ZETOR

This present operation manual provides information with operation and maintenance of your new tractor the

PROXIMA PLUS.

Despite the fact that many of you have rich experience with operation of other types of tractors, please read this

manual carefully to acquaint yourself with its contents as thoroughly as possible.

In the manual, you can find a lot of information how to utilise the best your tractor with various types of work.

When following the given principles of operation and maintenance of the tractor and safety of driving, your tractor

will become your reliable partner for many years.

The manufacture of your tractor wishes you thousands hours of satisfying work.

ZETOR

Brno

1

Information on the technical data, construction, equipment, material and appearance is valid at the time of printing. The manufacturer reserves the right of changes.

2

The operation manual includes description, operation and maintenance of standard accessories of the tractor. The accessory that is not installed by the manufacturer (manufacturing plant) as standard is not covered by the warranty. The

service cheque book for tractors is not

included in the operation manual; it is a

separate brochure that is delivered to

you with purchase of a new tractor.

CONTENTS

Page

Location of serial numbers..........................................................................................5

Safety instructions for the user.................................................................................... 7

Preventive daily maintenance ...................................................................................21

Getting to know the tractor........................................................................................27

Driving.......................................................................................................................61

Running-in the tractor................................................................................................81

Transport use............................................................................................................85

Drive of farming machines.........................................................................................93

Hydraulic system.....................................................................................................101

Mechanical hydraulics.............................................................................................107

Electro-hydraulic system......................................................................................... 121

Hitches....................................................................................................................139

Change of wheels tread..........................................................................................147

Additional weights...................................................................................................153

Electric installation ..................................................................................................159

Tractor maintenance ............................................................................................... 169

Maintenance instructions ........................................................................................189

Adjustments ............................................................................................................211

Essential technical parameters ............................................................................... 223

Index.......................................................................................................................245

3

TRACTORS PROXIMA PLUS

TRACTORS WITH FRONT DRIVING AXLE (4 x 4):

Type of

the tractor

Z90 60 64,3

Z100 66 70,4

Z110 74 78,4

Engine power

(kW)

EC 24 2000/25/EC

G1

4

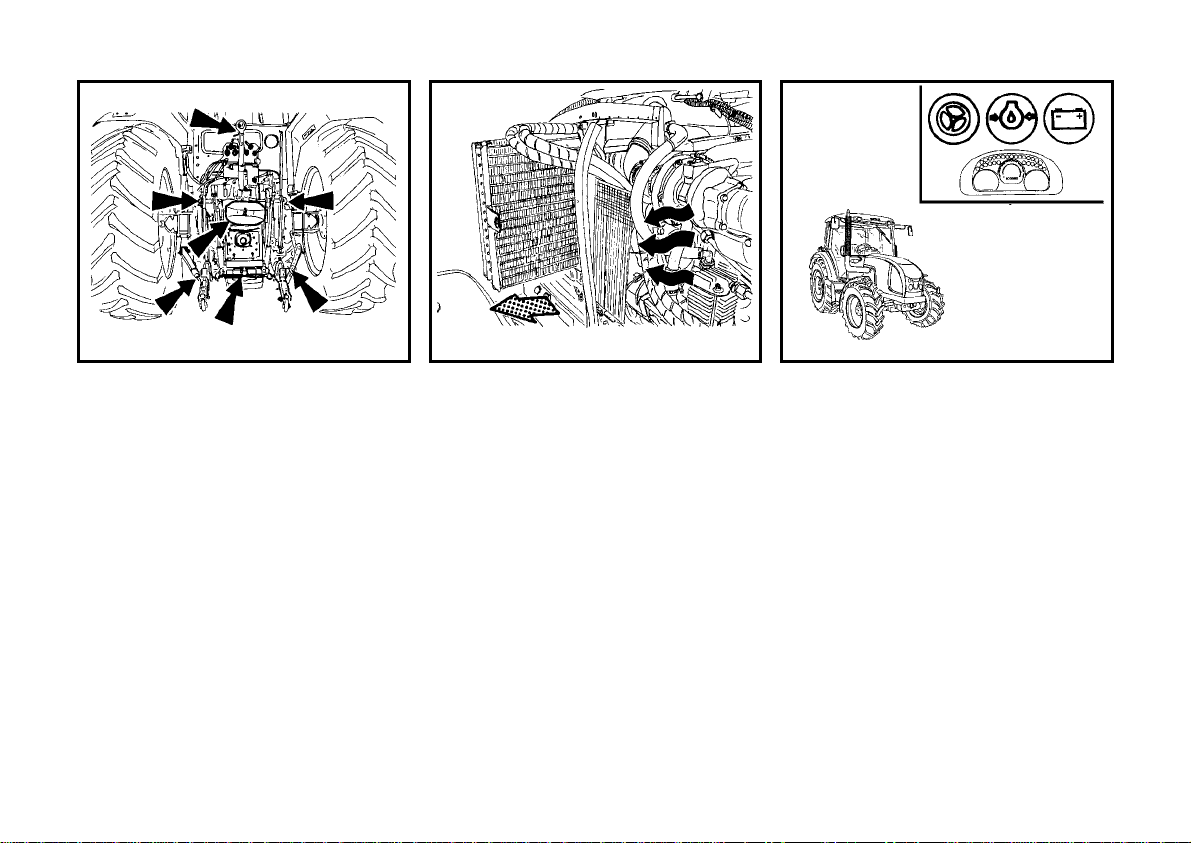

LOCATION OF SERIAL NUMBERS

G2

5

LOCATION OF SERIAL NUMBERS

When ordering spare parts and with all written and oral communication use please the data of your tractor that you shall write

down to the following frames.

Type of the tractor

Zetor Proxima Plus Z90

Zetor Proxima Plus Z100

Zetor Proxima Plus Z110

Designation "to the right", "to the left", "in

the front", "in the back" is meant in direction of drive of the tractor.

During production, the manufacturer reserves the right to carry out changes in

the construction and equipment for the

purpose of technical progress.

Serial number of the tractor

6

Serial number of the engine

G3

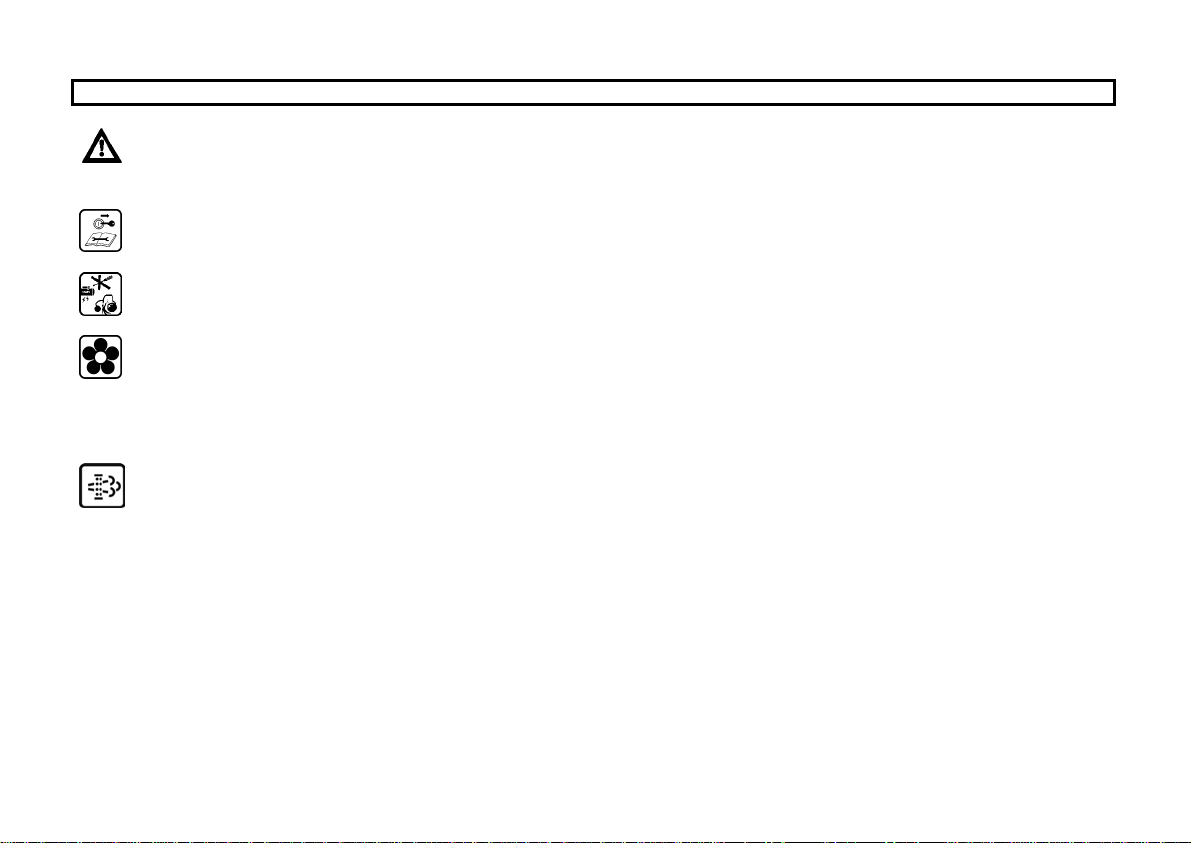

SAFETY INSTRUCTIONS FOR THE USERS

Pay proper attention to those sections of the operation and maintenance manual that are marked with this symbol .

You can find this symbol with all important warnings that relate to safety of operation.

Follow these warnings and behave with special attention in these cases!

Inform your colleagues and other users about these warnings.

The chapters marked with this symbol should be read thoroughly before any operating, repair or adjustment action on the

tractor.

You can find this symbol with all important warnings that relate to operation, adjustments and repairs of the starter.

Follow these warnings and behave with special attention in these cases!

This symbol appears with the parts of the operation manual that relates to protection of the environment.

This symbol indicates the tractor accessories mounted by the manufacturer on the customer’s request.

∗

Instruction manual´s passages related only to models equipped with DPF (diesel particle filter) are labelled with this symbol.

GENERAL SAFETY REGULATIONS

1. The tractor may only be operated by a trained worker having a valid qualification to drive the tractor and who is acquainted

thoroughly with the operational and safety principles.

2. In addition to the warnings relating to safety and given in the operational manual, it is necessary to respect all the generally applicable safety and traffic regulations of the country in which the tractor is used.

PROPER CLOTHING

3. Do not wear loose clothing and free flying long hair.

4. When executing any work, use suitable (prescribed) personal protective means (working shoes, gloves, etc.)

7

SAFETY INSTRUCTIONS FOR THE USERS

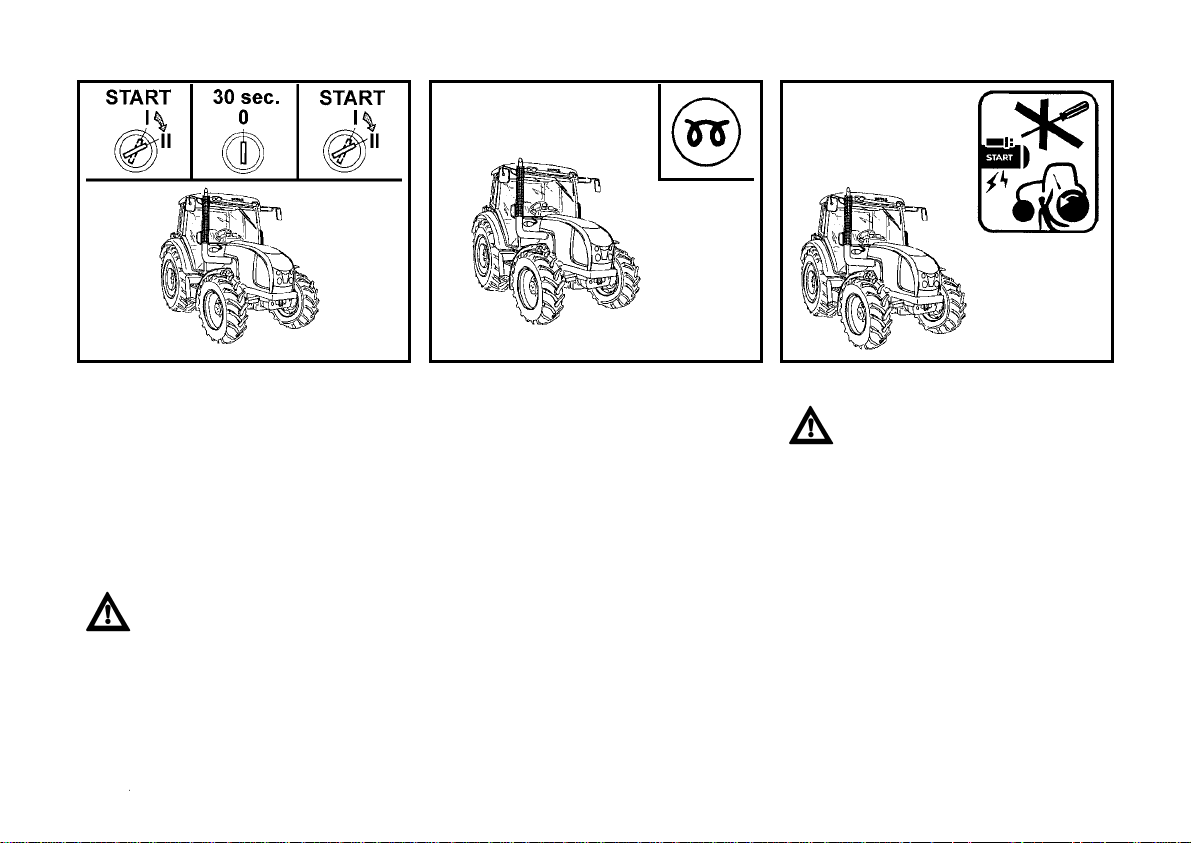

STARTING THE ENGINE

5. Starting of the engine by driving from slopes is not allowed.

6. Make the tractor moving for the purpose of starting the engine using other tractor or another vehicle is permitted only with use

of a tow bar.

7.Start the engine only from the driver’s seat with the shifting level in neutral position and clutch pedal depressed. Danger of

death when starting the engine using short-circuited terminals of the starter!

