3

ZETOR

This Operator’s Manual will help you to become familiar with the operation and maintenance of your new tractor.

In spite of the fact that many of you have reach experiences with operation of various tractors, please, read carefully

all safety rules, operating instructions and the other information in this Operator’s Manual.

You will find a lot of new information and receive a perfect overview how to use the tractor with the highest

efficiency at various operations.

Your new tractor will be your reliable and long-time friend if observing the mentioned safety rules, tractor

maintenance and safe operation.

The manufacturer of your tractor wishes you thousands of satisfactorily worked hours

ZETOR

Brno

4

Information about technical specifications, design, equipment, material, and external appearance is valid at the time of printing

this Operator’s Manual. The manufacturer reserves the right to make changes.

5

CONTENTS

The “Operator’s Manual” contains

descriptions, operation and maintenance

of standard and optional tractor

equipment, which are allowed to be

installed on a tractor. The option that is

not a part of standard tractor equipment

installed by the manufacturer cannot be

a subject of a claim. The tractor “Service

Coupon Booklet” is not a part of the

Operator’s Manual. This is a separate

booklet that is passed to you when you

purchase a new tractor.

Page

Location of serial numbers .......................................................................................... 7

Safety precautions for users........................................................................................ 9

Preventive daily maintenance ...................................................................................13

Acquaintance with tractor.......................................................................................... 21

Tractor operation....................................................................................................... 51

Tractor running-inn.................................................................................................... 69

Transportation use .................................................................................................... 75

PTO drive of agriculture machines ............................................................................ 85

Hydraulic system....................................................................................................... 93

Hitches .................................................................................................................... 107

Wheel tread change ................................................................................................ 117

Ballast weights ........................................................................................................ 125

Electrical system ..................................................................................................... 133

Tractor maintenance ...............................................................................................145

Maintenance instructions ........................................................................................ 165

Adjustment .............................................................................................................. 185

Main specifications.................................................................................................. 199

Index .......................................................................................................................217

6

TRACTORS Z 8541 - Z 10541

TRACTORS WITH FRONT DRIVING

AXLE (4 X 4):

Tractor type Engine output

(kW)

Z 8541 60

Z 9541 66

Z 10541 74

E1

7

LOCATION OF SERIAL NUMBERS

E2

Tractor type plate Engine serial No

Tractor serial No

Cab serial No

8

LOCATION OF SERIAL NUMBERS

When ordering the spare parts and when being in contact, no matter if written or oral, remember to use the data on your tractor,

which you can put down into the frames below.

Tractor model

Zetor 8541

Zetor 9541

Zetor 10541

The “left“, “right“, “front“ and “rear“ side

of the tractor hold so in the driving

direction.

The manufacturer reserves the right to

make changes in design and equipment

leading to improvements of tractor

features.

Tractor serial number

Engine serial number

E3

9

SAFETY PRECAUTIONS FOR USERS

Pay particular attention to articles in

Operator’s Manual that are marked

with these symbols.

You will find this symbol at all

important warnings regarding

safety of tractor operation.

Heed these warnings and be

very careful in these cases!

Inform your co-operators and

other users about these

warnings.

Study carefully chapters marked

with this symbol before starting

operation, service or adjustment

of the tractor.

You will find this symbol

whenever important information

on operation, adjustment and repairs of starter motor appears.

Heed these warnings and be

very careful in these cases!

This symbol refers to chapters in

Operator’s Manual dealing with

environmental protection.

GENERAL SAFETY REGULATIONS

1. Only a trained operator having a valid

driving license and being properly

acquainted with operating and safety

rules can operate the tractor.

2. Except for safety warnings mentioned

in this Operator’s Manual you must

respect all general safety and traffic

regulations of the country, in which the

tractor is in operation.

PROPER CLOTHING

3. Do not wear loose clothing and tie

long hair back behind your head.

4. Use suitable (prescribed) personal

protection means (working shoes,

gloves, etc.) at work.

STARTING THE ENGINE

5. It is not allowed to start the engine

when driving downhill.

6. Starting the tractor by means of towing

using another tractor or vehicle is

allowed only when the pull bar is used.

7. Start the tractor from the driver’s seat

only with the gearshift lever in

neutral and with the clutch pedal

depressed. Life hazard when

starting by means of the starter

connector short circuit.

8. The ignition key must be in position "I".

9. When preheating engine by electrical

heater, plug the heater first and

connect the cable into electricity after.

On termination of preheating,

disconnect the cable from electricity

first.

OPERATION

10. Hoses of hydrostatic steering, brakes

and fuel system must be checked

and replaced in case of any damage

indication. The signs of damage may

be for example: cracks on hose

surface, loosening of hose fittings (it

is possible to verify it easy by pulling

the hose from fitting) and mechanical

damage to hose. It is necessary to

replace the hoses with marked

service life immediately after

expiration of the marked service life.

11. Brake pedals must be latched with

trailers and implements when driving

on the road.

12. Brakes and steering must be

permanently in perfect condition.

13. Driving downhill without gear shifted

is forbidden!

14. Pay special attention when driving in

hilly, muddy, sandy, icy and uneven

terrain.

15. Do not exceed the maximum

specified angle of inclination, that

should be 12° as a maximum

10

SAFETY PRECAUTIONS FOR USERS

16. Do not exceed the maximum

combination weight mentioned on

the tractor type plate or on the rear

fender.

17. Do not use the differential lock when

driving in a curve.

18. It is forbidden to get in / out when the

tractor is moving.

19. Reduce the travelling speed to

15 km.h

-1

when driving with

agricultural implements hitched in

the front three-point hitch.

20. The front axle load must not fall

below 18 to 20 % of the

instantaneous combination weight

when agricultural implements hitched

in rear hitches are used.

TRANSPORTATION OF PERSONS,

OPERATION

21. Number of persons transported by

tractor must not exceed the number

mentioned in the tractor registration

document.

22. Persons, that are not authorized to

work with the attached implement,

must not stand between tractor and

hitched implement (machine).

23. Make sure neither any person nor

any obstacle allows driving before

starting tractor move.

24. Maximum allowed travelling speed of

the tractor and trailer (or semi-trailer)

combination equipped with air brakes

is 30 km.h-1. Only tractor models

equipped with braked front driving

axle can move with the maximum

allowed speed (tractor and trailer or

semi-trailer) of 40 km.h

-1

.

TRACTOR RESCUE, TOWING

25. To recover the bogged-down tractor,

use the tow bar or cable.

Never use chains! Danger of life

in case of the chain rupture!

26. It is life dangerous to stand near the

tow rope when recovering the

tractor.

27. Front hook assembled on front

tractor frame serves for pulling of the

tractor alone only, i.e. without trailer

or another implement.

28. Never use free wooden blocks or

bars being put between tractor and

pushed subject when pushing other

vehicles (trailers, implements etc.).

LEAVING THE TRACTOR

29. Do not park the tractor with attached

implement in lifted position.

30. Do not forget to set the tractor

parking brake (shift the gear and

move the reversing lever to forward

drive position), remove the ignition

key and lock the cab before leaving

the tractor.

31. Usually use the left-hand side tractor

door when leaving the tractor. Look

round whether any vehicle is coming,

that could jeopardize your safety

when getting out of the tractor.

32. Use steps and handles when leaving

the tractor. Pay attention to a space

of the gearshift lever and hand fuel

delivery throttle control lever.

33. Set the tractor parking brake before

leaving the tractor with running

engine.

WITH THE STOPPED ENGINE ONLY

34. All activities connected with refuel-

ling, cleaning, lubricating and

adjusting the tractor or attached

implement can be done with the

engine at standstill and stopped

moving tractor parts only, except for

brake, hydraulics and charging

function check.

35. It is always necessary to shut the

engine off before removal of hood.

The engine can run in an enclosed

building or room only when sufficient

ventilation is secured. Exhaust gases

are harmful to your health.

PRINCIPLES OF FIRE PREVENTION

36. Refuel the tractor with the engine off.

37. Do not refuel the fuel tank up to the

top in summer season. Wipe the fuel

immediately when spilled.

38. Do not refuel the tractor nearby open

flame and do not smoke.

11

SAFETY PRECAUTIONS FOR USERS

39. Do not smoke and do not use open

flame when checking the battery

electrolyte level. Keep properly the

fire prevention regulations in areas

with increased fire hazard (hay-lofts,

straw-stocks etc.).

40. If the tractor is equipped with a fire

extinguisher, keep it always ready for

use.

HEALTH AND

ENVIRONMENTAL

PROTECTION

41. Tractors are not furnished with

special filters of air that is sucked to the

cab. Therefore the tractors are not

intended for work with aerosols and

other substances harmful to health.

