Page 1

MINIPAN

®

digital panel meters, temperature

-

and mains controlling,

special purpose instruments for customer requirements www.ziehl.com

Operating manual

Limit Value Switch TR 210

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 1 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 2

Index Page

Application and short description ...................................................................................3

Overview of the functions...............................................................................................3

Connection plan.........................................................................................................3

Display- and operating elements ...................................................................................3

Programs .......................................................................................................................4

Important informations ...................................................................................................4

Installation......................................................................................................................6

Starting ..........................................................................................................................6

Display mode.............................................................................................................6

Menu mode................................................................................................................6

Parameter setting mode ............................................................................................6

Indication of the digital display ..................................................................................9

Operation Program 1 – 1 Sensor / 2 limit values .......................................................10

Operation Program 2 – 2 Sensors / per 1 limit value .................................................11

Operation Program 3 – 1 Sensor / 2 limit values day, 2 limit values night .................12

Operation Program 4 – 2 Sensors / per 1 limit value day and night...........................13

Operation Program 5 – 2 Sensors / difference in temperature S 2 minus S 1 ...........14

Operation Program 6 – 1 input 0–10 V or 0/4-10 mA / 2 limit values.........................15

Operation Program 7 – 2 inputs 0–10 V or 0/4-10 mA / per 1 limit value...................16

Operation Program 8 – 2 inputs 0–10 V or 0/4-10 mA / difference S 2 minus S 1.....17

Operation Program 9 – 2 Sensors / 2 Limits MIN/MAX .............................................18

Function diagram ......................................................................................................18

Factory setting and software version .............................................................................19

Error search and measures ...........................................................................................20

Technical data ...............................................................................................................20

Housing..........................................................................................................................22

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 2 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 3

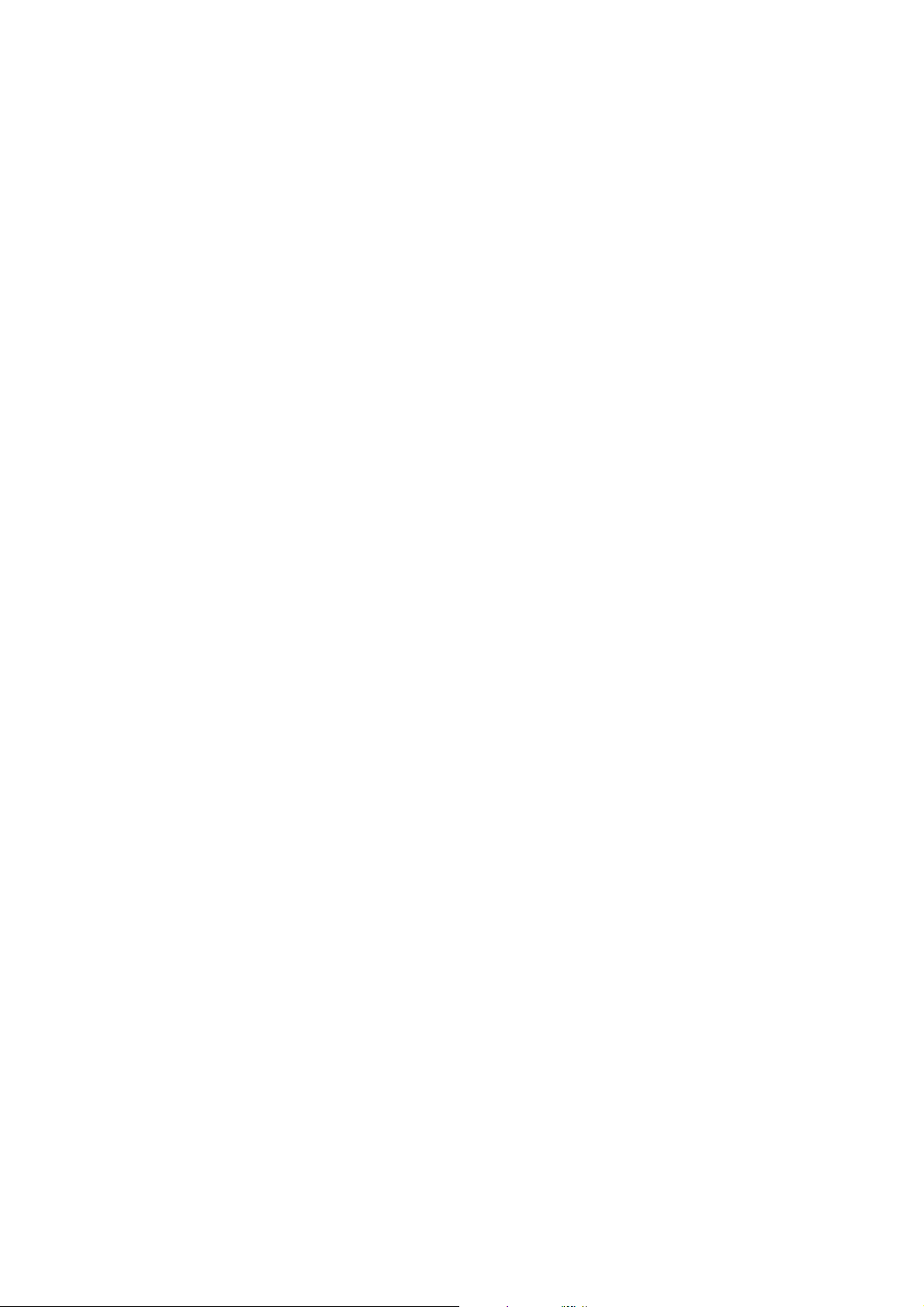

Connection Plan

Application and Short description

Control units type TR 210 control up to 2 limit values.

The TR 210 is used as:

• General temperature protection of machines and installations

• Temperature control unit, also for cooling applications

• Difference temperature controller unit for air-conditioning technology

Overview of functions

• 2 Sensor inputs:

• Pt 100, Pt 1000, KTY 83 or KTY 84

in 2- or 3-wire configuration

• Thermocouples

Type B, E, J, K, L, N, R, S, T

• Input signal DC 0-10 V;

DC 0/4-20 mA

• 0,1 °C resolution between

–199,9...999.9 °C

• 2 Relay outputs (each 1 change-over

contact)

• 1 Analogue output DC 0-10 V or

0/4-20 mA parameterizable (not potentially

separated from the inputs)

• Universal power supply AC/DC 24-240 V

• Several selectable programs

• Storage and indication of the measured

MIN- und MAX-values

• pluggable terminals

Display and operation parts

1, 3 LEDs state of relay

2 Digital display, 4 digits

4, 5 LEDs day/night switching

6 LED measuring of differences

7 Up pushbutton

8 Pushbutton set/reset

9 Down pushbutton

10, 11 LEDs sensor

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 3 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 4

Programs

9 programs (Pr), that are preset ex works, can be selected. Due to these programs, the

device can be adapted very easily to the application.

