ZETOR

This Operator’s Manual for the Zetor Forterra tractors, which we are presenting to you will help you to become

familiar with the operation and maintenance of your new tractor.

Although many of you have rich experience with the operation of other tractors, please, read the information

contained in this Operator’s Manual very carefully.

In the Manual you will find a lot of new information and get a perfect overview of how to use the tractor with

maximum efficiency during various kinds of work.

If you observe the rules of tractor operation and maintenance and driving safety, your new tractor will become your

reliable and long-term friend.

The manufacturer of the tractor wishes you thousands of hours of satisfactory work.

ZETOR

Brno

3

The technical specifications and information about the design, equipment, material and appearance are valid at the time of print.

The manufacturer reserves the right to implement changes.

4

The Operator’s Manual deals with the

description, operation and maintenance

of the standard version and accessories

that the tractor may be optionally

equipped with.

The service cheque book for tractors is

not part of the Operator’s Manual, but

forms a separate booklet that is handed

over to you at the purchase of your new

tractor.

CONTENTS

Page

Location of serial numbers ......................................................................................... 7

Safety instructions for users........................................................................................9

Preventive daily maintenance ................................................................................... 13

Acquaintance with the tractor ................................................................................... 19

Driving operation ....................................................................................................... 47

Running in the tractor ............................................................................................... 65

Transportation ........................................................................................................... 69

Drive of agricultural machines .................................................................................. 75

Hydraulic system ......................................................................................................81

Electro-hydraulic system ........................................................................................... 89

Hitches ...................................................................................................................... 99

Wheel track change ................................................................................................ 107

Ballast weights ........................................................................................................ 113

Electric installation ..................................................................................................121

Tractor maintenance ...............................................................................................131

Maintenance instructions......................................................................................... 145

Adjustment ............................................................................................................. 167

Main technical parameters ..................................................................................... 177

Index ......................................................................................................................191

5

Zetor Forterra 95........................... 66 kW

Zetor Forterra 105......................... 74 kW

Zetor Forterra 115 ......................... 81 kW

Zetor Forterra 125......................... 90 kW

ZETOR FORTERRA TRACTORS

6

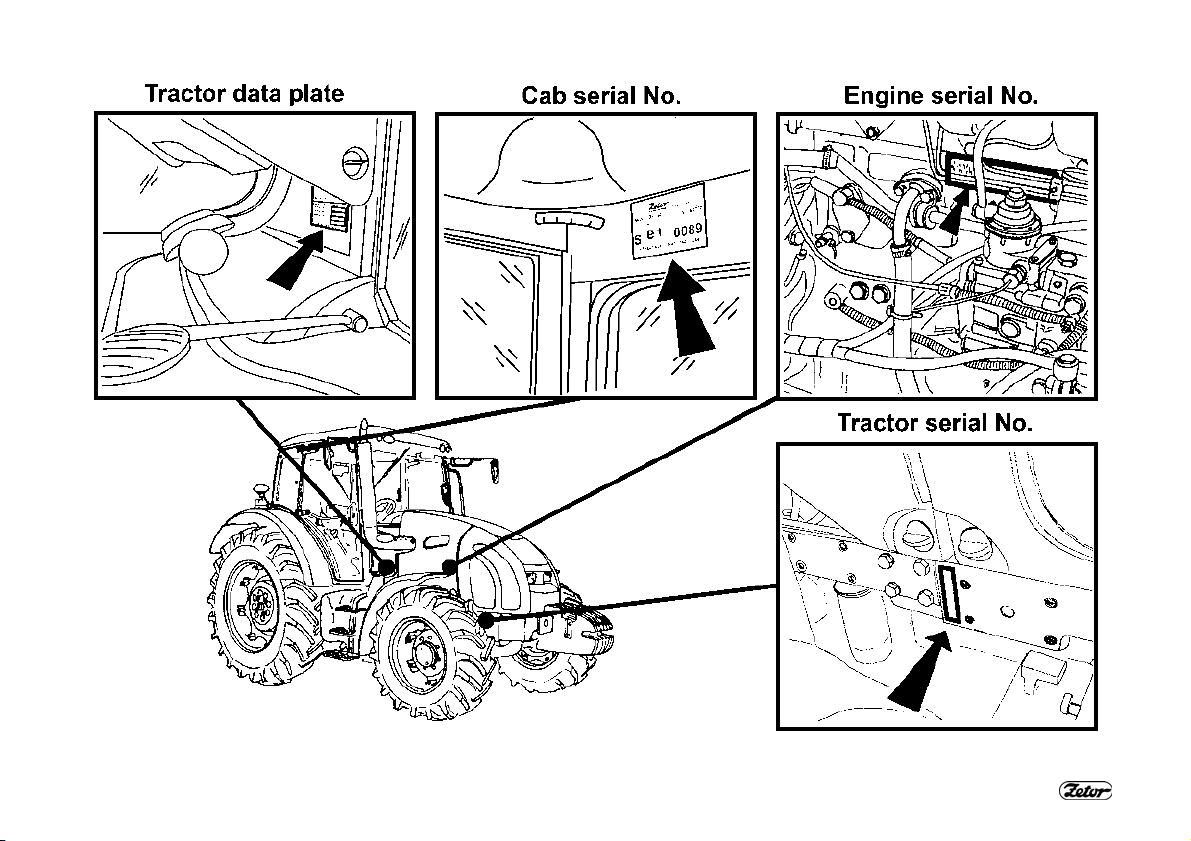

LOCATION OF SERIAL NUMBERS

XH154

7

LOCATION OF SERIAL NUMBERS

When ordering spare parts and within all written and oral communication always specify the data of your tractor that should be

written in the frames below.

Tractor type

Zetor Forterra 95

Zetor Forterra 105

Zetor Forterra 115

Zetor Forterra 125

The “right”, “left”, “front” and “back”

indications refer to the driving direction of

the tractor.

The manufacturer reserves the right to

implement changes of the design and

options during the production to improve

the features of the tractor.

Tractor serial number

8

Engine serial number

XF-02-101

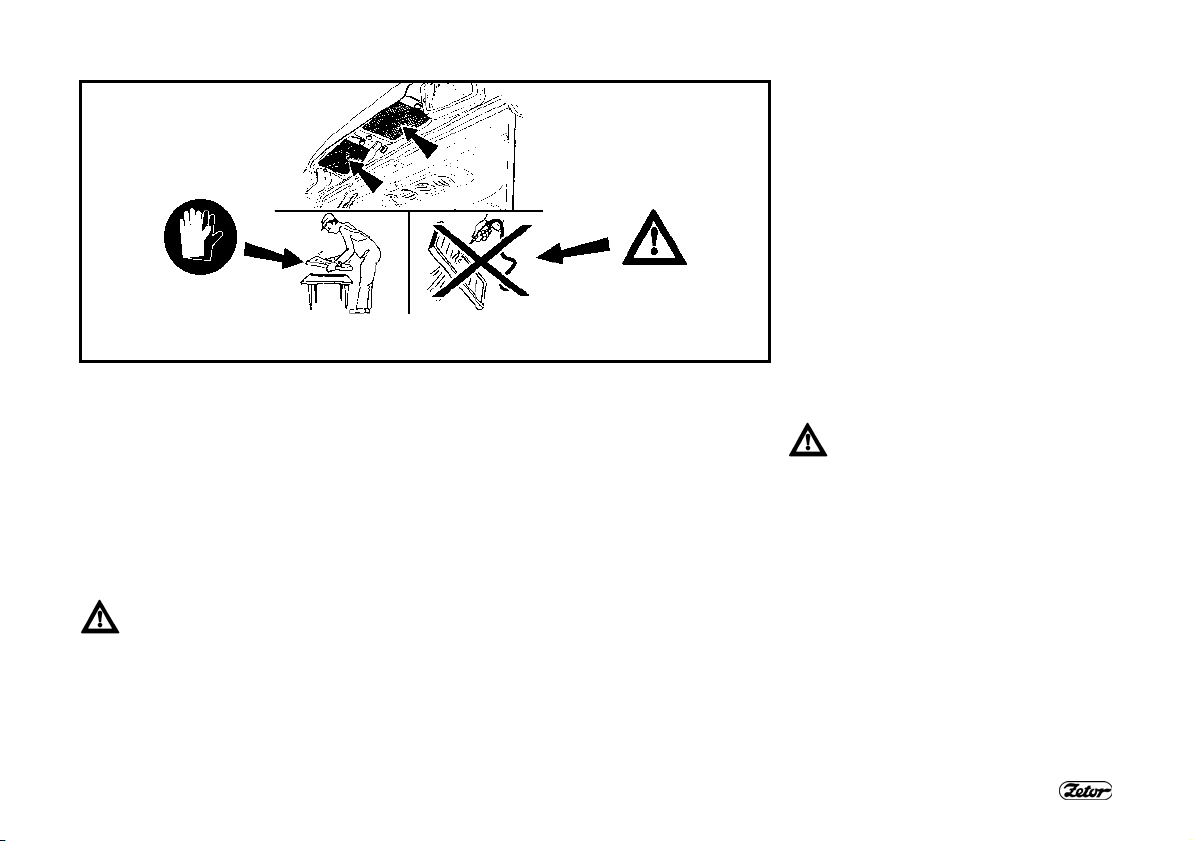

SAFETY INSTRUCTIONS FOR USERS

Please, pay increased attention to the

parts of the Operator’s Manual that are

marked with this symbol.

This symbol accompanies all

important warnings that concern

operation safety.

Observe these instructions

and be extremely careful in

these cases!

Inform your colleagues and

other users about these

warnings.

Carefully study the chapters

marked with this symbol before

starting to perform operation,

repairs and adjustments of your

tractor.

This symbol identifies all

important information concerning

operation, adjustment and

repairs of the starter motor.

Observe these instructions

and be extremely careful in

these cases!

This symbol marks parts of the

Operator’s Manual concerning

environment protection. Or

possibly sections describing

handling of dangerous waste.

This symbol refers to optional

∗

tractor accessories installed by

the manufacturer on the

customer’s request.

Accessories that are not

installed by the manufacturer in

the standard way or * optionally

on the customer’s request (in the

production plant) cannot be

subject to a claim.

GENERAL SAFETY REGULATIONS

1. The tractor may only be operated by

a trained person that has a valid driving

licence and has been thoroughly

acquainted with the operation and safety

rules.

2. Besides the safety instructions

mentioned in the Operator’s Manual you

are obliged to respect generally valid

safety and traffic rules of the country

where the tractor is used.

PROPER CLOTHING

3. Do not wear loose clothing and free

flying long hair.

4. During all work use suitable

(prescribed) means of personal

protection (working boots, gloves,

goggles, etc.)

9

STARTING THE ENGINE

5. It is not permitted to start the engine

by driving down a slope.

6. The tractor may be put in motion to

start the engine with the use of another

tractor or another vehicle with the use of

a towing bar only.

7. Only start the engine from the driver’s

seat with the clutch pedal fully

depressed.

Life hazard when starting by

means of short-circuiting the

starter terminals!

8. The key in the switch box must be in

the “I” position.

9. When heating the engine with the *

electric heater first plug the power supply

cord to the heater and only then to the

electric mains. After the end of heating

first disconnect the heater from the

electric mains.

Caution! Electric shock hazard!

SAFETY INSTRUCTIONS FOR USERS

DRIVING OPERATION

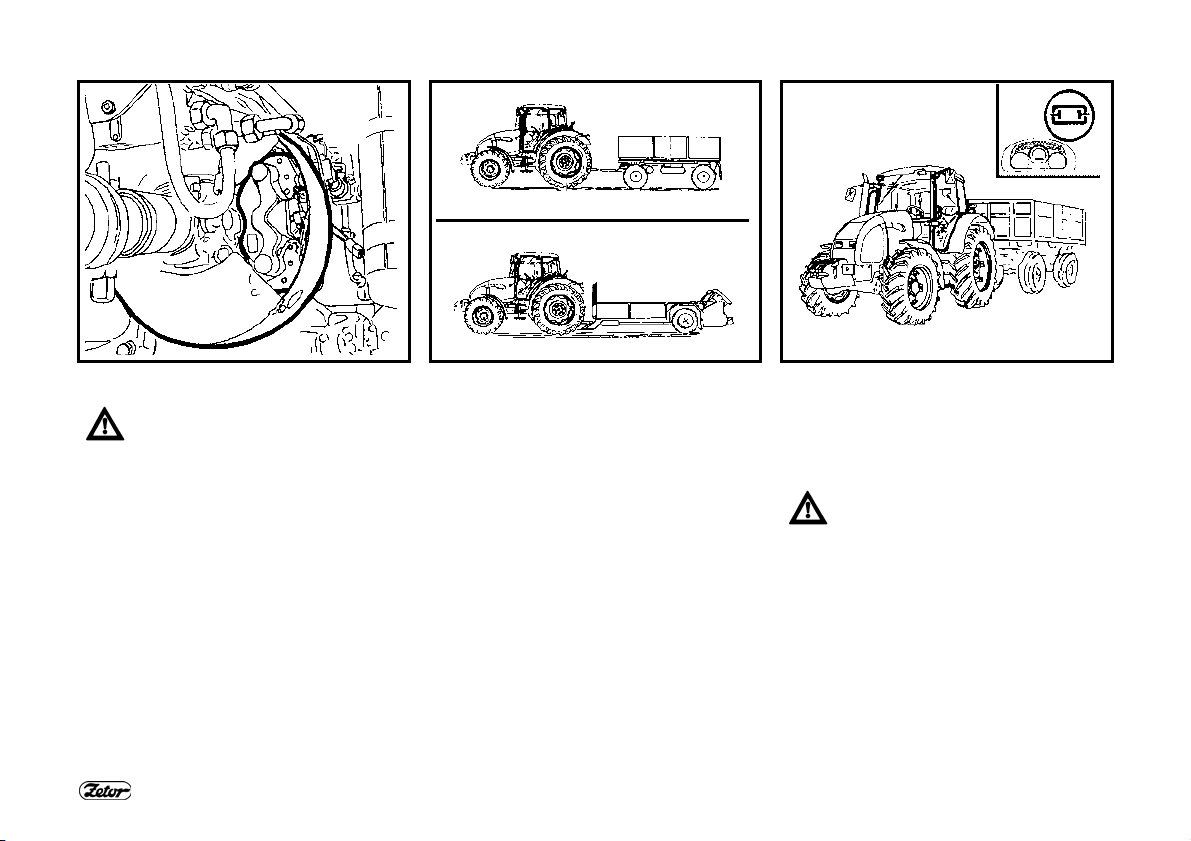

10. Hoses of the hydrostatic steering,

brakes and fuel system must be checked

and replaced immediately if any signs of

damage are found. These are some

examples of hose damage signs: cracks on the hose surface, releasing of

pre-tensioning of hose connection (which

can be verified by easy removal of the

hose from the connection) and

mechanical damage of the hose. Hoses

with indicated service life must be

replaced immediately after the expiration

of the service period.

11. If the tractor uses bio-fuel, the fuel

system must be equipped with REP

hoses (the fuel system is equipped with

REP 6 hoses by the manufacturer).

12. The brakes and steering must be in

the perfect condition all the time.

13. During driving on roads with trailers

and tools the brake pedals must be

connected with a latch.

14. Driving downhill without an engaged

gear is forbidden.

15. Pay special attention when driving on

a slope and muddy, sandy, icy or uneven

ground.

16. Observe the maximum prescribed

slope gradient of 12°.

17. Respect the total permissible weight

of the tractor and trailer specified on the

data plate of the tractor or on the rear

wheel mud-guard.

18. Do not use the differential lock when

driving into a bend.

19. It is forbidden to get into and out of a

moving tractor.

20. When driving with machines attached

to the rear hitches the load of the steered

axle must not drop below 18 % of the

current weight of the set.

21. When driving the tractor with

agricultural machines attached to the

front three-point hitch, reduce the driving

speed to 20 km/h.

22. During aggregation of Zetor Forterra

tractors with machines and implements

with high tensile resistance when the

engine speed drops and the engine

tends to stall, the 1R, 2R reduced gears

must not be used for the work with these

machines (risk of shaft twist-off). .

TRANSPORTATION OF PERSONS,

OPERATION

23. The number of persons transported

by the tractor must not exceed the

number specified in the technical

certificate of the tractor.

24. Persons that are not authorized to

work with the attached implement must

not stand between the tractor and the

hitched machine (implement).

25. Before putting the tractor in motion

10

make sure there is no person or obstacle

in the driving direction.

26. Observe the prescribed slope

gradient, which has the value of 12° for

the Zetor Forterra 95, 105, 115, 125

tractors.

RECOVERY, PUSHING

27. To recover a tractor that has sunk in

mud use a tow bar or rope attached to

the front hook.

Never use chains! Rupture of

the chain represents a danger

of death!

28. During recovery it is dangerous to

stand near the towing rope.

29. It is prohibited to use the tractor axles

(individual wheels) as a winch for

releasing a sunken tractor.

30. The front hook should be only use to

recover the entire tractor, i.e. without any

trailer or another attached implement.

31. Never recover the tractor with

reduced gears engaged.

32. When pushing other vehicles

(trailers, implements, etc.) with the

tractor never insert free wooden blocks

or bars between the tractor and the

pushed vehicle.

LEAVING THE TRACTOR

33. Do not park the tractor with an

attached implement in the lifted position.

SAFETY INSTRUCTIONS FOR USERS

34. Before leaving the tractor do not

forget to brake the tractor with the

parking brake (by engaging a gear).

Remove the key from the switch box and

lock the cab.

35. In the case of a tractor equipped with

reversing shift the reversing lever to the

forward position.

36. Before leaving the tractor with the

engine running brake the tractor with the

parking brake.

37. To get out of the tractor normally use

the left side of the tractor. Look around

to see whether a vehicle is coming that

could endanger your safety during

getting off and only then open the door.