8. The key in the ignition box shall be in position "I".

9. When warming up the engine using an electric heater, first plug in the power supply cord to the heater and then to the mains

socket. When the engine is warm, first disconnect the supply cord from the mains socket.

DRIVING

10. Hoses of hydrostatic steering, brakes and fuel system shall be checked regularly and in case that some traces of damage are

observed, replace the damaged components. The traces of damage include, for example, cracks, loose pre-stressing of hose

connections (this can be verified by easy pulling out the hose from the coupling) and mechanical damages of hoses. The hoses

with specified life span shall be replaced immediately after termination of the specified period.

11. When driving with trailers and implements on roads the brake pedals shall be connected by a latch.

12. Brakes and steering shall be always in perfect condition.

13. Driving downhill without shifted any gear is forbidden!

14. Special attention shall be paid to driving a tractor on slopes, muddy, sandy, icy and uneven surfaces.

15. Observe the permitted angle of the gradient accessibility, i.e. max. 12°.

16. Respect the total permitted weight of the vehicle train, given on the type plate of the tractor or mudguard of the rear wheel.

17. When driving through road bends, do not use the differential lock.

18. Getting on and off the moving tractor is forbidden.

19. When driving a tractor with agricultural machines suspended on the front three-point suspension reduce travel speed of the

tractor to 15 km.h

20. When driving a tractor with machines suspended in the rear hitch, loading of the steered axle shall not be reduced under 20%

of the immediate weight of the vehicle train. In case of travel speed reduced to 20 km/h, loading of the steered axle may be reduced to 19% of the immediate weight of the vehicle train (vehicle train up to 4.5t) and to 18% of the immediate weight (vehicle

train over 4.5t).

-1

.

8

SAFETY INSTRUCTIONS FOR THE USERS

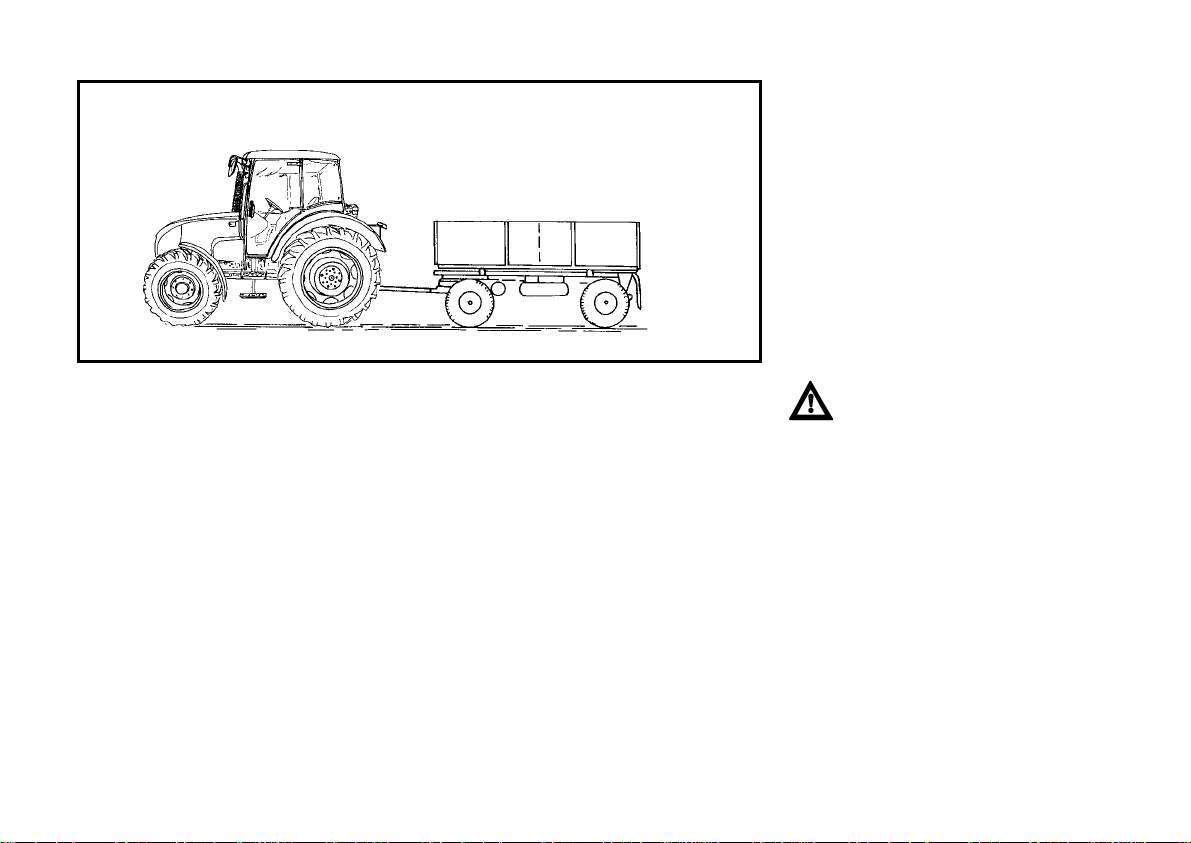

TRANSPORT OF VEHICLES, OPERATION

21. The tractor may transport only so many people as specified in the MOT certificate of the vehicle.

22. The persons that are not charged to work with the accessories of the tractor may not stay between the tractor and the hitched

machined (tools).

23. Before you bring the tractor in motion, check whether an unauthorised person or barrier obstructs your drive.

24. With aggregation of the tractor with machines and tools with great tractive resistance, when speed of the engine decreases

and the engine has a tendency to stop, the reduction gears 1R, 2R may not be used to work with these machines.

EXTRICATION, PULLING

25. Ung bars or ropes for extrication of a stuck tractor.

Never use chains! A risk of death in case of a chain rupture!

26. When extricating a tractor it is dangerous to stay close the towing rope.

27. A front hook is installed on the frame of the tractor; this hook can only be used for towing of the tractor itself, i.e. without trailer

or other additional equipment.

28. Then pushing other vehicles (trailers, etc.) by the tractor never use freely inserted balks or bars between the tractor and the

pushed object.

LEAVING THE TRACTOR

29. Do not park the tractor with carried tools in lifted position.

30. Before you leave the tractor, do not forget to brake the tractor using the hand brake, shift a gear and reversing lever move to

position for driving forward, remove the key from the ignition box and lock the cabin.

31. Use left side to get out of the tractor. Look around whether some vehicle does not come near to jeopardise your safety when

getting out of the vehicle.

32. When getting out of the tractor, use footboards and hold tight to the grab handles. Pay special attention close to the shifting

lever and lever of manual regulation of fuel supply.

33. When leaving the tractor with engine running apply the hand brake.

9

SAFETY INSTRUCTIONS FOR THE USERS

ONLY WITH ENGINE STOPPED

34. All works connected with refilling of fuel, cleaning, lubrication and adjustments of the tractor or suspension machines may only

be carried out with engine stopped and stopping of movable parts of the tractor, except check of function of brakes, hydraulics

and recharging of the battery.

35. Before removing the bonnet it is always necessary to stop the engine. In closed rooms the engine of the tractor may run only

if sufficient ventilation is provided. Exhaust gases are harmful for human health.

PRINCIPLES OF FIRE SAFETY

36. Carry out refilling of fuel with engine stopped.

37. In summer season do not refill fuel tank to its full capacity. Wipe immediately spilled fuel.

38. Do not refill fuel in vicinity of open flame and do not smoke.

39. When inspecting level of electrolyte in the battery, do not smoke and do not use open flame. Pay attention to consistent ob-

servation of fire safety instructions in environment of increased risk of fire (haylofts, straw stacks, etc.).

40. In case that the tractor is equipped with a fire extinguisher, have it still available.

PROTECTION OF HEALTH AND THE ENVIRONMENT

41. The tractors are not equipped with any special filters of air supplied to the cabin. Therefore the tractors are not designed for

work with aerosols and other harmful substances. Kerosene, diesel oil and other oil products that are used for operation and

treatment of the tractor may cause skin diseases with direct contact, show irritation effects to mucous membranes, eyes, digestive and upper respiratory tract. Some of them may cause general poisoning when swallowed.

42. The workers that come into contact with oil products are obliged to observe safety and hygienic directives, use suitable protective means and work in well ventilated rooms.

WHEN WORKING WITH OIL PRODUCTS

43. After end of your work of before taking a food it is necessary to wash the hands thoroughly with a non-irritating washing

preparation and use a suitable protective hand cream.

44. When connecting and disconnecting quick-couplings of hydraulic circuits remove, using any textile material, excessive hydraulic oil remaining in the socket or plug of the quick-coupling.

10

SAFETY INSTRUCTIONS FOR THE USERS

DISPOSAL OF WASTE

45. With disposal of the tractor or its parts (including its operational fluids) after termination of their service life it is necessary to

follow the applicable laws and executing notices to the laws of the country in which the tractor is used. Based on the act on

waste, when selling the tractor, the final dealer of the tractor is liable to inform the consumer about the way of back taking of

some used parts of the tractor. These include oils and other operational fluids, batteries and tyres. Back taking of these used

products shall be carried out without any demands for any payment from the consumer for this back taking.

DAILY PREVENTIVE MAINTENANCE

46. Perform this daily or at least every 8-10 working hours of the engine.

SAFETY CABIN

47. In case that the protective frame of the cabin is damaged from corrosion, accident or otherwise, the safety cabin shall be re-

placed for a new one.

AIR-CONDITIONING

48. In any case do not dismount, change direction or otherwise manipulate with the fitting of the air-conditioning system. This

may cause a sudden escape of the cooling medium and fast local cooling. A contact of such component with skin may result in a

serious injury.

49. The air-conditioning system is equipped with quick-couplings that allow, if necessary, to separate the cab from the tractor

body without any leakage of the cooling medium. Any interventions into the air-conditioning system should be performed by a

specialised service shop.

11

SAFETY INSTRUCTIONS FOR THE USERS

ELECTRIC INSTALLATION

50. No additional modifications of electric installation of the tractor shall be carried out (such as connection of other elec-

tric appliances) due to its possible overloading!

51. Values of electric installation:

Nominal voltage 12 V =

Grounded minus ( - ) pole

Use of starting trucks or other auxiliary sources with a different voltage or polarity may cause serious damages to the tractor.

52. When manipulating with the battery pay special attention and avoid short circuits. The tractors are equipped with a battery

disconnector that shall be switched off before any manipulation with the battery.

53. The tractors cannot be operated with disconnected battery; this may cause serious damages to the tractor.

12

SAFETY INSTRUCTIONS FOR THE USERS

FH13N002

FRONT PASSENGER´S SEAT NOTIFICATION

Transportation of personnel on front passenger’s seat is allowed only with road

transportation.

- Transportation of front passenger outside the seat designed for this pur-

pose is forbidden.

- Using the seat for front passenger during the work with a tractor (e.g. during

the work on the fields) is explicitly forbidden.

- The use of safety belt on front passenger’s seat is governed by valid regulations. In this respect, keep the regulations valid in the country, where the

tractor is operated.

13

FH13N003

PROTECTION OF CAB AGAINST

AEROSOLS

The cab of Zetor tractors in standard design is not designed for work with aerosols and other health hazardous substances.

The level of cab protection in standard

design complies with

EN 15695-1:2009 standard - level 2

(only dust proof cab)

SAFETY INSTRUCTIONS FOR THE USERS

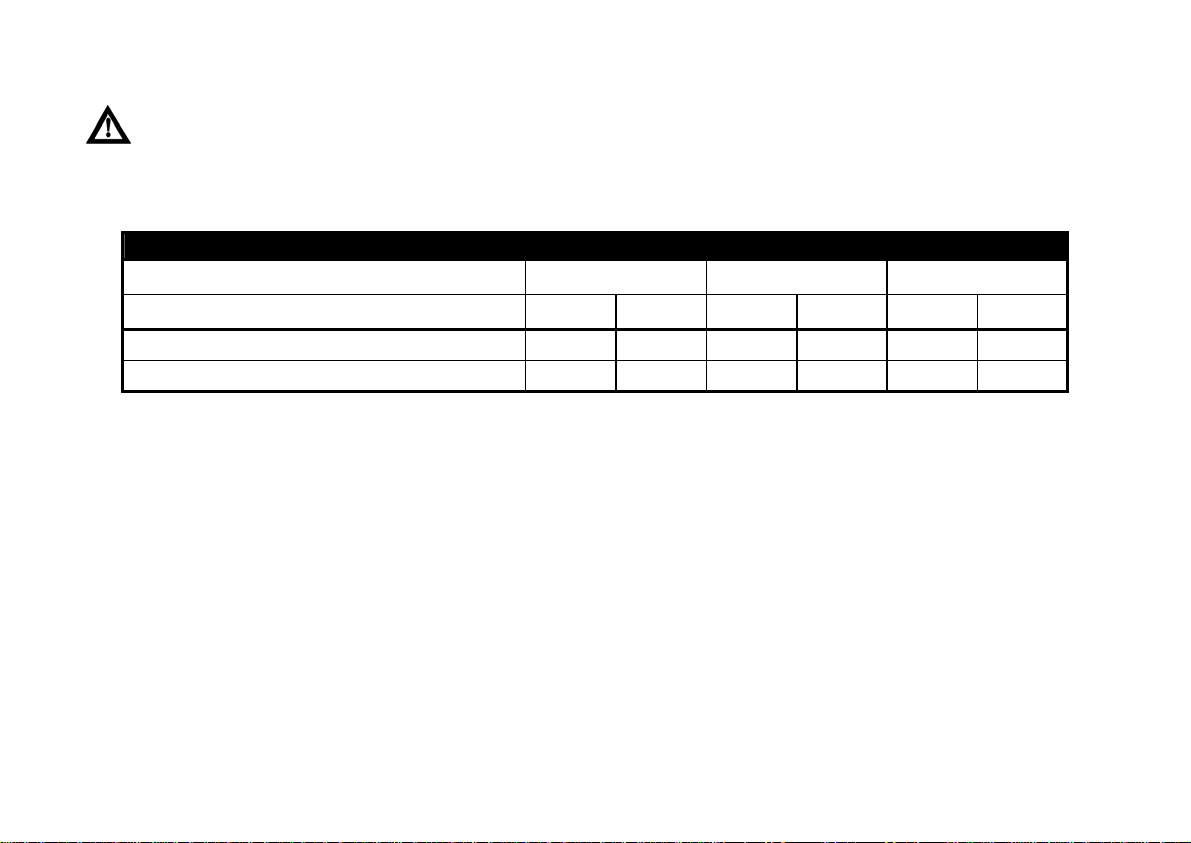

THE LEVEL OF EXTERNAL NOISE OF TRACTOR

The exposition to the effects of high levels of noise for a longer period of time may lead to hearing disorders or deafness.