Choose the program, which fits to your application and after that change the parameters! In

case of changing the program, each parameter is being resetted to "factory setting".

(see chart " factory setting")

Choosing the programs:

When applying the power supply hold the pushbutton Set for 10 s. Then the program

(Pr 1 ... Pr 9) can be selected with the pushbuttons up/down and confirmed with Set.

Pr Input Limit value

1* 1 temperature sensor 2

2 2 temperature sensors 1 per sensor

3 1 temperature sensor 2 day and 2 night

4 2 temperature sensors 1 day and 1 night per sensor

5 2 temperature sensors 2 difference temperature

6 1x 0-10 V or 0/ 4-20 mA 2

7 2x 0-10 V or 0/ 4-20 mA 1 per input

8 2x 0-10 V or 0/4- 20 mA 2 difference

9 2 temperature sensors 2 MIN/MAX

* factory setting

Please note:

Pr 1, 2, 5-9: Y1 / Y2 = remote – reset (external)

Pr 3+4: Y1 / Y2 = switching day / night

Important Information

To use the equipment flawless and safe, transport and store properly, install and start

professionally and operate as directed.

Only let persons work with the equipment who are familiar with installation, start and use

and who have appropriate qualification corresponding to their function. They must

observe the contents of the instructions manual, the information which are written on the

equipment and the relevant security instructions for the setting up and the use of electrical

units.

The equipments are built according to DIN / EN and checked and leave the plant

according to security in perfect condition. To keep this condition, observe the security

instructions with the headline „Attention“ written in the instructions manual. Ignoring of the

security instructions may lead to death, physical injury or damage of the equipment itself

and of other apparatus and equipment.

If, in any case the information in the instructions manual is not sufficient, please contact

our company or the responsible representative.

Instead of the industrial norms and regulations written in this instructions manual valid for

Europe, you must observe out of their geographical scope the valid and relevant

regulations of the corresponding country.

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 4 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 5

Dangerous electrical voltage!

May lead to electrical shock and burn.

Before beginning of work switch unit and equipment free of voltage.

Observe the maximum temperature permissible when installing in switching

cabinet. Make sure sufficient space to other equipment or heat sources. If the

cooling becomes more difficult e.g. through close proximity of apparatus with

elevated surface temperature or hindrance of the cooling air, the tolerable

environmental temperature is diminishing.

Attention! Connecting the temperature sensors

The temperature sensors are connected to the clamps 1T1, 1T2, 1T3 and so on. These

pluggable terminals have a special contact material and may only be used for the connection

of the sensors.

When connecting 2 thermocouples they must be isolated from each other.

Attention! Universal power supply

The unit is equipped with an universal power supply, that is suitable for DC- and AC-voltages.

Before connecting the unit to the current, make sure that the allowed scope of voltage of the

control voltage Us, written on the lateral type plate, corresponds to the supply voltage of the

unit.

ATTENTION

Attention!

When all relays are programmed in operation current mode

(= pick up at alarm), a loss of the supply voltage or an instrument failure

can remain unidentified.

!

When the relay is applied as control instrument, the operator must ensure,

that this error is recognized by regular examinations.

We recommend to program and accordingly evaluate at least one relay

in the closed-circuit current mode.

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 5 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 6

Installation

The unit can be installed as follows:

• Installation in switchgear cabinet on 35 mm mounting rail according to EN 60715

• With screws M4 for installation on walls or panel. (additional latch included in delivery)

Connection according to connection plan or type plate.

Putting into operation

Decimal point behind the last digit:

Off = display mode, displays values of measuring inputs

On = menu mode, select the menu items

blinking = parameter setting mode

Display mode

Indication of the current sensor temperature. The temperature is shown in degrees

centigrade. The indication for voltage (0-10 V) and current (0/4-20 mA) can be scaled.

LED relay (K1, K2)

ON = relay picked up

LED sensor

ON = appropriate value in the display

flashes = sensor error

Function of buttons UP/DOWN

Push short change into menu mode

Push for > 2 s Display of the stored MIN- or MAX values of the chosen sensor

Function button SET/RESET

Push short

two sensors Display sensor 1 / sensor 2 (/ difference)

one sensor Display sensor / alarm limit 1 / alarm limit 2

Push for 2 s Reset restart interlock

Push for 4 s Display of chosen program

Push for 10 s Display of software version

Menu mode (Decimal point behind the last digit ON)

Selection of the menu items for changing the parameters. In the menu items for sensorand alarm parameterizing the LEDs indicate the special classification sensor-alarmday/night - difference.

Function button UP/DOWN

Push short Selection of menu item; Change into display mode

Function button SET/RESET

Push short Change into parameter setting mode

Parameter setting mode (Decimal point behind the last digit FLASHES)

LEDs indicate sensors and relays concerned by the selected parameter setting point as

well as day/night-switching and differentiation measurement.

Function button UP/DOWN

Press short/long Adjustment of parameter value (slow/fast)

Function button SET/RESET

Press short Storage of setting and choice of next parameter.

Change into menu mode after the last parameter

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 6 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 7

Parmeterizing the sensors (S 1 / S 2):

Dependent on the chosen program: temperature (Pr 1-5, 9) or current/voltage (Pr 6-8)

Choose menu item with up/down until in indication S 1 and type of sensor alternate.

Here it can be read clearly, which type of sensor is selected and on which alarm the sensor

works (corresponding LEDs alarm on).

Enter with Set in parameterizing sensor e.g. S 1 / 100 for Pt 100.

Choose sensor type with up/down

Set cable resistance or 3-wire configuration (3-L).

2-wire configuration, cable resistance compensation:

Short-circuit the wires nearby the sensor and measure the cable resistance. Set

parameter „LA“ on this value.

With 2-wire connection and a common wire for all sensors, all sensor measuring currents

will be added on the common wire. The compensation value LA to be set is calculated as

follows:

LA = 3 x RL/2 (RL = resistance of two wires)

We recommend 3-wire connection for each sensor.

Parameterizing of the alarms (AL 1 / AL 2):

Choose menu item with up/down until AL 1 and limit (limit value) alternate in display, e.g.

AL 1 und 130 for 130 °C.

Here it can be read clearly, which limit value is parameterized and to which sensor works

on the alarm (yellow LEDs sensor on).

