Tractor is Zetor. Since 1946.

PROXIMA GP

80

OPERATOR´S MANUAL

07/2017

90

ZETOR

This Operator’s Manual for the Zetor tractors, which we are presenting to you will help you to

become familiar with the operation and maintenance of your new tractor.

Although many of you have rich experience with the operation of other tractors, please, read the

information contained in this Operator’s Manual very carefully.

In the Manual you will find a lot of new information and get a perfect overview of how to use the

tractor with maximum efficiency during various kinds of work.

If you observe the rules of tractor operation and maintenance and driving safety, your new tractor will

become your reliable and long-term friend.

The manufacturer of the tractor wishes you thousands of hours of satisfactory work.

ZETOR

Brno

The technical specifications and information about the design, equipment, material and appeara nce are valid at the time

of print. The manufacturer reserves the right to implement changes.

The instructions for use are a part of the machine.

1

2

Location of serial numbers .............................................................................................................................. 9

Safety instructions for users ......................................................................................................................... 11

General safety regulations ........................................................................................................................... 11

Proper clothing ............................................................................................................................................ 11

Starting the engine ..................................................................................................................................... 12

Driving operation ......................................................................................................................................... 12

Transportation of persons, operation .......................................................................................................... 12

Fire prevention principles ............................................................................................................................ 13

Preventive daily maintenance...................................................................................................................... 14

Driver's seat ................................................................................................................................................. 15

Front passenger´s seat notification ............................................................................................................. 15

Protection of cab against aerosols .............................................................................................................. 16

The level of external noise of tractor ........................................................................................................... 16

The level of internal sound of tractor ........................................................................................................... 16

The level of vibrations on driver´s seat ........................................................................................................ 17

Aggregation tractor - machine/trailer ........................................................................................................... 17

Tractors equipped with front end loader ...................................................................................................... 17

Principles for operating tractors equipped with front end loader ................................................................. 18

Zetor tractors used for work in the woods ................................................................................................... 19

Safety labels ................................................................................................................................................ 19

Preventive daily service ................................................................................................................................. 21

Preventive daily maintenance...................................................................................................................... 21

Fuel system leaks ........................................................................................................................................ 21

Engine oil level ............................................................................................................................................ 21

Cooling system ............................................................................................................................................ 21

Liquid brakes ................................................................................................................. .............................. 22

Trailer brakes ............................................................................................................................................... 22

Hydrostatic steering ..................................................................................................................................... 22

Air cleaner ................................................................................................................................................... 23

Cab filtration ................................................................................................................................................ 23

Hitches ......................................................................................................................................................... 23

After work with front implements and in case of cooler clogging ............................................................... 23

Tyres and wheels ........................................................................................................................................ 24

Short functional test .................................................................................................................................... 24

Getting to know the tractor ............................................................................................................................ 25

Safety cab .................................................................................................................................................... 25

Openi

ng doors from the outside .................................................................................................................. 25

Opening the

door from the inside ................................................................................................................ 25

Rear window ................................................................................................................................................ 26

Side window ................................................................................................................................................ 26

Right rear panel ........................................................................................................................................... 26

Rear view mirrors ........................................................................................................................................ 27

Sun screen................................................................................................................................................... 27

Internal lighting ............................................................................................................................................ 27

Washer nozzle ............................................................................................................................................. 28

Windshield washer tank .............................................................................................................................. 28

Washer control ............................................................................................................................................ 28

Passenger´s seat ......................................................................................................................................... 29

Driver's seat Mars Svratka .......................................................................................................................... 30

Driver's seat Sears ...................................................................................................................................... 31

Driver´s seat ................................................................................................................................................ 31

Tilt steering wheel ........................................................................................................................................ 32

Tilting and protrusion of steering wheel ....................................................................................................... 32

*Air filter with active carbon ......................................................................................................................... 33

Heating control panel, * air-condition .......................................................................................................... 33

Heating valve control (A) ............................................................................................................................. 34

Switch air-condition (C) ............................................................................................................................... 34

Air circulation in cabin control (D) ................................................................................................................ 34

Proper function of the heating and air-condition system ............................................................................. 35

Fast heating of the cabin area ..................................................................................................................... 35

Fast cooling of the space of the cabin ......................................................................................................... 35

Operation of heating or air-condition with tractor´s work ............................................................................. 36

Immediately after cooling the cabin ............................................................................................................. 36

CONTENTS

3

Air-condition and heating registers (A) ........................................................................................................ 37

Front windshield (B) defrosting .................................................................................................................... 37

