Zetor 8621 Forterra turbo, 9641 Forterra turbo, 10641 Forterra turbo, 11641 Forterra, 8641 Forterra turbo Operator's Manual

...

2

ZETOR

This operator’s manual will help you to become familiar with the operation and maintenance of your new tractor.

In spite of fact that many of you have reach experiences with operation of various tractors, please, read carefully all

safety rules and operating instructions in this operator ’s manual before attempting to operate the tractor.

You will find a lot of new information and receive a perfect overview how to use the tractor with highest efficiency at

various operations.

Your new Zetor tractor will be your reliable friend if observing the mentioned safety rules, tractor maintenance and

safe operation

Manufacturer of Your tractor wishes you thousands of satisfactorily worked hours.

ZETOR

Brno

3

Information about technical specifications, design, equipment, material, and external appearance is valid in the time of printing

this operator’s manual. Manufacturer reserves all rights for changes.

4

The operator’s manual contains description, operation and maintenance of

standard and optional tractor equipment.

Service checkbook isn’t a part of

operator’s manual. This is the separate

booklet that is passed to you when

purchasing new tractor.

CONTENTS

Page

Location of serial numbers ................................................................

Safety instructions for user........................................................................................ 12

Preventive daily service ............................................................................................ 15

Acquintance with tractor ............................................................................................ 23

Electronic engine governor ....................................................................................... 51

Operation .................................................................................................................. 63

Tractor running in ...................................................................................................... 83

Transportation ........................................................................................................... 91

Driving the agricultural machines ............................................................................ 101

Hydraulic system ..................................................................................................... 107

Electro-hydraulic ................................................................ ................................ ..... 121

Hitches ................................................................................................ .................... 133

Wheel tread setting ................................................................ ................................. 145

Balast weights ................................................................ ......................................... 155

Maintenance instructions ........................................................................................ 163

Adjustment ................................................................................................ .............. 189

Electrical installation ................................................................ ............................... 203

Planned technical maintenance ................................................................ .............. 219

Main technical parameters ...................................................................................... 239

.......................... 9

5

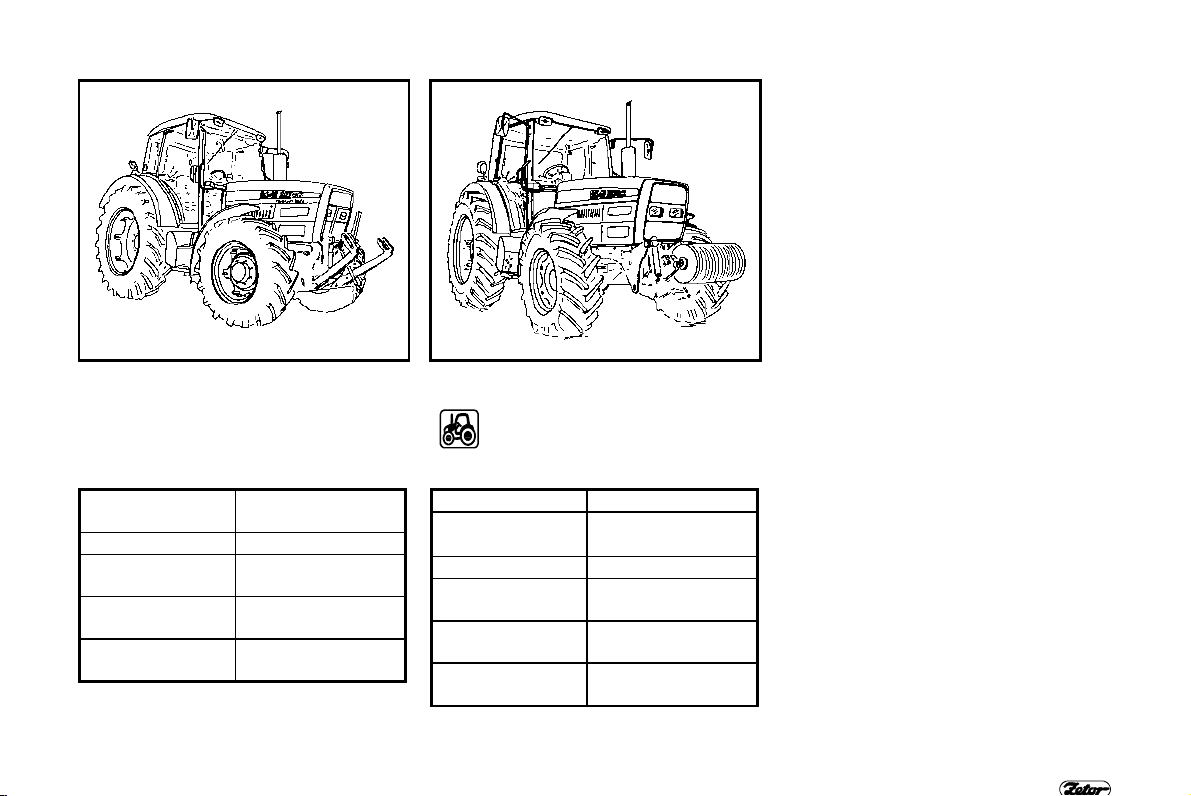

Zetor 8621 Forterra turbo - 60 kW

Zetor 9621

Forterra turbo - 67,5 kW

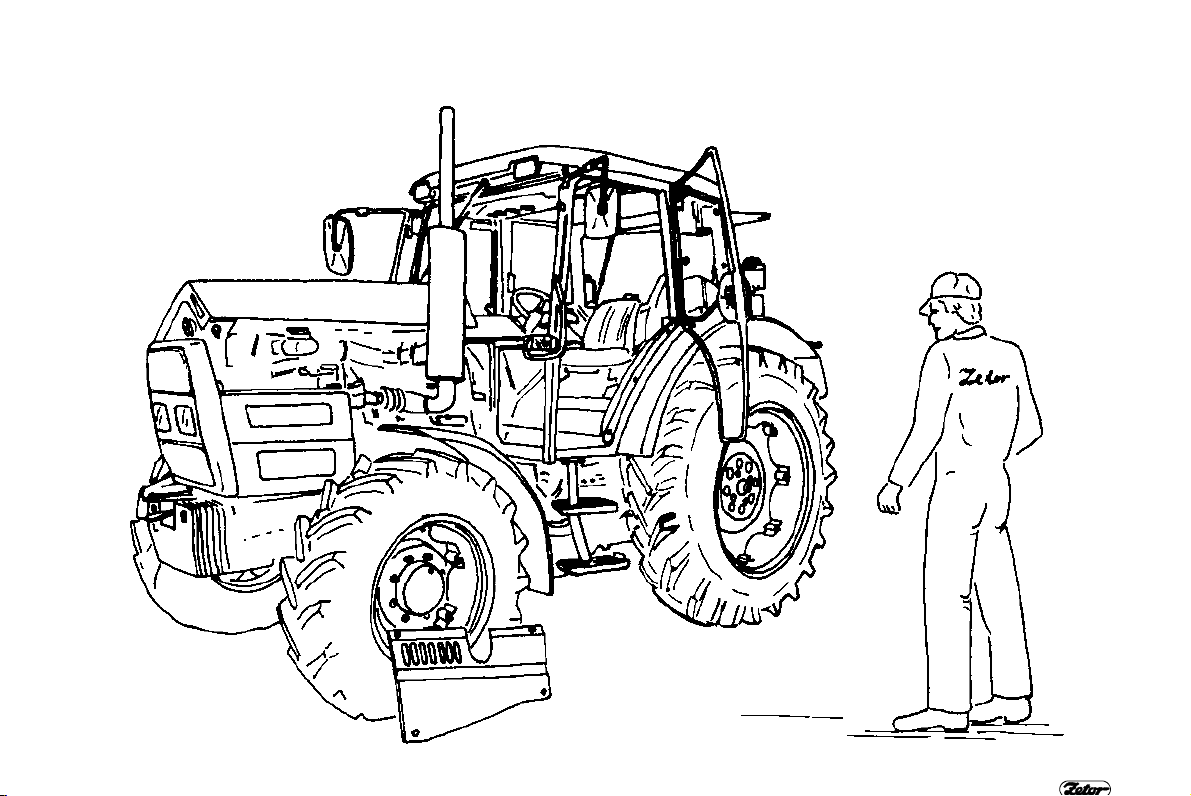

ZETOR 8621, 9621 FORTERRA TURBO

F 1

6

ZETOR 8641, 9641, 10641 FORTERRA TURBO

Zetor 8641 Forterra turbo - 60 kW

Zetor 9641

Zetor 10641 Forterra turbo - 76 kW

Forterra turbo - 67,5 kW

F 2

7

Zetor 11641 Forterra - 81 kW

ZETOR 11641 FORTERRA

F 3

8

LOCATION OF SERIAL NUMBERS Z 8621 - Z 10641 FORTERRA TURBO

F 4

9

LOCATION OF SERIAL NUMBERS Z 11641 FORTERRA

10

F 5

LOCATION OF SERIAL NUMBERS

Whenever you contact your authorized service dealer or the factory for order of service parts, always know the model and serial

numbers of your tractor. For your convenience, write those numbers in the frames below.

Tractor model

ZETOR 8621, 8641, 9621, 9641, 10641

ZETOR 11641

The “left“, “right“, “front“ and “back“ side

of the tractor is determined by traveling

direction.

Manufacturer reserves rights for

changes of design and option, that

improve the tractor features.

Tractor serial number Engine serial number

F 6

11

SAFETY INSTRUCTIONS FOR USERS

Keep extreme attention when

reading parts of operator’s manual

that are marked by these symbols.

You will find this symbol at all

important warnings identifying

the safety of tractor operation.

Keep these safety massages

and however regardless of the

hazard, be extremely careful!

Inform your cooperators and

other users about these messages.

This symbol marks all chapters

speaking about different operation, maintenance, adjustment

and safety rules at tractors

Z 11641Forterra.

Study carefully chapters marked

by this symbol before starting

with operating, servicing or

adjusting the tractor.

You will find this symbol whenever important informations on

operation, adjustment and repairs of starter motor.

Keep these regulations and be

extremely careful in these

cases!

This symbol marks such tractor

∗

equipment that is not assembled

as a standard (optionally

assembled equipment only).

GENERAL SAFETY REGULATIONS

1. Only a trained operator having a valid

driving license and being properly

acquainted with operating and safety

rules can operate the tractor.

2. Except of safety warnings mentioned

in this operator’s manual you must

respect all general safety and traffic

regulations of country where the tractor

works.

PROPER CLOTHING

3. Don’t wear loose clothing and free

flying long hair at operation.

4. Use suitable (prescribed) personal

protection means (working boots, gloves

etc.) at work.

STARTING ENGINE

5. Starting the engine when driving trac-

tor downhill is forbidden.

6. Starting tractor by means of towing

with another tractor or vehicle is allowed

only when the pull bar is used.

7. Tractor Z 11641 can not be

started without battery, with dis-

charged battery or without external source (see electronic governor of

injection pump).

12

7. Start the tractor from

driver’s seat only with

shifting lever in neutral

position. Life hazard when

starting by starter connec-

tor short circuit.

8. The key of the key switch must be in

position "I".

9. When preheating engine by electrical

heater, plug the heater first and connect

the cable into electricity after. After preheating disconnect the cable from

electricity first.

WARNING! Electrical shock hazard

OPERATION

11. Hoses of hydrostatic steering, brakes

and fuel system must be checked and

replaced in case of any damage indication. The damage indication is for

example: cracks on hose surface,

loosening of hose fittings (verify it by pulling of hose from fitting) and mechanical

damage of hose.

12. Brakes and steering must be permanently in perfect condition.

13. Brake pedals must be latched at

transportation with trailers and implements on the road.

14. Driving downhill without shifted gear

is forbidden!

SAFETY INSTRUCTIONS FOR USERS

15. Pay

special attention when driving on

hilly, muddy, sandy, icy and uneven terrain.

16. Don’t exceed the max. specified incli-

nation angle 120 for 4WD tractors (respectively 110 for 2WD tractors).

17. Don’t exceed the max. total weight of

trailers mentioned in the tractor serial

number plate or rear fender label.

18. Don’t use the differential lock when

driving into the turning.

19. Never get out or into the driving tractor. This is forbidden.

20. Reduce the travel speed to 20 km/h

when transporting agricultural implements hitched in the front three point

hitch.

21. The front axle load must not be lower

than 18 to 20 % of immediate total tractor weight when transporting agricultural

implements hitched in the rear three

point hitch.

TRANSPORTATION OF PERSONS,

OPERATION

22. Number of persons transported by

tractor must not exceed number mentioned in tractor technical license.

23. Persons, unauthorized to work with

attached implement, must not stand

between tractor and hitched implement

(machine).

24. Make sure neither any person nor

any obstacle allows driving before starting tractor move.

25. Max. allowed travel speed of tractor

and trailer equipped with one hose air

trailer brakes is 25 km/h.

26. Don’t exceed the max. specified

inclination angle 110 for tractors Z 8621

and Z 9621 and 120 for tractors Z 8641,

Z 9641, Z 10641, Z 11641.

RELEASING AND PUSHING TRACTOR

27. Use a pull bar or a rope for releasing

an immobilized tractor. Never use

chains. It is life dangerous to stand near

the rope when releasing the tractor

28. Front hook assembled on front tractor

frame serves for pulling the alone tractor

only, i.e. without trailer or another implement.

29. Never use free wooden blocks,

planks or bars put between tractor and

pushed subject when pushing other vehicles (trailers, wagons etc.).

LEAVING TRACTOR

30. Do not park the tractor with attached

implement in lifted position.