Begin to parameterize with Set.

Adjust limit with up/down. Adjust hysteresis. Negative hysteresis = MAX-switching point, the

relay switches when the adjusted limit is reached and switches back when the signal is

fallen by the hysteresis. E.g. limit 130 °C and hysteresis -5 °C: Relais switches at 130 °C

and switches back at 125 °C. Positive hysteresis vice versa = MIN-switching point.

Alarm delay time dAL: An alarm is suppressed for the adjusted time, short-timed exceeding

of the limit does not cause an alarm.

Switch-back delay doF: An alarm is only switched off after the signal is below the limit and

after delay of this time, e.g. a cooling ventilator can cool further on for this time to avoid,

that it has to switch be switched on again after a short time.

Function of relay:

rrrr-Closed-current circuit mode, relay is picked up in GOOD-state (=limit not reached) and

releases when the limit is exceeded. Advantage: errors and faults normally cause an

alarm. Disadvantage: alarm also when supply-voltage is switched off and after

switching on until the relay has picked up. Unfavourable e.g. with transformers,

particularly, when the supply-voltage of the TR 210 comes from the monitored

transformer.

AAAA-Operating-current mode: relay is released in GOOD state and picks up when the limit is

exceeded. No alarm at errors and when supply-voltage switched off. Used normally

switch ventilators or heatings or for tripping of transformers.

rrrr----L / A

L / A----LLLL: alarm switches locked. Set back with reset only after fall short of the limit (with

L / AL / A

hysteresis) and end of the switch-back delay. Ready for Reset is indicated with „A12LLLL“

in the display mode.

Error report: With Err it can be selected, if the relay switches in the alarm state in case of

sensor-error Er1-9 (short circuit or break). (on / oFF)

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 7 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 8

Test relay (tSt):

Here it can be programmed, that a relay switches into the alarm state after a certain time

don, e.g. 1 weeks (= 168 hours) for the time doF, e.g. 10 s, to make a ventilator or a pump

run for a short time, to make them move and protect the bearings from damage through

long standstill.

Choice of the alarm with up/down. Set switches to don and doF.

don = oFF = test not active.

Sensor simulation (Si):

A sensor can be selected, and a measured temperature can be simulated with the buttons

up/down. All functions of the unit work as if this temperature was really measured. If there

is no button pushed for 15 minutes, the device automatically switches back into the display

mode.

CodE:

After setting all parameters they can be protected by activating the code lock. After pushing

Set, the display indicates Pin. Adjust with buttons up/down Pin 504 (factory setting). After

pushing Set, code lock can be activated or switched off. After pushing Set again, an

individual Pin can be selected (write down).

When code lock is activated all parameters can be seen but not be changed anymore.

In case of problems with the code lock (forgotten Pin) the lock can be switched off and the

Pin can be set back to 504, by pushing button set while connecting the device to supplyvoltage until Code / ofF is indicated in the display.

Tips:

- With the pre-set programs Pr1 to Pr9 the most important parameters can be set in

advance, so that only little modifications are necessary, e.g. setting of the limits (limit

values) for each alarm.

- After finishing one menu item it is switched automatically on the next one. E.g. after

programming the line resistance of sensor 1 and pushing Set, the devices switches on to

sensor 2.

- When the right decimal point in the 7 segment display is on, the display mode has been

left, and the menu items can be chosen with up/down (menu mode).

- When the right decimal point blinks, you are in the parameter setting mode and can change

the setting with up/down.

- Long pushing on up/down speeds up the changes in the display.

- Pushing button up and down at the same time sets values to zero.

- With reset (press set/reset for 2s) the display mode can be reached from every position

(exception: simulation) of the parameter setting mode (the last selected value in is being

stored).

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 8 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 9

Indication of the digital display:

Pr1

Pr1 ... Pr9

Pr1Pr1

A1

A1, A2

A1A1

A12

A12 = alarm 1 and alarm 2 active

A12A12

Pr9 = program number

Pr9Pr9

A2 = alarm 1 or alarm 2 active

A2A2

additional L = alarm locked, for setting back „reset“ is necessary.

SSSS = sensor

100

100, 1000

1000 = Pt 100, Pt 1000

100100

10001000

83

83, 84

84 = KTY-sensor 83, 84

8383

84 84

LA

LA = 2-wire cable resistance

LALA

3333----LLLL = 3-wire configuration

Thermocouples (th..)

Display

thb thE

thbthb

thE thJ

thEthE

thJ thk

thJthJ

thk thL

thkthk

thL thn

thLthL

thn thr

thnthn

thr thS

thrthr

thS tht

thSthS

tht

thttht

thb

Type B E J K L N R S T

CoMP

CoMP = compensation of the reference temperature of thermocouples

CoMPCoMP

int

int = internal reference temperature or fix reference temperature

intint

0000----10

0/4

SCAL

Auto

USEr

____

dP

AL 1

AL 1, AL 2

AL 1AL 1

ALd

Aln

10 = 0-10 V voltage input

1010

0/4----20

20 = 0/4-20 mA current input

0/40/4

2020

SCAL = scaling of display for voltage- and current input

SCALSCAL

Auto = to adopt zero point, full scale and decimal point from the chosen type

AutoAuto

USEr = free scaling of zero point, full scale and decimal point

USErUSEr

____ = zero point value for 0 V, 0/4 mA

________

,,,,

,,,,

,,,,,,,,

= full scale value for 10 V, 20 mA

dP = decimal point

dPdP

AL 2 = alarm limit

AL 2AL 2

ALd = alarm limit day

ALdALd

Aln = alarm night

AlnAln

HHHH = hysteresis

dAL

dAL = alarm delay (time delay until alarm)

dALdAL

doF

doF = switch back delay (time delay until alarm switches back to good)

doFdoF

rEL

rEL = function of relay

rELrEL

rrrr, AAAA = closed-circuit current mode, operating current mode

rrrr----LLLL, AAAA----LLLL = closed-circuit- / operating current with interlocked switching (LLLLocked)

tst

tst = relay test periodically in hours after the time don for the duration doF

tsttst

don

don = periodical time in hours for testing alarm/relay (oFF = no test)

dondon

doF

doF = duration of test

doFdoF

EEEE = exit (leave loop)

ovt

ovt = analogue output: oFF, 0-10 V, 0-20 mA, 4-20mA parameterizable

ovtovt

SEn

SEn = sensor select for analogue output

SEnSEn

S12,

S12, = maximum value of sensor 1 or sensor 2 is put out

S12,S12,

S12_

S12_ = minimum value of sensor 1 or sensor 2 is put out

S12_S12_

____

____ = value, at which 0 V, 0/4 mA is put out

________

,,,,

,,,,

,,,,,,,,

= value, at which 10 V, 20 mA is put out

diF

diF = difference sensor 2 minus sensor 1

diFdiF

on

on, oFF

oFF = on/off

onon

oFFoFF

Si

Si = simulation

Si Si

CodE

CodE = code (pin)

CodECodE

Pin

Pin = factory setting of Pin: 504

PinPin

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 9 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 10

Parameter setting mode

Display mode

Menu mode

Operation: Pr1

Pr1 / 1 temperature sensor, 2 limit values

Pr1Pr1

2 s = Max

Sensor 1

2 s = Min

SSSS 1111

AAAALLLL 1111

Limit

Typ

AAAALLLL 1111

----222288880000

...2222000000000000

111100000000

1111000000000000

88883333

88884444

tttthhhh..