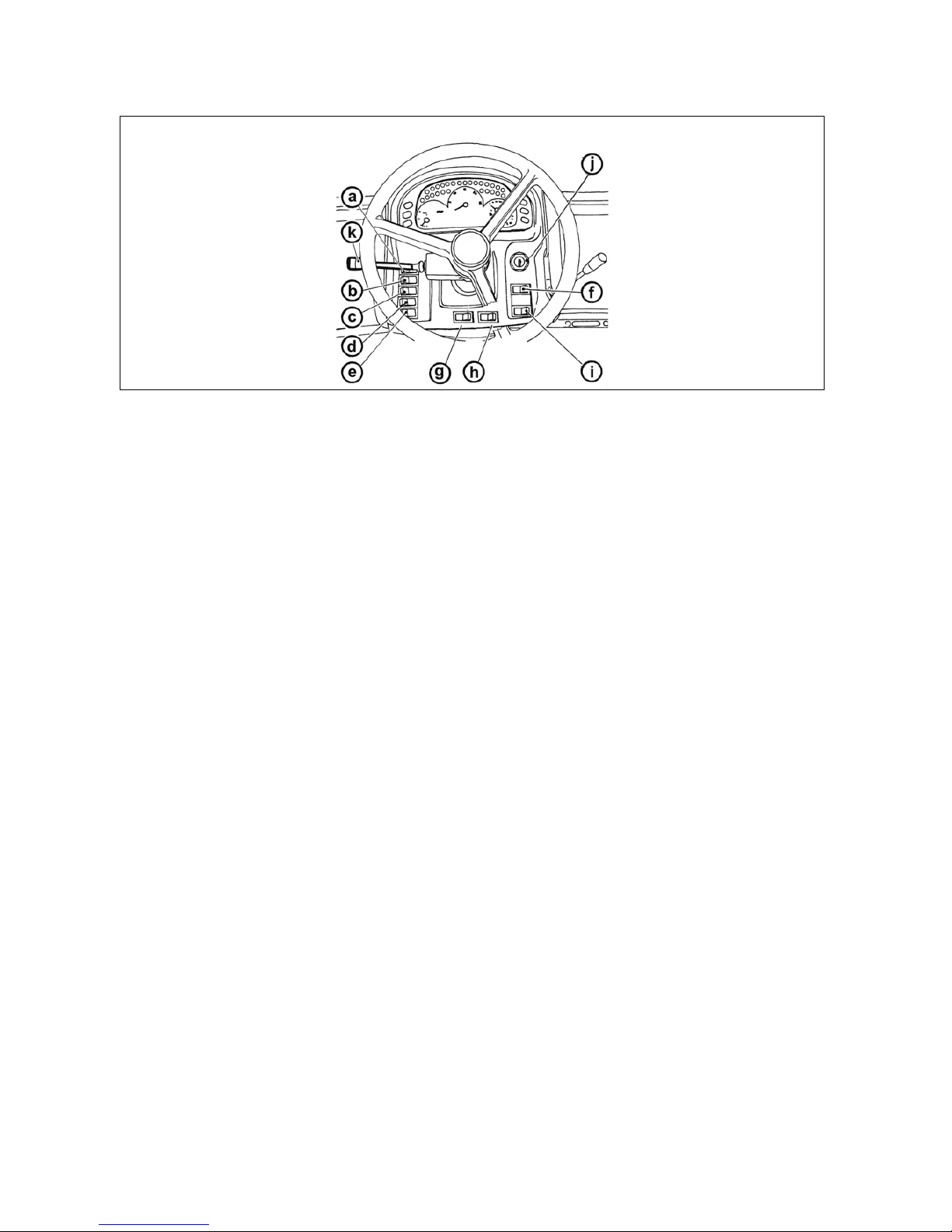

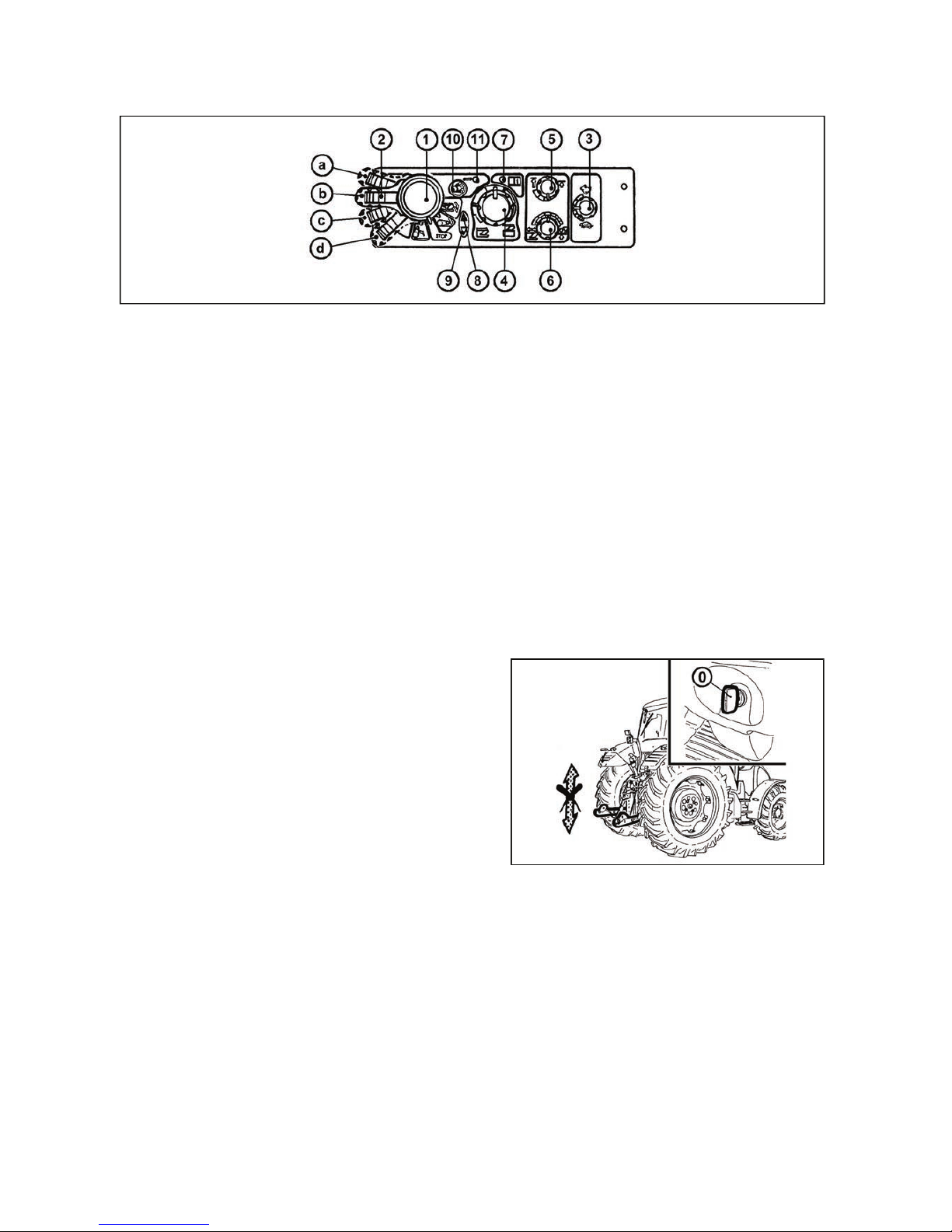

Control panel on right cab pillar ................................................................................................................... 38

Dashboard ................................................................................................................................................... 40

Display of PTO speed .................................................................................................................................. 41

Panel of the instrument panel ...................................................................................................................... 42

Lights switch ................................................................................................................................................ 43

Switch of warning lights ............................................................................................................................... 43

Lights switch between the grill and the cabin .............................................................................................. 43

Direction lights, lower beam head lights, head lights and horn switches .................................................... 44

Front wheel drive switch .............................................................................................................................. 44

Push button of rear, front differential locks .................................................................................................. 44

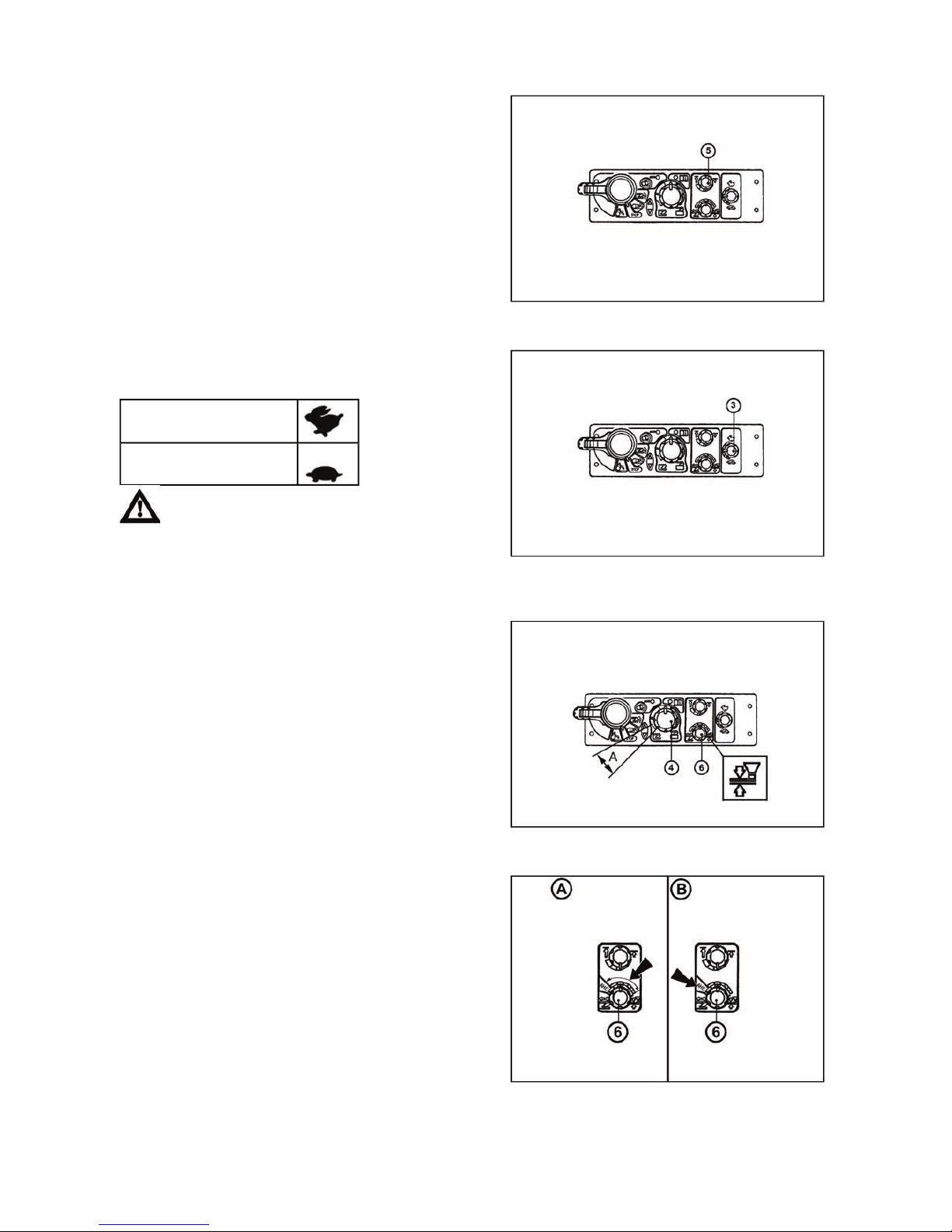

Switch box ................................................................................................................................................... 45