31. Don’t forget to brake the tractor with

parking brake (shift the gear) remove the

key from key switch and lock the cab

before leaving tractor.

32. Shift the reverse lever into forward

position.

13

33. Brake the tractor with parking brake

before leaving tractor with running engine.

34. Usually use the left-hand side of tractor- left door when leaving tractor. Look

round if any vehicle coming, that could

jeopardize your safety when leaving and

open the door.

35. Use steps and handles when leaving

the tractor. When leaving tractor by the

right door pay attention being in space of

shifting levers and hand throttle control.

AT STOPPED ENGINE ONLY

36. All activities like refueling cleaning,

lubricating and adjusting tractor or

attached implement can be done at

stopped engine and stopped moving

tractor parts only, except of brake,

hydraulics and charging function inspection.

37. It is necessary to stop the engine

before removing bonnet side shields.

The engine can run in closed room and

house only when the perfect ventilation

works. Exhaust gases are health

dangerous.

SAFETY INSTRUCTIONS FOR USERS

FIRE PREVENTION RULES

38. Refuel

job and with stopped engine.

39. Don’t refuel the fuel tank up to the top

in summer season. Wipe the fuel

immediately when spilled.

40. Don’t refuel the tractor nearby an

open flame. Don’t smoke.

41. Don’t smoke and don’t use an open

flame when inspecting the battery

electrolyte level.

42. Keep properly the fire prevention regulations in areas with increased fire

hazard (hay-lofts, straw-stocks etc.).

43. If the tractor is equipped with a fire

extinguisher keep it ready for use.

44. Use the spark arrestor when working

in fire hazard environment.

HEALTH AND ENVIRONMENT PROTECTION

45. Tractors are not equipped with spe-

cial ventilation filters of inlet air coming

to the cab. That’s why tractors are not

intended for work with aerosols and

other substances harmful to health.

Kerosene, diesel fuel, mineral oils and

other products from crude oil used for

operation and maintenance of tractor

may cause an injury in case of direct

contact with skin and it can irritate

mocous membranes, eyes, digestive or

the tractor after finishing the

respiratory organs. Some of them might

cause the total poisoning when used.

46. Persons working with crude oil products must properly keep safety and

hygienic regulations, they must use the

suitable protectors and work in properly

ventilated areas.

WORKING WITH CRUDE OIL PRODUCTS

47. Wash properly your hands with mild

detergent and treat them with suitable

skin ointment or cream after finishing

work or before eating.

48. Remove oil drops from quick-couplers (from male and female) by textile

material after disconnecting or connecting hydraulic circuit.

PREVENTIVE DAILY SERVICE

49. Do this service every day or at least

every 10 hours.

SAFETY CAB

50. If corrosion or accident damages the

frame of safety cab it is necessary to

exchange the cab.

AIRCONDITIONING

51. In any case do not disassemble, turn

or manipulate with fittings of AC system.

This might create a sudden escape of

fluid and local freeze. This could create

a serious damage of tissue when

touching or when frozen in hands.

14

PREVENTIVE DAILY SERVICE

Do this service every day or at least every 10 hours

15

F 7

F 8 F 9 F 10

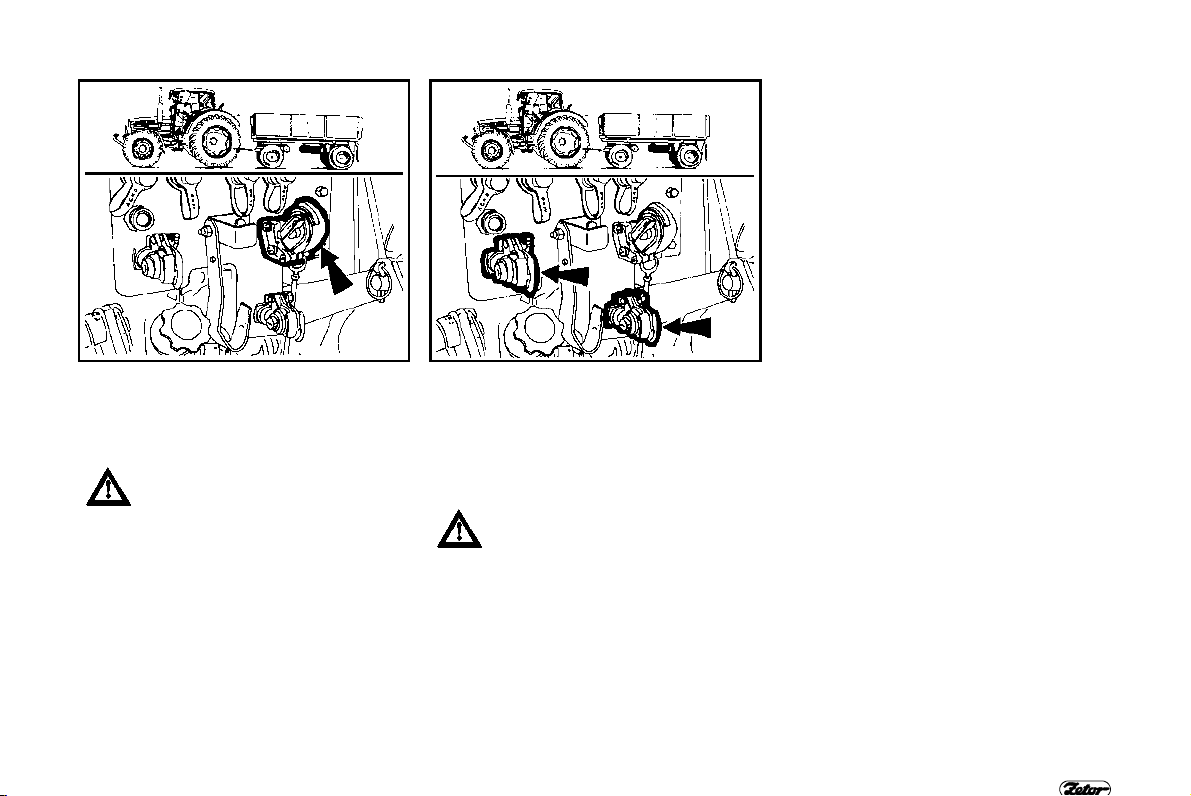

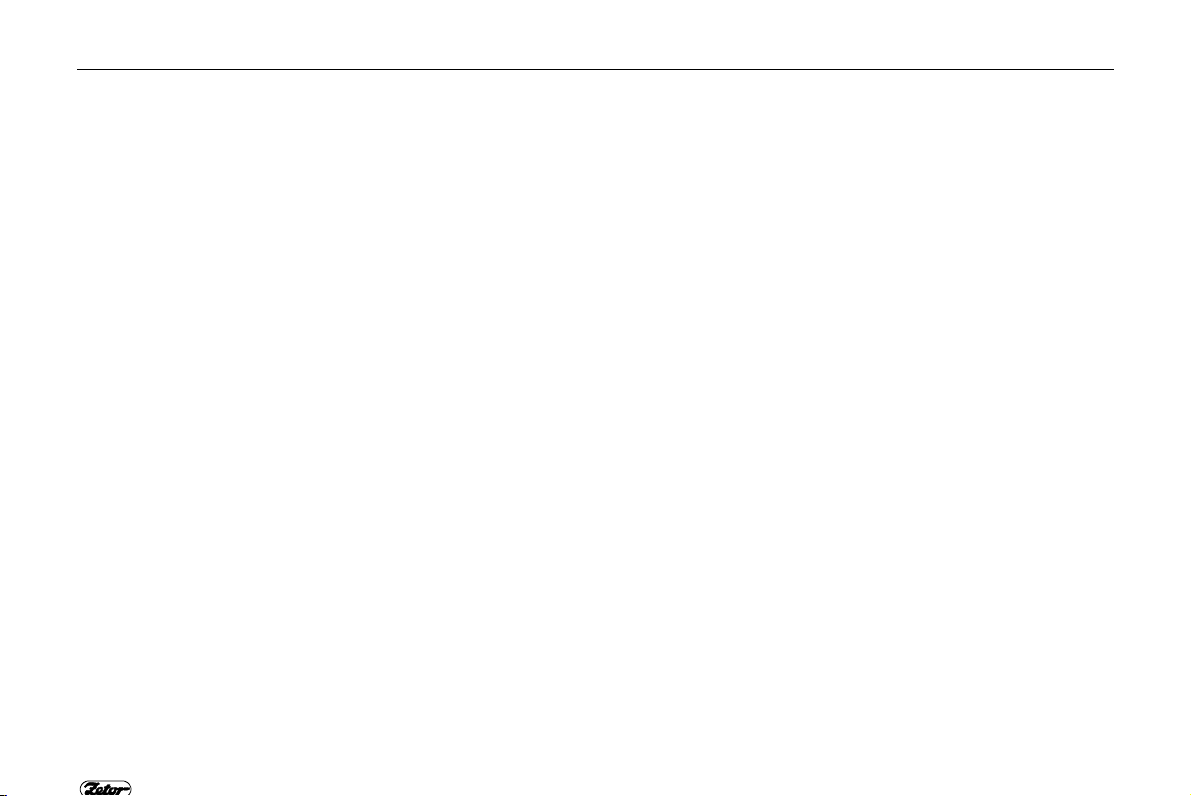

FUEL SYSTEM LEAKAGE

Inspect the fuel system for leakage including the fuel tank. Repair immediately

any leaks.

PREVENTIVE DAILY SERVICE

ENGINE OIL LEVEL

Check the engine oil and inspect the

lubrication system for leakage. Add the

oil to prescribed level.

COOLING SYSTEM

Inspect the engine cooling system for

leaks. Check the coolant level in the

expansion tank. Add the coolant to

"MAX“ level. The minimum allowed level

is on the lower mark.

16

F 11 F 12 F 13

FLUID SERVICE BRAKES

Inspect the brake and clutch circuit for

leaks and check the brake fluid level in

the brake fluid expansion reservoir.

PREVENTIVE DAILY SERVICE

AIR TRAILER BRAKES

Inspect the air brake system leak and

tractor break efficiency with trailer (see

„inspection of air brake leak“).

HYDRAULIC TRAILER BRAKES

Inspect the hydraulic brake system leak.

17

F 14 F 15 F 16

STEERING

Check oil level in the hydrostatic steering

oil tank. Retighten bolts and nuts of

steering tie-rods and arms.

PREVENTIVE DAILY SERVICE

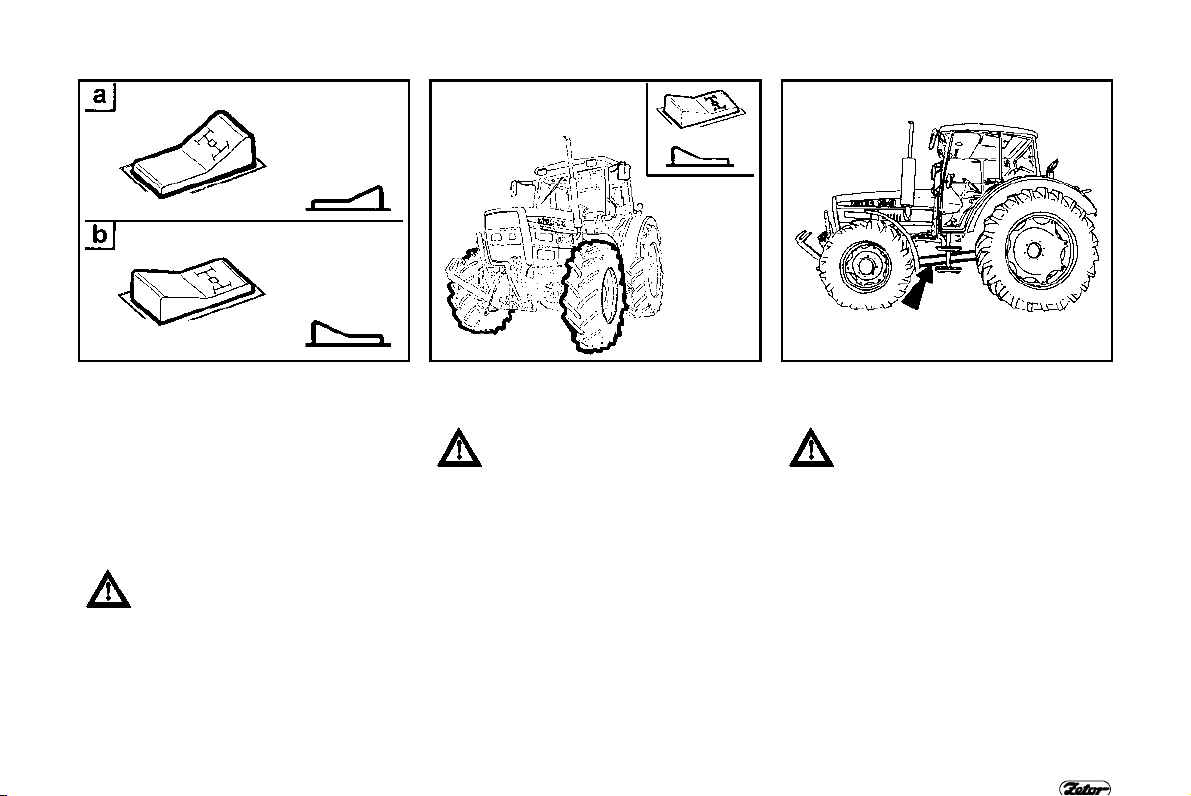

TIRES AND WHEELS

Check the inflation air pressure of front

and rear tires. Inflate them up to the

recommended pressure according to

operating conditions. Check, eventually

retighten bolts of front and rear wheels.

Never drive tractor with loosened bolts of

wheels.