Protect your hearing with protective means, e.g. headphones, ear plugs etc.

Resulting levels of noise when measuring noise for hearing of a person near a tractor

Based on European directive 2009/63/EC – Amendment VI

TRACTORS PROXIMA PLUS

Model Proxima Plus 90 Proxima Plus 100 Proxima Plus 110

Travel speed 30 km 40 km 30 km 40 km 30 km 40 km

Tractor noise levels when travelling dB(A) 81 80.5 80.5 80.5 81.5 80.5

Tractor noise levels when standing dB(A) 79.5 82.5 80.5 81 81.5 81.5

14

SAFETY INSTRUCTIONS FOR THE USERS

THE LEVEL OF INTERNAL SOUND OF TRACTOR

The exposition to the higher sound levels for longer periods of time may lead to hearing disorders or deafness. Protect

your hearing with protective measures, e.g. headphones, ear plugs etc.

Resulting levels of noise when measuring noise for hearing of driver

Based on European directive 2009/76/EC – Amendment VI

TRACTORS PROXIMA PLUS

Model Proxima Plus 90 Proxima Plus 100 Proxima Plus 110

Travel speed 30 km 40 km 30 km 40 km 30 km 40 km

Noise levels – Closed windows dB(A) 80.5 78.5 79.5 78 80 78.5

15

SAFETY INSTRUCTIONS FOR THE USERS

THE LEVEL OF VIBRATIONS ON DRIVER´S SEAT

ZETOR tractors are classified in A category in classes I and II. “A” category includes all tractors with set level of vibrations owing

to similar specifications of construction:

Results of measurement on testing bench are listed in the following table pursuant to directive 78/764/EEC. The value a*

adjusted value of effective acceleration balanced according to vibration movement.

The following table is valid for all type series of Zetor tractors.

Class I & II

Brand of seat Model Springing

(1)

a*

wS

(m/s²)

(2)

a*

wS

(m/s²)

GRAMMER MSG85/721 mechanical 1.18 0.8

GRAMMER MSG95A/721 pneumatic 1.16 1.1

MARS 78/764-73xx mechanical 1.25 1.23

SEARS 3008 mechanical 1.24 1.06

SEARS 3045 pneumatic 1.13 1.03

(1) Values corresponding to driver’s weight of 50 kg.

(2) Values corresponding to driver’s weight of 120 kg.

is an

wS

16

SAFETY INSTRUCTIONS FOR THE USERS

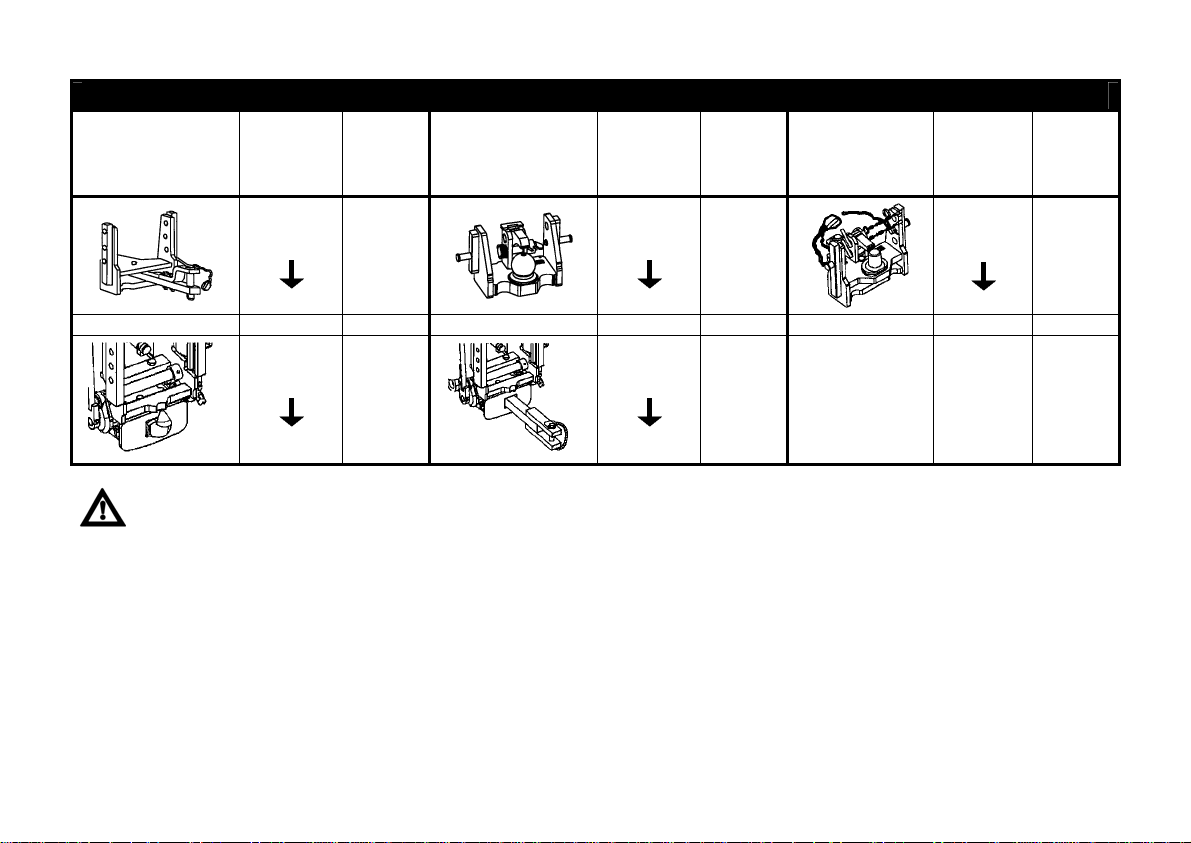

TRACTORS EQUIPPED WITH FRONT END LOADER

Zetor Tractors in standard design are designed for utilization in agriculture and are not designed for special purposes.

Tractors designed for operation within the European Union must be equipped, in case of using front end loader, with a protective

structure (FOPS – Falling Object Protective Structure) protecting drivers from potential falling objects.

It is necessary to observe applicable local valid regulations in countries which are not part of the European Union.

Two types of cab roofs are mounted to Zetor tractors.

1. Standard cab roof

2. Cab roof designed for tractors equipped with front end loader meeting the OECD code 10 (FOPS) conditions.

Tractors ZETOR supplied already from production with front end loader are equipped with cab roof according to point 2.

From safety reasons, series ZETOR tractors supplied without front end loader with standard roof pursuant to point 1 must not be

equipped or used with front end loader.

In case of additional front end loader assembly, it is necessary to equip tractor with cab roof pursuant to point 2.

Only front end loaders approved by ZETOR TRACTORS may be mounted to ZETOR tractor.

Additional assembly of front end loader approved by ZETOR TRACTORS can be done only by authorized ZETOR

service.

It is forbidden to use front end loaders unapproved of by ZETOR TRACTORS.

Not observing this instruction may cause serious accidents.

Carefully observe instructions for use supplied by the manufacturer of front end loader.

17

SAFETY INSTRUCTIONS FOR THE USERS

PRINCIPLES FOR OPERATING TRACTORS EQUIPPED WITH FRONT END LOADER

Carefully study operation manual supplied by the manufacturer of front end loader.

In case of discord of Principles for operating tractors equip ped with front end loader and operation manual for

front end loader, which was supplied by the manufacturer of front end loader, the wording listed in operation

manual supplied by the manufacturer of front end loader shall apply.

- The use of front end loader for transporting material at places accessible to the public is forbidden.

- The use of front end loader for transporting material in places inaccessible to the public is possible only in a limited way. In

such case, instructions in user’s manual supplied by the loader manufacturer must be observed.

- Observe local valid regulations at all times.

- A strict ban on transportation and lifting of people by means of loader is in effect.

- No matter whether the front end loader is loaded or empty, no-one may stand in front of the loader if it is in lifted position. When

driving with a lifted loader, there is a risk of load transported by front end loader falling (there is a risk of disrupting the balance

of the tractor).

- Never leave the tractor standing with the loader in lifted position.

- If it is necessary to open the bonnet of the engine at intervention, disconnect the front end loader first or secure hydraulic rollers

of front end loader by metallic props designed for this purpose.

- Hydraulic circuit of the front end loader is designed in such a way to endure the maximum operation pressure of 20 MPa (200

bar). Do not do any changes on couplers of hydraulic circuit hoses.

- Any front end loader ZETOR mounting without observing the recommendation of ZETOR TRACTORS valid to the day of purchase revokes the validity of guarantee for the whole of supply.

- The loader may be used, maintained and repaired only by people who perfectly know the machine and who are informed about

potential risks.

- When driving on roads do not transport any material on the front end loader.

- It is necessary to observe special instructions related to accidents prevention and general rules related to technical safety, labour medicine, labour hygiene and regulation defining operation on roads.

- The manufacturer does not bear any responsibility for any potential damage incurred as a result of changes conducted on the

loader without their consent.

- Do not ever adjust the front end loader by yourselves and do not use the adjusted front end loader without prior ZETOR´s approval. The loader may become dangerous as a result of not observing these instructions. ZETOR TRACTORS shall not be

held responsible in case of any damage or injury.

18

SAFETY INSTRUCTIONS FOR THE USERS

- Use front end loader without additional weights on the tractor (danger of mutual contact). The load of front and rear drive axle

must not exceed the maximum permitted load listed in the manual. The use of front end loader requires mounting of counter

weight in the rear part of the tractor.

- Each working tool was reconstructed for the purpose of specific usage and has its own tolerance of resistance and tightness.

- It is forbidden to use front end loader for cultivating soil and stubbing. Such work needs to be done with a special tool, front end

loader is not designed for doing this.

- Using controls which would set the loader into motion without driver holding the gear shifting lever is strictly forbidden and results in installation not meeting the prescribed standard.

- To penetrate the loaded material, better use the kinetic energy of the tractor rather than pressing force which causes higher

strain of both the loader and the tractor.

- Do not overload hydraulic parts if the load is too heavy or pistons are in end positions.

- Control the loader exclusively from driver’s seat, if you are sitting on driver’s seat.

- Do not leave the seat if you have not blocked any movement of controls.

- No people can be present in the working zone of the loader.

- When working with a lifted loader, mind electric and external cables etc.

- Loader/tractor set needs to be parked on a horizontal and solid base, the arms of the lifting device must be set in the lower position. After using the front end loader, park the tractor and lower the tool to the ground.

You will find more information in user’s manual to front end loader.

Important notification:

Work always safely and with consideration.

19

SAFETY INSTRUCTIONS FOR THE USERS

ZETOR TRACTORS USED FOR WORK IN THE WOODS

Standard tractors Zetor do not provide sufficient protection for operation in forest terrain as, for example, protection against a falling tree or branch on a cab or penetration of objects to a cab.

If Zetor tractor is utilized for forest work, a tractor operated within the European Union must be protected against these risks.

It is necessary to observe applicable local valid regulations in countries which are not part of the European Union.

To ensure this protection, it is advisable to conduct assembly of a specific protective structure, like for example FOPS / OPS (Falling Object Protective Structure / Operator Protective Structure), tested according to standards for forest machines.

Only forest superstructures approved by ZETOR TRACTORS can be mounted to ZETOR tractors.

In case of additional assembly of further tractor equipment for working in the woods, full responsibility is borne by the supplier and

manufacturer of the protective structure that all the safety regulations (e.g: OPS / FOPS), all the conditions of homologation (e.g.

the area of driver’s view, lighting, parameters, permissible weight etc.) are met, same as for the provision of due assembly of protective equipment. The supplier/manufacturer of protective construction is also obliged to conduct all the necessary validation

(approval) steps required by the legislature of the country in which the tractor is operated.

20

DAILY PREVENTIVE MAINTENANCE

Carry out this maintenance every day or at least every 8-10 working hours of the engine

21

G4

DAILY PREVENTIVE MAINTENANCE

G5 E6g G716c

TIGHTNESS OF THE FUEL SYSTEM

Check tightness of the fuel system, including the fuel tank discharge plug.

Eliminate immediately all leakages.

LEVEL OF OIL IN THE ENGINE

The oil gauge rod can be found on the

right side of the engine. After screwing

and pulling out the rod, check level of oil

in the engine and tightness of connections of the engine lubrication system.

Keep level of oil between the gauge rod

marks.

22

COOLING SYSTEM

Check tightness of connections of the

engine cooling system and level of cooling fluid in the expansion tank.

The expansion tank is accessible after

opening of the front bonnet. Refill the

missing volume up to the upper gauge

mark MAX. The minimum permissible

level of cooling fluid is at the gauge mark

MIN.

Release the overpressure lid after the cooling fluid has cooled

down. Risk of scalding!

DAILY PREVENTIVE MAINTENANCE

G735a G9 G751b

FLUID BRAKES

Check tightness of fluid brakes, fluid control of the clutch and level of brake fluid

in the expansion tank. The tank can be

found on the left side of the tractor, in

front of the cabin and is accessible after

lifting of the front bonnet.

Keep level of the brake fluid within 3/4

(max.) and 1/2 (min.) of the tank volume.

When manipulating with the

brake fluid, keep strictly cleanness. Check level of brake fluid

every day before driving.