Limit alarm 1

----222288880000...

2222000000000000

AAAALLLL 2222

LLLLAAAA

CCCCooooMMMMPPPP

----222288880000

...2222000000000000

0000..111100000000

3333----LLLL

0000..111100000000

iiiinnnntttt

----111199999999....9999

...999999999999....9999

ddddAAAALLLL

0000..9999999999999999 s

Operation with pushbuttons:

Up

Set

Down

ddddooooFFFFHHHH rrrrEEEELLLL

0000..9999999999999999 s

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

Reset

= >2s Set

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

AAAALLLL 2222

oooovvvvtttt

CCCCooooddddEEEE

Limit

Zyklus

Relay

ttttSSSStttt

SSSSiiii

Typ

oooonnnn

EEEELLLL

ooooFFFFFFFF

....

AAAALLLL

PPPPiiiinnnn

AAAALLLL1111

AAAALLLL2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

----222288880000

...2222000000000000

0000..

9999999999999999

EEEE

ddddoooonnnn ddddooooFFFF

ooooffffffff

1111..9999999999999999 h

________________ ,,,,

----222288880000

...2222000000000000

Zero

o.k.

3x EEEErrrrrrrr

oooonnnn

EEEELLLL

ooooFFFFFFFF

1111..

9999999999999999 s

----222288880000

...2222000000000000

Fullscale

PPPPiiiinnnn

0000..

9999999999999999

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset = 2 s set while switching

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 10 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 11

Parameter setting mode

Menu mode

Display mode

Operation: Pr2

2 s = Max

2 s = Min

Pr2 / 2 temperature sensors, each 1 limit value

Pr2Pr2

Sensor 1

SSSS 1111

SSSS 2222

Typ

Typ

2 s = Max

Sensor 2

2 s = Min

....

111100000000

1111000000000000

88883333

88884444

tttthhhh..

LLLLAAAA

CCCCooooMMMMPPPP

0000..111100000000

3333----LLLL

0000..111100000000

iiiinnnntttt

Operation with pushbuttons:

Up

Set

Down

Reset

= >2s Set

AAAALLLL 1111

Limit ----222288880000...

AAAALLLL 2222

Limit

Zyklus

Relay

ttttSSSStttt

oooovvvvtttt

Typ

SSSSiiii

Limit alarm 1

2222000000000000

....

AAAALLLL

EEEE

AAAALLLL 1111

AAAALLLL 2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

SSSS 1111

SSSS 2222

ddddoooonnnn

SSSSEEEEnnnn

ooooffffffff

1111..9999999999999999 h

SSSS 1111

SSSS 2222

SSSS11112222,,,,

SSSS11112222____

----222288880000

...2222000000000000

----111199999999....9999

...999999999999....9999

____ , ,,,

ddddAAAALLLL

ddddooooFFFF

----222288880000

...2222000000000000

0000..9999999999999999 s

1111...

9999999999999999 s

Zero Fullscale

ddddooooFFFFHHHH rrrrEEEELLLL

0000..9999999999999999 s

----222288880000

...2222000000000000

EEEErrrrrrrr

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset = 2 s set while switching

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

oooonnnn

ooooFFFFFFFF

CCCCooooddddEEEE

oooonnnn

PPPPiiiinnnn

EEEELLLL

ooooFFFFFFFF

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 11 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

0000..

9999999999999999

o.k.

3x EEEErrrrrrrr

oooonnnn

EEEELLLL

ooooFFFFFFFF

PPPPiiiinnnn

0000..

9999999999999999

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

Page 12

Menu mode

Parameter setting mode

Display mode

Operation: Pr3

2 s = Max

2 s = Min

Pr3 / 1 temperature sensor, 2 limit values day and 2 limit values night

Pr3Pr3

Sensor 1

SSSS 1111

AAAALLLLdddd1111

Typ

Limit ---- 222288880000...

AAAALLLLdddd1111

Limit day 1

----222288880000

...2222000000000000

111100000000

1111000000000000

88883333

88884444

tttthhhh..

2222000000000000

AAAALLLLnnnn1111

LLLLAAAA

CCCCooooMMMMPPPP

AAAALLLLnnnn1111

----222288880000

...2222000000000000

0000..111100000000

3333----LLLL

0000..111100000000

iiiinnnntttt

---- 222288880000

...2222000000000000

AAAALLLLdddd2222

----222288880000

...2222000000000000

----111199999999.9999

...999999999999.9999

Operation with pushbuttons:

Up

Set

Reset

= >2s Set

0000..9999999999999999 s

AAAALLLLnnnn2222

ddddAAAALLLL

Down

----222288880000

...2222000000000000

ddddooooFFFFHHHH

0000..9999999999999999 s

AAAALLLLdddd2222

oooovvvvtttt

Limit

Zyklus

Relay

ttttSSSStttt

SSSSiiii

Typ

....

AAAALLLL

EEEE

AAAALLLL 1111

AAAALLLL 2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

---- 222288880000

...2222000000000000

ddddoooonnnn

____

ooooffffffff

1111..9999999999999999 h

----222288880000

...2222000000000000

ddddooooFFFF

,,,,

Zero Fullscale

1111...

9999999999999999 s

----222288880000

...2222000000000000

rrrrEEEELLLL

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset =

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

2 s

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

set while switching

CCCCooooddddEEEE

oooonnnn

PPPPiiiinnnn

EEEELLLL

ooooFFFFFFFF

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 12 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

0000..

9999999999999999

o.k.

3x EEEErrrrrrrr

oooonnnn

EEEELLLL

ooooFFFFFFFF

PPPPiiiinnnn

0000..