AIR CLEANER

The indicator indicates clogging of the

air cleaner, this indicator switches the

lamp on the dashboard in case of strong

clogging.

18

F 17 F 18 F 19

CAB FILTRATION

Check and eventually clean cab filters

located under the roof in front part. Filter

exchange interval depends upon dustiness of working condition. The partial

regeneration of filters can be done by

shaking-out or blowing by press air.

Filters are accessible after removing of

grills located in front of cab roof.

PREVENTIVE DAILY SERVICE

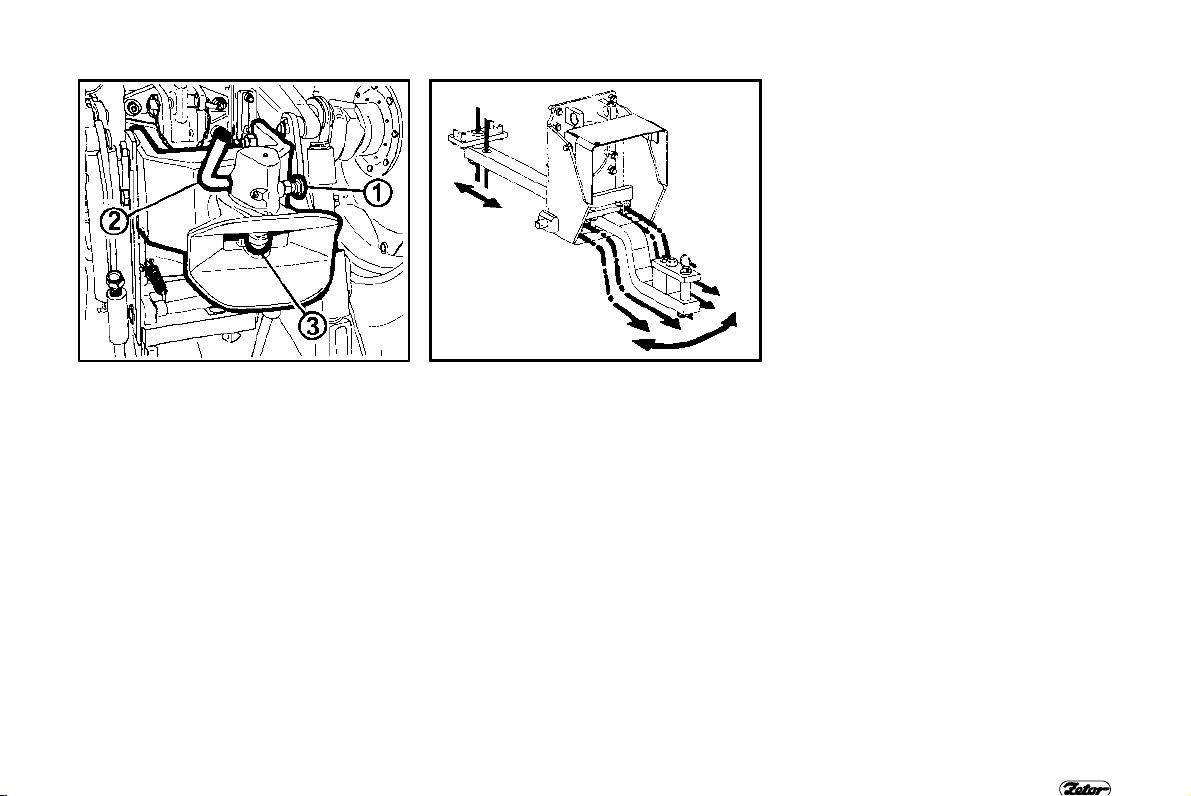

HITCHES

Check the status of hitches and attachments including the trailer.

AFTER OPERATION WITH FRONT

IMPLEMENTS

Remove the front mask to be able to

blow out impurities outside the tractor.

Clean the front part of radiators (radiators of transmission, AC condenser) by

the press air, blow it in direction from the

engine. Remove the rest of impurities

under the bonnet, otherwise their repeated suction into the cooling system

might appear.Inspect

hitch hydraulic circuit for leaks.

front three-point

19

F 20

SHORT FUNCTIONAL TEST

Check the lubrication indicator light is

“off“ after starting engine. Check the

function of charging (charging control

lamp must be off). Check the hydraulic

circuit of hydrostatic steering for leaks

and its function.

PREVENTIVE DAILY SERVICE

20

Tractor user must be properly

acquainted with recommended

operating and safety rules in

advance. It is too late to do it

within operation!

ACQUAINTANCE WITH TRACTOR

Safety cab ................................

Opening the door from outside.................................................................................. 23

Opening the door from inside .................................................................................... 23

Rear window................................................................ ................................ .............. 24

Side window .............................................................................................................. 24

∗Tiltable roof lid ......................................................................................................... 24

Opening for implementation purposes ......................................................................25

Windshield washer ................................ ................................ .................................... 25

Washer tank.............................................................................................................. 25

Washer control.......................................................................................................... 25

∗Passengerřs seat................................................................................................ ..... 26

Space for driverřs needs and toolbox................................ ................................ ........ 26

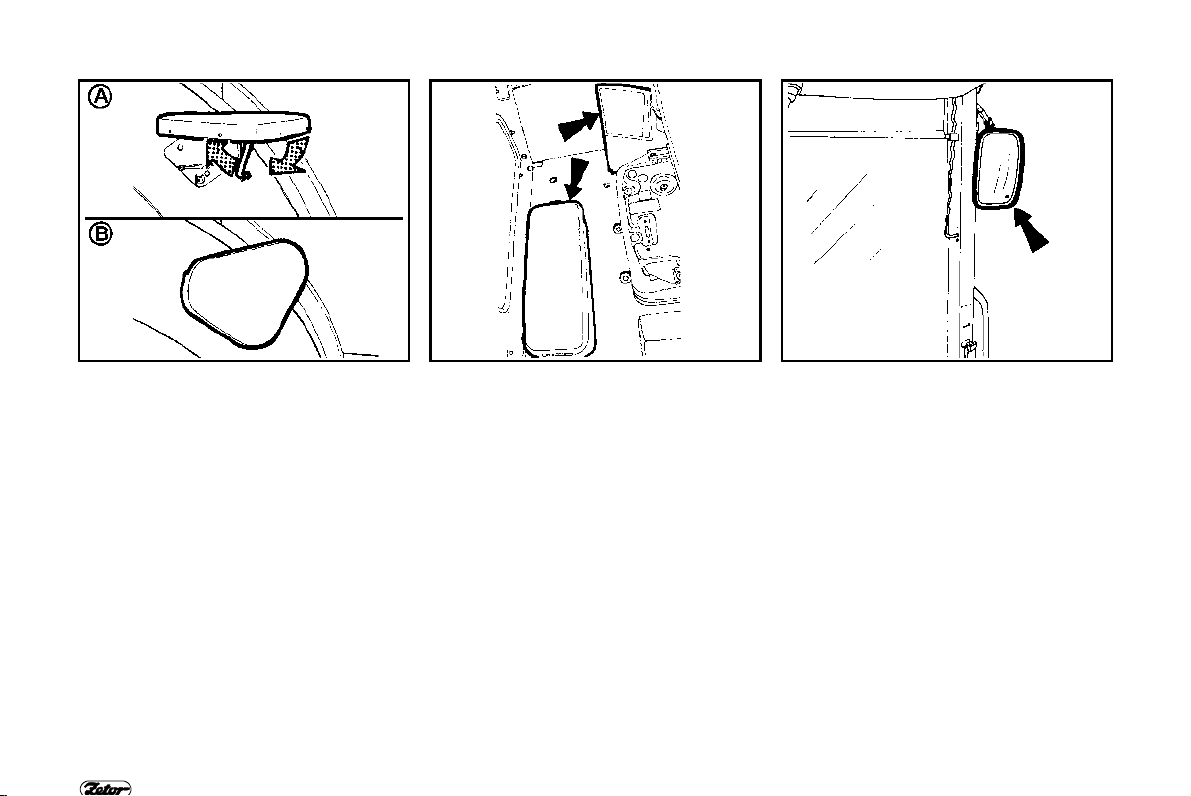

Rearview mirrors ................................................................ ................................ ....... 26

Seat adjustment for driverřs weight ................................ ........................................... 27

Longitudinal seat adjustment .................................................................................... 27

Vertical seat adjustment ................................ ................................ ............................ 27

Driverřs seat ∗ Grammer ................................................................ ........................... 28

Seat adjustment for driverřs weight ................................ ........................................... 28

Longitudinal seat adjustment .................................................................................... 28

Driverřs seat ∗ Cobo ................................ ................................ .................................. 29

Seat adjustment for driverřs weight ................................ ........................................... 29

Longitudinal seat adjustment and backrest adjustment ................................ ............ 29

Tiltable steering wheel .............................................................................................. 30

Angle adjustment ................................................................ ................................ ...... 30

Telescopic adjustment .............................................................................................. 30

Control panel of heating, ∗airconditioning and ∗ radio .............................................. 31

Four-speed switch of heating blowers ....................................................................... 31

Control panel on right cab pillar ................................ ................................................ 31

Ventilation outlets and radio speakers ...................................................................... 32

Defrosting the front windshield ................................................................ .................. 32

∗ Ac control ............................................................................................................... 33

Cooling the cab ......................................................................................................... 33

21

................................................................ ................. 23

Page

ACQUAINTANCE WITH TRACTOR

∗ Ac operation ................................

Location of dashboard .............................................................................................. 35

Description of instruments ........................................................................................ 35

Indicator lights........................................................................................................... 35

Location of dashboard .............................................................................................. 37

Description of instruments ........................................................................................ 37

Indicator lights and push buttons ................................................................ .............. 37

Switches with levers................................................................................................ .. 38

Light switch (a).......................................................................................................... 39

Front wheel drive switch (d) ...................................................................................... 39

Hazard light switch (f) ............................................................................................... 39

Switch of grill and cab headlight (g) .......................................................................... 40

Switch of rear (front) differential lock (j) .................................................................... 40

Turn signal, headlight and horn toggle switch (i) ...................................................... 40

Key switch................................................................................................................. 41

Key in "0" position ................................................................ ..................................... 41

Key in "I" position ...................................................................................................... 41

Key in “II“ position ................................................................................................ ..... 42

Throttle control lever ................................................................................................. 43

Stopping device ................................................................ ........................................ 43

Electronic hand throttle control ................................................................................. 43

Pedals and levers ................................................................ ..................................... 44

Main gear shifting lever and reversor lever ............................................................... 44

Shifting lever of road speed and reduced speed ...................................................... 44

PTO selection control lever for shifting of pto independent and ground speed ........ 45

Parking brake lever and ∗ pick up hitch control lever................................................ 45

Hydraulic control ................................................................................................ ....... 45

Hand control of selection control valve ..................................................................... 46

Fuel tank ................................................................ ................................ ................... 46

Draining plug of fuel tank .......................................................................................... 46

Average fuel consumption in litters per operating hour ............................................. 47

Battery switch................................ ............................................................................ 47

Location of information and safety decals ................................ ................................ 48

................................................................ ........... 33

22

SAFETY CAB

Use steps and handles when

getting out and in.

SAFETY CAB

F 21 F 22 F 23

OPENING THE DOOR FROM OUTSIDE

Cab doors can be locked from outside.

OPENING THE DOOR FROM INSIDE

1.

Lever for opening from inside.

2. Lever for locking from inside.

Door is kept in the opened position with

a gas strut.

Going with opened door is not recommended. Door might be damaged.

23

F 24 F 25 F 26

REAR WINDOW

Rear window is equipped with handle

and is kept in the open position by gas

struts.

We recommend latching the window in closed position when driving on uneven terrain - danger of

window cracking. Before starting

the job with machines implemented in the rear three point hitch

be sure that the interference

between hitched implement and

opened rear window is avoided

at the maximal lifting of the rear

three point hitch. In case of

interference we recommend to

work with closed window.

SAFETY CAB

SIDE WINDOW

A plastic latch in the opened position

locks side window.

∗TILTABLE ROOF LID

Pressing the mechanism opens roof lid.

Tiltable lid is kept with gas struts in the

opened position.

Tractor height is increased when

opened lid. That’s why close the

lid when passing through low

profiles.

24

F 27 F 28 F 29

OPENING FOR IMPLEMENTATION

PURPOSES

The bottom window is rigid and is

equipped with opening for connection of

controls with attached implements.

SAFETY CAB

WINDSHIELD WASHER

The washer nozzle is adjustable by

needle of max. diameter 0,8 mm.

WASHER TANK

Washer tank is accessible after tilting

the hood or after removing the front

mask.

WASHER CONTROL

The windshield washer sprays after

pressing the switch of front double

speed wiper. This switch is located on

the right cab pillar. Maximal time of uninterrupted spraying is 20 s.

25

F 30 F 31 F 32

∗PASSENGER’S SEAT

Passengerřs seat is tiltable.

Unlock the seat strut and tilt the

A -

seat.

B - Seat is locked in its tilted position on

fender.

SAFETY CAB

SPACE FOR DRIVER’S NEEDS AND

TOOLBOX

The space is located on the left-hand

side nearby driverřs seat. Toolbox is

located behind the driverřs seat in the

rear part of cab.

REARVIEW MIRRORS

Adjust rearview mirrors before driving or

starting the job to be able to see the

road or the field.