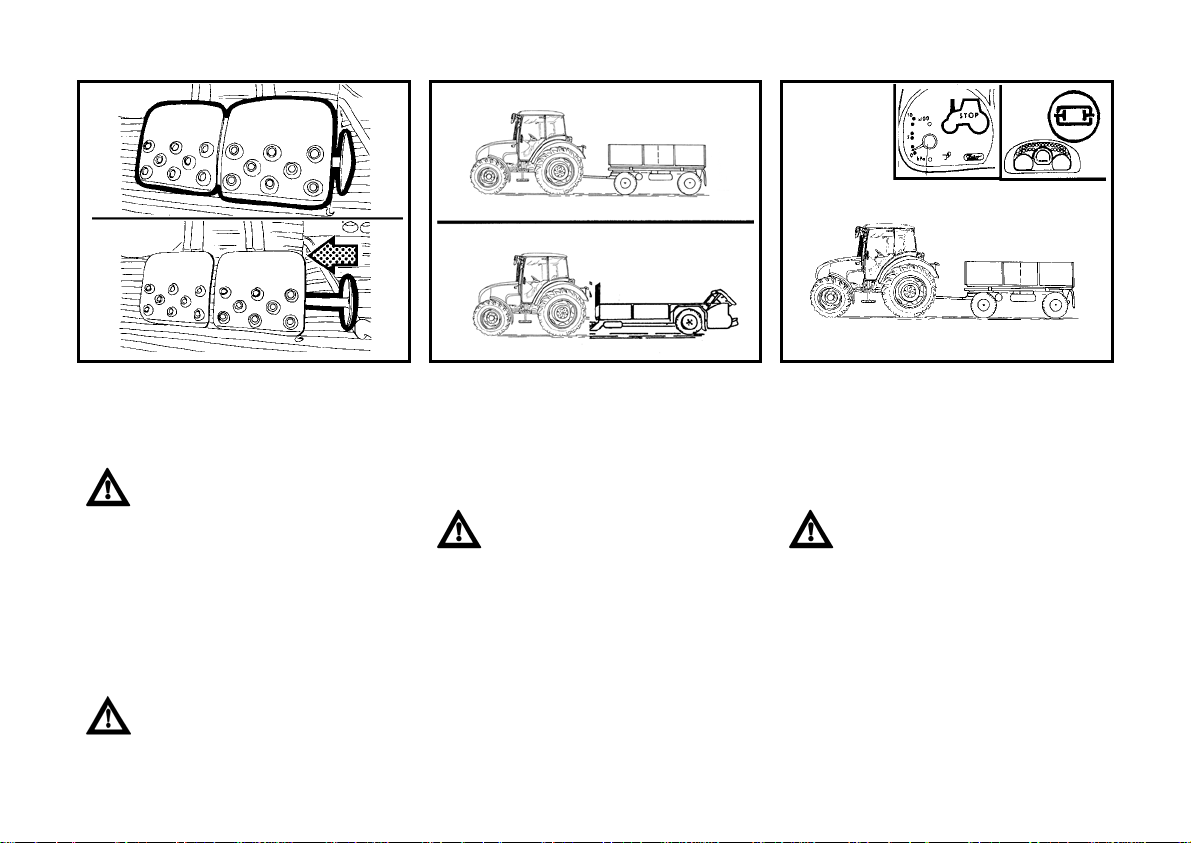

AIR BRAKES OF THE TRAILER

Check tightness of the air system of the

brakes and effectiveness of brakes of the

tractor with a trailer.

HYDRAULIC BRAKES OF THE TRA ILER

Check tightness of hydraulic brakes of

the trailer and effectiveness of brakes of

the tractor with a trailer.

23

HYDROSTATIC STEERING

Using the oil gauge rod check level of oil

in the hydrostatic steering tank that can

be found on the left side of the tractor. It

is accessible after lifting of the front bonnet.

If necessary, refill oil up to the oil gauge

rod mark that defines its correct volume.

Check condition of all hoses of the hydraulic steering circuit for any damage

and oil leakage.

Check tightening of bolts and nuts of

steering rods and levers.

DAILY PREVENTIVE MAINTENANCE

G11 G710b E13

TYRES AND WHEELS

Check air pressure in the front and rear

tyres. According to nature of work, adjust

correct pressure. Check and tighten if

necessary all screws of the front and

read wheels (connection rim/disk and

disk/wheel shaft).

Never drive with loose wheel

screws!

AIR CLEANER

Maintenance of the air cleaner shall be

carried out after indication of the indicator of clogging.

The indicator is accessible after lifting of

the bonnet. It is located close to the inlet

pipe elbow.

24

FILTRATION OF THE CAB

Check and clean if necessary air filters

for ventilation of the cab in the front

overhang of the roof.

Replacement of filters depends on

amount of dust in the working environment.

Partial regeneration can be carried out

by dusting of blowing with compressed

air.

Carry out cleaning or replacement of filter cartridges after dismounting of cover

grilles in the roof overhang.

At the customer’s request we supply filters with active carbon.

Don’t clean the filter; don’t flush it

with compressed air.

DAILY PREVENTIVE MAINTENANCE

E14 E15 G16

SUSPENSION EQUIPMENT

Check condition of suspension and connection equipment including the trailer.

AFTER WORK WITH FRONT-CARRIED

MACHINESI

After work with front-carried machines:

− Check tightness of connections of the

external hydraulic circuit for control of the

front three-point suspension.

Clogging of radiators:

1. Tilt up the bonnet.

2. Release and slide out the A/C con-

denser to the left side of the tractor.

3. Clean the front walls of the engine ra-

diator (A/C condenser) using compressed air (blow air in direction from

the engine).

4. Remove remaining dirt from the

space under the bonnet (to prevent its

re-sucking).

25

SHORT FUNCTIONAL TEST

After starting the engine check whether

the indicator of hydrostatic steering fault,

indicator of engine lubrication and indicator of recharging are off.

Check function and tightness of hydraulic steering circuits.

NOTES

26

The user of the tractor shall learn

beforehand the recommended

procedures and instructions for

safe operation of the tractor. It is

too late to do it during operation!

GETTING TO KNOW THE TRACTOR

Safety cabin .............................................................................................................. 29

Opening of doors from outside .................................................................................. 29

Opening of doors from inside .................................................................................... 29

Rear window .............................................................................................................30

Side window .............................................................................................................. 30

Right rear panel......................................................................................................... 31

Window mirrors ......................................................................................................... 31

Sun shield .................................................................................................................32

Internal lighting.......................................................................................................... 32

Washer nozzle .......................................................................................................... 33

Washer tank .............................................................................................................. 33

Washer activation...................................................................................................... 33

Passenger´s seat ...................................................................................................... 34

Driver’s seat Mars Svratka ........................................................................................ 35

Adjustment according to the driver’s weight.............................................................. 35

Longitudinal adjustment ............................................................................................35

Vertical adjustment.................................................................................................... 35

Driver’s seat Grammer Maximo................................................................................. 36

Driver’s seat Grammer S........................................................................................... 36

Driver's seat Sears .................................................................................................... 37

*Air filter with active carbon....................................................................................... 38

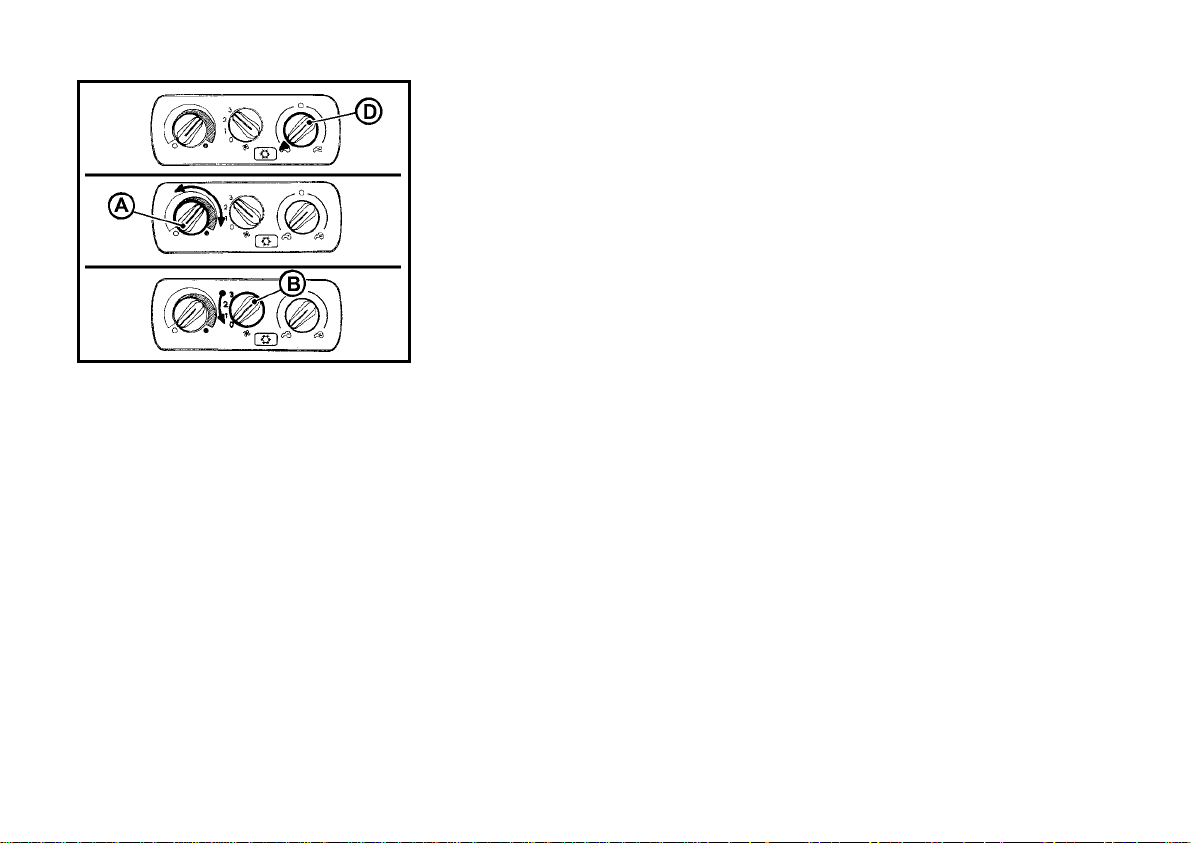

Heating control panel, ∗A/C, ∗radio........................................................................... 39

Heating valve control (A)........................................................................................... 39

Fan control (B) .......................................................................................................... 39

∗Air-condition switch () .............................................................................................. 39

Control of air circulation in the cabin (D) ...................................................................40

Correct function of the heating and a/c systems .......................................................40

Fast warming-up of the cabin space ......................................................................... 40

Fast cooling of the cabin space................................................................................. 41

Operation of heating of air-conditioning with work of the tractor................................ 41

When the cabin is cooled .......................................................................................... 42

Control panel on the cab right piller........................................................................... 43

Page

27

GETTING TO KNOW THE TRACTOR

*Tilt steering wheel.................................................................................................... 44

*Tilt and telescope steering wheel ............................................................................ 44

Air-condition and heating registers (a) ...................................................................... 45

Front windshield (B) defrosting ................................................................................. 45

Dashboard ................................................................................................................ 47

Display of pto speed ................................................................................................. 50

Switchers, switches and levers ................................................................................. 51

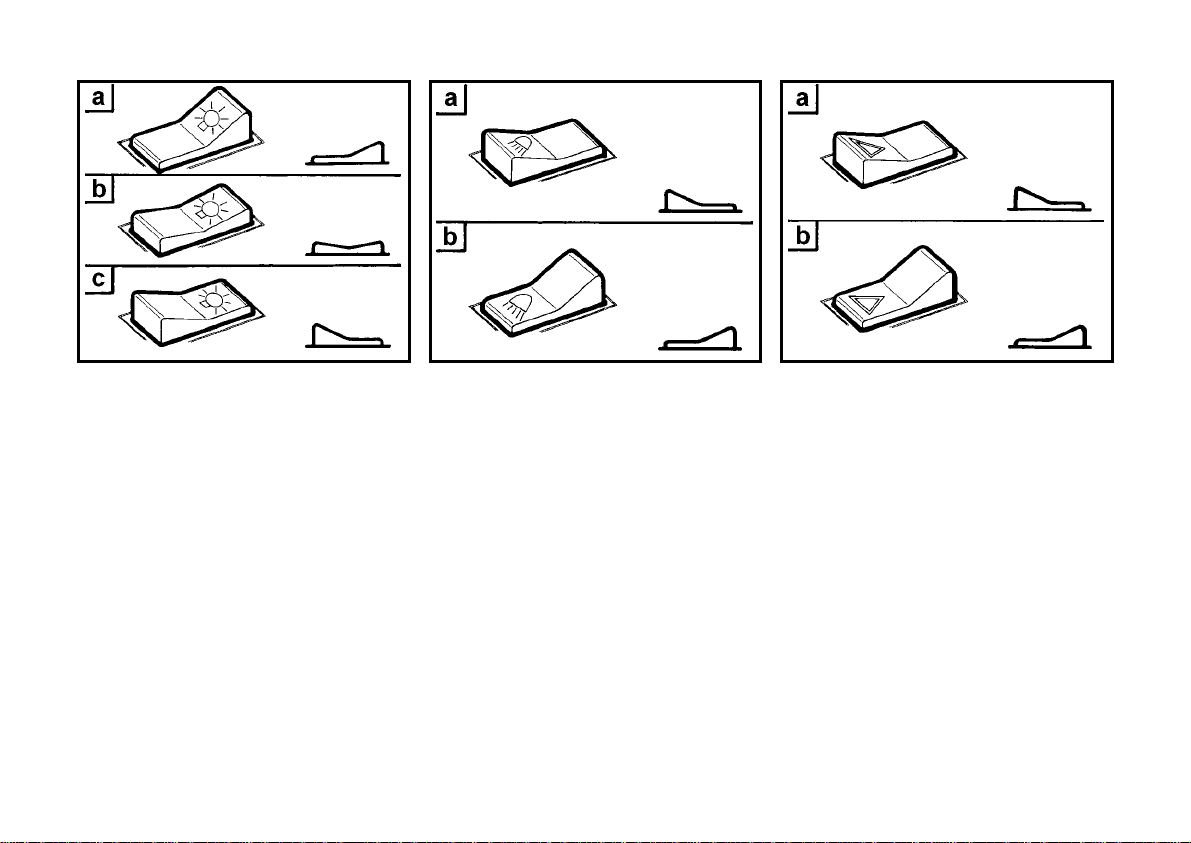

Lights switcher (a)..................................................................................................... 52

Switch for switching over lights in the mask and on the roof (b)................................ 52

Switch of warning lights (e) ....................................................................................... 52

Front driving axle switch (f) ....................................................................................... 53

Pushbutton of rear differential lock (j) ....................................................................... 53