9999999999999999

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

Page 13

Menu mode

Para

meter setting mode

Display mode

Operation: Pr4

2 s = Max

2 s = Min

Pr4 / 2 temperature sensors, each 1 limit value day and 1 limit value night

Pr4Pr4

Sensor 1

SSSS 1111

SSSS 2222

Typ

Typ

2 s = Max

Sensor 2

2 s = Min

....

111100000000

1111000000000000

88883333

88884444

tttthhhh..

LLLLAAAA

CCCCooooMMMMPPPP

0000..111100000000

3333----LLLL

0000..111100000000

iiiinnnntttt

Operation with pushbuttons:

Up

Set

Down

Reset

= >2s Set

AAAALLLLdddd1111

Limit ---- 222288880000...

AAAALLLLdddd2222

Limit

Zyklus

Relay

ttttSSSStttt

oooovvvvtttt

Typ

SSSSiiii

Limit day 1

....

AAAALLLL

AAAALLLL 1111

AAAALLLL 2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

SSSS 1111

SSSS 2222

EEEE

2222000000000000

ddddoooonnnn

SSSSEEEEnnnn

AAAALLLLnnnn1111

SSSS 1111

SSSS 2222

SSSS11112222,,,,

SSSS11112222____

---- 222288880000

...2222000000000000

---- 222288880000

...2222000000000000

ooooffffffff

1111..9999999999999999 h

____

----111199999999.9999

...999999999999.9999

ddddooooFFFF

----222288880000

...2222000000000000

1111...

9999999999999999 s

,,,,

---- 222288880000

...2222000000000000

Zero Fullscale

ddddAAAALLLL

ddddooooFFFFHHHH

0000..9999999999999999 s

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset =

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

0000..9999999999999999 s

rrrrEEEELLLL

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

2 s

set while switching

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

CCCCooooddddEEEE

oooonnnn

EEEELLLL

ooooFFFFFFFF

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 13 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

PPPPiiiinnnn

0000..

9999999999999999

o.k.

3x EEEErrrrrrrr

oooonnnn

EEEELLLL

ooooFFFFFFFF

PPPPiiiinnnn

0000..

9999999999999999

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

Page 14

Menu mode

Parameter setting mode

Display mode

Operation: Pr5

2 s = Max

2 s = Min

SSSS 1111

SSSS 2222

Pr5 / 2 temperature sensors, temperature difference S 2

Pr5Pr5

Sensor 1

Typ

Typ

2 s = Max

Sensor 2

2 s = Min

....

111100000000

1111000000000000

88883333

88884444

tttthhhh..

2 s = Max

Difference

2 s = Min

CCCCooooMMMMPPPP

LLLLAAAA

0000..111100000000

3333----LLLL

0000..111100000000

iiiinnnntttt

S 2 minus S 1

S 2S 2

S 1

S 1S 1

Operation with pushbuttons:

Up

Set

Down

Reset

= >2s Set

AAAALLLL1111

Limit ---- 222288880000...

AAAALLLL 2222

Limit

Zyklus

Relay

ttttSSSStttt

oooovvvvtttt

Typ

SSSSiiii

Limit alarm 1

2222000000000000

....

AAAALLLL

EEEE

AAAALLLL 1111

AAAALLLL 2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

SSSS 1111

SSSS 2222

ddddiiiiFFFF

ddddoooonnnn

SSSSEEEEnnnn

SSSS 1111

SSSS 2222

SSSS11112222,,,,

SSSS11112222____

ddddiiiiFFFF

---- 222288880000

...2222000000000000

ddddooooFFFF

----222288880000

...2222000000000000

Zero

ddddAAAALLLL

0000..9999999999999999 s

1111...

9999999999999999 s

,,,,

Fullscale

----111199999999.9999

...999999999999.9999 0000..9999999999999999 s

ooooffffffff

1111..9999999999999999 h

____

ddddooooFFFFHHHH

---- 222288880000

...2222000000000000

rrrrEEEELLLL

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset =

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

2 s

set while switching

CCCCooooddddEEEE

oooonnnn

EEEELLLL

ooooFFFFFFFF

PPPPiiiinnnn

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 14 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

0000..

9999999999999999

o.k.

3x EEEErrrrrrrr

oooonnnn

EEEELLLL

ooooFFFFFFFF

PPPPiiiinnnn

0000..

9999999999999999

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

Page 15

Menu mode

Parameter setting mode

Display mode

Operation: Pr6

2 s = Max

2 s = Min

Pr6 / 1 input 0-10 V or 0/4-20 mA, 2 limit values

Pr6Pr6

Sensor 1

SSSS 1111

AAAALLLL 1111

Typ

Limit

AAAALLLL 1111

----1111999999999999

...9999999999999999

0000----11110000

0000----22220000

4444----22220000

Limit alarm 1

----1111999999999999

...9999999999999999

SSSSCCCCAAAALLLL

AAAALLLL 2222

----1111999999999999

...9999999999999999

UUUUSSSSEEEErrrr

AAAAUUUUttttoooo

----1111999999999999

...9999999999999999

Operation with pushbuttons:

____ ,,,,

----1111999999999999

...9999999999999999

Zero Fullscale

ddddAAAALLLL

0000..9999999999999999 s

Up

Down

ddddPPPP

----1111999999999999

...9999999999999999

ddddooooFFFFHHHH rrrrEEEELLLL

0000..9999999999999999 s

0000....0000....0000....0000

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

Set

Reset

= >2s Set

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

AAAALLLL 2222

oooovvvvtttt

CCCCooooddddEEEE

Limit

Zyklus

Relay

ttttSSSStttt

SSSSiiii

Typ

oooonnnn

EEEELLLL

ooooFFFFFFFF

....

AAAALLLL

PPPPiiiinnnn

AAAALLLL1111

AAAALLLL2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

----1111999999999999

...9999999999999999

EEEE

0000..

9999999999999999

ddddoooonnnn

____

o.k.

3x EEEErrrrrrrr

ooooFFFFFFFF

1111..9999999999999999 h

----1111999999999999

...9999999999999999

Zero

oooonnnn

EEEELLLL

ooooFFFFFFFF

ddddooooFFFF

,,,,

----1111999999999999

...9999999999999999

Fullscale

PPPPiiiinnnn

1111..

9999999999999999 s

0000..

