UTILIX HT

OPERATOR´S MANUAL

2/2019

45

Tractor is Zetor. Since 1946.

55

1

ZETOR

This Operator’s Manual for the Zetor tractors, which we are presenting to you will help you to

become familiar with the operation and maintenance of your new tractor.

Although many of you have rich experience with the operation of other tractors, please, read the

information contained in this Operator’s Manual very carefully.

In the Manual you will find a lot of new information and get a perfect overview of how to use the

tractor with maximum efficiency during various kinds of work.

If you observe the rules of tractor operation and maintenance and driving safety, your new tractor will

become your reliable and long-term friend.

The manufacturer of the tractor wishes you thousands of hours of satisfactory work.

ZETOR

The technical specifications and information about the design, equipment, material and app earance are valid at the time

of print. The manufacturer reserves the right to implement changes.

The instructions for use are a part of the machine.

Brno

2

Tractor identification ........................................................................................................................................ 9

CONTENTS

3

Warranty of the product ................................................................................................................................. 9

Parts .............................................................................................................................................................. 9

About this manual .......................................................................................................................................... 11

Introduction & Description ............................................................................................................................ 13

Tractor an introduction ................................................................................................................................. 13

Description ................................................................................................................................................... 14

ROPS (Roll over protection structures) ....................................................................................................... 15

Roll over protective structures (ROPS) ....................................................................................................... 15

Danger ......................................................................................................................................................... 15

Use of the tractor with the ROPS lowered can cause fatal injuries ............................................................. 15

Damage of the ROPS .................................................................................................................................. 15

How to adjust the Seat ................................................................................................................................ 16

For sliding seat ............................................................................................................................................ 16

Seat suspension adjustment knob .............................................................................................................. 17

Cushion strength adjustment ....................................................................................................................... 17

Safety instructions, Do's & Don'ts ................................................................................................................ 19

Introduction to safety information ................................................................................................................ 19

Signal words ................................................................................................................................................ 19

Introduction to safety instructions Introduction to safety instructions .......................................................... 19

Protection children ....................................................................................................................................... 19

Use of rops and seat belt ............................................................................................................................ 20

Precaution to avoid tipping .......................................................................................................................... 20

Safe parking of the tractor ........................................................................................................................... 20

Keep riders off tractor .................................................................................................................................. 20

Handle fuel safely-avoid fires ...................................................................................................................... 21

Stay clear of rotating shafts ......................................................................................................................... 21

Always use safety lights and devices .......................................................................................................... 21

Practice safe maintenance .......................................................................................................................... 22

Avoid high-pressure fluids ........................................................................................................................... 22

Prevent battery explosions .......................................................................................................................... 22

Prevent acid burns ....................................................................................................................................... 23

Service tractor safely ................................................................................................................................... 23

Work in ventilated area ................................................................................................................................ 24

Tractor runaway

Safety starter switch .................................................................................................................................... 24

Emergency exits .......................................................................................................................................... 24

Safety precautions

Towing safely ............................................................................................................................................... 27

Falling object protective structure (FOPS) .................................................................................................. 27

Operator protective structure (OPS) ............................................................................................................ 27

Use of hazardous substances ..................................................................................................................... 28

Safety tips during maintenance ................................................................................................................... 30

Mounting and demounting implements ....................................................................................................... 31

The following precautions are suggested to help prevent accidents .......................................................... 32

Do's-for better performance ......................................................................................................................... 35

Don'ts - for safe operation .......................................................................................................................... 36

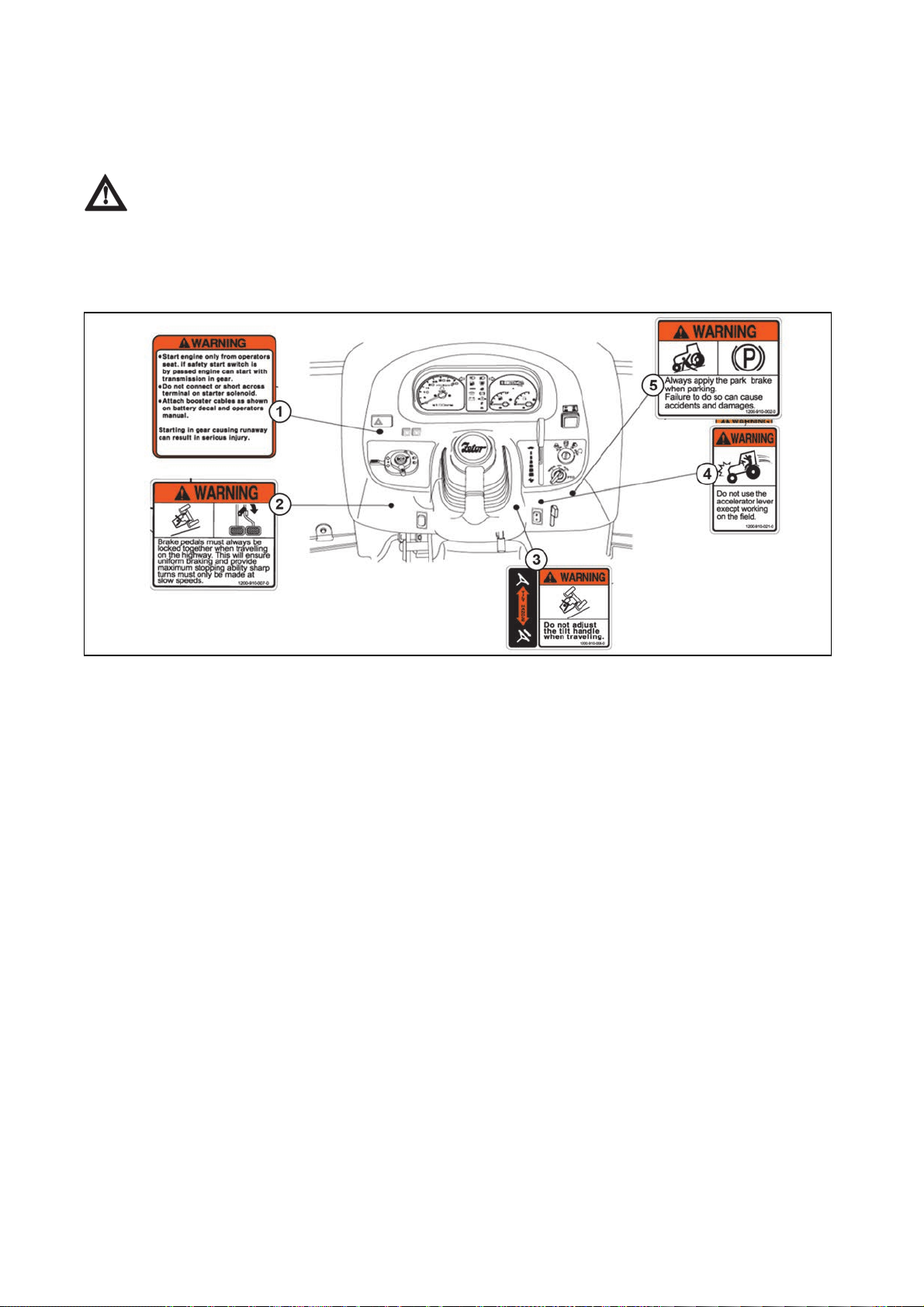

Safety signs ..................................................................................................................................................... 37

General safety information .......................................................................................................................... 37

Decals on the dash cover ............................................................................................................................ 37

Decals on the chassis .................................................................................................................................. 38

Decals on the cabin ..................................................................................................................................... 39

Universal symbols .......................................................................................................................................... 41

Controls, Instruments & Operations ............................................................................................................. 43

Description of tractor controls ...................................................................................................................... 43

Battery disconnector .................................................................................................................................... 43

Instrument and switches .............................................................................................................................. 44

Main switch (key switch) .............................................................................................................................. 45

Headlights, turn signal lights, beacon and horn switch ............................................................................... 45

Tachometer.................................................................................................................................................. 46

Hour meter ................................................................................................................................................... 46

Fuel gauge and water temperature gauge ................................................................................................. 46

Hazard warning signal switch ...................................................................................................................... 46

........................................................................................................................................... 24

when using the loader .................................................................................................. 25

Warning lights ............................................................................................................................................. 47

CONTENTS

4

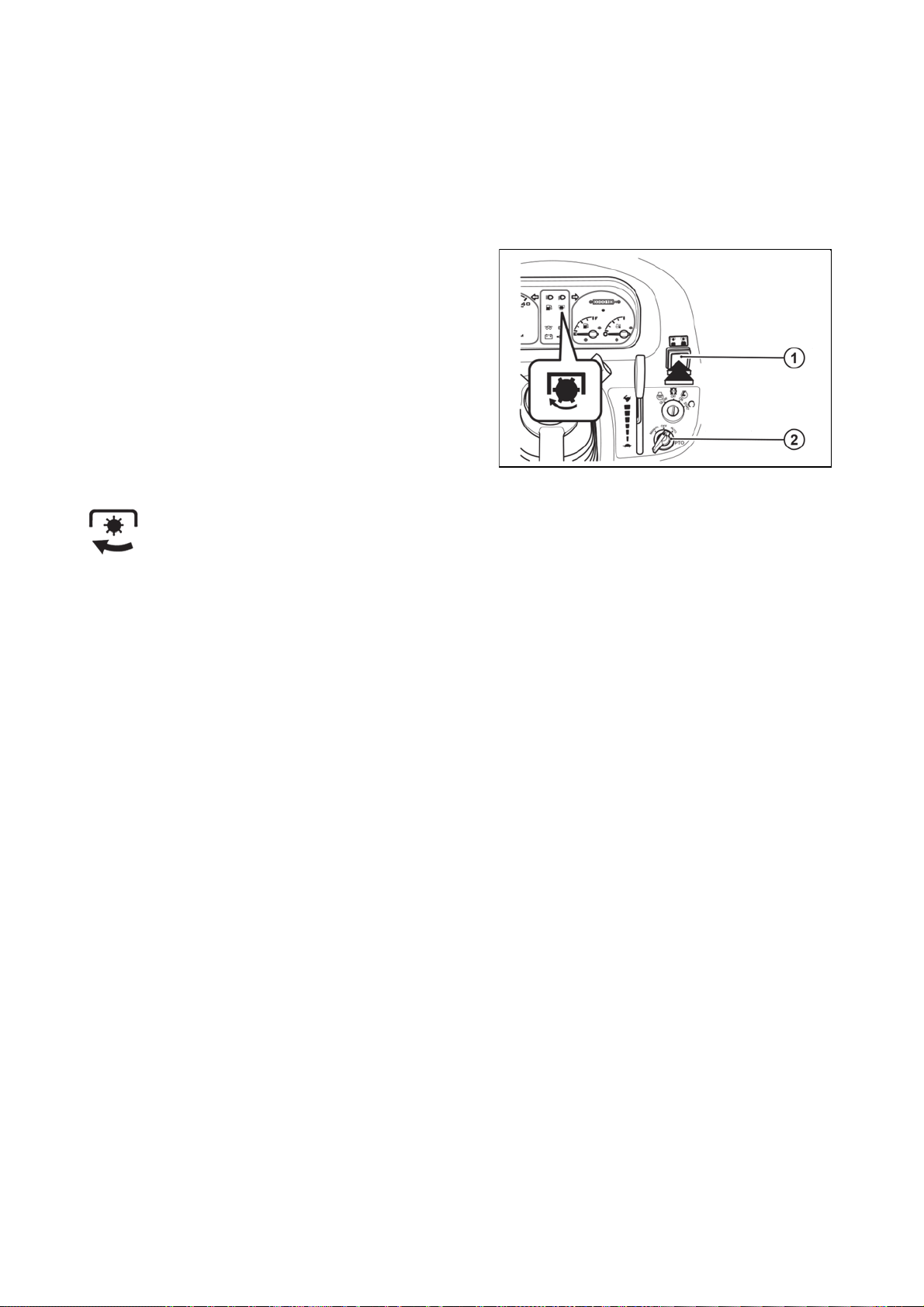

Independent PTO ........................................................................................................................................ 48

PTO shaft revolutions 540 and 1000 rpm shifting lever .............................................................................. 50

Connecting and disconnecting implement ................................................................................................... 51

Cruise control button ................................................................................................................................... 52

Cruise speed control switch ......................................................................................................................... 52

Load sensing button .................................................................................................................................... 52

Mode (sensitivity) switch .............................................................................................................................. 53