Combined switch of indicator lights, low and high beams and flash lights (k) ........... 53

Ignition box ............................................................................................................... 54

Key in position "0" ..................................................................................................... 54

Key in position "i" ...................................................................................................... 54

Key in position ”ii”...................................................................................................... 55

Lever of manual refulation of fuel.............................................................................. 55

Control of engine stop............................................................................................... 55

Pedals....................................................................................................................... 56

Lever of shifting gears............................................................................................... 56

Scheme of shifting of gears ...................................................................................... 56

Reversing lever ......................................................................................................... 57

Lever of shifting of road and reduced gears.............................................................. 57

Torque multiplier ....................................................................................................... 57

Switching on output shaft drive ................................................................................. 58

Lever of shifting of speed 540 (or 540e) and 1,000 rpm of the rear output shaft ...... 58

Lever of switching on rear output shaf drive ............................................................. 59

Lever of hand brake and hitch for single-axle trailer ................................................. 59

Tractors with travel speed 40 km.h

Fuel tank ................................................................................................................... 60

Draining plug of the fuel tank .................................................................................... 60

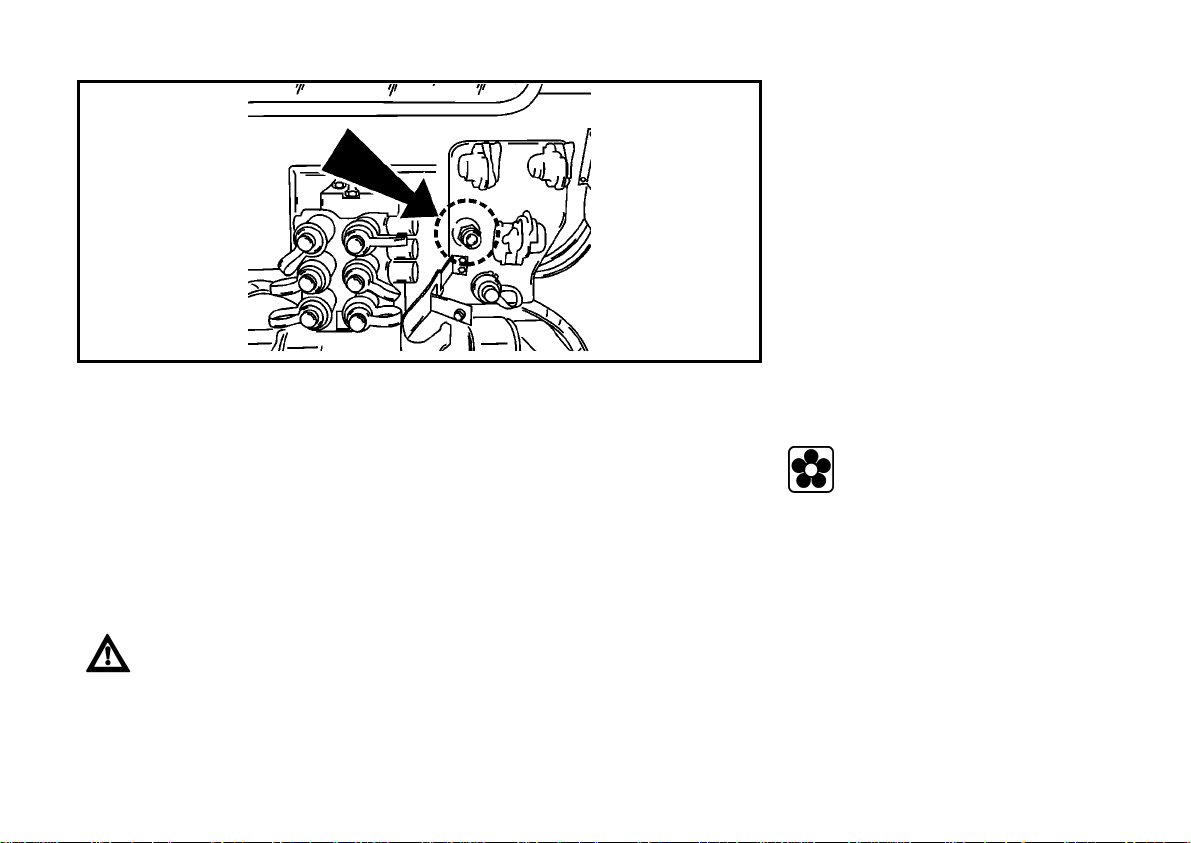

Battery disconnector ................................................................................................. 60

-1

......................................................................... 60

28

Page

GETTING TO KNOW THE TRACTOR

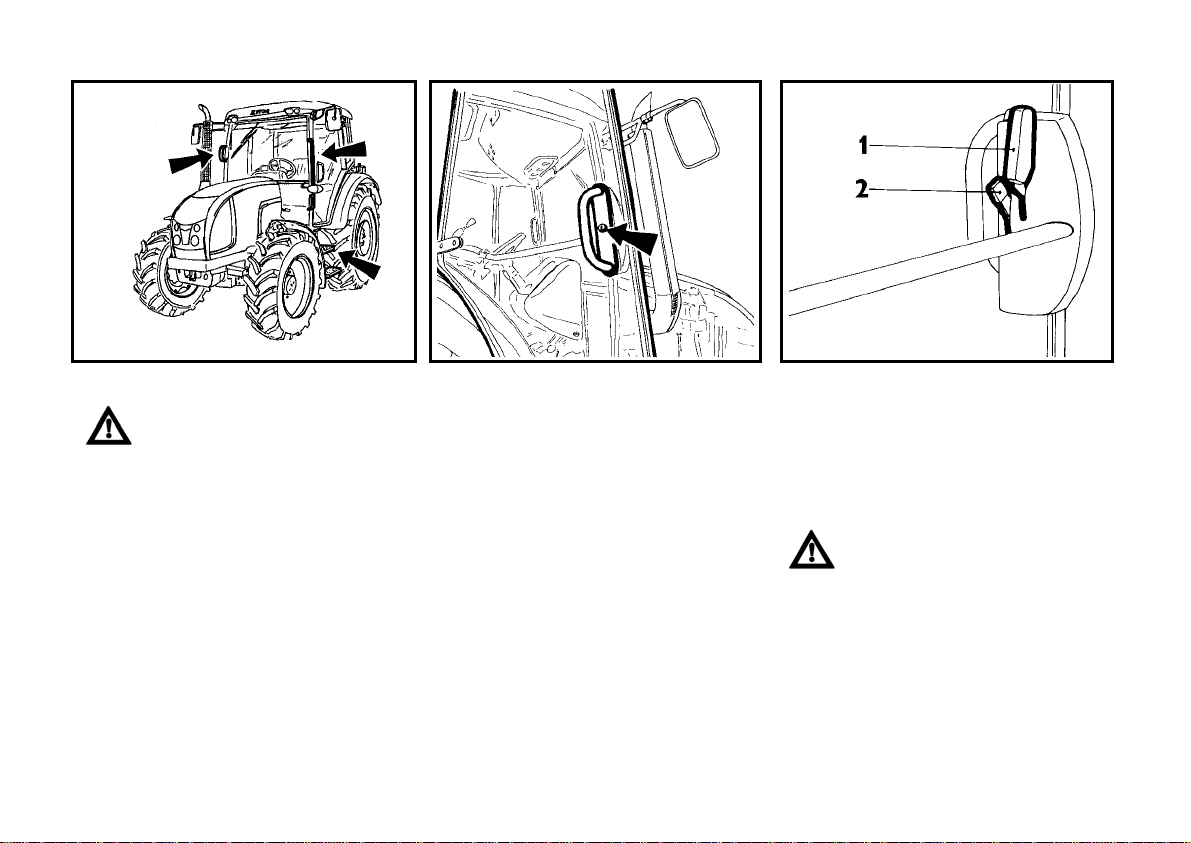

SAFETY CABIN

Use commonly left side of the

tractor for getting in and out the

cabin.

Use footboards for getting in and

out the cabin and hold tight to the

grab bars.

Pay special attention in space of

the shifting lever and lever of

manual regulation of fuel.

G101 E102 E103

OPENING OF DOORS FROM OUTSIDE

The cabin doors can be locked from the

outer side. Doors can be opened after

unlocking and pulling the grab bar.

29

OPENING OF DOORS FROM INSIDE

1. Lever for opening of the door from inside.

2. Lever for opening of the lock from inside.

With full opening the door is held by a

gas strut.

It is forbidden driving with open

door due to its possible damage.

GETTING TO KNOW THE TRACTOR

E104 E105

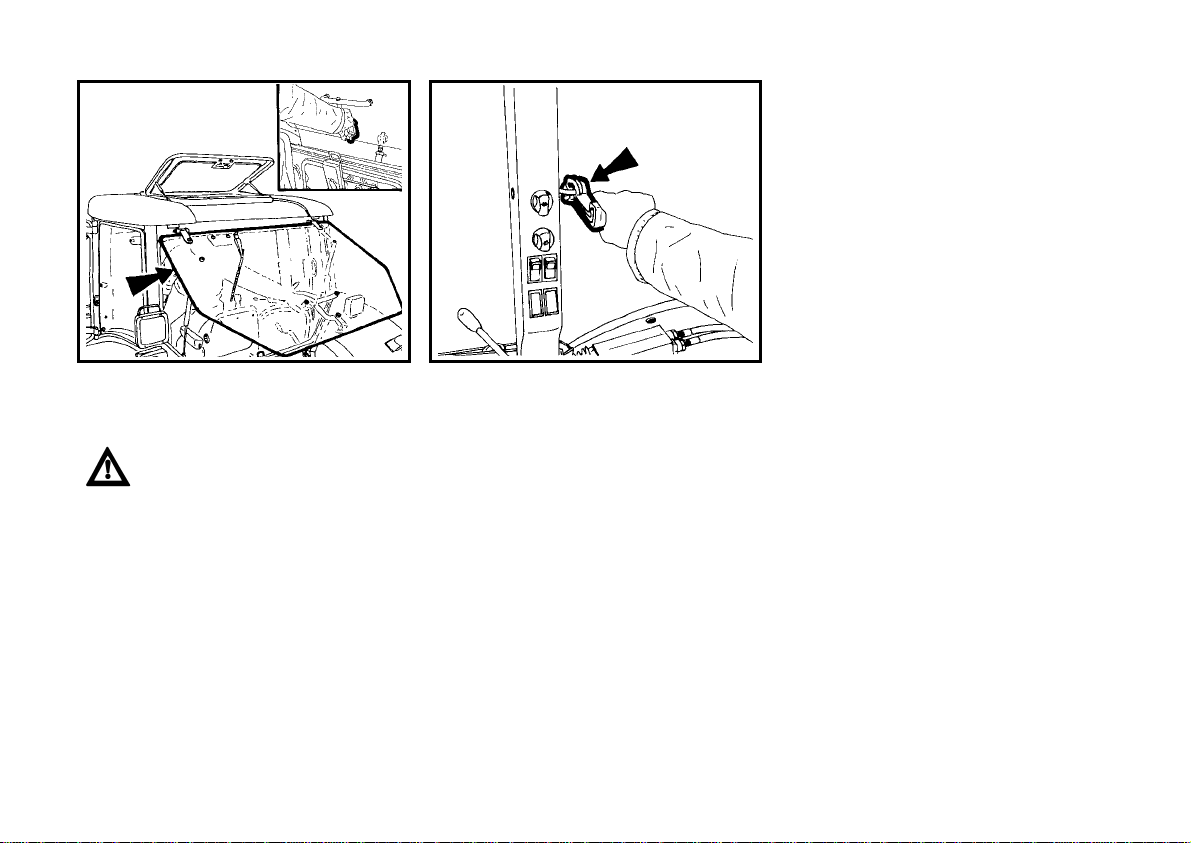

REAR WINDOW

It is provided with a grab bar and in open

position it is held by gas struts.

When driving on an uneven

surface it is advisable to secure

the window in closed position due

to danger of a glass break.

Before commencement of work

with machines carried in the rear

three-point suspension make

sure if there is no risk of a

collision between the carried tool

with maximum stroke of the rear

three-point suspension and open

rear window. In case of a collision

it is recommended to work with

rear window closed.

SIDE WINDOW

In partly open position it is held by a

plastic window handle. The window can

be opened by lifting the handle upwards

and its pushing to lock it in the groove;

this secures the window in a fixed

position.

30

GETTING TO KNOW THE TRACTOR

E108 E109

RIGHT REAR PANEL

The right rear panel includes a storage

place for a PET bottle (1), socket 12V (2)

and cigarette lighter (3).

WINDOW MIRRORS

Before driving or commencement of work

adjust window mirrors to enable observation of whole driving lane or working field.

31

GETTING TO KNOW THE TRACTOR

FH13N009 F13BN014

SUN SHIELD

You can draw out the sun shield by pulling the handle in the direction of the arrow. The shield gets back to initial position after pressing the button (1) by an

applicable shield.

INTERNAL LIGHTING

To be turned on and off by means of a

button marked with the arrow.

32

GETTING TO KNOW THE TRACTOR

E110 E111 E112

WASHER NOZZLE

The nozzle is installed on the bonnet in

front of the windscreen and adjustable

using a needle or steel wire with diameter 0.8mm.

WASHER TANK

The tank is installed on the rear wall of the

cabin on the outer side.

Volume of the tank is 2.5 litres. In winter

season it is necessary to fill it with antifreeze mixture for windscreen washers.

33

WASHER ACTIVATION

The key in the ignition box shall be in

position II. The windscreen washer can

be activated after pressing of the front

two-speed wiper on the right column of

the cabin. The maximum time of continuous run of the washer pump is 20 s.