26

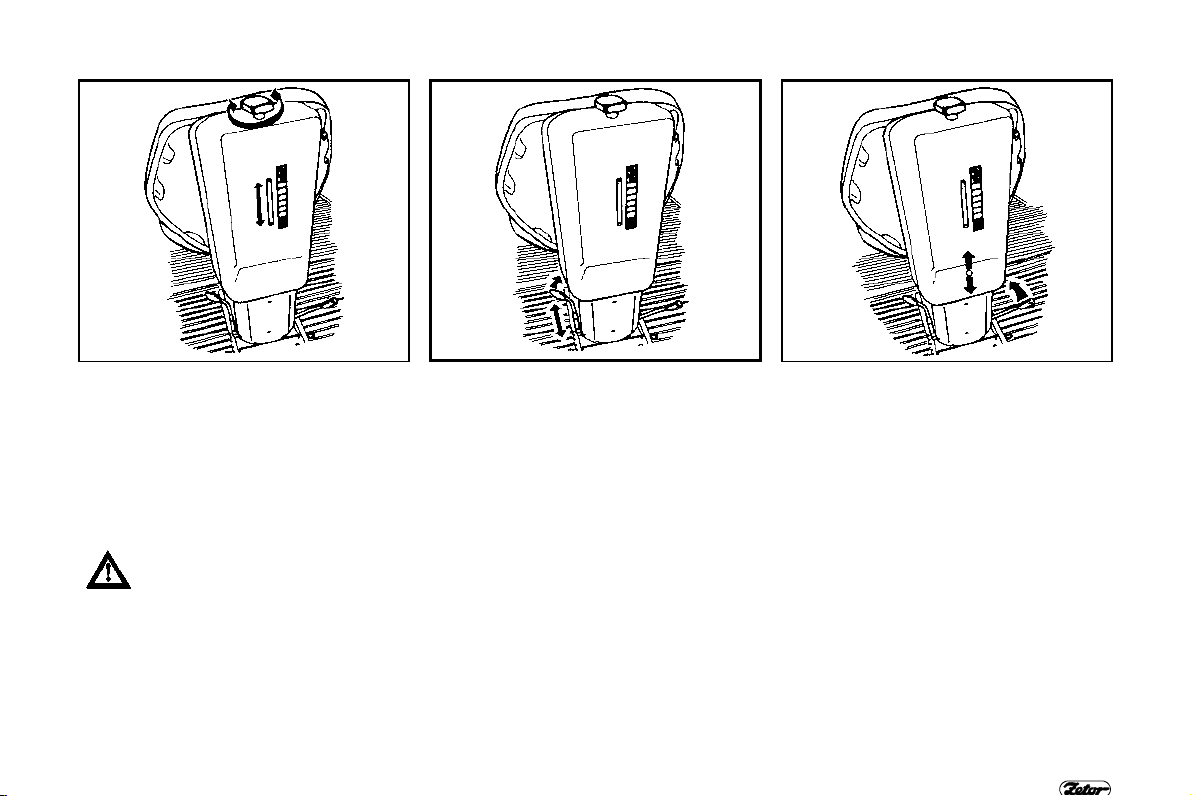

F 33 F 34 F 35

SEAT ADJUSTMENT FOR DRIVER’S

WEIGHT

The suspension of seat is adjustable for

driverřs weight from 50 up to 120 kg.

Turning of square knob does adjustment. Weight indicator is located in the

slot of rear seat cover. Spring stroke is

120 mm.

Do not adjust the seat on the go.

Danger of accident.

DRIVER’S SEAT MARS

LONGITUDINAL SEAT ADJUSTMENT

The seat can be longitudinally adjusted

within range „ 75 mm (11 positions).

VERTICAL SEAT ADJUSTMENT

The right hand side lever does vertical

seat adjustment within range „ 30 mm

( 3 positions).

27

F 36 F 37 F 38

DRIVER’S SEAT ∗ GRAMMER

Tractor can be equipped with the seat

Grammer as an option.

DRIVER’S SEAT - GRAMMER

SEAT ADJUSTMENT FOR DRIVER’S

WEIGHT

Adjust the seat by a plastic knob located

on the front part of seat support.

LONGITUDINAL SEAT ADJUSTMENT

Adjust the longitudinal position of seat by

a lever located on the left hand side of

the seat.

28

F 39 F 40 F 41

DRIVER’S SEAT ∗ COBO

Tractor can be equipped with the seat

Cobo as an option.

DRIVER’S SEAT - COBO

SEAT ADJUSTMENT FOR DRIVER’S

WEIGHT

Adjust the seat by rotating the lever after

its tilting into working position.

LONGITUDINAL SEAT ADJUSTMENT

AND BACKREST ADJUSTMENT

Adjust the seat by lever on the right

hand side of seat.

Adjust the backrest by rotating a plastic

knob located on the right, rear side of

seat.

29

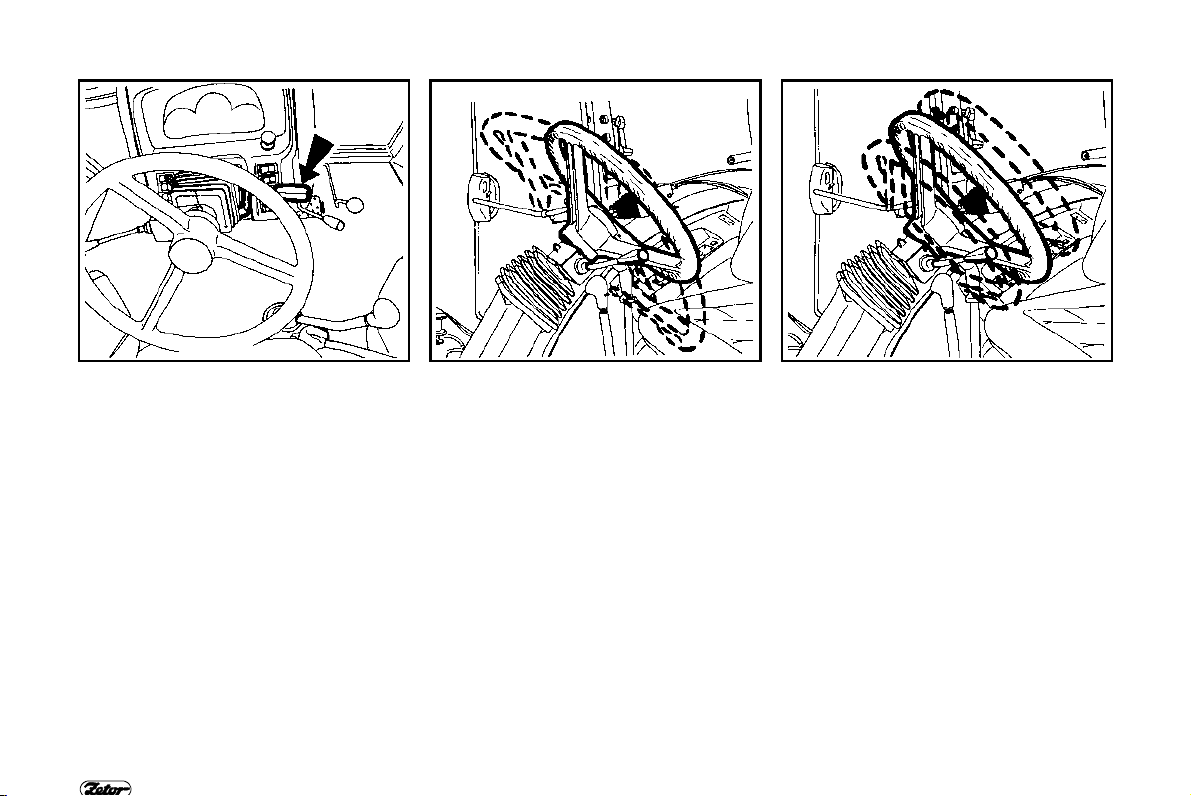

F 42 F 43 F 44

TILTABLE STEERING WHEEL

Tiltable steering column enables variable

angle and height adjustment of the

steering wheel. Both functions are operated by one lever.

CONTROLS

ANGLE ADJUSTMENT

Angle adjustment enables 10 positions

with step 4 in range: -16 up u to +24

down.

TELESCOPIC ADJUSTMENT

Steering wheel is adjustable within range

0 - 80 mm in any angle position.

30

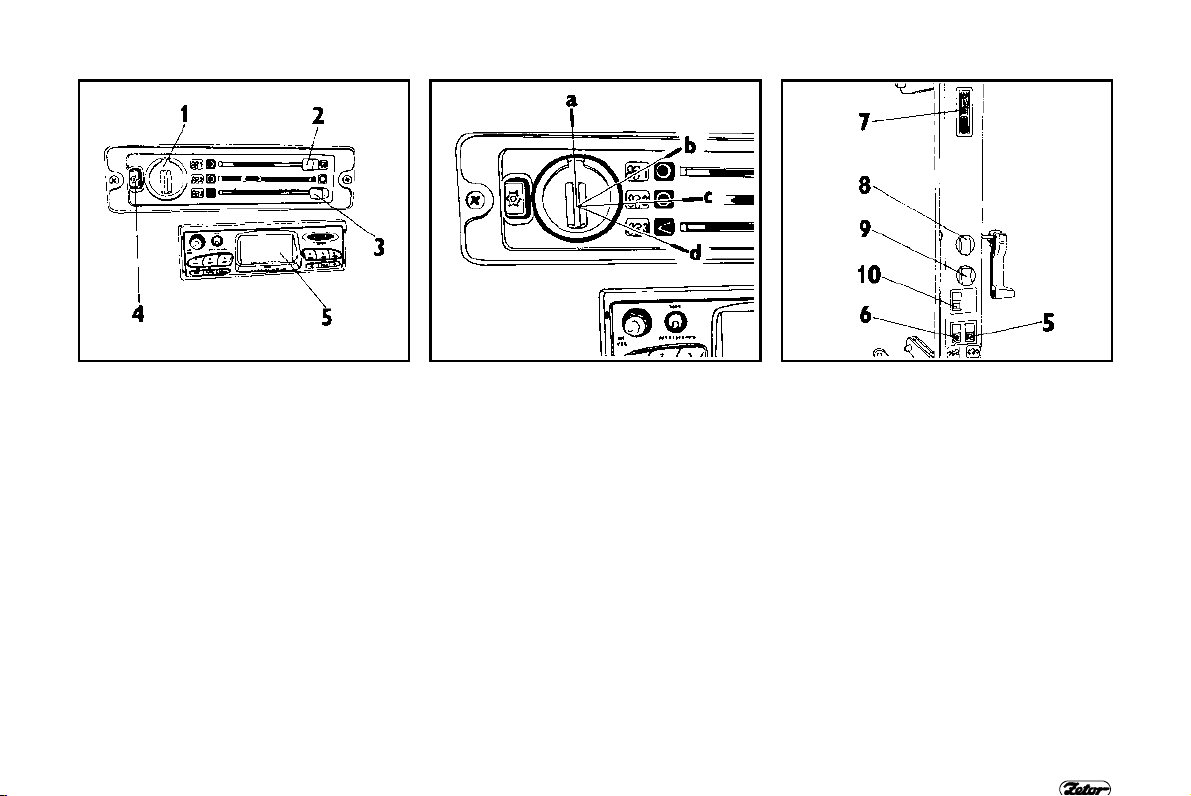

F 45 F 46 F 47

CONTROL PANEL OF HEATING, ∗AIRCONDITIONING AND ∗ RADIO

1.

Four-speed switch of heating blowers

2. Shut off heater and AC recycling

control

3. Heater valve control lever

- right - heating “on“

- left - heating “off“

4. ∗ switch of air-conditioning

5. ∗ Radio can be assembled into the

space under the heating panel

CONTROLS

FOUR-SPEED SWITCH OF HEATING

BLOWERS

a - vertical position - blower is “off“

b - first right position - blower low speed

c - second right position - blower middle

speed

d - third right position - blower high

speed

CONTROL PANEL ON RIGHT CAB

PILLAR

5. Control switch of rear PTO

6. ∗ Control switch of front PTO

7. Cab illumination

8. Two speed switch of front windshield

wiper and front washer.

9. Switch of rear window wiper.

10. ∗ Control switch of three point hitch

lifting (for lifting the implement when

turning in the field)

31

F 48 F 49

VENTILATION OUTLETS AND RADIO

SPEAKERS

Adjustable outlets of ventilation,

11.

heating and ∗AC

12. Radio speakers (only in case of

preparation assembly for ∗radio)

CONTROLS

DEFROSTING THE FRONT WINDSHIELD

For fast defrosting of front windshield the “A“ middle outlets needs to be directed to

the front windshield with 45 angle from vertical position the "B" side outlets directed

towards front corners of cab.

After front wind shield defrosting the side outlets can be directed towards door

glasses for their step by step defrosting. After defrosting the outlets should be

adjusted that way not to blow the air directly to the driver but to driver řs legs.

32

F 50 F 51 F 52

∗ AC CONTROL

The switch with symbol of flake controls

air-conditioning.

It is necessary to create overpressure in

the cab for the proper function of AC.

Thatřs why we recommend to shut all

windows, doors and cab roof cover.

CONTROLS

COOLING THE CAB

For fast cooling the inner space of cab

move the heating shut off lever (2) into

the left position (i.e. fresh air inlet is

closed). Choose the desired blower

speed by the four speed blower switch

(position 1, 2, 3). Set outlets with desired

angle to avoid direct blowing to persons

in the tractor cab (possible injury

because of intensive cooling of person řs

body).

AC OPERATION

With switched AC and permanently

closed heating shut off lever (2) in left

position (i.e. fresh air circuit closed) the

inner air is breathed out. Persons could

become tired. Thatřs why we recommend do move the lever (2) into the right

position (fresh air opened) immediately

after cooling down and reduction of the

inner temperature to desired level. The

fluent regulation of system is carried out

by partial opening of the heating valve

with heating control lever (3).

