Page 1

Operator

&

Service

NSN

A.T.S.º

6515-01-287-0607

Manual

1500

TOURNIQUET

Z

SYSTEM

Zimmer

Page 2

()

SCOPE

Zimmer,

During

OF

Inc.

the

materials

Limited

described

SHALL

WHICH

Warranty

NOT

HAS

DISCLAIMER

The

foregoing

ZIMMER

ABILITY

MAKES

OR

LIMITATION

In

no

case

breach

breach

apply.

of

warranty

in

certain

WARRANTY

In

the

event

1.

Notify

Customer

contact

Product

shipping

your

serial

authorization.

WARRANTY

warrants

warranty

or

workmanship

is

made

in

this

Limited

APPLY

BEEN

OF

IMPLIED

Express

NO

FITNESS

OF

REMEDIES

shall

Zimmer,

or

transactions.

CLAIMS

of a warranty

Service

local

Zimmer

number.

LIMITED

the

period

only

Warranty

TO

ANY

Product

Zimmer

or

(A.T.S.

will

which

fails

to

the

original

are

PRODUCT

SUBJECTEDTO

WARRANTIES

Limited

OTHER

Warranty

WARRANTIES

FOR A PARTICULAR

Inc.

be

liable

for

other

legal

theory.

In

such

claim

within

the

Department,

representative.

Upon

receipt

of

this

ONE YEAR

1500

repair

to

meet

purchaser

the

exclusive

WHICH

MISUSE

is

given

INCLUDING

PURPOSE.

any

special,

Some

states

states,

the

warranty

Zimmer

Please

information

Tourniquet

or

replace,

the

published

of

remedies

HAS

OR

ABUSE.

in

lieu

incidental

do

not

limits

in

period

Patient

provide

details

Zimmer

WARRANTY

System)

at

its

the

Product

BEEN

of

any and

THE

or

allow

this

paragraph

please

Care

about

will

for

one

option,

product

for

ALTERED

IMPLIED

any

specification

and

is

breach

OR

all

other

WARRANTIES

consequential

limitations

on

and

take

the

following

Division,

provide

the

Dover,

nature

you

year

from

date

Product

non-transferable.

of

warranty.

MODIFIED

express

which

for

THIS

or

implied

that

IN

OF

damages

warranties

the

preceding

steps:

Ohio

of

the

with a date

whether

or

on

paragraph

at

1-800-321-5533

problem

for

service

of

purchase.

is

defective

model.

The

remedies

WARRANTY

ANY

WAY

warranties.

MERCHANT-

based

remedies

do

and

include

or a return

in

This

OR

on

for

not

or

the

2.

Upon

the

Your

shipping

receipt

authorization.

compliance

of

with

the

shipping

these

The

Rev.

authorization,

steps

will

revision

letter

level

printed

Zimmer

P.O.

Box

10,

Phone:

forward

help

assure

of

this

on

this

Patient

200

West

(330)

Manual

the

that

manual

page

Ohio

equipment,

you

receive

is

completely

and

Care

Avenue,

freight

prompt

specified

by

any

errata

Division®

Dover,

OH

prepaid,

warranty

that

44622

343-8801 / 1-800-321-5533

Number

60-4019-002

to

the

service

by

the

follow.

location

for

your

specified

Product.

in

Unit

Serial

Number.

Page 3

SECTION

1.0

11

12

13

1.4

15

16

TABLE

OF

CONTENTS

&

LIST

A.T.S.

TITLE

GENERAL

EEE

SpechieaOns:

Contraindications

PrecautionsinUse....................................

Adverse

1500

INFORMATION

MERE

EEE

2205s

AA

AS

Effects

.

.

OF

ILLUSTRATIONS

TOURNIQUET

EEE

usimaau

EE

ss uy 4d yn y OSS

mess

eksem

EE

EE

rime

GS

LY YR EE K VVS

rr

rr

SYSTEM

RS

AS

RMS

A A AOR

iie

mme

mee

nn

renen

0

MM

A

ne

Rea

kama

-

meen

PAGE

È

er

3

3

4

5

5

5

6

»

Ko

O

一

2.0

21

2.2

23

2.4

25

26

27

28 Alarm

281

30

31

3.2

3.21

322

3.2.3

3.2.4

3.25

3.2.6

3.2.7

3.28

3.29

3.2.10

33

40

41

4.2

43

431

43.2

433

434

INSTALLATION

Initial

Functional

Installation

Controls,

Single

Dual

Bier

Pressure

THEORY

Block

Detailed

Power

Microprocessor

Control'Line'

Sound

WatchDogTlimer...................................

DISPIAVS

Switches

Pressure

A/D:Gonverter

ο ο ο

Autozero

MAINTENANCE

General

Accessdo

Periodic/

CARO

INSPECTION

Functional

Calibration

AND

OPERATING

Inspection

and

.

Indicators

Cuff

Operationw

Cuff

Operation « «us

Block

Operaton

Conditions

Alarms.........................................................

GP

OPERATİON»

Diagram

Circuit

Supply/BatteryCharger

Decoder 5 «0

Generaller.

and

the

Transducers

ου

Maintenance

ParlS:

Maintenance: : 4

ra

,

and

し

に

Calibration

.

565 4 s à 4 4 à à à i vě

Description

and

Switch

pics

Εμμ

р

da

Calibration

Check.

and

Connectors

cssssemensaszassosanmeau

............................

«sas

Memory

onsau

R

Latch

and

Amplifiers

is

seni

Information.

use

ibra

Checks

INSTRUCTIONS

............................................

に

に

ο

ο

esnemeye

K

..............................................

.

uns

ee

aa

eee

ο

ce

в

.

.........................................

PEA

BE

EROI

ο

...........................................

nada

...........................................

a ο ο

le e I

...............................

aaa

«νε

ων

νε

ων

ων εν ων

ut

idee

O

Komen

rana

раны В ыы

PROTO,

A

es

dia

SONORE

ennen

RARES

usas

0500408

e

kk

E E ER

LEH

Ag HE

RSI

VE

PE

kernen

suado

ennen

ORR

peau

AM

LA

и

ο

ου

ARRE

posar

keen

ET

RGUERE

SISSA

bbb

e

nens

νεο

ea

nuns

nunne

uma

SORE

benne

aaa

bane

nr

A

O

νο ν ων

ua

ROA

RA

A

nnnee

GR RR RE

eee

kr

nnnnne

EA

RULES

UN

KUKA

Rad な な

ν

ete

eee

nnrnne

ーー

9

κ ρ

ον

9

AN

RE

11

sis a 12

14

14

16

17

17

nne

17

17

20

RES

20

20

22

en

22

25

25

SEI

26

26

어 이 27

ーー

29

29

Е

29

ga

29

να

ων

29

29

30

30

7

7

7

1

Page 4

A.T.S.

4.3.4.1

4.3.4.2

4.3.4.3

4.3.4.4

4.3.5

4.3.6

4.3.7

4.3.8

4.3.9

44

4.4.1

4.5

4.6

4.7

4.8

4.9

4.10

4.11

1500

Transducer

Common

Span

Iteration

Watchdog

Leak

Power

Battery

Overpressure

Unscheduled

Troubleshooting

Replaceable

Parts

100V

220V

240V

Storage

Supplied

Offset

Mode

.....

Adjustment

of

Adjustments ..

Timer

Testing

Supply/Battery

Voltage

Ordering

Version

Version..

Version..

....

Check

Regulator

Maintenance

Parts

Information

Equipment...

....

..

Test

Guide

......

..

Charger

and

Battery

.......

....

...

Service

..

.