GETTING TO KNOW THE TRACTOR

FH12N020

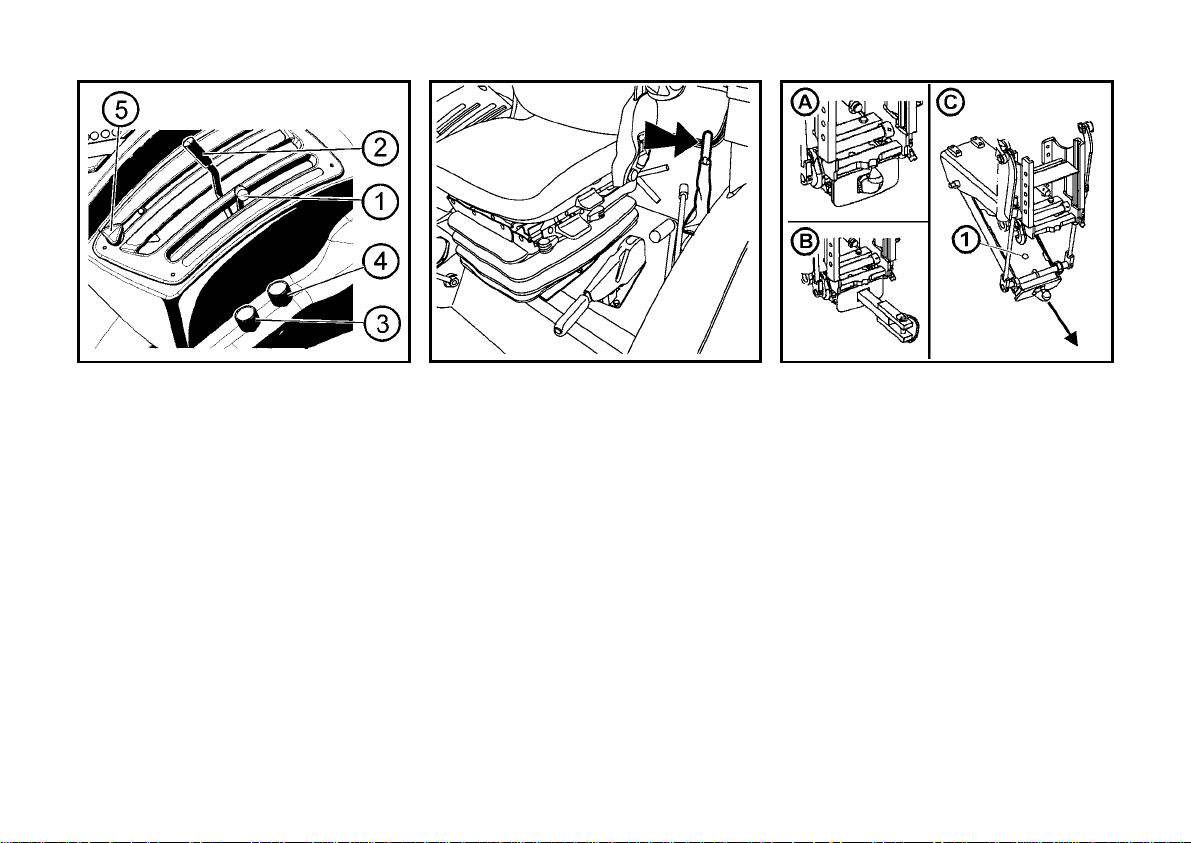

PASSENGER´S SEAT

Passenger´s seat is tiltable and placed on the left mudguard of the cabin.

SEAT TILTING OUT

Passenger´s seat to be tilted out in the direction of an arrow (1) upward. Locking of the seat is done automatically

SEAT TILTING

Lift the passenger´s seat in the direction of an arrow (2), pull the lever (3) to the direction of the driver´s seat, tilt the seat in the direction of an arrow (4).

34

GETTING TO KNOW THE TRACTOR

E113 E114 E115

DRIVER’S SEAT MARS SVRATKA

ADJUSTMENT ACCORDING TO THE

DRIVER’S WEIGHT

Cushioning of the seat is adjustable for

driver’s weight from 50 to 120kg. Adjustment is carried out using a rotary

square handle. Indicator of adjustment of

the weight can be found in a recess of

the seat rear cover. Cushioning stroke is

120mm.

Do not adjust during drive!

Risk of an accident!

LONGITUDINAL ADJUSTMENT

The seat can be adjusted longitudinally

within range ±75mm (11 positions) after

unlocking by the left lever.

35

VERTICAL ADJUSTMENT

The seat can be adjusted vertically by a

lever on the right side within range

±30mm from the middle position to both

marginal positions.

GETTING TO KNOW THE TRACTOR

E116

DRIVER’S SEAT GRAMMER MAXIMO

1. Lever for adjusting of cushioning of the seat according weight of the driver (adjustment by turning in direction as shown on the pictogram on the seat bellow).

2. Lever of longitudinal adjustment of the seat (located on the right side of the seat).

3. Turning of the seat (can be turned by 20° to both sides).

4. Control of adjustment of absorption of vibrations of the seat (tilting of the controller

forwards adjusts a floating position of the seat).

5. Control of adjustment of the seat inclination.

6. Control of adjustment of the back shape.

7. Height-adjustable backrest (pulling or pushing in direction of the arrow adjusts the

backrest within range 170mm).

8. Tiltable armrest.

9. Control of adjustment of the armrest (turning of the controller adjusts height of the

armrest).

DRIVER’S SEAT GRAMMER S

Here only items 1, 2 and 5 are used.

36

GETTING TO KNOW THE TRACTOR

P13N003

DRIVER'S SEAT SEARS

The driver's seat Sears can be made with a mechanical (A) or pneumatic (B) suspension.

1. The seat suspension adjustment controller according to the driver's weight (turn it in the direction based on icons shown on the

seat bellows)

2. The seat height adjustment controller (release the controller to increase the seat height, tighten the controller to decrease the

seat height)

3. The longitudinal seat adjustment lever (pull the lever to adjust the seat lengthwise, return the lever back to its original position

to lock the longitudinal adjustment)

4. The seat backrest inclination adjustment controller (pull the lever to adjust the seat backrest inclination, return the lever back

to its original position to lock the backrest position)

5. Foldable armrest

6. The armrest height locking adjustment (release the controller to adjust the height of the armrest, tighten the controller to lock

the armrest position)

7. The seat vibration absorption setting (move the controller up to get the float seat position, move the controller to the lower

position to lock it)

8. The seat height adjustment and seat suspension adjustment according to the weight of the driver (push the controller to increase the air pressure in the pneumatic suspension of the seat - when the driver´s weight is bigger, pull the controller to decrease the air pressure in the pneumatic suspension of the seat - at the lower weight of the driver

37

GETTING TO KNOW THE TRACTOR

F13BN015

*AIR FILTER WITH ACTIVE CARBON

Filters with active carbon are installed instead of the standard dust filter and replacement is carried out in the same way as in the common filters. The filter should be located with the white surface on the grid. Installation directions are stated in the chapter “Instructions for Maintenance”.

The filter is used only when spraying pesticides, after the work the paper filter should

be reinstalled, because the carbon filter would be choked with dust after a short period of time. Upon work the re-circulation controller should be in the position “air is

drawn into from the outside”.

The fan controller should be in the position “fan maximum work”.

• WARNING: The filter does not provide full protection against toxic substances.

• When handling the filter, wear protective gloves.

• Don’t clean the filter; don’t flush it with compressed air.

DANGER: The filter with active carbon should be replaced after every 200

hours or 36 months (manufacture date is stated on the filter). If you can smell

pesticides in the cabin, replace the filter immediately and check the cabin sealing. Used filters should be disposed in special disposal centres.

When spraying pesticides and

using the heating filter with active

carbon, the re-circulation controller should be in position “air is

drawn into from the outside” and

the fan controller should be in the

position “fan maximum work” to

create overpressure in the cabin.

38

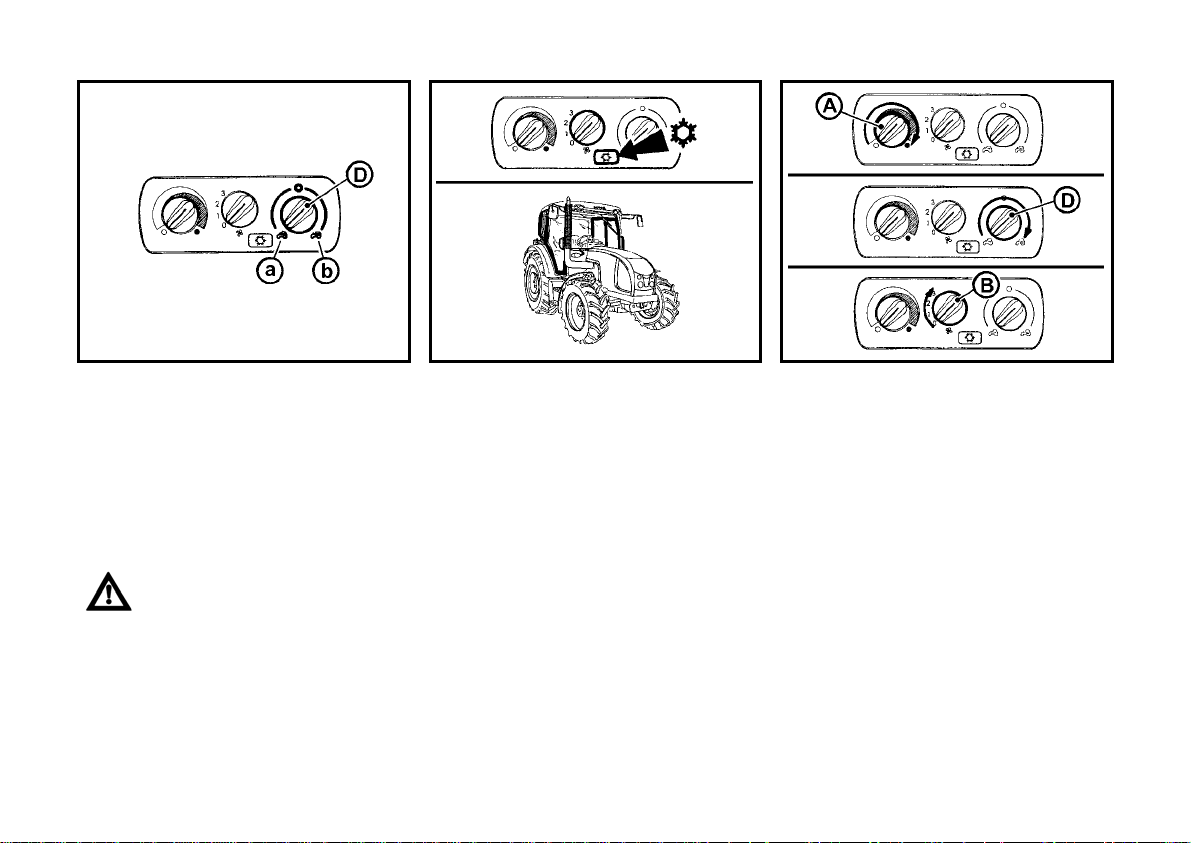

GETTING TO KNOW THE TRACTOR

F13BN009 E118 E119

HEATING CONTROL PANEL, ∗A/C

A - Heating valve control

B - Fan control

C - Air-conditioner (A/C) switch

D - Control of air circulation in the cabin

HEATING VALVE CONTROL (A)

a - Heating valve closed

b - Heating valve open

FAN CONTROL (B)

0. Fan off

1. Fan slow run

2. Fan medium run

3. Fan fast run

39

∗AIR-CONDITION SWITCH (C)

The A/C system can be switched on/off

using the pushbutton switch with a symbol of a snow flake (C).

Pressing of the pushbutton activates the

A/C system (the snow flake symbol is

on) and next pressing the A/C system

deactivates (the snow flake symbol is

off).

GETTING TO KNOW THE TRACTOR

E120 G121 E122

CONTROL OF AIR CIRCULATION IN

THE CABIN (D)

a - Ambient (outdoor) air is sucked

through the filters into the cabin; sucking of air from inside is closed;

b - Air is sucked from inside and ex-

hausted to the cabin again (inner circulation for fast adjustment of temperature in the cabin).

Intake of air from outdoor is completely closed and there is no

overpressure in the cabin to prevent penetration of non-filtrated

air into the cabin!

Use this control position for necessary period only!

CORRECT FUNCTION OF THE

HEATING AND A/C SYSTEMS

It is necessary to create overpressure in

the cabin for correct function of heating

or air-conditioning. Therefore it is recommended to close all windows, doors

and upper cover.

FAST WARMING-UP OF THE CABIN

SPACE

Proceed as follows:

1. Turn the heating valve control (A) to

the right (fully open heating valve).

2. Set the air circulation in the cabin

control (D) to position of inner recirculation.

3. Select the desired speed of the fans

(position 1, 2, 3) using the fan control

(B).

4. Adjust angles of the air outlets to

prevent direct blowing of persons in

the cabin.

40

GETTING TO KNOW THE TRACTOR

E123 E124

FAST COOLING OF THE CABIN

SPACE

1. Turn the heating valve control (A) to

the left.

2. Set the air circulation in the cabin

control (D) to inner recirculation.

3. Select the desired speed of the fans

(position 1, 2, 3) using the fan control

(B).

4. Switch of the A/C system using the

button (C).

5. Adjust angles of the air outlets to

prevent direct blowing of persons in

the cabin (risk of an disease due to

intensive cooling of body parts).

OPERATION OF HEATING OF AIRCONDITIONING WITH WORK OF THE

TRACTOR

In case that inner recirculation is activated, fresh air supply is closed and all the

air in the cabin becomes breathed up.

This situation may cause a feeling of fatigue.

Note: When working with the tractor, set

the control (D) to fit your individual requirements for temperature, i.e. between

positions (a) and (b) so that the fan will

suck outdoor air through the filters.

When spraying pesticides and

using the heating filter with active

carbon, the re-circulation controller should be in position “air is

drawn into from the outside” and

the fan controller should be in the

position “fan maximum work” to

create overpressure in the cabin.

41

GETTING TO KNOW THE TRACTOR

E125

WHEN THE CABIN IS COOLED

When the cabin is cooled to the desired

air temperature, we recommend:

− Set the air circulation control (D) from

position ‘b’ (air recirculation) to position

‘a’ (sucking of outdoor air).

− Carry out regulation of air temperature

with A/C switched on by partial opening/closing of the heating valve (A). In

case of this setting air, coming to the

cabin from the air outlets, is not dried

so intensively.

− Desired setting of temperature with

A/C switched on can also be carried

out by reducing speed of the fan by

setting the control (B) to position1 or 2.