Kerosene, diesel fuel, mineral oils and

other products from crude oil used for

operation and maintenance of tractor

may cause an injury in case of direct

contact with skin and it can irritate

mucous membranes, eyes, digestive or

respiratory organs. Some of them can

cause poisoning when swallowed.

42. The operators who come in contact

with oil products are obliged to heed

strictly safety and hygienic

instructions, make use of appropriate

protecting means, and work in wellventilated areas.

CRUDE OIL PRODUCTS

HANDLING

43. On termination of work or prior to

start eating, wash yourself with a

non-irritant agent and treat your

hands with a suitable skin ointment

or cream.

44. When connecting and disconnecting

the quick couplings of hydraulic

circuit, remove – with a piece of any

cloth – the residual oil, which

remains in the coupling socket or

possibly on the plug.

WASTE DISPOSAL

45. When disposing of the tractor or

some of its parts (including the

service liquids), as soon as their

service life is over, everybody is

obliged to proceed in accordance

with the provisions of the relevant

acts and regulations being in force in

a country, in which the tractor is

operated. The last tractor seller is

obliged – under the Waste Disposal

Act – to inform the consumer – when

selling the tractor – on the ways of

taking back some of the consumed

parts of the tractor. In question are

the oils and other service liquids,

storage batteries, and tires. These

components must be accepted back

from the consumer free of charge.

PREVENTIVE DAILY MAINTENANCE

46. Carry it out daily or after 8 to 10

working hours at latest.

SAFETY CAB

47. If corrosion, crash or other accident

cause damage to the protective

frame of safety cab, it is necessary to

replace the cab.

AIR-CONDITIONING

48. In any case it is not allowed to

disassemble, turn or otherwise

manipulate the screw joints of the airconditioning system, because

sudden leak of the coolant and quick

local cooling may occur. Contact or

freezing of components in your

hands may result in serious injury of

some tissues.

49. The air-conditioning system is

equipped with quick couplings, which

allow separation of the cab from the

tractor body if necessary, without any

leak of the coolant. Entrust the

interventions into the air conditioning

system to the service specialists.

12

SAFETY PRECAUTIONS FOR USERS

ELECTRICAL INSTALLATION

50. No additional interventions

into the tractor electrical

equipment (connection of

other electrical appliances)

are allowed because of its

possible overloading!

51. The values of electrical installation

are:

Nominal voltage 12 V =

Earthed pole ( - ) pole

Using of starting trucks or starting aid

devices with different voltage or

polarity may cause serious failures to

tractor.

52. It is necessary to be careful when

handling the battery and to avoid

short circuits. Tractors are equipped

with a battery cut-off switch;

remember to turn it off when handling

the battery.

53. Tractors must not be run with the

disconnected battery because

serious failure of tractor could occur.

13

PREVENTIVE DAILY MAINTENANCE

Carry it out daily or after every 8 - 10 engine working hours at the latest

E4

14

PREVENTIVE DAILY MAINTENANCE

E5 E6 E7

FUEL SYSTEM LEAKAGE

Check the fuel system for leakage

including the drain plug of the fuel tank.

Repair any leaks immediately.

ENGINE OIL LEVEL

The oil dipstick is situated on the righthand side of the engine. Having

unscrewed and removed the oil dipstick

check the engine oil level and check

connections of engine lubrication system

for leaks. Maintain the oil level between

the dipstick marks.

COOLING SYSTEM

Check connections of engine cooling

system for leaks and coolant level in the

expansion tank. The expansion tank is

accessible after removing the right-hand

side part of the hood. Add the missing

coolant up to the upper MAX mark. The

minimum permissible coolant level is

marked with MIN mark.

Loosen the overpressure filler

cap only after cooling down of

coolant. Danger of scalding!

15

PREVENTIVE DAILY MAINTENANCE

E8 E9 E10

FLUID BRAKES

Check fluid brakes and clutch fluid

control for leaks and check the brake

fluid level in the expansion tank. The

expansion tank is accessible after

removal of the left-hand side part of the

hood.

Keep the brake fluid level within 3/4

volume of the vessel (maximum level) up

to 1/2 vessel volume (minimum level).

Keep absolute cleanness when

handling the brake fluid. Check

the brake fluid level daily before

the tractor operation.

TRAILER AIR BRAKES

Check the air brake system for leaks and

check the air brakes of tractor and trailer

for efficiency.

TRAILER HYDRAULIC BRAKES

Check the hydraulic brake system for

leaks and check the hydraulic brakes of

tractor and trailer for efficiency.

HYDROSTATIC STEERING

Check the oil level in the hydrostatic

steering oil tank with dipstick. The

hydrostatic steering oil tank is accessible

after removing the left-hand side part of

the hood. In case of need add the oil up

to the mark on the dipstick, which

determines a correct oil level.

Check all hoses of hydrostatic steering

circuit for damage and oil leaks.

Check bolts and nuts of steering rods

and arms whether they are tightened

properly.

16

PREVENTIVE DAILY MAINTENANCE

E11 E12 E13

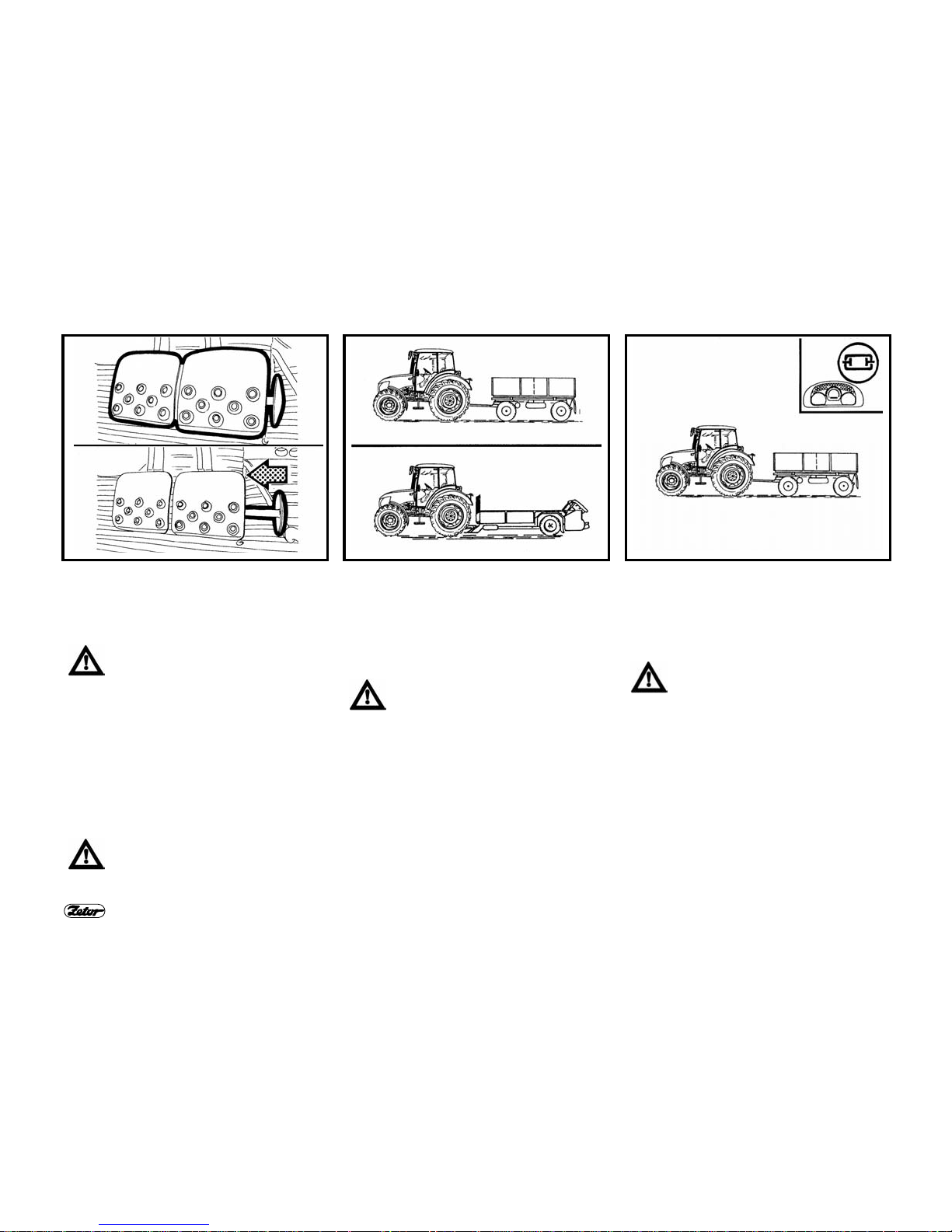

TIRES AND WHEELS

Check the inflation air pressures of front

and rear tires. Inflate them up to the

recommended pressures according to

operating conditions. Check, eventually

retighten bolts of front and rear wheels

(connections rim / disc and disc / wheel

shaft).

