handling

Technology

GEP/GED5000 series

Electric gripper

THE KNOW-HOW FACTORY

Page 2

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

1. Supporting documents

Note:

The following documents are available for download on our website.

Only the documents currently available on the website are valid.

• Catalog

• Drawings, performance data, information about accessory parts, etc.

• General terms and conditions, including warranty information

2. Proper use

Note:

The gripper is to be used only in its original state with its original accessories, without any unauthorized

changes and within the scope of its dened parameters of use.

ZIMMER GmbH shall accept no liability for any damage caused by improper use.

The gripper is designed exclusively for electric operation using a supply voltage of 24 V DC.

The gripper is used as dened under "Proper use" in enclosed rooms to temporarily grip, handle and hold parts.

The gripper is not suitable for clamping workpieces during a machining process.

Direct contact with perishable goods/food is not permitted.

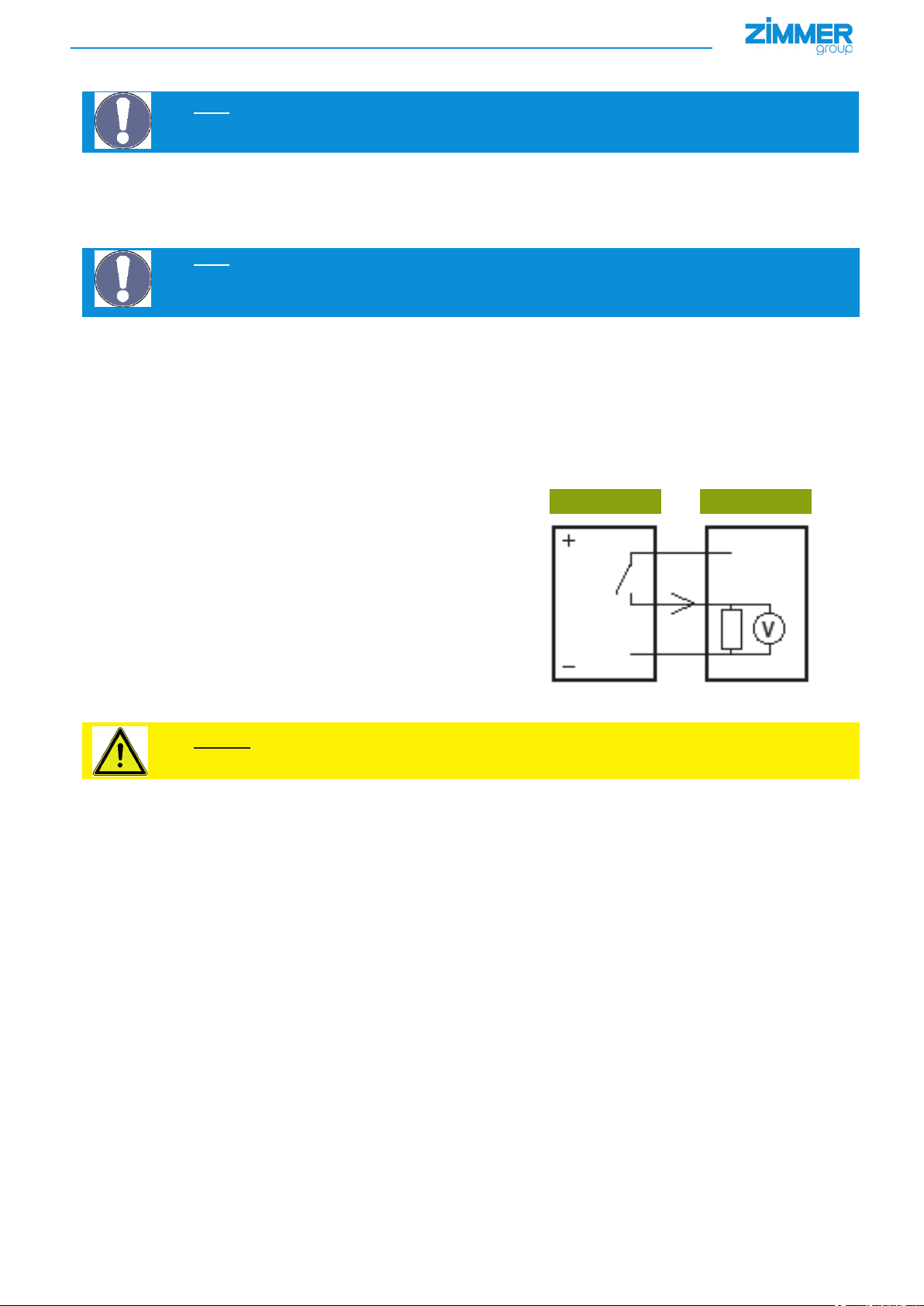

3. PNP switching logic used

If a sensor is connected to the input stage of a PLC, the input stage detects the state that the sensor is in (on or o). The prerequisite is that the PLC features the same switching logic as the sensor.

PNP sensor PNP input

When a PNP sensor is connected to a PNP input,

current ows from the sensor to the input. This means that a PNP input

must lower the current at the location where a PNP sensor draws current

Signal

Source current Sink current

Caution:

In the reverse case, an NPN sensor lowers current and an NPN input draws current.