9999999999999999

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset =

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

2 s

set while switching

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 15 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 16

Menu mode

Parameter setting mode

Displ

ay mode

Operation: Pr7

2 s = Max

Sensor 1

2 s = Min

SSSS 1111

SSSS 2222

AAAALLLL 1111

AAAALLLL 2222

Zyklus

Relay

ttttSSSStttt

oooovvvvtttt

SSSSiiii

CCCCooooddddEEEE

Pr7 / 2 inputs 0-10 V or 0/4-20 mA, each 1 limit value

Pr7Pr7

Operation with pushbuttons:

2 s = Max

Sensor 2

2 s = Min

Typ

Typ

Limit

Limit

Typ

oooonnnn

EEEELLLL

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

....

Limit alarm 1

----1111999999999999

...9999999999999999

....

AAAALLLL

EEEE

AAAALLLL1111

AAAALLLL2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

SSSS 1111

SSSS 2222

PPPPiiiinnnn

0000..

9999999999999999

SSSSCCCCAAAALLLL

ddddoooonnnn

SSSSEEEEnnnn

o.k.

3x EEEErrrrrrrr

ooooFFFFFFFF

1111..9999999999999999 h

SSSS 1111

SSSS 2222

SSSS11112222,,,,

SSSS11112222____

----1111999999999999

...9999999999999999

____

UUUUSSSSEEEErrrr

AAAAUUUUttttoooo

----1111999999999999

...9999999999999999

____ ,,,,

ddddAAAALLLL

ddddooooFFFF

----1111999999999999

...9999999999999999

Zero Fullscale

oooonnnn

EEEELLLL

ooooFFFFFFFF

PPPPiiiinnnn

----1111999999999999

...9999999999999999

Zero Fullscale

0000..9999999999999999 s

1111..

9999999999999999 s

0000..

9999999999999999

,,,,

----1111999999999999

...9999999999999999

ddddooooFFFFHHHH rrrrEEEELLLL

0000..9999999999999999 s

----1111999999999999

...9999999999999999

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

Up

Set

Down

ddddPPPP

0000....0000....0000....0000

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset =

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

2 s

Reset

= >2s Set

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

set while switching

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 16 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 17

Menu mode

Display mode

Parameter setting mode

Operation: Pr8

Pr8 / 2 inputs 0-10 V or 0/4-20 mA, difference S 2

Pr8Pr8

S 2 minus S 1

S 2S 2

S 1

S 1S 1

Operation with pushbuttons:

ddddPPPP

Up

Down

rrrr

AAAA

rrrr----LLLL

AAAA----LLLL

Set

Reset

= >2s Set

EEEErrrrrrrr

oooonnnn

ooooFFFFFFFF

2 s = Max

Sensor 1

2 s = Min

SSSS 1111

SSSS 2222

AAAALLLL 1111

Typ

Typ

Limit

2 s = Max

Sensor 2

2 s = Min

....

Limit alarm 1

0000----11110000

0000----22220000

4444----22220000

2 s = Max

2 s = Min

----1111999999999999

...9999999999999999

Difference

SSSSCCCCAAAALLLL

UUUUSSSSEEEErrrr

AAAAUUUUttttoooo

----1111999999999999

...9999999999999999

____

----1111999999999999

...9999999999999999

Zero

ddddAAAALLLL

0000..9999999999999999 s

,,,,

----1111999999999999

...9999999999999999 0000....0000....0000....0000

Fullscale

ddddooooFFFFHHHH rrrrEEEELLLL

0000..9999999999999999 s

AAAALLLL 2222

oooovvvvtttt

CCCCooooddddEEEE

Limit

Zyklus

Relay

ttttSSSStttt

SSSSiiii

Typ

oooonnnn

EEEELLLL

ooooFFFFFFFF

....

AAAALLLL

PPPPiiiinnnn

AAAALLLL1111

AAAALLLL2222

ooooFFFFFFFF

0000----11110000

0000----22220000

4444----22220000

SSSS 1111

SSSS 2222

ddddiiiiFFFF

EEEE

0000..

9999999999999999

ddddoooonnnn

SSSSEEEEnnnn

o.k.

3x EEEErrrrrrrr

ooooFFFFFFFF

1111..9999999999999999 h

SSSS 1111

SSSS 2222

SSSS11112222,,,,

SSSS11112222____

ddddiiiiFFFF

----1111999999999999

...9999999999999999

oooonnnn

EEEELLLL

ooooFFFFFFFF

____

ddddooooFFFF

----1111999999999999

...9999999999999999

Zero

PPPPiiiinnnn

1111..

9999999999999999 s

0000..

9999999999999999

,,,,

----1111999999999999

...9999999999999999

Fullscale

3x oooonnnn/EEEELLLL/OOOOFFFFFFFF

LEDs on type plate show

corresponding in- output.

up/down at the same time sets

values on zero.

code-reset =

on power-supply.

(Pin = 504)

error messages:

Er 1 = sensor short circuit

Er 2 = sensor break

Er 3 = over-current for 0/4-20 mA

Er 4 = thermocouple poled wrong

Er 8/9 = error in unit

Err = general error

EEEE = sensor values too high

-EEE = sensor values too low

2 s

set while switching

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 17 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 18

Operation: Pr9

Pr9 / 2 temperature sensors, 2 limit values MIN / MAX

Pr9 Pr9

At MAX-limit the warmest sensor switches the relay, at MIN the coldest.

Operation see program Pr2

Action chart:

ϑ

sensor

ϑ

1

ϑ

2

Relay (r), LED

Relay locked (rL)

t

M

dAL

t

M

doF

t

Reset

t M = m easuring time

ϑ

1 = LIMIT

ϑ

2 = LIMIT+Hys teresis

Reaction time of the unit – measuring time t M

The reaction time of the unit depends on the number of the connected sensors and the

measuring function. If the temperature is changing constantly, the measuring time t M is

about 2 s. If the temperature is changing rapidly, e.g. through simulation of the temperature

with an external potentiometer, the measuring time t M is about 4 … 6 s. In case of sensor

error the measuring time t M raises to 7…10 s.

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 18 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 19

Factory setting:

In case of programme change all parameters are set back upon factory setting.