Never drive the tractor with

loosened wheel bolts!

AIR CLEANER

After signalling of the clogging indicator it

is necessary to perform maintenance of

the cleaner.

The indicator is accessible after

removing of the left-hand side part of the

tractor hood. It is situated near the

suction pipe elbow.

Clogging is mechanically indicated by

the red field that appears after clogging

of the filtration elements directly on the

clogging indicator.

A

cleaner is not clogged

B

cleaner is clogged, perform

maintenance

see chapter Maintenance

instructions

CAB FILTRATION

Check and eventually clean cab filters

located under the roof in front part.

Filter replacement interval depends upon

dustiness of working condition.

The partial regeneration of filters can be

done by shaking-out or blowing by the

pressurized air.

Cleaning or replacement of filter

elements can be performed after

removal of grills located in front of the

cab roof.

17

PREVENTIVE DAILY MAINTENANCE

E14 E15 E16

HITCHES

Check the hitches and attachments

including the trailer if they are in a good

condition.

AFTER USE OF FRONT IMPLEMENTS

After operation with front implements:

– Check connections of outer hydraulic

control circuit of the front three-point

hitch for leaks.

Clogging of coolers:

1. remove the side part of hood

2. loosen and move the air-conditioning

condenser to the left-hand tractor side

3. clean the front part of the engine

radiator (air-conditioning condenser)

by means of pressurized air (blow air

in direction from the engine)

4. remove the rest of impurities from the

space under the bonnet (to avoid their

repeated suction)

SHORT FUNCTIONAL TEST

Check if warning lights of hydrostatic

steering malfunction, engine lubrication

and battery charging have gone off after

starting the engine.

Check hydraulic steering circuits for a

correct function and leaks.

18

NOTES

19

NOTES

20

NOTES

21

ACQUAINTANCE WITH TRACTOR

Page

The tractor user must be properly

acquainted with recommended

operating and safety rules for the

safe tractor operation in advance.

It is too late to do it during operation!

Safety cab ...........................................................................................................................23

Door opening from outside.................................................................................................. 23

Door opening from inside....................................................................................................23

Rear window .......................................................................................................................24

Side window........................................................................................................................24

∗Tilting roof hatch................................................................................................................ 24

∗Passenger’s seat............................................................................................................... 25

Toolbox ...............................................................................................................................25

Opening for implementation purposes, rear right panel .....................................................25

Rear-view mirrors................................................................................................................ 25

Washer nozzle ....................................................................................................................26

Windshield washer tank ...................................................................................................... 26

Windshield washer control .................................................................................................. 26

Driver’s seat Mars Svratka..................................................................................................27

Adjustment related to driver’s weight.................................................................................. 27

Longitudinal adjustment......................................................................................................27

Vertical adjustment..............................................................................................................27

Driver´s seat GRAMMER MAXIMO ....................................................................................28

Driver´s seat GRAMMER S ................................................................................................28

Heating control panel, ∗air-conditioning, ∗radio.................................................................. 29

Heating valve control (A)..................................................................................................... 29

Fan control (B) ....................................................................................................................29

∗Air-conditioning switch (C) ................................................................................................29

Cab air circulation control (D)................................................................................................30

Correct function of heating and air-conditioning.....................................................................30

Quick cab interior heating .....................................................................................................30

C

oolin

g the cab interior quickly ........................................................................................... 31

Heating or air-conditioning operation during tractor operation ...........................................31

Immediately after the cab cooling ....................................................................................... 31

Heating and air-conditioning outlets,∗radio speakers......................................................... 32

Defrosting the windshield....................................................................................................32

Control panel on the right cab pillar .......................................................................................... 32

Tilting steering wheel ..........................................................................................................33

Angular adjustment ............................................................................................................. 33

22

ACQUAINTANCE WITH TRACTOR

Page

Height adjustment ............................................................................................................ 33

Dashboard........................................................................................................................ 35

Digital dashboard ............................................................................................................. 37

Switches ........................................................................................................................... 38

Rocker light switch (a)...................................................................................................... 39

Switch of grill and cab headlight (b)................................................................................. 39

Emergency flasher switch (e)........................................................................................... 39

Front wheel drive switch (f) .............................................................................................. 40

Rear differential lock (j) push-button ................................................................................ 40

Turn signals, low / high beam and horn toggle switch (k)................................................ 40

Ignition lock ...................................................................................................................... 41

Key in "0" position ............................................................................................................ 41

Key in "I" position .............................................................................................................41

Key in “II” position ............................................................................................................42

Hand fuel delivery throttle control lever............................................................................ 42

Engine stopping device .................................................................................................... 42

Pedals .............................................................................................................................. 43

Gearshift lever.................................................................................................................. 43

Shift schema..................................................................................................................... 43

Reversing gearshift lever ................................................................................................. 44

Gearshift lever of road and reduced speeds.................................................................... 44

Torque multiplier .............................................................................................................. 44

PTO shaft drive engagement ........................................................................................... 45

Rear PTO shaft gearshift lever 540 and 1000 rpm (or 540E).......................................... 45

Rear PTO shaft drive control lever................................................................................... 45

Hand brake lever and hitch lever for the one-axle trailer................................................. 46

Hydraulic system control panel........................................................................................ 46

A

ddit

ional hydraulic distributor control................................................................................. 46

Batteries cut-off switch ..................................................................................................... 46

Tractors with travelling speed of 40 km.h

-1

...................................................................... 47

Fuel tank........................................................................................................................... 47

Fuel tank drain plug.......................................................................................................... 47

Average fuel consumption in litres per operating hour for Zetor tractors..................................... 47

23

ACQUAINTANCE WITH TRACTOR

E101 E102 E103

SAFETY CAB

Generally use the left side of the

tractor to enter and to leave the

cab.

Use steps and handles to go on/

out of the cab.

Pay extreme care in the space of

the gearshift lever and hand

throttle control lever of the fuel

delivery.

DOOR OPENING FROM OUTSIDE

Cab doors can be locked from outside.

After unlocking depress the lock button

and pull the handle to open the door.

DOOR OPENING FROM INSIDE

1. Lever to open the door from inside

2. Lever to unlock the door from inside

The door is kept in fully opened position

with a gas strut.

It is not allowed to drive the tractor with the open door because of

its possible damage.

24

ACQUAINTANCE WITH TRACTOR

E104 E105 E106

REAR WINDOW

The rear window is equipped with handle

and is kept in the open position by gas

struts.

We recommend locking the window in closed position when driving on uneven terrain - danger of

window glass cracking. Before

starting work with machines implemented in the rear three-point

hitch, be sure that a collision between the hitched implement and

opened rear window at the maximum lift of the rear three-point

hitch is avoided. In case that collision could occur, we recommend

working with closed window.

SIDE WINDOW

A plastic latch locks the side window in

the half-opened position.

∗TILTING ROOF HATCH

The tilting roof hatch can be opened by

turning the arresting lever and by halfopening.

Tractor total height is increased

when the hatch is open. Therefore always close the hatch when

passing through low clear height

or when parking there.

25

ACQUAINTANCE WITH TRACTOR

E107 E108 E109

∗PASSENGER’S SEAT

The passenger’s seat (1) is tilting and is

situated on the left cab fender.

To make the driver’s seat better accessible, it is possible to tilt the passenger’s

seat upwards.

TOOLBOX

The toolbox (2) is situated on the left

side of the driver’s seat.

OPENING FOR IMPLEMENTATION

PURPOSES, REAR RIGHT PANEL

The bottom window is rigid and is

equipped with opening for connection of

attached implements controllers.

The storage compartment for the PET

bottle (2), socket 12V (3) and cigarette

lighter (4) is situated on the rear right

panel.

REAR-VIEW MIRRORS

Adjust rear-view mirrors before driving or

starting the work to be able to see the

entire road or the working field.

26

ACQUAINTANCE WITH TRACTOR

E110 E111 E112

WASHER NOZZLE

The washer nozzle is situated in the upper part of the hood and is adjustable by

needle or steel wire of maximum diameter 0,8 mm.

WINDSHIELD WASHER TANK

The washer tank is located on the cab

rear wall from outside.

The washer tank capacity is 2.5 litres.

Antifreeze mixture for washers must be

used in winter season to fill the washer

tank.