38. When leaving the tractor use the

steps and handles. Pay increased

attention in the area of the shifting lever

and the manual throttle lever as well as

the upper step.

WITH STOPPED ENGINE ONLY

39. All work connected with refuelling,

cleaning, lubricating and adjusting the

tractor or attached implements may only

be performed with the engine and

moving parts of the tractor stopped

except functional checks of the brakes,

hydraulic system and charging.

40. Before removing the side plates of

the hood it is always necessary to stop

the engine. The tractor engine can only

run in a closed building or room if

sufficient ventilation is ensured. Exhaust

gases are harmful for health.

FIRE PREVENTION PRINCIPLES

41. Refuel the tractor best after the end

of work and with the engine stopped.

42. Do not refill fuel up to the top of the

fuel tank in summer. Wipe spilt fuel

immediately.

43. Do not refuel the tractor near open

flame and do not smoke.

44. Do not smoke and do not use open

flame when inspecting the battery

electrolyte level.

45. Make sure that fire safety instructions

are strictly observed in environments with

an increased danger of fire (hay-lofts,

straw-stacks, etc.).

46. The tractors are not equipped with a

fire extinguisher from the production

plant.

HEALTH AND ENVIRONMENT

PROTECTION

47. The tractors are not equipped with

special filters of air aspirated to the cab.

Therefore, they are not designed for

work with aerosols and other harmful

substances.

48. Coolant, brake liquid, kerosene,

diesel fuel, mineral oil and other oil

products that are used for the operation

11

and maintenance of the tractor may

cause various skin disorders in case of

direct contact with your skin and can

irritate mucous membranes, eyes, the

digestive system and upper respiratory

ways. Some of them may even cause

systemic poisoning when swallowed.

49. Persons that handle oil products are

obliged to strictly observe safety and

hygienic regulations, use suitable means

of protection and work in well-ventilated

rooms.

WORKING WITH OIL

PRODUCTS

50. After the end of work or before a

meal you should wash yourself with a

mild agent and treat your hands with a

suitable ointment or cream.

51. When connecting and disconnection

quick-couplers of the hydraulic circuits

use any piece of cloth to remove residual

oil remaining in the socket or on the plug

of the quick-coupler.

SAFETY INSTRUCTIONS FOR USERS

WASTE DISPOSAL

52. When disposing of the tractor or its

parts (incl. operation liquids) after the

end of their service life you must observe

relevant provisions of valid acts and

implementation directives of these acts

of the country where the tractor is used.

The last seller of the tractor is obliged in

accordance with the Waste Act to inform

the consumer - during the sale of the

tractor - about the way of collection of

some used parts of the tractor. This is

the case of oil and other operation

liquids, batteries and tyres. These used

products must be received from the

consumer without any obligation of the

consumer to pay for this service.

PREVENTIVE DAILY MAINTENANCE

53. Perform this maintenance daily or

after every 8 - 10 hours of operation at

the latest.

SAFETY CAB

54. If the protective frame of the safety

cab is damaged by corrosion, an

accident or otherwise, the safety cab

must be replaced.

AIR-CONDITIONING

55. Disassembling, turning or otherwise

handling the screw union of the airconditioning system is not allowed in any

case. Sudden leak of the coolant may

occur, causing quick local cooling.

Contact or freezing of components in

hands may cause serious damage of

some tissues.

56. The air-conditioning system is

equipped with quick-couplers that make

it possible to separate the cab from the

tractor body if necessary without any

coolant leak. Entrust interventions into

the air-conditioning system to a

specialized repair shop.

ELECTRIC INSTALLATION

57. No additional interventions

into the electric installation

(connection of other electric

appliances) are permissible due

to its possible overloading!

58. The values of the electric installation

are:

Nominal voltage 12 V =

Grounded minus

pole

Using starting trucks or auxiliary power

supplies with a different voltage or

polarity may cause serious failures of the

tractor.

( - ) pole

12

59. When handling the battery you must

pay increased attention and avoid shortcircuits. In tractors equipped with a

battery disconnector switch the

disconnector off when handling the

battery.

60. Zetor Forterra tractors must not be

operated with a disconnected battery as

this may lead to a serious failure of the

tractor.

PREVENTIVE DAILY MAINTENANCE

Perform this maintenance daily or after every 8 - 10 hours of operation at the latest.

13

XF_02_148

PREVENTIVE DAILY MAINTENANCE

F_02_192 XF_02_193 F_02_3a1

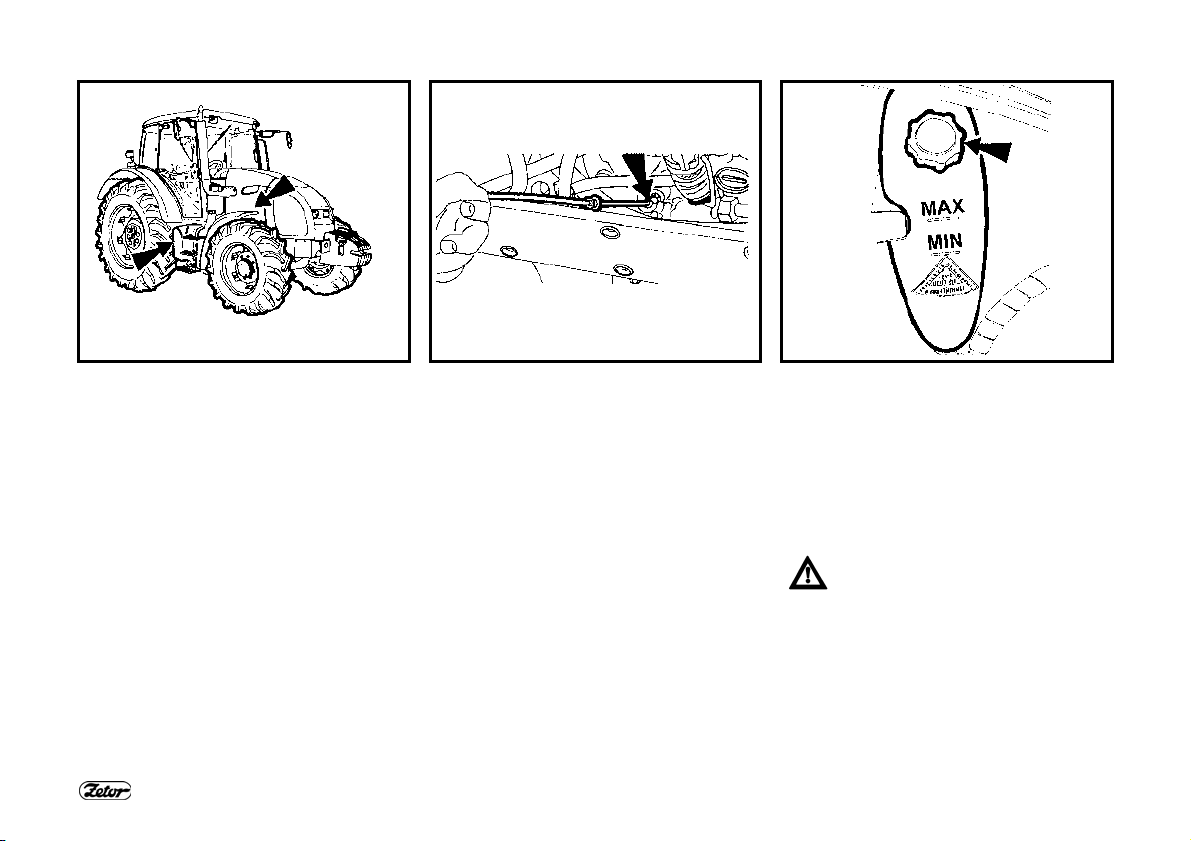

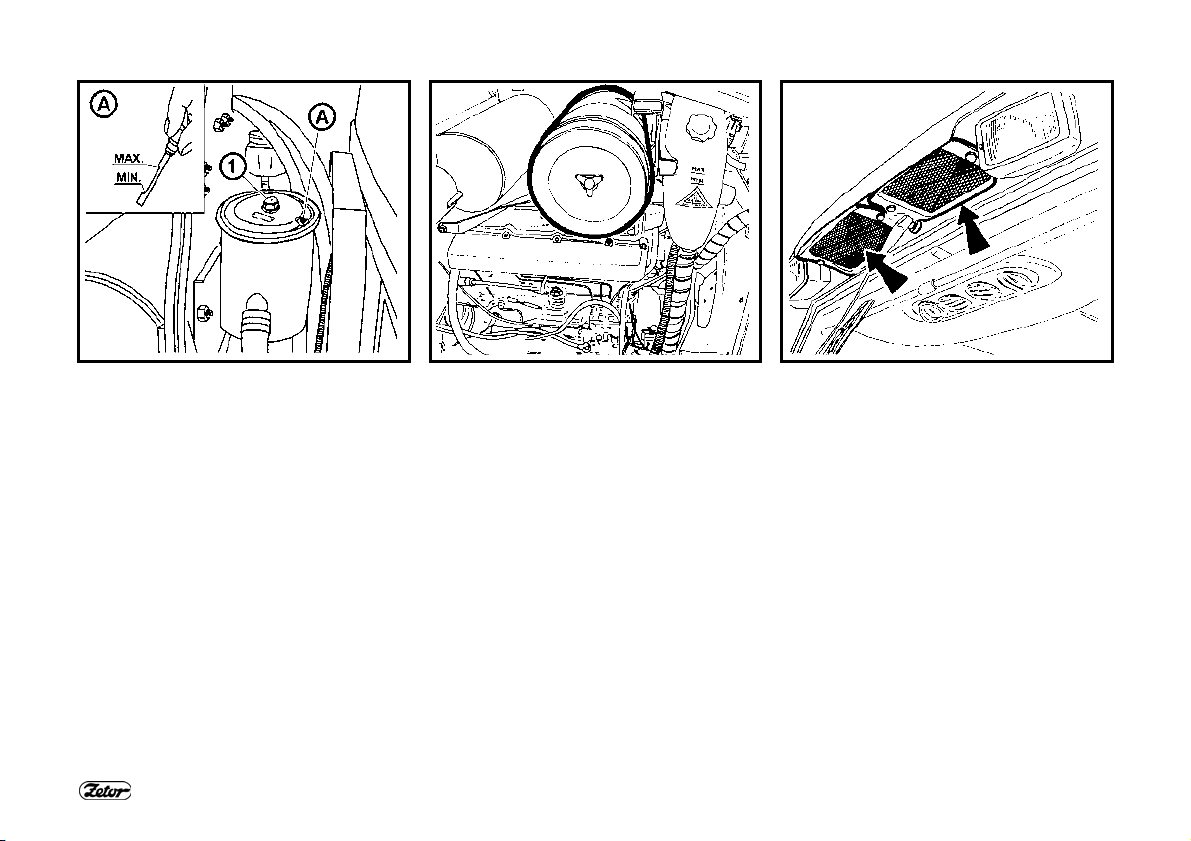

FUEL SYSTEM LEAKS

Check the fuel system for leaks,

including the fuel tank. Repair any leaks

immediately. The hole for draining dirt

from the fuel tank is found in its bottom.

ENGINE OIL LEVEL

After unscrewing and removing the oil

dip-stick check the oil quantity in the

engine and then check the connection of

the engine lubrication system for leaks.

Maintain the oil level between the dipstick marks.

14

COOLING SYSTEM

Check the connections of the engine

cooling system for leaks and the coolant

quantity in the expansion tank.

Replenish the missing quantity up to the

upper mark indicated MAX. The

minimum acceptable cooling liquid level

is indicated by the MIN mark.

Only release the overpressure

plug when the coolant has cooled

down! There is a danger of

scalding!

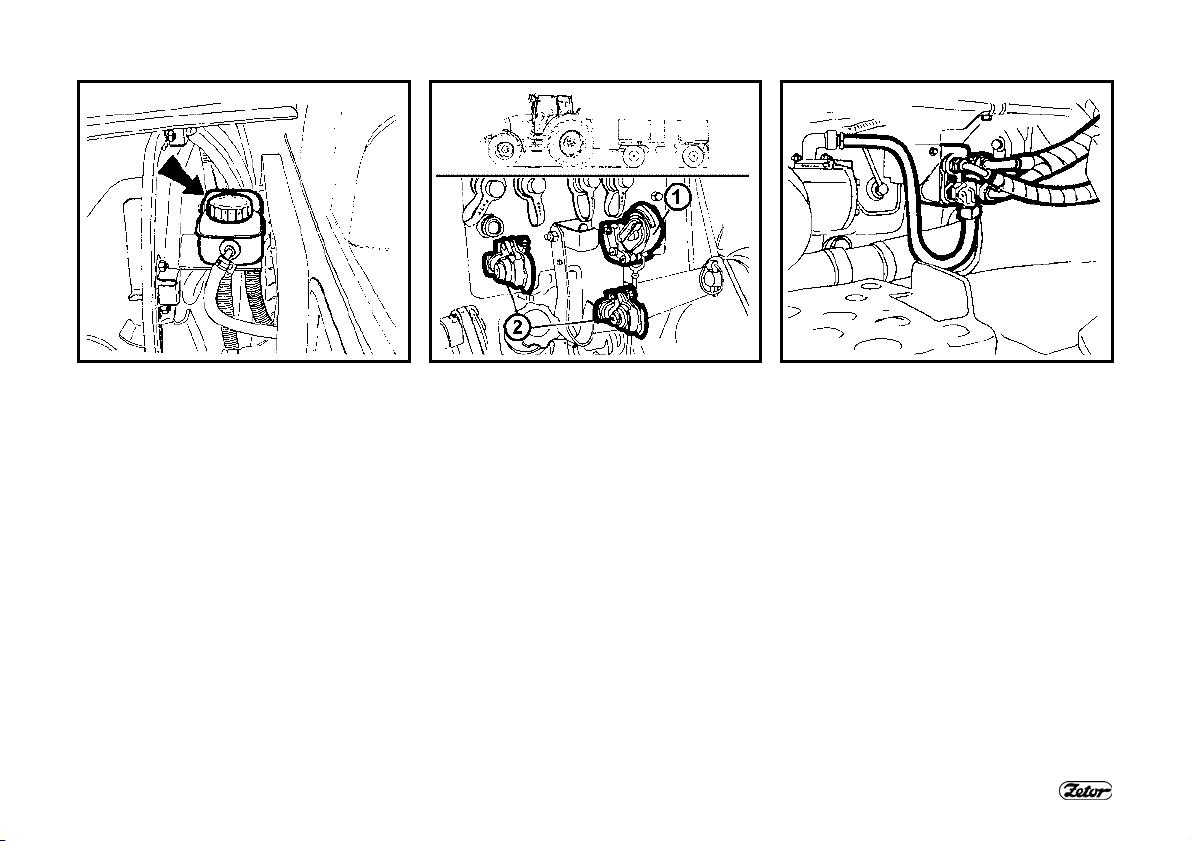

PREVENTIVE DAILY MAINTENANCE

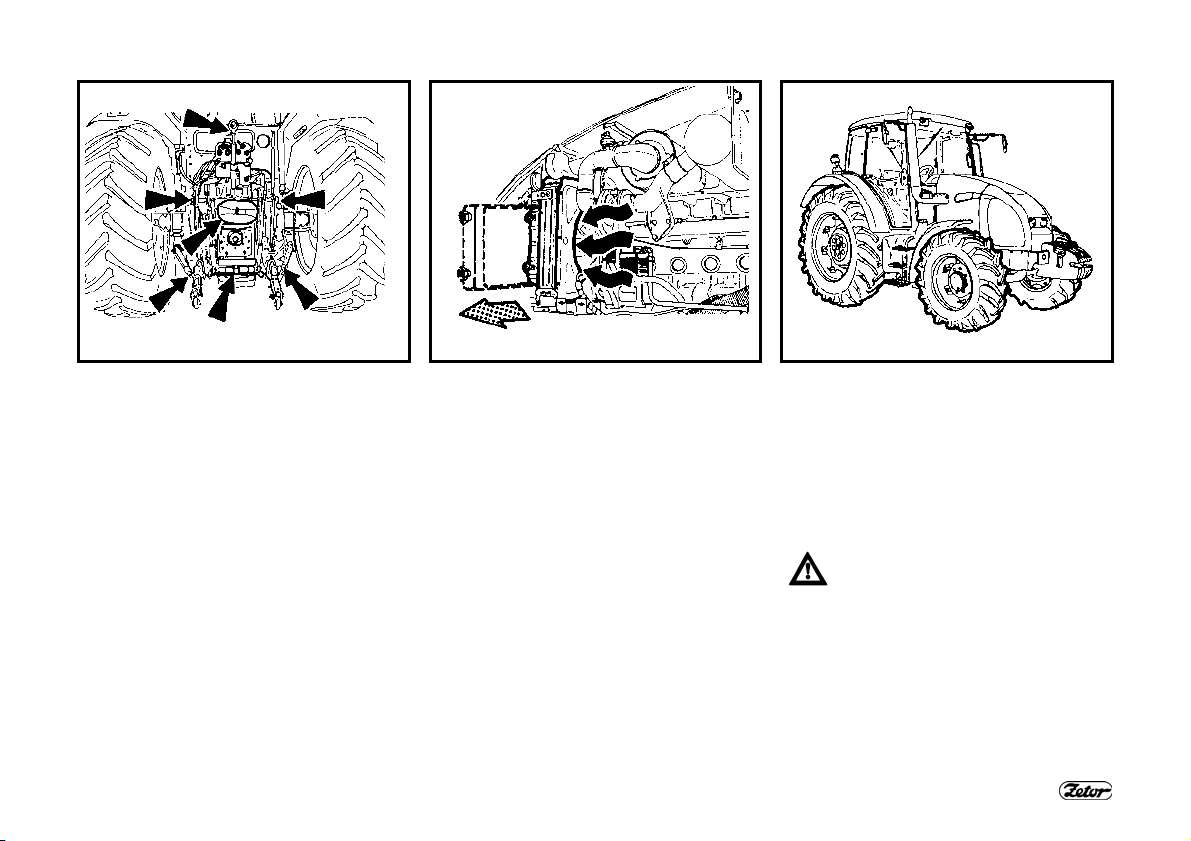

F_02_4 F_02_56 F13

LIQUID BRAKES

Check the liquid brakes for leaks as well

as the liquid control of the clutch and the

braking liquid level in the expansion tank.