At the same time dry air from AC system

becomes moisture by this way.

33

DASHBOARD (

analogue)

34

F 53

LOCATION OF DASHBOARD

Analogue dashboard is assembled as a

standard equipment at tractors Z 8621, Z

8641, Z 9621, Z 9641, Z 10641.

DESCRIPTION OF INSTRUMENTS

A - indicator lights

B - air pressure gauge

C - tachometer with mechanical hour-

counter

D - fuel gauge

E - coolant thermometer

DASHBOARD (

INDICATOR LIGHTS

1. High beam light (blue). It lights if high

beam head lights are “ON .

2. Turn signal indicator light (green).

3. Turn signal indicator light (green) first trailer

4. Turn signal indicator light (green) second trailer

5. Indicator light of min. air pressure in

braking system (red): it lights if the

air pressure of air trailer brakes

drops under a critical margin i.e. 450

kPa.

6. Parking brake (red). It is “on“ if the

hand brake is set.

7. Charging indicator light (red). This is

“on“ after charging failure.

8. Lubrication indicator light (red). It is

“on“ if the engine oil pressure drops

below 120 to 60 kPa.

9. Air cleaner clogging indicator light is

“on“ after air cleaner clogging

(yellow).

10. Indicator light of hazard lamp

11. Indicator light of critical coolant

temperature (red) is “on“ after

exceeding temperature approx.

above 100 C (not connected).

12. Indicator light of Hi-Lo (torque

multiplier) (green 1st stage)

13. Indicator light of Hi-Lo (torque

multiplier) (green 2nd stage)

analogue)

14. Indicator light indicating critical failure in hydrostatic steering (not nocnnected)

15. Min. fuel level indicator light (orange). It lights if 1/6 to 1/10 of fuel tank

capacity stays at the fuel tank

16. PTO indicator light

17. Indicator light indicates wearing of

cardan brake.

18. Glowing indicator light (yellow)

19. Free

20. Free

35

DIGITAL DASHBOARD

36

F 54

LOCATION OF DASHBOARD

Digital dashboard is assembled as a

standard equipment on tractors Z 11641

and as an option on Z 8621 - Z 10641.

DESCRIPTION OF INSTRUMENTS

A -

indicator lights

B - air pressure gauge

C - tachometer with hour-counter

D - fuel gauge

E - coolant thermometer

F - display

DIGITAL DASHBOARD

INDICATOR LIGHTS AND PUSH

BUTTONS

Location of indicator lights on digital

dashboard is equal to analogue dashboard.

21. Indicator light of immediate travel

speed

22. Indicator light of PTO 1000 RPM

23. Indicator light of PTO 540 RPM

24. Symbol of immediate travel speed km/h

25. Symbol of RPM

26. symbol of voltage - V

27. Symbol of km

28. Symbol of battery

29. Symbol of traveled distance

30. Reset button for resetting the (day)

displayed data.

31. Button of battery voltage. Voltage is

displayed (with accuracy 0,1 V) and

simultaneously the indicator lights No

26 and 28 are “ON“.

32. Button of traveled distance (within

the day or from the time of last

resetting). No of kilometers is

displayed and simultaneously the

indicator lights No 27 and 29 are

“ON“.

33. Button of immediate travel speed in

v km.h-1, the speed is displayed and

simultaneously the indicator light No

21 and 24 is “ON“.

34. Button of PTO 1000 RPM. Speed

with accuracy 10 RPM is displayed

and simultaneously the indicator

lights No 22 and 25 are “ON“.

35. Button of PTO 540 RPM is displayed

and simultaneously the indicator

lights No 23 and 25 are “ON“.

37

CONTROLS

SWITCHES WITH LEVERS

Light switch

a b - Switch of front grill light and roof

light (low beam)

c - Fog light switch (ON - OFF). Functi-

on of fog light is indicated by illuminated symbol.

d - Working light switch (ON - OFF).

Function of working light is indica ted

by illuminated symbol.

e - Warning light switch

f - Front wheel drive control switch. En-

gaged front wheel drive axle is in-

dicated by switch symbol - ON .

g - plugged

h - plugged

i - plugged

j - differential lock (locks) button

k - stopping device - at tractors Z 8621

- 10641)

l - Toggle switch - turn signal, horn,

lights, high and low beam headlight

switch, acoustic horn.

38

F 55

F 56 F 57 F 58

LIGHT SWITCH (

a - Lights are “OFF“

b - Clearance lights and tail lights ,

license plate light and illumination of

instruments are “ON“

c - All electrical appliances are nocn-

nected as in “b“ position. Moreover

low and high beam lamps are ON

according to the position of toggle

switch.

a)

CONTROLS

FRONT WHEEL DRIVE SWITCH (d)

Use the front driving axle for

increasing the pulling force when

rear wheels slippage.

a - front driving axle disengaged

b - front driving axle engaged

Front driving axle is engaged at stopped

tractor (braked tractor, stopped engine).

Front driving axle is engaged in the

basic position (indicator lamp “ON ) and

the switch disengages the axle.

HAZARD LIGHT SWITCH (f)

a - Hazard lights are “off“.

b - Hazard lights are “on

Flashing of indicator light on the

dashboard indicates function of hazard

lights.

39

F 59 F 60 F 61

SWITCH OF GRILL AND CAB HEADLIGHT (

a - cab roof headlights are “OFF

b - cab roof headlights are “ON

The switch controls the headlights in the

mask grill or in the tractor cab roof.

Use the cab roof headlights only if the

front grill headlights are covered by

attached implement hitched in the front

three point hitch. Symbol on the switch

indicates that cab roof headlights are

“ON . High beam can light in the grill

mask only.

g)

CONTROLS

SWITCH OF REAR (FRONT) DIFFERENTIAL LOCK (j)

a - differential lock disengaged

b - differential lock engaged

Diff lock is engaged by pressing the diff

lock push button that is returned into the

previous position after loosing.

Symbol on the switch indicates that the

diff lock is engaged.

Differential lock is automatically

disengaged after pressing brake pedals.

At tractors equipped with front driving

axle with pin lock, this is engaged

simultaneously with the rear diff lock.

TURN SIGNAL, HEADLIGHT AND

HORN TOGGLE SWITCH (i)

a - Turn signal - right.

b - Turn signal - left.

c - Acoustic horn press the toggle

switch in axis direction

d - High beam light

40

F 62 F 63 F 64

KEY SWITCH

Key switch is located on the front part of

steering wheel support under the

dashboard.

KEY SWITCH

KEY IN "0" POSITION

All electrical appliances controlled by the

key switch are disconnected. The key

can be removed.

KEY IN "I" POSITION

All electrical appliances controlled by the

key switch are connected except of

starter motor. The key is located in this

position when running the engine.

41

F 65

KEY IN “II“ POSITION

Starter motor is connected in this position. All electrical appliances controlled

by the key switch are connected except

of wipers, washer, blower of cab and AC.

The key is turned automatically to “I“

position after starting.

KEY SWITCH

42

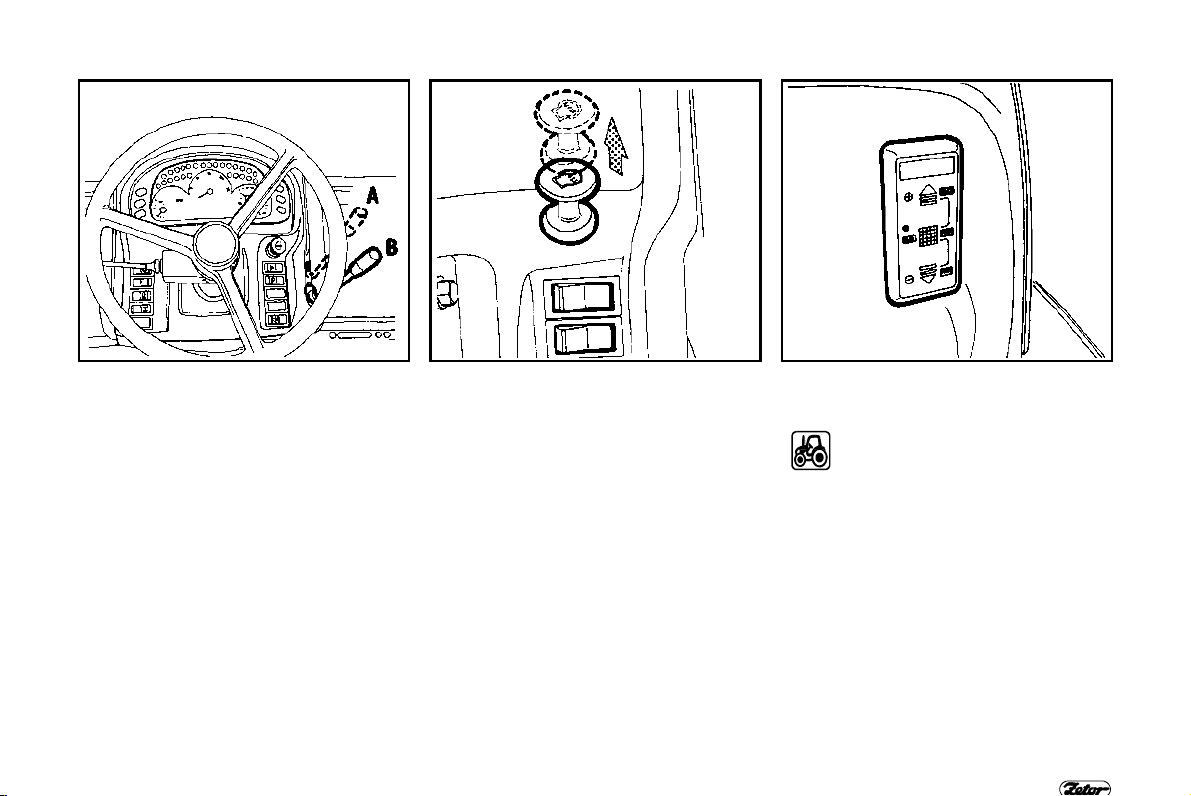

THROTTLE CONTROL LEVER

A -

Max. throttle

B - Stop

Only at tractors Z 8621 - Z 10641.

CONTROLS

F 67 F 68 F 69

STOPPING DEVICE

Pull the stopping device upwards and

keep it in pulled position, the engine will

be immediately stopped.

Only at tractors Z 8621 - Z 10641.

ELECTRONIC HAND THROTTLE

CONTROL

The system electronically controls speed of engine and controls

fuel delivery (see chapter

Electronic governor). Engine is stopped

by turning the key into “0“ position at this

system.

43

F 70 F 71 F 72

PEDALS AND LEVERS

Travel clutch pedal

1.

2. Foot operated service brake pedals

connected by latch

3. Foot throttle pedal

CONTROLS

MAIN GEAR SHIFTING LEVER AND

REVERSOR LEVER

1. Main shifting lever with push buttons

for three-stage Hi-Lo (torque multiplier)

2. Reversor lever

SHIFTING LEVER OF ROAD SPEED

AND REDUCED SPEED

The lever is located on the right hand

side at driverřs seat.

H - road speeds

N - neutral

L - reduced speeds

44

F 73 F 74 F 75

PTO SELECTION CONTROL LEVER

FOR SHIFTING OF PTO INDEPENDENT AND GROUND SPEED

Lever is located on the right hand side at

driverřs seat.

PTO -

N - Neutral position

PTO

synchro - PTO ground speed is

Independent PTO speed is

shifted

shifted (RPM depends upon

tractor travel speed)

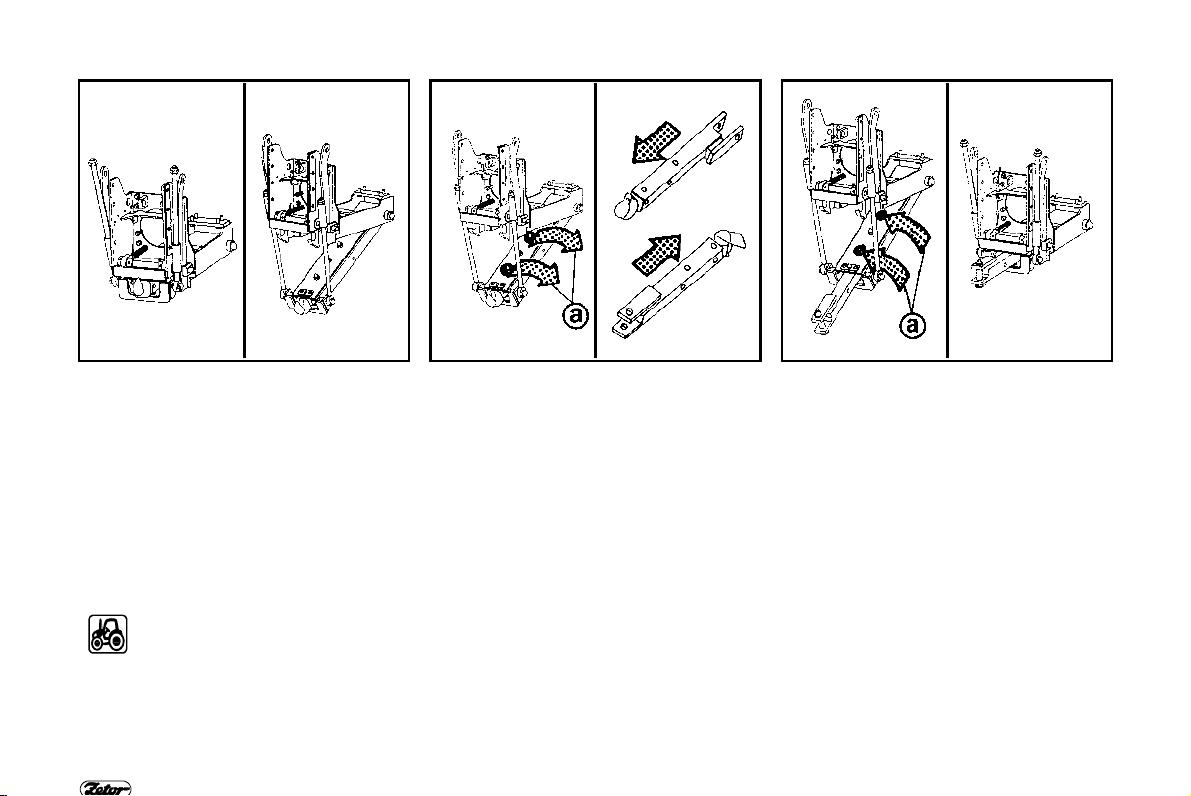

CONTROLS

PARKING BRAKE LEVER AND ∗ PICK

UP HITCH CONTROL LEVER

1. Parking brake lever

a - disbraked

b - braked

2. Pick up hitch control lever

a - transport position

b - pick up hitch is unlocked (lowered)

HYDRAULIC CONTROL

a - mechanical hydraulic control

b - Electro-hydraulic

Description of hydraulic control is mentioned in chapter hydraulic equipment.