WINDSHIELD WASHER CONTROL

The windshield washer is put in operation after pressing the switch of front twospeed wiper, which is located on the

right cab pillar. The maximum time of uninterrupted operation of washer pump is

20 s.

27

ACQUAINTANCE WITH TRACTOR

E113 E114 E115

DRIVER’S SEAT MARS SVRATKA

ADJUSTMENT RELATED TO

DRIVER’S WEIGHT

The seat suspension may be adjusted to

the driver’s weight ranging from 50 up to

120 kg. Turn the square knob to do it.

The weight indicator is located in the recess of the rear seat cover. The spring

stroke is 120 mm.

Do not adjust the seat when driving!

Danger of accident!

LONGITUDINAL ADJUSTMENT

The seat can be adjusted longitudinally

within the range of ± 75 mm (11 positions) after unlocking by the left hand

side lever.

VERTICAL ADJUSTMENT

The vertical seat adjustment is done by

the right-hand side lever from the middle

position to two marginal positions within

the range of ± 30 mm.

28

ACQUAINTANCE WITH TRACTOR

E116

DRIVER´ S SEAT GRAMMER MAXIMO

1. Driver´s seat suspension control according to driver´s weight

2. Lever to adjust the seat longitudinally (situated on the right-hand side of the seat)

3. Seat turning control (the seat may be turned by 20° to both sides)

4. Seat vibrations absorption control (tilt it forwards to set the seat floating position)

5. Seat backrest inclination control

6. Seat backrest shape control

7. Height-adjustable backrest (push or pull it in the arrow direction to adjust it within

the range of 170 mm)

8. Tilting armrest

9. Armrest control (turn it to adjust the required armrest height)

DRIVER´ S SEAT GRAMMER S

Only positions 1, 2 and 5 are applicable.

29

ACQUAINTANCE WITH TRACTOR

E117 E118 E119

HEATING CONTROL PANEL, ∗AIRCONDITIONING, ∗RADIO

A - heating valve control

B - fan control

C - air-conditioning switch

D - control of air circulation in cab

E - space for additional radio installation

HEATING VALVE CONTROL (A)

a - heating valve shut

b - heating valve open

FAN CONTROL (B)

0. fan OFF

1. fan low speed

2. fan middle speed

3. fan maximum speed

∗AIR-CONDITIONING SWITCH (C)

Use the switch marked with symbol of

flake (C) to turn the air-conditioning on

and off.

Depress the switch to put the airconditioning into operation (symbol of

flake lights).

Depress the switch repeatedly to turn the

air-conditioning off (symbol of flake does

not light).

30

ACQUAINTANCE WITH TRACTOR

E120 E121 E122

CAB AIR CIRCULATION CONTROL (D)

a - surrounding (ambient) air is sucked

through filters into the cab - air suction

from the cab is closed.

b - air is sucked from the cab interior and

again drawn into the cab (inner air recirculation for the fast temperature

adaptation in cab)

In this position the air inlet from

outside of the cab is fully closed

and in the cab no overpressure,

which prevents penetration of

non-filtered air into the cab, is

created! Use this position of the

control for urgently necessary

time only!

CORRECT FUNCTION OF HEATING

AND AIR-CONDITIONING

It is necessary to create overpressure in

the cab for a proper function of heating

or air-conditioning. Therefore we recommend shutting all windows, doors and

cab roof cover.

QUICK CAB INTERIOR HEATING

Proceed as follows:

1. Turn the heating valve control (A) to

the right-hand position (heating

valve fully open).

2. Set the air circulation control in the

cab (D) to the position of inner recirculation.

3. Choose the desired fan speed (positions 1, 2, 3) by the fan switch (B).

4. Set outlets to desired angle to avoid

direct blowing to persons in the cab.

31

ACQUAINTANCE WITH TRACTOR

E123

COOLING THE CAB INTERIOR

QUICKLY

1. Move the heating valve control (A) to

the left-hand position.

2. Set the air circulation control in the

cab (D) to the position of inner recirculation.

3. Choose the desired fan speed (positions 1, 2, 3) by the fan switch (B).

4. Use the switch (C) to turn on the airconditioning.

5. Set outlets to desired angle to avoid

direct blowing to persons in the cab

(possible illness because of intensive

cooling of parts of persons bodies).

E124

HEATING OR AIR-CONDITIONING

OPERATION DURING TRACTOR

OPERATION

With the inner air recirculation switchedon, the inlet of fresh air is closed and it

comes to breathing-up of the cab space

by operators. This state can cause feelings of tiredness.

Note: When working, set the control (D)

according to your individual requirements

to temperature in a position between (a)

and (b) so that the fan could suck the air

from outside of the cab through filters.

E125

IMMEDIATELY AFTER THE CAB

COOLING

Immediately after cooling the cab and

reduction of the inner temperature to desired level we recommend:

− Switch over the air circulation control

(D) from position (b - air recirculation)

to position (a - outer air suction).

− Perform fluent regulation of air temperature with switched-on airconditioning by means of half-opening

of the heating valve (A). During this

setting, air flowing into the cab from

vents is not dried so intensively.

− You can perform fluent regulation of air

temperature with switched-on airconditioning by decreasing the fan

output so that you switch over the control (B) to position 1 or 2.

32

ACQUAINTANCE WITH TRACTOR

E126 E127

HEATING AND AIR-CONDITIONING OUTLETS,∗RADIO SPEAKERS

A - Adjustable outlets of heating (2) and ∗air-conditioning (1).

Radio speakers are installed only in case of preparation for ∗radio installation.

DEFROSTING THE WINDSHIELD

B - To assure a quick windshield defrosting, direct the middle outlets of heating (3)

under angle of about 45° towards the windshield. Direct the side outlets (4) under

angle of about 45° towards cab corners.

After defrosting the windshield, direct the side outlets towards side door windows

and defrost them one after another. After defrosting, direct the outlets so that the

air is not directed towards the driver directly but down to driver’s legs.

CONTROL PANEL ON THE RIGHT CAB

PILLAR

1. switch of the rear PTO shaft

2. switch of the front PTO shaft

3. cab illumination

4. windshield wiper & washer two-

position change-over control switch

5. rear window wiper switch

6. ∗rear-view mirrors heating switch

7. ∗rear window heating switch

33

ACQUAINTANCE WITH TRACTOR

E128 E129 E130

TILTING STEERING WHEEL

The tilting steering column allows to

change angular and height adjustment of

the steering wheel. Both functions are

operated by one lever.

ANGULAR ADJUSTMENT

The angular adjustment offers 10 positions per 4° within the range from -16° up

to +24° down. To adjust the steering

wheel inclination, first move the lever in

the arrow direction to unlock the steering

wheel.

HEIGHT ADJUSTMENT

The steering wheel is adjustable within

the range of 0 – 80 mm under any angle

position. To adjust the steering wheel

height, first move the lever in the arrow

direction to unlock the steering wheel.

34

ACQUAINTANCE WITH TRACTOR

E131

35

ACQUAINTANCE WITH TRACTOR

DASHBOARD

DESCRIPTION OF INSTRUMENTS

A - indicator lights

B - air pressure gauge

C - tachometer with mechanical hour-

counter

D - fuel gauge

E - coolant thermometer

INDICATOR LIGHTS

1. high beam (blue). It lights with high

beam lights “ON”.

2. turn signal indicator light (green) –

tractor.

3. turn signal indicator light - 1

st

trailer

(green).

4. turn signal indicator light – 2nd trailer

(green).

5. indicator light of the minimum air pressure in braking system (red). It lights if

the air pressure of air trailer brakes

drops below its critical value, i.e. 450

kPa.

6. parking brake (red). It lights with the

hand brake lever fully pulled up.

7. charging warning light (red). With the

engine running, it lights to indicate the

charging malfunction. With the engine

at standstill, the indicator light must be

“on“.

8. oil pressure warning light (red). It

lights if the engine oil pressure drops

below 120 to 60 kPa with the engine

running. When the engine at standstill, this light must be “on“.

9. open.

10. emergency flasher warning light

(red).

11. open.

12. torque multiplier indicator light “on”

(green).

13. open.

14. hydrostatic steering system malfunction warning light (red).

15. fuel (orange) - it lights if 1/6 to 1/10 of

the fuel tank capacity remains in the

fuel tank.

16. clutch PTO shaft disengagement in-

dicator light (red).

17. open.

18. glow-plug indicator light (yellow) - it

indicates operation of the engine cold

start unit.

19. open.

20. open.

21. warning light (red) - it lights if the air

pressure drops below its critical

value, i.e. 450 kPa or if the hand

brake lever is set.

22. symbols indicating the engine speed,

at which the rear PTO shaft nominal

speed is achieved when related to

the rear PTO shaft engaged speed.