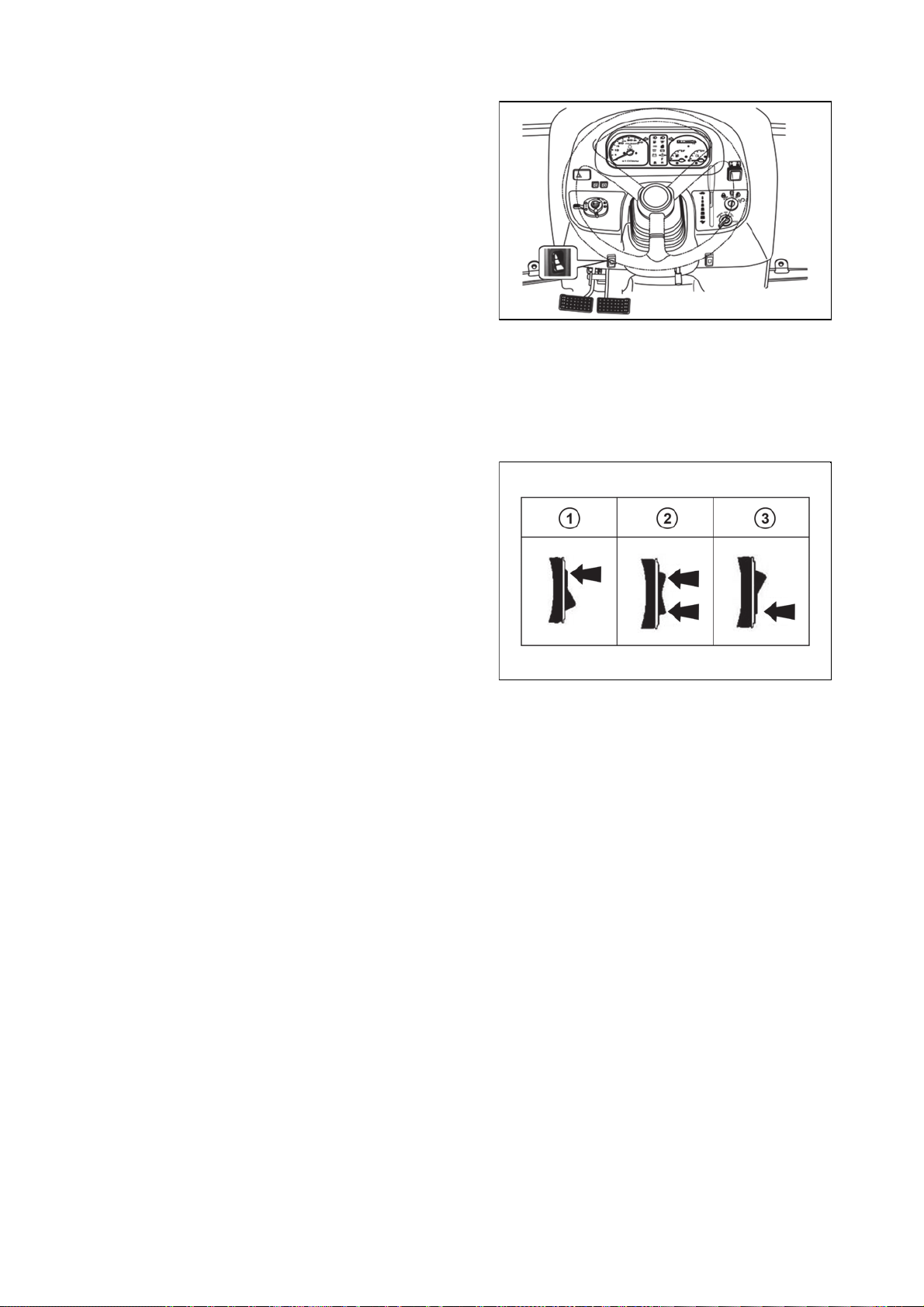

Tractor controls ............................................................................................................................................ 54

Hand throttle (Throttle lever)........................................................................................................................ 55

Speed and direction control pedals ............................................................................................................. 55

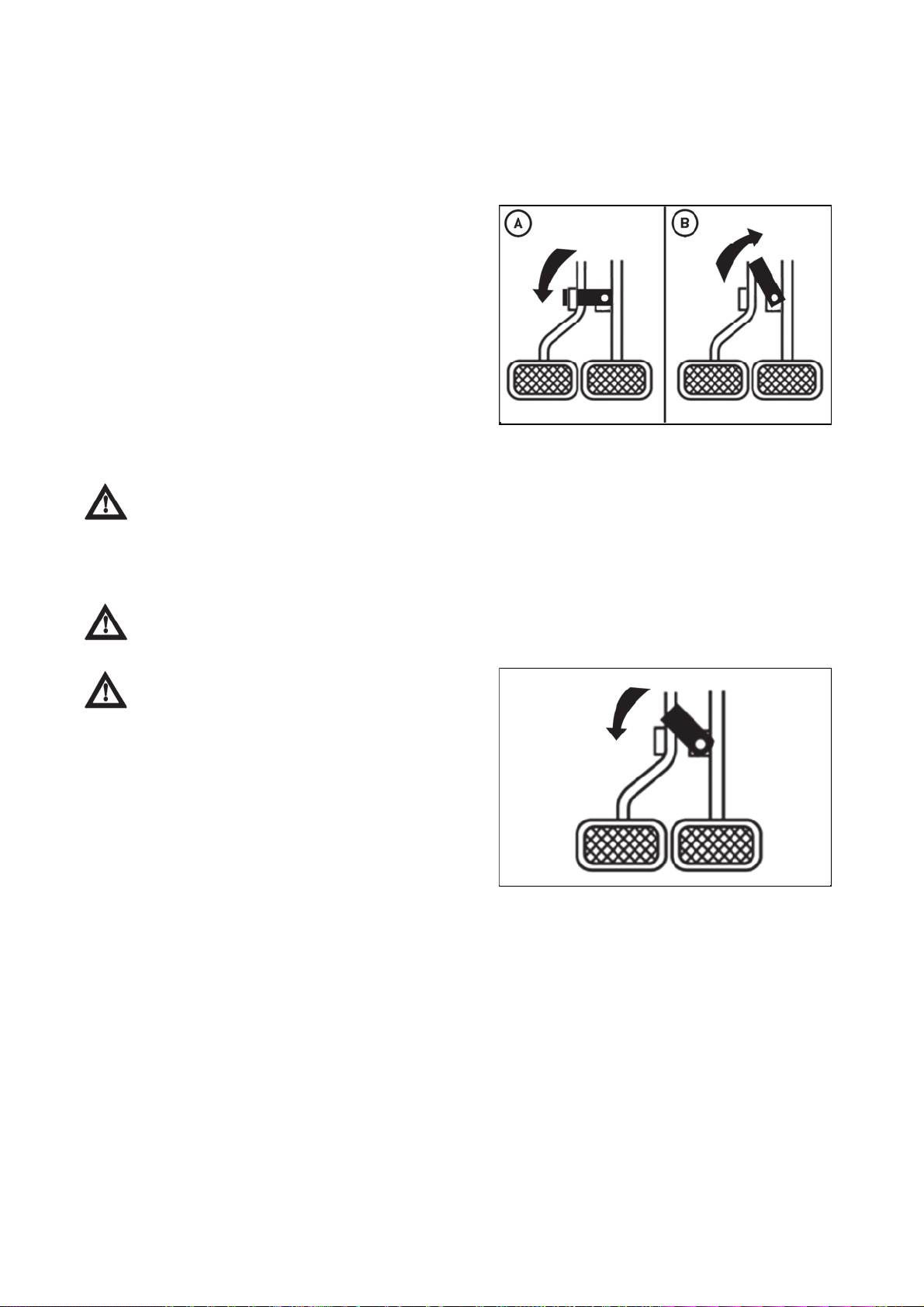

Foot brakes .................................................................................................................................................. 56

Parking brake lever ...................................................................................................................................... 57

To avoid personal unjury: ............................................................................................................................ 57

Air brakes of trailers and semi-trailers ......................................................................................................... 57

Air pressure indication ................................................................................................................................. 57

The button for temporary deactivation of brakes of the trailer or semi-trailer ............................................. 58

One-hose and two-hose brakes .................................................................................................................. 59

One-hose brakes ......................................................................................................................................... 59

Two-hose brakes ......................................................................................................................................... 59

Sub gear lever (Linear shift lever) ............................................................................................................... 60

Diff-lock pedal .............................................................................................................................................. 60

Front axle drive lever ................................................................................................................................... 61

Driver's seat ................................................................................................................................................. 61

Tilt lever ....................................................................................................................................................... 62

Operating the hydraulics .............................................................................................................................. 63

Position control ............................................................................................................................................ 63

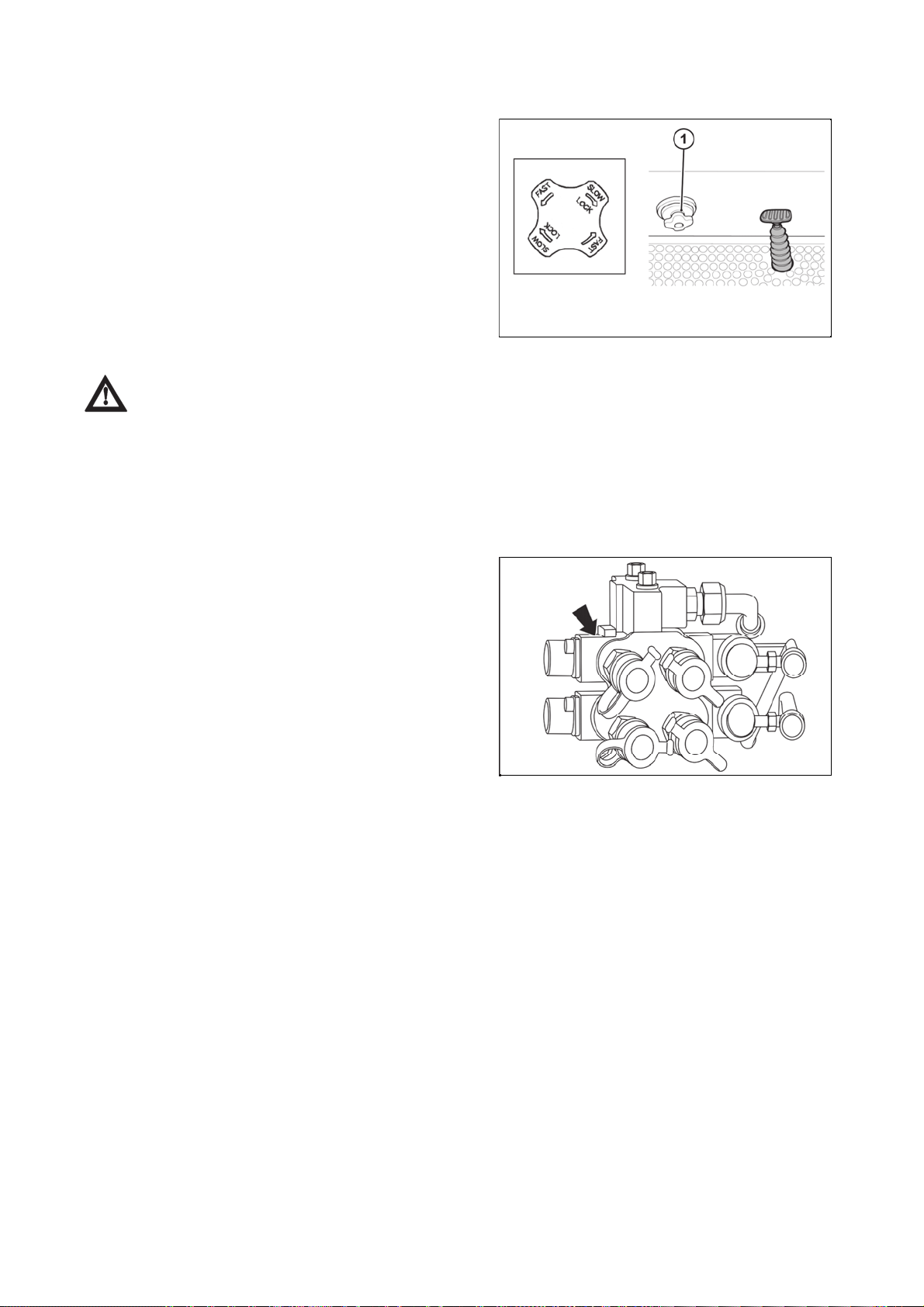

Lowering speed control knob for the 3 point hitch ....................................................................................... 64

Outer hydraulic circuit .................................................................................................................................. 64

Outer hydraulic circuit controls .................................................................................................................... 65