45

F 76 F 77 F 78

HAND CONTROL OF SELECTION

CONTROL VALVE

At tractors equipped with ∗hydraulic

control of pick up hitch, lowering the pick

up hitch is controlled by SCV control

lever (a) (usually the right hand side

SCV lever or by operatorřs choice).

ACQUAINTANCE WITH TRACTOR

FUEL TANK

Plastic fuel tank with capacity 180 liters

is assembled as a standard.

Do not step on the fuel tank!

DRAINING PLUG OF FUEL TANK

The opening for draining impurities and

fuel is located in the bottom part of fuel

tank.

46

F 79 F 80

AVERAGE FUEL CONSUMPTION IN

LITTERS PER OPERATING HOUR

Tractor type

Z 8621, 8641 17,99 14,39 10,07

Z 9621, 9641 20,07 16,06 11,24

Z 10641 21,86 17,49 12,24

Z 11641 28,30 22,64 15,84

Engine load

100% 80% 50%

ACQUAINTANCE WITH TRACTOR

BATTERY SWITCH

Battery switch is located on the left hand

side underneath the front part of cab.

47

ACQUAINTANCE WITH TRACTOR

LOCATION OF INFORMATION AND

SAFETY DECALS

2. Warning decal - hand

3. Decal 4-speed transmission

5. warning of operating space

48

6. coefficient of absorption 0,86

F 81

7. warning of starter motor

8. ECE label

9. EPA label

ACQUAINTANCE WITH TRACTOR

49

NOTE

50

ELECTRONIC ENGINE GOVERNOR

Schema of electronic engine control system

Push button - MAX ................................................................................................ .... 53

Push button - MIN ..................................................................................................... 53

Push button - MEM....................................................................................................53

Indicator lamp H/O ....................................................................................................54

Function of electronic governor ................................................................................. 54

Setting the temporary memory .................................................................................. 54

Resetting and deleting the temporary memory ......................................................... 55

Setting the permanent memory ................................................................................. 55

Permanent memory recall - H/O lamp is off .............................................................. 56

Permanent memory recall - H/O lamp is on .............................................................. 57

Memory reset - return to pedal control ...................................................................... 57

1. Setting the entry and exit speed at tillage and enter to memory ........................... 58

2. Setting the operating speed and enter to temporary memory ............................... 58

3. Tillage with operating speed temporarily memorised ............................................ 58

4. Reset of temporary memory and recall of entry and exit speed memory .............. 59

5. Reset of permanent memory, setting the operating speed and its temporary

memorising................................................................................................................ 59

6. Tillage with operating speed temporarily memorised ............................................ 59

1. Setting the PTO speed ................................ ................................ .......................... 60

2. Setting the constant travel speed .......................................................................... 60

3. PTO speed engagement and setting the PTO speed for 540 or 1000 RPM ......... 60

4. Temporary memorising the PTO speed ................................................................ 61

5. Manoeuvring with tractor and reset of temporary memory .................................... 61

............................................................. 52

Page

All tractors Z 11641 are equipped

with electronic engine governor.

51

ELECTRONIC ENGINE GOVERNOR

SCHEMA OF ELECTRONIC ENGINE

CONTROL SYSTEM

System consists of the following main

components and of wiring harness.

Electronic control unit ( E.C.U.)

A B - Hand throttle control ’ the control

has three keypads and LED.

C - Potentiometer ’ mechanically linked

with foot throttle pedal

D - Engine speed sensor

E - Governor ’ control actuator

52

RPM

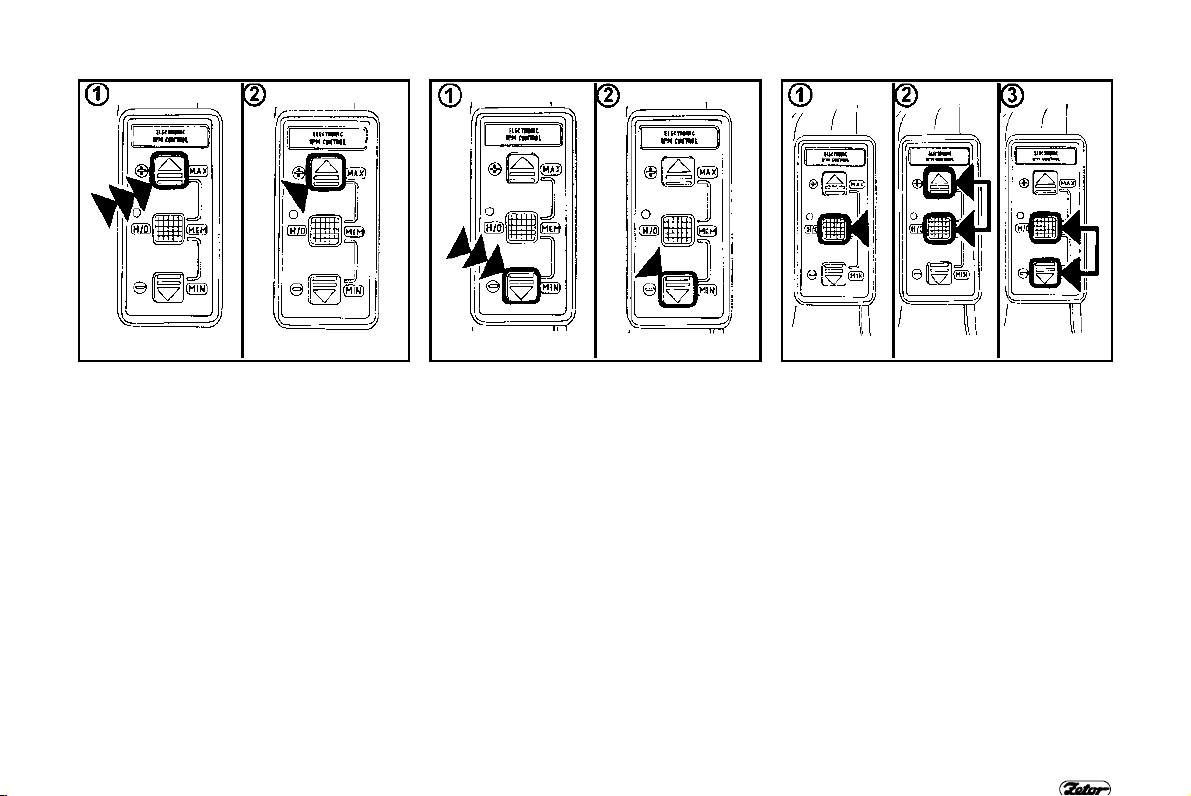

ELECTRONIC ENGINE GOVERNOR

RPM1 RPM2 RPM3

PUSH BUTTON - MAX

Push button (keypad) - max serves for

increasing the engine speed. Engine

speed can be increased by keypad max. by two ways.

1.

Pulse pressing the keypad causes

gradual change of engine speed.

2. Permanent pressing the keypad

causes the immediate increase of

engine speed. Engine speed is increased up to time when you release

the keypad.

This keypad controls the memory if

combined with keypad MEM.

PUSH BUTTON - MIN

Push button (keypad) - MIN serves for

decreasing the engine speed. Control of

keypad MIN is equal to control of keypad

MAX for increasing the engine speed (1,

2).

This keypad controls the memory if

combined with keypad MEM.

PUSH BUTTON - MEM

Push button (keypad) - MEM serves for

entering, recalling and resetting the

engine speed in memory of system. This

keypad is used either separately (1) or in

connection with keypads MIN or MAX

(2, 3).

53

RPM4 RPM5 RPM6

INDICATOR LAMP

Indicator lamp H/O indicates switching

on or off the function of keypad MEM.

Indicator lamp indicates entering, recalling and resetting the engine speed in

memory of system and moreover it indicates limiting the range of engine

speed increase or decrease.

H/O

ELECTRONIC ENGINE GOVERNOR

FUNCTION OF ELECTRONIC GOVERNOR

1. Setting the temporary memory

2. Resetting and deleting the temporary

memory

3. Setting the permanent memory

4. Permanent memory recall - H/O lamp

is off

5. Permanent memory recall - H/O lamp

is on

6. Memory reset - return to pedal control

Engine speed, determined for memorizing to memory system, can be set

either by throttle control or by foot

throttle control (throttle pedal). Enter,

recall and reset of memory is possible

on the keyboard of hand throttle control.

SETTING THE TEMPORARY MEMORY

1. Indicator lamp H/O must be off.

2. Set the desired engine speed by

hand (keypad MIN or MAX) or foot

throttle control, for example 1600

RPM.

3. Press the keypad MEM; indicator

lamp H/O turns on.

4. Set engine speed 1600 RPM is

memorized.

Since this setting, it is not necessary to

set the engine speed anymore. You can

loose the foot throttle pedal. Engine

speed is maintained in the constant level

(for example 1600 RPM) temporarily

memorized, independently upon tractor

load.

54

RPM7 RPM8 RPM9

With such way set constant value (for

example 1600 RPM) it is possible to set

the engine speed by means of hand or

foot throttle control and the entered

memory will not be lost.

a -

You can increase or decrease the

engine speed by hand throttle control. Increase or decrease the engine

speed by interrupted pressing of

keypad MIN or MAX.

b - You can only increase the engine

speed by foot throttle control. After

loosing the foot throttle pedal the

engine speed drops again to the

value entered in temporary memory

(for example 1600 RPM).

ELECTRONIC ENGINE GOVERNOR

RESETTING AND DELETING THE

TEMPORARY MEMORY

1. Indicator lamp H/O is on.

2. Press the keypad MEM.

3. Indicator lamp H/O turns off. Temporary memory is off. It is not possible

to recall it again. In this time the set

value (for example 1600 RPM) is definitively deleted. The same will happen after switching off the key in the

key switch.

SETTING THE PERMANENT MEMORY

1. Indicator lamp H/O must be off.

2. Set the desired engine speed by

hand (keypads MIN or MAX) or foot

throttle control.

3. Press both keypads MEM and MIN

or MAX depending if you want to

enter into memory minimal or

maximal engine speed.

4. Indicator lamp H/O is on. Since this

setting the engine speed is entered

into the permanent memory.

55

RPM10 RPM11 RPM12

In case the minimal engine speed is

1.

being entered it is not possible to

enter the value higher than 1500

RPM. If you will try it the system will

automatically enter 1500 RPM.

2. In case the maximal engine speed is

being entered it is not possible to

enter the value smaller than 1500

RPM. If you will try it the system will

automatically enter 1500 RPM.

ELECTRONIC ENGINE GOVERNOR

Two values can be entered into

permanent memory i.e. chosen minimal

and maximal engine speed. These

values will be memorized in the

permanent memory even after stopping

the engine and removing the key from

the key switch.

If you will enter the new minimal and

maximal engine speed into the

permanent memory the previously

entered values will be deleted and

replaced by new ones i.e. new values

set by you.

PERMANENT MEMORY RECALL - H/O

LAMP IS OFF

1. Indicator lamp H/O is off.

2. Press the keypad MIN or MAX

(depending if you want to recall

maximal or minimal speed entered in

memory) and keep it pressed (longer

time than 0,5 sec.).

3. Indicator lamp H/O turns on. Memory

is recalled. Engine will maintain the

recalled constant speed.

Engine speed can be set after this action

by:

56

RPM13 RPM14 RPM15

a -

by hand throttle control i.e. by

interrupted pressing the keypads

MIN or MAX. After loosening the

keypads, the engine speed will be

changed to engine speed recalled

from the permanent memory.

b - by foot throttle control (by throttle

pedal) and the engine speed can be

increased only. After loosening the

keypads, the engine speed will be

changed to engine speed recalled

from the permanent memory.

ELECTRONIC ENGINE GOVERNOR

PERMANENT MEMORY RECALL - H/O

LAMP IS ON

1. Indicator lamp H/O is on. Indicator

lamp is on in that case if you have

already recalled minimal or maximal

speed from the permanent memory.

Or if the set speed is entered in the

temporary memory.

2. Press the keypad MIN or MAX depending on which speed you want to

switch the memory of system and

keep it pressed (longer time than 0,5

sec.).

Attention! In case the indicator lamp

H/O indicated the function of temporary

memory (set speed was entered in the

temporary memory) this engine speed

will be definitively deleted after recall of

values from permanent memory.