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

2

Page 3

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

4. Function

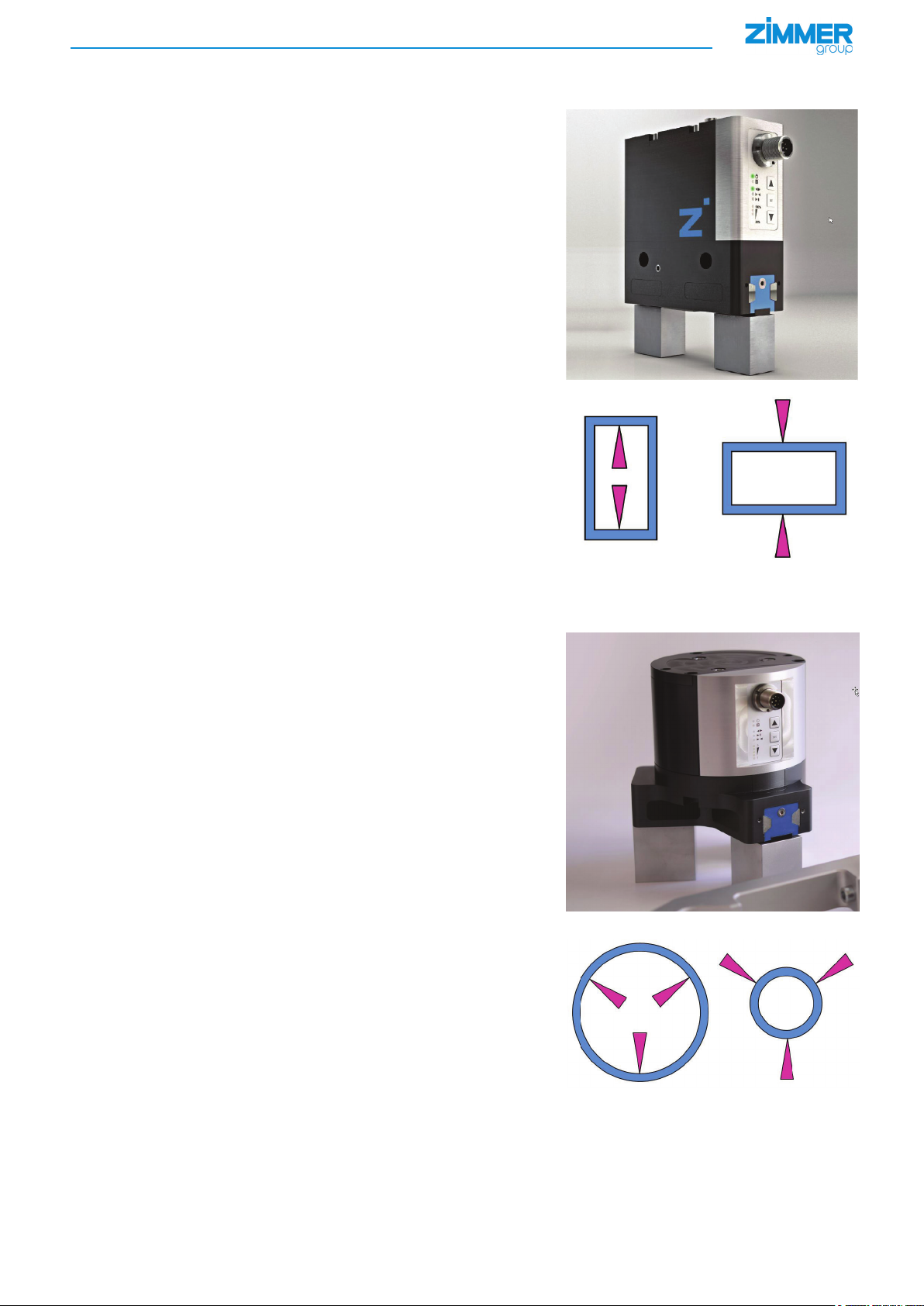

4.1 GEP5000 function

The gripper ngers of the parallel gripper are arranged successively on two

shared guide rails and can be moved alongside each other.

A brushless DC motor* is used as the drive.

The rotational movement of the motor is converted into a linear movement using

a spindle drive to generate the opening and closing movement of the gripper.

The gripper is suitable for outward gripping. (NO = normally open) This means

the gripper moves at high speed back into the starting position

The gripper is suitable for inward gripping. (NC = normaly closed) This means

the gripper moves at high speed back into the starting position

4.2 GED5000 function

The gripper ngers of the three-jaw gripper are each positioned between two

steel guide rails.

A brushless DC motor* is used as the drive.

The rotational movement of the motor is converted into a linear movement using

a spindle drive to generate the opening and closing movement of the gripper.

The gripper is suitable for outward gripping. (NO = normally open) This means

the gripper moves at high speed back into the starting position

NCNO

The gripper is suitable for inward gripping. (NC = normally closed) This means

the gripper moves at high speed back into the starting position

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

NCNO

3

Page 4

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

5. Personnel qualications

Installation, commissioning and operation may be undertaken by trained specialists only. They must have read and understood the

installation and operating instructions in full.

6. Installation

6.1 Safety notes

CAUTION:

Non-compliance may result in minor to serious injuries

Switch o the power supply for the electronics before any assembly, installation or maintenance work.

►

Risk of injury

NOTE:

Non-compliance may result in damage to the system

Switch o the power supply for the electronics before any assembly, installation or maintenance work.

►

6.2 Installing the gripper

The gripper can be installed from several sides on a mounting surface that meets the specications for evenness.