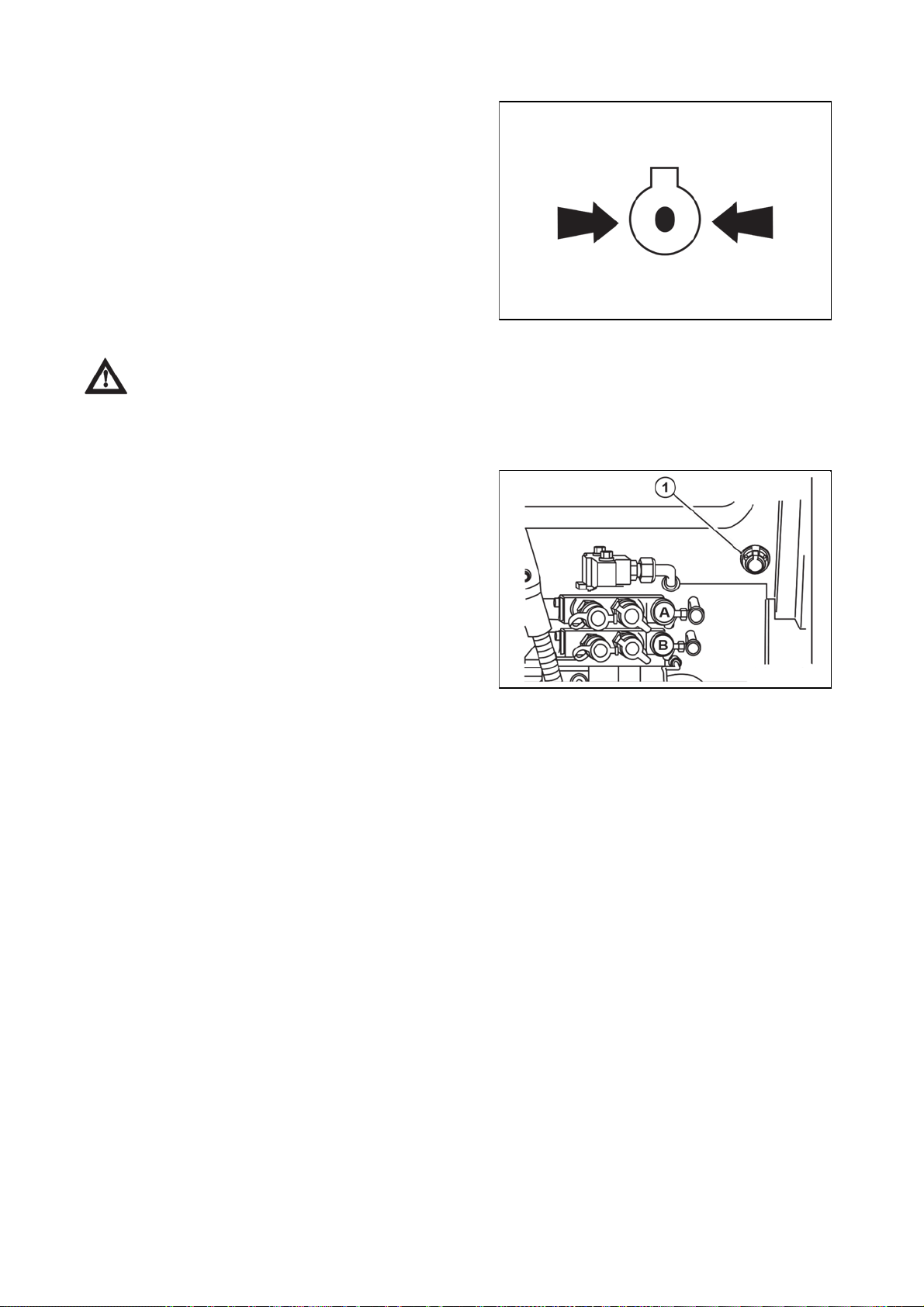

Remote hydraulic control valve coupler connecting and disconnecting ...................................................... 65

Connection................................................................................................................................................... 65

Disconnection .............................................................................................................................................. 65

Joystick lever ............................................................................................................................................... 66

Safety implement for joystick lever .............................................................................................................. 66

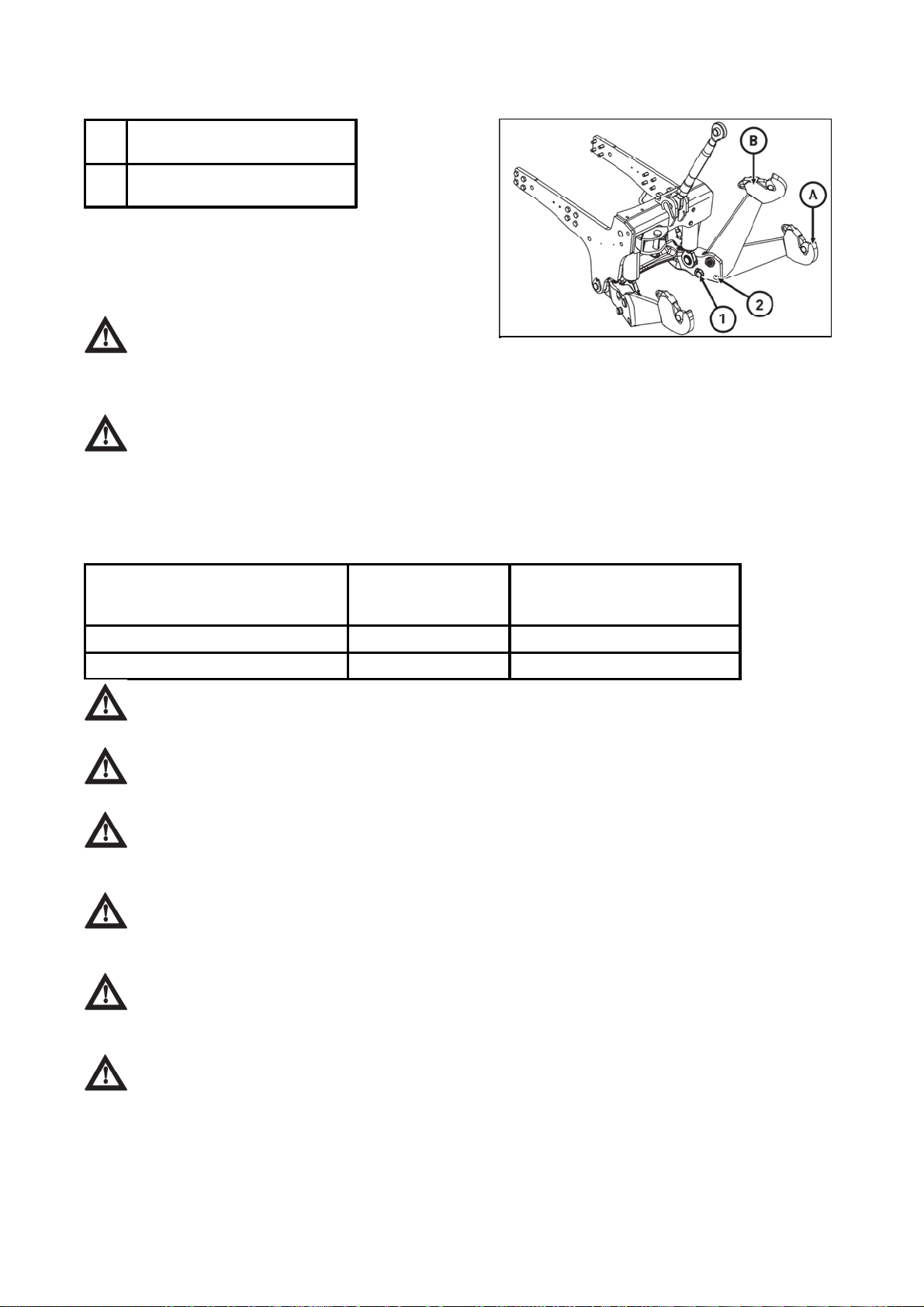

Rear three-point hitc

Adjustment of the top link ............................................................................................................................ 68

Adjustment of the lift link on the lower link

Mounting implement .................................................................................................................................... 69

*Front three-point hitch ................................................................................................................................ 70

Controlling front three-point hitch ................................................................................................................ 70

Hydraulic lock of the front three-point hitch ................................................................................................. 71

Working and transport position of the front three-point hitch ...................................................................... 72

Driving with agricultural machines attached to the front three-point hitch ................................................... 72

Towing equipment ....................................................................................................................................... 72

Maximum permissible load of the hitch ....................................................................................................... 72

Lower hitch ................................................................................................................... ............................... 73

Connection and disconnection of implements ............................................................................................. 73

Multistage adjustable suspension ............................................................................................................... 73

Disassembly of the rear PTO cover ............................................................................................................ 73

Lower hitch disassembly ............................................................................................................................. 74

Height adjustment and disassembly of the multi-level hitch attachment tail piece ..................................... 74

Starting the engine ...................................................................................................................................... 75

Stopping the engine ..................................................................................................................................... 75

Warming up ................................................................................................................................................. 75

Warming up in cold weather ........................................................................................................................ 75

Running-in Period ........................................................................................................................................ 75

Sharp change of direction in the field .......................................................................................................... 76

Normal service braking and parking ............................................................................................................ 76

Driving downhill ........................................................................................................................................... 77

Operation of the diff lock .............................................................................................................................. 77

Check during driving .................................................................................................................................... 78

Oil pressure light .......................................................................................................................................... 78

h .................................................................................................................................. 67

.................................................................................................. 69

Battery charging .......................................................................................................................................... 78

CONTENTS

5

Fuel gauge ................................................................................................................................................... 78

Engine cooling water ................................................................................................................................... 79

Trailer socket (seven terminal electrical socket type) ................................................................................. 79

Treads .......................................................................................................................................................... 80

Changing the front wheel tread ................................................................................................................... 81

Changing the rear wheel tread .................................................................................................................... 81

Front drive axle fenders ............................................................................................................................... 81

Setting wheel stops with front drive axle ..................................................................................................... 82

Front loader mounting points ....................................................................................................................... 83

Main technical parameters ............................................................................................................................ 85

Check and service ....................................................................................................................................... 85

Service inspections ...................................................................................................................................... 85

Pre-start checks ........................................................................................................................................... 85

Engine coolant ............................................................................................................................................. 85

Engine oil ..................................................................................................................................................... 86

Transmission oil ........................................................................................................................................... 87

Fuel .............................................................................................................................................................. 87

Tyre pressure .............................................................................................................................................. 88

Tire size and inflation pressure.................................................................................................................... 88

Tire inflation ................................................................................................................................................. 88

Steering ....................................................................................................................................................... 89

Brake ........................................................................................................................................................... 89

Electrical installation .................................................................................................................................... 89

Installation of the front loader ...................................................................................................................... 89

Maintenance and adjustment schedule ....................................................................................................... 90

Periodical check and service table .............................................................................................................. 90

Diagram of filling points and lubrication points ............................................................................................ 93

Fuels, coolants and lubricants used - amounts ........................................................................................... 94

Recommended SAE viscosity grades for engine oil ................................................................................... 94

ZETOR service fillings ................................................................................................................................. 94

Motor oils ..................................................................................................................................................... 94

Oil in the gearbox and final drivehousing .................................................................................................... 94

Oil for the front driving axle .......................................................................................................................... 94

Other recommended service fillings tested on Zetor tractors ...................................................................... 94

Oil to gear systems of tractors ..................................................................................................................... 94

Fuel .............................................................................................................................................................. 94

Procedure to open the front hood

Front bonnet opening .................................................................................................................................. 95

Opening the side cover ................................................................................................................................ 95

Fuel sys

Bleeding the fuel system ............................................................................................................................. 96

Changing oil in tractor .................................................................................................................................. 97

Changing engine oil ..................................................................................................................................... 97

Draining oil from engine ............................................................................................................................... 98

Engine oil filter ............................................................................................................................................. 98

Pouring oil to engine .................................................................................................................................... 98

Changing the transmission oil ..................................................................................................................... 99

Changing front axle oil ............................................................................................................................... 100

Cleaning and replacing filters .................................................................................................................... 101

Engine oil filter ........................................................................................................................................... 101

Fuel filter .................................................................................................................................................... 102

Hydraulic oil filter ....................................................................................................................................... 102

Changing coolant ....................................................................................................................................... 103

Anti freeze.................................................................................................................................................. 103

Cleaning the radiator ................................................................................................................................. 104

Greasing the tractor ................................................................................................................................... 105

Setting the play of controls ........................................................................................................................ 106

Adjusting the brake .................................................................................................................................... 106

Adjusting method ....................................................................................................................................... 106

Adjusting the throttle lever ......................................................................................................................... 106

Adjusting toe-in .......................................................................................................................................... 106

Checking the battery .................................................................................................................................. 107

tem ................................................................................................................................................. 96

................................................................................................................ 95

Battery maintenance .................................................................................................................................. 107

CONTENTS

6

Battery charging ........................................................................................................................................ 108

Battery disconnect ..................................................................................................................................... 108

Battery disconnector .................................................................................................................................. 108

Fan belt adjustment ................................................................................................................................... 109

Alternator inspect ....................................................................................................................................... 109

Alternator and fan belts inspect/adjust/replace ......................................................................................... 109

Air conditioner compressor belt adjustment .............................................................................................. 110

Air filter maintenance ................................................................................................................................. 110

Checking hoses and lines .......................................................................................................................... 111

Checking the wiring harness and fuses ..................................................................................................... 111

Replacing fuses ......................................................................................................................................... 112

Main fuses .................................................................................................................... ............................. 112

Storage ...................................................................................................................................................... 113

For daily or short term storage ............................................................................................... ................... 113

Long-term storage ..................................................................................................................................... 113

Re-use after long term storage .................................................................................................................. 113

Fuel saving tips .......................................................................................................................................... 113

Air cleaning system ................................................................................................................................... 113

Engine ........................................................................................................................................................ 114

Fuel system ............................................................................................................................................... 114

Oil system .................................................................................................................................................. 114

Cooling system .......................................................................................................................................... 114