Switch box key in the position (0) ................................................................................................................ 45

Switch box key in the position (I) ................................................................................................................. 45

Switch box key in the position (II) ................................................................................................................ 45

Manual throttle ............................................................................................................................................. 46

Pedals and levers ........................................................................................................................................ 46

Gear shifting lever ....................................................................................................................................... 46

Gear shifting scheme ................................................................................................................................... 46

Reversing lever ............................................................................................................................................ 47

Road and reduced speeds shifting lever ..................................................................................................... 47

Torque multiplier .......................................................................................................................................... 47

Switching on output shaft drive ................................................................................................................... 47

Lever of shifting of speed 540 (or 540E) and 1,000 rpm of the rear output shaft ....................................... 48

PTO selection control lever ......................................................................................................................... 48

Lever of hand brake and hitch for single-axle trailer ................................................................................... 48

Battery disconnector .................................................................................................................................... 49

Fuel tank ...................................................................................................................................................... 49

Fuel tank drain plug ..................................................................................................................................... 49

Driving.............................................................................................................................................................. 51

Before you start the engine ......................................................................................................................... 51

Starting the engine ...................................................................................................................................... 51

If engine does not start

................................................................................................................................ 52

Ignition syst

em failure signalization ............................................................................................................. 52

Manipulation with starter .............................................................................................................................. 52

Immediately after start ................................................................................................................................. 52

Engine heating ............................................................................................................................................. 53

*Coolant heater ............................................................................................................................................ 53

Starting the engine while using coolant heater............................................................................................ 54

Drive away ................................................................................................................................................... 54

Diesel particle filter ...................................................................................................................................... 55

Diesel particle filter - system failures signalization ...................................................................................... 55

Diesel particle filter failure codes ................................................................................................................. 56

Diesel particle filter regeneration ................................................................................................................. 56

Gear shifting ................................................................................................................................................ 57

Shifting road and reduced speeds ............................................................................................................... 57

Reversing lever ............................................................................................................................................ 57

Torque multiplier .......................................................................................................................................... 58

Indication of function of the multiplier .......................................................................................................... 58

Gear shifting from lower to higher gears ..................................................................................................... 58

Gear shifting from higher to lower gears ..................................................................................................... 58

Travelling up the slope ................................................................................................................................ 59

Travelling down the slope ............................................................................................................................ 59

Differential lock ............................................................................................................................................ 59

Control of front driving axle .......................................................................................................................... 60

Driving with engaged front driving axle ....................................................................................................... 60

Foot brakes .................................................................................................................................................. 60

Air brakes of trailers and semi-trailers ......................................................................................................... 61

Warning indication of air pressure drop ....................................................................................................... 61

One-hose and two-hose brakes .................................................................................................. ................ 61

One-hose brakes ......................................................................................................................................... 61

Two-hose brakes ......................................................................................................................................... 62

CONTENTS

4

Hydraulic brakes of trailers .......................................................................................................................... 62

Connecting and disconnecting quick couplings of trailer hydraulic brakes ................................................. 62

Stopping the tractor - manual brake ............................................................................................................ 63

Stopping the engine ..................................................................................................................................... 63

Leaving the tractor ....................................................................................................................................... 63

Warning signalization of hydrostatic steering failure ................................................................................... 64

Important warnings ...................................................................................................................................... 64

Running-in the tractor .................................................................................................................................... 65

General principles of new tractor run-in in first 100 hours of operation ...................................................... 65

In first 10 hours of operation ........................................................................................................................ 65

From 100 hours of operation ....................................................................................................................... 65

Drive of farming machines ............................................................................................................................ 67

Work with PTO shaft .................................................................................................................................... 67

Front and rear PTO shaft control ................................................................................................................. 67

Replaceable end points of rear PTO shaft .................................................................................................. 68

Facilitating connection of joint shaft of an aggregated machine to the tractor ............................................ 68

Front PTO shaft ........................................................................................................................................... 69

Maximum transferred output ........................................................................................................................ 69

Drive of machines with greater inertia masses ............................................................................................ 69

Transport use .................................................................................................................................................. 71

Front hook.................................................................................................................................................... 71