The following work steps are to be carried out to install the gripper:

► Insert centering sleeves into the provided matching parts on the gripper

► Position the gripper on the designated mounting surface using the centering sleeves

► Secure the gripper with cylinder screws of strength class 8.8

► Install the KAG1000B8 power supply cable (straight plug) or the KAW1000B8 power supply cable (angled plug)

Damage to the electronics possible

NOTE:

Non-compliance may result in damage to the system

For details on the tightening torque, screw diameter and maximum weight and length of the gripper ngers, refer

to the "Technical data" tables on the website www.zimmer-group-de.

Static charge

The seals move with the gripper jaws. This creates low voltages as a result of static charging. These charges cannot be

dissipated if the gripper is installed on an insulated surface,

nor can they be discharged through the workpiece.

NOTE:

Non-compliance may result in damage to the system

Grounding the gripper attachment/gripper jaws is recommended if ESD-sensitive parts* come into contact with

the gripper.

Heat dissipation

In the event of high ambient temperatures and a high clock frequency, the gripper has to be installed on heat-dissipating

materials.

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

4

Page 5

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

7. Commissioning

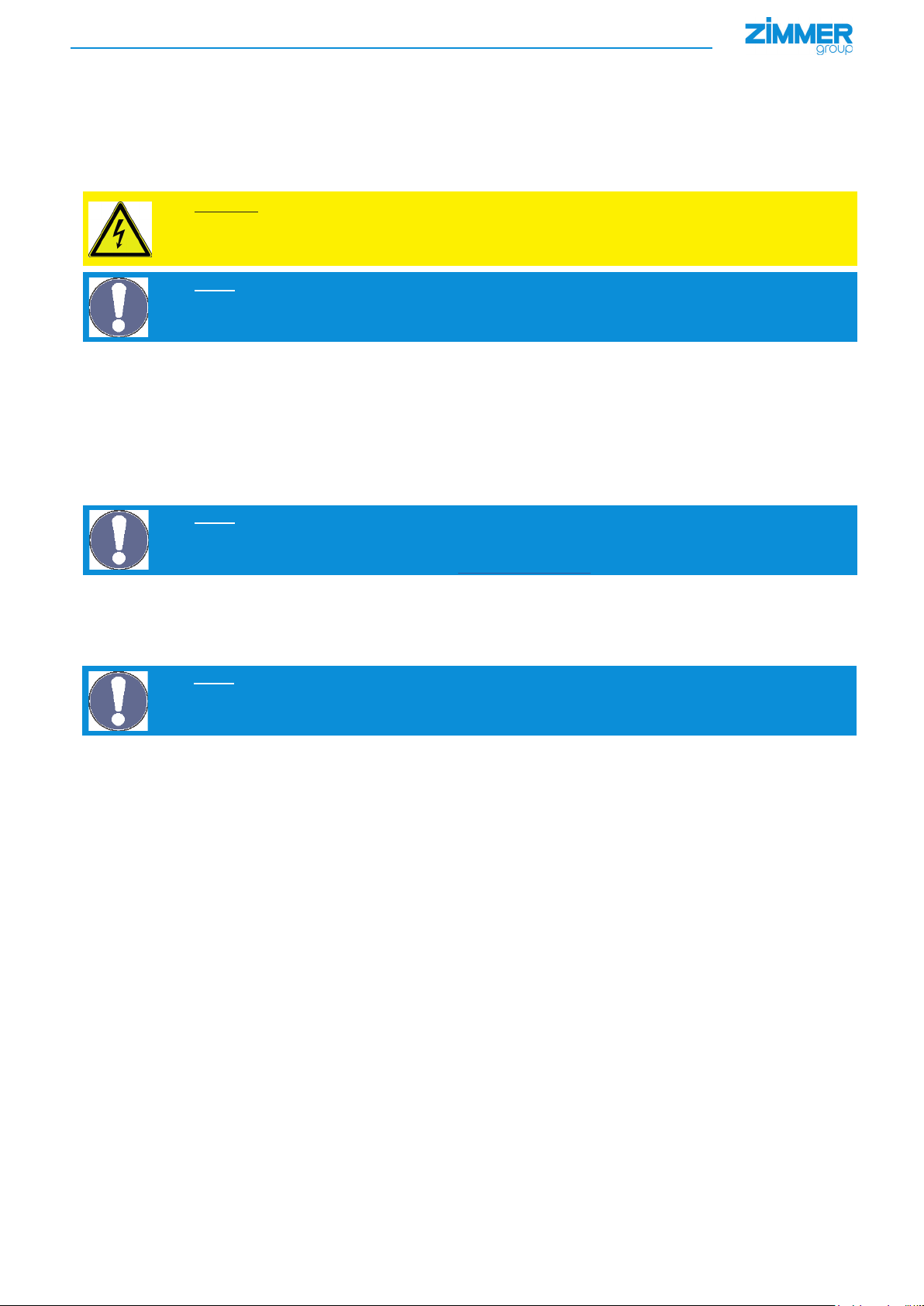

7.1 Control

To use the gripper, a voltage supply is required at pin 8 (0V) as well as at pin 6 (24 V DC/5 A).

Pin 1 serves as the control input used to open and close the gripper.

The signal of pin 1 must remain present until a counter movement of the gripper jaws is required.

The energy consumption during the movement of the gripper jaws is ≤ 5 A.

At resting position, the energy consumption of the gripper is < 150 mA.