How to use of jacks ................................................................................................................................... 115

Cabin .............................................................................................................................................................. 117

Instruments and related parts .................................................................................................................... 117

Doors ......................................................................................................................................................... 118

Rear window .............................................................................................................................................. 118

Side window .............................................................................................................................................. 118

Work light

Rearview mirrors ....................................................................................................................................... 119

Cab ceiling ................................................................................................................................................. 119

How to c

Interior devices .......................................................................................................................................... 120

Ventilation .................................................................................................................................................. 120

Re-circulation inlets fully closed ................................................................................................................ 120

Control panel on right cab pillar ................................................................................................................. 121

Windscreen washer tank ........................................................................................................................... 121

Interior lamp ............................................................................................................................................... 122

Blower control switch ................................................................................................................................. 122

Temperature control .................................................................................................................................. 122

Air conditioner switch ................................................................................................................................. 122

Circulation diffuser ..................................................................................................................................... 123

Heating system .......................................................................................................................................... 123

Heating system configuration .................................................................................................................... 123

Compressor belt adjustment ...................................................................................................................... 124

Air conditioning system .............................................................................................................................. 124

Roof hatch (if equipped) ............................................................................................................................ 124

Cab air intake filter ..................................................................................................................................... 125

Radio, CD player (if equipped) .................................................................................................................. 125

Ash tray ...................................................................................................................................................... 126

Cigarette lighter ......................................................................................................................................... 126

Main technical parameters .......................................................................................................................... 129

Maximum permissible weight of the unit (tractor with trailer or semi-trailer) ............................................. 131

Maximum permissible tractor axle load ..................................................................................................... 131

Permitted maximum weight of set 'tractor + mounted machine' (kg) ........................................................ 131

Manoeuvrability condition .......................................................................................................................... 131

Permissible wheel combination for tractors and load capaci

Traveling speed ......................................................................................................................................... 132

Noise levels .................................................................................................................. ............................. 133

Vibration referred to the operator position ................................................................................................. 134

Fault tracing .................................................................................................................................................. 135

Engine troubleshooting .............................................................................................................................. 135

s (front and rear) ........................................................................................................................ 118

ontrols cabin ................................................................................................................................ 120

ty of tires ...................................................... 131

Brake and hydraulic system troubleshooting ............................................................................................. 137

CONTENTS

78

Steering wheel and electric instruments troubleshooting .......................................................................... 138

Towing the tractor ........................................................................................................................................ 139

Wiring Diagram ............................................................................................................................................. 141

UTILIX HT 45 / UTILIX HT 55 Electric system diagram (1) ....................................................................... 141

UTILIX HT 45 / UTILIX HT 55 Electric system diagram (2) ....................................................................... 142

UTILIX HT 45 / UTILIX HT 55 Cabin wiring diagram (1) ........................................................................... 143

UTILIX HT 45 / UTILIX HT 55 Cabin wiring diagram (2) ........................................................................... 144

UTILIX HT 45 / UTILIX HT 55 Cabin wiring diagram (3) ........................................................................... 145

Power train .................................................................................................................................................... 147

Index ............................................................................................................................................................... 149

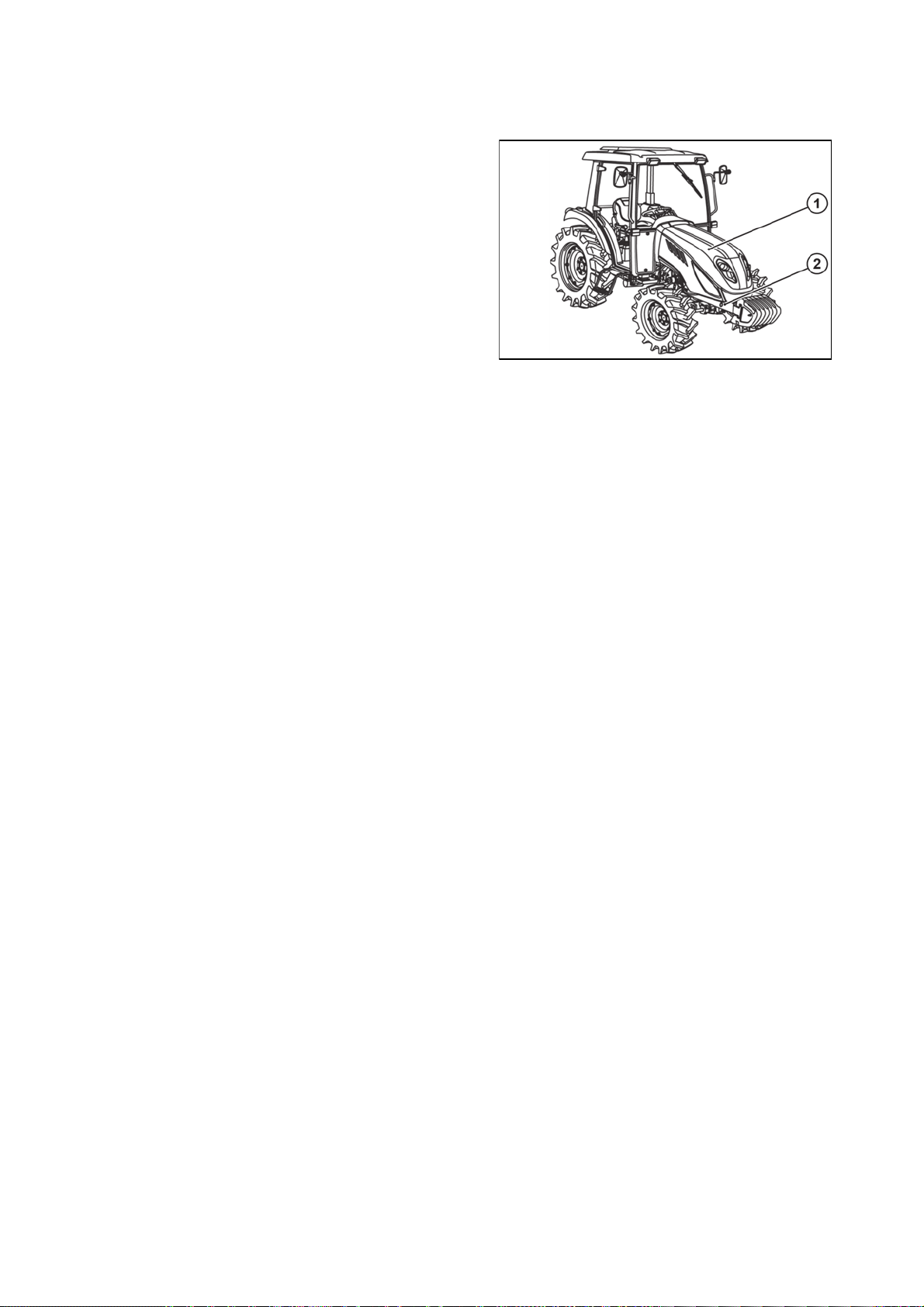

The engine number is stamped on the left hand side of the engine block.

TRACTOR IDENTIFICATION

9

The chassis number is shown on the left hand side of the tractor as shown in the drawing.

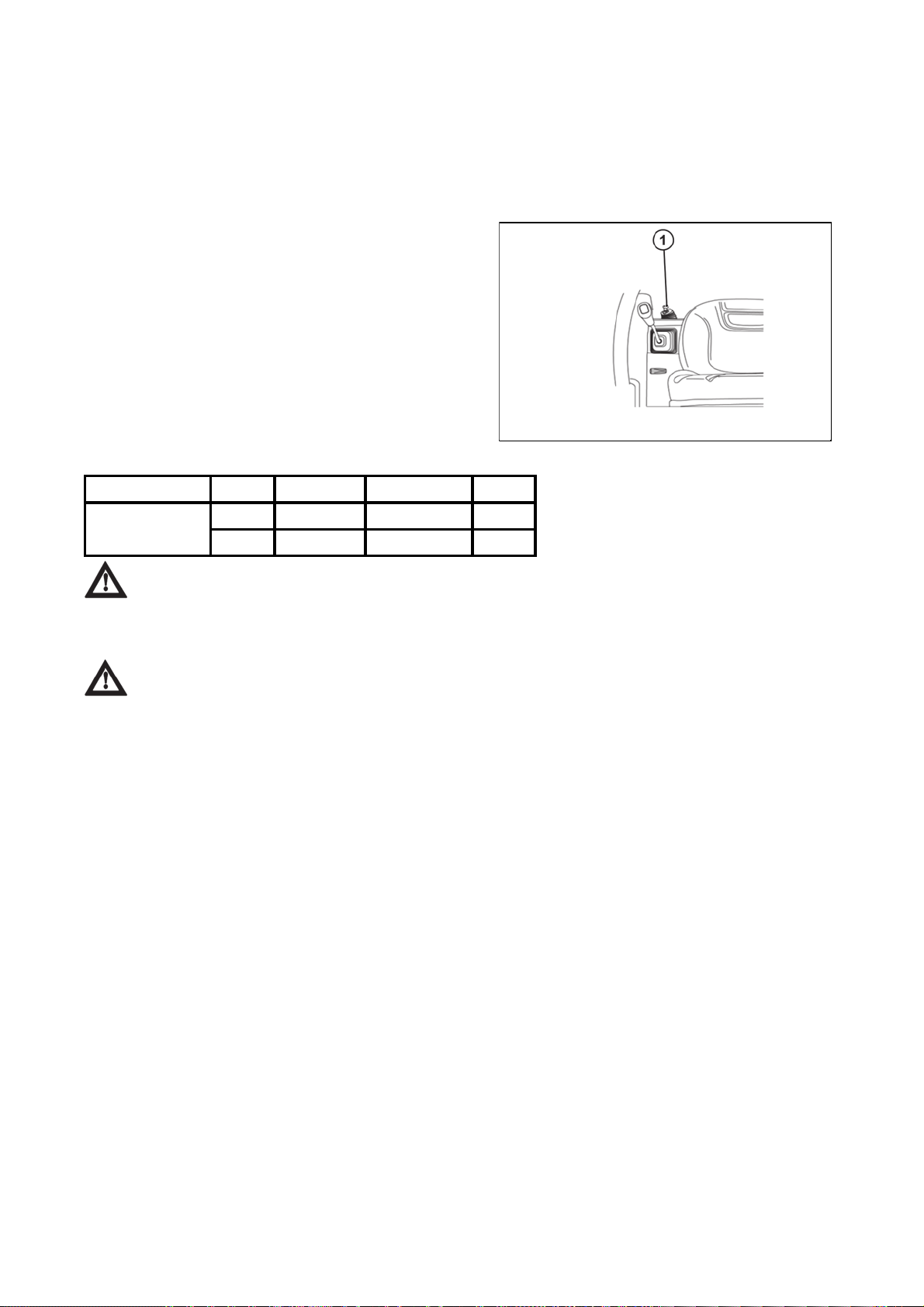

1 - Stamped position of the Engine type or Number

2 - Stamped position of the chassis number

U18N001

Warranty of the product

The manufacturer warrants this product and full details of the warranty are provided on a separate warranty

schedule.

Parts

To obtain spare parts please contact your nearest dealer and give him the details listed below.

Tractor model

Tractor serial number

Tractor engine number

Part number and description

Quantity required

NOTES

10

This manual has been prepared to assist you in following / adopting the correct procedure for running-in

ABOUT THIS MANUAL

11

operation and maintenance of your new ZETOR Tractor.

Your tractor has been designed and built to provide maximum performance, low fuel consumption and ease

of use. To maintain the condition and ensure trouble-free performance, it is important that maintenance is

performed at the recommended intervals as described in this manual.

Read this Manual carefully and keep it in a convenient place for future reference.

If at any time you require advice concerning your Tractor, do not hesitate to contact your Authorized ZETOR

dealer / Distributor. He has trained personnel, genuine parts and necessary equipments to undertake all your

service requirements.

All data given in this book is subject to production variations. Dimensions & weight are approximate only and

the illustrations do not necessarily show Tractors in standard condition.

For exact information about any particular Tractor, please consult your ZETOR dealer / Distributor.

NOTES

12

Tractor an introductio

n

p

.