Maintain the brake liquid level in the

range of 3/4 of the tank content (max.

level) and 1/2 of the tank content

(minimum level).

TRAILER AIR BRAKES

Check the air system of the brakes for

leaks and the efficiency of the tractor

brakes with a trailer (see the

Maintenance instructions chapter; the

Checking the air systems for leaks

section of this Operator’s Manual).

TRAILER HYDRAULIC BRAKES

Check the hydraulic brakes of the trailer

for leaks.

15

PREVENTIVE DAILY MAINTENANCE

D402 F_02_6a F_02_9

HYDROSTATIC STEERING

- Check the oil level in the hydrostatic

steering tank.

- Check the tightening of screws and

nuts of the steering rods and levers.

- Check the condition of all the hoses of

the hydraulic steering circuit for

damage and for oil leaks.

AIR CLEANER

If the air cleaner is heavily clogged with

dirt, this condition is indicated by a

sensor that lights up an indicator on the

dashboard.

16

CAB FILTRATION

Check and if necessary clean the cab

ventilation air filters installed in the front

overhang of the roof.

The filter exchange interval depends on

the dustiness of the working

environment.

Partial regeneration can be performed by

beating out or blowing with compressed

air.

Do the cleaning or replacement of the

filter elements after removing the

covering grills in the roof overhang.

PREVENTIVE DAILY MAINTENANCE

F18 F_02_100 F_02_7

HITCHES

Check the condition of the hitching and

attachment systems of the tractor and

trailer.

AFTER WIRK WITH FRONT

IMPLEMENTS AND IN CASE OF

COOLER CLOGGING

After work with front implements:

− Check the connections of the external

hydraulic circuit of the control of the

front three-point hitch for leaks

Clogging of the coolers:

− Remove the side plate of the hood.

− Release and slide the cooler to the left

side of the tractor.

− Clean the front walls of the engine

(gearbox, air-conditioning condenser)

cooler with compressed air (blow air in

the direction from the engine).

− Remove residual dirt from the space

under the hood so that it should not be

suctioned again.

17

TYRES AND WHEELS

Check the air pressure in the front and

rear tyres. Depending on the character

of work adjust the pressure to the

recommended value. Check and if

necessary retighten the bolts of the front

and rear wheels (the rim / disc and disc /

wheel shaft connection).

Never drive with loose wheel

bolts!

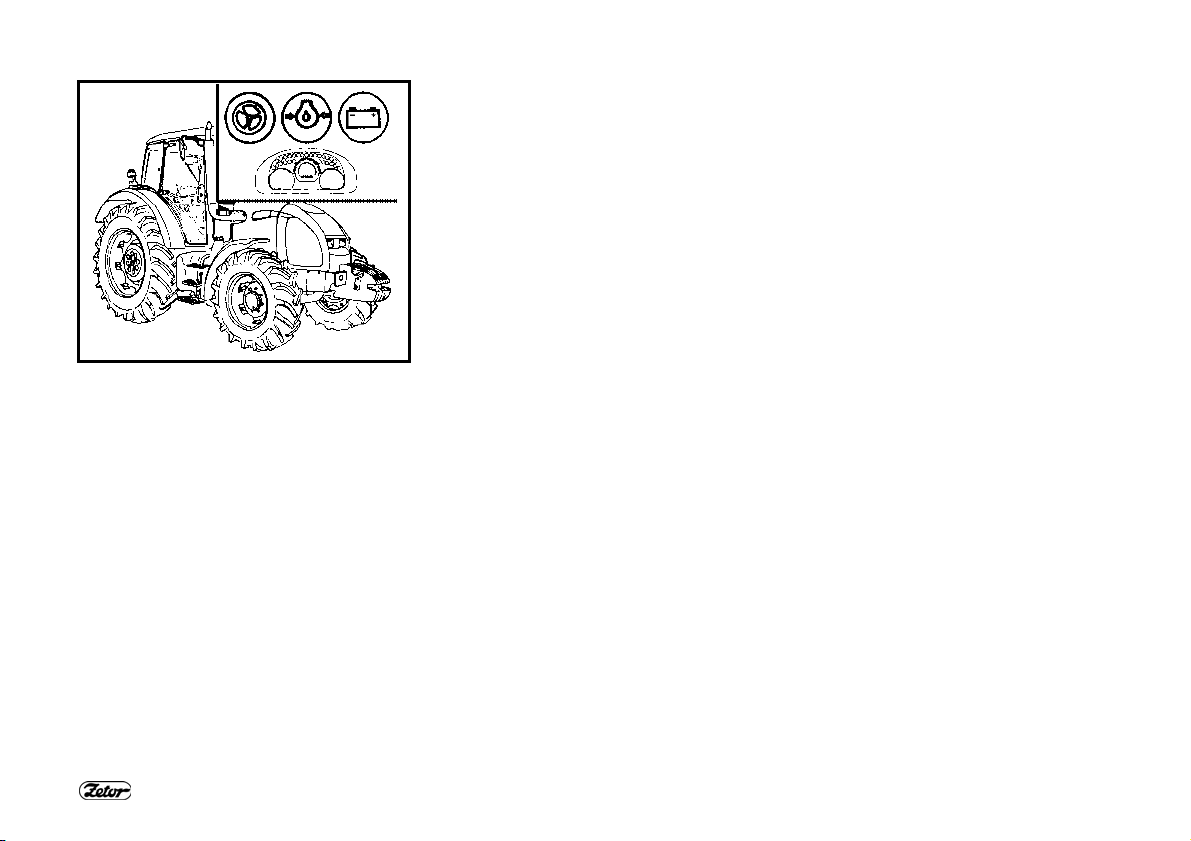

PREVENTIVE DAILY MAINTENANCE

F_02_102a

SHORT FUNCTIONAL TEST

After starting the engine check whether

the hydrostatic steering failure, engine

lubrication and charging indicators have

gone off.

Verify the function of the hydraulic

steering circuits and check them for

leaks.

18

The tractor user is obliged to get

acquainted with the recommended procedures and instructions for safe operation of the

tractor in advance. It is too late to

do so during operation!

ACQUAINTANCE WITH THE TRACTOR

Safety cab ................................................................................................................. 21

Door opening from the outside .................................................................................. 21

Door opening from the inside .................................................................................... 21

Rear window..............................................................................................................22

Side window .............................................................................................................. 22

∗Tilting lid .................................................................................................................. 22

Washer nozzle ..........................................................................................................23

Washer tank.............................................................................................................. 23

Washer control .......................................................................................................... 23

Passenger’s seat....................................................................................................... 24

Storage compartment and tool box ...........................................................................24

Rearview mirrors ....................................................................................................... 24

MARS SVRATKA driver’s seat.................................................................................. 25

Adjusting the seat for the driver’s weight................................................................... 25

Longitudinal adjustment of the seat........................................................................... 25

Vertical adjustment of the seat .................................................................................. 25

GRAMMER MAXIMO driver’s seat............................................................................ 26

GRAMMER S driver’s seat........................................................................................ 26

*Air filter with active carbon....................................................................................... 27

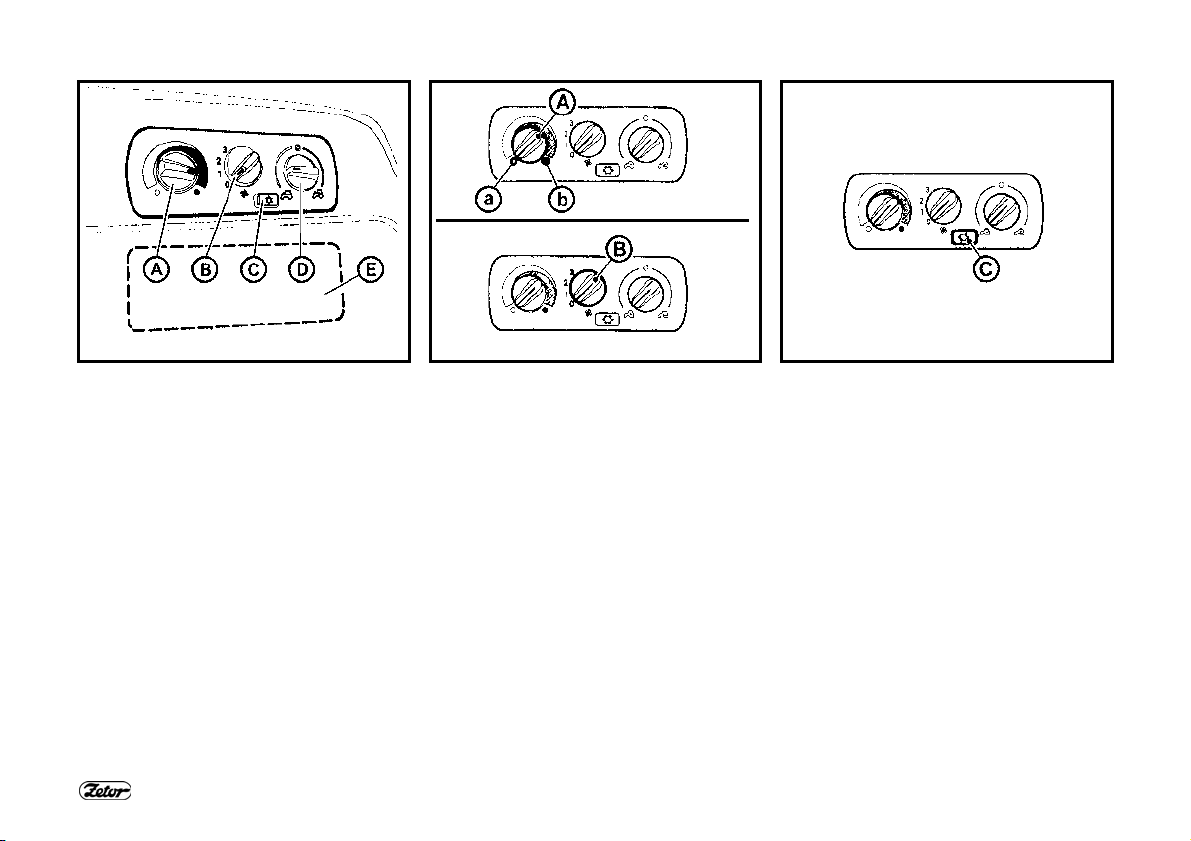

Control panel of heating, *air-conditioning, *radio .....................................................28

Heating valve control (A)........................................................................................... 28

Fan control (B) ..........................................................................................................28

*Air-conditioning switch (C) ....................................................................................... 28

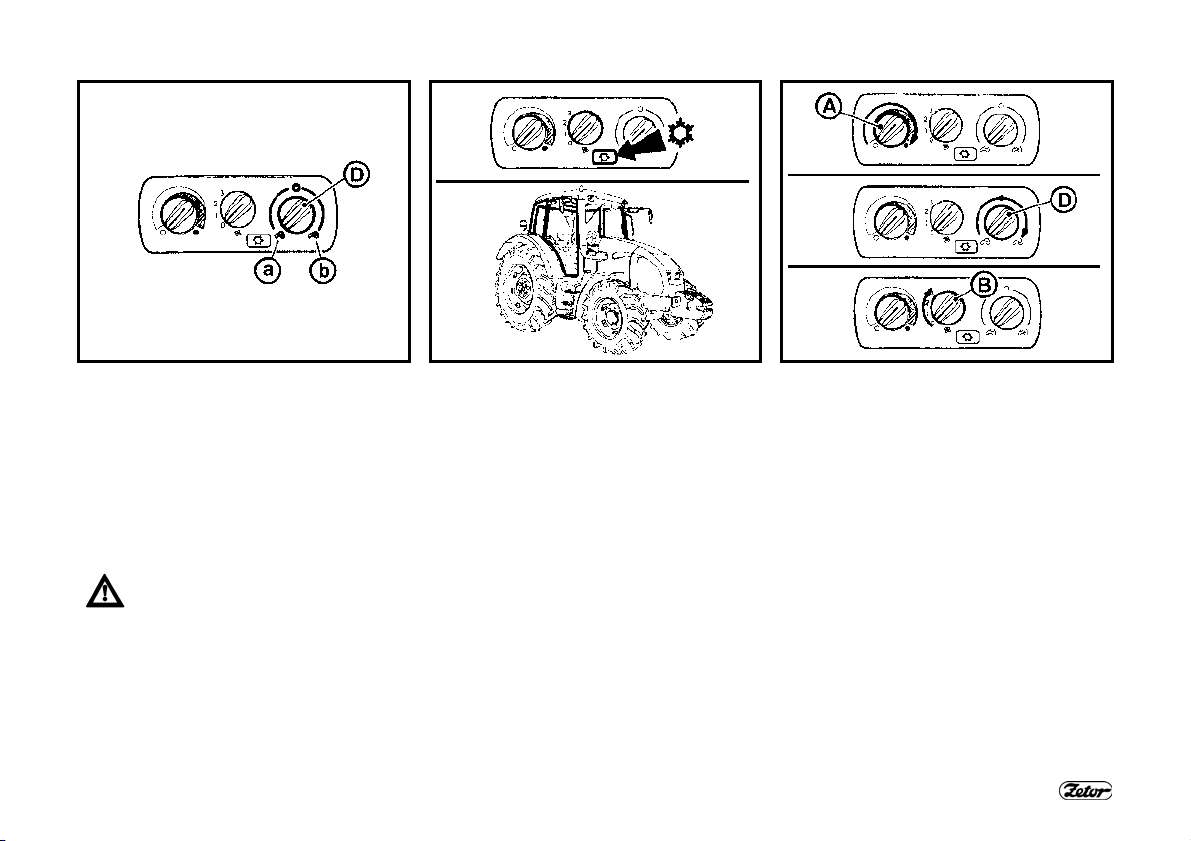

Control of air circulation in the cab (D)......................................................................... 29

Proper function of the heating and air-conditioning system ........................................... 29

Fast heating of the cab space .....................................................................................29

Quick cooling of the cab space ............................................................................ 30

Heating or air-conditioning operation during work of the tractor ................................ 30

Immediately after cooling down the cab .................................................................... 30

Heating and air-conditioning outlets (A) (∗radio speakers)........................................ 31

Front windshield (B) defrosting.................................................................................. 31

Analog dashboard ..................................................................................................... 33

19

Page

ACQUAINTANCE WITH THE TRACTOR

Page

∗Digital dashboard .................................................................................................... 35

Selectors, switches and levers.................................................................................. 36

Light switch (A) ......................................................................................................... 37

Switch of the front driving axle (F)............................................................................. 37

Warning light switch (E) ............................................................................................ 37

Selector of the grill and cab headlights (B)................................................................ 38

Front, rear differential lock button (J) ........................................................................ 38

Selector of turn signal, low and high beam lights and horn (L).................................. 38

Switching box............................................................................................................ 39

Key in “0” position ..................................................................................................... 39

Key in “I” position ...................................................................................................... 39

Key in “II” position ..................................................................................................... 40

Lighter and three-pin socket...................................................................................... 40

Manual throttle lever ................................................................................................. 40

Engine stopping control............................................................................................. 41

Torque multiplier preselection switch (i).................................................................... 41

Pedals and levers ..................................................................................................... 42

Main shifting lever and reversing lever...................................................................... 42

Shifting lever of road and reduced gears .................................................................. 42

Shifting lever of dependent and independent PTO rpm ............................................ 43

Levers of the parking brake and hitch for a single-axle trailer ................................... 43

Hydraulic control panel.............................................................................................. 43

Control of the auxiliary hydraulic distributor (external hydraulic circuit) .......................... 44

Control panel on the right cab pillar........................................................................... 44

Battery disconnector ................................................................................................. 44

Fuel tank ................................................................................................................... 45

Drain plug of the fuel tank ......................................................................................... 45