42

GETTING TO KNOW THE TRACTOR

P+13N009

CONTROL PANEL ON THE CAB RIGHT PILLER

Switches placement in standard tractor (A) design

1. rear PTO shaft switch

2. front shaft switch

3. two-position switch of the windscreen wiper and washer

4. rear window wiper switch

5. switch of front working lights on cab roof

6. switch of rear working lights on cab roof

7. *rear mirrors heating switch

8. *rear window defroster switch

If a tractor is equipped with electrohydraulics EHR, the switches (1) and (2) are

placed on the external hydraulic circuit control panel (B).

43

GETTING TO KNOW THE TRACTOR

W1 F205

*TILT STEERING WHEEL

Adjusting the angle of the wheel

The angle can be adjusted by tilting the

wheel after it is unlocked by moving the

lever (1) in the direction shown by the arrow. After adjusting, lock the wheel by

pressing the lever (1) in the opposite direction than shown by the arrow.

*TILT AND TELESCOPE STEERING

WHEEL

Tilt column of the steering wheel enables

to adjust the angle and height of the

wheel.

Adjusting the height

To adjust height, pull the wheel up or

push it down after it is unlocked by moving the lever (1) in the direction shown by

the arrow. After adjusting, lock the wheel

by pressing the lever (1) in the opposite

direction than shown by the arrow.

Adjusting the angle

To adjust angle, tilt the wheel after it is

unlocked by moving the lever (2) in the

direction shown by the arrow. After adjusting, lock the wheel by pressing the

44

lever (2) in the opposite direction than

shown by the arrow.

After adjusting, tilt the lever (2)

towards the dashboard and the

lever (1) in such a way so that it

is parallel to the steering wheel

column axis.

Pushing the levers in the

direction farther from the steering

wheel column changes the

position of the levers as desired.

GETTING TO KNOW THE TRACTOR

F13BN010 F13BN011

AIR-CONDITION AND HEATING REGISTERS (A)

Positionable heating and ∗ air-condition registers, front (A), rear (B).

45

FRONT WINDSHIELD (B)

DEFROSTING

To ensure quick defrosting of the front

windshield direct the central heating outlets (1) under the angle of approx. 45°

towards the windshield. Direct the side

outlets (2) under the angle of approx. 45°

to the cab corners.

After defrosting of the front windshield direct the side outlets to the side glasses

of the doors as necessary and gradually

defrost them. After defrosting direct the

outlets in such a way that the air should

not be blown directly to the driver, but

down to the driver’s legs.

ACQUAINTANCE WITH TRACTOR

46

F13BN001

DASHBOARD

DEVICES DESCRIPTION

A - Indicators

B - Air pressure gauge

C - speedometer

F - fuel gauge

G - coolant thermometer

H - display

ACQUAINTANCE WITH TRACTOR

INDICATORS

1 - High beam lights (blue). Lights up

when high beam headlights are on.

2 - Tractor turn signal indicator (green)

3 - 1st trailer turn signal indicator (green)

4 - 2nd trailer turn signal indicator

(green)

5 - Indicator of minimum air pressure in

the brake system (red). Lights up if

the air pressure for the air brakes of

the trailer drops below the critical lim-

it, i.e. 450 kPa.

6 - Parking brake (red). Lights up when

the parking brake lever is in the “on”

position.

7 - Charging. During engine operation it

lights up in case of a charging failure.

If the engine is stopped, it must light

up. For more information see Electri-

cal installation chapter

8 - Lubrication (red). During engine op-

eration it light up if the engine oil

pressure drops below 120 to 60 kPa.

If the engine is stopped, it must light

up.

9 - Free

10 - Free

11 - Free

12 - Indicator of engagement of mul-

tiplier (green).

13 - Free

14 - Indicator of error signalization in the

system of hydrostatic steering (red)

47

With engine engaged lights up with

failure of hydrostatic steering. If engine is at standstill, it must be lit.

15 - Fuel (orange). It is lit with residue of

1/6 - 1/10 of tank volume.

16 - Indicator of PTO engagement (or-

ange) is not engaged.

17 - Engine glowing (yellow). Signals ac-

tivity of device for easing the start of

engine.

18 - Diesel particle filter control

(green) , for more see chap-

ter „Driving operation“

19 - Free

20 - Warning indicator (red). Lights up with

pressure drop under critical limit i.e.

450 kPa, with engaged parking brake,

with charging failure, with low pressure of oil in the engine or with brake

lining of the front brake wear off.

21 - Diesel particle filter control

(red), for more see “Driving

operation”

22 - Free

23 - Free

24 - Free

ACQUAINTANCE WITH TRACTOR

F13BN001

48

ACQUAINTANCE WITH TRACTOR

SELECTORS AND SWITCHES

After pressing the selected switch, the

applicable symbol and data is displayed

on the display.

25 - Battery voltage button: The voltage

value is displayed on the display

(with the resolution of 0.1 V).

26 - Button of the num ber of covered kil-

ometres (per day or since the last

reset). The number of kilometres is

shown on the display. The value can

be reset with long pressing of the

button.

27 - Button of immediate travel speed

in km.h-1, which is displayed on the

display.

28 - Free

29 - PTO button. T he rpm value with the

resolution of 10 rpm is shown on the

display.

Serves only for operation data

display

30 - The switch of hours of operation.

The information is displayed on the

display.

49

GETTING TO KNOW THE TRACTOR

F54e

DISPLAY OF PTO SPEED

By pressing the switch marked with the arrow, you will display the PTO speed in the

left and right parts of the display. It is a number of revolutions with engaged PTO

independent revolutions.

By pressing the buttons gradually, you will induced the number of PTO revolutions for

individual gears of PTO revolutions.

A - for 1000 revolutions

B - for 540 revolutions

C - for 540E revolutions

The button serves only for displaying data.

50

GETTING TO KNOW THE TRACTOR

SWITCHERS, SWITCHES AND LEVERS

a - Lights switcher (off, parking lights, headlamps).

b - Switcher of low beams in the mask of the tractor

and low beams on the cabin.

∗ Optionally this switch can control the lights on

the cabin independently on the lights in the

mask of the tractor (on/off).

c - Switch of the rear fog lamp (on/off). Function of

the fog lamp is indicated by the illuminated symbol on the switch.

d - Switch of the rear working headlamp on the col-

umn of the cabin (on/off). Function of the working

headlamp is indicated by the illuminated symbol

on the switch.

e - Switch of warning lights.

f - Switch of the front driving axle. Engaged front

driving axle is indicated by the illuminated symbol

on the switch.

g - Switch of the light beacon (on/off).

h - Switch of the working lights in the mask of the

tractor (on/off). Function of the working lights is

indicated by the illuminated symbol on the switch.

i - Blinded.

j - Pushbutton of lock of the differential.

k - Engine stopping device.

l - Combined switch of direction indicators, low and

E133

high beams and acoustic horn and flash lights.

m - Ignition box.

51

GETTING TO KNOW THE TRACTOR

E134 E135 E136

LIGHTS SWITCHER (A)

a - Lighting off.

b - Marker and tail and registration plate

lights and illumination of instruments

on.

c - All consumers on as in position “b“.

In addition to this, also low or high

beams are on (according to position

of the direction indicators, headlamps and flash lights switch).

SWITCH FOR SWITCHING OVER

LIGHTS IN THE MASK AND ON THE

ROOF (B)

a - Lights on the roof off.

b - Lights on the roof on.

The switch controls lights in the mask or

on the roof of the cabin. Use the lights on

the roof of the cabin only if some implements, covering the headlamps in the

mask, are installed in the front threepoint suspension. Lighting headlamps on

the roof of the cabin are indicated by the

illuminated symbol on the switch.

The high beams may only light in the

front mask of the tractor.

SWITCH OF WARNING LIGHTS (E)

a - Warning lights off.

b - Warning lights on.

Function of warning lights is indicated by

a flashing indicator on the dashboard.

52

GETTING TO KNOW THE TRACTOR

E137 E138 E139

FRONT DRIVING AXLE SWITCH (F)

Use the front driving axle with

slipping of rear wheels to increase the tractive force of the

tractor.

a - Front driving axle off.

b - Front driving axle on.

When the tractor is laid up (the tractor is

braked, key in the ignition box in position

off) the front driving axle is switched on.

The front driving axle is switched on in

the basic position (indicator is on) and

can be switched off by the same switch

(the indicator is off).

PUSHBUTTON OF REAR

DIFFERENTIAL LOCK (J)

Press the pushbutton to switch on the

lock; the pushbutton then returns to its

original position.

Switched on lock is indicated by the illuminated symbol on the pushbutton.

Depressing brake pedals switches off

automatically the differential lock.

COMBINED SWITCH OF INDICATOR

LIGHTS, LOW AND HIGH BEAMS AND

FLASH LIGHTS (K)

a - Acoustic horn (depress the switch in

direction of the axis

b - Low beams

c - Right direction indicators

d - Left direction indicators

e - Flash lights

f - High beams

53

GETTING TO KNOW THE TRACTOR

E140

IGNITION BOX

The ignition box is located on the dashboard, see the arrow.

KEY IN POSITION "0"

Voltage to all consumers, controlled

through the key, is disconnected. The key

can be removed.

54

E141 E142

KEY IN POSITION "I"

Voltage is connected to all consumers

except the starter. The key is in this position when the engine is running. The key

cannot be removed.

GETTING TO KNOW THE TRACTOR

E143 E144 X145b

KEY IN POSITION ”II”

The key is in this position when starting

the engine; voltage is connected to the

starter and all consumers except wipers,

washers, cabin fan and A/C equipment.

After start of the engine the key returns

automatically back to position ”I”.

LEVER OF MANUAL REFULATION OF

FUEL

A - Maximum speed of the engine

B - Idle run

The lever allows setting of speed of the

engine within range A to B.

55

CONTROL OF ENGINE STOP

Pulling up the control knob causes immediate stop of the engine and it slight

turning in pulled up position locks its position.

After the engine is stopped, turn back the

control knob to its original position.

The engine cannot be started if

the control knob remains pulled

up.

GETTING TO KNOW THE TRACTOR

G146 E147 G148

PEDALS

1. Travel clutch pedal

2. Foot brake pedals, connected with a

latch

3. Pedal of foot regulation of fuel supply

LEVER OF SHIFTING GEARS

- Main shifting lever

56

SCHEME OF SHIFTING OF GEARS

Reverse can be shifted only using the

reversing lever. The scheme is attached

in the left lower corner of the windscreen.

GETTING TO KNOW THE TRACTOR

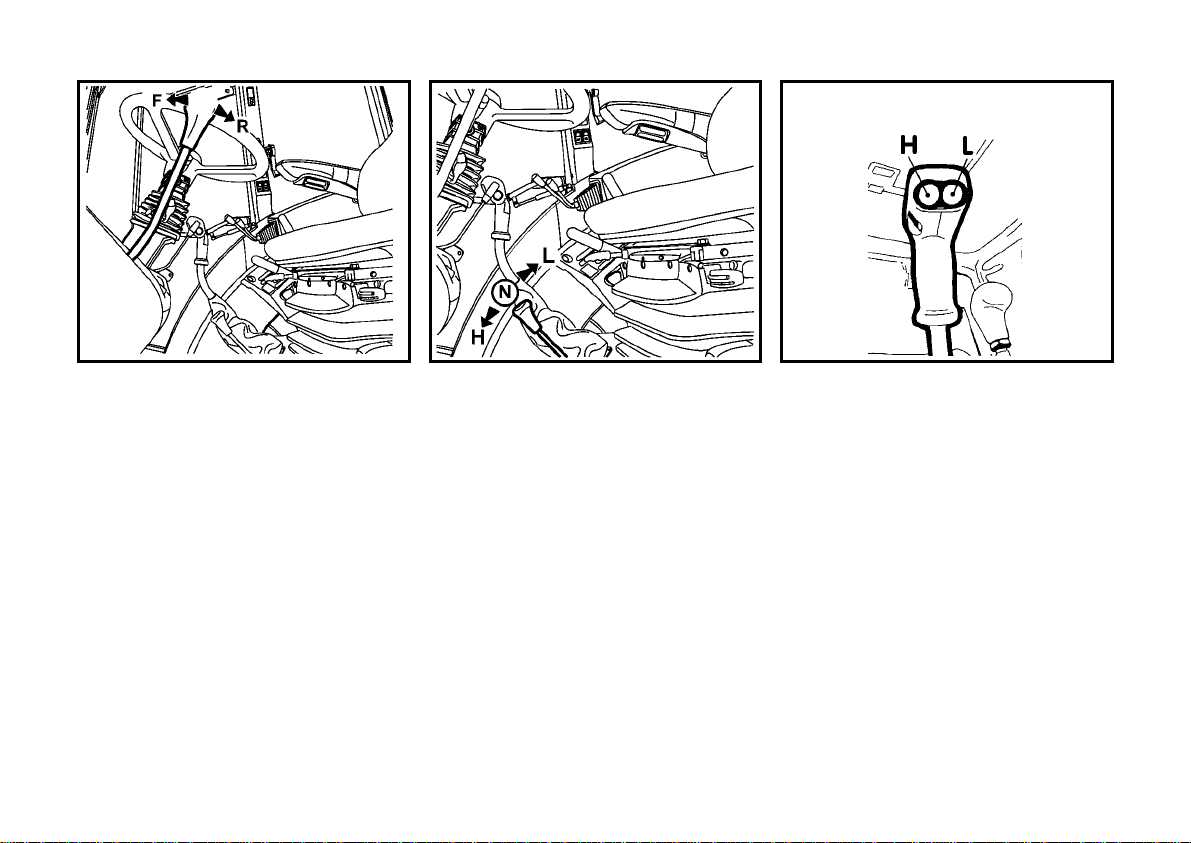

P+11NE149 G150 E151

REVERSING LEVER

F – Travel forwards; lever forwards

R – Travel backward; lever backward

LEVER OF SHIFTING OF ROAD AND

REDUCED GEARS

H

Road gears

N

Neutral

L

Reduced gears

Shifting is carried out with tractor in

standstill.

57

TORQUE MULTIPLIER

The multiplier is controlled electrohydraulically using the pushbuttons located on the shifting lever.

Activation (pushbutton L) is indicated by

illumination of the indicator on the dashboard.

GETTING TO KNOW THE TRACTOR

P+11NH127b G153

SWITCHING ON OUTPUT SHAFT

DRIVE

This drive can be switched on using

switches on the right column of the cabin.