36

ACQUAINTANCE WITH TRACTOR

E132

37

ACQUAINTANCE WITH TRACTOR

DIGITAL DASHBOARD

The digital dashboard is installed on

customer’s wish.

DESCRIPTION OF INSTRUMENTS

A – indicator lights

B – air pressure gauge

C - tachometer

D – fuel gauge

E – coolant thermometer

F - display

INDICATOR LIGHTS & PUSHBUTTONS

The layout of indicator lights on the

digital dashboard is identical to that

on the analogous dashboard.

When you press the required button,

the corresponding symbol and data

appear on the display.

23. push-button of engine hours

worked out - the data is displayed.

24. accumulator battery voltage voltage in volts appears on the

display (with accuracy of 0.1 V).

25. button to show a number of kilometres covered (in a day or from

the last reset). Number of km is

displayed. Hold the button depressed for a while to reset it.

26. button to show the instantaneous

travelling speed in km.h

-1

, which

is indicated on the display.

27. button of the PTO shaft 1,000

rpm. Number of revolutions with

accuracy of 10 rpm is shown on

the display.

28. button of the PTO shaft 540 rpm.

Number of revolutions with accuracy of 10 rpm is shown on the

display.

38

ACQUAINTANCE WITH TRACTOR

E133

SWITCHES

a - low / high beam switch

b - front grill light and roof light (low

beam) change-over switch

c - fog light switch (OFF - ON). Function

of fog light is indicated by illuminated

symbol in the switch

d - working headlamp switch (OFF -

ON). Function of working headlamp

is indicated by illuminated symbol in

the switch

e - emergency flasher switch

f - front wheel drive control switch. The

engaged front wheel drive is indi-

cated by illuminated symbol in the

switch

g - not used (plugged)

h - not used (plugged)

i - not used (plugged)

j - differential lock (locks) button

k - engine shut-off (stopping device)

l - toggle switch - turn signals, high /

low beam and horn

39

ACQUAINTANCE WITH TRACTOR

E134 E135 E136

ROCKER LIGHT SWITCH (a)

a - lights “OFF“

b - ON - side marker lights and tail

lights, license plate light, illumination

of instruments

c - ON - all electrical appliances as in

the “b“ position. In addition, low and

high beam lights are ”ON” (according to position of the toggle switch

for turn signals, low / high beam and

horn)

SWITCH OF GRILL AND CAB

HEADLIGHT (b)

a - cab roof headlights “OFF”

b - cab roof headlights “ON”

The switch controls the headlights in the

mask grill or in the tractor cab roof. Use

the cab roof headlights only if the front

grill headlights are covered by attached

implement fitted in the front three-point

hitch. Symbol in the switch indicates that

cab roof headlights are “ON”.

The high beam can light in the hood grill

only.

EMERGENCY FLASHER SWITCH (e)

a - emergency flasher “OFF“

b - emergency flasher “ON“

The indicator light on the dashboard

flashes to indicate a function of the

emergency flasher.

40

ACQUAINTANCE WITH TRACTOR

E137 E138 E139

FRONT WHEEL DRIVE SWITCH (f)

Use the front axle drive to increase the tractor pulling force

when rear wheels are slipping.

a - front axle drive disengaged

b - front axle drive engaged

With a tractor at standstill (parking brake

is set, engine is stopped, ignition is off),

the front axle drive is engaged.

In the basic position, the front axle drive

is engaged (the indicator light is “ON”) use the switch to disengage it (indicator

light is “OFF”).

REAR DIFFERENTIAL LOCK (j) PUSHBUTTON

a - differential lock disengaged

b - differential lock engaged

The differential lock is engaged by pressing the differential lock push button that

returns into the initial position after releasing.

Illuminating of the symbol in the switch

indicates that the differential lock is engaged.

The differential lock is disengaged automatically after depressing the brake pedals.

TURN SIGNALS, LOW / HIGH BEAM

AND HORN TOGGLE SWITCH (k)

a - acoustic horn – push the toggle

switch in the axis direction

b - low beam

c - turn signal - right

d - turn signal - left

e - headlight flasher

f - high beam

41

ACQUAINTANCE WITH TRACTOR

E140

E141 E142

IGNITION LOCK

The ignition lock is situated on the front

side of the steering wheel support panel

under the dashboard.

KEY IN "0" POSITION

All electrical appliances controlled by the

key switch are disconnected. The key

can be removed.

KEY IN "I" POSITION

All electrical appliances controlled by the

key switch are connected except for

starter motor. The key is located in this

position with the engine running.

42

ACQUAINTANCE WITH TRACTOR

E143 E144 E145

KEY IN “II” POSITION

In this position the starter motor and all

electrical appliances except for wipers,

washer, cab fan and air-conditioning are

connected. After starting the engine, the

key returns automatically to “I“ position.

HAND FUEL DELIVERY THROTTLE

CONTROL LEVER

A - maximum fuel delivery

B - idle run

ENGINE STOPPING DEVICE

Pull out the stopping device control to

stop the engine immediately and turn it in

the pulled-out position to lock it.

Move the controller back in the initial position after stopping the engine.

If the controller remains being

„pulled out“, the engine cannot be

started.

43

ACQUAINTANCE WITH TRACTOR

E146 E147 E148

PEDALS

1. travel clutch pedal

2. foot-operated service brake pedals

connected by latch

3. foot-operated fuel delivery throttle

control pedal

GEARSHIFT LEVER

- main gear-shift lever

SHIFT SCHEMA

The reverse gears can be engaged by

means of the reversing lever only.

44

ACQUAINTANCE WITH TRACTOR

E149 E150 E151

REVERSING GEARSHIFT LEVER

F – forward run; lever forwards

N – neutral

R – reverse run; lever backwards

In combination with gear reduction and

torque multiplier, 16 forwards gears and

16 reverse gears are possible in total.

GEARSHIFT LEVER OF ROAD AND

REDUCED SPEEDS

R

road gears

N

neutral

S

reduced gears

Shifting is made with tractor at standstill.

TORQUE MULTIPLIER

The torque multiplier is controlled electro-pneumatically by means of buttons

situated on the gearshift lever.

The indicator light on the dashboard indicates the multiplier function.

45

ACQUAINTANCE WITH TRACTOR

E152 E153 E154

PTO SHAFT DRIVE ENGAGEMENT

The switches on the right cab pillar are

used to engage it.

The tractor standard model is equipped

with the 6-spline end of the rear PTO

shaft.

REAR PTO SHAFT GEARSHIFT

LEVER 540 AND 1000 RPM (OR 540E)

a -

1000 rpm (or 540E)

n -

neutral

b -

540 rpm

Shifting is made with tractor at standstill.

∗Tractor can be equipped with six-,

eight- or twenty-one-spline shaft end.

Speed shifting of either 540 or

1000 rpm is possible regardless

to assembled shaft end. The PTO

shaft speed and shaft end type

must be chosen depending on

the prescribed speed of the implemented machine.

REAR PTO SHAFT DRIVE CONTROL

LEVER

a -

independent speed of the PTO

shaft drive

- speed depends on the engine

speed

n -

neutral

b -

dependent speed of the transmission PTO shaft

- speed depends on the gear

shifted

Shifting is made with tractor at standstill.

46

ACQUAINTANCE WITH TRACTOR

E155 E156 E157

HAND BRAKE LEVER AND HITCH

LEVER FOR THE ONE-AXLE TRAILER

1. hand brake lever

2. hitch control lever for one-axle trailer

HYDRAULIC SYSTEM CONTROL

PANEL

The hydraulic system control panel (1) is

situated in the space of the right-hand

fender.

ADDITIONAL HYDRAULIC

DISTRIBUTOR CONTROL

The additional hydraulic distributor control

(2) is situated on the upper part of the

right-hand fender.

BATTERIES CUT-OFF SWITCH

During a long-term shutdown, repairs, failure or crash remember

to disconnect the battery by

means of the battery cut-off

switch immediately.

The battery cut-off switch is located on

the left-hand tractor side in front of the

cab.

a - battery connected

b - battery disconnected

47

ACQUAINTANCE WITH TRACTOR

E158 E159 E160

TRACTORS WITH TRAVELLING

SPEED OF 40 KM.H

-1

All tractor models with front driving axle,

which have brakes installed in front

wheels gear reductions, may reach the

travelling speed of 40 km.h

-1

.

FUEL TANK

The fuel tank is fitted on the right-hand

tractor side. The plastic fuel tank with

capacity of 120 litres is assembled as

standard for all tractor types.

Do not step on the fuel tank!