20

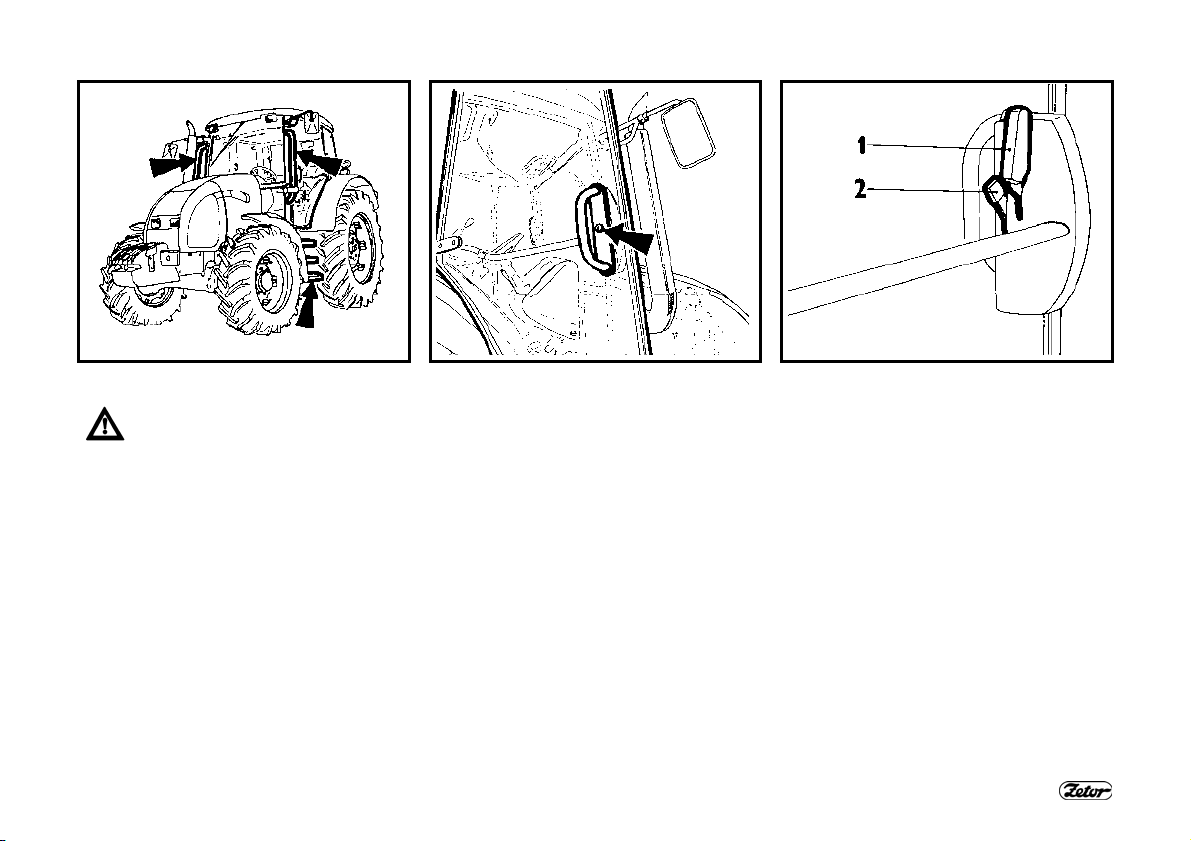

ACQUAINTANCE WITH THE TRACTOR

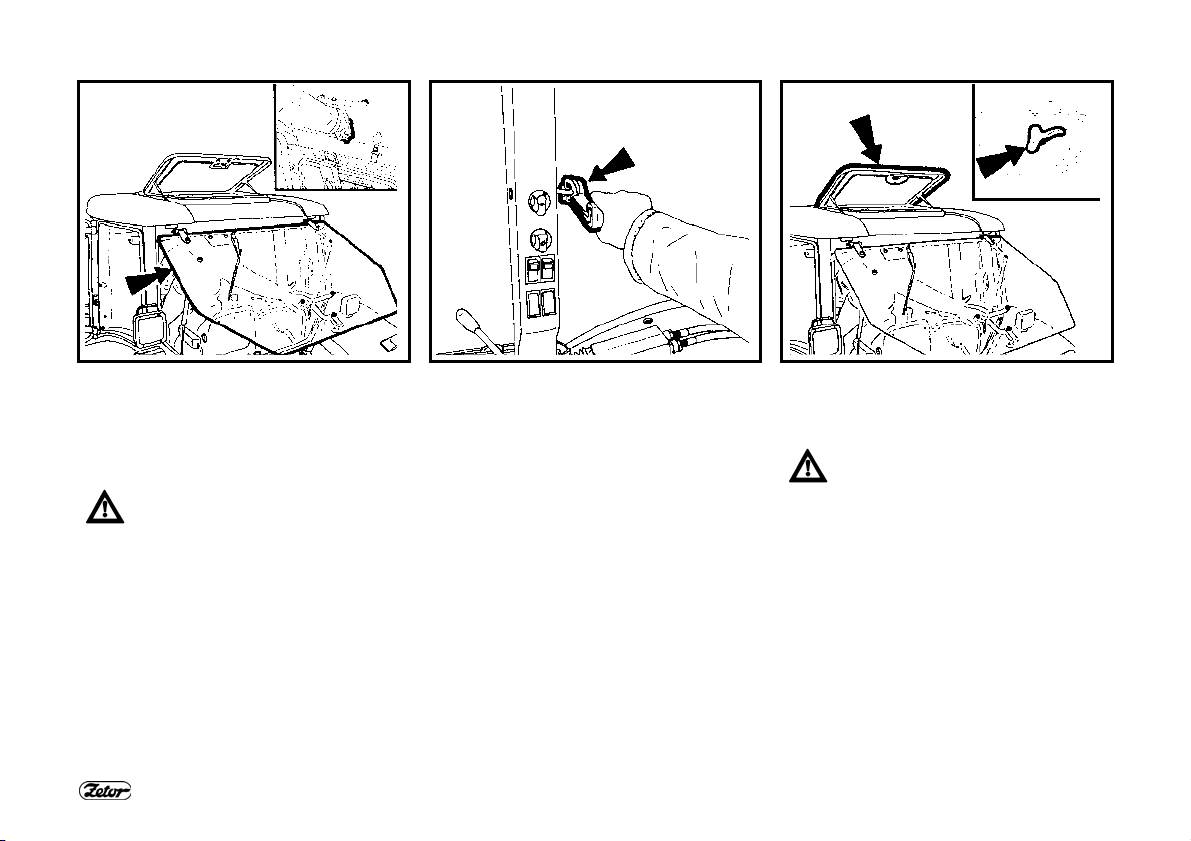

F_02_8 F_02_11 F23

SAFETY CAB

Normally use the left side of the

tractor to enter and leave the cab.

When entering and leaving the

cab use the three-stage steps

and handles.

Pay increased attention in the

area of the shifting lever and the

manual throttle lever.

The safety cabin is equipped with tinted

glass as standard.

DOOR OPENING FROM THE OUTSIDE

The cab doors can be locked from the

outside.

DOOR OPENING FROM THE INSIDE

1. Lever for door opening from the inside

2. Lever for lock opening from the inside

The door is held in the fully open position

by a gas strut.

Driving with an open door is not recommended as the door may get damaged.

21

ACQUAINTANCE WITH THE TRACTOR

F24 F25 F_02_14

REAR WINDOW

The rear window is equipped with a handle and in the open position it is held by

gas struts. The rear window may be *

heated.

We recommend you to latch the

window in the closed position

when driving on an uneven

ground - danger of cracking of the window. Before you start work with implements attached to the rear three-point

hitch make sure there is no danger of

collision between the attached implement

in the position of maximum lift of the

three-point hitch and the open rear window. In case of interference we recommend you to work with the window

closed.

SIDE WINDOW

The window is secured in the partly open

position with a plastic latch.

∗TILTING LID

It can be opened by partial turning of the

locking lever and half-opening.

By opening the tilting lid you will

increase the total height of the

tractor. Therefore, always close

the lid when passing through or

parking in places with a lowered

profile.

22

ACQUAINTANCE WITH THE TRACTOR

F28 F_02_152a F_02_137

WASHER NOZZLE

The nozzle is adjustable with a needle

with the max. thickness of 0.8 mm.

WASHER TANK

The washer tank is located on the outer

rear wall of the cab.

WASHER CONTROL

The windshield washer is activated by

pressing of the selector of the front twospeed wiper located on the right pillar of

the cab. The maximum period of uninterrupted operation of the washer pump is

20 s.

23

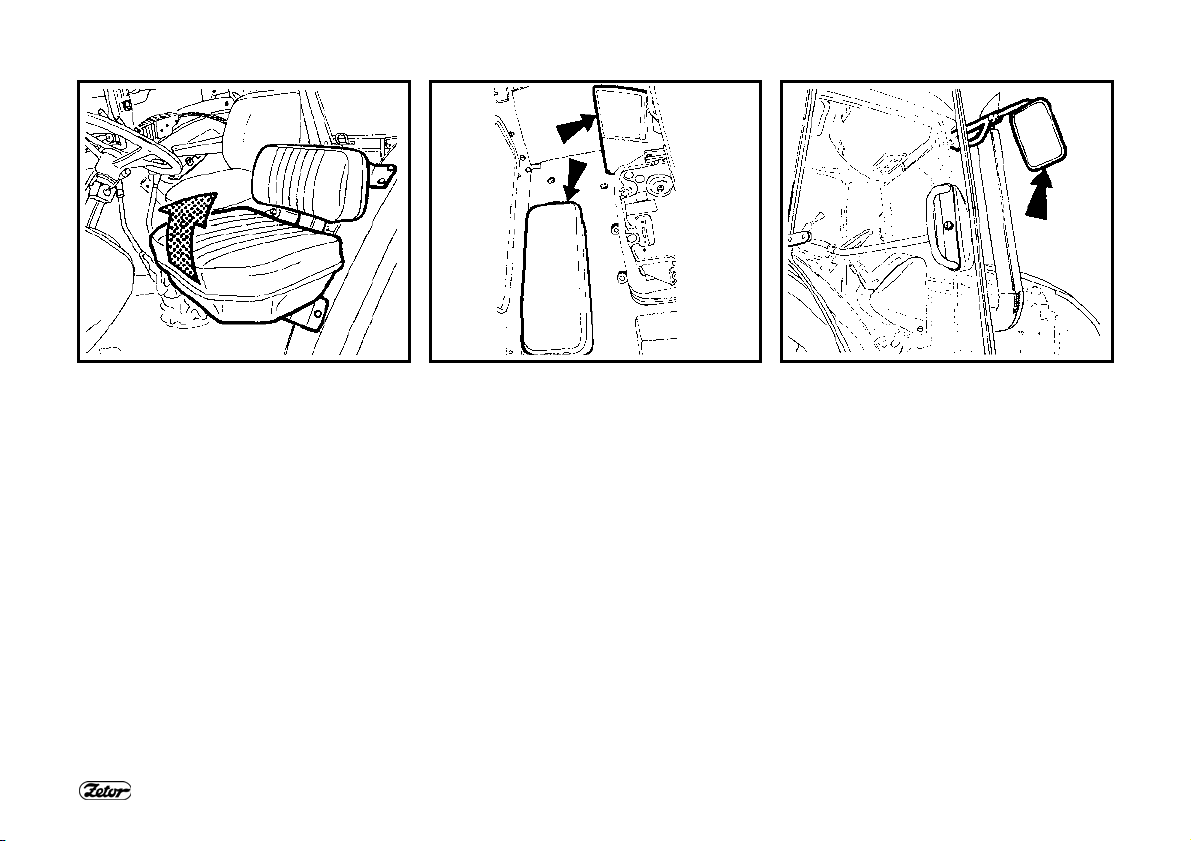

ACQUAINTANCE WITH THE TRACTOR

F_02_13 F31 F_02_12

PASSENGER’S SEAT

Passenger’s seat is tilting and is situated

on the left cab fender.

Note: To facilitate access to the driver's

seat you can tilt the passenger’s seat

upwards.

STORAGE COMPARTMENT AND

TOOL BOX

The storage compartment is located at

the left side of the driver’s seat.

The toolbox is positioned in the rear part

of the cab behind the driver’s seat.

REARVIEW MIRRORS

Before driving or starting work adjust the

rearview mirrors to be able to see the entire road or the working field.

The rearview mirrors may be * heated.

24

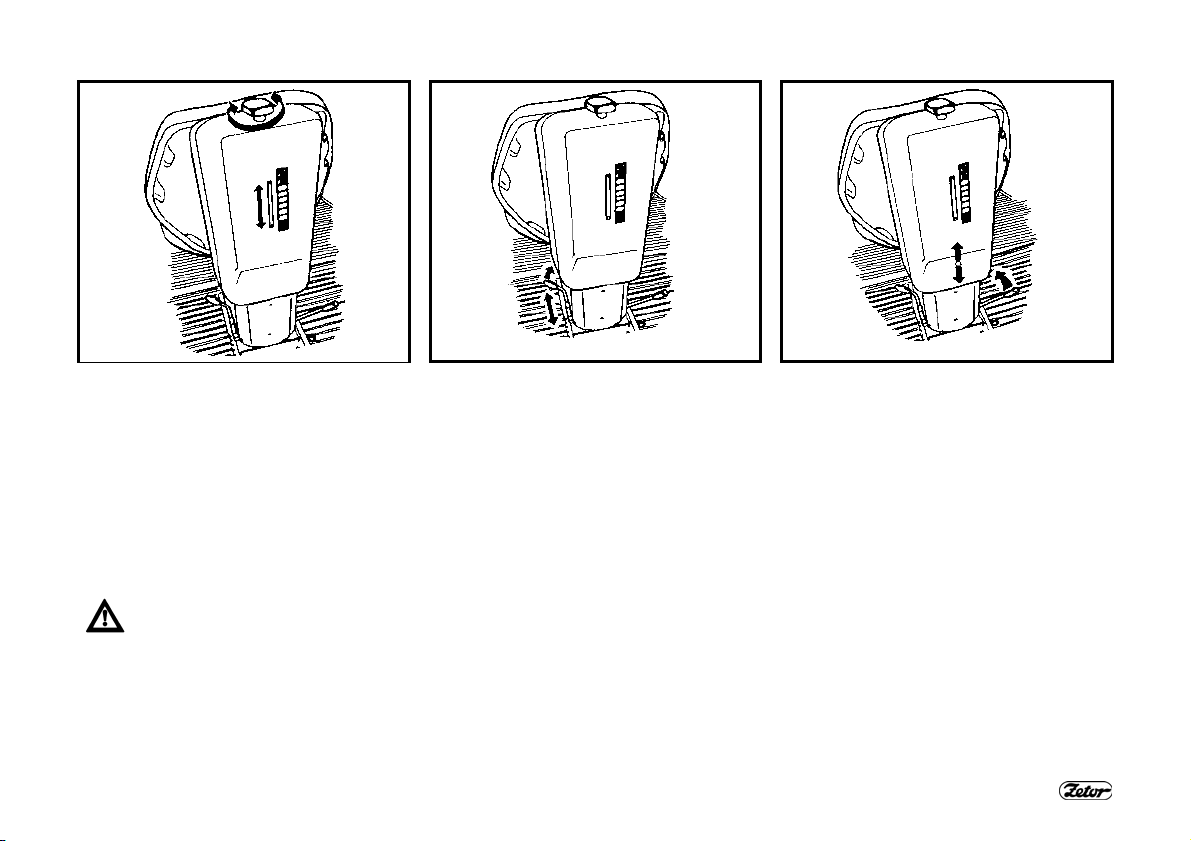

ACQUAINTANCE WITH THE TRACTOR

F33 F34 F35

MARS SVRATKA DRIVER’S SEAT

ADJUSTING THE SEAT FOR THE

DRIVER’S WEIGHT

The seat suspension is adjustable for the

driver’s weight from 50 to 120 kg. The

adjustment is performed by turning a

square handle. The weight adjustment

indicator is located in the recess of the

rear seat cover. The spring stroke is 120

mm.

Do not adjust the seat when driv-

ing. Danger of accident!

LONGITUDINAL ADJUSTMENT OF

THE SEAT

You can adjust the seat longitudinally

with the left lever in the range of ± 75

mm (11 positions).

25

VERTICAL ADJUSTMENT OF THE

SEAT

The seat is adjusted vertically with the

lever at the right-hand side in the range

of ± 30 mm (3 positions).

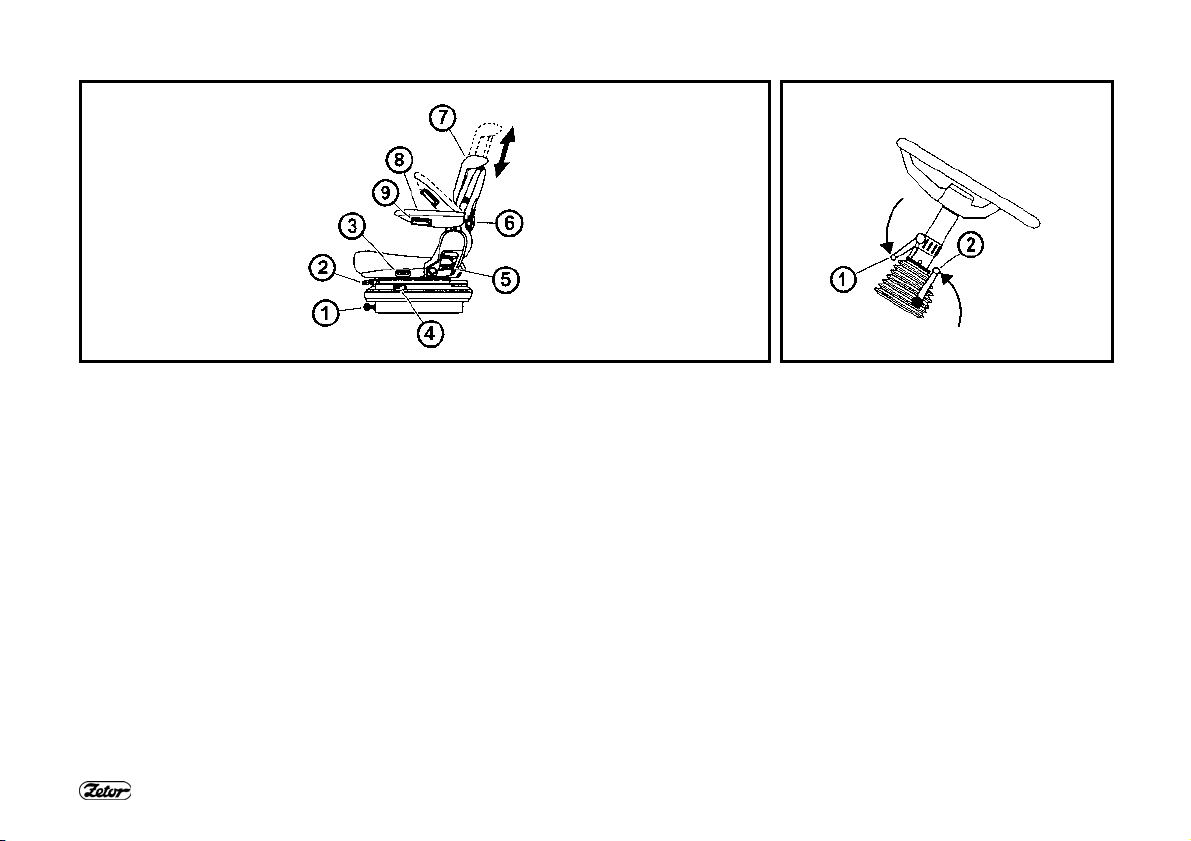

ACQUAINTANCE WITH THE TRACTOR

D104 F205

GRAMMER MAXIMO DRIVER’S SEAT

1- Seat suspension adjustment control by the driver’s weight (adjustment by turning,

direction in accordance with the pictogram on the seat bellows).