INTRODUCTION & DESCRIPTION

13

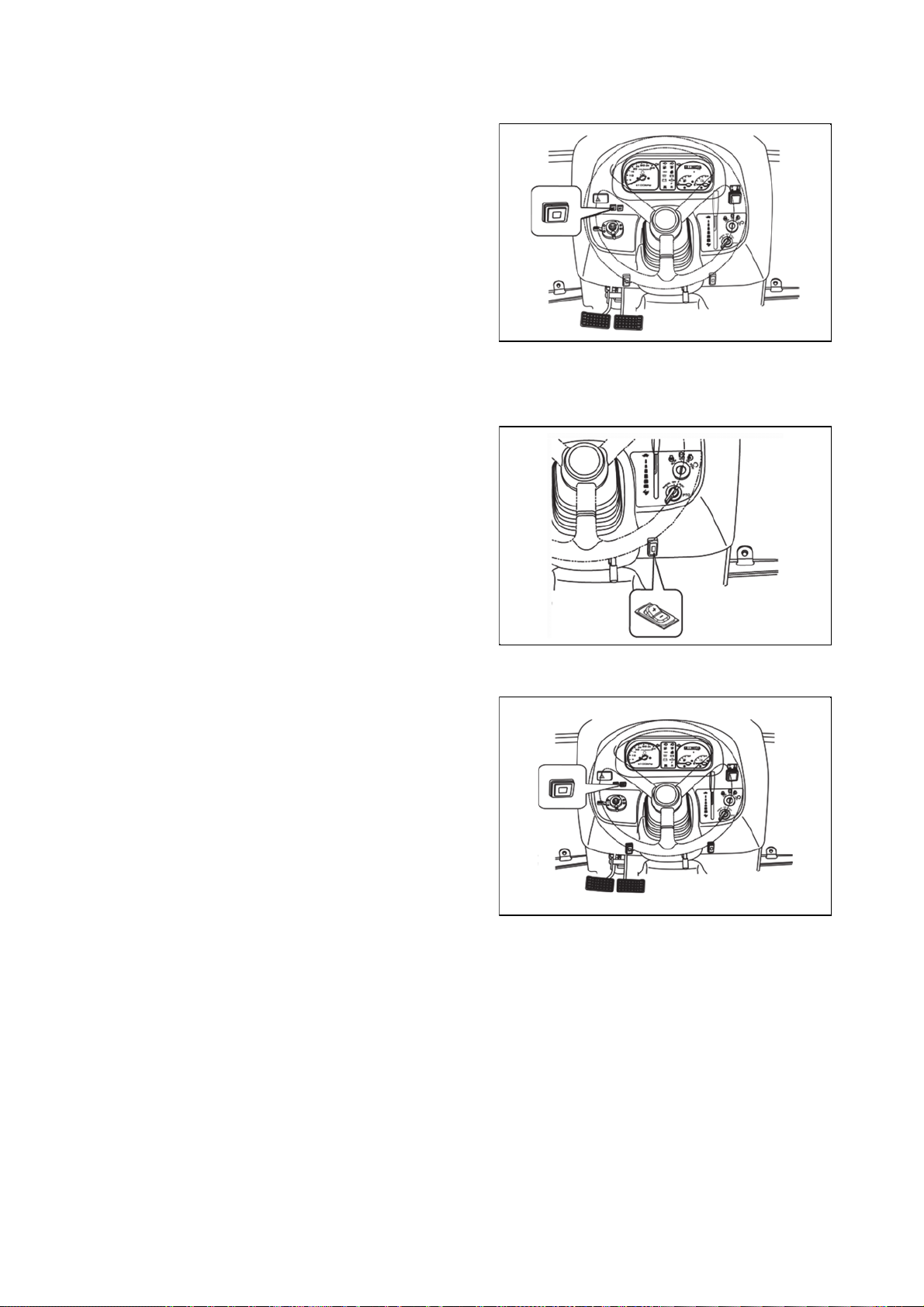

1 - Right turn (Clockwise)

2 - Right

3 - Front

4 - Left

5 - Rear

6 - Left turn (Counterclockwise)

U18N002

The word 'tractor' is derived from 'traction', which means towing.

A tractor is necessary for drawing or towing equipment, implements or carts that are suitably connected to

the tractor body.

The tractor can also be used as a driving machine, thanks to the Power Take-off or PTO shaft.

This manual provides instructions for the operation, maintenance and storage of all Zetor tractor models.

This material has been elaborated in detail to help you better understand maintenance and efficient

operation.

If you need information not provided in this manual or the services of a trained mechanic, please contact

Zetor Dealer/distributor at your location. Dealers and distributors are kept informed about the latest methods

of servicing tractors.

They are supplied with original spare parts and are fully supported by the manufacturer.

Through this manual

The use of the terms LEFT, RIGHT, FRONT and REAR must be understood, to avoid any confusion when

following the introductions. The LEFT and RIGHT means left and right sides of the Tractor when facing

forward in the driver's seat, Reference to the FRONT indicates the radiator end of the Tractor, while the

REAR, indicates the drawbar end (Fig. U18N002).

When spare parts are required, always specify the Tractor and engine serial number when ordering these

parts. (See Fig. U18N001).This will facilitate faster delivery and help ensure that the correct parts for your

particular Tractor is received. The tractor serial number is punched on a plate attached to the left hand side

of the engine body (See Fig. U18N001), For easy reference, we suggest you to write the number in the

ace provided in the owner's personal data

s

Descriptio

n

INTRODUCTION & DESCRIPTION

14

General construction

The transmission case, clutch, clutch housing, engine and front axle support are bolted together to form

a rigid unit.

Front Axle and wheels

The 4WD front axle is a center-pivot, reverse Eliot type. The front wheel drive mechanism is incorporated as

a part of the axle.

The front wheel drive power is taken off the rear transmission and transmitted to the differential in the front

axle where the power is divided into right and left and to the respective final cases.

In the final cases, the transmitted revolution is reduced by the level gears to drive the front wheel. The 4WD

mechanism with level gears provides wider steering and greater durability.

Engine

The tractors are fitted with fuel efficient engine with 4 cylinders manufactured by Perkins.

Hydrostatic transmission

The tractor is equipped with a three-speed hydrostatic transmission with power steering, individual speed

ranges are shifted using the selector lever. The tractor is equipped with two pedals, for speed and for

forward / reverse travel. The tractor with an independent PTO is equipped with an electro-hydraulic clutch.

Brakes

Tractors are equipped with independent disc brakes. The handbrake lever is adapted for parking.

Rear axle and wheels

This is mounted on ball bearings and is enclosed in removable housing which are bolted to the transmission

case. The rim & Disc fitted with rear tires are bolted to the outer flange of rear axle.

Hydraulic system & Linkages

ZETOR Tractors are fitted with Live independent, very touch of hydraulic System.

Three point Linkages can be used for Category 1 type of implements.

Steering

It consists of hydrostatic power steering system, which has a hydraulic cylinder and tandem type hydraulic

pump.

Electrical system

A 12 Volt lead acid propylene battery is used to activate the engine through the starter motor and the

electrical system comprising horn, head lamp. Side indicator lamps, plough lamp, brake light, gauge lamp,

hazard lamp. Generator or alternator, fuse box also from part of the electrical system.

Warning: When operating the tractor at High speed, Do not attempt to make sharp turns by

using the brakes. This may result in overturning of the Tractor causing serious injury or DEATH.

Roll over protective structures (ROPS)

ROPS (ROLL OVER PROTECTION STRUCTURES)

15

ZETOR Tractors are equipped with a frame for the protection of operators.

In the case of cab tractors the frame is incorporated in the cab structure.

The objective of the frame or cab structure is to protect the operator in the event of a roll over and they are

designed to support the entire weight of the tractor in that event.

Each ZETOR ROPS frame or cab structure is designed and has been tested to meet industry and or

Government standards.

Included in these tests were all mounting bases and bolts or other fasteners.

DANGER

For ROPS frames to be effective and protect the operator, the seat belt provided must be worn in

order to keep operators within the ROPS protected area in the event of a roll over. Failure to use the

seat belt can still cause serious injury or death.

On some models the ROPS frame has a fold down feature, which can be used to enter low buildings etc.

Take care when lowering the upper section of the ROPS frame and take extreme care while driving the

tractor with the ROPS frame lowered.

Do not wear the seat belt with the ROPS lowered and please remember that the fold down facility is for

special circumstances only and must not be lowered for general use.

Use of the tractor with the ROPS lowered can cause fatal injuries

As the ROPS frame or cab together with the seat belt was designed to meet certain standards, they must be

maintained in good order and condition. To achieve this objective, both the structure and the seat belt should

be inspected on a regular basis (every time the tractor is serviced).

In the event that the seat belt is damaged or frayed, it should be replaced and in the event that the ROPS

frame or any part of the mounting structure is damaged or cracked, the faulty component must be replaced

with a new unit. Such a unit must meet all of the test criteria of the original unit. Fitment of an inferior item or

items affects the certification of the entire ROPS structure and the effectiveness of the structure in the event

of an accident. Drilling or welding of the ROPS structure is forbidden.

Damage of the ROPS

Cabin type

If the tractor has rolled over or the ROPS has damaged

(such as striking an overhead object during transport), it

must be replaced to provide the original protection. After

an accident, check for damages to the 1.ROPS.2.Seat

3.seat belt & seat mountings. Before you operate

a Tractor, replace all damaged parts.

U18N003

Warning: Do not weld, drill or straighten the ROPS.

Warning: Never attach chains, ropes to the ROPS for pulling purposes; this will cause the

Tractor to tip backwards. Always pull from the Tractor drawbar. Be careful when driving through

door opening or under low overhead objects. Make sure there is sufficient overhead clearance for the

ROPS fatal injuries.

Warning: If the ROPS is removed or replaced, make certain that the proper hardware is used to

replace the ROPS and the recommended torque values are applied to the attaching bolts.

Warning: Always wear your seat belt if the tractor is equipped with ROPS.

How to adjust the Seat

t

ROPS (ROLL OVER PROTECTION STRUCTURES)

16

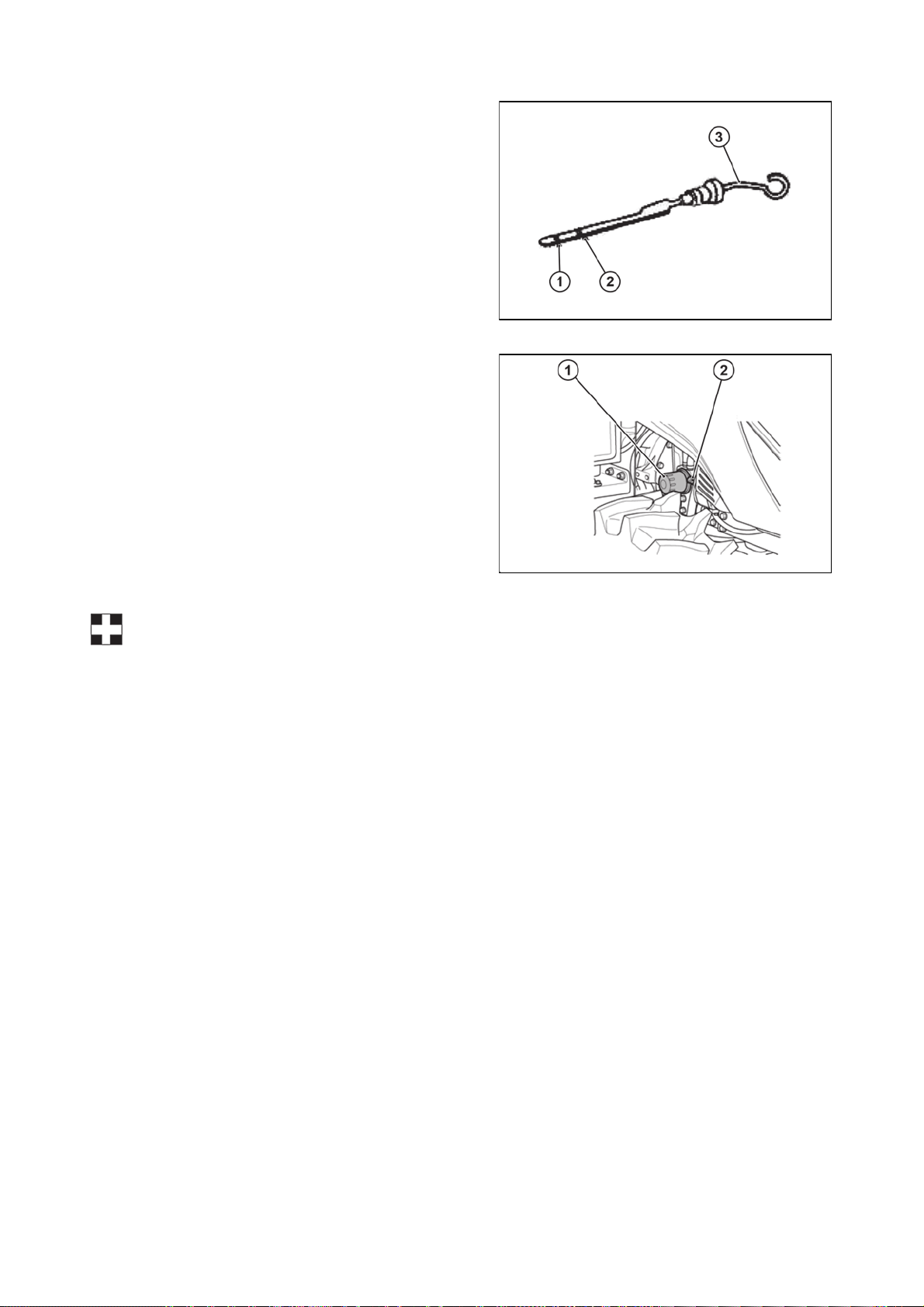

1 - Seat Bel

2 - Forward / Backward adjustment lever

3 - Knob for weight adjustment

U18N005

NOTE: Do not use solvents to clean the seat. Use warm water with a little detergent added.