The parameters can be set using the arrow keys on the membrane keyboard. (see section 7.3)

Cableconguration

Pin Color Function Explanation

1 White DIR* INPUT, open/close gripper control input, 24 V DC

2 Brown Work position OUTPUT, gripper in work position message

3 Green Error OUTPUT, error message

4 Yellow Teach position OUTPUT, gripper in programming position message

5

Gray Base position OUTPUT, gripper in programming position message

6 Pink +24 V DC +24 V DC/5A voltage supply

7 Blue Teach/adjust INPUT, control input, program/adjust workpiece

8 Red GND* Voltage supply 0V DC

7

1

8

2

3

6

5

4

Schematic view of controlling the GEP/GED 5000

10 11 12

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

10

11

12

Gripper

Internal sensors, gripper position sensing

External control and programming unit

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

5

Page 6

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

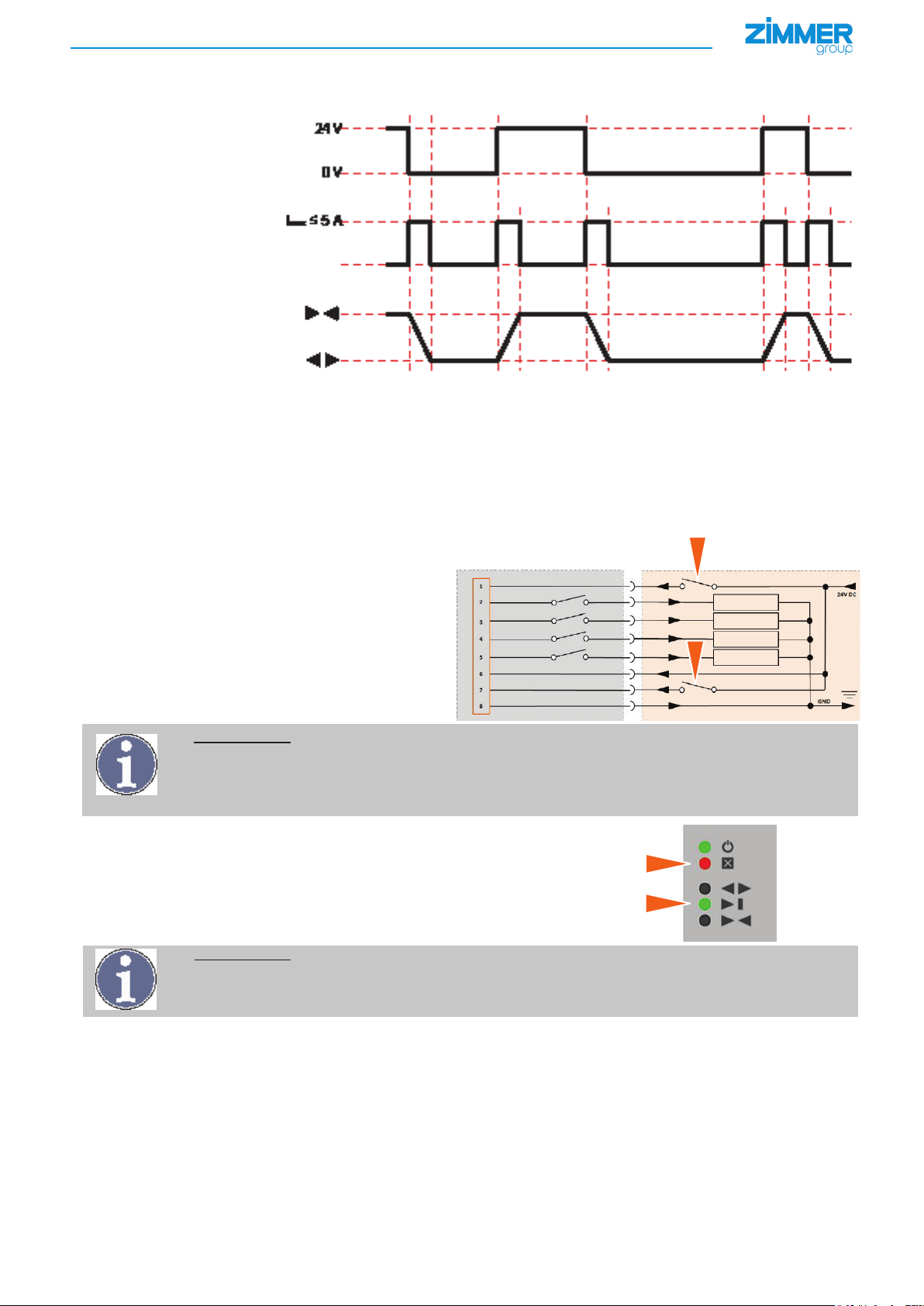

7.2 Switching sequence

Input 1 (DIR)

----------------------------------------------------------------------------------

Current draw

----------------------------------------------------------------------------------

Gripper position

-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

7.3 Intermediate position

• The intermediate position also called "workpiece gripped" can be programmed as desired.

• This requires moving the gripper jaws to the desired position (e.g. by gripping the workpiece).

• A signal (+24 V) is then applied to the pin 7 input (teach/adjust)* for a minimum of 0.5 seconds and a maximum of 3 seconds.

• Feedback is received via the pin 4 output (teached position)* in the process.

• The statuses are also shown on the gripper via the LED display.

Course of action for teaching the gripper with workpiece

1

► Put the gripper jaws into the desired position –

for instance by inserting a workpiece

► Close the gripper by applying a signal (+24V) at the PIN 1

(arrow 1) input

Error display lights up red (arrow A)

2

INFORMATION:

Important for handling the product.

The error message (A) appears because the gripper is not able to reach its end position as a result of the

inserted workpiece.

"The gripper is not yet aware that it has a workpiece between the gripper jaws."