FUEL TANK DRAIN PLUG

The hole to drain impurities is located at

the bottom of fuel tank.

AVERAGE FUEL CONSUMPTION IN

LITRES PER OPERATING HOUR FOR

ZETOR TRACTORS

Tractor type Engine load

100% 80% 50%

Z 8541 18.42 14.44 9.21

Z 9541 20.34 16.27 10.17

Z 10541 22.63 18.11 11.32

48

NOTES

49

NOTES

50

NOTES

51

TRACTOR OPERATION

Be familiar with shifting pattern

and test all positions of shifting

lever with the stopped engine

before driving a new tractor.

Before driving under normal

operation, first make sure that the

operating condition of the tractor

corresponds to regulations of the

safe traffic operation.

Page

Before engine starting............................................................................................... 52

Engine starting..........................................................................................................52

If the engine does not start........................................................................................53

Signalling of glowing system failures.........................................................................53

Starter motor handling...............................................................................................53

Immediately after start...............................................................................................54

Engine preheating..................................................................................................... 54

∗Coolant heater......................................................................................................... 55

Starting the engine using the coolant heater.............................................................55

Gear-shifting..............................................................................................................56

Reversing shift lever..................................................................................................56

Road and reduced gear shifting................................................................................56

Shifting from lower to higher gear speeds.................................................................57

Shifting from higher to lower gear speeds.................................................................57

Torque multiplier .......................................................................................................58

Multiplier function indication......................................................................................58

Setting in motion .......................................................................................................59

Driving uphill

..............................................................................................................60

Driving downhill.........................................................................................................

60

Differential lock..........................................................................................................61

Front driving axle control...........................................................................................61

Driving with the front driving axle engaged ...............................................................61

Service brakes ..........................................................................................................62

Air brakes of trailers and semi-trailers.......................................................................62

Air pressure drop warning light..................................................................................62

Single and double-hose brakes.................................................................................63

Single-hose brakes ...................................................................................................63

Double-hose brakes.................................................................................................. 63

Hydraulic trailer brakes .............................................................................................64

Connecting and disconnecting the trailer hydrau lic brake q uick couplings...........................64

Stopping the tractor - parking brake..........................................................................65

Stopping the engine..................................................................................................65

Leaving the tractor ....................................................................................................65

Hydrostatic steering malfunction warning light.......................................................... 66

Important notification.................................................................................................66

52

TRACTOR OPERATION

E201

E202

E203

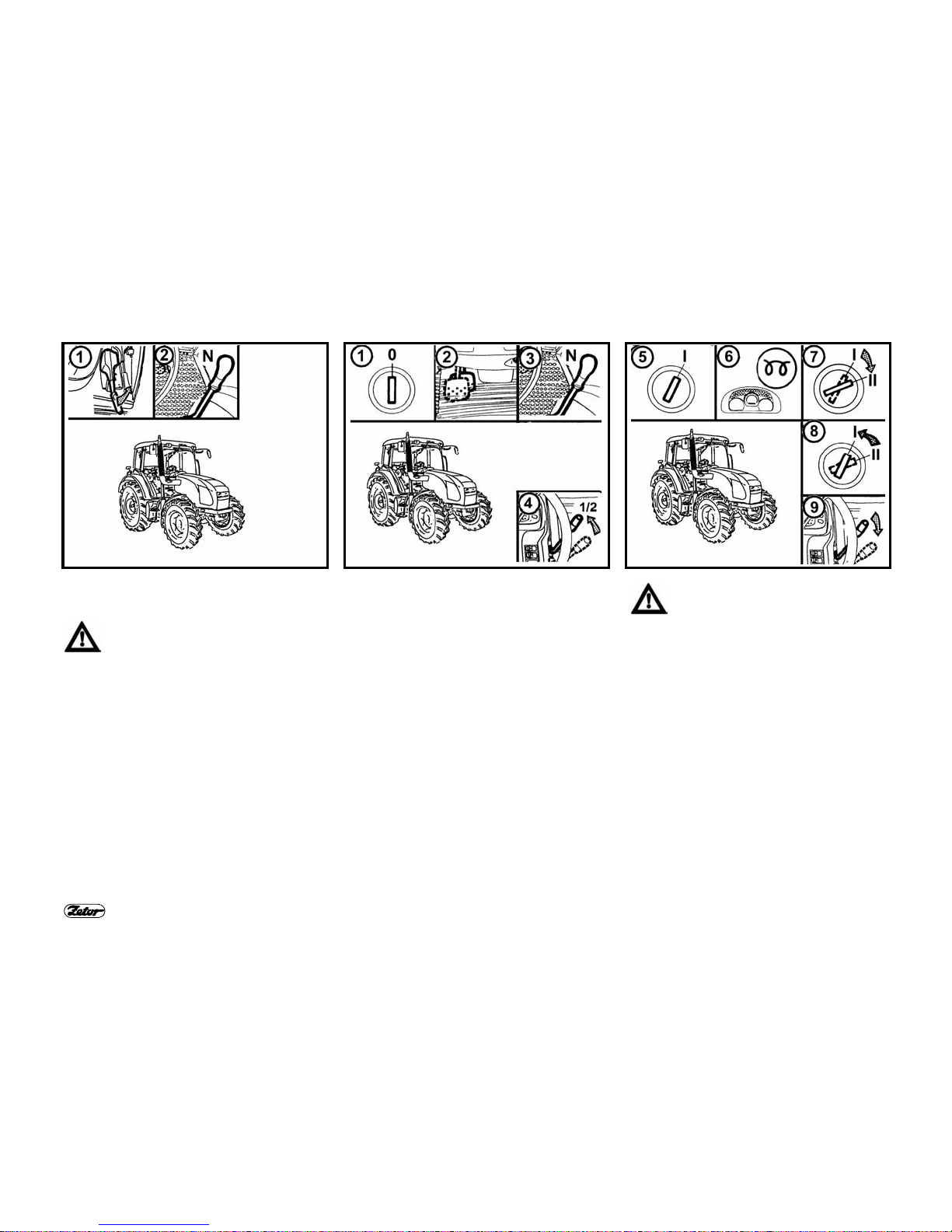

BEFORE ENGINE STARTING

Before starting the engine be sure that:

1. tractor is braked properly

2. main gearshift lever is in neu-

tral position.

If the clutch pedal is not depressed, the tractor cannot be

started - the start safety switch is

not actuated.

Note: Before starting proper we recommend to prime the fuel system by several

strokes of hand fuel delivery pump.

ENGINE STARTING

1. Insert the key into the ignition lock

("0" position).

2. Depress the clutch pedal.

3. Move the main gearshift lever into

neutral position.

4. Set throttle to increased fuel delivery

(approx. 1/2 of maximum delivery).

5. Turn the key from “0” position to "I"

position. The glow-plug indicator light

comes on.

6. Wait until the indicator light goes out

(the time depends on the coolant

temperature).

In case that the indicator light

flashes only instead of lighting,

the glowing system failed (see

Chapter Signalling of glowing

system failures). Have the indicated failure corrected at the

authorized service centre.

7. Immediately after the indicator light

has gone out (max. within 5 s), turn

the key from position "I" into position

"II" (start).

8. Release the key immediately after

starting the engine, it returns automatically into ”I” position. Do not op-

erate the starter for more than 15 s.

9. After starting the engine, gradually

reduce the fuel delivery.

53

TRACTOR OPERATION

E204 E205 E206

IF THE ENGINE DOES NOT START

Turn the key into position "0", wait 30

seconds and repeat the start.

Maximum 6 starting cycles are allowed

(15 seconds starting and 30 second

interruption make one cycle). Further

engine starting attempt is allowed after

cooling down of starter motor to the

ambient temperature.

Never help the stopping engine

by the starter motor. It may be

suffer damage this way.

SIGNALLING OF GLOWING SYSTEM

FAILURES

Flashing of the glowing indicator light

indicates failure in the glowing system.

- If the glo wing indicator light is flashing

once in a second with the stopped engine, glowing will take place in emergency regime as at low temperature

regardless to coolant temperature.

- If the glo wing indicator light is flashing

twice in a second with the stopped engine, the glowing is put of operation.

- If the glo wing indicator light is flashing

permanently with the engine running,

failure of the glowing regulator occurred and glowing was not finished. It

is necessary to correct the failure immediately, because there is danger of

battery discharging.

STARTER MOTOR HANDLING

It is forbidden to start the tractor by short circuit of starter

motor connectors!

Start the tractor from the

driver’s seat only!

When handling or repairing the

starter motor, remember to disconnect the negative battery

terminal and move all gearshift

levers into neutral position, including PTO shaft engagement!

Starter motor connectors are

covered with caps.