2- Longitudinal adjustment lever of the seat (located at the right side of the seat)

3- Seat turning control (the seat can be turned by 20° to both the sides)

4- Seat vibration absorption control (by flipping the control to the front you will select

the floating position of the seat)

5- Backrest angle adjustment control

6- Backrest shape adjustment control

7- Height-adjustable backrest (by pulling or pushing in the arrow direction you can

adjust it in the range of 170 mm)

8- Tilting armrest

9- Armrest adjustment control (by turning the control you can adjust the height of the

armrest)

GRAMMER S DRIVER’S SEAT

It only uses positions 1, 2 and 5.

26

ADJUSTABLE STEERING WHEEL

The tilting steering column allows variable angle and height adjustment of the

steering wheel.

Steering wheel height adjustment

The adjustment is done by extending or

retracting the steering wheel after releasing the lock by turning the lever (1) in the

arrow direction. After setting the steering

wheel lock the lever (1) by tightening

against the arrow direction.

Steering wheel angle adjustment

The adjustment is done by tilting the

steering wheel after releasing the lock by

turning the lever (2) in the arrow direction. After setting the steering wheel lock

the lever (2) by tightening against the arrow direction.

ACQUAINTANCE WITH THE TRACTOR

E730a

*AIR FILTER WITH ACTIVE CARBON

Filters with active carbon are installed instead of the standard dust filter and they are

replaced in the same way as the normal filters. The filter must be inserted with the

white side towards the grill. You will find the installation instructions in the “Maintenance instructions” chapter.

The filter is only used during spraying of pesticides; then it must be replaced with a

paper filter again as flying dust would clog the carbon filter in a very short time.

During its use the recirculation control must be in the position of “air suctioned from

the outside”

The fan control must be in the “maximum” position.

• WARNING: The filter does not provide complete protection from toxic substances

• When handling the filter wear protective gloves

• Do not clean or blow the filter with compressed air.

DANGER: Replace the active carbon filter every 200 hours or 36 months (the

production date is printed on the filter). If you feel the smell of pesticides in the

cab, replace the filter immediately and have the cab sealing checked. Used filters must be disposed of in specialized collection centres.

27

When pesticides are sprayed and

a heating filter with active carbon

is used, the recirculation control

must be in the “air suctioned from

the outside” position and the fan

control in the “maximum” position

to create overpressure in the cab.

ACQUAINTANCE WITH THE TRACTOR

F_02_15 F_02_16 F_02_17a

CONTROL PANEL OF HEATING, *AIRCONDITIONING, *RADIO

A - Heating valve control

B - Fan control

C - Air-conditioning switch

D - Control of air circulation in the cab

E - Space for additional radio installation

HEATING VALVE CONTROL (A)

a - Heating valve closed

b - Heating valve open

FAN CONTROL (B)

0 - Fan off

1 - Slow fan speed

2 - Medium fan speed

3 - Maximum fan speed

28

*AIR-CONDITIONING SWITCH (C)

The air-conditioning system is switched

on and off with the switch with the snowflake symbol (C).

By pressing the switch you will put the

air-conditioning system in operation (the

snowflake symbol is lit).

You can switch off the air-conditioning

system by pressing the switch again (the

snowflake symbol is off).

ACQUAINTANCE WITH THE TRACTOR

F_02_17b F_02_52 F_02_18a

CONTROL OF AIR CIRCULATION IN

THE CAB (D)

a - Surrounding (external) air is suctioned

to the cab via filters - air suctioning

from the cab is closed.

b - Air is suctioned from the inside of the

cab and blown into the cab again (air

recirculation fast quick adjustment of

temperature in the cab).

In this position the air inlet from

the outside of the cabin is completely closed and in the cabin

there is no overpressure that prevents penetration of unfiltered air

to the cabin!

Do not use this position of the

control during working operation

of the tractor!

PROPER FUNCTION OF THE HEATING

AND AIR-CONDITIONING SYSTEM

To ensure proper functioning of the heating or air-conditioning system it is necessary to create overpressure in the cab.

Therefore, we recommend you to close

all the windows, doors and tilting lid of

the cabin.

FAST HEATING OF THE CAB SPACE

Proceed as follows:

1 - Turn the heating valve control (A) to

the right position (heating valve fully

open).

2 - Set the control of air circulation in the

cab (D) to the internal circulation position.

3 - Use the fan control (B) to select the

corresponding fan speed (position 1,

2, 3)

4 - Set the outlets to the required angle to

avoid direct blowing of air to the persons in the cab.

5 - After heating of the cab space set the

control of air circulation in the cab (D)

to the position of suctioning external

air - see fig. F_02_17b, position (a).

29

ACQUAINTANCE WITH THE TRACTOR

F_02_18 F_02_19 F_02_20

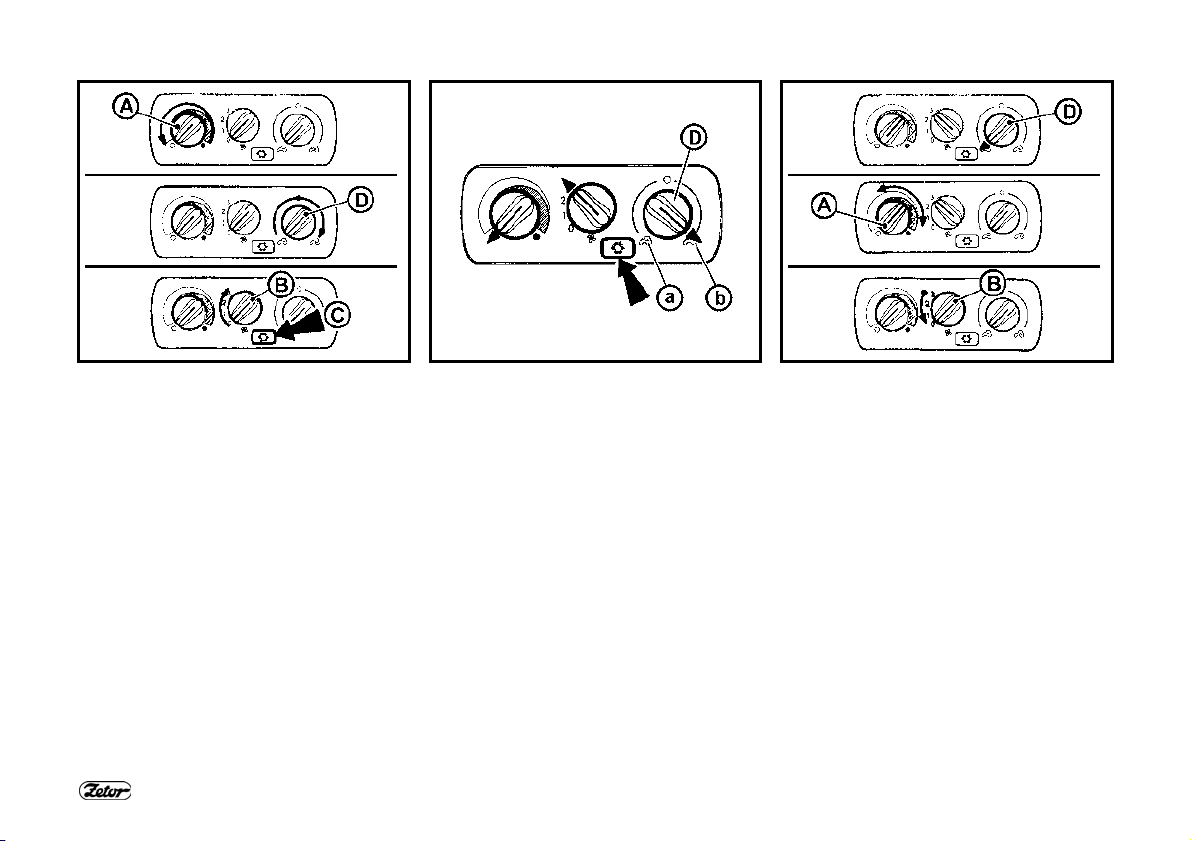

QUICK COOLING OF THE CAB

SPACE

Proceed as follows:

6 - Turn the heating valve control (A) to

the left position.

7 - Set the control of air circulation in the

cab (D) to the position of suctioning

external air.

8 - Use the fan control (B) to select the

corresponding fan speed (position 1,

2, 3)

9 - Use the switch (C) to switch on the air-

conditioning system.

10 - Set the outlets to the required angle

to avoid blowing of air directly to the

persons in the cabin (possible occurrence of an illness due to intensive

cooling of body parts).

HEATING OR AIR-CONDITIONING

OPERATION DURING WORK OF THE

TRACTOR

When internal air circulation is on, the

fresh air inlet is closed and the air in the

cab space may be breathed up by the

operators. This situation may cause the

feeling of tiredness and further due to

overpressure loss in the cab dust may

penetrate to the cab.

Note: During work set the switch (D) in

accordance with individual requirements

to a temperature in a position between

(a) and (b) so that the fan can suction air

from the outside via filters.

IMMEDIATELY AFTER COOLING

DOWN THE CAB

Immediately after cooling of the cab and

reduction of the internal temperature to

the required value we recommend you

to:

− Perform smooth regulation of air temperature with the air-conditioning on by

partially opening the heating valve (A).

At this setting the air entering the cabin

from the outlets is not dried so intensively.

− You can also smoothly regulate the air

temperature with the air-conditioning

on by reducing the fan output by

switching the control (B) to position 1

or 2.

30

ACQUAINTANCE WITH THE TRACTOR

F_02_151

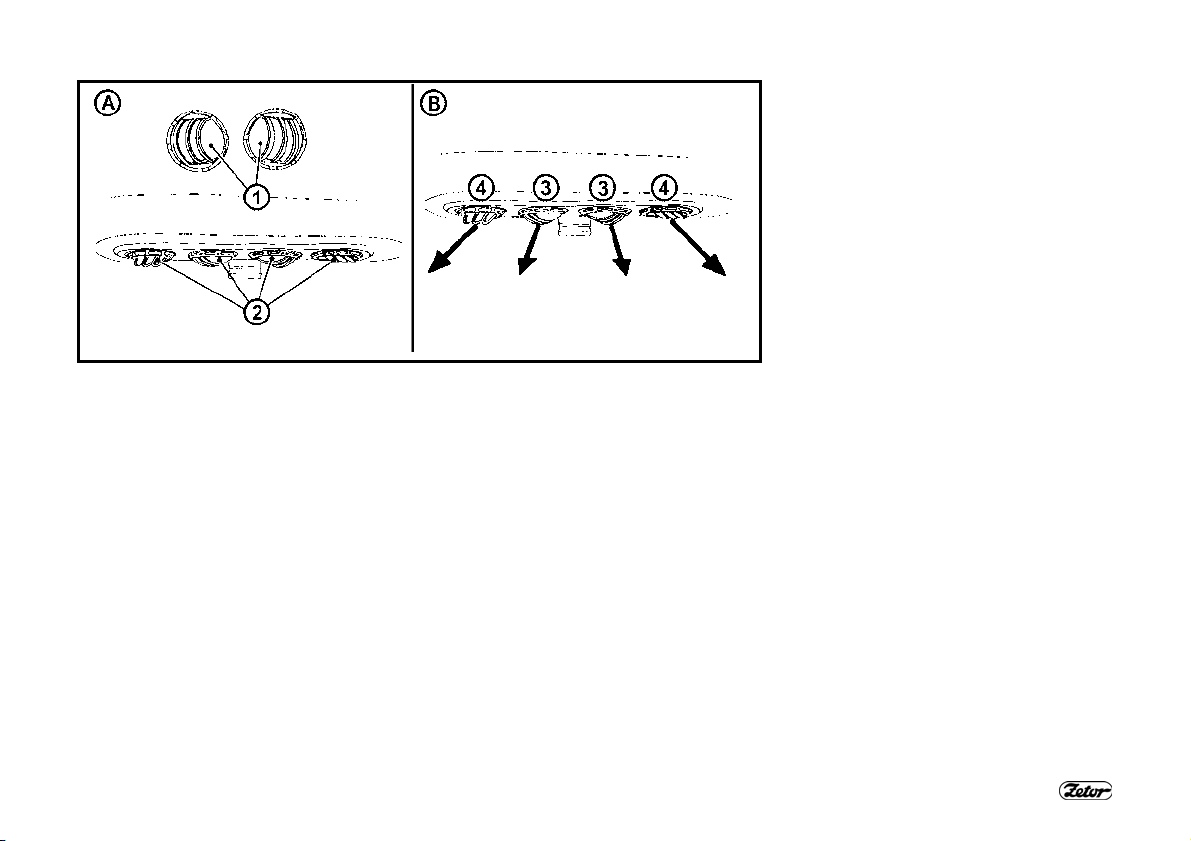

HEATING AND AIR-CONDITIONING OUTLETS (A) (∗RADIO SPEAKERS)

Adjustable outlets of heating (2) and *air-conditioning (1)

Radio speakers are only installed in case of preparation for the *radio installation.

FRONT WINDSHIELD (B) DEFROSTING

To ensure quick defrosting of the front windshield direct the central heating outlets (3)

under the angle of approx. 45° towards the windshield. Direct the side outlets (4) under the angle of approx. 45° to the cab corners.

After defrosting of the front windshield direct the side outlets to the side glasses of the

doors as necessary and gradually defrost them. After defrosting direct the outlets in

such a way that the air should not be blown directly to the driver, but down to the

driver’s legs.

31

ACQUAINTANCE WITH THE TRACTOR

B21a

32

ACQUAINTANCE WITH THE TRACTOR

ANALOG DASHBOARD

The analog dashboard is installed as

standard equipment.

DESCRIPTION OF INSTRUMENTS

A - Indicators

B - Air pressure meter

C - Engine revolution meter with a

counter of operation hours

D - Fuel gauge

E - Coolant thermometer

INDICATORS

11 - High beam lights (blue). Lights up

when high beam headlights are on.

12 - Tractor turn signal indicator (green)

st

13 - 1

trailer turn signal indicator (green)

nd

14 - 2

trailer turn signal indicator (green)

15 - Indicator of minimum air pressure in

the brake system (red). Lights up if

the air pressure for the air brakes of

the trailer drops below the critical

limit, i.e. 450 kPa.

16 - Parking brake (red). Lights up when

the parking brake lever is engaged.

17 - Charging (red). During engine opera-

tion it lights up in case of a charging

failure. If the engine is at standstill, it

must be lit

18 - Lubrication (red). During engine op-

eration it lights up if the engine oil

pressure drops below 120 to 60 kPa.

If the engine is at standstill, it must be

lit

19 - Air cleaner clogging (yellow). It lights

up if the air filter is clogged.

20 - Indicator of warning lights (red)

21 - The indicator of a critical temperature

of the coolant (red) lights up when the

temperature of approx. 100°C is

achieved (not connected).

22 - Multiplier on indicator (green - 1

stage)

23 - Multiplier on indicator (green - 2

st

nd

stage)

33

24 - Indicator of a failure in the hydro-

static steering system (red). During

engine operation it lights up in case

of a hydrostatic steering failure. If the

engine is at standstill, it must be lit

25 - Fuel (orange) Lights up when the

remaining quantity of fuel in the tank

amounts to 1/6 - 1/10 of the tank vol-

ume.

26 - PTO on indicator

27 - The indicator informs about wear of

plates of the cardan brake of the front

driving axle (red)

28 - Engine glowing (yellow) Indicates ac-

tivation of the engine start facilitation

device.

29 - Reserve

30 - Warning indicator (red) It lights up if

the air pressure drops below the criti-

cal limit, i.e. 450 kPa or when the

parking brake lever is engaged.

ACQUAINTANCE WITH THE TRACTOR

F54b

34

ACQUAINTANCE WITH THE TRACTOR

∗DIGITAL DASHBOARD

The digital dashboard is installed as optional equipment on the customer’s request.

DESCRIPTION OF INSTRUMENTS

F - Indicators

G - Air pressure meter

H - Engine revolution meter

I - Fuel gauge

J - Coolant thermometer

K - Display

INDICATORS AND BUTTONS

The arrangement of indicators on the

digital dashboard is the same as on the

analog dashboard.

After pressing of the selected button the

corresponding symbol and value will appear on the display.

31 - Button of the operation hour counter.

The value will appear on the display.

32 - Battery voltage button: The voltage

value is displayed on the display

(with the resolution of 0.1 V).

33 - Button of the number of covered

kilometres (per day or since the last

reset). The number of kilometres is

shown on the display. The value can

be reset with long pressing of the

button.

34 - Button of the current travelling speed

in km/h, which is shown on the display.

35 - 1000 rpm PTO button. The rpm

value with the resolution of 10 rpm is

shown on the display.

36 - 540 rpm PTO button. The rpm value

with the resolution of 10 rpm is

shown on the display.