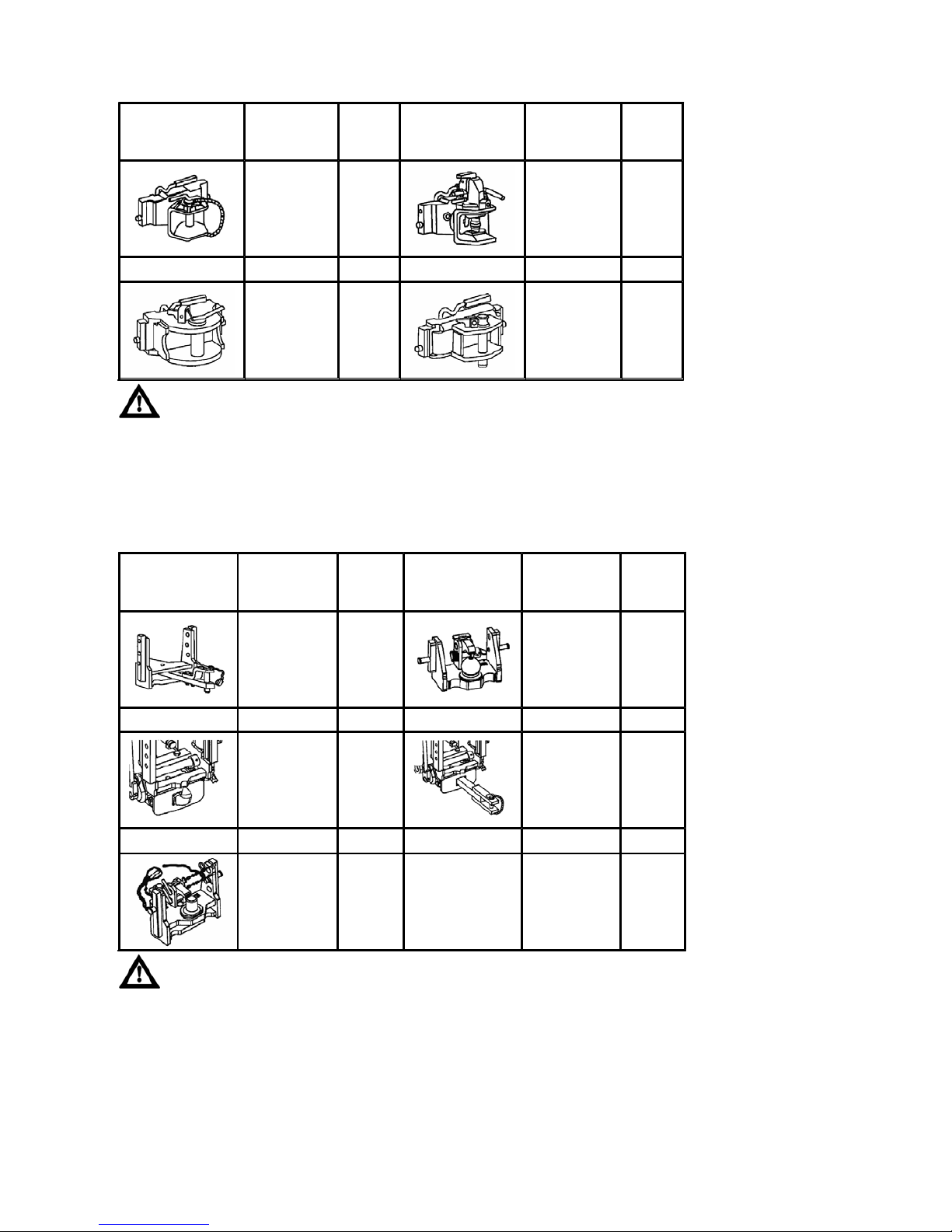

Multistage adjustable suspension ............................................................................................................... 71

Height adjustment and disassembly of the CBM stage hitch ...................................................................... 71

Automatic mouth of the CBM stage hitch .................................................................................................... 72

Modular system of hitches for trailers and semi-trailers .............................................................................. 72

Swinging draw-bar console module ............................................................................................................ 72

Swinging draw-bar console with a fixed pin module ................................................................................... 72

Console with a ø 80 ball module ................................................................................................................. 73

Towing bar ................................................................................................................................................... 73

Hitch for a single-axle CBM semi-trailer ...................................................................................................... 73

Coupling of a single-axle trailer ................................................................................................................... 73

Uncoupling of a single-axle trailer

............................................................................................................... 74

Hook of the mounting for a single-axle trailer .............................................................................................. 74

Coupling with a trailer or

semi-trailer ........................................................................................................... 74

Hydraulic system ............................................................................................................................................ 77

Hydraulic system ......................................................................................................................................... 77

Hydraulics control panel .............................................................................................................................. 77

Amount of oil taken from outer hydraulic drives .......................................................................................... 78

Connecting and disconnecting quick-couplers ............................................................................................ 78

Quick-couplings with drip collection ............................................................................................................ 78

Connecting machines and tools to External hydraulic circuit ...................................................................... 79

Front outlets of the external hydraulic circuit ............................................................................................... 79

Control of the external hydraulic circuit front outlets ................................................................................... 80

Mechanical hydraulics ................................................................................................................................... 81

Ways to regulate inner hydraulic circuit ....................................................................................................... 81

Controlling the inner hydraulic circuit .......................................................................................................... 81

Free (floating) position ................................................................................................................................. 82

Adjustable stop ............................................................................................................................................ 82

Three-point hitch lowering speed control .................................................................................................... 82

Hydraulic system sensitivity control ............................................................................................................. 83

Position regulation of the lifting of the rear three-point hitch ....................................................................... 83

Power regulation of the lifting of the rear three-point hitch .......................................................................... 84

Mixed regulation of lifting the rear three-point hitch .................................................................................... 84

Exterior rear hydraulic arms controls ........................................................................................................... 85

Outer hydraulic circuit .................................................................................................................................. 85

Outer hydraulic circuit controls .................................................................................................................... 86

Locking control levers .................................................................................................................................. 86

Different functions of outer hydraulic circuit control levers .......................................................................... 87

Electro-hydraulic system ............................................................................................................................... 89

Control element functions ............................................................................................................................ 89

Equipment 'OFF' .......................................................................................................................................... 89

Blocking cancellation ................................................................................................................................... 90

Quick sinking ............................................................................................................................................... 90

CONTENTS

5

Transport of implements .............................................................................................................................. 91

Stop position ................................................................................................................................................ 91

Vibration compensator (damper) ................................................................................................................. 91

Limitation of the upper position of the three-point hitch .............................................................................. 92

Lowering speed ........................................................................................................................................... 92

Free position ................................................................................................................................................ 92

Setting the control of three-point hitch ......................................................................................................... 92

Manual setting of control of three-point hitch .............................................................................................. 93

Automatic control of three-point hitch .......................................................................................................... 93

Using the rear control .................................................................................................................................. 94

External control buttons of the electro-hydraulic system ............................................................................. 94

Indication of EHR-B errors ........................................................................................................................... 95

Description of minor errors of the EHR-B electro-hydraulic system ............................................................ 96

Outer hydraulic circuit .................................................................................................................................. 96

Outer hydraulic circuit controls .................................................................................................................... 97

Locking control levers .................................................................................................................................. 97

Different functions of outer hydraulic circuit control levers .......................................................................... 98

Hitches ........................................................................................................................................................... 101

Rear three-point hitch ................................................................................................................................ 101

Safety principles of working with the three-point hitch .............................................................................. 101

Height adjustment of the lifting draw-bars ................................................................................................. 102

Fixed and free position of the lower hydraulic draw-bars .......................................................................... 102

Limiting draw-bars ..................................................................................................................................... 102

Upper pull rod ............................................................................................................................................ 103

Selection of holes in the bracket ............................................................................................................... 103

*Lower draw bar with slipping out end pieces ........................................................................................... 103

*Lower draw bar with CBM hooks ............................................................................................................. 104

Securing lower draw bars with CBM hooks ............................................................................................... 104

*Front three-point hitch .............................................................................................................................. 104

Controlling front three-point hitch .............................................................................................................. 105

Adjus

ting the lowering rate of the front three-point hitch ........................................................................... 105

Hydraulic lock of the front three-point hitch ............................................................................................... 105

Working and transport position of the front three-point hitch .................................................................... 106

Driving with agricultural machines attached to the front three-point hitch ................................................. 106

Change of wheels tread ............................................................................................................................... 107

Change of front wheels track with front drive axle..................................................................................... 107

Gauges of the front wheels of the front drive axle of the tractors equipped with screwed footer discs .... 107

Possible adjustable tracks of the front wheels of the front driving axle of the tractors .............................. 107

Front wheels track of front drive axle in tractors equipped with non-removable discs .............................. 108

Front wheels toe-in .................................................................................................................................... 108

Adjustment of toe-in of the wheels of the front driving axle ....................................................................... 109

Setting wheel stops with front drive axle ................................................................................................... 109

Front drive axle fenders ............................................................................................................................. 110

Rear wheels wheel track ........................................................................................................................... 110

Gauges of the tractor rear wheels equipped with screwed footer discs .................................................... 110

Rear wheel track change ........................................................................................................................... 111

The gauges of the tractor rear wheels equipped with solid discs .............................................................. 111

Additional weights ........................................................................................................................................ 113

Weights in front of the bonnet mask .......................................................................................................... 113

Weights of the front three-point hitch ........................................................................................................ 113

Weights of rear wheels .............................................................................................................................. 113

Valve for filling tyre tubes with liquid ......................................................................................................... 114

Chocking of front wheels ........................................................................................................................... 114

Procedure of filling the tyres with liqui

d ..................................................................................................... 114

Procedure of draini

ng liquid from the tyres ................................................................................................ 115

Antifreeze solution for tyre filling ............................................................................................................... 115

Electric installation ....................................................................................................................................... 117

Basic service information ........................................................................................................................... 117

Accumulator battery ................................................................................................................................... 117

Accumulator battery maintenance ............................................................................................................. 118

Alternator ................................................................................................................................................... 118

Alternator maintenance ............................................................................................................................. 119