► Apply a signal (+24 V) (arrow 2) on the pin 7 input (teach/

adjust*) for 0.5 to 3 seconds

The middle LED position display lights up green

(arrow B)

A

B

INFORMATION:

Important for handling the product.

"The gripper has learned where the workpiece is."

After the teach-in, the error message (arrow A) disappears during the next gripping movement.

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

6

Page 7

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

7.4 End positions

End position conrmation occurs via pin 2 (work position)* and pin 5 (base position)*.

The statuses are visualized on the gripper via the LED display.

The gripper's end position sensing is preset by the plant.

If necessary, end positions can be re-set via an automatic traversing routine*.

► To do so, a signal (+24 V DC) must be applied to the pin 7 output (teach/adjust)* for at least 15 seconds.

A requirement is that the DIR signal is simultaneously set to "0".

► After approximately 3 seconds, the traversing routine* begins and is completed after 5 gripping cycles.

NOTE: Non-compliance may result in damage to the system

If the signal (+24 V DC) is interrupted before the end of the traversing routine, the procedure must be repeated

because the end positions are not correctly determined.

INFORMATION: Important for handling the product.

The setting of the intermediate position (Section 6.3) is lost when teaching-in the end positions!

After teaching-in the end positions, the intermediate position must be taught-in once again!

7.5 Minimum travel path

The gripper requires a minimum travel path of > 1,25 mm per jaw before it is permitted to reach a workpiece.

Failure to do so means the gripper cannot establish the desired gripping force and displays an error.

The minimum travel path applies to both movement directions and is independent of the gripper's starting position.

8. Operation

8.1 Control panel

The control panel of the gripper continuously displays the current status of the device and provides the option to modify various settings of the gripper using multiple menus

1 Power LED, power supply

2 Error LED, error display

3 Position display, menu display

4 Parameter display, binary error code display

5 Plus key, increase parameter value

6 Set button

7 Minus key, decrease parameter value

8.2 Position display

The positions of the gripper are displayed on the operator panel via three LEDs.

Gripper in base position

NC = gripper jaws open

NO = gripper jaws closed

Gripper is on a teached-in workpiece item

(teach-in position/teach position)

Base position Work position

Gripper is at the work position

(working position)

1

5

2

6

3

7

4

Teach position

If the gripper has been taught-in at an end posi-

tion, two LEDs are switched on simultaneously.

(Ex.: End position, work position and teach

position

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

7

Page 8

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

8.3 Menu structure

Remaining operational life

Not assigned

"Position" teach area

"Gripper mode" menu

"Width" teach area

Remaining operational life

Based on 30 million cycles

Menu

Not assigned

Changing the

value

Value

Teach - Oset 1 - 5

Changing the

value

Value

Universal mode

NC, NO - operation

Changing the

value

Value

Window width 1 - 5

Changing the

value

Force setting

3 sec.

Main menu

3 sec.

8.4 Menu cycle course of action

► Call up the main menu by pressing SET (3 seconds)

The menu display LEDs will ash

► You can access the edit mode of a value by pressing SET once again

Parameter display LEDs will ash

Only possible in menus that feature a selection point

► A value can be changed in a range from 1 to 5 using the arrow keys

► Pressing SET saves the value and goes back to the menu display

These LEDs will now ash

► You can scroll through the menu items using the arrow keys

► You can only leave the menu by pressing SET in the main menu

No LED will ash

Value

Force mode 1 - 5

Display

Error diagnosis

EN/2015-10-07

INFORMATION: Important for handling the product.

If no input occurs after 3 minutes, the menu is left without saving the values.

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

8

Page 9

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

8.5 Menu functions

Menu Designation Description

Menu 0

Main menu

Main menu

The error codes are also displayed here.

Refer to the "Error display diagnosis" section

Menu 1

Menu 2

Menu 3

Setting for the gripping force and travel speed in 5 steps

1= low gripping force/slow travel speed

Force setting

"Width" teach area

"Gripper mode" menu

If the gripping direction is dened, the corresponding gripper mode 2 or 3 shall be used.

The entire gripping cycle is sped up on the basis of the shorter return time of the gripper jaws.

As a result, the gripper is operated mechanically and electrically milder, to ensure a long operational life.

5= high gripping force/fast travel speed

(For details, refer to the "Technical data" section)

Default value: 4

Setting for the width in 5 steps

1 = small width

5 = large width

(For further details, see "Technical data" section)

Default value: 3

1 = universal operation in accordance with inward or outward gripping, both

movements with the same speed

2 = NC operation inward gripping with the desired force mode, quick outward

movement for reducing the cycle time

3 = NO operation outward gripping with the desired force mode, quick inward

movement for reducing the cycle time

Default value: 1

The gripper cannot drive to a permanent limit stop (such as a workpiece) during a fast backward movement, because it would be stressed beyond the permissible forces!

Menu 4

Menu 5

Menu 6

EN/2015-10-07

"Position" teach area

Menu not used

Remaining operational life

Oset for the teached-in position in 5 steps

1 = large oset in the direction of the base position

2 = small oset in the direction of the base position

3 = no oset

4 = small oset in the direction of the work position

5 = large oset in the direction of the work position

(For further details, see "Technical data" section)

Default value: 3

The parameter display LEDs show the remaining operational life of the gripper

relative to 30 million cycles.