35

ACQUAINTANCE WITH THE TRACTOR

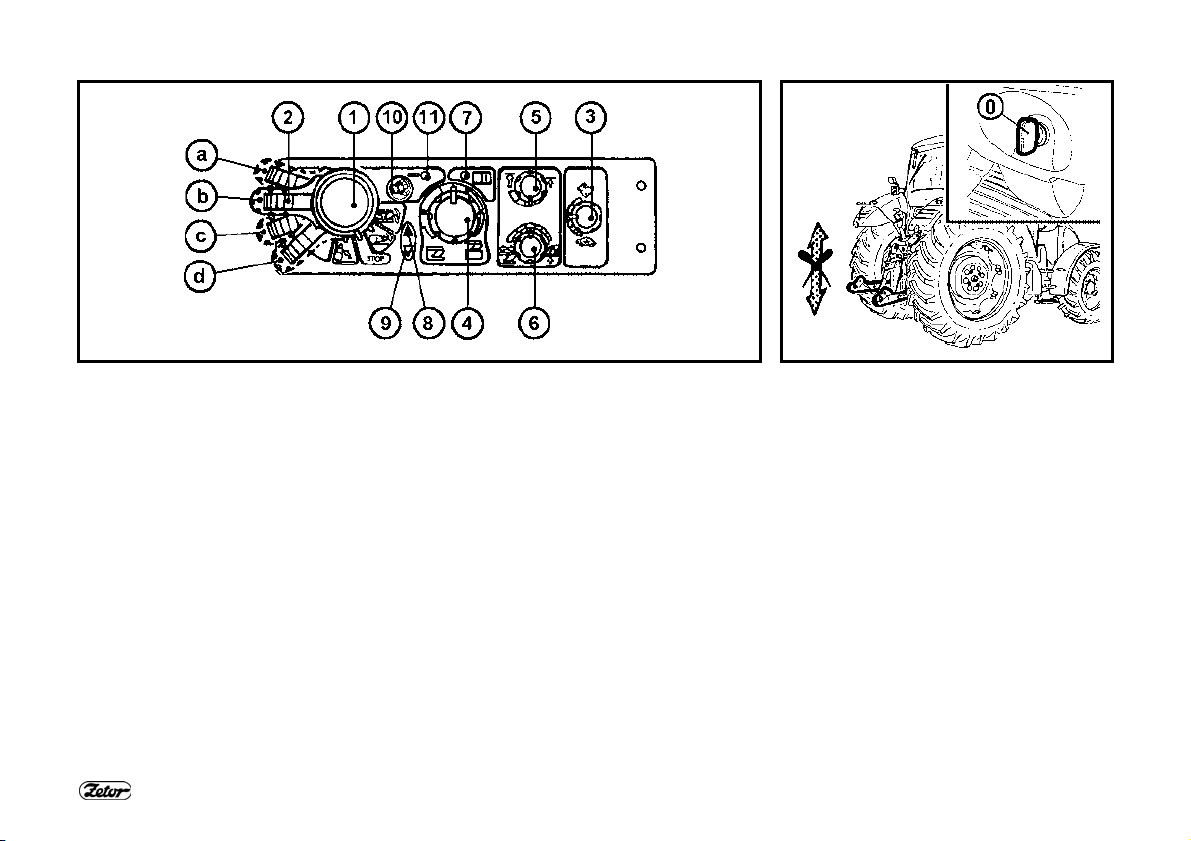

SELECTORS, SWITCHES AND

LEVERS

a - Light switch (off, parking, main head-

lights)

b - Selector of low beam lights in the

tractor grill and working lights on the

tractor cab.

c - Fog light switch (off - on). The func-

tion of the fog light is indicated by

the illuminated symbol on the switch.

d - Working headlight switch (off - on).

The function of the working headlight

is indicated by the illuminated sym-

bol on the switch.

e - Warning light switch

f - Switch of the front driving axle. En-

gaged front driving axle is indicated

by the illuminated symbol on the

switch.

g - Beacon switch (off - on).

h - Free position

i - Torque multiplier preselection switch

j - Differential lock button

k - Stopping the engine run (stopping de-

vice)

l - Selector of turn signal, low and high

beam lights and the acoustic and

light warning signal

m - Switching box

XF101

36

ACQUAINTANCE WITH THE TRACTOR

F56 F57 F58

LIGHT SWITCH (A)

a - Lights “OFF”

b - Sidelights and tail lights, registration

sign and instrument lighting “ON”

c - All the electric appliances are ON as

in position “b” In addition, low or high

beam lights are “ON” (depending on

the position of the selector of the

turn signal, lights and horn)

SWITCH OF THE FRONT DRIVING

AXLE (F)

Use the front driving axle in case

the rear wheels slip to increase

the traction of the tractor.

a - Front driving axle “OFF”

b - Front driving axle “ON”

When the tractor is stopped (the tractor

is braked, engine stopped, key of the

switching box off), the front driving axle is

“ON”.

The front driving axle is on in the basic

position (indicator lit) and it can be deactivated with the switch (indicator off).

WARNING LIGHT SWITCH (E)

a - Warning lights “OFF”

b - Warning lights “ON”

The function of the warning lights is signalled by intermittent flashing of the indicator on the dashboard.

37

ACQUAINTANCE WITH THE TRACTOR

F59 F60 F_02_181

SELECTOR OF THE GRILL AND CAB

HEADLIGHTS (B)

a - Lights in the roof “OFF”

b - Lights in the roof “ON”

This selector controls the lights in the grill

or roof of the tractor cab. Only use the

lights in the cab roof if an implement is

attached to the front three-point hitch that

covers the headlights in the grill.

Switched on lights in the cabin roof are

indicated by the illuminated symbol on

the switch.

High beam lights are only available in the

tractor grill.

FRONT, REAR DIFFERENTIAL LOCK

BUTTON (J)

a - Differential lock engaged

b - Differential lock disengaged

The differential lock is engaged by pressing of the button, which returns to the

original position after being released.

The engagement of the differential lock is

indicated by the illuminated symbol on

the switch.

The differential lock is automatically disengaged on pressing of the brake pedals.

In tractors equipped with the front driving

axle with controlled differential lock the

front differential lock is activated together

with the rear differential lock.

SELECTOR OF TURN SIGNAL, LOW

AND HIGH BEAM LIGHTS AND HORN

(L)

a - Acoustic horn - push the selector in

the axial direction

b - Low beam lights

c - Right turn signal

d - Left turn signal

e - Light warning signal

f - High beam lights

38

ACQUAINTANCE WITH THE TRACTOR

E140 S43 S44

SWITCHING BOX

The switching box is located on the

dashboard, see arrow.

KEY IN “0” POSITION

The voltage of all appliances controlled

via the key is disconnected. The key can

be removed.

KEY IN “I” POSITION

Voltage is connected to all appliances

except the starter motor. The key is in

this position during engine operation.

39

ACQUAINTANCE WITH THE TRACTOR

S45 F_02_53n E144

KEY IN “II” POSITION

In this position the starter motor and all

the electric appliances are connected

except wipers, washers, cab fan and airconditioning. After starting the key automatically returns to the “I” position.

LIGHTER AND THREE-PIN SOCKET

The lighter (1) and three-pin socket are

located on the panel of the right rear

fender.

MANUAL THROTTLE LEVER

A - Maximum delivery

B - Idle run

40

ACQUAINTANCE WITH THE TRACTOR

E145b D102

ENGINE STOPPING CONTROL

By pulling the control upwards you will

stop the engine run immediately and by

turning it in the pulled position you will

lock its position.

When the engine run has stopped, return

the control to the original position.

If the control remains pulled up,

the engine cannot be started.

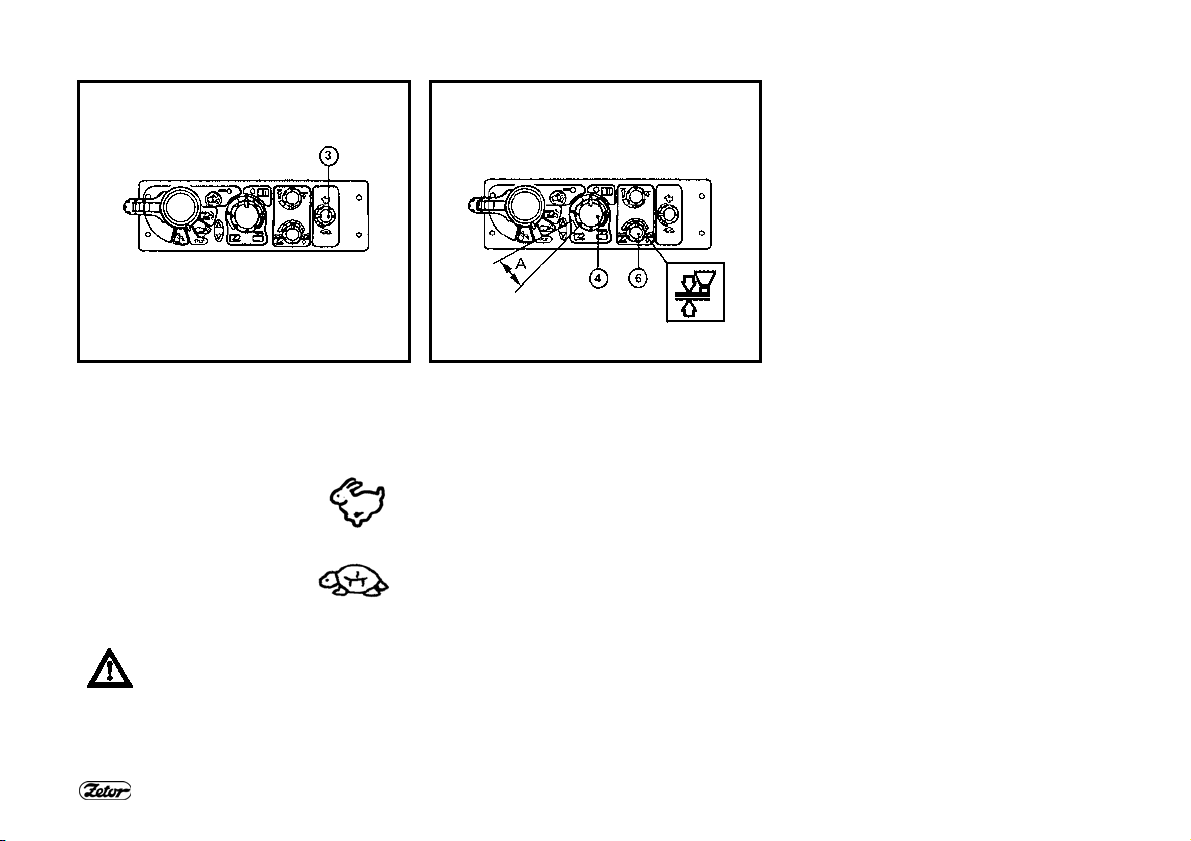

TORQUE MULTIPLIER

PRESELECTION SWITCH (I)

a - Preselection switch “OFF”

b - Preselection switch “ON”

Position (b) - preselection switch “ON” is

indicated by the illuminated symbol on

the switch.

If the preselection switch (b) is “ON”, on

each pressing of the clutch pedal the

medium stage of the multiplier M is

automatically engaged - on the

dashboard one indicator with the tortoise

symbol is lit (see chapter Driving Operation / Indication of the multiplier function

of the “Operator’s Manual”)

After releasing of the clutch pedal the

multiplier can be controlled with the buttons on the shifting lever.

41

During engine starting the switch

must be in the “OFF” position (a).

ACQUAINTANCE WITH THE TRACTOR

F_02_83 F_02_21 F72

PEDALS AND LEVERS

37 - Travel clutch pedal

38 - Foot brake pedals connected with a

latch

39 - Foot throttle pedal

MAIN SHIFTING LEVER AND

REVERSING LEVER

40 - Main shifting lever with three-stage

multiplier control buttons

41 - Reversing lever

SHIFTING LEVER OF ROAD AND

REDUCED GEARS

The lever is located at the left side of the

driver’s seat.

- Road gears

H -

Neutral

N -

- Reduced gears

L -

42

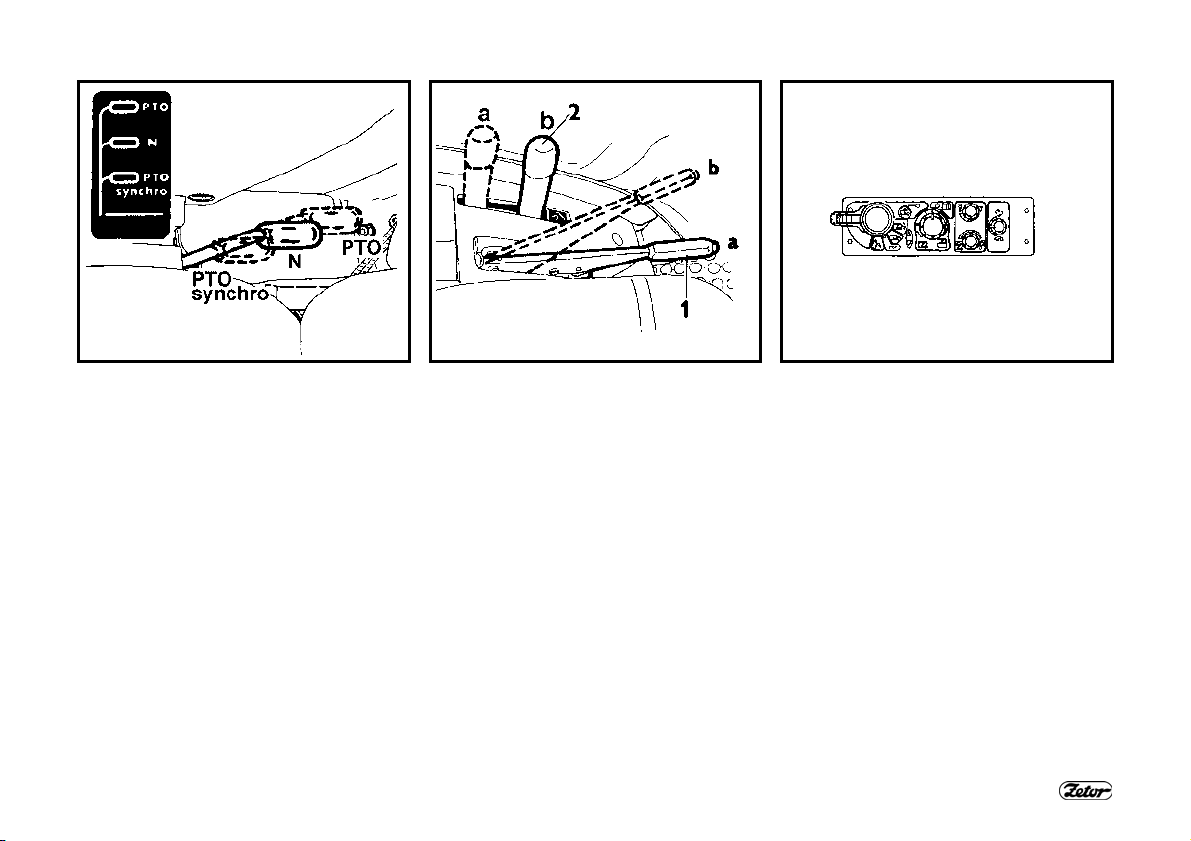

ACQUAINTANCE WITH THE TRACTOR

F73 F74 XF_02_213

SHIFTING LEVER OF DEPENDENT

AND INDEPENDENT PTO RPM

The lever is located at the right side of

the driver’s seat.

PTO -

N -

PTO

synchro -

Independent rpm of the

PTO engaged

Neutral position

Use this position to facilitate

the connection of the articulated shaft of an agricultural

machine.

The end piece of the rear

PTO can be rotated freely.

Dependent rpm of the PTO

engaged (the rpm value depends on the travelling

speed of the tractor)

LEVERS OF THE PARKING BRAKE

AND HITCH FOR A SINGLE-AXLE

TRAILER

42 - Parking brake lever

a - Unbraked

b - Braked

43 - Hitch control lever for a single-axle

trailer

a - Transport position

b - Carrying hooks tilted off, the pull-

ing hook with the carrier can be

lowered

HYDRAULIC CONTROL PANEL

It is located in the area of the right

fender.

Bosch electro-hydraulic system

You will find a detailed description of the

control and functions in the “Hydraulic

system” and “Electro-hydraulic system”

chapters of this Operator’s Manual.

43

ACQUAINTANCE WITH THE TRACTOR

XF_02_51 XF_02_156 F_02_175a

CONTROL OF THE AUXILIARY

HYDRAULIC DISTRIBUTOR

(EXTERNAL HYDRAULIC CIRCUIT)

It is located on the upper part of the right

fender.

You will find a detailed description of the

control and functions of the integrated

hydraulic distributor (external hydraulic

circuit) in the "Hydraulic system" chapter

of this Operator's Manual.