35

FIGURE

2.1

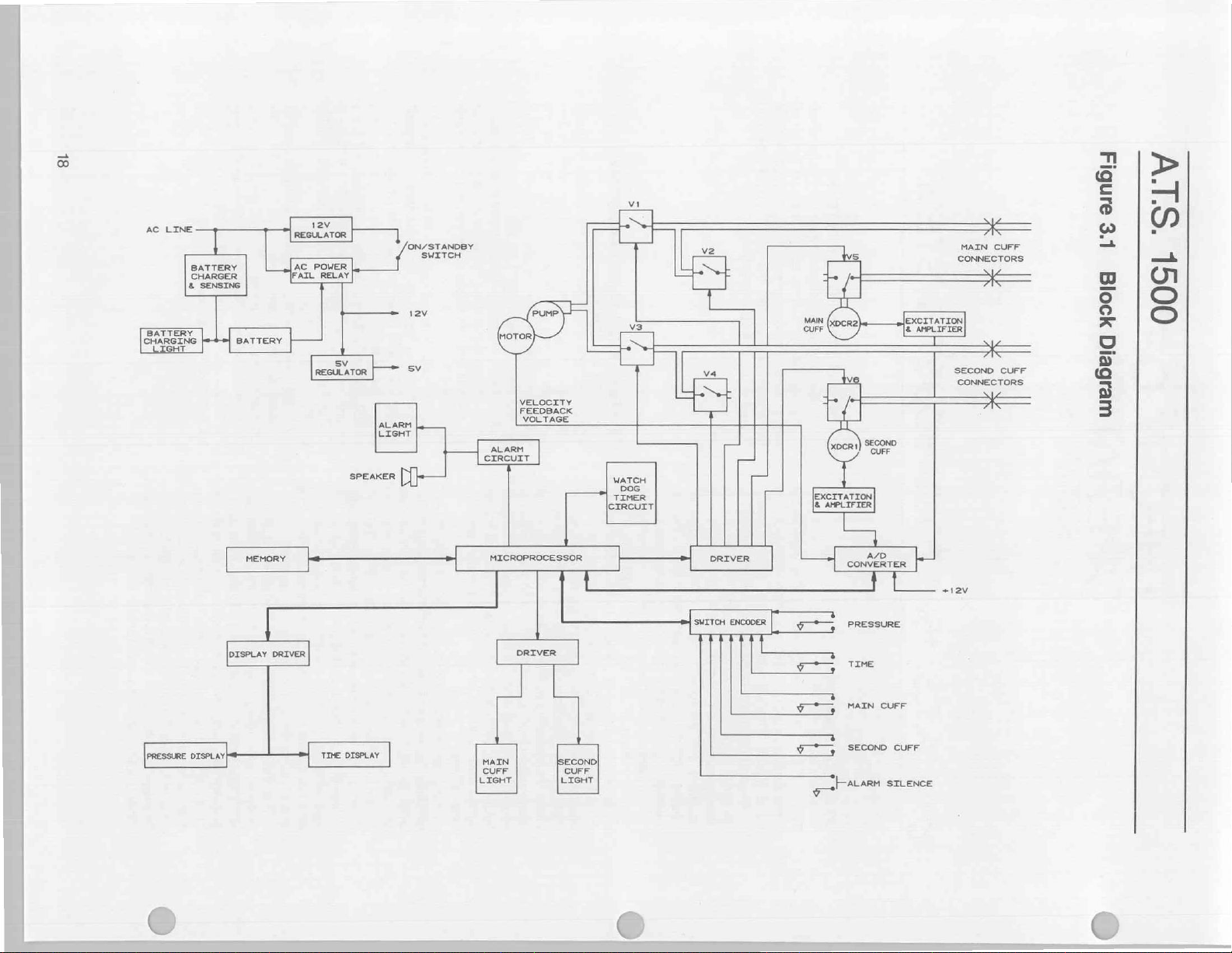

3.1

3.2

3.3

3.4

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.12

TABLE

LIST

OF

ILLUSTRATIONS

TITLE

Controls,

Block

Microprocessor

WDTSTB

WDT

A1

A2

Rear

Front

Valve

Internal

Calibration

Common-Mode

Schematic

Schematic

Alternate

TITLE

Indicators & Connectors

Diagram

Synchronization

Timing

Logic

PWB

Power

Supply

Panel

Panel

Cover

Assembly

Speaker

Assembly

Assembly

Kit:

Diagram,

Diagram,

Timing

Diagram

Assembly

PWB

Assembly

Location

“T”

Hose

Display

Location

Diagram

Timing

...........

Assembly

......

Assembly

Sequence

A2

Power

A1

Logic

Diagram

.

....

Supply

Board.

..

PAGE

.

as

..

24

PAGE

2.1

2:2

4.1

4.2

Alarm

Conditions

Hardware

Switch

Expected

Functions & Display

Malfunction

Test

Point

Reading

Displays

Indications

...

in

το

the

Calibration

πο

πο

ο

Mode

ο

ο

ο

ο

ο

%

37

Page 5

GENERAL

INFORMATION

A.T.S.

1.1

FEATURES

The

A.T.S.

1500

processor-based

features

M

Bilateral

E

during

E

sensing

to

EH

EH

a

B

ating

has

venient

I

distance.

include:

The

ability

to

procedure.

Moroprocessor

Bier

Block

Uses

dual

line

cuff

pressure

pressurize

Built

Precision

microprocessor

Built-in

room

been

Large,

the

in

battery

pressure

inflation

staff

reached.

means

bright

Tourniquet

pneumatic

control

control

cuff

switching.

tubing

from

cuff

via

charger

transducers

based

time

alarm

when

the

This

to

monitor

LED

displays

1500

is

an

automatic,

tourniquet

two

cuffs

in a Bier

prevents

and

dual

port

one

line

the

other.

and

charging

in

control

anticipated

system

and

system.

system

also

record

for

easy

SECTION

TOURNIQUET

micro-

system.

loss

of

cuffs

to

and

supplying

indicator.

conjunction

to

alert

cuff

inflation

provides a con-

total

inflation

viewing

Its

Block

or

occlusion

facilitate

air

with

the

oper-

time

time.

from

a

1.0

Il

Self-testing

tion,

and

certain

each

time

the

testing

occurs

E

Automatic

compensate

I A variety

user

to

abnormal

not

within

acceptable

low,

and

hardware

ment

malfunctions,

that

identify

isolation

I

alarm

E

disassembly.

IM

repair.

IB

IV.

time.

An alarm

tones

Simple

Modular

calibration

Portable

poles.

SYSTEM*

of

alarm

tones,

portions

unit

continuously

zeroing

for

system

of

audible

conditions

the

cause

silence

for

30

construction

and

designed

of

is

turned

of

pressure

drift.

and

limits,

failure.

the

unit

of

switch

seconds.

that

the

For

will

the

may

for

displays,

hardware

on.

In

addition,

during

normal

transducer

visual

alarms

including

time

alarm,

certain

display

error,

thus

to

permit

be

performed

ease

of

to

be

mounted

system

calibra-

and

software

some

operation.

circuits

to

alert

sensed

silencing

maintenance

battery

types

error

messages

reducing

on

pressure

voltage

of

equip-

of

without

existing

self-

to

the

fault

most

and

4,469,099;

Patents

*U.S.

B1

4,520,820;

4,548,198;

4,573,888

Page 6

ΑΤ.5.

1.2

SPECIFICATIONS

Line

Voltage

105-130

For

other

Line

Current:

485

mA

300

mA

Input

Power:

58 W Maximum

36 W Nominal

Battery

Rechargeable,

Battery

Unit

will

(minimum

Battery

24

hours

Power

Type

SIT,

Power

Hospital

Line

Protection:

05

A,

250

Cuff

Pressure

50-475

Pressure

+ 5 mmHg

Range:

VAC,

50/60

available

RMS

RMS

Type:

Discharge

operate

with

Recharge

(Maximum)

Cord:

AWG

Plug:

Grade, 3 prong

V, 5 x

mmHg

Accuracy:

(50-475

1500

Hz

voltages

Maximum

Nominal

Sealed

fully

18,

*

Range:

Time:

on

charged

Time:

13

20

mm

mmHg)

Lead

battery

ft. 2 in.

straight

See

Acid,

power

battery).

(401m)

SLO-BLO

Pgs.

12

VDC,

for

blade,

Fuse

58-62.

2.3

15

15

A

AH

minutes

Pressure

+

6mm

of

(10

second

transient

external

conditions

leaks)

Maximum

475

mmHg

600

mmHg

Time

Alarm

0-240

min.; 1 min.

Timer

Accuracy:

0.25% + 1

Internal

Program,

Transducer

Diagnostics:

SIZE:

Height:

16.13

in.

(41.0

Width:

8.75

in.

(22.3

Depth:

74

in.

(179

WEIGHT:

198

Lbs

(9

Regulation:

Set

Point

average

under

without

Pressure:

(Normal

Operation)

(Internally

Set

Ranges:

increments

sec.

Memory,

Calibration,

Watchdog

cm)

cm)

cm)

(including 2 in.

Kg)

not

Limited)

Timer,

Improper

clamp)

Valve

Actuation.

ALARMS:

CONDITION:

Over

Pressure

Under

Pressure

Sustained

Exceeded

Battery

Hardware

Cuff

Leak

Set

Voltage

Failure Failure

Not

Deflated

CONTROLS:

On/Standby

Control

Pressure

Controls

Time

Controls

setpoint.

Cuff

Controls

second

to

apply

Touch-Switches:

to

increase

Touch-Switches:

to

Touch-Switches:

to

cuff.