LEVER OF SHIFTING OF SPEED 540

(OR 540E) AND 1,000 RPM OF THE

REAR OUTPUT SHAFT

Shifting can be carried out when the tractor is in standstill by pulling up or pushing

down the lever.

a - 1,000 min-1(or 540E min-1)

b - 540 min

-1

∗The tractor can be equipped optionally

by 6-, 8- or 21-groove termination of the

output shaft.

58

Shifting of 540 and 1,000 (or

540E) min

less to the number of grooves on

the installed termination. Speed

of the output shaft and type of the

termination shall be chosen depending on the prescribed speed

of the aggregated machine.

-1

is possible regard-

GETTING TO KNOW THE TRACTOR

G154 E155

LEVER OF SWITCHING ON REAR

OUTPUT SHAF DRIVE

Shifting can be carried out when the tractor is in standstill by pulling up or pushing

down the lever.

a -

Independent rpm of the output

shaft drive-

- Speed depends on speed of

the engine.

n -

Neutral

b -

Dependent speed of the output

shaft speed through a gearbox.

- Speed depends on the engaged gear.

LEVER OF HAND BRAKE AND HITCH

FOR SINGLE-AXLE TRAILER

1. Hand brake lever.

2. Lever of the single-axle trailer hitch

control.

59

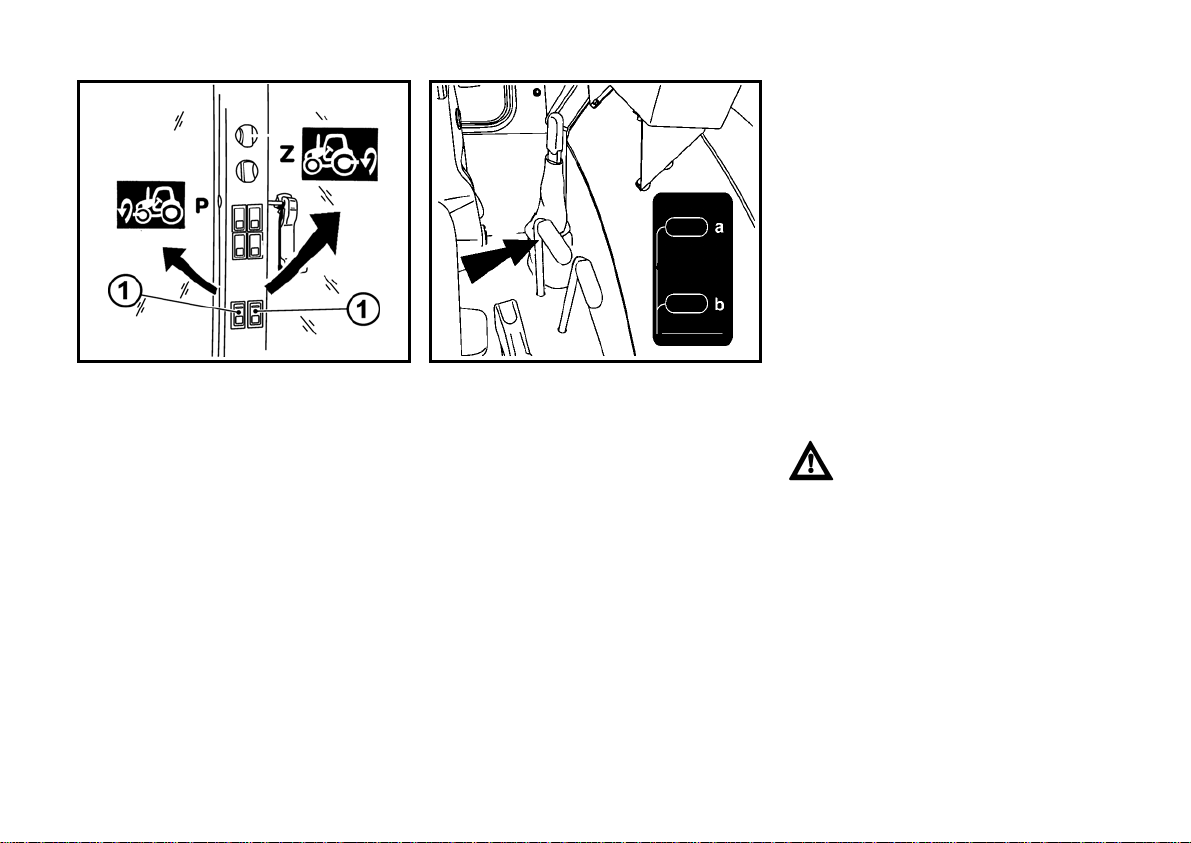

GETTING TO KNOW THE TRACTOR

E158 E159 E157

TRACTORS WITH TRAVEL SPEED

40 KM.H

All types of tractors with driven front axle

that includes brakes in reducers of front

wheel can be equipped with travel speed

40 km.h

-1

-1

.

FUEL TANK

The fuel tank is located on the right side

of the tractor. The volume of this plastic

tank is 150 litres.

Do not step onto the fuel tank!

DRAINING PLUG OF THE FUEL TANK

A plug for draining of dirt from the fuel

tank is installed in its bottom.

60

BATTERY DISCONNECTOR

Disconnect the battery immediately using the battery disconnector in case of a long-term standstill, repairs, fault or accident.

The battery disconnector is located on

the left side of the tractor, in front of the

cabin.

a - Battery connected

b - Battery disconnected

Before a drive with the new tractor get to know how to shift

gears and try individual positions

of the shifting lever when the

engine is stopped.

During normal operation and before you set up, make sure that

the technical condition ensures

safe operation of the tractor.

DRIVING

Page

Before you start the engine.......................................................................................63

Starting the engine.................................................................................................... 63

In case the engine does not start..............................................................................64

Indications of faults in the heating system.................................................................64

Manipulation with the starter.....................................................................................64

Immediately after starting..........................................................................................65

Warming-up of the engine.........................................................................................65

∗Heater of cooling fluid..............................................................................................66

Starting of the engine using heater of cooling fluid....................................................66

Diesel particle filter....................................................................................................67

Diesel particle filter – system failures signalization ................................................... 68

Diesel particle filter - failure codes ............................................................................68

Diesel particle filter - regeneration.............................................................................69

Shifting of gears........................................................................................................70

Reversing lever.........................................................................................................70

Shifting of road and reduced gears...........................................................................70

Shifting from lower to higher gear ............................................................................. 71

Shifting from higher to lower gear .............................................................................71

Torque multiplier .......................................................................................................72

Indication of function of the multiplier........................................................................ 72

Moving off..................................................................................................................73

Driving uphill..............................................................................................................74

Driving downhill.........................................................................................................74

Differential lock..........................................................................................................75

Control of front driving axle .......................................................................................75

Driving with engaged front driving axle .....................................................................75

Foot brakes...............................................................................................................76

Air brakes of trailers and semi-trailers.......................................................................76

Warning indication of air pressure drop.....................................................................76

Single-hose and double-hose brakes........................................................................77

Single-hose brakes ...................................................................................................77

Double-hose brakes.................................................................................................. 77

61

DRIVING

Page

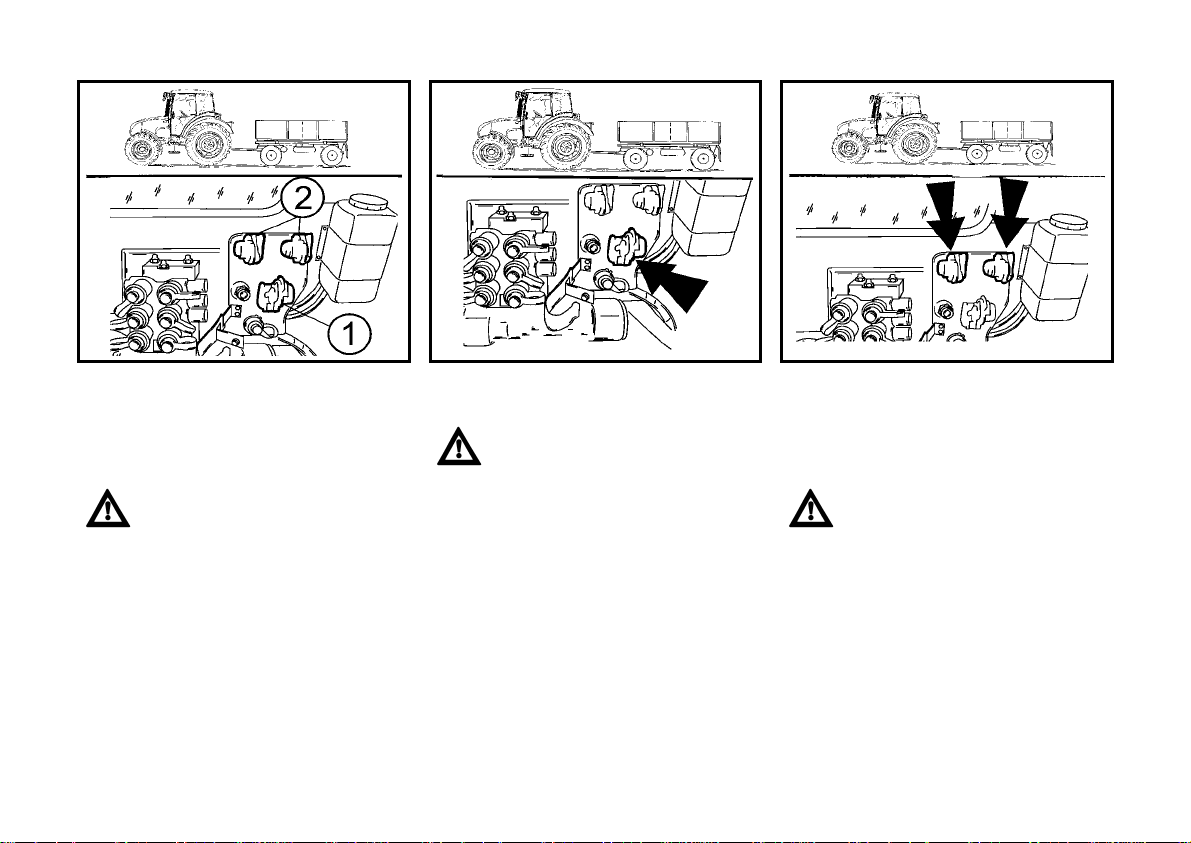

Trailer hydraulic brakes............................................................................................. 78

Connection and disconnection of quick couplings of the trailer hydraulic brakes...... 78

Stopping the tractor - hand brake.............................................................................. 79

Stopping the engine.................................................................................................. 79

Leaving the tractor.................................................................................................... 79

Warning indication of a hydrostatic steering fault...................................................... 80

Important warnings ................................................................................................... 80

62

DRIVING

G201

BEFORE YOU START THE ENGINE

Before you start the engine, make

sure:

1. If the tractor is properly

braked.

2. If the main shifting lever is in

neutral position.

Unless the clutch pedal is depressed, the

engine cannot be started, as the start

security switch is not closed.

Note: Before starting of the engine it is

advisable to pressurise the fuel system

by several strokes of the manual feeding

fuel pump.

P+11NG202

STARTING THE ENGINE

1. Put the key in ignition - ”0” position.

2. Depress the clutch pedal.

3. Move the gear lever to the neutral position.

4. Turn the key to “I“ position. The glow

plug indicator illuminates.

5. Wait till the glow plug indicator goes

out (the time depends on the temperature of the liquid coolant).

63

P+11NG203

If the glow plug indicator does not

illuminate but flashes, there is an

error of the ignition system (Ignition system error signals chapter). Have the error repaired in a

specialized service station.

6. When the indicator goes out, turn the

key immediately (do not wait for

longer than 5 sec. at maximum) to “II“

position (start).

7. After ignition, release the key immediately, it automatically turns back to ”I”

position. Do not extend th e starting

process to more than 15s.

8. After ignition, decrease the amount of

fuel gradually.

G204 G205 G206

IN CASE THE ENGINE DOES NOT

START

Turn the ignition key back to position ”0”,

wait for 30 seconds and repeat starting.

It is permitted to execute 6 starting cycles (15 sec starting and 30 sec pause).

Next starting of the engine is permitted

after the starter is cooled down to the

ambient temperature.

Never activate the starter if the

tractor is stopping. The starter

should be exposed to a risk of

damage.

DRIVING

INDICATIONS OF FAULTS IN THE

HEATING SYSTEM

A fault of the heating system is indicated

by a flashing indicator of heating.

- Flashing of the indicator in second intervals during standstill of the engine

indicates heating in an emergency regime as at low temperatures regardless to temperature of the cooling fluid.

- Flashing of the indicator two times per

second during standstill of the engine

indicates stopped (non-functioning)

heating.

- Permanent flashing of the indicator of

heating during run of the engine indicates a fault of the regulator of heating, whilst heating continues. The fault

shall immediately be eliminated to prevent discharge of the battery.

64

MANIPULATION WITH THE STARTER

It is forbidden to start the engine using short-circuited

starter terminals!

The tractor can only be started

from the driver’s seat!

With any manipulation of repair of

the starter it is necessary to

disconnect the minus pole of the

battery and move all levers including shifting of the output shaft

to neutral position! The starter

contacts are protected by caps.

DRIVING

G207

IMMEDIATELY AFTER STARTING

After starting of the engine adjust

speed to 800-1000 min

the engine running without loading for approx. 2 minutes.

In this period perform checks of lubrication and recharging of the battery (the

indicator shall be off) and other functions

providing proper run of the engine. The

time of run without loading shall be observed, particularly in winter period.

-1

and let

WARMING-UP OF THE ENGINE

Further warming-up of the engine should be performed during driving.

Warming-up of the engine using long idle run or sudden increase of speed is

harmful for the engine.

Unless temperature of cooling fluid reaches 45 °C, do not exceed speed of

the engine 2000 min

-1

.

65

G208

DRIVING

E209 E210a

∗HEATER OF COOLING FLUID

It is installed on the right side of the engine block.

Power: 1000W

Voltage: 220V

STARTING OF THE ENGINE USING HEATER OF COOLING FLUID

Heating of cooling fluid facilitates starting of the engine at low temperatures. Power

supply installation and its protection against dangerous contact shall be made according to the applicable regulations.

1. First insert the plug into the heater.

2. Then connect the heater to the power supply mains with voltage 220V.