CONTROL PANEL ON THE RIGHT

CAB PILLAR

1 - ∗Front PTO switch

2 - Rear PTO switch

3 - Switch of the front working lights on

the cab roof

4 - Switch of the rear working lights on

the cab roof

5 - ∗Switch of rearview mirror heating

6 - ∗ Switch of rear window heating

7 - Rear wiper switch

8 - Two-position selector of the front

wiper and control of the front washer

44

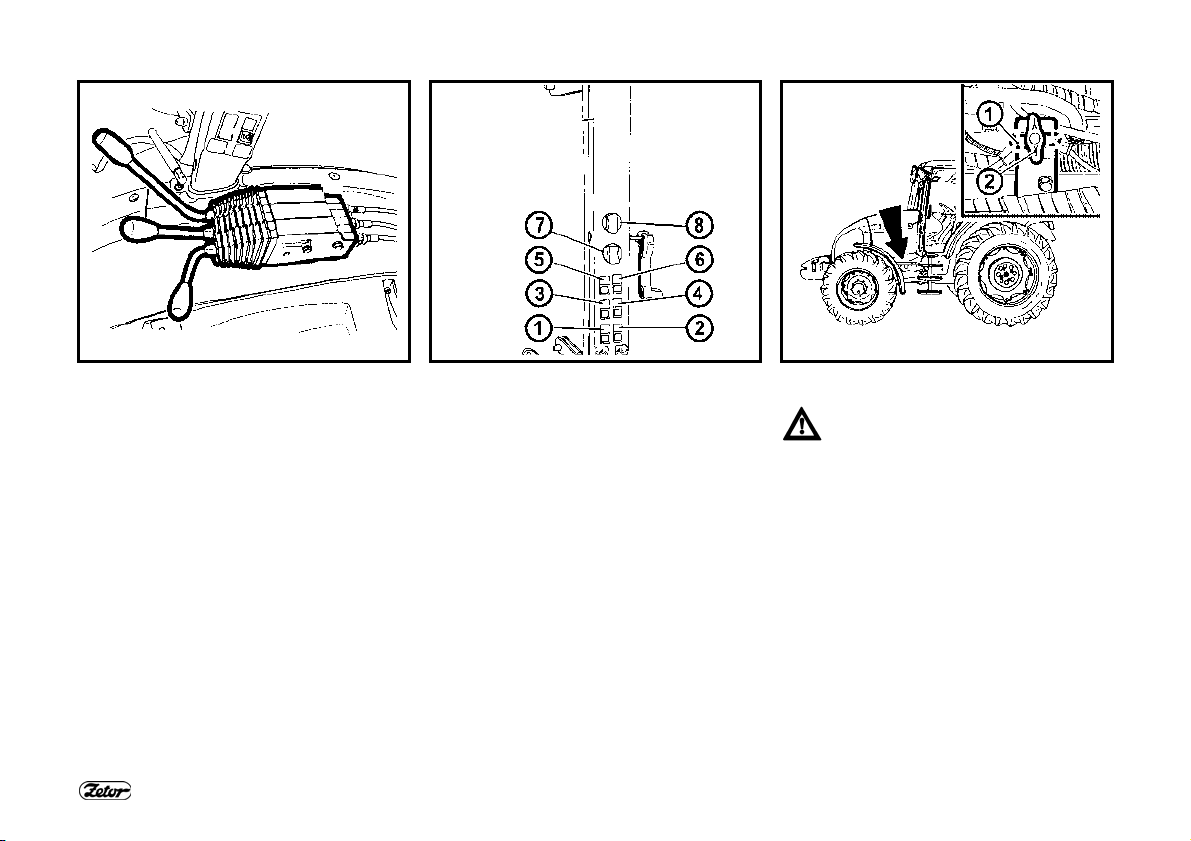

BATTERY DISCONNECTOR

In case of long periods of inactivity, repairs, failures or an accident

immediately disconnect the battery with the battery disconnector,

which is found at the left side of

the tractor.

1 - Battery disconnected

2 - Battery connected

ACQUAINTANCE WITH THE TRACTOR

F_02_22

FUEL TANK

All the tractor types are equipped with a

plastic fuel tank with the volume of 180 l

as standard.

Do not step on the fuel tank!

DRAIN PLUG OF THE FUEL TANK

The hole for draining dirt and fuel from

the fuel tank is found in its bottom.

45

H800

NOTES

46

Before driving the new tractor first

get acquainted with the gear shifting pattern and test individual positions of the shifting lever at the

engine standstill.

Also check whether the technical

condition corresponds to traffic

safety requirements.

DRIVING OPERATION

Page

Before you start......................................................................................................... 49

If the engine will not start........................................................................................... 49

Prohibited starting methods....................................................................................... 49

Starting the tractor engine......................................................................................... 50

Indication of errors of the glowing system ................................................................. 50

∗Coolant heater......................................................................................................... 51

Starting the engine with the use of the coolant heater............................................... 51

Immediately after starting.......................................................................................... 52

Engine preheating ..................................................................................................... 52

Gear shifting.............................................................................................................. 53

Reversing lever .........................................................................................................53

Shifting of road and reduced gear speeds................................................................. 53

Shifting from lower to higher gear speed................................................................... 54

Shifting from higher to lower gear speed................................................................... 54

Three-stage torque multiplier .................................................................................... 54

Indication of the multiplier function ............................................................................ 55

Shifting the stages of the torque multiplier ................................................................ 55

Increasing, reducing the travelling speed by two gears............................................. 55

Setting in motion ....................................................................................................... 56

Driving uphill.............................................................................................................. 57

Driving downhill ......................................................................................................... 57

Foot brakes ............................................................................................................... 57

Front Cardan brake

Air brakes of trailers and semi-trailers....................................................................... 58

Warning indication of an air pressure drop................................................................ 58

Single-hose and double-hose brakes ........................................................................ 59

Single-hose brakes.................................................................................................... 59

Double-hose brakes .................................................................................................. 59

Hydraulic brakes of trailers........................................................................................ 60

Connecting and disconnecting quick-couplers of hydraulic brakes of the trailer........ 60

Front driving axle control........................................................................................... 61

Driving with the front driving axle engaged................................................................ 61

................................................................................................... 58

47

DRIVING OPERATION

Page

Ensuring free space for the Cardan shaft of the front driving axle ............................ 62

Stopping the tractor - parking brake.......................................................................... 62

Stopping the engine .................................................................................................. 62

Leaving the tractor .................................................................................................... 63

Warning indication of a hydrostatic steering error ..................................................... 63

48

BEFORE YOU START

Before you start the engine,

make sure:

1. that the tractor is properly

braked

2. that the main gear shifting lever

and the reversing lever is in

the neutral position

3. that the PTO switches on the

right cab pillar are off.

If the clutch pedal is not pressed,

the engine cannot be started - the

starting interlock switch is not actuated.

DRIVING OPERATION

F_02_28 F_02_31 F_02_32

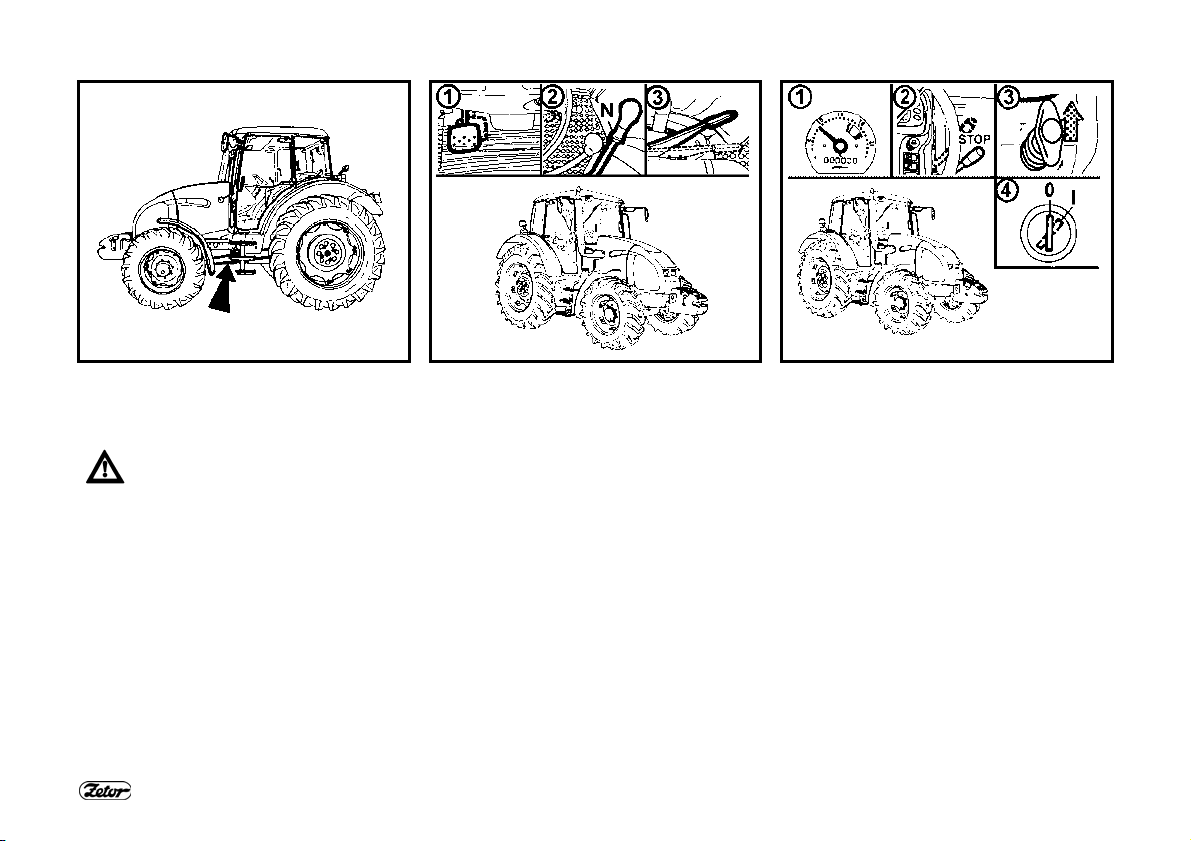

IF THE ENGINE WILL NOT START

Return the key to position “0”. Wait for 30

seconds and repeat the start.

Never support the stopping engine with the starter motor. There

is a danger of damaging the

starter motor.

PROHIBITED STARTING METHODS

It is forbidden to start the engine

by short-circuiting the starter

motor terminals. Only start the

tractor from the driver’s seat!

During any handling or repair of

the started motor the minus pole of

the battery must be disconnected

and all the shifting levers, incl.

PTO must be moved to the neutral

position. The starter motor contacts are covered with a cap.

49

F_02_29 F_02_30 F_02_176

STARTING THE TRACTOR ENGINE

The tractors are equipped with glowing

plugs in the cylinder heads as standard.

1. Insert the key into the switching box

(position “0”).

2. Depress the clutch pedal.

3. Move the main shifting lever and the

reversing lever to the neutral position.

4. Adjust the throttle for increased fuel delivery (approx. 3/4 of the maximum

quantity).

5. Turn the key to position “I”. The yellow

indicator signalling proper function of

glowing will light up on the dashboard.

DRIVING OPERATION

6. Wait until the glowing indicator goes off

(the time depends on the temperature

of the cooling liquid).

If the glowing indicator only

flashes instead of lighting, an error has occurred in the glowing

system (chapter Indication of errors of the glowing system). Have

the reported error repaired in a

specialized repair shop.

7. Turn the key to position “II” (start).

8. Release the key immediately after starting the engine. Do not start the engine

for more than 15 s.

9. After starting the engine gradually reduce the fuel delivery. Thus, you will

prevent unnecessary operation of the

engine at high engine speed.

50

INDICATION OF ERRORS OF THE

GLOWING SYSTEM

An error of the glowing system is indicated by flashing of the glowing indicator.

- If at engine standstill the glowing indicator flashes once a second, the glowing

will occur in the emergency mode as at

low temperatures regardless of the

coolant temperature.

- If at engine standstill the glowing indicator flashes twice a second, the glowing

is off (out of operation).

- If the glowing indicator flashes permanently during engine operation, the

glowing controller is faulty and the

glowing has not been finished. This

failure must be removed immediately

as the battery might get discharged.

DRIVING OPERATION

XF_02_185a F91

∗COOLANT HEATER

The coolant heater is installed on the engine block.

The output of the heater is 1000 W at the

220 VAC supply voltage.

STARTING THE ENGINE WITH THE USE OF THE COOLANT HEATER

Heating the coolant facilitates engine starting at low ambient temperatures. The electric installation of the power supply and its protection against electric shock must

comply with valid regulations.

1. First, insert the connector to the heater.

2. Then, connect the heater to electric mains with the voltage of 220 V.

With regard to reduced wear of the engine during starting at low temperatures, the

use of the heater is recommended by the manufacturer. The heating time depends on

the ambient temperature (1 - 2 hours before the planned start should be sufficient).

After the end of heating first disconnect the device from the electric mains and

only then remove the connector from the heater!

Electric shock hazard!

It is necessary to ensure instructing of the tractor operator and regular

inspections of the coolant heater, incl. the power supply cable in the

sense of valid standards of the state where the tractor is operated, at

least before every winter.

51

DRIVING OPERATION

F_02_33a F_02_35

IMMEDIATELY AFTER STARTING

After starting set the engine

speed to 800 - 1000 rpm and let

the engine run without loading for

approx. 2 minutes.

During this time check the lubrication,

charging, hydrostatic steering (the indicators must go off) and other functions ensuring proper operation of the engine.

The period of running the engine without

loading must be observed, especially in

winter.

ENGINE PREHEATING

Continue preheating the engine while driving. Preheating the engine by

means of a long idle run or abrupt increasing of the engine speed is harmful

for the engine.

Until the coolant temperature reaches 45°C, do not exceed the engine speed

of 2000 rpm.

52

F_02_34 F_02_43 F96

GEAR SHIFTING

The tractors are equipped with a fourspeed synchronized gearbox, threestage torque multipliers and two-speed

reduction.

The four-speed gearbox is controlled

with the main shifting lever with control

buttons of the torque multiplier (1). The

forward and reverse motion of the tractor

is selected with the reversing lever (2).

The gearbox does not make it

possible to use the fourth speed

for the reverse motion.

DRIVING OPERATION

REVERSING LEVER

The reversing lever is used to select the

driving direction of the tractor (forward,

reverse).

Forward drive

F -

Neutral

N -

Reverse drive

R -

The reversing gearbox offers 18 reverse

speeds that are approximately as fast as

the forward speeds. Therefore, consider

well and select a suitable reverse speed

for the particular character of work.

Shift the reversing lever with the

clutch pedal depressed and the

tractor standing. To drive in the

reversing direction move the reversing lever to the R position.

SHIFTING OF ROAD AND REDUCED

GEAR SPEEDS

- Road gears

H -

Neutral

N -

- Reduced gears

L -

Shifting of gears of the main gearbox at

reduced gear speeds is the same as in

the case of road speeds

The shifting lever of road and reduced speeds can only be shifted

with the tractor at standstill.

53

F_02_44 F_02_45 F99

SHIFTING FROM LOWER TO HIGHER

GEAR SPEED

Depress the clutch pedal (clutch disengaged). At the same time release the

foot throttle pedal and shift the required

higher gear. Smoothly release the clutch

pedal (the clutch starts engaging) and at

the same time increase the engine

speed.

DRIVING OPERATION

SHIFTING FROM HIGHER TO LOWER

GEAR SPEED

Depress the clutch pedal and move the

shifting lever via the neutral position to

the lower gear.

Note: To extend the life of the syn-

chromesh you can shift the gear from

higher to lower speed using the “double

clutch depressing”.

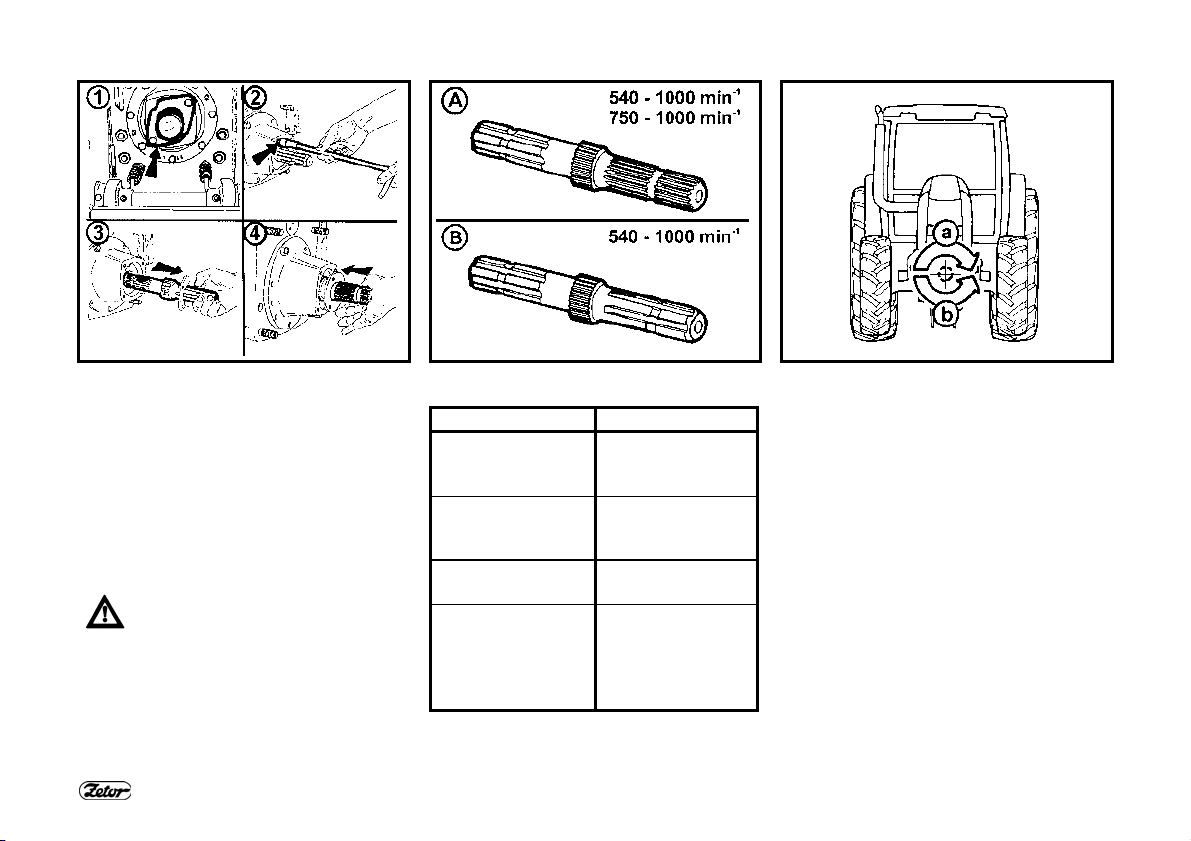

THREE-STAGE TORQUE MULTIPLIER

The three-stage multiplier is standard

equipment of all tractor types.

Shifting of individual stages of the threestage multiplier is controlled with two buttons on the main shifting lever head.

It is performed without depressing of the

travelling clutch pedal (under load).

The entire shifting is automatic even

when the tractor is loaded.