Time Time

Low

Switch:

power

to

unit.

or

increase

inflate

or

decrease

or

deflate

the

decrease

the

main

VISUAL

Pressure

Pressure

Pressure

Message

On

Failure

On

pressure

the

cuff

INDICATION:

Display & Cuff

Display & Cuff

Display & Cuff

Display

On

Messages

Time & Pressure

Message

Time & Pressure

setpoint.

time

alarm

and/or

Flashes

Time

Appear

Appears

the

LED

LED

LED

Display

Displays

Displays

Alarm

Control

alarm

DISPLAYS:

Pressure:

Red

Pressure,

Time:

Red

Time,

Flashes

Flashes 996

Flashes

Silence

tones

LED

LED

and

allow

to

for

Display

and

Display

Hardware

Switch:

operator

30

seconds.

for

Pressure

Hardware

for

Time

Failure

AUDIBLE

996

Hz

Hz

996

Hz

488

Hz

244

Hz

996

Hz

966

Hz

manually

to

Setting,

Failure

Condition

Alarm

Condition

TONE:

(Modulated)

silence

Sensed

Messages.

Setpoint,

Elapsed

Messages.

certain

Cuff

Page 7

Main

Cuff

Light:

Yellow

light

bar

to

indicate

pressure

junction

Second

Yellow

or

conjunction

Battery

Yellow

receiving a charge.

SPECIFICATIONS

OUT

1.3

The

used

occlude

gical

been

field

including:

alarm

with

Cuff

light

bar

pressure

alarm

with

Charging

light

bar

NOTICE.

INTENDED

A.T.S.1500

by

qualified

blood

procedures

found

in

surgical

Reduction

Kirschner

Tumor

and

in

the

the

Pressure

Light:

to

the

to

ARE

USE

Tourniquet

flow

on

useful

procedures

of

certain

wire

cyst

Subcutaneous

Nerve

Injuries

Tendon

Bone

Total

Replacement

Knee

Repair

Grafts

wrist

joint

joint

replacements

of

Amputations

Replantations

notuse

of

flow

media.

for

beyond

medical

whether

physician.

Do

CO;

safety

the

procedures.

cuff

emphysema

literature

WARNING:

distal

distention

evaluated

flow

gas

insufflation

tourniquet

subcutaneous

1.4

CONTRAINDICATIONS

The

contraindications.

decision

attending

inflation

main

cuff

of

when

the

main

flashing

cuff

in

Display.

indicate

in

inflation

the

second

Pressure

of

the

cuff

when

Display.

second

flashing

Light:

indicate

medical

in a patients

in

that

the

backup

SUBJECT

TO

CHANGE

System

professionals

is

extremities

those

extremities.

producing a bloodless operating

involving

battery

intended

to

temporarily

during

Tourniquets

the

extremities

fractures

removal

excisions

fasciotomy

replacement

joints

of

the

fingers

control

to

tourniquet

any

or

Tourniquet

effectiveness

or

surgical

Possible

manner

this

in

lists

However

a

use

to

cuffs

gases

other

cuffs

during

site

effects

include

proximal

following

the

every

in

tourniquet

used

not

have

controlling

in

arthroscopic

using

of

serious

cuff.

the

to

possible

as

the

case

with

rests

or

con-

cuff

in

is

WITH-

to

be

sur-

have

the

as

been

final

the

a

a

Open

fractures

Post-traumatic

Severe

Elbow

Severe

Skin

crushing

surgery

swelling)

hypertension

grafts

readily

distinguished

in

Compromised

artery

disease

Diabetes

The

contraindication.

The

who

dures

1.5

I

The

and

checked

IB

The

therefore

handled

ders

envelope

of

the

the

M

Do

in

cases

malignant

where

in

the

The

@

location

within

tourniquet

the

cuff

forces

i

manent

Tourniquet

insufficient

dangerous,

ble

time

the

i

and

avoid

mellitus

presence

use

of a tourniquet

are

undergoing

after

immobilization.

PRECAUTIONS

tourniquet

in

operable

regularly

tourniquet

towel

with

special

must

be

to

preclude

bladder.

cuff

manufacturer

not

use

where

cells

it

could

vessels.

tourniquet

the

on

appropriate

an

over

ankle.

or

knee

rotating

by

which

Prolonged

damage

paralysis

resulting

irreversible

also

can

with

blood

Inflation

veins

must

as

return

of

the

lengthy

injuries

(where

which

vascular

of

sickle

(See

secondary

IN

system

condition.

for

leaks

cuff

clips

used

care.

completely

ballooning

Cleaning

an

elastic

this

will

to

spread

dislodge

cuff

for

limb,

area

the

Do

because

it

damage

may

ischemia

tissues,

to

may

pressure.

in

functional

produce

increase

an

done

be

simultaneously

near

blood

of

ATS.

leg

hand

reconstruction

there

is

concomitant

all

bleeding

circulation,

cell

disease

Precautions

should

should

must

pressure

not

changes

into

USE

must

Accessories

and

should

near

Cuffs

enclosed

and

assembly

be

bandage

cause

to

the

thrombi

be

“safe”

a

the

of

readjust

this

the

lead

may

blood

result

The

passive

loss.

in

rapidly

the

be

be

other

never

the

with

and

bacteria,

general

that

applied

range.

peroneal

underlying

from

latter

congestion

Prolonged

clotting

limb.

1500

points

e.g.,

peripheral

is a relative

in

Use)

avoided

or

delayed

kept

well

defects.

be

system

inner

rubber

by

possible

instructions

followed

period

produces

to

vessels,

in

carefully.

for

exsanguination

exotoxins,

circulation,

may

have

in

of

Never

nerve

already

an

temporary

excessive

either

may

coagulability

the

time.

occlude

to

possible,

as

excess

must

be

in

patients

proce-

calibrated

should

be

punctured;

must

be

blad-

the

outer

rupture

of

or

or

formed

proper

the

and

time,

a

apply

over

or

inflated

shearing

tissue.

per-

or

nerves.

and

or

more

be

possi-

with

tourniquet

of

arteries

to

and

Page 8

A.T.S.

HB

No

known

vals

during

established.

10

and

preferably

minutes

M

During

safe

zone

should

This

is

necessary

distally.

bandage

complete

free

tourniquet

may

be

blood

will

vascular

painful

and

exsanguination

done

elevating

№

deflated

reinflation.

lead

deflation

or

niquet

a

the

should

pH

about

ing

sure

wrinkle-free

fractures,

in

amputations

without

In

case

to

intravascular

Tourniquet

two

tourniquet

will

№

Test

for

tourniquet

tourniquet

be

should

Select

EB

3

and

build-up.

protected

be

applied

is

as

(such

contact

the

cases

most

may

and

any

and

removed

the

Even

congestion

to

lead

tive

field.

1500

safe

prolonged

Tissue

subsequently.

exsanguination

of

uncovered

be

maintained

Cuff

effectiveness

is

wound

exsanguination

time.

desirable

aid

in

the

structures.

before

the

the

limb

of

failure,

and

the

Reinflation

users

sequence

cuffs

not

be

hemoglobin

on

patients

is

carefully

be

closely

proper

the

inches.

6

to

wrinkling

The

from

application

any

over

Webril)

the

closures

padding

additional

cause

underlying

soon

as

slightest

limit

to

the

number

tourniquet

aeration

15

to

periods

minutes

with

skin

between

prevent

up

to

the

first

an

Esmark

about one

cuff

the

is

also

the

reportedly

However,

in

certain

visualization

In

the

after

the

because

tourniquet

use

for 3 to 5 minutes.

the

limb

over

partial

cases

and

presence

patient

of

application

of

an

elastic

tourniquet

exsanguinated

blood-filled

thrombosis.

must

be

familiar

when

using a dual-cuff

together,

released

type

used

exsanguinated

monitored.

cuff

Too

lead

and

under

skin

so

that

accidentally.

and

its

with

sickle-cell

for

these

allow

to

size

overlap

much

localized

to

tourniquet

the

mechanical

If

cuff.

the

of

may

material

fibers

as

impedance

and

that

may

reduce

and

not

has

wrinkles.

bandages

tourniquet

pooling

become

their

been

should

pressure

of

of

of

aeration

time

has

should

time

last

and

at

15

bandage,

inch

and

bandage.

cuff

from

slipping

reduced

cuff.