5 = long remaining operational life

1 = short remaining operational life (less than 2 million cycles)

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

9

Page 10

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

8.6 Menu settings

8.6.1 Menu 1: "Force settings"

INFORMATION:

For the technical data and gripping force charts, please visit our website:

www.zimmer-group.de

Should you have further questions about products or technical data, please contact ZIMMER GmbH Customer

Service. For this purpose, please call our technology hotline at +49 7844 9138-0.

8.6.2 Menu 2: "Width" teach area

Teach area Width [mm]

Teach area "width" [1] ≃ 0,2 mm

Teach area "width" [2] ≃ 0,4 mm

Teach area "width" [3] ≃ 0,6 mm

Teach area "width" [4] ≃ 1,2 mm

GEP5006/GED5006

Teach area "width" [5] ≃ 2,4 mm

Teach area Width [mm]

Teach area "width" [1] ≃ 0,2 mm

Teach area "width" [2] ≃ 0,4 mm

Teach area "width" [3] ≃ 0,6 mm

Teach area "width" [4] ≃ 1,2 mm

GEP5008/GED5008

Teach area "width" [5] ≃ 2,4 mm

Teach area Width [mm]

Teach area "width" [1] ≃ 0,2 mm

Teach area "width" [2] ≃ 0,4 mm

Teach area "width" [3] ≃ 0,6 mm

Teach area "width" [4] ≃ 1,2 mm

GEP5010/GED5010

Teach area "width" [5] ≃ 2,4 mm

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

10

Page 11

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

8.6.3 Menu 3: "Gripper mode"

N positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] 540 620 710 860 960

Gripping force during opening [N] 540 620 710 860 960

Travel time during closing [s] 0,22 0,2 0,18 0,16 0,15

Travel time during opening [s] 0,22 0,2 0,18 0,16 0,15

Eective closing time [s] 0,255 0,235 0,215 0,195 0,185

Eective opening time [s] 0,255 0,235 0,215 0,195 0,185

GEP5006/GED5006

Max. length of gripper jaws [mm] 100 90 90 85 85

Response time [s] 0,035 0,035 0,035 0,035 0,035

NC positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] 540 620 710 860 960

Gripping force during opening [N] - - - - -

Travel time during closing [s] 0,22 0,2 0,18 0,16 0,15

Travel time during opening [s] 0,13 0,13 0,13 0,13 0,13

Eective closing time [s] 0,255 0,235 0,215 0,195 0,165

Eective opening time [s] 0,165 0,165 0,165 0,165 0,165

GEP5006/GED5006

Max. length of gripper jaws [mm] 100 100 90 85 85

Response time [s] 0,035 0,035 0,035 0,035 0,035

NO positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] - - - - -

Gripping force during opening [N] 540 620 710 860 960

Travel time during closing [s] 0,13 0,13 0,13 0,13 0,13

Travel time during opening [s] 0,22 0,2 0,18 0,16 0,15

Eective closing time [s] 0,165 0,165 0,165 0,165 0,165

Eective opening time [s] 0,255 0,235 0,215 0,195 0,185

GEP5006/GED5006

Max. length of gripper jaws [mm] 100 100 90 85 85

Response time [s] 0,035 0,035 0,035 0,035 0,035

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

11

Page 12

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

N positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] 650 790 920 1090 1150

Gripping force during opening [N] 650 790 920 1090 1150

Travel time during closing [s] 0,29 0,27 0,25 0,22 0,18

Travel time during opening [s] 0,29 0,27 0,25 0,22 0,18

Eective closing time [s] 0,335 0,305 0,285 0,255 0,215

Eective opening time [s] 0,335 0,305 0,285 0,255 0,215

GEP5008/GED5008

Max. length of gripper jaws [mm] 125 115 115 105 105

Response time [s] 0,035 0,035 0,035 0,035 0,035

NC positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] 650 790 920 1090 1150

Gripping force during opening [N] - - - - -

Travel time during closing [s] 0,29 0,27 0,25 0,22 0,18

Travel time during opening [s] 0,15 0,15 0,15 0,15 0,15

Eective closing time [s] 0,335 0,305 0,285 0,255 0,215

Eective opening time [s] 0,185 0,185 0,185 0,185 0,185

GEP5008/GED5008

Max. length of gripper jaws [mm] 125 115 115 105 105

Response time [s] 0,035 0,035 0,035 0,035 0,035

NO positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] - - - - -

Gripping force during opening [N] 650 790 920 1090 1150

Travel time during closing [s] 0,15 0,15 0,15 0,15 0,15

Travel time during opening [s] 0,29 0,27 0,25 0,22 0,18

Eective closing time [s] 0,185 0,185 0,185 0,185 0,185

Eective opening time [s] 0,335 0,305 0,285 0,255 0,215

GEP5008/GED5008

Max. length of gripper jaws [mm] 125 115 115 105 105

Response time [s] 0,035 0,035 0,035 0,035 0,035

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

12

Page 13

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

N positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] 980 1080 1200 1400 1520

Gripping force during opening [N] 980 1080 1200 1400 1520

Travel time during closing [s] 0,32 0,29 0,27 0,24 0,21

Travel time during opening [s] 0,32 0,29 0,27 0,24 0,21

Eective closing time [s] 0,335 0,325 0,305 0,275 0,245

Eective opening time [s] 0,345 0,325 0,295 0,275 0,245

GEP5010/GED5010

Max. length of gripper jaws [mm] 160 145 145 135 135

Response time [s] 0,035 0,035 0,035 0,035 0,035

NC positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] 980 1080 1200 1400 1520