1.00 ratio (high stage)

H -

1.16 ratio (medium stage)

M -

1.34 ratio (low stage)

L -

54

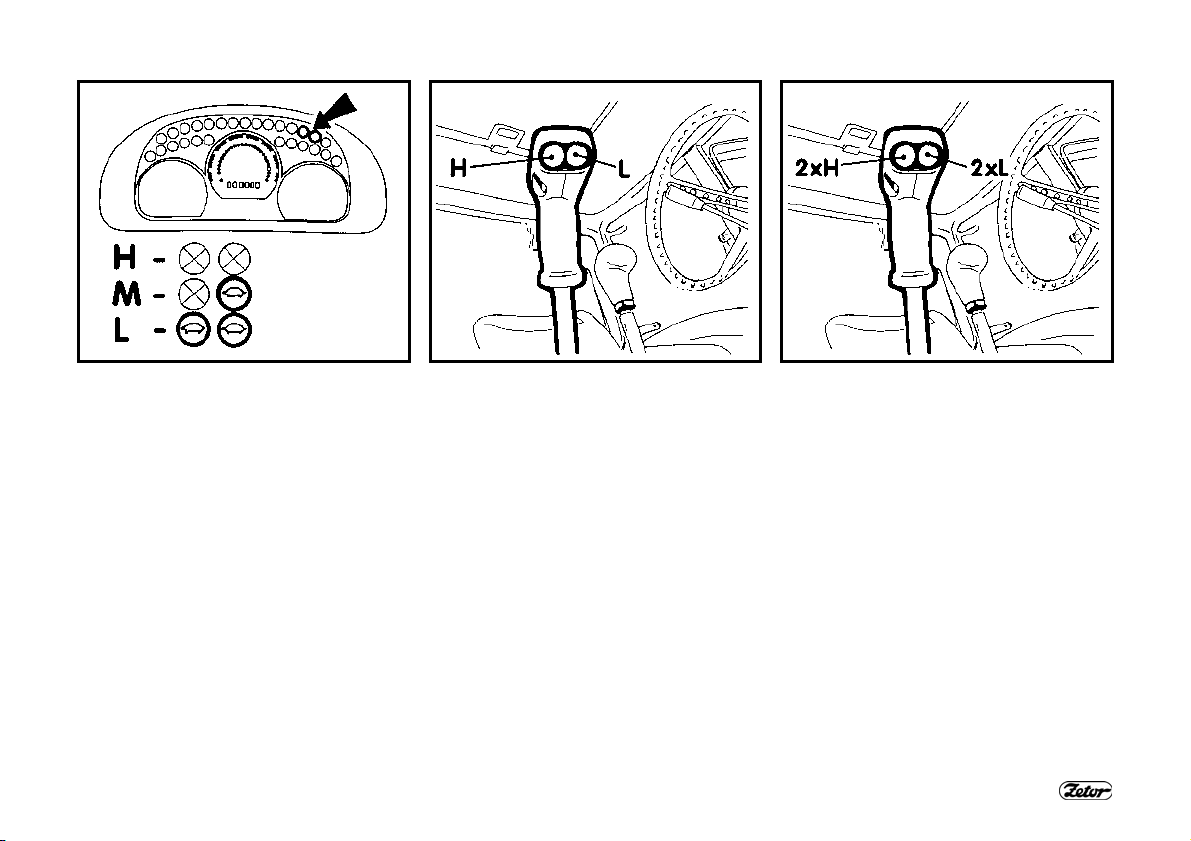

F100 F101 F102

INDICATION OF THE MULTIPLIER

FUNCTION

Individual engaged stages of the multiplier (H,M,L) are signalled by indicators

on the dashboard with the tortoise symbol.

Symbols OFF

H -

One indicator with the tortoise

M -

symbol is lit.

Two indicators with the tortoise

L -

symbol are lit.

Note: On starting or stopping of the tractor engine the H stage is always engaged

automatically.

DRIVING OPERATION

SHIFTING THE STAGES OF THE

TORQUE MULTIPLIER

Increasing the travelling speed

H -

Reducing the travelling speed

L -

INCREASING, REDUCING THE

TRAVELLING SPEED BY TWO GEARS

Increases the travelling speed by

2xH

two gears

Reduces the travelling speed by

2xL

two gears

55

SETTING IN MOTION

1. Select road or reduced gears.

2. Depress the clutch pedal.

3. Shift the main shifting lever and the

reverse lever to the neutral position

and switch off the PTO switches on

the right cab pillar.

4. Start the engine

5. Set the engine speed to 800 rpm.

6. Shift the reversing lever to the requested driving direction of the tractor (forward or reverse).

7. Select the suitable gear for putting the

tractor in motion.

8. Slightly increase the engine speed.

9. Get the parking brake ready for releasing.

DRIVING OPERATION

F_02_36

10. Release the clutch pedal until the

travel engagement point and while simultaneously increasing the engine

speed continue releasing the clutch

pedal smoothly.

11. Release the parking brake completely.

12. Start moving smoothly and slowly.

Very fast acceleration may cause overloading of the power train, increased fuel

consumption, excessive wear of tyres

and damage of the transported load.

Only use the 1

motion when driving with a heavy trailer

uphill and in rough terrain.

st

gear to put the tractor in

56

When shifting individual gear

speed (1-4) or reversing (F-R)

observe the instructions for putting the tractor in motion and gear

shifting in this manual. When the

tractor has been started and is

still standing, depress the clutch

pedal and wait for approx. 2 seconds. Only then shift the required

gear speed or select the reverse

direction.

To increase safety and to avoid

unexpected situations use the

foot brake during the shifting as

well.

F_02_37 F_02_38 F106

DRIVING UPHILL

When driving uphill, shift from the

higher to the lower speed in time

to avoid the engine speed dropping below 800 rpm and avoid

such driving that would lead to

stopping of the engine due to

overloading.

DRIVING OPERATION

DRIVING DOWNHILL

Driving downhill without an engaged gear is prohibited. When

driving down a longer slope, shift

the lower gear, the steeper the

slope is. If possible, shift the

lower gear before the slope already.

Note: The gear that allows you to get

uphill reliably is also suitable for getting

down the hill safely.

FOOT BRAKES

The foot brakes are of the disc, wet, hydraulically controlled, double-pedal type

with an automatic pressure compensator.

During driving on a road both the

pedals must be connected with a

latch. Only use unlatched pedals

for braking the right or left wheel

separately during terrain work

and in the field.

Note: When driving down a steep slope

with a trailer or semi-trailer equipped with

air or hydraulic brakes you must use the

foot brake from the beginning of the

slope already.

During braking with one brake

pedal the trailer brakes are not

in operation!

57

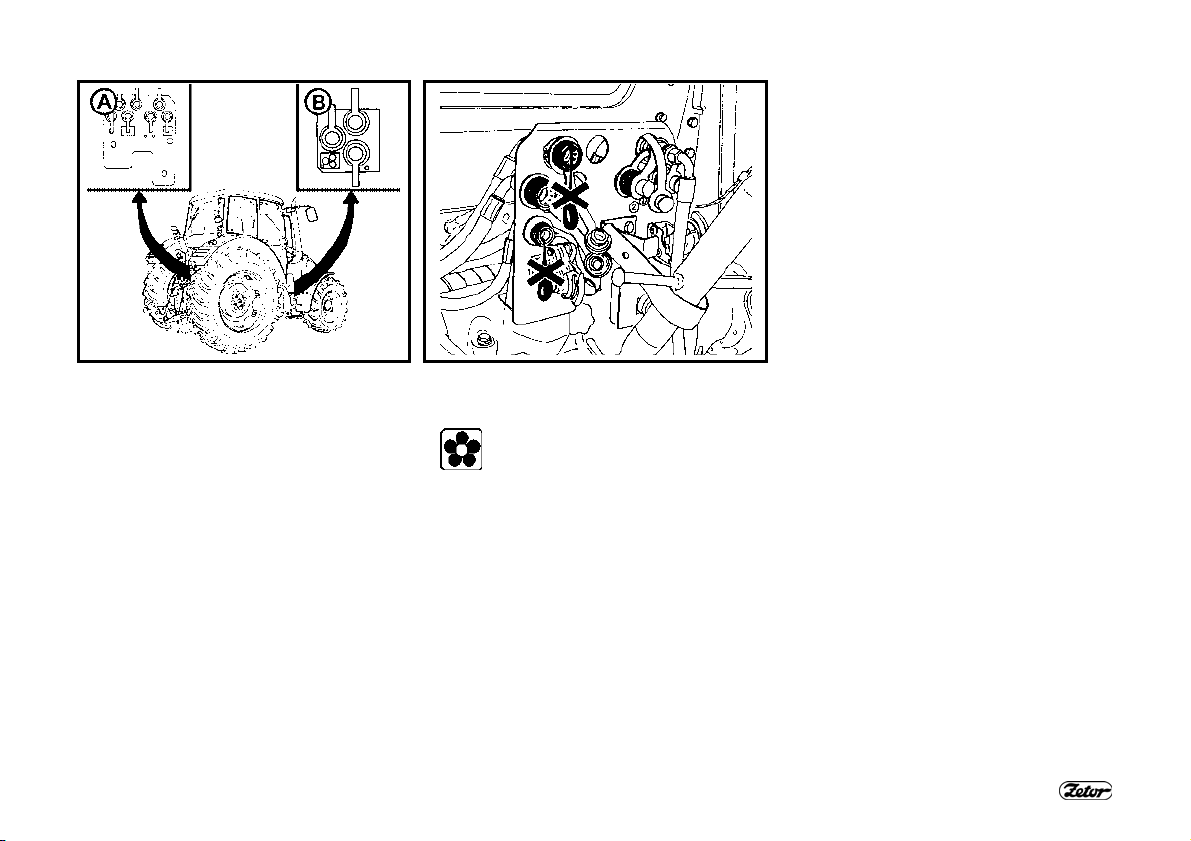

FRONT CARDAN BRAKE

If only one brake pedal is used,

the Cardan brake is not activated.

DRIVING OPERATION

F108 F_02_39 F_02_55

AIR BRAKES OF TRAILERS AND

SEMI-TRAILERS

The control of the air brakes of trailers

(semi-trailers) and the control of the tractor brakes is designed in such a way that

the braking effect of both the vehicles is

synchronized.

The working pressure is set by the pressure controller to 740 ± 20 kPa. If the

pressure drops below 550 - 40 kPa, the

relief valve puts the secondary devices

(differential lock, engagement of the front

driving axle, etc.) out of operation.

WARNING INDICATION OF AN AIR

PRESSURE DROP

A pressure drop below 450 kPa is signalled by lighting up of the red indicator

located on the dashboard.

In case of a pressure drop below

450 kPa in the air pressure system a tractor with a braked trailer

or semi-trailer must not continue

travelling until the air pressure increases again.

58

F_02_56 F_02_57 F_02_58

SINGLE-HOSE AND DOUBLE-HOSE

BRAKES

1. Coupling of single-hose brakes

2. Couplings of double-hose brakes

After disconnection or without a

connected trailer (semi-trailer) the

couplings must be closed with a

cap.

DRIVING OPERATION

SINGLE-HOSE BRAKES

The cap is marked black.

After connection of a trailer

(semi-trailer) with the maximum

permissible speed approved for

the particular tractor type the

maximum allowed speed of the

set is 30 km/h.

The maximum permissible speed

of the set results from the maximum permissible speed of the

slower vehicle in the set.

DOUBLE-HOSE BRAKES

The cap of the left coupling is marked

yellow (braking branch) and the cap of

the right coupling is marked red (filling

branch).

After connection of a trailer

(semi-trailer) with the maximum

permissible speed approved for

the particular tractor type the

maximum allowed speed of the

set is 40 km/h.

The maximum permissible speed

of the set results from the maximum permissible speed of the

slower vehicle in the set.

59

DRIVING OPERATION

E230a

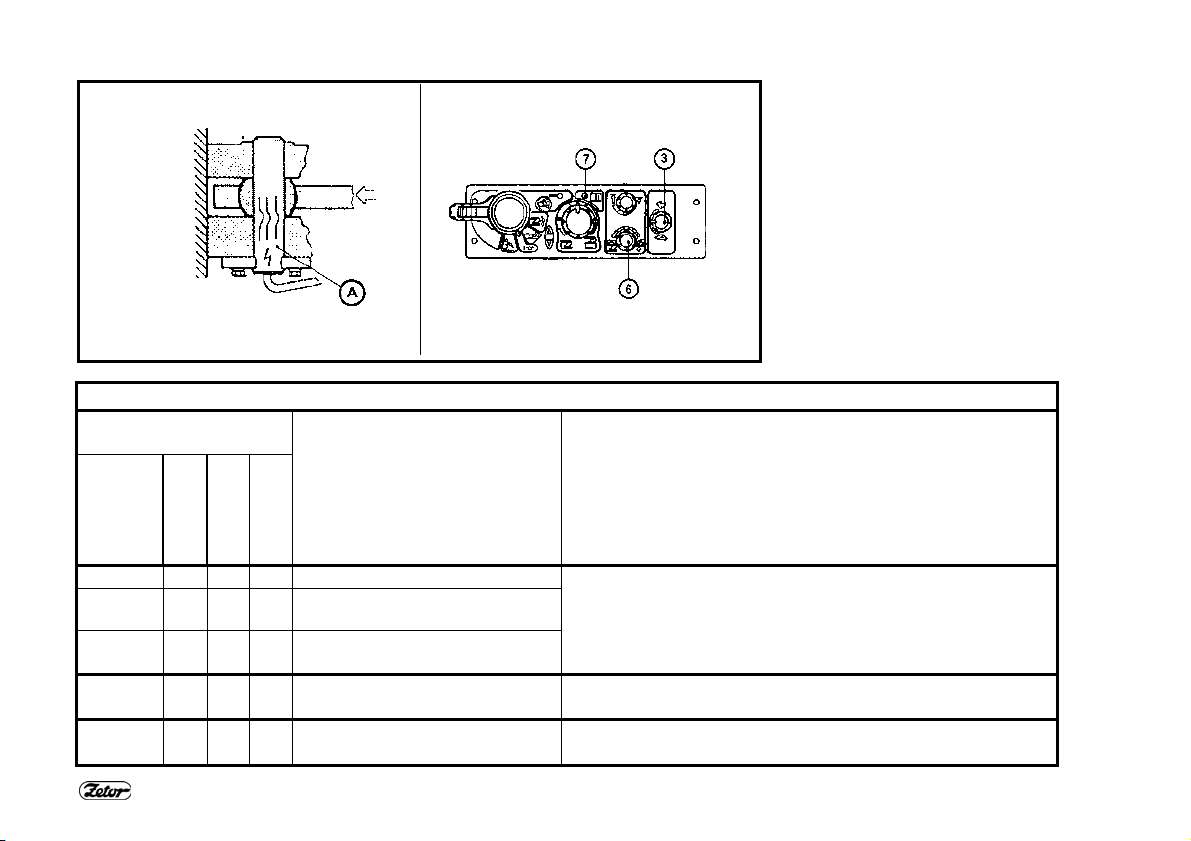

HYDRAULIC BRAKES OF TRAILERS

Connect the hydraulic brakes of a trailer or semi-trailer to the quick-coupler marked

with an arrow.

The control of the hydraulic brakes of trailers (semi-trailers) and the control of the

tractor brakes is designed in such a way that the braking effect of both the vehicles is

synchronized. The working pressure is applied by oil delivered by a permanent gear

pump of the hydraulic system.

The brake valve of the trailer is controlled by the pressure of the brake liquid from the

main brake cylinders depending on the force applied onto the brake pedal. At the

maximum depression of the brake pedal the pressure at the coupling must amount to

12 - 15 MPa. The brake valve makes sure that the brake function overrides the hydraulic function.

If during depression of the foot brake pedals shocks occur in the hydraulic circuit, it is

necessary to bleed the hose leading from the brake valve to the quick-coupling.

During driving with a hitched trailer or semi-trailer the pedals of the foot brake

must be connected and secured with a latch.

During braking with one brake pedal the hydraulic brakes of the trailer

are not in operation.

CONNECTING AND DISCONNECTING

QUICK-COUPLERS OF HYDRAULIC

BRAKES OF THE TRAILER

When connecting and disconnecting the quick-couplers pay

increased attention with regard to

the residual oil that remains in the

socket or on the plug of the

quick-coupler.

For environmental reasons after

every disconnection of quickcouplers this residual oil must be

removed with any textile material.

60

F116 H223

FRONT DRIVING AXLE CONTROL

The front driving axle is “ON” in basic

position (the indicator lights up). It can be

disengaged with the corresponding

switch on the dashboard.

a - Front driving axle “ON”

b - Front driving axle “OFF”

When the tractor is stopped (the tractor

is braked, engine stopped, key of the

switching box off), the front driving axle is

“ON”.

DRIVING OPERATION

DRIVING WITH THE FRONT DRIVING AXLE ENGAGED

Use the front driving axle in case the rear wheels slip to increase the traction

of the tractor.

On a road and hard surface driving with the front driving axle engaged is acceptable up to the maximum speed of 15 km/h (driving with the front axle engaged causes increased wear of the front tyres).

Permanent engagement of the front driving axle is permissible if an agricultural machine or implement is attached to the front of the tractor. This condition is mentioned

in the operator’s manual of the corresponding machine.

The maximum allowable speed of these sets is 15 km/h.

61

F_02_40 F_02_60 XF_02_186

ENSURING FREE SPACE FOR THE

CARDAN SHAFT OF THE FRONT

DRIVING AXLE

When installing auxiliary units or

connecting implements make

sure that around the Cardan shaft

of the front driving axle there is at

least 10mm free space all along

its length at any oscillation of the

axle.

If this principle is not observed,

there is a danger of damaging

the tractor and machine.

DRIVING OPERATION

STOPPING THE TRACTOR - PARKING

BRAKE

Under normal conditions stop the tractor

slowly. Shortly before stopping:

1. Depress the clutch pedal.

2. Shift the main gear shifting lever to the

neutral position.

3. After every stopping secure the tractor

against accidental movement with the

parking brake. Activation of the parking brake is signalled by illumination of

the corresponding indicator on the

dashboard.

STOPPING THE ENGINE