Charging control ........................................................................................................................................ 119

CONTENTS

6

Fuse box .................................................................................................................................................... 119

Lay out of fuses in the fuse box ................................................................................................................. 120

Checking the adjustment of the front grill headlights ................................................................................ 121

Adjusting the front grill headlights ............................................................................................................. 121

Checking the adjustment of the cab roof headlights ................................................................................. 122

List of lamps .............................................................................................................................................. 122

Tractor maintenance .................................................................................................................................... 123

Service inspections .................................................................................................................................... 123

Steps performed daily before the start of work .......................................................................................... 123

Steps performed every 50 hours of work .................................................................................................. 123

Steps performed every 100 hours of work ................................................................................................ 123

Steps performed every 500 hours of work ................................................................................................ 123

Steps performed outside the interval of 500 hours of work ....................................................................... 124

Monthly performed actions ........................................................................................................................ 124

Filling and filter replacement...................................................................................................................... 124

Fuels, coolants and lubricants used - amounts ......................................................................................... 125

ZETOR service fillings ............................................................................................................................... 125

Oils for Zetor engines which are equipped with diesel particle filter ......................................................... 125

Oil to gear systems of tractors ................................................................................................................... 125

Oil for the front driving axle ........................................................................................................................ 125

Oil for the hydrostatic steering of the tractors ............................................................................................ 125

Specification of oils for Zetor engines equipped by diesel particle filter .................................................... 126

Specification of oil for tractor transmission devices .................................................................................. 126

Specification of oil for the front driving axle ............................................................................................... 126

Specification of oil for the tractor hydrost

atic control system .................................................................... 126

Other recommended service fillings tested on Zetor tractors .................................................................... 126

Oils for Zetor engines which are equipped with diesel particle filter ......................................................... 126

Oils for tractor transmission gearing .......................................................................................................... 127

Front PTO oil ............................................................................................................................................. 127

Oil for the front driving axle ........................................................................................................................ 128

Oil for the hydrostatic steering of the tractors ............................................................................................ 128

Plastic lubricant for the tractor ................................................................................................................... 128

Hydraulic brake liquid for the tractors ........................................................................................................ 129

Liquid for the cooling system of the tractors .............................................................................................. 129

Fuel for Zetor engines which are equipped with diesel paricle filter .......................................................... 129

Tractor greasing plan ................................................................................................................................. 130

Safety instructions for lubrication of the tractor ......................................................................................... 130

Solid front drive axle .................................................................................................................................. 130

Hitch for a single-axle semi-trailer ............................................................................................................. 130

Front three-point hitch ............................................................................................................................... 130

Three-point hitch ........................................................................................................................................ 131

Hitch mouth for a trailer ............................................................................................................................. 131

Upper linkage bracket ................................................................................................................................ 131

Pin of coupling switching off ...................................................................................................................... 132

Reversion lever pin .................................................................................................................................... 132

Technical maintenance of the tractors after a general overhaul of the main groups ............................... 132

Maintenance instructions ............................................................................................................................ 133

Front bonnet openi

ng ................................................................................................................................ 133

Checking oil levels in engine

..................................................................................................................... 133

Draining oil from engine ............................................................................................................................. 133

Replacing full-continuous motor oil filter .................................................................................................... 134

Pouring oil to engine .................................................................................................................................. 134

Fuel filter element replacement ................................................................................................................. 134

Fuel system venting ................................................................................................................................... 134

Dry air filter maintenance - pollution indicator ........................................................................................... 135

Contamination indicator function ............................................................................................................... 135

Maintenance instruction of dry air filter ...................................................................................................... 135

Main air filter element regeneration ........................................................................................................... 136

Replacing dry filter locking element ........................................................................................................... 136

Back assembly of air filter elements .......................................................................................................... 136

Checking amount of oil in hydrostatic steering tank .................................................................................. 136

Replacing oil and hydrostatic steering filter element ................................................................................. 137

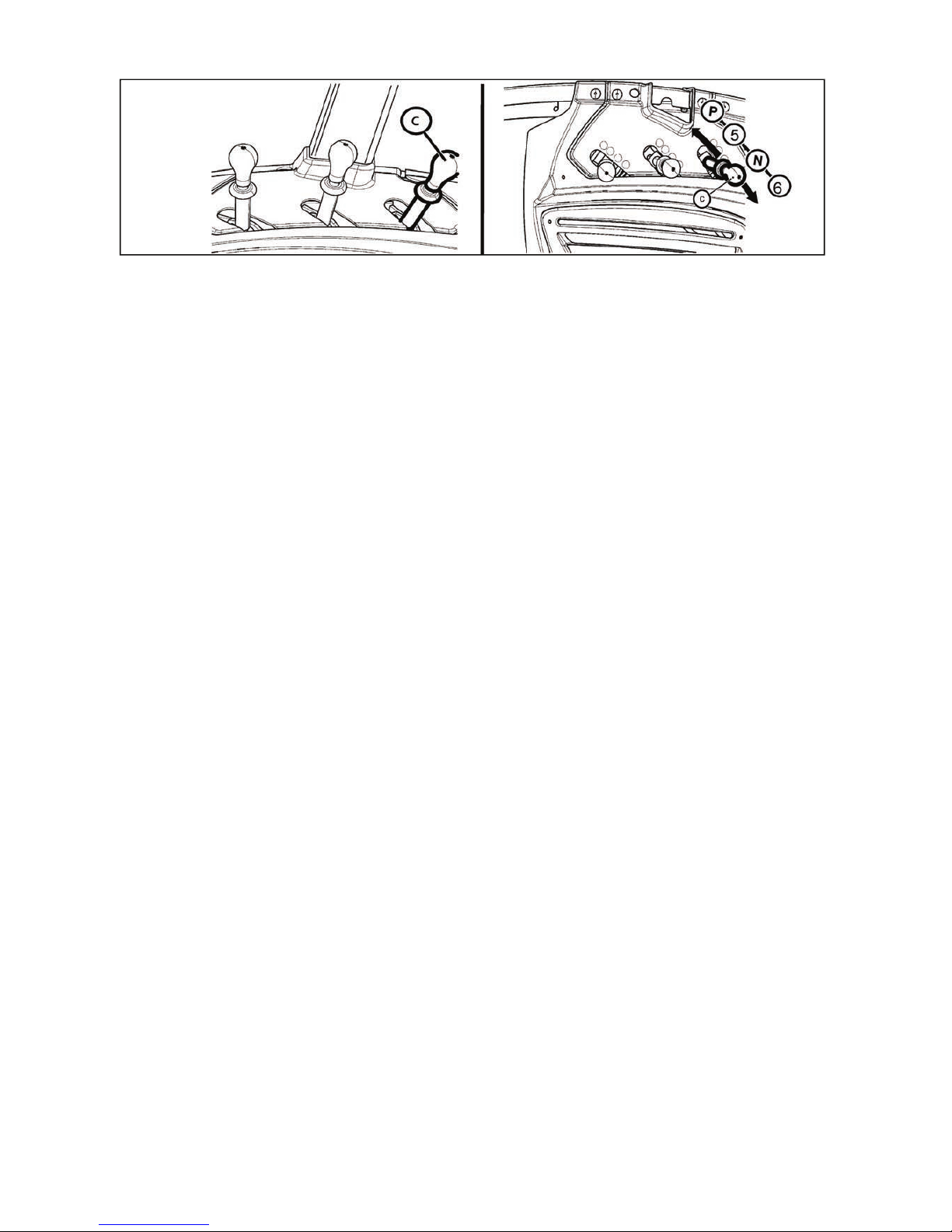

Venting hydraulic circuit of hydrostatic steering ........................................................................................ 138