57

MEMORY RESET - RETURN TO PEDAL CONTROL

1. Indicator lamp H/O is on. Tractor

works with engine speed entered in

temporary or permanent memory.

2. Press the keypad MEM.

3. Indicator lamp H/O turns off. Temporary or permanent memory is

switched off. Set engine speed in

temporary memory is deleted, set

engine speeds in permanent memory

are kept.

Now engine speed can be set by foot

throttle pedal or hand throttle control

without any restriction (by interrupted

pressing of keypad MIN or MAX).

. SETTING THE ENTRY AND EXIT

1

SPEED AT TILLAGE AND ENTER TO

MEMORY

1. Indicator lamp H/O is off.

2. Set the entry and exit travel speed of

tractor by the keypad MIN or MAX

(for example 1600 RPM)

3. Press both keypads MAX and MEM.

(the speed is entered into permanent

memory).

4. Indicator lamp H/O is on.

ELECTRONIC ENGINE GOVERNOR

2. SETTING THE OPERATING SPEED

AND ENTER TO TEMPORARY MEMORY

1. Turn off the indicator lamp H/O by

keypad MEM.

2. Set the operating engine speed by

foot throttle control (foot throttle

pedal)

3. Press the keypad MEM. Indicator

lamp H/O turns on. The speed is

entered in permanent memory.

RPM16

3. TILLAGE WITH OPERATING SPEED

TEMPORARILY MEMORISED

Since you entered the operating engine

speed into the temporary memory no

correction of speed is necessary.

System automatically maintains the

constant level of operating engine speed

entered in the temporary memory

independently upon tractor load.

58

4. RESET OF TEMPORARY MEMORY

AND RECALL OF ENTRY AND EXIT

SPEED MEMORY

1.

Increase engine speed by foot

throttle control to avoid sudden dropping of speed.

2. Press the keypad MEM. Indicator

lamp H/O turns off. Temporary memory is switched off and entered

value is definitively lost.

3. Press and keep (longer than 0,5

sec.) the keypad MAX. You will recall

the value entered in permanent memory by this way. Now the engine

works in regime of entry and exit

speed.

ELECTRONIC ENGINE GOVERNOR

5. RESET OF PERMANENT MEMORY,

SETTING THE OPERATING SPEED

AND ITS TEMPORARY MEMORISING

1. Press the keypad MEM. Indicator

lamp H/O turns off. Permanent memory is switched off.

2. Again set the operating engine speed

by foot throttle control (foot throttle

pedal).

3. Press the keypad MEM. Indicator

lamp H/O turns on. The speed is now

entered into temporary memory.

RPM16

6. TILLAGE WITH OPERATING SPEED

TEMPORARILY MEMORISED

Activities that are mentioned in point 6

are equal to point 3.

59

. SETTING THE PTO SPEED

1

Choose the PTO speed 540 or 1000

RPM by the end of rear PTO shaft.

ELECTRONIC ENGINE GOVERNOR

2. SETTING THE CONSTANT TRAVEL

SPEED

1. Set the engine speed by keypad MIN

or MAX corresponding to desired

travel speed.

2. Indicator lamp H/O stays off.

RPM17

3. PTO SPEED ENGAGEMENT AND

SETTING THE PTO SPEED FOR 540

OR 1000 RPM

1. Engage the independent speed of

PTO shaft.

2. Set the engine speed by foot throttle

control (foot throttle pedal) corresponding to desired speed of PTO

shaft in range 540 or 1000 RPM.

60

4. TEMPORARY MEMORISING THE

PTO SPEED

1.

Press the keypad MAX. Indicator

lamp H/O turns on.

Since this the set engine speed corresponding the PTO speed 540 or 1000

RPM is entered in the temporary memory. System will automatically maintain

the constant speed of PTO independently upon load of tractor.

ELECTRONIC ENGINE GOVERNOR

RPM17

5. MANOEUVRING WITH TRACTOR

AND RESET OF TEMPORARY

MEMORY

1. Disengage the PTO shaft when

manoeuvring the tractor with implement.

2. Press the keypad MEM. Indicator

lamp H/O turns off.

Since this the temporary memory is

switched off and values entered in temporary memory are definitively lost. The

engine works with speed corresponding

to travel speed set by keypads MIN or

MAX.

61

NOTE

62

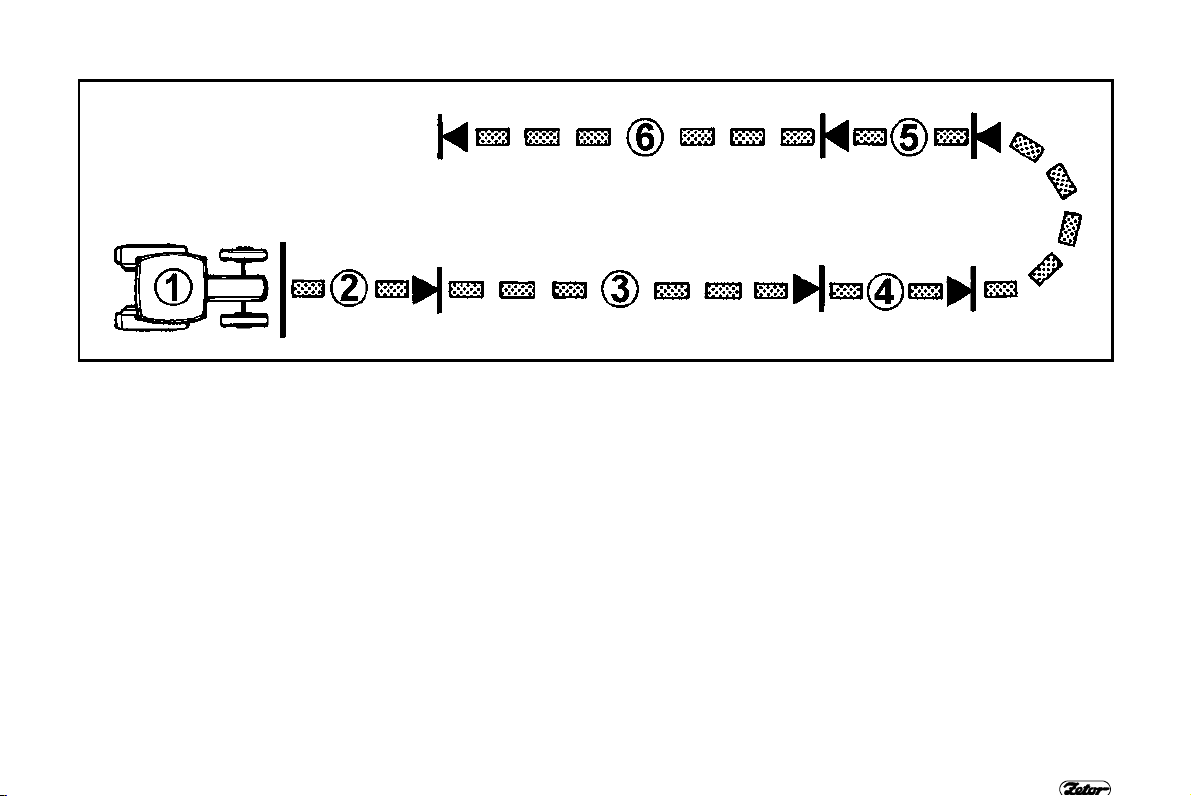

Be familiar with shifting

pattern and test all positions of shifting lever at

stopped engine before driving the new tractor.

Be sure that the technical

status of tractor corresponds to the safety traffic

condition before driving.

OPERATION

Page

Before starting

Starting the engine equipped with glow plugs ........................................................... 65

Starting the engine equipped with electronic thermostart ......................................... 66

If engine doesnřt start................................................................................................ 67

Forbidden starts ........................................................................................................ 67

∗ Coolant heater........................................................................................................ 68

Starting the engine with coolant heater ..................................................................... 68

Immediately after starting ................................ ................................ .......................... 69

Preheating the engine ................................................................ ............................... 69

Gear shifting.............................................................................................................. 70

Reversor lever........................................................................................................... 70

Shifting the road and reduced speeds ................................ ................................ ...... 70

Shifting from lower to higher gear speed ..................................................................71

Shifting from higher to lower gear ............................................................................. 71

Three stage hi-lo (torque multiplier) .......................................................................... 71

Indication of hi-lo function ......................................................................................... 72

Hi-lo shiftinng ................................................................ ............................................ 72

Acceleratig the tractor ............................................................................................... 73

Driving uphill.............................................................................................................. 74

Driving downhill ................................................................ ......................................... 74

Service brakes ................................................................ .......................................... 74

Front drum brakes ..................................................................................................... 75

∗ Front cardan brake ................................................................ ................................. 75

Air trailer brakes ........................................................................................................ 75

Warning device of air pressure drop ......................................................................... 76

∗Single and double hose air brakes .......................................................................... 76

Air tanks ................................................................................................ .................... 76

Single hose air trailer brakes..................................................................................... 77

Double hose air trailer brakes ................................................................ ................... 77

Hydraulic trailer brakes ............................................................................................. 78

Control of front driving axle ................................................................ ....................... 79

Driving with engaged front driving axle ................................ ..................................... 79

................................................................ ........................................... 65

63

OPERATION

Page

Free space round cardan shaft

Stopping the tractor - parking brake.......................................................................... 80

Stopping the engine .................................................................................................. 80

Leaving the tractor .................................................................................................... 80

................................................................ ................. 79

64

BEFORE STARTING

Before starting the engine be

sure that

1.

the tractor is braked by

parking brake.

2. main shifting lever and reversor lever is in neutral position.

If the shifting lever is in a different then neutral position tractor can not be started - safety interlock switch is not actuated.

OPERATION

F 82 F 83 F 84

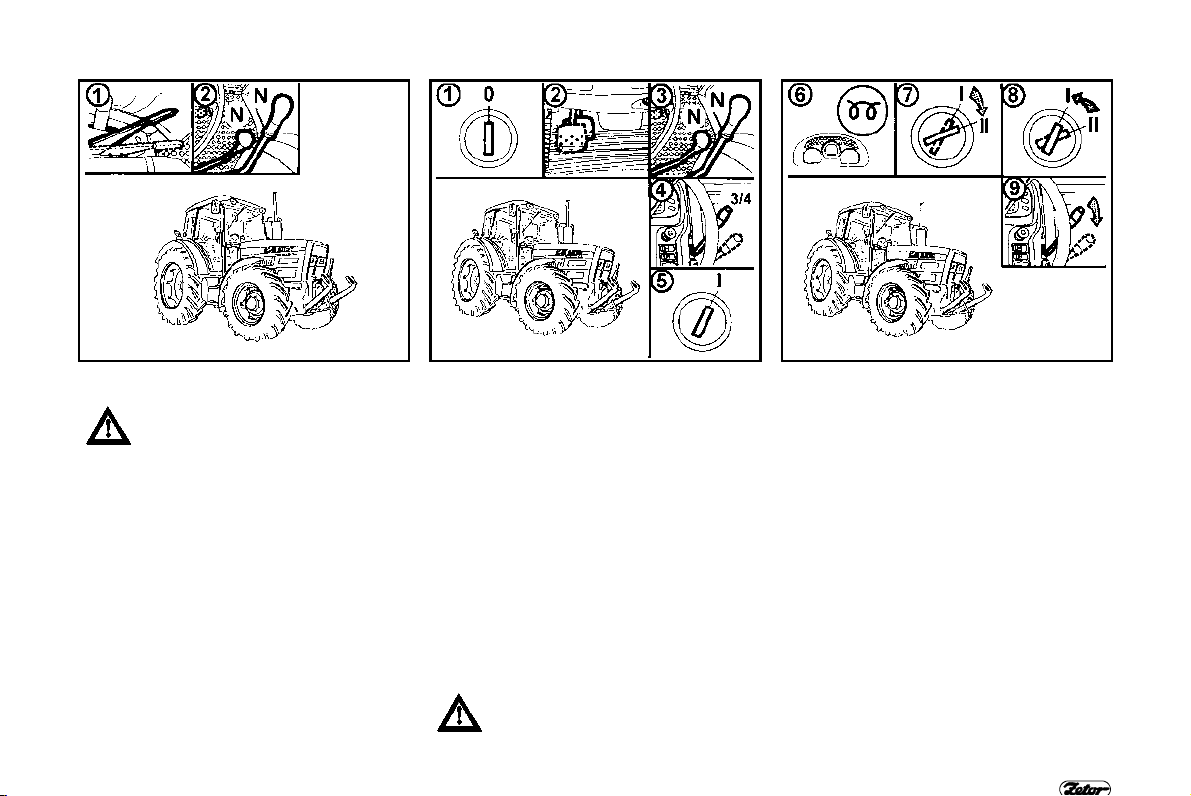

STARTING THE ENGINE EQUIPPED

WITH GLOW PLUGS

Tractors Z 8621 - 10641 are equipped

with glow plugs as a standard.

1. Insert the key into the key switch

("0" position).

2. Depress the clutch pedal.

3. Move the main shifting lever and

reversor lever into neutral.

4. Set the increased throttle control

(approx. 3/4 maximal delivery).

5. Turn the key into "I" position. Yellow

indication lamp on the dashboard is

“ON“. The indication lamp indicates

correct function of glowing.

In case the indication lamp is

flashing the glowing system

failed. In spite of this, the engine

can be started but without function of

65

glow plugs. Let repair the indicated

failure in a specialized workshop.

6. Wait until the indication lamp is off.

7. Turn the key into "II" position (start).

8. Release the key immediately after

starting the engine. Do not start longer then 15 sec.

9. After starting the engine, reduce

gradually the fuel delivery. Avoid

running the engine at high speed.