Careful

prolongs

exsanguination

where

the

residual

identification

of

infection

has

been

in

a cast,

malignant

cuff

vasculature

with

the

level

tumors,

must

bandage

must

be

again

before

the

inflation-

tourniquet,

wrong

before

anemia.

patients,

and

for

injury

the

shed

the

PO2

the

overlap

an

cause

may

excessive

cuff

smooth,

by

tourniquet

loose

embedded

effectiveness.

necessary

found

deflated

The

completely

be

released.

is

venous

blood

return

the

in

inter-

been

least

to

20

a

wide

if

the

and

pain-

of

and

be

by

fully

may

tour-

using

When

limb

and

of

roll-

pres-

must

cuff

fibers

in

In

cuff

may

opera-

圖

|f

skin

preparations

should

where

the

back

elevating

sure

If

release,

below

mended

20

requiring

anesthetic

tourniquet

about

not

they

Hi

Whenever

wound

by

release

full

color

body

i

Whenever

minutes

15

be

may

should

applying pressure

the

limb.

can

does

the

limb

level.

that

from

only a few

agent

several

seconds;

seconds.

1.6

ADVERSE

A

dull

aching

throughout

Pathophysiologic

hypercarbia,

become

use.

ysis

prioceptive

the

significant

Symptoms

and

loss

responses.

Intraoperative

1.

By

the

slight

surized

venous

2.

cient

3.

and

inflation

to

4,

long

cuff

(and

return

By

blood

exsanguination.

inadequate

By

diastolic

and

enter while

By

blood

entering

bones,

are

allowed

the

to

flow

cause

chemical

tourniquet

be

protected

dressings

Transient

be

not

should

infiltration

the

tourniquet

the

can

times.

reinflation

pain

lessened

return

within

be

placed

anesthesia

remain

time

of

injection.

minutes,

be

prevented

Deflation

EFFECTS

pain

(tourniquet

limb

following

changes

and

acidosis

after

about

of

tourniquet

of

sense

of

touch,

bleeding

impeding

its

at

the

remaining

tourniquet

blood

deflation,

preventing

such

as

may

effect

padding,

beginning

in

the

pressure

all

of

venous

through

the

humerus.

used

preoperatively,

and

collect

burns.

cuff

pressure

from

and,

upon

by

elevation

3 to 4

in a position

is

used,

inflated

For a procedure

too

rapid

by

periods

periods

pain)

use.

due

to

pressure,

of

the

tissues

1-1/2

hours

paralysis

pressure,

be

caused:

exerted

if

used),

of

the

limb

because

pressure

of

the

which

allow

return.

the

nutrient

under

the

is

released,

blood

surging

if

necessary,

tourniquet

of

the

minutes

slightly

it

is

recom-

for

at

release

reinflating the

of

should

about

30

to

may

develop

hypoxia,

occur

of

tourniquet

are

motor

and

by

an

unpres-

which

prevents

operation.

of

insuffi-

(between

patient),

systolic

or

arterial

vessels

they

cuff

pres-

limb.

after

least

the

last

45

and

paral-

pro-

slow

blood

of

the

Page 9

INSTALLATION

&

OPERATING

INSTRUCTIONS

2.1

INITIAL

Unpack

physically

that

recommend

qualified

thoroughly

the

your

inspection

calibration

2.2

The

following

so

necessary

1.

power

nameplate.

2.

and

the

inspect

may

biomedical

familiar

unit

is

found

Zimmer

check

FUNCTIONAL

unit

shall

steps,

indicates

repairs

Connect

compatible

Move

the

observe

a)

The

word

display;

display;

b) A series

PRESSURE

BACKUP

nated;

c)

The

Alarm

unit

The

d)

amedium

tone

(244

tones

The

e)

glows

extinguished;

Both

f)

display

sensed

A.T.S.

INSPECTION

A.

7.S.1500

have

that

to

representative

results

produce

exactly

that

the

power

ON/STANDBY

the

SELF

the

of

BATTERY

both

Silence

emits

pitched

Hz);

are

more

CUFF

reads

pressure

Tourniquet

the

unit

for

occurred

this

inspection

engineer

with

electronic

be

damaged,

are

satisfactory, a functional

should

the

are

be

AND

CALIBRATION

the

as

device

made.

plug

with

the

ratings

switch

following

sequence:

appears

word

TEST

zeros

and

and

TIME

CHARGING

yellow

CUFF

Switch

pitched

high

a

tone

silenced;

brightly

are

lights

PRESSURE

the

0;

(near

1500

upon

any

obvious

during

immediately.

performed.

results

indicated.

is

of

asterisks

(448

the

for

extinguished;

zero).

shipment.

be

performed

or

other

medical

notify

the

explained

Failure

not

to

be

the

unit

to a source

listed

to

the

on

the

appears

appear

displays;

Light

lights

illuminate;

illuminates;

(996

tone

Hz);

then a low

Silence

Alarm

moment

a

display

SECTION

2.0

TOURNIQUET

3.

Test

the

receipt

on

ON

PRESSURE

on

and

damage

We

by

person

devices.

carrier

and

If

the

initial

and

CHECK

in

the

to

used

until

the

units

position

the

TIME

on

the

yellow

is

illumi-

then

Hz),

pitch

Switch

then

TIME

the

reads

a

If

do

of

the

is

a)

Press

DECREASE)

b)

The

c)

The

pressure

d)

The

momentarily;

e)

The

by units

pressure

f)

The

momentarily;

g)

The

by

mum

h)

Releasing

blink

zero);

i)

Once

DECREASE)

second;

SURE

step

j)

Release

4.

Test

a)

Press

DECREASE)

b)

The

c)

The

setting,

d)

The

e)

The

units

PRESSURE

and

PRESSURE

PRESSURE

setpoint,

PRESSURE

PRESSURE

of

setpoint

PRESSURE

PRESSURE

units

of

of

0)

twice,

again press

after

display

g)

above;

the

the

TIME

and

TIME

TIME

for

TIME

TIME

of

one

SYSTEM

setpoint

hold

the

PRESSURE

touch-switch;

display

display

for

approximately

display

display

one,

until

display

five

to a maximum

mmHg;

the

touch-switch

then

touch-switch

momentary

should

PRESSURE

alarm

hold

touch-switch;

display

display

approximately

display

display

until

210

(or

in

increments

display

display

the

PRESSURE

read

system

the

will

blank

will

read

will

again

increases

70

(or

50),

increases

increases

TIME

system

will

reads

as

INCREASE

blank

“200,’

follows;

momentarily;

the

1.5

seconds;

again

(or

decreases)

190),

thus

altering

of 1 mmHg;

again

(or

decreases)

of

475

(or a mini-

causes

sensed

the

display

pressure

INCREASE

for

approximately

blanking,

the

last

the

setting

touch-switch.

as

follows:

INCREASE

momentarily;

“60/

the

default

1.5

seconds;

blank

momentarily;

(or

decreases)

thus

altering

(or

default

blanks

the

blanks

to

(near

(or

1

PRES-

from

(or

alarm

by

the

time

Page 10

A.T.S.

alarm

f)

The

g)

The

units

of 0)

h)

Releasing

blink

i)

Press

touch-switch

))

After

should

k)

Release

5.

Calibration

NOTE:

described

pressure

performed

transducers

resulting

range

reading

calibration

unit

would

self

checks

detected

use.

Even

power-up,

mended

information

a)

Connect a manometer,

working

hose

this

available

NOTE:

be a cuff

hose

operate

CAUTION:

ble

1500

setpoint

TIME

display

TIME

display

of

five

to a

minutes

the

twice

then

the

TIME

momentary

read

the

Check

During

pressure readings

connection. A suitable

of

the

above,

the

transducers

by

momentarily

to

the

would

and/or a hardware

go

into a CAL

indicates

and

that

though

at

the

following

regular

on

autozero.

the

order,

assembly

from

In

addition

or

assembly

properly.

The

developing

manometers

pressure

measured

b)

Set

the

to

by

desired

PRESSURE

switches. A test

recommended.

c)

Press

the

MAIN

OBSERVE:

increase

accuracy

point.

results

d)

If

the

6

mmHg

to

of

It

is

suggested

of

each

unit

does

of

The

within 6 mmHg

the

the

Calibration.

e)

Repeat

steps a thru

in

increments

again

increases

maximum

of

inflation

touch-switch

display

INCREASE

for

approximately

blanking,

the

last

setting

TIME

touch-switch.

power-up

unit

completes

and

amplifiers.

connecting

atmosphere

as

indicate

FAIL

no

out

the

unit

is

unit

completes

quantitative

intervals.

to

will

Zimmer

other

A.7-S.

can

be

your

See

the

main

normally

see

to

the

volume

to

insure

1500

pressures

measure.

within

manometer.

test

increase

pressure

CUFF

and/or

INFLATE

manometer

manometer)

that a record

calibration

not

inflate

setpoint,

d for

of 1 minute;

blanks

momentarily;

(or

decreases)

of

240

(or a minimum

before

the

alarm

causes

elapsed

(or

one

the

from

the

time

DECREASE)

TIME

step

diagnostic

an

autozero

This

the

and

by

zero

pressure.

an

amplifier

problem

state.

of

sufficiently

exists

Completion

range

reading

calibrated

this

check

check

Section

known

cuff

connector.

be

required

“T”

hose

Figure

to

4.7).

manometer,

attached

the

tourniquet

Tourniquet

greater

Select

the

the

range

pressure

decrease

of

250

touch-switch.

reading

(plus

or

of

the

pressure

be

check

to

identify

the

manometer

please

see

Section

the

SECOND

by

sounds;

display

(zero);

second;

to

display

g)

above;

self-tests,

of

the

autozero

pressure

taking

An

is

and

out

out

of

the

the

the

was

for

during

is

recom-

33

for

more

be

in

good

(A

“T”

to

make

assembly

there

must

to

the

“T”

will

is

capa-

than

some

calibration

that

can

be

using

the

touch-

mmHg

is

should

minus

the

set-

kept

of

the

trends.

to

within

4.3.4,

CUFF.

is

of

of

is

6.