Menu-

item

Sensor 1

S 1

S 1

S 1S 1

Sensor 2

S 2

S 2

S 2S 2

Alarm 1

AL 1

AL 1

AL 1AL 1

Alarm 2

AL 2

AL 2

AL 2AL 2

tst

tst

tsttst

ovt

ovt

ovtovt

Code

Code

CodeCode

Parameter

Pr1

Pr1 Pr2/9

Pr1Pr1

100

100 100

Sensor type

LA

LA

(Cable compensation)

LALA

comp

comp

(Compensation, th.)

compcomp

sCal

sCal

(Scaling)

sCalsCal

User____

____

(Zero)

________

User,,,,

,,,,

(Fullscale)

,,,,,,,,

User dp

dp

(Decimal point)

dp dp

100100

3333----llll 3333----llll 3333----llll 3333----llll 3333----llll

int

int int

intint

- - - - -

- - - - - - -

- - - - - - -

- - - - - - -

Sensor type -

LA

LA

(Cable compensation)

LALA

comp

comp

(Compensation, th..)

compcomp

sCal

sCal

(Scaling)

sCalsCal

User____

____

(Zero)

________

User,,,,

,,,,

(Fullscale)

,,,,,,,,

User dp

dp

(Decimal point)

dp dp

Limit 1

ALn1

ALn1

ALn1ALn1

HHHH

dAL

dAL

dALdAL

dof

dof

dofdof

rel

rel

relrel

Er

Errrrr

ErEr

Limit 2

ALn2

ALn2

ALn2ALn2

HHHH

dAL

dAL

dALdAL

do

doffff

dodo

rel

rel

relrel

Err

Err

ErrErr

AL 1

AL 1

AL 1AL 1

AL 2

AL 2

AL 2AL 2

(day)

(night)

(Hysteresis)

(Alarm-delay)

(Delay-Alarm off)

(Relais function)

(Sensor-Error)

(night)

(Hysteresis)

(Alarm-delay)

(Delay-Alarm off)

(Relais function)

(Sensor-Error)

(day)

don

don

(Test time)

dondon

doF

doF

(Test duration)

doFdoF

don

don

(Test time)

dondon

doF

doF

(Test duration)

doFdoF

Type

sEn

sEn

(Sensor)

sEnsEn

____

____

(Zero)

________

,,,,

,,,,

,,,,,,,,

on

on / oFF

oFF

onon

oFFoFF

Pin

Pin 504

PinPin

(Fullscale)

-

-

- - - - - -

- - - - - - -

- - - - - - -

- - - - - - -

100.0

100.0

100.0100.0

- -

----2.0

2.0

2.02.0

0000 0000 0000 0000 0000 0000 0000 0000

0000 0000 0000 0000 0000 0000 0000 0000

rrrr rrrr rrrr rrrr rrrr rrrr rrrr rrrr

on

on on

onon

150.0

150.0

150.0150.0

- -

----2.0

2.0

2.02.0

0000 0000 0000 0000 0000 0000 0000 0000

0000 0000 0000 0000 0000 0000 0000 0000

rrrr rrrr rrrr rrrr rrrr rrrr rrrr rrrr

on

on on

onon

off

off off

offoff

1111 1111 1111 1111 1111 1111 IIII IIII

off

off off

offoff

1111 1111 1111 1111 1111 1111 IIII IIII

0000----10

10

1010

-

0.0

0.0 0.0

0.00.0

200.0

200.0

200.0200.0

off

off off

offoff

504 504

504504

Pr2/9 Pr3

Pr2/9Pr2/9

100 100

100100

int int

intint

100

100

100100

3333----llll

int

int

intint

100.0

100.0

100.0100.0

----2.0

2.0 ----2.0

2.02.0

on on

onon

100.0

100.0

100.0100.0

----2.0

2.0 ----2.0

2.02.0

on on

onon

off off

offoff

off of

offoff

0000----10

s12,

s12,

s12,s12,

0.0 0.0

0.00.0

200.0

200.0

200.0200.0

off off

offoff

504 504

504504

10

1010

Pr3 Pr4

Pr3Pr3

100 100

100100

int int

intint

-

-

-

22220.0

0.0 20.0

0.00.0

15.0

15.0 15.0

15.015.0

2.0 ----2.0

2.02.0

on on

onon

20.0

20.0 20.0

20.020.0

15.0

15.0 15.0

15.015.0

2.0 ----2.0

2.02.0

on on

onon

off off

offoff

offfff off

ofof

0000----10

10

1010

-

0.0 0.0

0.00.0

200.0

200.0

200.0200.0

off off

offoff

504 504

504504

Value

Pr4 Pr5

Pr4Pr4

100 100

100100

int int

intint

100

100 100

100100

Pr5 Pr6

Pr5Pr5

100 0000----10

100100

int

intint

100

100100

3333----llll 3333----llll

int

int int

intint

20.0 10.0

20.020.0

15.0

15.015.0

on on

onon

20.0 10.0

20.020.0

15.0

15.015.0

on on

onon

off off

offoff

off off

offoff

0000----10

s12,

s12,

s12,s12,

0.0 0.0

0.00.0

200.0

200.0

200.0200.0

off off

offoff

504 504

504504

int

intint

10.0 1.000

10.010.0

- - -

2.0 ----2.0

2.02.0

2.0 ----.020

2.02.0

on on

onon

10.0 1.000

10.010.0

- - -

2.0 ----2.0

2.02.0

10

1010

2.0 ----.020

2.02.0

on on

onon

off off

offoff

off off

offoff

0000----10

dif

dif

difdif

0.0 0.000

0.00.0

222200.0

00.0

00.000.0

off off

offoff

504 504

504504

10

1010

Pr6 Pr7

Pr6Pr6

10

1010

- -

- -

auto

auto

autoauto

-

- -

- -

1.000

1.0001.000

.020

.020.020

on on

onon

1.000

1.0001.000

.020

.020.020

on on

onon

off off

offoff

off off

offoff

0000----10

10

1010

-

0.000

0.0000.000

9.999

9.999

9.9999.999

off off

offoff

504 504

504504

Pr7 Pr8

Pr7Pr7

0000----10

auto

auto

autoauto

0000----10

auto

auto

autoauto

1.000

1.000

1.0001.000

----.020

.020

.020.020

on on

onon

1.000

1.000

1.0001.000

----.020

.020

.020.020

on on

onon

off off

offoff

off off

offoff

0000----10

s12,

s12,

s12,s12,

0.000

0.000

0.0000.000

9.999

9.999

9.9999.999

off off

offoff

504 504

504504

Pr8

Pr8Pr8

10

0000----10

1010

Auto

Auto

AutoAuto

10

0000----10

1010

Auto

Auto

AutoAuto

1.000

1.000

1.0001.000

----.020

1.000

1.000

1.0001.000

----.020

off

offoff

off

offoff

10

0000----10

1010

dif

dif

difdif

0.000

0.000

0.0000.000

9.999

9.999

9.9999.999

off

offoff

504

504504

.020

.020.020

on

onon

.020

.020.020

on

onon

User

data

10

1010

-

-

----

----

----

10

1010

----

----

----

----

----

----

----

10

1010

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 19 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 20

Error search and measures

• Display

EE

EEEEEEEEEE sensor break or temperature too high

EEEE

----EEEEEEEEEEEE sensor interruption or temperature too low

• Unit cannot be programmed – Code lock

The code lock gives protection against unauthorized manipulation of the unit. When code

lock is activated the parameters can not be changed. The pin can be set by the user.