CONTENTS

7

Replacing the hoses of hydrostatic steering .............................................................................................. 139

Replacing coolant ..................................................................................................................................... 139

Check and replacement of oil in gearbox, axle drive and rear axle portals .............................................. 139

Drainage and inspection holes .................................................................................................................. 140

Changing suction filter ............................................................................................................................... 140

Replacement of the transmission oil cleaner element with hydraulic pump suction filter ........................ 141

Front PTO ................................................................................................................................................. 141

Filling, controlling and draining hole of oil of front drive axle ..................................................................... 142

Filling, controlling and draining hole of oil of front wheels reducers .......................................................... 142

Brake fluid replacement ............................................................................................................................. 142

Cleaning the heating filters ........................................................................................................................ 143

Air filter with active carbon ........................................................................................................................ 143

Carbon filter installation instructions .......................................................................................................... 143

Air-conditioning maintenance ................................................................................................................... 144

Draining condensate from the air reservoir .............................................................................................. 144

Checking the air systems for leaks ........................................................................................................... 144

Working pressure of air brakes ................................................................................................................ 145

Maintenance and treatment of tyres ......................................................................................................... 145

Storing the tractor ...................................................................................................................................... 145

Diesel particle filter maintenance ............................................................................................................. 145

Gearbox distributor - replacement of oil cleaner cartridge ........................................................................ 146

Adjustments .................................................................................................................................................. 147

Cogged belt tension ................................................................................................................................... 147

Bleeding of tractor brake system ............................................................................................................... 147

1. Bleeding of pressure air brake system for trailers ................................................................................. 148

2. Bleeding of rear wheel brakes ............................................................................................................... 148

3. Bleeding of the brake system of front driving axle ................................................................................ 149

4. Bleeding the hydraulic brakes of a trailer .............................................................................................. 149

Check and adjustment of service and parking brakes .............................................................................. 150

Service brake adjustment .......................................................................................................................... 150

Parking brake adjustment .......................................................................................................................... 151

Adjustment of free travel of brake pedals .................................................................................................. 152

Adjustment of free travel of clutch pedal ................................................................................................... 152

Bleeding of hydraulic clutch circuit ............................................................................................................ 152

Engine travel clutch adjustment ................................................................................................................ 153

Adjustment of hitch for single-axle trailers ................................................................................................. 153

Adjustment of bowden cable ..................................................................................................................... 153

Calibration of travel speed of digital dashboard ........................................................................................ 154

Main technical parameters .......................................................................................................................... 155

Main tractor's parameters (mm) ................................................................................................................ 155

Technical specifications of engines of tractors Proxima (Stage III B 16V) ................................................ 156

Permitted maximum load of front axle (kg) ................................................................................................ 157

Permitted maximum load of rear axle (kg) ................................................................................................ 157

Permitted maximum weight of vehicle set 'tractor + mechanism' (kg) ...................................................... 157

Condition of steerage ................................................................................................................................ 157

Loading capacity of front tyres .................................................................................................................. 158

Change of the load-bearing capacity of the front tyres (%) ....................................................................... 158

Loading capacity of rear tyres ................................................................................................................... 159

Change of the load capacity of the rear tyres (%) ..................................................................................... 161

Permitted combinations of wheel

s for tractors .......................................................................................... 161

Power ......................................................................................................................................................... 161

Lifting forc eof three-point hitch ................................................................................................................. 161

Tensile force .............................................................................................................................................. 161

Forward travel speed of the tractor - 30 km/h ........................................................................................... 162

Backward travel speed of the tractor - 30 km/h ......................................................................................... 163

Forward travel speed of the tractor - 40 km/h ........................................................................................... 164

Backward travel speed of the tractor - 40 km/h ......................................................................................... 165

Rear independent PTO shaft rotation ........................................................................................................ 166

Speed of front output shaft ........................................................................................................................ 166

Outer contour and track wheeling diamater .............................................................................................. 166

Calculation of tractor load limit .................................................................................................................. 167

Index ............................................................................................................................................................... 171

CONTENTS

8

P15N069

1. Tract

or data plate

2. Cab serial number

3. Engine serial number

4. Tractor serial number

When ordering spare parts and within all written and oral communication always specify the data of your

tractor that should be written in the frames below.

Tractor type

Tractor serial number

Engine serial number

LOCATION OF SERIAL NUMBERS

9

The 'right', 'left', 'front' and 'back' indications refer to the

drivin

g direction of the tractor.

G3

LOCATION OF SERIAL NUMBERS

10

Please, pay increased attention to the parts of the Operator´s Manual that are marked with this

symbol.

This s

ymbol accompanies all important warnings that concern operation safety. Observe these

instructions and be extremely careful in these cases! Inform your colleagues and other users about these

warnings.

Carefully study the chapters marked with this symbol before starting to perform operation, repairs and

adjustm

ents of your tractor.

This symbol identifies all important information concerning operation, adjustment and repairs of the

starter motor. Observe these instructions and be extremely careful in these cases!

This symbol marks parts of the Operator´s Manual concerning environment protection. Or possibly

sections describing handling of dangerous waste.

∗

This sym

bol refers to optional tractor accessories installed by the manufacturer on the customer´s

request.

Instruction manual´s passages related only to models equipped with DPF (diesel particle filter) are

labelled with this symbol.

Accessories that are not installed by the manufacturer in the standard way or * optionally on

the customer´s request (in the production plant) cannot be subject to a claim.

General safety regulations

The tractor may only be operated by a trained person that has a valid driving licence and has been

thoroughly acquainted with the operation and safety rules.

Besides the safety instructions mentioned in the Operator´s Manual you are obliged to respect

generally valid safety and traffic rules of the country where the tractor is used.

Proper clothing

Do not wear loose clothing and free flying long hair.

During all work use suitable (prescribed) means of personal protection (working boots, gloves,

goggles, etc.)

SAFETY INSTRUCTIONS FOR USERS

11

Starting the engine

Only start the engine from the driver´s seat with the clutch pedal fully depressed.

Life

hazard when starting by means of short-circuiting the starter terminals!

The key in the switch box must be in the 'I' position.

When heating the engine with the * electric heater first plug the power supply cord to the heater and

only then to the electric mains. After the end of heating first disconnect the heater from the electric

mains.

Starting the engine when driving tractor downhill is forbidden.

Starting tractor by means of towing with another tractor or vehicle is allowed only when the pull bar is

used.

Driving operation

Hoses of the hydrostatic steering, brakes and fuel system must be checked and replaced immediately

if any signs of damage are found. These are some examples of hose damage signs: - cracks on the

hose surface, releasing of pretensioning of hose connection (which can be verified by easy removal of

the hose from the connection) and mechanical damage of the hose. Hoses with indicated service life

must be replaced immediately after the expiration of the service period.

The brakes and steering must be in the perfect condition all the time.

During driving on roads with trailers and tools the brake pedals must be connected with a latch.

Driving downhill without an engaged gear is forbidden.

Pay special attention when driving on a slope and muddy, sandy, icy or uneven ground.