Under

Pressure

Create a leak

the

leak

attempting

more

than

a)

The

begin

b)

The

c)

After

will

in

large

enough

to

maintain

15

mmHg

PRESSURE

to

flash.

Alarm

approximately 1 second,

sound

condition.

nuisance

Stop

the

returns

to

the

Alarm

7.

Leak

Test

The

A.T7.S.

1500

cuff

with a substantial

desirable

minimum.

leakage

Connect

would

commonly

some

or

tightly

to

475

Inflate the

to

stabilize.

to

the

the

resume

Section

using

PRESSURE

current

400

table

traced

should

nectors

to

For

is

recommended.

be

best

used.

object

around

mmHg.

STANDBY

switch

under

2.5

the

ALARM

pressure

mmHg.

leak

rate,

and

be

the

may

keep

both

if

(cylinder,

main

Now

back

part 3 for a description).

touch-switch

Values

corrected.

be

using a bubble

50/50),

combinations.

the

and

has

second

NOTE:

Luer

together

connect

leak,

8.

the

or

source

the

unit

been

cuff.

Luer

connector

snugly

or

it

must

Ifall of

the

A.T.S.

by

testing

Elimination

of

the

should

repaired.

connectors

disconnect.

be

previous

1500

Alarm

the

main

cuff

that

pressure,

below

display

Silence

announcing

This

Switch

delay

alarms.

leak

and

observe

within

limits,

Silence

Switch

Tourniquet

leak

plumbing

this

reason, a check

pairs

of

cuff

the

cuffs

were

The

cuffs

should

coffee

themselves.

Ensure

cuff

move

that

and

the

position.

to

the

ON

Cuff

Inflated

SILENCE

for

setpoint.

and

less

the

This

than

source

The

Luer

connectors

tested

by

solution

different

of

leak

points

be

removed

Repeat

have a finite

is

used,

the

but not

requiring

If a Luer

replaced.

seven

Tourniquet

Check

while

it

is

inflated.

even

though

setpoint.

and

illuminates.

the

is

the

audible

light

is

capable

inflated.

leaks

connectors

the

can

Set

all

connections

allow

the

the

pressure

Observe:

MAIN

CUFF

an

audible

pressure-out-of-limits

used

to

that

the

tone

extinguishes.

of

Naturally

to

an

for

significant

to

ones

that

be

wrapped

or

something

the

desired

the

ON/STANDBY

After

10

minutes,

position.

Start-up

Operation

Conditions

Cancel

pushbutton.

one

value

this

of

first

connection

of

submersing

(soap

cuffs

the

cuff

to

the

same

two

mating

Activate

second

should

indicate

the

leak

the

cuffs.

them

and

water

and/or

and

cuff

leak

being

from

service

procedures

life.

parts

all

of

your

and

an

Whenever

connector

checks

is

ready

were

successful,

for

use.

Make

unit

will

be

still

falls

light

tone

preclude

pressure

ends,

and

keeping

it

absolute

cuffs.

are

most

around

similar)

pressure

are

snug.

pressure

switch

move

will

(see

the

alarm

either

view

the

be

at

least

unaccep-

should

to

check

The

in

be

con-

water,

mixture

cuff

hose

hoses

as

internal

until

for

should

strength

is

found

a

is

It

it

a

fit

to

to

o

Page 11

2.3

INSTALLATION

The

A.TS.

mounted

range

of

the

accommodate

(1.25

to

3.8

The

power

restraining

of

the

IV.