54

TRACTOR OPERATION

E207

E208

IMMEDIATELY AFTER START

After starting set the engine

speed to 800 - 1,000 rpm and let

the engine run at idle for about 2

minutes without load.

In the meantime check lubrication,

charging (indicator lights must go out)

and other functions assuring a correct

engine operation. Be sure to keep the

time of engine idle run without any load,

especially in winter season.

ENGINE PREHEATING

Continue to preheat the engine already while driving. W arming up the engine

by long idle run time or fast increase of speed is dangerous for the engine.

Do not exceed the engine speed of 2,000 rpm until the coolant te mperature

reaches 45 °C.

55

TRACTOR OPERATION

E209 E210

∗COOLANT HEATER

The coolant heater is installed on the

right-hand side of the engine block.

Output 1,000 W

Voltage 220 V

STARTING THE ENGINE USING THE COOLANT HEATER

The heater allows starting the engine at low ambient temperatur e by preheating the

coolant. The electrical system and its protection against ele ctrical shock hazard must

be done according to valid regulations.

1. Plug the heater first.

2. Plug the cable with connected heater to 220 V mains after.

With regard to reduction of engine wear when starting at low t emperatures, the producer recommends to use the heater. The preh eating time depends upon the ambient temperature (1 to 2 hours before supposed starting are sufficient).

Having finished the heating, unplug the mains first and the heater only after!

Electrical shock hazard!

It is necessary to ensure instruction of tractor operators and regular

revisions of the coolant heater including the inlet cabl e in accordance

with valid standards of the country, in which the tractor is operated,

minimum before each winter season.

56

TRACTOR OPERATION

E211 E212 E213

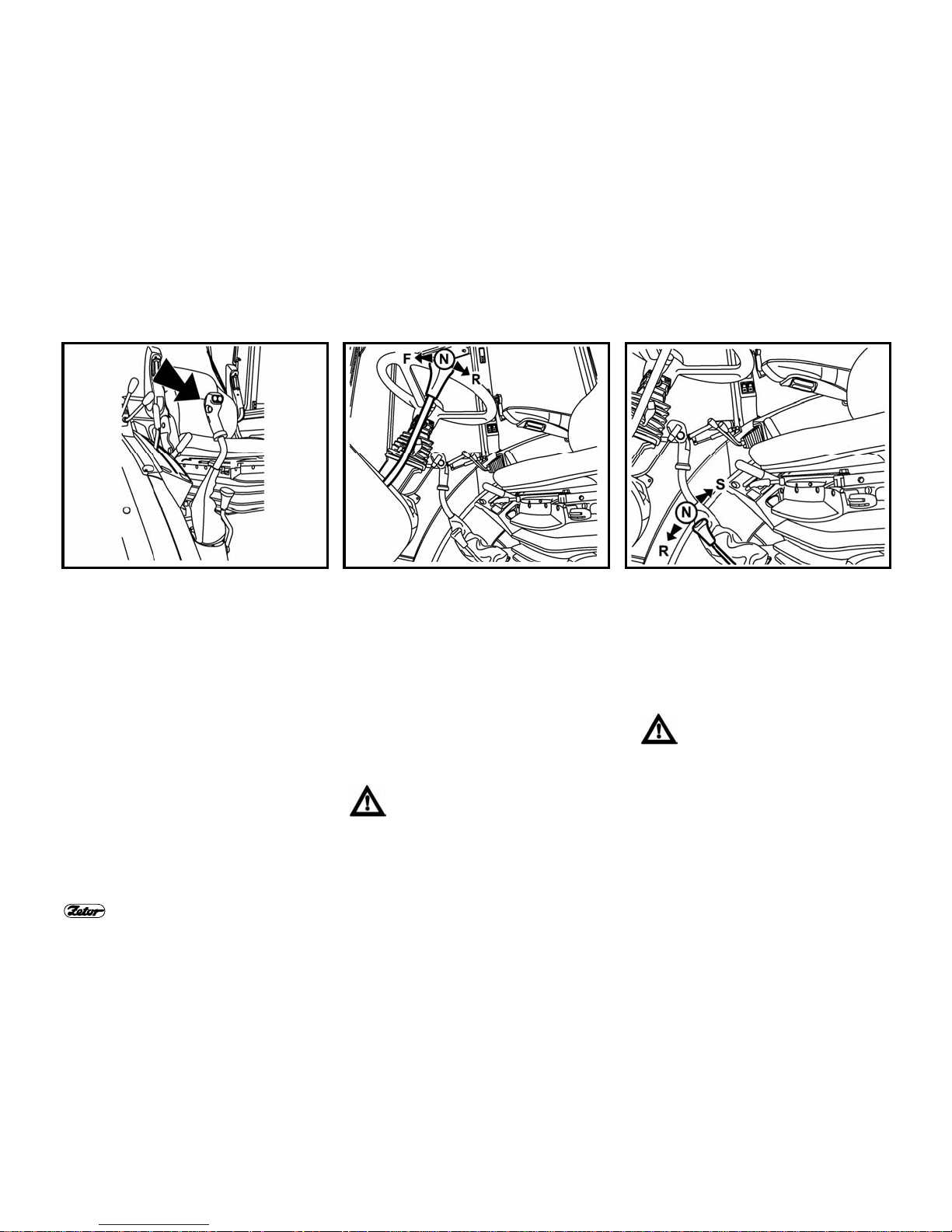

GEAR-SHIFTING

Tractors are equipped with the fourspeed synchronized gearbox, torque

multiplier, reversing unit and two-speed

reduction gear.

The main gearshift lever with buttons to

control the torque multiplier is used to

shift to gears in the four-speed gearbox.

The reversing lever is used to engage

forward and rearward tractor gears.

REVERSING SHIFT LEVER

Use the reversing shift lever to select the

tractor driving direction (forward or reverse).

F - forward drive (16 gears)

N - neutral

R - reverse run (16 gears)

The reversing gearbox has 16 reverse

gears, which are approximately so fast

as forward gears. Therefore consider it

well, which gear for the work you will

select.

Shift to the reversing gear with

the clutch pedal depressed at

tractor standstill.

ROAD AND REDUCED GEAR SHIFTING

S - road gear speeds

N - neutral

R - reduced gear speeds

The gear shifting of reduced gears of the

main gearbox is identical to gear shifting

of normal road gears.

The gearshift lever of road and

reduced gears may be shifted

with tractor at standstill only.

57

TRACTOR OPERATION

E214

SHIFTING FROM LOWER TO HIGHER

GEAR SPEEDS

Depress the clutch pedal (clutch disengaged). In the same time release the

throttle pedal and shift into proper higher

gear speed. Fluently release the clutch

pedal (the clutch starts engaging) and

simultaneously increase the engine

speed.

Note: To increase the service life of

synchronizers, it is possible to apply the

so-called double-declutching when shifting from lower to higher gears.

E215

SHIFTING FROM HIGHER TO LOWER

GEAR SPEEDS

Depress the clutch pedal and move the

gearshift lever through neutral position to

lower gear speed.

Note: To increase the service life of

synchronizers, it is possible to apply the

so-called “neutral acceleration” when

shifting from higher to lower gears.

58

TRACTOR OPERATION

E216 E217

TORQUE MULTIPLIER

The two-stage torque multiplier is standard for all tractor models.

Two buttons on the main gearshift lever

handle are used to shift to individual

gears of the two-speed multiplier.

Push the respective button without depressing the clutch pedal to shift. The

shifting of individual speeds is automatic

even on tractor under load.

Shifting of torque multiplier speeds:

H -

travelling speed increase

L -

travelling speed decrease

Note: When starting or stopping the

engine, always the “H” gear is shifted.

MULTIPLIER FUNCTION INDICATION

The indicator light on the dashboard

indicates the torque multiplier function

(operation velocity reduction).

59

TRACTOR OPERATION

E218

SETTING IN MOTION

1. Depress the clutch pedal.

2. Move the main gearshift lever into neutral.

3. Start the engine.

4. Set the engine speed to 750 up to 800 rpm.

5. Select road or reduced gear.

6. Move the reversing lever into the desired direction of tractor movement (forward

or reverse).

7. Shift into proper gear speed suitable for setting in motion.

8. Slightly increase the engine speed.

9. Prepare the parking brake for releasing.

10. Release the clutch ped al up to the point where the tractor starts to move and

simultaneously with the engine speed increasing, contin ue to release the clutch

pedal smoothly.

11. Fully release the parking brake.

12. Start smoothly and slowly.

Very fast start can cause overload of the drive train, increased

fuel consumption, excessive tire

wear and damage to transported

load. Shift to 1

st

gear to start the

tractor only when driving while

hauling a heavy trailer uphill and

in heavy terrain.