Note: According to the personal

experiences of driver it is possible to

start sooner then glow indicating lamp is

off. Proceed similarly when starting the

hot engine.

F 85 F 86 F 87

STARTING THE ENGINE EQUIPPED

WITH ELECTRONIC THERMOSTART

Tractors Z 11641 are equipped

with electronic

standard.

Thermostart enables starting the engine

at lower temperatures. Time of glowing

and the process of fuel ignition in suction

manifold is controlled automatically.

Note: Before proper starting we recommend to prime the fuel system by several strokes of fuel delivery pump.

thermostart as a

OPERATION

1. Insert the key into the key switch

("0" position).

2. Depress the clutch pedal.

3. Move the main shifting lever and

reversor lever into neutral.

4. Turn the key through "I" position into

"II" position and (start) crank the

engine only (when “hot starts„ this

point can be eliminated).

5. Turn the key into "I" position. Yellow

indication lamp on the dashboard is

“ON“. The indicator lamp indicates

correct function of thermostart

glowing (when higher ambient temperatures the thermostart function is

not initiated).

6. Wait until the indication lamp is off.

7. Turn the key into "II" position (start).

8. Release the key immediately after

starting the engine. Do not start

longer time then 10 sec.

9. After starting the engine, avoid running the engine at high speed.

66

F 88 F 89

IF ENGINE DOESN’T START

Wait 30 seconds. Turn the key into position "0" and repeat starting.

Never help to the stopping

engine by starter motor. You will

avoid damage of starter motor.

Never start longer than 10 sec. at

tractors Z 11641. Start needs to

be repeated.

OPERATION

FORBIDDEN STARTS

It is forbidden to start the

tractor by short circuit of

starter motor connectors.

Start from the driver’s seat

only.

Disconnect the ground battery

pole, shift all levers into neutral

position, including PTO engagement, when any manipulation

with starter or repairing it. A

cover protects starter motor connectors.

67

F 90 F 91

∗ COOLANT HEATER

Coolant heater is assembled into engine

block as an option. At tractors Z 8621 Z 10641output of heater is 1000 W with

voltage 220 V of alternating electrical

current.

At tractors Z 11641 output of

heater is 500 W with voltage 220

V of alternating electrical current

OPERATION

STARTING THE ENGINE WITH COOLANT HEATER

Heater enables starting the engine at low ambient temperature by preheating the

coolant. The electrical installation and its protection against electrical shock hazard

must be done according to the proper regulations

Plug the heater first.

1.

2. Plug the cable with heater into 220 V electricity after.

With regard to reduction of engine wear when starting at low temperatures, producer

recommends to use heater. The time of preheating depends upon the ambient

temperature (1 to 2 hours are sufficient before supposed starting).

After heating, unplug the electricity first and the heater after.

ELECTRICAL SHOCK HAZARD!

68

F 92 F 93

IMMEDIATELY AFTER STARTING

After starting set the engine

speed to 800 up to 1000 RPM

and let the engine idle for 3

minutes without load.

In this time check for proper lubrication,

charging (indicator lights must be “off“)

and other functions assuring the correct

engine operation. Time of engine idle

without load must be kept especially in

winter season.

OPERATION

PREHEATING THE ENGINE

Continue with farther preheating the engine already while driving. Warming

up the engine by long idle run or fast increase of speed is dangerous for the

engine.

Do not exceed engine speed above 2 000 RPM until the coolant temperature

reaches 45°C.

69

F 94 F 95 F 96

GEAR SHIFTING

Tractors are equipped with four speed

synchronized gearbox, three stage

power shift - Hireversor, and two stage reduction gear.

Four-speed gearbox is shifted by the

main shifting lever with grip push buttons

intended for Hi-Lo control (1). Forward

and reverse speed is shifted by reversor

lever (2).

The fourth speed can not be

shifted when shifted reverse

speed (it is blocked).

Lo (torque multiplier)

OPERATION

REVERSOR LEVER

You select the tractor direction by

reversor shifting lever (forward, reverse).

Forward speed (24 speeds)

F -

Neutral

A -

reverse speed (18 speeds)

R There are 18 reverse gears available at

reversible gearbox, the reverse speeds

are approximately so fast as forward

speeds. Thatřs why take this well into

consideration and choose the suitable

reverse speed for the given character of

the operation.

Shift the reversor with depressed

clutch pedal and with stopped

tractor.

Shift the reverse lever into position R

SHIFTING THE ROAD AND REDUCED

SPEEDS

Road speeds

H -

neutral

N -

Reduced speeds

L Gear shifting of reduced speeds is the

same as shifting of road speeds.

Shifting lever of road - reduced

speeds can be shifted at stopped

tractor only.

70

F 97 F 98 F 99

SHIFTING FROM LOWER TO HIGHER

GEAR SPEED

Depress the clutch pedal (clutch

disengaged). In the same time loosen

the throttle pedal and shift the proper

higher gear speed. Fluently release the

clutch pedal (the clutch starts engaging)

and simultaneously increase engine

speed.

OPERATION

SHIFTING FROM HIGHER TO LOWER

GEAR

Depress the clutch pedal and shift the

shifting lever through neutral position to

lower gear speed.

Note: So-called double clutching can be

used for increasing the life of

synchronizers when shifting from higher

to lower gears.

THREE STAGE HI-LO (TORQUE MULTIPLIER)

Three stage Hiequipment of all tractor types.

The particular stage of Hi-Lo is shifted

by means of two push buttons located

on the shifting lever grip.

Shifting is done without depressing the

travel clutch (power shift).

The shifting alone is automatic even

under the load of tractor.

gear ratio 1,00 (Hi)

H

gear ratio 1,16 (middle)

M

gear ratio 1,34 (

L

Lo is a standard

Lo)

71

OPERATION

F 100 F 101

INDICATION OF HI-LO FUNCTION

The particular shifted stages of Hi-

Lo

(H,M,L) are indicated by indicator lamps

with symbols of turtles.

Lamps with symbols are off

H

One lamp with turtle symbol is on

M

Two lamps with turtle symbol are

L

on

Note: The stage is automatically

shifted when starting or stopping the

tractor.

HI-LO SHIFTINNG

Travel speed increased

H

Travel speed decreased

L

72

F 102

Travel speed increased by two

2xH

stages

Travel speed decreased by two

2xL

stages

Note: Description of push buttons right,

left“ is taken in forward direction of

tractor travel.

ACCELERATIG THE TRACTOR

1.

Select road or reduced gear.

2. Depress the clutch pedal.

3. Shift the main shifting lever and

reversor lever into neutral.

4. Start the engine.

5. Set the engine speed to 750 up to

800 RPM.

6. Shift the reversor lever into the

desired direction of tractor movement

(forward or reverse).

7. Shift the proper gear speed suitable

for starting the movement

8. Slightly increase the engine speed.

9. Prepare the parking brake for re-

leasing.

10. Release the clutch pedal up to point

where the tractor starts to move and

simultaneously with engine speed

OPERATION

F 103

increasing, continue with smooth

releasing the clutch.

11. Fully release the parking brake.

12. Accelerate smoothly and slowly.

Fast acceleration can cause the

overload of transmission, increased fuel

consumption, excessive tire wear and

damage of the transported load.

Use the 1st gear only for accelerating

when driving with heavy trailer uphill and

in heavy terrain.

73

DRIVING UPHILL

Shift from higher to lower speed

in time when going uphill, to

avoid dropping the engine speed

below 800 RPM and stopping the

engine by overloading.

OPERATION

F 104 F 105 F 106

DRIVING DOWNHILL

Driving downhill without the shifted gear is forbidden. If driving

down the long hill, shift so low

gear the sharper one the hill is. If

possible shift the lower gear

before driving downhill.

Remember: The gear you use reliably

for driving uphill is safely suitable for

driving downhill.

SERVICE BRAKES

Service brakes are of disc wet type,

hydraulically actuated with double pedal,

and automatic pressure compensator.

Both brake pedals must be

latched together when driving on

the road.

Use unlatched pedals only for

braking right or left wheel

separately when working in

terrain and fields.

74

F 107 F 108 F 109

FRONT DRUM BRAKES

Front drum brakes are assembled on

tractors with front non-driven axle

Z

8621, Z 9621 as an option.

Front brake is not in function

when braking with one pedal

only.

OPERATION

∗ FRONT CARDAN BRAKE

Front cardan brake is assembled on

tractors with front driving axle as an

option.

Front cardan brake is assembled as a

standard on 4WD tractors with transmission for 40 km/h.

Moreover there is a cardan brake

amplifier as standard equipment

at tractors Z 11641.

Front cardan brake is not in

function when braking with one

pedal only.

AIR TRAILER BRAKES

The control of air trailer brake is

synchronized with tractor brake control

including the brake effect.

Operating pressure is set by a pressure

valve (regulator) adjusted to 740 20

kPa. If the pressure drops under 550

40 kPa the priority valve disconnects

pneumatic circuits of secondary appliances: differential lock control, front

wheel drive control, three point hitch

pneumatic control, Hi-Lo (torque multiplier), PTO control.

75

F 110 F 111 F 111a

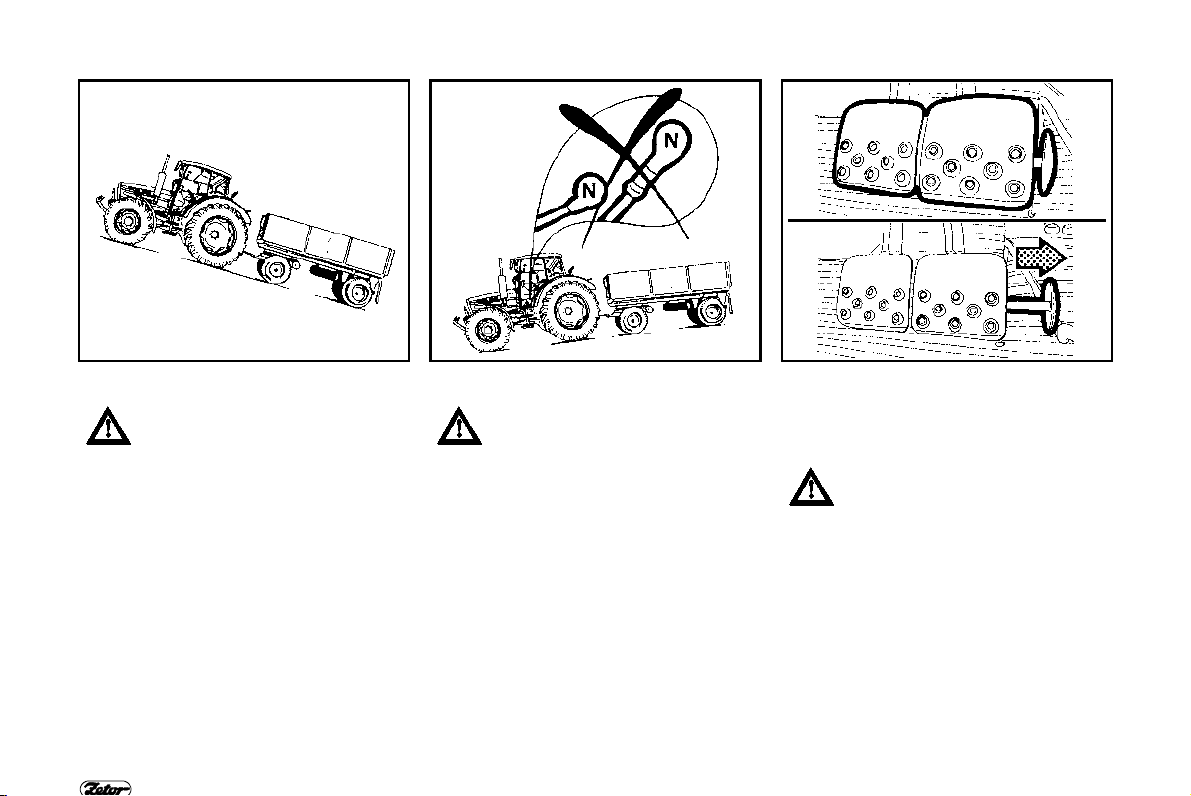

WARNING DEVICE OF AIR PRESSURE DROP

Dropping of air pressure under critical

margin 450 kPa is indicated by red

indicator lamp located on the dashboard.

Tractor with a braked trailer can

not continue in driving when air

pressure drops under the critical

margin and until the pressure is

increased

OPERATION

∗SINGLE AND DOUBLE HOSE AIR

BRAKES

Coupling of single hose air brake

I -

system.

II - Couplings of double hose air brake

system.

Couplings must be covered by a

cap if the trailer is not hitched.

AIR TANKS

Tractors are equipped with an air tank of

capacity 12 l as a standard. The air tank

is located on the right side of tractor in

front of the rear axle.

When the tractor is equipped with air

trailer brakes an extra air tank of capacity 12 l is assembled on the left hand

side of tractor in front of the rear axle as

a standard.

Both air tanks are assembled on

tractors Z 11641 as a standard

76

F 112 F 113

SINGLE HOSE AIR TRAILER BRAKES

Operating pressure is set by a pressure

valve (regulator) adjusted to 600 20

kPa. Capacity of both air tanks is 24

The allowed speed of tractor

equipped with single hose air

trailer brakes and with hitched

trailer is max. 25 km/h.

l.

OPERATION

DOUBLE HOSE AIR TRAILER

BRAKES

Operating pressure is set to 740 20

kPa Capacity of air tanks is 24 l. Left

coupling cover is yellow, right coupling

cover is red.

The allowed speed of tractor

equipped with double hose air

trailer brakes and with hitched

trailer is max. 40 km/h .

77

OPERATION

F 114

HYDRAULIC TRAILER BRAKES