the

likelihood

the

event

of

Connect

polarized

and

those

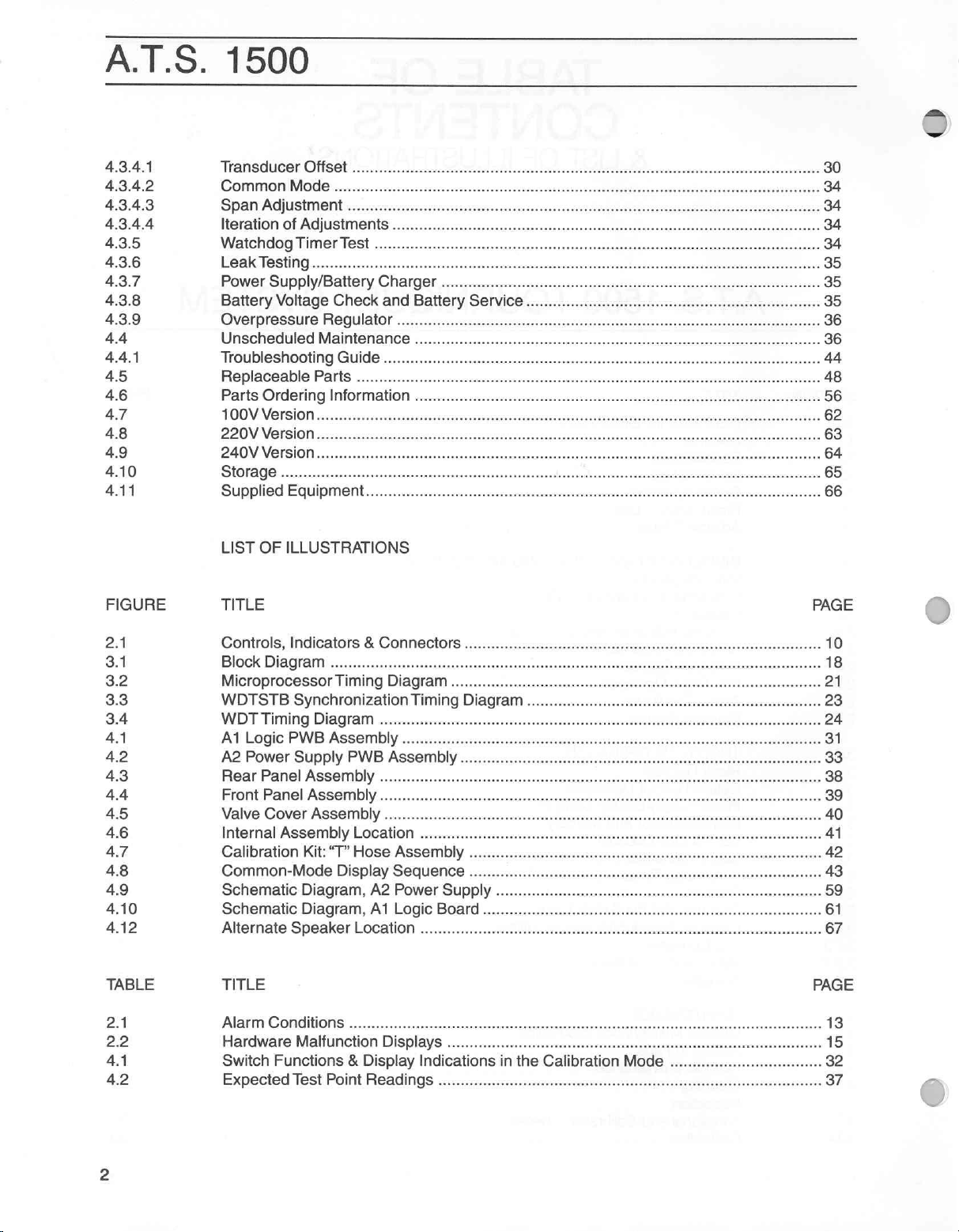

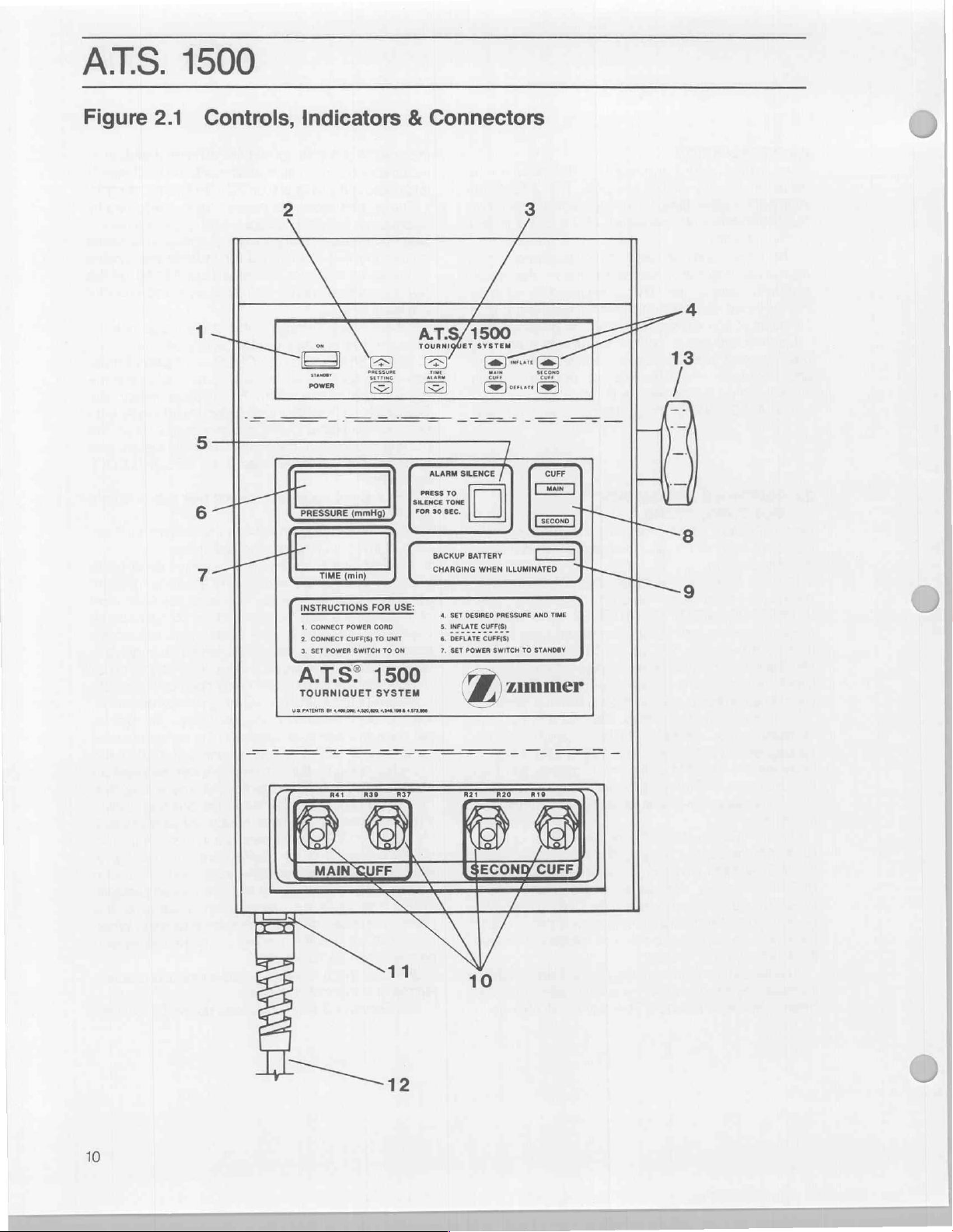

2.4

Refer

indicators,

and

frequency

listed

The

A.T.S.

CONTROLS,

AND

CONNECTORS

to

Figure

and

described

1.

POWER

nected,

2.

current

ting

PRESSURE

ting

current

increase

desired

this

PRESSURE

pressure

touch-switch

for a moment,

cuff

To

change

(+)

setting

increments

in

increments

switch

is

released

reached.

Other — See

tions

of

the

3.

TIME

ALARM

time

alarm

switch

for

up

blank,

display

then

return

the

touch-switch

To

change

increase

desired

(+)

setting

1500

Tourniquet

on

any

stable

pole

clamp

on

pole

diameters

cm).

cord

of

each

strap

that

should

pole

in

use.

This

of

upsetting

an

inadvertant

the

power

cord

grounded

characteristics

on

the

nameplate

1500

Tourniquet

INDICATORS,

2.1

for

the

connectors.

below.

SWITCH — With

switch

turns

the

SETTING

setting,

for

display

pressure

of 1 mmHg

will

and

when

pressure

or

decrease

is

reached.

blank,

then

setting,

for

of 5 mmHg

or

the

Section

switches

4.3.4

during

SWITCHES — To

setting,

to

depress

to

1.5

seconds.

the

time

alarm

displaying

is

released.

time

alarm

or

decrease

is

reached.

the

setting,

is

designed

I.V.

pole.

The

the

right

side

of the

of

0.5

to

unit

is

eguipped

be

attached

is

intended

the

pole

jerk

on the

of

the

power

source

are

of

the

is

locations

Their

primary

the

unit's

unit

on

to

mounted

power

unit

to a properly

whose

compatible

unit.

now

ready

of

the

unit's

functions

power

and

SWITCHES — To

depress

up

the

the

limits

either

to

1.5

seconds.

display

touch-switch

(—)

The

first

thereafter

of

the

return

to

depress

touch-switch

setting

10

mmHg,

until

of O or

this

475

manual

pressure

displaying

and

will

Calibration.

view

either

time

alarm

The

TIME

setting

for a

moment,

current

(—)

The

inflation

depress

and

touch-switch

setting

will

to

adjustment

unit

1.5

inches

with

the

bottom

to

minimize

unit

cord.

voltage

for

use.

controls,

cord

con-

off.

view

The

pressure

is

released.

hold

until

change

and

then

the

touch-

mmHg

for

func-

the

current

touch-

display

time

when

hold

until

change

be

will

a

in

with

are

the

set-

set-

the

the

the

in

are

will

and

the

the

in

increments

increments

is

released

The

depressing

switches

enable

at

the

power

setpoint).

of 1 min.

of 5 minutes

or

the

accumulated

the

simultaneously

the

unit

same

pressure

(and

thus

Other — See

tions

of

these

switches

4.

INFLATE/DEFLATE

tion

of

the

cuff(s)

appropriate

DEFLATE

one

second

main

cuff

when

the

light

is

NOTE:

other

cuff

touch-switch.

touch-switch

before

is

inflated,

second

on.

It

is

not

possible

is

inflating.

Other — See

tions

of

these

switches

5.

ALARM

button

conditions

of

these

depressing

lighted

when

malfunction,

6.

PRESSURE

with

will

show

range

the

other

in

the

be

viewed

touch-switches

above.

within

when

Section

When

pressures

both

pressures

See

alarms

See

SILENCE

switch

will

exist.

The

alarms

this

until

the

alarm

an

alarm

condition

the

tone

DISPLAY — During

no

touch-switches

the

pressure

of 0 to

475

deflated,

inflated

on

cuff.

this

are

When

the

15

mmHg

there

is a sustained

2.81,

this

both

cuffs

sensed

cuffs

are

deflated,

will

be

Section

Section

or

abnormal

2.8

4.3.4

A.T.S.

for

the

first

10

thereafter

limits

of O or

inflation

time

increase

for

to

be

used

setting

erasing

Section

the

4.3.4

during

SWITCHES — Inflation

is

accomplished

must

deflation

the

MAIN

cuff

is

inflated,

to

Section

4.3.4

during

SWITCH — This

light

when

audible

may

be

silenced

switch.

The

conditon

is a result

cannot

being

sensed

mmHg.

the

display

The

desired

display

operated

sensed

of

the

pressure

desired

leak

display

are

inflated,

in

the cuffs

will

the

displayed.

for

other

conditions.

for

indications

until

240

minutes

time

may

and

two

seconds.

for

multiple

without

previously

of

this

Calibration.

For

greater

be

depressed

commences.

CUFF

the

deflate

of

this

Calibration.

any

of a

tone

associated

push-button

is

corrected.

be

silenced

depressed,

in

With

one

will

pressure

when

the

in

accordance

pressure

present

flash

the

an

will

be

highest

possible

1500

min.

and

the

touch-switch

are

reached.

be

set

to

decrease

This

procedures

turning

stored

manual

by

SECOND

one

manual

number

for

of

an

normal

the

cuff

show

pressure

in

the

sensed

average

displayed.

of

the

indications

during

for

depressing

safety,

longer

When

light

is

cuff

when

for

lighted

with

30

seconds

will

In

internal

by

this

operation,

this

cuff(s)

over

inflated

the

pressure

setting

with

cuff(s)

setting,

as

described

pressure.

two

Calibration.

then

in

zero

by

touch-

would

off

the

pressure

func-

or

defla-

the

the

than

the

on,

and

CUFF

the

func-

push-

of

alarm

most

by

remain

general,

circuit

switch.

display

the

and

may

setting

item

2

is

not

or

in

of

the

When

sensed

during

O

Page 12

ΑΤ.5.