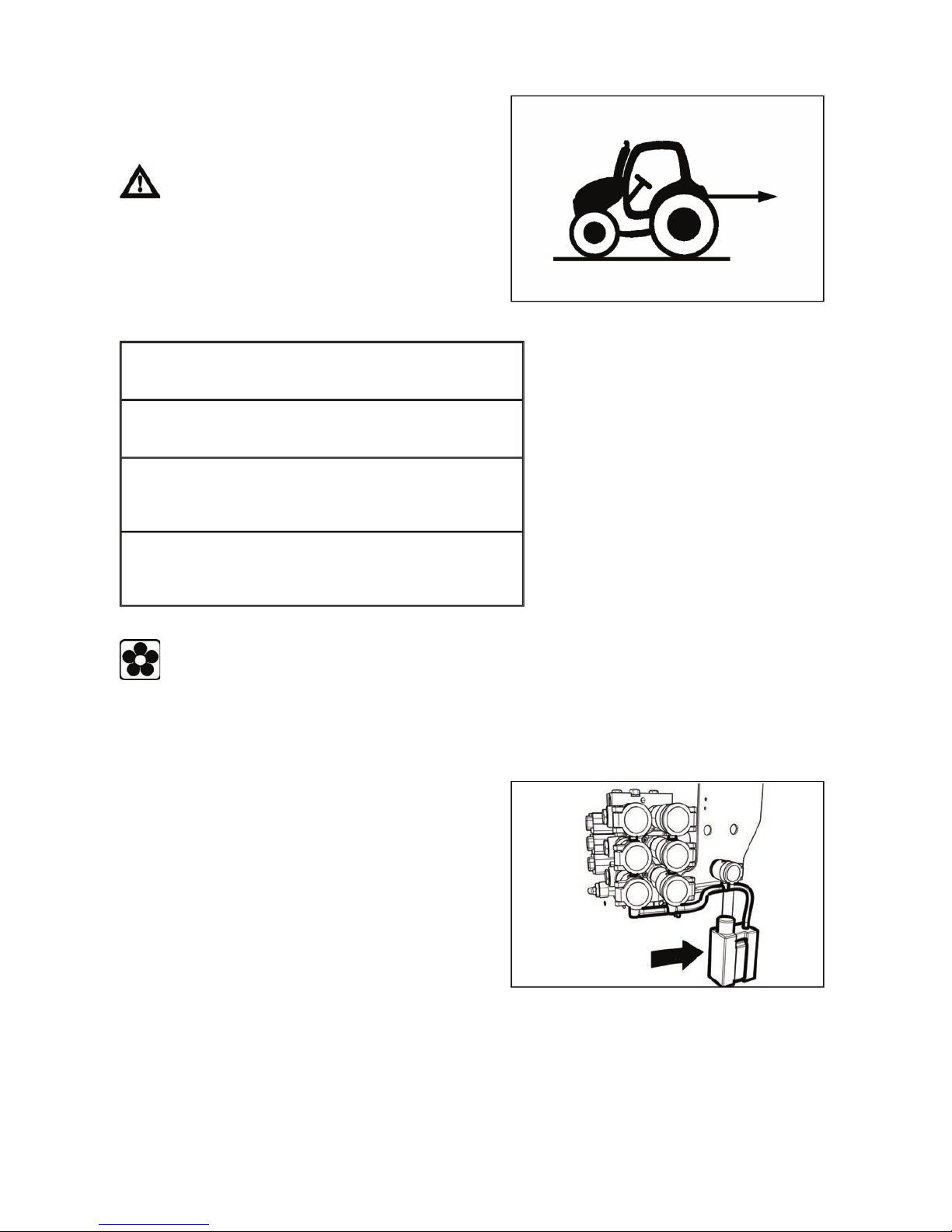

Observe the maximum set angle of slope availability 12° with tractors with front drive axle.

During aggregations of the tractor with machines pay attention to possible worsening of stability of the

aggregated unit which may be influenced by the connected machine.

Respect the total permissible weight of the tractor and trailer specified on the data plate of the tractor

or on the rear wheel mudguard.

Do not use the differential lock when driving into a bend.

It is forbidden to get into and out of a moving tractor.

When driving with machines attached to the rear hitches the load of the steered axle must not drop

below 18 % of the current weight of the set.

When driving the tractor with agricultural machines attached to the front three-point hitch, reduce the

driving speed to 20 km/h.

During aggregation of Zetor tractors with machines and implements with high tensile resistance when

the engine speed drops and the engine tends to stall, the 1R, 2R reduced gears must not be used for

the work with these machines (risk of shaft twist-off).

Transportation of persons, operation

The number of persons transported by the tractor must not exceed the number specified in the

technical certificate of the tractor.

Persons that are not authorized to work with the attached implement must not stand between the

tractor and the hitched machine (implement).

Before putting the tractor in motion make sure there is no person or obstacle in the driving direction.

SAFETY INSTRUCTIONS FOR USERS

12

Recovery, pushing

To recover a tractor that has sunk in mud use a tow bar or rope attached to the front hook

Neve

r use chains! Rupture of the chain represents a danger of death!

During recovery it is dangerous to stand near the towing rope.

It is prohibited to use the tractor axles (individual wheels) as a winch for releasing a sunken tractor.

The front hook should be only use to recover the entire tractor, i.e. without any trailer or another

attached implement.

Never recover the tractor with reduced gears engaged.

When pushing other vehicles (trailers, implements, etc.) with the tractor never insert free wooden

blocks or bars between the tractor and the pushed vehicle.

In case of use of the tractor for wrecking or towing purposes, use only the rear hitch.

When towing the tractor, the reduction gear shift lever must be in the neutral position.

Leaving the tractor

Park the tractor only on an even land and where not possible, support with a shim assy.

Do not park the tractor with an attached implement in the lifted position.

Usually use the left-hand side tractor door when leaving the tractor. Look round whether any vehicle is

coming, that could jeopardize your safety when leaving the tractor.

Use steps and handles when leaving the tractor. When leaving the tractor by the right-hand side door

pay attention being in space of shifting lever and hand throttle control.

Brake the tractor with parking brake before leaving tractor with running engine.

Do not forget to brake the tractor with parking brake (shift the gear), remove the key from key switch

and lock the cab before leaving the tractor.

At tractor equipped with reversor gear, shift the reversor lever into forward drive position.

With stopped engine only

All work connected with refuelling, cleaning, lubricating and adjusting the tractor or attached

implements may only be performed with the engine and moving parts of the tractor stopped except

functional checks of the brakes, hydraulic system and charging.

Before removing the side plates of the hood it is always necessary to stop the engine. The tractor

engine can only run in a closed building or room if sufficient ventilation is ensured. Exhaust gases are

harmful for health.

Fire prevention principles

Refuel the tractor best after the end of work and with the engine stopped.

Do not refill fuel up to the top of the fuel tank in summer. Wipe spilt fuel immediately.

Do not refuel the tractor near open flame and do not smoke.

Do not smoke and do not use open flame when inspecting the battery electrolyte level.

Make sure that fire safety instructions are strictly observed in environments with an increased danger

of fire (hay-lofts, straw-stacks, etc.).

The tractors are not equipped with a fire extinguisher from the production plant.

SAFETY INSTRUCTIONS FOR USERS

13

Health and environment protection

The tr

actors are not equipped with special filters of air aspirated to the cab. Therefore, they are not

designed for work with aerosols and other harmful substances.

Coolant, brake liquid, kerosene, diesel fuel, mineral oil and other oil products that are used for the

operation and maintenance of the tractor may cause various skin disorders in case of direct contact

with your skin and can irritate mucous membranes, eyes, the digestive system and upper respiratory

ways. Some of them may even cause systemic poisoning when swallowed.

Persons that handle oil products are obliged to strictly observe safety and hygienic regulations, use

suitable means of protection and work in well ventilated rooms.

Working with oil products

After the end of work or before a meal you should wash yourself with a mild agent and treat your

hands with a suitable ointment or cream.

When connecting and disconnection quick-couplers of the hydraulic circuits use any piece of cloth to

remove residual oil remaining in the socket or on the plug of the quick-coupler.