Before operating a Tractor it is important to adjust the seat to the most comfortable position & check whether

it is properly locked in its position. Figure 1 identifies the seat fitted to your Tractor.

For sliding seat

To select seat position, move adjusting lever and slide

seat closer to or away from dash panel and controls.

3

Caution: Do not put a hand between the seat and the slides when adjusting the seat position.

You can get injured unexpectedly.

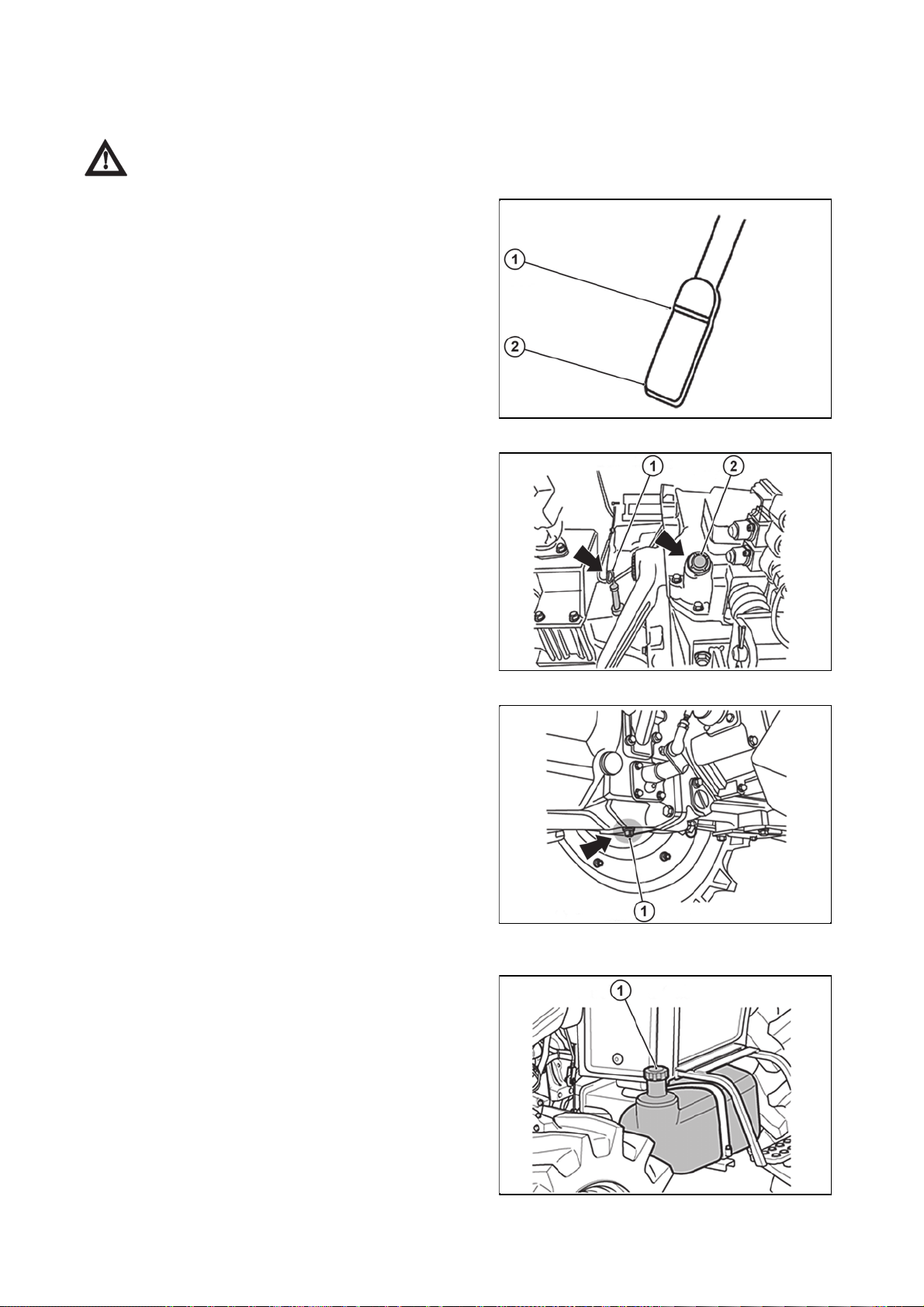

Seat suspension adjustment knob

ROPS (ROLL OVER PROTECTION STRUCTURES)

17

To adjust the seat correctly, turn Weight adjustment knob clockwise or counterclockwise, while seated in the

driving position.

Caution: Do not put a hand between the seat and the slides when adjusting the seat position.

You can get injured unexpectedly.

Danger: Check whether the seat properly locked in its position before driving the tractor.

Danger: Always use the seat belt when the ROPS is installed. Do not use the seat belt if

a foldable ROPS is down or there is no ROPS. Check the seat belt regularly and replace if frayed or

damaged.

Danger: Check whether the seat properly locked in its position before driving the tractor.

Danger: Always use the seat belt when the ROPS is installed. Do not use the seat belt if

a foldable ROPS is down or there is no ROPS. Check the seat belt regularly and replace if frayed or

damaged.

Cushion strength adjustment

The seat cushion can be adjusted according to the weight of the driver.

Turning the cushion adjustment lever counterclockwise to the 50 kg position makes the cushion lighter, and

turning the lever clockwise to the 130 kg position makes the cushion heavier.

NOTES

18

Introduction to safety informatio

n

.

SAFETY INSTRUCTIONS

19

This symbol means ATTENTION! YOUR SAFETY IS INVOLVED. The message that follows the

symbol contains important information about safety. Carefully read the message.

Signal words

Danger

Warning

Caution

A signal word - DANGER, WARNING OR CAUTION - is used with safety alert symbol. DANGER identifies

the most serious hazards. Safety signs with signal Word - DANGER OR WARNING - are typically near

specific hazards. General precautions are listed on CAUTION safety signs.

Introduction to safety instructions Introduction to safety instructions

Carefully read all safety instructions given in this manual

for your safety. Tempering with any of the safety devices

can cause serious injuries or death. Keep all safety signs

in good condition.

Replace missing or damaged safety sings.

Keep your tractor in proper condition and do not allow any

unauthorized modifications to be carried out on the tractor,

which may impair the function/safety and affect tractor life

Protection children

When using the tractor, prevent other persons from

accessing the tractor.

Reverse travel

- Look around if someone is not behind the tractor.

- Do not allow anyone to ride on the tractor or implement.

U18N134

U18N135

Use of rops and seat belt

.

p

.

SAFETY INSTRUCTIONS

20

The Roll Over Protective Structure (ROPS) has been

certified to industry and/or government standards. Any

damage or alternation to the ROPS, mounting hard-ware,

or seat belt voids the certification and will reduce or

eliminate protection for the operator in the event of a rollover. The ROPS, mounting hardware, and seat belt

should be checked after the first 100 hours of tractor and

every 500 hours thereafter for any evidence of damage,

wear or cracks. In the event of damage or alternation, the

ROPS must be replaced prior to further operation of the

tractor.

The seat belt must be worn during machine operation

when the machine is equipped with a certified ROPS

Failure to do so will reduce or eliminate protection for the

erator in the event of a roll over

o

Precaution to avoid tipping

Do not drive where the tractor could slip or tip.

Stay alert for holes and rocks in the terrain, and other

hidden hazards.

Slow down before you make a sharp turn.

Driving forward out of a ditch or mired condition could

cause tractor to tip over backward. Back out of these

situations if possible.

U18N136

Safe parking of the tractor

Before working on the tractor:

Lower all equipment to the ground.

Stop the engine and remove the key.

Keep riders off tractor

Do not allow other persons to ride on the tractor besides

the operator.

Persons on the tractor are exposed to the risk of injury,

e.g. due to the impact of a foreign object or falling from the

tractor.

U18N137

U18N138

U18N139

Handle fuel safely-avoid fires

SAFETY INSTRUCTIONS

21

Handle fuel with care; it is highly flammable. Do not refuel

the tractor while smoking or near open flame or sparks.

Always stop engine before refueling tractors.

Always keep your tractor clean of accumulated grease,

and debris. Always clean up spilled fuel.

Stay clear of rotating shafts

Entanglement in rotating shaft can cause serious injury or

death.

Keep PTO shield in place at all times.

Wear close fitting clothing. Stop the engine and be sure

PTO drive is stopped before making adjustments,

connections, or cleaning out PTO driven equipment.

U18N140

Always use safety lights and devices

Use of hazard warning lights and turn signals are

recommended when towing equipment on public roads

unless prohibited by state or local regulations.

Use slow moving vehicle (SMV) sign when driving on

public road during both day & night time, unless prohibited

by low.

U18N141

U18N142

Practice safe maintenance

.

SAFETY INSTRUCTIONS

22

Be thoroughly familiar with the service procedure before

performing work.

Keep the tractor area clean and dry.

Do not attempt to service the tractor while it is in motion.

Be careful not to let your body or clothing get into the

rotating shaft.

Always lower all attached equipment on the ground. Turn

off the engine.

Remove the ignition key. Let the tractor cool down before

any repairs.

All parts of the tractor that need to be lifted for service

work must be securely supported.

Keep all parts in good conditions and properly installed.

Replace worn or damaged parts. Replace

damaged/missing plates.

Remove any accumulated excess grease or oil from the

tractor.

Disconnect the battery ground cable (-) before making

adjustments to electrical systems or performing welding

work on the tractor

Avoid high-pressure fluids

Liquid escaping under pressure can penetrate the skin

and cause serious injury. Be especially careful when

handling the injection elements - there is a risk of injecting

liquids under high pressure under the skin of your hands

or other parts of your body. If ANY liquid penetrates the

skin, contact your doctor immediately.

U18N143

Prevent battery explosions

Keep sparks, lighted matches, and open flame away from

the top of battery. Battery gas can explode. Never check

battery charge by placing a metal object across the poles.

U18N144

U18N145

Prevent acid burns

SAFETY INSTRUCTIONS

23

Protect the top of the battery from sparks, flammable

materials and open flames. Accumulated battery fumes

can explode. Never check the battery charge by

connecting the battery terminals with a metal object.

Sulfuric acid in the battery electrolyte is hazardous to

health. It is strong enough to burn the skin, burn through

the clothing and cause blindness when it gets into the

eyes.

To ensure adequate safety, always:

1. Refill the batteries in a well-ventilated place.

2. Wear eye protection and acid-resistant gloves.

3. Do not inhale the released vapors after the

electrolyte has been added.

4. Do not add water to the electrolyte, as it may cause

expansion and subsequent severe burns.

If you get stained with acid:

1. Rinse skin with water.

2. Rinse eyes with water for 10 - 15 minutes. Seek

medical advice immediately.

U18N146

Service tractor safely

Do not wear a tie, scarf or any other loose clothing when

working near moving parts. If any of these garments is

caught, a serious injury may occur.

Do not wear rings or other jewellery to avoid electrical

short circuits and entanglement in moving parts.

U18N147

Work in ventilated are

a

r

:

SAFETY INSTRUCTIONS

24

Do not start the tractor in an enclosed building unless the

doors & windows are open for proper ventilation, as tracto

fumes can cause sickness or death. If it is necessary to

run an engine in an enclosed area remove the exhaust

fumes by connecting exhaust pipe extension.

U18N148

Tractor runaway

1. To increase safety, leave the emergency stop control (fuel cut-off control) in the fully extended

position. When using the starter switch or other work on the tractor, the foot brake pedal must be

depressed and the PTO lever disengaged.

Safety starter switch

1. On some models, the starter switch is available on the 'high / low' gearshift lever and the PTO shift

lever. The tractor can only be started when the 'high / low' gearshift lever is in the neutral position.

2. Do not disable or modify this starter switch. It is recommended that only authorized dealers handle the

starter switch.

Caution: Safety starter switch is to be replaced after every 2 000 hours / 4 years, whichever is

earlier.