Gripping force during opening [N] - - - - -

Travel time during closing [s] 0,32 0,29 0,27 0,24 0,21

Travel time during opening [s] 0,16 0,16 0,16 0,16 0,16

Eective closing time [s] 0,345 0,325 0,295 0,275 0,245

Eective opening time [s] 0,2 0,2 0,2 0,2 0,2

GEP5010/GED5010

Max. length of gripper jaws [mm] 160 145 145 135 135

Response time [s] 0,035 0,035 0,035 0,035 0,035

NO positioning mode

Force setting Value 1 Value 2 Value 3 Value 4 Value 5

Gripping force during closing [N] - - - - -

Gripping force during opening [N] 980 1080 1200 1400 1520

Travel time during closing [s] 0,16 0,16 0,16 0,16 0,16

Travel time during opening [s] 0,32 0,29 0,27 0,24 0,21

Eective closing time [s] 0,2 0,2 0,2 0,2 0,2

Eective opening time [s] 0,345 0,325 0,295 0,275 0,245

GEP5010/GED5010

Max. length of gripper jaws [mm] 160 145 145 135 135

Response time [s] 0,035 0,035 0,035 0,035 0,035

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

13

Page 14

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

8.6.4 Menu 4: "Position" teach area

"Position" teach area Oset[mm]

Teach area "oset" [1] ≃ - 0,8 mm

Teach area "oset" [2] ≃ - 0,4 mm

Teach area "oset" [3] ≃ 0 mm

Teach area "oset" [4] ≃ + 0,4 mm

GEP5006/GED5006

Teach area "oset" [5] ≃ + 0,8 mm

"Position" teach area Oset[mm]

Teach area "oset" [1] ≃ - 0,8 mm

Teach area "oset" [2] ≃ - 0,4 mm

Teach area "oset" [3] ≃ 0 mm

Teach area "oset" [4] ≃ + 0,4 mm

GEP5008/GED5008

Teach area "oset" [5] ≃ + 0,8 mm

"Position" teach area Oset[mm]

Teach area "oset" [1] ≃ - 0,8 mm

Teach area "oset" [2] ≃ - 0,4 mm

Teach area "oset" [3] ≃ 0 mm

Teach area "oset" [4] ≃ + 0,4 mm

GEP5010/GED5010

Teach area "oset" [5] ≃ + 0,8 mm

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

14

Page 15

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

9. Maintenance

9.1 Maintenance intervals

The gripper does not require maintenance.

The operational life of up to 30 million cycles may become reduced under the following circumstances:

• Dirty environment

• Improper use

• Unapproved performance data and parameters for use

• Use of sealing air

9.2 Disassembling the gripper

We recommend using the Zimmer Group Repair Service for repairs.

Unauthorized dismantling and reassembly of the gripper can result in complications as in some cases, special mounting equipment

is required. In addition, the warranty is void if the gripper is opened.

10. Remedy

10.1 Error diagnosis

The red error LED indicates that an error has occurred. The main menu must be selected to see the error code. The ve lower LEDs

represent the current error code in binary form.

In the following example, error code 7 is active:

The error is acknowledged via a new DIR signal.

1 "Error" LED display

2 Position display

3 Error code display

1

2

3

10.2 Display troubleshooting

Error code Error Possible cause •Measure

0

1

2

3

No error

Motor has slight overcurrent in

several consecutively following

cycles

Motor has strong excess

current

Motor has excess current in

idle mode

• Gripper is dicult to move

• Travel path of the gripper is

impeded

• Object being gripped or gripper

• Check the gripper's freedom of

movement

• Check the object being gripped

and gripper jaws

jaws are elastic

• Gripper is blocked

• Internal error

• Restore the free movement of the

gripper once again

• Zimmer Group Service

• Internal error • Zimmer Group Service

4

Motor output stage

temperature above the limit

value

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

• Ambient temperature too high

• Gripper is overloaded

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

• Provide sucient ventilation/

cooling

• Check the object to be gripped or

the gripper jaw

15

Page 16

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

5

6

7

8

9

Gripper is in reference run

mode

Gripper has no reference on

the jaw position

Motor is in setting drive mode

at the end positions

(see Section 6.4)

Gripper did not reach the end

position (base, teach-in or work

position)

Gripper does not reach the

target speed

• Internal error • Zimmer Group Service

• Gripper has lost its reference

position

• Setting drive has been started

(Caution: During the setting run,

positions are not evaluated)

• The gripper does not reach its work,

base or teach-in position

• Diculty moving the guide • Zimmer Group Service

• Zimmer Group Service

• Wait for completion of the

adjustment procedure

• Check the object being gripped

or the gripper jaws

10

11

12

13

14

The "jaw position" sensor has

an error

The temperature sensor has

an error

The gripper has a general

system error

DIR signal = 0, but the gripper

does not reach the base

position or the teach-in position

DIR signal = 1, but the gripper

does not reach the work

position or the teach-in position

• Internal error • Zimmer Group Service

• Internal error • Zimmer Group Service

• Internal error • Zimmer Group Service

• Gripper is blocked

• Diculty moving the guide

• Gripper is blocked

• Diculty moving the guide

• Restore the ease of movement of

the gripper

• Zimmer Group Service

• Restore the ease of movement of

the gripper

• Zimmer Group Service

15

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

Gripper is blocked • Gripper is dicult to move

• Travel path of the gripper is

impeded

●

• Restore the ease of movement of

the gripper

Fax: +49 7844 9138-80 ● www.zimmer-group.de

16

Page 17

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

16

17

18

The gripper has exceeded the

maximum travel time

Gripper does not reach

the target speed when

approaching

Gripper is in NC or NO mode

and is blocked from free run

(see Section 7.5, menu 3 menu

function)

• Gripper is dicult to move

• Travel path of the gripper is impeded

• Diculty moving the guide • Zimmer Group Service

• Gripper is dicult to move

• In its fast backward movement, the

gripper moves to a xed stop (i.e.

object being gripped)

• Restore the ease of movement of

the gripper

• Change gripper mode

• Zimmer Group Service

INFORMATION:

Important for handling the product.