Figure

2.1

1500

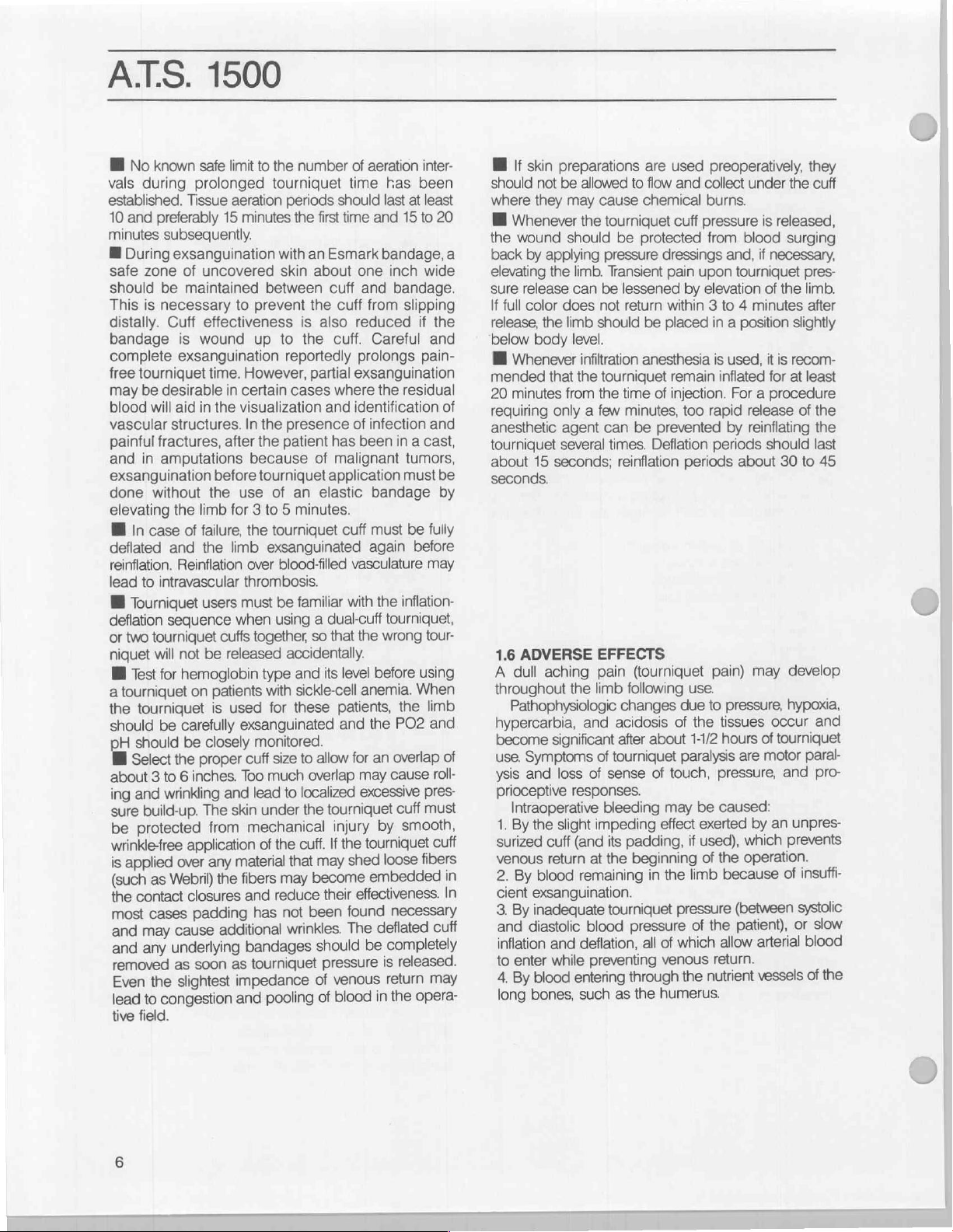

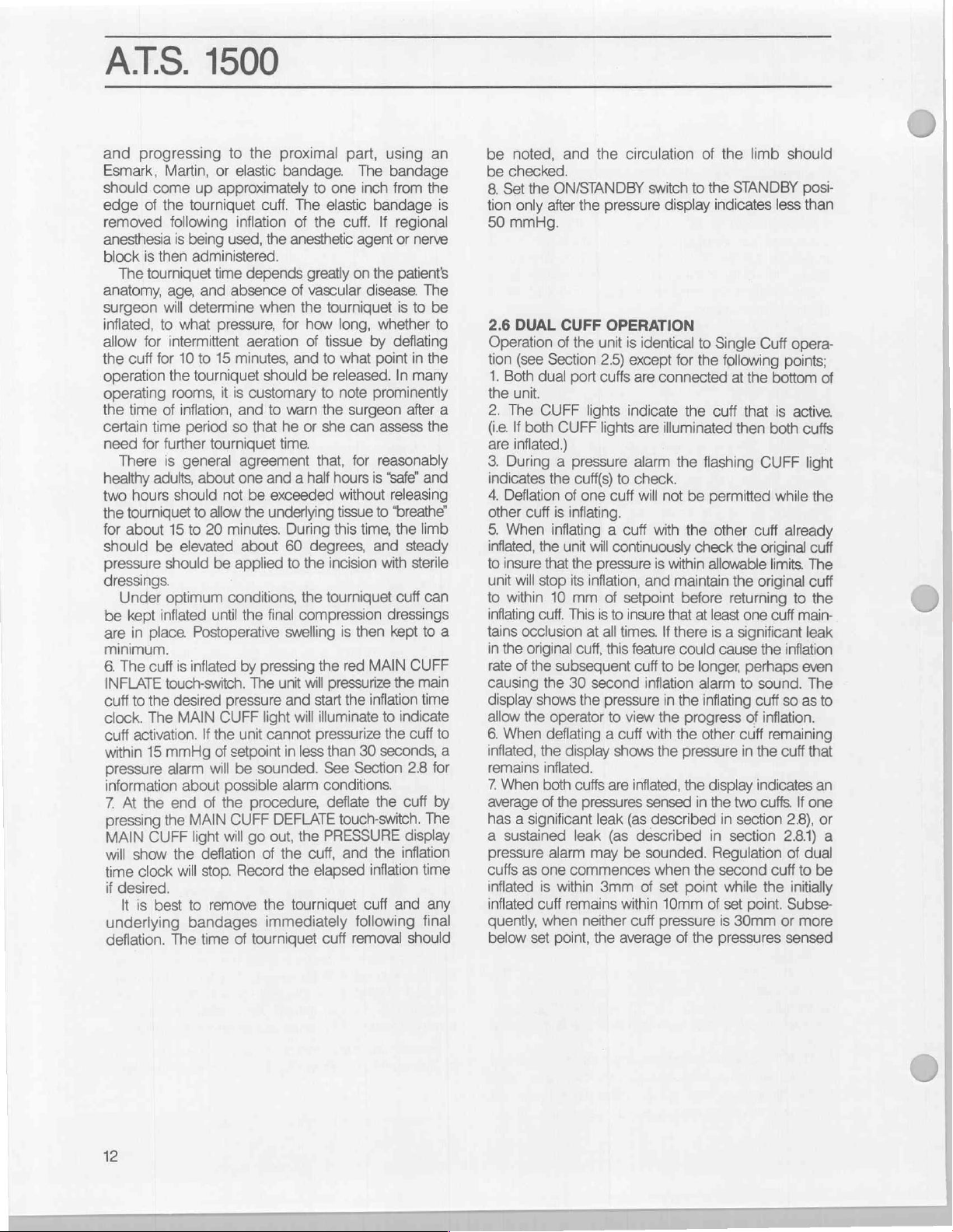

Controls,

Me

i

MT

6

7

—İ

TT

Indicators & Connectors

2 3

x 7

HT

PRESSURE

厂

INSTRUCTIONS

=a

TIME

4.

CONNECT

2.

CONNECT

3.

SET

N

EA

(min)

POWER

CUFF(S)

POWER

(mmHg)

FOR

CORD

TO

SWITCH

(

‘SILENCE

|”

USE:

UNIT

TO

ON

AT.

PRESS

“

ALARM

SILENCE

TO

TONE

SEC.