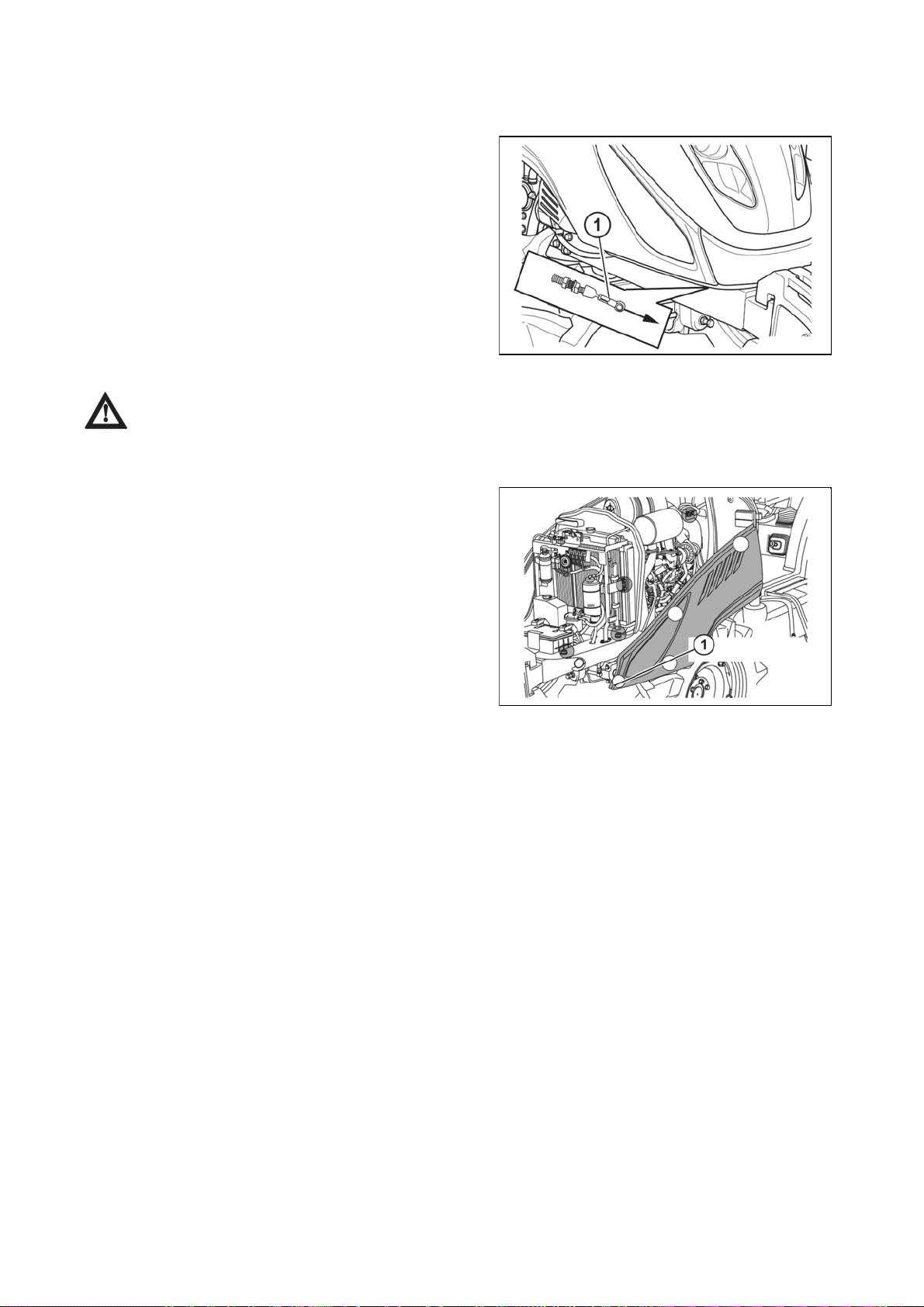

Emergency exits

If exit from the cab side doors is blocked (following an accident or vehicle overturn) the alternative safety

exits are indicated by decals.

The possible safety exits are

z Rear window hatch (all tractors)

z Front window (for versions with openable front

window).

U18N005_1

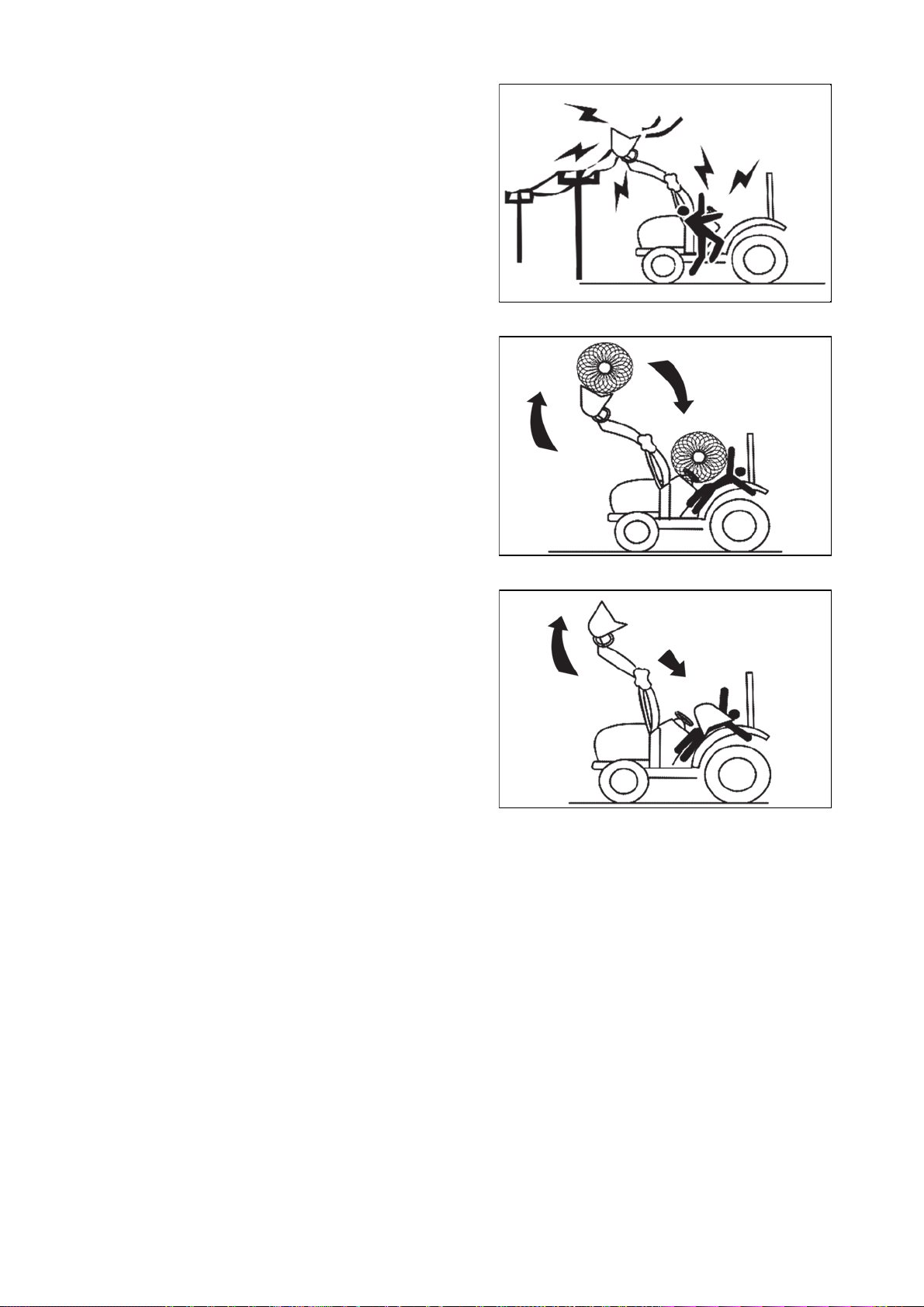

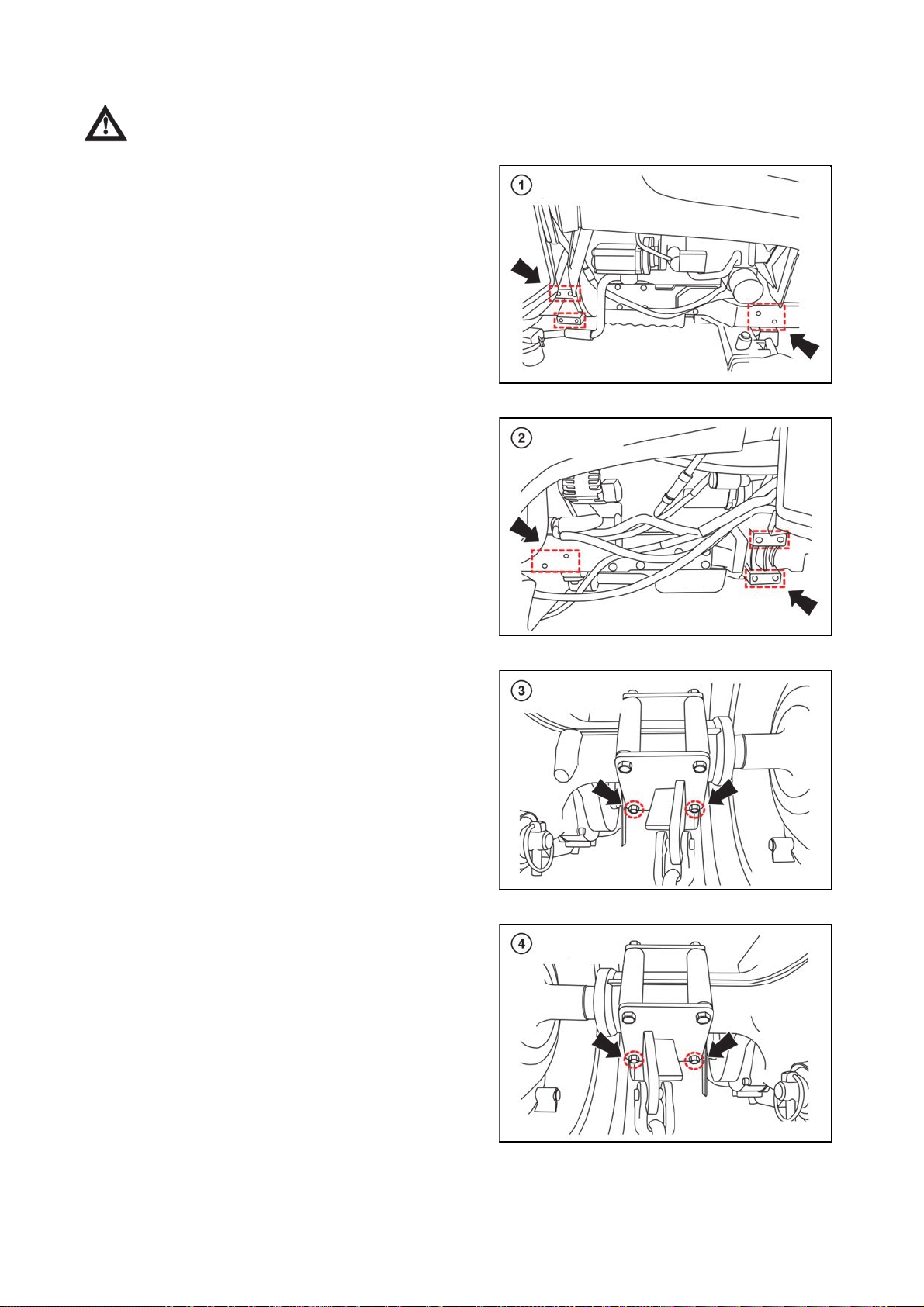

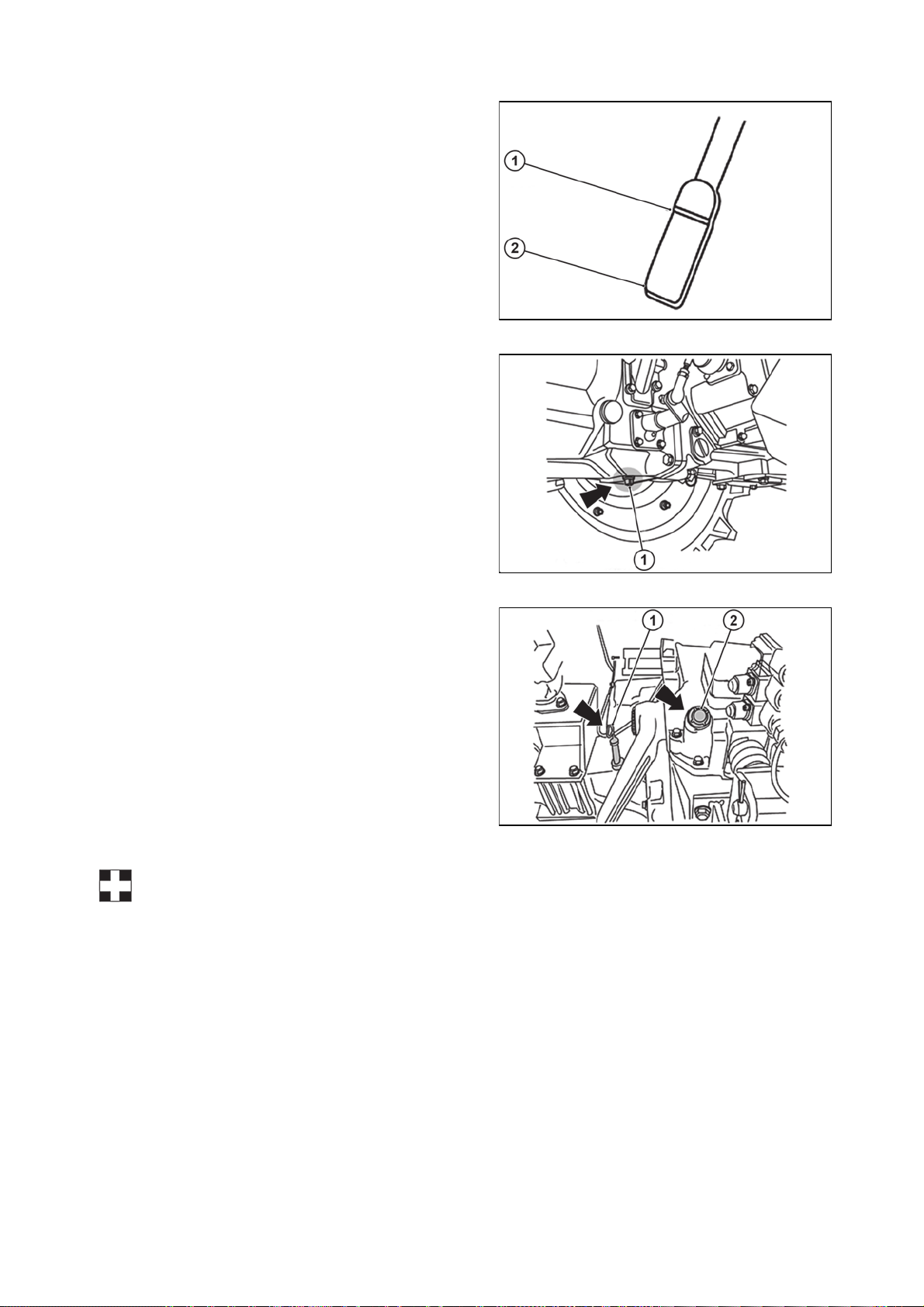

Safety precautions when using the loade

r

SAFETY INSTRUCTIONS

25

Do not allow persons to enter the attached loader adapter

or the loader boom operating area. Failure to do so may

result in serious injuries or even death.