Errors remain active until a switchover of the DIR signal or a zero crossing of the grippers' voltage supply. An

error can therefore be acknowledged with a switchover of the DIR signal.

EN/2015-10-07

*) See "Glossary" section for denitions

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

17

Page 18

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

11. Declaration of Incorporation

in the context of EU Machinery Directive 2006/42/EC (Annex II 1 B)

Name and address of the manufacturer:

ZIMMER GmbH, Im Salmenkopf 5, D-77866 Rheinau, Germany, Phone: +49 7844 91380,

www.zimmer-group.de

We hereby declare that the incomplete machines described below

Product designation: Electric parallel gripper, electric three-jaw gripper

Type designation: GEP5

���-/GED5���-Series

conform to the requirements of the Machinery Directive, 2006/42/EC, Article 2g, Annex VII,b – Annex II,b, in their

design and the version we put on the market.

The following harmonized standards have been used:

• Basic health and safety requirements: No. 1.1.2, No. 1.1.3, No. 1.1.5, No. 1.3.1, No. 1.3.2, No. 1.3.4, No. 1.3.7, No. 1.5.1,

No. 1.5.3, No. 1.5.4, No. 1.6.4, No. 1.7.1, No. 1.7.3.

•DIN EN ISO 12100:2011-03 Safety of machinery – General principles for design - Risk assessment and risk reduction

•DIN EN 60204-1 Safety of machinery – Electrical equipment of machines, part 1

•DIN EN ISO 13849-1 Safety function for superimposed hazards

•DIN EN ISO 13849-2 Safety related parts of control system

A full list of applied standards can be obtained from the manufacturer.

Commissioning of the incomplete machine is prohibited until it has been found that—where applicable—the

machine in which the above-mentioned incomplete machine is to be installed complies with the Machinery Directive

(2006/42/EC).

Authorized representative for compiling the

relevant technical documents

Kurt Ross See manufacturer's address Rheinau, Germany, 2013-11-21 Martin Zimmer

First name, last name Address (Place and date of issuance) (Legally binding signature)

Managing Partner

12. Declaration of Conformity

in the context of EC Directive 2014/30/EC on electromagnetic compatibility

Name and address of the manufacturer:

ZIMMER GmbH, Im Salmenkopf 5, D-77866 Rheinau, Germany, Phone: +49 7844 91380,

www.zimmer-group.de

We hereby declare that the products described below

Product designation: Electric gripper

Type designation: GEP5

���-/GED5���-Series

conform to the requirements of the Electromagnetic Compatibility Directive 2014/30/EU in their design and the

version we put on the market.

The following harmonized standards have been used:

DIN EN ISO 12100:2011-03 Safety of machinery - General principles for design - Risk assessment and risk reduction

DIN EN 61000-6-3 EMC Generic standard, Emission standard for residential, commercial and light-industrial

environments

DIN EN 61000-6-2 EMC Generic standard, Immunity for industrial environments

DIN EN 61000-6-4 EMC Generic standard, Emission standard for industrial environments

A full list of applied standards can be obtained from the manufacturer.

Authorized representative for compiling the

relevant technical documents

EN/2015-10-07

Kurt Ross See manufacturer's address Rheinau, Germany, 2013-11-21 Martin Zimmer

First name, last name Address (Place and date of issuance) (Legally binding signature)

Managing Partner

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

18

Page 19

INSTALLATION AND OPERATING INSTRUCTIONS: ELECTRIC GRIPPER GEP/GED5000 SERIES

13. Accessories/scope of delivery

If any accessories not sold or authorized by Zimmer Group are used, the function of the gripper cannot be guaranteed. Zimmer

Group's range of accessories is specially tailored to the individual grippers.

Corresponding optional accessories and those included in the scope of supply can be found at www.zimmer-group.com.

14. Glossary

AC motor Motor run on AC power

Adjust Congure

Base position Base position of the gripper

DC motor Motor run on DC power

DIR Direction/24 V supply line

Error Fault, error message

ESD Electrostatic discharge, electrostatic sensitivity

GED Gripper/electrically powered/three-jaw design

GEP Gripper/electrically powered/2 parallel jaws

GND Abbreviation for "Ground" – ground connection

LED Light-emitting diode

NO "Normally Open" gripper mode – inward gripping - the gripper is open when not activated

NC "Normally Closed" gripper mode – outward gripping - the gripper is closed when not activated

Oset Correction value

Teach position Programming/teaching the gripper to the position of the workpiece

Work-Position Work position of the gripper

VAC Volts in AC current

VDC Volts in DC current

Traversing routine Dened process for the movement of the clamping jaws

Travel path Path on which the gripper jaws return

EN/2015-10-07

DDOC00198/t

Zimmer GmbH ● Im Salmenkopf 5 ● 77866 Rheinau, Germany ● Phone: +49 7844 9138-0

●

Fax: +49 7844 9138-80 ● www.zimmer-group.de

19

Loading...

Loading...