Waste disposal

When disposing of the tractor or its parts (incl. operation liquids) after the end of their service life you

must observe relevant provisions of valid acts and implementation directives of these acts of the

country where the tractor is used. The last seller of the tractor is obliged in accordance with the Waste

Act to inform the consumer - during the sale of the tractor - about the way of collection of some used

parts of the tractor. This is the case of oil and other operation liquids, batteries and tyres. These used

products must be received from the consumer without any obligation of the consumer to pay for this

service.

Preventive daily maintenance

Perform this maintenance daily or after every 8 - 10 hours of operation at the latest.

Safety cab

If the protective frame of the safety cab is damaged by corrosion, an accident or otherwise, the safety

cab must be replaced.

Air-conditioning

Disassembling, turning or otherwise handling the screw union of the air-conditioning system is not

allowed in any case. Sudden leak of the coolant may occur, causing quick local cooling. Contact or

freezing of components in hands may cause serious damage of some tissues.

The air-conditioning system is equipped with quick-couplers that make it possible to separate the cab

from the tractor body if necessary without any coolant leak. Entrust interventions into the air-

conditioning system to a specialized repair shop.

SAFETY INSTRUCTIONS FOR USERS

14

Electric installation

No additional interventions into the electric installation (connection of other electric

applia

nces) are permissible due to its possible overloading!

The values of the electric installation are:

Nominal voltage 12 V =

Grounded minus pole ( - ) pole

Using starting trucks or auxiliary power supplies with a different voltage or polarity may cause serious

failures of the tractor.

When handling the battery you must pay increased attention and avoid short-circuits. In tractors

equipped with a battery disconnector switch the disconnector off when handling the battery.

Zetor tractors must not be operated with a disconnected battery as this may lead to a serious failure of

the tractor.

Work in a chemically aggressive environment

If the tractor is operating in a chemically aggressive environment (e.g. working with chemical sprays,

fertilizers, in environments with high concentrations of salt, etc.), it is always necessary to clean the

tractor thoroughly from chemically aggressive substances and neutralize them after the termination of

the work according to the manufacturer's instructions.

Driver's seat

If the driver's seat is equipped with a safety belt, this retaining system must be used during

operation of the tractor.

Front passenger´s seat notification

ATTENTION:

Transp

ortation of personnel on front passenger´s seat is

allowed only with road transportation.

- Transportation of front passenger outside the

seat designed for this purpose is forbidden.

- Using the seat for front passenger during the work

with a tractor (e.g. during the work on the fields) is

explicitly forbidden.

- The use of safety belt on front passenger´s seat is

governed by valid regulations. In this respect, keep

the regulations valid in the country, where the tractor

is operated.

FH13N002

SAFETY INSTRUCTIONS FOR USERS

15

Protection of cab against aerosols

The level of external noise of tractor

The ex

position to the effects of high levels of noise for a longer period of time may lead to

hearing disorders or deafness. Protect your hearing with protective means, e.g. headphones, ear

plugs etc.

Resulting levels of noise when measuring noise for hearing of a person near a tractor. Based on European

direct

ive 2009/63/EC - Amendment VI.

The level of internal sound of tractor

The exposition to the higher sound levels for longer periods of time may lead to hearing

disorders or deafness. Protect your hearing with protective measures, e.g. headphones, ear plugs

etc.

Resulting levels of noise when measuring noise for hearing of driver. Based on European directive

2009/76/EC.

The cab of Zetor tractors in standard design is not

designed for work with aerosols and other health

hazardous substances.

The level of cab protection in standard design complies

with

EN 15695-1:2009 standard - level 2 (only

dust proof

cab).

FH13N003

Model Proxima GP 100 Proxima GP 110

Travel speed 40 km 40 km

Tractor noise levels when travelling dB 80,5 80,5

Tractor noise levels when standing dB 81 81,5

Model Proxima GP 100 Proxima GP 110

Travel speed 40 km 40 km

Noise levels - Closed windows dB 78 78,5

SAFETY INSTRUCTIONS FOR USERS

16

The level of vibrations on driver´s seat

ZETOR tractors are classified in A category in classes I and II. ´A´category includes all tractors with set level

of vib

rations owing to similar specifications of construction:

Results of measurement on testing bench are listed in the following table pursuant to directive 78/764/EEC.

The value a*wS is an adjusted value of effective acceleration balanced according to vibration movement.

The following table is valid for all type series of Zetor tractors.

(1) Values corresponding to driver´s weight of 50 kg.

(2) Values corresponding to driver´s weight of 120 kg.

Aggregation tractor - machine/trailer

While working with machines, trailers or semi-trailers, all instructions from the manufacturers

of these aggregations must be adhered to!

Tractors equipped with front end loader

Zetor Tractors in standard design are designed for utilization in agriculture and are not designed for special

purposes.

Tractors designed for operation within the European Union must be equipped, in case of using front end

loader, with a protective structure (FOPS - Falling Object Protective Structure) protecting drivers from

potential falling objects.

It is necessary to observe applicable local valid regulations in countries which are not part of the European

Union.

Two types of cab roofs are mounted to Zetor tractors.

1. Standard cab roof

2. Cab roof designed for tractors equipped with front end loader meeting the OECD code 10 (FOPS)

conditions.

Tractors ZETOR supplied already from production with front end loader are equipped with cab roof according

to point 2.

From safety reasons, series ZETOR tractors supplied without front end loader with standard roof pursuant to

point 1 must not be equipped or used with front end loader.

In case of additional front end loader assembly, it is necessary to equip tractor with cab roof pursuant to point

2.

Only front end loaders approved by ZETOR TRACTORS may be mounted to ZETOR tractor.

Additional assembly of front end loader approved by ZETOR TRACTORS can be done only by

authorized ZETOR service.

It is forbidden to use front end loaders unapproved of by ZETOR TRACTORS.

Not observing this instruction may cause serious accidents.

Carefully observe instructions for use supplied by the manufacturer of front end loader.

Attachment points for assembly of the front loader to the tractor are specified in the manual of

the loader manufacturer. The manual must be approved by the company ZETOR TRACTORS.

Brand of seat Model Springing

Class I & II

a*

wS

(1)

(m/s²

)

a*

wS

(2)

(m/s²

)

GRAMMER MSG85/721 mechanical 1,18 0,8

GRAMMER MSG95A/721 pneumatic 1,16 1,1

MARS 78/764-73xx mechanical 1,25 1,23

SEARS 3008 mechanical 1,24 1,06

SEARS 3045 pneumatic 1,13 1,03

SAFETY INSTRUCTIONS FOR USERS

17

Principles for operating tractors equipped with front end loader

Carefully study operation manual supplied by the manufacturer of front end loader.

In cas

e of discord of Principles for operating tractors equipped with front end loader and operation

manual for front end loader, which was supplied by the manufacturer of front end loader, the wording

listed in operation manual supplied by the manufacturer of front end loader shall apply.

The use of front end loader for transporting material at places accessible to the public is forbidden.

The use of front end loader for transporting material in places inaccessible to the public is possible

only in a limited way. In such case, instructions in user's manual supplied by the loader manufacturer

must be observed.

Observe local valid regulations at all times.

A strict ban on transportation and lifting of people by means of loader is in effect.

No matter whether the front end loader is loaded or empty, no-one may stand in front of the loader if it

is in lifted position. When driving with a lifted loader, there is a risk of load transported by front end

loader falling (there is a risk of disrupting the balance of the tractor).

Never leave the tractor standing with the loader in lifted position.

If it is necessary to open the bonnet of the engine at intervention, disconnect the front end loader first

or secure hydraulic rollers of front end loader by metallic props designed for this purpose.

Hydraulic circuit of the front end loader is designed in such a way to endure the maximum operation