Do not stay under the lifted loader or do not approach it.

Lower the loader boom to the ground before leaving the

tractor. Failure to do so may result in serious injuries or

even death.

U18N005_2

When mounting or dismounting the loader, secure all parts

that are attached to the adapter and the boom. The

adaptor or the boom may unexpectedly drop, which can

lead to injury or even death.

U18N005_3

U18N005_4

Do not allow the boom or attached adapter or equipment

SAFETY INSTRUCTIONS

26

to come into contact with electrical lines or other electrical

equipment. Electric current causes serious injuries or

death.

For safe handling of loads, always use a suitable type of

adapter for your work. While driving, keep the boom

loaded with a load at a low position above the mat. Failure

to do so may result in machine damage, serious injury or

even death.

U18N005_6

When mounting or dismounting the loader, secure all parts

that are attached to the adapter and the boom. The

adaptor or the boom may unexpectedly drop, which can

lead to injury or even death.

U18N005_7

U18N005_8

Towing safel

y

SAFETY INSTRUCTIONS

27

For the maximum permissible load of the hitch, see 'Maximum hitch load' in the Specifications section.

- Maintain a suitable speed taking into account the weight of the load towed or carried by the tractor and the

inclination of the surrounding terrain, remembering that the braking distances will be greater than that of

a unloaded tractor. Attached trailers or semi-trailers with or without brakes that exceed the specified

technically permissible maximum authorized weight may cause loss of control of the tractor unit.

- Always take into account the total weight of the attached machine and its load.

-When semitrailers are attached to the tractor, remember to switch all controls to neutral position, lock the

parking brake, turn off the engine, engage first gear (for mechanical transmission), and remove the ignition

key before leaving the operator's seat. ALWAYS secure the wheels of the tractor and the trailer with wedges.

The safest and recommended way to transport a damaged tractor is to transport it on a low-load trailer.

Always attach the tractor to the low-load trailer with chains. Before transporting the tractor on a low-load

trailer or on a railway wagon, make sure that the engine cover, door, openable roof (if available) and

windows are closed and securely locked. Never tow the tractor at a speed higher than 10 km/h. In this case,

the operator must remain in the operator's seat to drive and brake the tractor.

Caution: When a trailers is hitched to the tractor, before you leave the driving seat remember

to put all the controls in neutral, apply the handbrake, switch off the engine, engage first gear (if the

tractor has a mechanical transmission) and remove the key from the starter switch. If the tractor is

not parked on level ground, ALWAYS place chocks under the wheels of both the tractor and the

trailer For further information on safe working procedures, refer to the chapter 'Parking the tractor' in

the safe section of this manual.

ROPS (roll-over protective structure), sun visor and cab

are not FOPS protective structures (falling-object

protective structure).

It can never protect the operator from falling objects.

Avoid driving in dangerous terrain or areas where

a foreign object can fall on the roof of the cabin and injure

or even kill the operator.

U18N005_5

Falling Object Protective Structure (FOPS)

The term F.O.P.S refers to structure installed on the tractor intended to reduce the risk to the operator of

injury from falling objects during normal use of the vehicle.

Important:

z This tractor is equipped with a FOPS.

z The energy level of drop test is 1 365J.

Operator Protective Structure (OPS)

The term OPS refers to a protective structure installed on a tractor in order to minimize risk of operator injury

caused by objects penetrating into the operator position area.

Use of hazardous substances

SAFETY INSTRUCTIONS

28

European standard EN 15695-1 is applicable to the cabs of agricultural or forestry tractors and self-propelled

sprayers. The purpose of the standard is to limit the exposure of the operator (driver) to hazardous

substances when applying plant protection products and liquid fertilisers.

In accordance with the provisions of EN 15695-1 concerning cab classification, the measurement of

the internal positive pressure difference shall be made in accordance with ISO 14269-5:

1. Engine operating at rated speed;

2. Maximum air flow brought to the cab (closed recirculation);

3. Fan set to maximum speed.

The following terms and definitions are applied:

- Hazardous substances: substances such as dust, vapours and aerosols, with the exception of fumigants

which can be dispersed during the application of plant protection products and liquid fertilisers, which may

have a harmful effect on the operator.

- Dust general term identifying solid air-borne particles, finely divided and sedimented

- Aerosol: suspension of solid, liquid or solid and liquid particulate in agaseous medium with a negligible fall

rate (gener-ally less than 0.25 ms-1) Vapour: gaseous phase of a substance whose liquid or solid state is

stable at 20° Cand 1 bar (absolute). This cab, even when closed, does not protect against the inhalation of

hazardous substances. If the manufacturer's instructions for using these substances recommend personal

protective equipment, wear the equipment even in the cab.

Cabs are classified as follows:

Category 1: the cab does not provide protection against hazardous substances.

Category 2: the cab provides protection exclusively from dust.

Category 3: the cab provides protection from dust and aerosol.

Category 4: the cab provides protection from dust, aerosol and chemical vapours.

Danger: Use all the personal protective equipment suitable for the tasks in hand and relative

substances, in compliance with the requirements of statutory legislation in your country.

Use of Hazardous Substances

SAFETY INSTRUCTIONS

29

The category of the cab installed on this series of tractors, classified according to ISO 14269-5, is

listed below:

- Engine operating at rated speed

- Maximum air flow brought to the cab (closed recirculation) - with fan set to maximum speed

The manufacturer of your tractor has made every effort to make it as safe as is humanly possible.

Beyond this point it is the responsibility of the operator to avoid accidents and we ask that you read and

implement our suggestions for your safety.

Ensure that this tractor is only used by trained and authorized operators. Ensure that the operators are fully

familiar with the machine and understand all its controls and safety features. Operators should not operate

a tractor or attached machines or equipment if they are not properly trained or if they are physically unfit to

operate the machine. To avoid accidents, make sure that the operators wear clothes that might not get

caught in the moving parts of the tractor or the machine and, on the contrary, protect them from these

elements. When applying or using chemicals, ensure that clothes and protective equipment are used to

prevent breathing problems or skin irritation.

For detailed information contact the manufacturer of chemicals.

To avoid prolonged exposure to noise, ensure that the protection of ears is used.

If modification of the tractor or machine is necessary, ensure that the tractor or machine is stopped

beforehand.

When operating the tractor a certified roll-over protective structure (ROPS) must be used.

When operating the tractor a safety belt must be worn.

Under all circumstances, it is necessary to ensure the safety of the operator and others near the machine.

Ensure that no one is between the tractor and the towed vehicle (trailer or implement).

Ensure that this tractor is used only by trained and competent operators. Ensure that the operators are fully

familiar with the machine and understand all its controls and safety features. Operators should not operate

a tractor or attached machines or equipment if they are not properly trained or if they are physically unfit to

operate the machine. To avoid accidents, make sure that the operators wear clothes that might not get

caught in the moving parts of the tractor or the machine and, on the contrary, protect them from these

elements. When applying or using chemicals, ensure that clothes and protective equipment are used to

prevent breathing problems or skin irritation.

Technical data

CAB / ROPS

Category of cab protection against hazardous substances

Category 1

Safety tips during maintenance

SAFETY INSTRUCTIONS

30

1. Check all oil levels at least once a day. Check the amount of water in the radiator and the electrolyte

level in the battery and perform service according to the service schedule of the machine.

2. Ensure that the tire pressure is even and corresponds with the work to be performed.

3. Check that all preventive and service operations are properly performed on the tractor.

4. Ensure that adequate service facilities are available for maintenance and minor repairs.

5. Ensure that all service work and repairs are performed on flat concrete surface or similar surface. Do

not perform service work on the tractor until it is stopped, the parking brake is applied, and the wheels

are secured with wedges. If the tractor is started in an enclosed area, ensure that the area is well

ventilated as the exhaust fumes are very harmful and can cause intoxication or death.

6. It is forbidden to perform service work on the mounted equipment in the lifted position.

7. When changing wheels or tires, ensure that a suitable stand is placed under the axle before removing

the wheel and that the remaining wheels are secured with wedges.

8. If it is necessary to remove guards or covers when servicing or repairing, ensure that the guards or

covers are properly installed before starting the tractor.

9. Never fill the fuel near open flames or with an overheated engine. The engine must be stopped before

filling the fuel.

10. The cooling system operates under pressure, so be careful not to scald yourself with steam or hot

water when removing the hot engine radiator cap. Do not add water to the radiator when the engine is

hot. Only add water to the radiator after the engine has cooled down completely.

11. To prevent fire, keep the tractor, including its engine, clean and free from combustible material, at

a safe distance from fuel and other combustible material.

Mounting and demounting implements

.

SAFETY INSTRUCTIONS

31

1. Ensure that all assembly and disassembly of implements (attachments) is carried out on a secure,

level surface. To prevent accidental injuries, ensure that no one is between the tractor and the

implement or under the implement.

2. After mounting the implement, ensure that all hanging parts such as chains or hoses are properly

secured and, where PTOs are used, properly fastened and secured.

3. Where heavy implements are used, ensure that the unit is well balanced, using suitable ballast to

ensure this balance.

4. Before leaving the tractor, lower the implement onto the ground, deactivate the PTO, apply the

parking brake and stop the engine.

5. When working with an implement that uses PTO, make sure that no other persons are near the

moving parts and do not make any modifications to the implement while the machine is in operation.

6. A tractor equipped with a ROPS protective frame only performs its function in combination with

a fastened seat belt.

7. If children are present in the immediate vicinity of the machine or unit, caution and anticipation of

possible risks related to the movement and operation of the machine are necessary.

8. The tractor may only be used by trained operators who must ensure that no worker is injured. Extra

caution is necessary in dusty environment with significantly reduced visibility.

9. Never start the tractor unless the transmission is in the neutral position, the operator is in the driver's

seat, and there is no other danger when the engine is started up.

10. Only the operator sitting in the driver's seat can operate the tractor. Never turn or brake suddenly at

high speed, as this may cause the tractor to roll over, resulting in serious injury or death.

11. When driving on public roads, observe all legal requirements of the country in which the tractor is

operated, including the requirements for accompaniment. When driving with wide implements, use the

warning devices specified by the applicable legislation in the country in which the machine is used.

12. When operating under adverse conditions, in hilly or bad terrain, adjust the speed of the tractor to the

following conditions:

Never drive down the hill rashly or with the transmission in the neutral position.

Use engine braking capability together with service brakes.

Do not attempt to shift gears in a steep slope and engage a suitable gear before starting to drive the

tractor.

13. When driving uphill with a heavy implement, be careful to prevent overloading and loss of front axle

adhesion and consequent loss of control.

14. Never remove or modify the seat belt.

15. Never remove, modify or repair the ROPS protective frame.

PLEASE REMEMBER THAT A LITTLE BIT OF EXTRA CARE CAN PREVENT SERIOUS INJURY OR

TEATH AND AVOID DAMAGE TO YOUR TRACTOR

The following precautions are suggested to help prevent accidents

y

SAFETY INSTRUCTIONS

32

The best operator is the careful operator. Most accidents can be prevented by observing certain safety

measures. Before using the tractor, read the following measures and observe them to avoid accidents. The

tractor may only be operated by authorized persons who are properly trained for this operation.

Tractor

1. Read the operating and maintenance manual of the machine carefully before operating the tractor.

Insufficient knowledge of machine operation can lead to accidents.

2. For safe operation, use an approved protective structure and seat belt. Roll-over of a tractor without

a protective structure can result in serious injuries or even death.

3. Do not remove the roll-over protective structure (ROPS). Always use the seat belt.

4. The laminated roof of the tractor cab does not provide protection against the breakthrough of external

objects with higher weight.

5. To avoid falling while entering and leaving the cab, keep the stairs and platform clean, free of mud