Pin unknown? Make code-reset: When switching in supply-voltage keep pushed button

„Set“ for 2 s.

Display indicates: "8888"; "CodE"; "oFF"; "8888" release button „Set“.

Code = oFF, Pin = 504.

• Indicated temperature does not correspond to the sensor temperature

Check connected sensor type

Check cable resistance

• Display indicates „Er1 or Er2“

Er1 Sensor short circuit

Er2 Sensor interruption, (4-20 mA input: current below 3,8 mA)

Er3 Current input > 25 mA at the 0/4-20 mA input; measuring input is switched to high

impedance

Er4 Thermocouple input voltage too negative, check polarity

Er8 and Er9 are internal faults of the device. Switch off- and on the power-supply, eventually

reset parameters upon factory preset.

If after that there still is an error indicated, the unit must be sent to the factory for repair.

• Indication of the software version: select display mode and push button „Set“ for 10 s.

Technical data

Rated supply voltage Us: AC/DC 24 – 240 V, 0 / 50 / 60 Hz < 3 W < 5 VA

Tolerance DC 20, 4 - 297 V, AC 20 - 264 V

Relais output: 2 x 1 change-over contacts (CO)

Switching voltage max. AC 415 V

Switching current max. 5 A

Switching capacity max. 1250 VA (ohmic load)

max.48 W at DC 24 V

Reduction factor for cos ϕ 0,7 0,5

UL electrical ratings: 3 A Resistive, 240 VAC

D300 1 A 240 VAC

Nominal operational current Ie:

AC15

Ie = 2 A Ue = 250 V

Ie = 1 A Ue = 400 V

DC13 Ie = 2 A Ue = 24 V

Ie = 0,2 A Ue = 125 V

Ie = 0,1 A Ue = 250 V

Recommended fuses for contacts T 3,15 A (gL)

Expected life mechanical 1 x 10

7

Switching cycles

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 20 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 21

Expected life electrical 1 x 105 Switching cycles at AC 250 V / 5 A

2 x 105 Switching cycles at 250 V / 3 A

6 x 105 Switching cycles at AC 250 V / 1 A

Test conditions EN 50178 / EN 60 947

Rated impulse voltage 4000 V

Overvoltage category III

Contamination level 3

Rated insulation voltage Ui 250 V

On-time 100 %

Maximum ambient temperature -20 °C ... +60 °C

EN 60068-2-1 Dry Heat

EMV – interference resistance EN 61000-6-2

EMV – emitted interference EN 61000-6-3

Vibration resistance EN 60068-2-6 2…25 Hz ±1,6 mm

25 ... 150 Hz 5 g

Sensor connection:

Measuring cycle/Measuring time t M < 2,5 s

< 5 s in case of changes > 5 K or < 1 K

< 15 s in case of sensor error

The times depend on quantity and nature of the connected sensors.

Pt 100, Pt 1000 according to EN 60751:

Measuring

range °C

Short circuit

Ohm

Break

Ohm

Sensor resistance

+ line resistance

Sensor min max < > max

Pt 100 -199 860 15 400 500

Pt 1000 -199 860 150 4000 4100

KTY 83 -55 175 150 4000 4100

KTY 84 -40 150 150 4000 4100

Tolerance ±0,2 % of measured value ±0,5 K (KTY ±5 K)

Sensor current ≤0,8 mA

Temperature drift <0,04°C/K

Thermocouples according to EN 60 584, DIN 43 710:

Measuring range

°C Precision

Type min max

±2 °C

B 0 1820

T > 300°C

E -270 1000 ±1 °C

J -210 1200 ±1 °C

K -200 1372 ±2 °C

L -200 900 ±1 °C

N -270 1300 ±2 °C

R -50 1770 ±2 °C

S -50 1770 ±2 °C

T -270 400 ±1 °C

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 21 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 22

Temperature drift < 0,01 % / K

Measuring error of the sensor wire +0,25 µV / Ω

Reference junction ±1 °C

Voltage- / Current input

Precision

Maximum

Input resistance

Input signal

(from

FullScale)

0 – 10 V 13 kΩ 20 V 0,1 %

0/4-20 mA 22 Ω

*

if input currents are > 25 mA the input resistance is switched to 13 kΩ and the error Er3 is

25 mA* 20 V

0,5 %

indicated. Error reset: break circuit.

Temperature drift < 0,02 %/K

Input Y1-Y2: 18 V / 3 mA Switching threshold approx. 9 V

Analogue output: not electrically insulated from the inputs

Voltage output 0-10 V max. 10 mA Precision 0,1 % of FullScale

Temperature drift < 0,01 %/K

Current output 0/4-20 mA max. 500 Ω Precision 0,15 % of FullScale

Temperature drift < 0,015 %/K

Error from impedance (250 Ω - impedance)/250 Ω * 0,15 % of current

If error short circuit Er1 0 V or 0 mA is put out.

For all other faults 10 V or 20 mA is put out.

Housing: Design V4, switchgear mounting

Mounting height 55 mm

Width 4 TE

Dimensions (width x height x depth) 70 x 90 x 58 mm

Wire connection, one wire each 1 x 1,5 mm2

Stranded wire with insulated ferrules each 1 x 1,0 mm2

Protection class housing IP 30

Protection class terminal IP 20

Installation Snap mounting on mounting rail 35 mm according to

EN 60 715 or with screws M 4

(additional bar in scope of delivery)

Weight approx. 200 g

Subject to technical changes

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 22 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 23

Housing Design V4:

58

48

45

61,8

Dimensions in mm

16,5

5

(90)

4

70

Option

98

116

3

1

2

3

1 Cover

2 Base

3 Bar for snap mounting

4 Latch for sealing

5 Front panel

6 Position downward

7 For fixing to wall with screws, Ø 4,2 mm.

7

6

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 23 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Page 24

This and other operating manuals, as far as available also in other languages, you find on our

homepage:

www.ziehl.com

datum / name : 13.12.2007 Fu Z. Nr.: 1185 0710.4

Page 24 of 24 Type: TR 210

ZIEHL industrie-elektronik GmbH + Co KG, Daimlerstr.13, D-74523 Schwäbisch Hall, Tel.: +49 791 504-0, Fax: -56, e-mail: info@ziehl.de

Loading...

Loading...