60

TRACTOR OPERATION

E219 E220

DRIVING UPHILL

Shift from higher to lower speed

in time when going uphill, to

avoid engine speed dropping

below 800 rpm and do not admit

driving leading to engine stopping

in consequence of overloading.

DRIVING DOWNHILL

Driving downhill without shifted

gear is forbidden. If driving down

a longer hill, shift to such lower

gear the sharper one the hill is. If

possible, shift to the lower speed

gear still before driving downhill.

Note: Remember that the gear you use

reliably for driving uphill is safe enough

to drive downhill.

61

TRACTOR OPERATION

E221 E222 E223

DIFFERENTIAL LOCK

Push the switch to engage the lock; the

switch will return in the initial position

after releasing.

Engagement of the differential lock is

indicated by the lighting symbol in the

switch.

When depressing the brake pedals, the

differential lock will disengage automatically.

Do not use the differential lock

when driving in a curve.

FRONT DRIVING AXLE CONTROL

In the basic position, the front driving

axle is engaged.

Engagement of the front driving axle is

signalled by the lighting symbol in the

switch.

Disengagement is made with the switch

that is situated on the dashboard.

a - Front drivin g axle disengaged

b - Front drivin g axle engaged

With the stopped tractor (braked tractor,

stopped engine, ignition key in “0” position), the front driving axle is engaged.

At sudden air pressure drop in

the tractor air pressure system,

the front driving axle is automatically engaged.

DRIVING WITH THE FRONT DRIVING

AXLE ENGAGED

Use the front driving axle when rear

wheels are slipping to increase the

tractor traction force. On the road a nd

on hard ground the driving with the front driving

axle engaged is permissible within maximum

speed of 15 km/h (the driving with the front

driving axle engaged on the road and on hard

ground causes excessive wear of front tires).

Permanent engagement of front driving

axle is permitted if the agriculture machine or implement is attached to front of

the tractor. This condition is specified in

Operator’s Manual of each particular

machine. Maximum permitted speed of

the tractor combination is 15 km/h in that

case.

62

TRACTOR OPERATION

E224 E225 E226

SERVICE BRAKES

Foot brakes are of disc, wet, hydraulically actuated, double pedal type with

automatic pressure compensator.

Both brake pedals must be

latched together on the move.

Use unlatched pedals to brake

the right or left wheel separately

when working in terrain and field

at low travelling speed only.

Note: When driving downhill in sharp descent with a trailer or semi-trailer being

equipped with air or hydraulic brakes, it is

necessary to apply the service brake already from the beginning of the downhill

drive!

When braking with one brake

pedal, the trailer brakes are not

actuated!

AIR BRAKES OF T RAILERS AND SEMI-TRAILERS

Control of air brakes of trailers (semitrailers) is performed in such manner that

the brake effect of both vehicles is synchronized.

When driving with the hitched

trailer or semi-trailer, the service

brake pedals must be connected

together and secured with latch!

When braking with one brake

pedal, the trailer air brakes do

not operate.

Note: At pressure drop, the relief valve

puts secondary appliances (differential

lock, disengagement of front driving axle)

out of operation.

AIR PRESSURE DROP WARNING

LIGHT

The red indicator light located on the

dashboard indicates the air pressure

drop below the critical value of 450 kPa.

Tractor with a braked trailer or

semi-trailer must not continue to

drive when the air pressure drops

below the critical value of 450

kPa in the air system, until the air

pressure increases.

63

TRACTOR OPERATION

E227 E228 E229

SINGLE AND DOUBLE-HOSE

BRAKES

1. coupling head of single-hose air brak e

system.

2. coupling heads of double-hose air

brake system.

After disconnecting or without

any hitched trailer or semi-trailer,

it is necessary to cover the couplings with caps.

SINGLE-HOSE BRAKES

The operating pressure has been set

with the control valve to 600 ± 20 kPa.

The permitted speed of the tractor combination with a hitched

trailer (or semi-trailer) loaded to

maximum weight, as approved

for the stated tractor model, is 30

km/h!

The maximum permitted speed of

the vehicle combination is stated

as the maximum permitted speed

of the slower vehicle of this com

bination.

DOUBLE-HOSE BRAKES

The operating pressure has been set to

740 ± 20 kPa. The left coupling cap head

is marked with yellow colour (braking

branch); the right coupling cap head is

marked with red colour (filling branch).

The permitted speed of the tractor

combination with a hitched trailer

(or semi-trailer) loaded to maximum weight, as approved for the

stated tractor model, is 40 km/h!

The maximum permitted speed of

the vehicle combination is stated

as the maximum permitted speed

of the slower vehicle of this combination.

64

TRACTOR OPERATION

E230 E231

HYDRAULIC TRAILER BRAKES

The control of hydraulic trailer (semi-trailer) brake an d the tractor brake is performed

so that their braking effect is synchronized. The oil pressure is created by the oil,

which is drawn from the gear-type disengaging hydr aulic pump (1). The brake valve

(2) is installed behind the pump into the circuit.

The brake fluid pressure from master brake cylinders controls the trailer brake valve

in dependence on the force acting on the brake pedal. Pressure in the br ake cou pling

(3) must be 12 - 15 MPa at maximum depression of the brake pedal. The trailer brake

valve prefers the brake system function to the hydraulic system function. When

bleeding the tractor brakes, do not forget to bleed also the brake valve. In case that

during depression of service brake pedals shocks occur in the piping of the hydraulic

circuit, it is necessary to de-aerate the hose (4) leading fr om the brake valve (2) to

the quick coupling (3).

Brake pedals must be connected and secured with latch when driving the

tractor with attached trailer or semi-trailer!

When braking with one brake pedal, the hydraulic trailer brakes are n ot functioning.

CONNECTING AND DISCONNECTING

THE TRAILER HYDRAULIC BRAKE

QUICK COUPLINGS

When connecting and disconnecting the quick couplings, pay

particular attention to the residual

oil, which remains in a socket or

plug of the quick coupling.

For environmental protection

reasons, it is necessary to wipe

the residual oil after each disconnection of quick coupling

using a piece of cloth.

65

TRACTOR OPERATION

E232 E233 E234

STOPPING THE TRACTOR - PARKING

BRAKE

Proceed smoothly under normal conditions. Remember to do shortly before

stopping:

1. Depress the clutch pedal and apply

the service brake.

2. Move the main gearshift lever into

neutral.

3. Set the parking brake to secure the

tractor against accidental movement

always when stopping the tractor. The

indicator light on the dashboard indicates the parking brake setting.

STOPPING THE ENGINE

Let the tractor engine cool down after a

full load operation.

1. Reduce the engine speed to 800 1,000 rpm before stopping the engine

and let it run at idle for about 5 minutes.

2. Move the hand throttle control lever of

the fuel delivery into MIN position.

3. Pull up the controller of the engine

stopping device and turn it in the

pulled position. After the engine stops

push the controller back

4. After stopping the engine it is possible

to turn the ignition key from “I” position into “0“ position (with the engine

at standstill only - the charging warning light must come on).

LEAVING THE TRACTOR

Be sure to remove the key from the ignition lock in “0” position before leaving the

tractor safety cab (the key cannot be

removed when in “I” or “II” position).

The tractor must be secured

against spontaneous setting in

motion as follows:

1. shut the engine off

2. shift to 1

st

gear

3. set the parking brake

In addition, when the tractor stands on a

hill, be sure to underlay the wheels with

chocks.

Lock the cab.

Note: With the stopped engine the front

driving axle is automatically engaged.

66

TRACTOR OPERATION

E235 E236

HYDROSTATIC STEERING MALFUNCTION WARNING LIGHT

When the oil pressure drops below 120

kPa behind the pump, it means a malfunction of hydrostatic steering pump,

which is indicated by lighting of the corresponding symbol on the dashboard.

Note: The warning light can flash during

the engine start or at low engine speed;

if it goes out after starting the engine or

after engine speed increase, there is no

malfunction. The system is OK.

IMPORTANT NOTIFICATION

In case that the oil pressure / charging /

hydrostatic steering malfunction warning

light comes on during the tractor operation, shut the engine off immediately and

have the malfunction located and corrected at the authorized service centre.

In such a manner you prevent a serious

defect or tractor accident.

67

NOTES

68

NOTES

69

TRACTOR RUNNING-IN

Page

General rules for running in a new tractor during the first 100 operating hours.........70

In the course of the first 10 operating hours..............................................................70

After 70 operating hours............................................................................................ 71

More than 100 operating hours.................................................................................72

70

TRACTOR RUNNING-IN

E251 E252