30

BACKUP

CHARGING

4.

SET

5.

INFLATE

6.

DEFLATE

7.

SET

a

500

ma

/

圖

BATTERY

WHEN

DESIRED

PRESSURE

CUFF(S)_

CUFF(S)

POWER

SWITCH

t

ILLUMINATED.

CUFF

(esses)

[==

AND

TIME

TO

STANDBY

TA

+

—

=

H

\

|

|

/

L

>

|

8

440000:

432000,

2

4346100

CUFF

m

US.

PATENTE

DV

01

MAIN

P

437.00

VA

ECOND/

0

ammer

CUFF

/

10

Page 13

7.

TIME

DISPLAY — During

touch-switches

the

inflation

to a

maximum

may

be

touch-switches

above.

If

setting,

See

Section

abnormal

See

Section

8.

CUFF

active.

Lights

indicate

9,

BACKUP

when

the

higher

illuminated

nected

battery

for

being

time

of

the

of

240

viewed

the

the

on

are

operated

inflation

display

2.8

conditions.

4.3.4

LIGHTS — Indicates

flash

which

cuffs

BATTERY

backup

level

charging

when

the

more

than a few

in

the

unit,

receiving a charge.

intervals,

charged

transition

also

be

up

or

between

off

while

to a few

the

battery

the

recover a severely

Section

10.

cuff(s).

11.

against

replaced

12.

unit

13.

unit

2.5

1.

tion,

source

nameplate

2.

connectors.

3.

unit

described

completion

to

CAUTION:

that

during

declare

3.2.1

for

battery

CUFF

CONNECTORS

PRIMARY

POWER

when

POLE

on

an

SINGLE

With

the

connect

that

LINE

internal

only

with

CORD — Supplies

connected

CLAMP — Adjustable

IV.

pole.

CUFF

ON/STANDBY

the

is

compatible

of

the

Connect a dual

Set

the

ON/STANDBY

will

execute a self-check

in

Section

of

the

use.

Special

if

either

cuff

power-up,

it

an

abnormal

overloads.

one

power

device.

port

self-check

is

normal

depressed,

cuff(s)

minutes.

this

display

in

time

has

will

flash

for

indications

for

indications

operation,

this

in 1 min.

The

time

when

accordance

exceeded

the

current

during

during

which

when a pressure

to

check.

LIGHT — This

battery

is

states.

power

charging

The

cord

has

seconds

or

if

the

battery

The

light

may

go

minutes,

charging

trickle

discharged

charger

FUSE

of

to

appropriate

if

charger

states.

charger

—

Ports

—

Protects

This

the

same

primary

the

has

battery.

operation.

to

clamp

OPERATION

switch

in

the

cord

to

an

with

the

ratings

cuff

to

the

unit

switch

to

the

diagnostic

2.2

of

this

manual.

indicates

note

should

pressurized

the

A.T.S.

be

to

50

1500

start-up

with

display

will

increments

alarm

the

time

with

the

time

inflation

alarms

Calibration.

cuff

or

cuffs

alarm

occurs

light

is

illuminated

in

one

light

will

not

been

discon-

or

if

there

is

incapable

off

for

varying

battery

just

made

The

light

is

attempting

Refer

connect

fuse

type

receptacle.

power

should

and

AC

to

mount

tubing

rating.

power

STANDBY

electrical

listed

at

the

main

ON

position.

test

Successful

the

unit

is

made

of

the

mmHg

or

Tourniquet

sequence.

no

show

up

setting

alarm

item

3

alarm

time.

or

are

to

of

the

be

is

no

of

is

fully

a

will

to

to

to

line

be

to

the

posi-

power

on

the

cuff

The

as

ready

fact

more

will

It

will

assume

will

cuff

the

(depending

in

the

pitched

light.

pressure

alarm

that a surgical

adopt

the

as

the

new

inflation

excess

of

operator

tone

The

operator

set

is

cleared

higher

mode

on

whether

50

of

this

and

point

Switch.

4.

In

the

absence

preset

values

for

time

alarm

of

200

These

decrease

to

tive

applied

the

5.

The

the

the

values

pressing

For

each

the

minimum

pressure

account

normal,

operative

pated

rise

Set the

ing

the

switch

until

desired

(+)

or

decrease

Prepare

lished

procedures

may

the

PRESSURE

(—)

touch-switch

patient,

should

factors

to

an

upper

hyperthrophied,

systolic

in

systolic

desired

PRESSURE

the

desired

inflation

the

patient

precautions

offered

possible

cular

positions

niquet

area

of

inflated

wrinkles.

be

the

pared

and

as a guide

In

most

cases a tourniquet

widest

part

to

lie

between

structures

are the

thigh.

In

certain

cuff

can

proximal

the

to

hand, a sufficiently

around

Apply a leak-free

The

valve

placed

limb

so

is

positioned

and

draped

deeper

that

tissues

exsanguination

Exsanguinate

of 2 minutes

and

ATS.

procedure

of

the

set

point.

It

and

regulate

either

mmHg)

effective

such

(—)

of

susceptible

be

the

of

the

to

condition,

illuminate

should

and

readjust

by

depressing

of

operator

desired

mmHg

and

be

observed

and/or

tourniquet

pressure.

be

determined

as:

or

lower

or

pressure;

pressure

cuff

pressure

increase

setting

time

alarm

touch-switches.

in

accordance

and

cuff

of

Section 1 and

to

assist

the

limb

the

upper

arm and

cases

of

applied

the

malleoli. For

wrist.

tourniquet

stem

and

the

tubing

for

surgery.

for

surgery.

should

the

limb

limb

by

wrapping

is in

pressures

will

the

the

the

immediately

cuff

60

for

up

whether

limb;

obese;

and

(+)

is

using

manufacturer's

sensed

automatically

either

or

or

both

had

new

set

point.

unit

will

Alarm

Silence

it

if

necessary.

the

Alarm

action,

the

pressure

minutes

on

the

TIME

increase

to

1.5

seconds.

pressure

The

the

should

minimum

by

cuff

whether

the

the

maximum

during

the

by

pressing

or

decrease

reached.

the

TIME

with

the

in

this

process.

cuff

should

to

allow

as

much

cuff

and

any

nerves

to

damage.

fore-foot

around

small

cuff

tube

will

The

be

and

tourniquet

elevating

it,

starting

The

the

proximal

surgery,

the

calf

emergency

tourniquet

smoothly

connections

not

be

The

limb

viability

established

it

for a minimum

from

1500

process

sound a high

unit

and

respectively.

displays

patients

procedure.

Similarly

instructions.

following

be

kinked

and

in

each

go

into

both

cuffs

pressures

To

alert

Switch

check

the

The

Silence

adopts

inflation

by

(+)

or

be

set

effec-

taking

is

the

into

to

be

limb

is

pre-

antici-

and

hold-

(—)

touch-

set

increase

your

estab-

are

applied

tissue

as

or

vas-

optimum

third

the

tour-

or

to

the

surgery

can

be

without

at

of

should

when

is

then

pre-

of

the skin

prior

to

inflation.

the

distal

1

Page 14

ATS.

and

progressing

Esmark,

should

edge

removed

anesthesia

block

The

anatomy,

surgeon

inflated,

allow

the

operation

operating

the

certain

need

healthy

two

the

for

should

pressure

dressings.

be

are

minimum.

6.

INFLATE

cuff

clock.

cuff

within

pressure

information

7.

pressing

MAIN

will

time

if

desired.

underlying

deflation.

Martin,

come

of

the

following

is

is

then

tourniquet

age,

will

to

what

for

intermittent

cuff

for

10

the

rooms,

time

of

time

for

further

There

is

adults,

hours

should

tourniquet

about

15

be

elevated

should

Under

optimum

kept

inflated

in

place.

The

cuff

is

touch-switch.

to

the

desired

The

MAIN

activation.

15

mmHg

alarm

At

the

end

the

CUFF

show

the

clock

will

It

is

best

The

1500

to

the

or

elastic

up

approximately

tourniquet

being

administered.

and

determine

to

tourniquet

inflation,

period

tourniquet

general

about

to

allow

to

20

be

until

Postoperative

inflated

If

the

will

about

of

MAIN

light

deflation

stop.

to

remove

bandages

time

cuff.

inflation

used,

the

time

depends

absence

when

pressure,

aeration

15

minutes,

should

it

is

customary

and

so

that

agreement

one and a half

not

be

the

minutes.

about

applied

conditions,

the

by

pressing

The

pressure

CUFF

light

unit

cannot

of

setpoint

be

sounded.

possible

the

procedure,

CUFF

will

go

of

Record

the

immediately

of

tourniquet

proximal

bandage.

to

one