Zetor 12441, 11741, 11441, 10641, 11741.4c Operator Manual

...

ZETOR

The supplement to the instruction manual for tractors with 4-cylinder engines, type Z 11741.4C with engines TIER II

and types Z 9641, Z 10641, Z 11441, Z 12441 with engines TIER III, which is hereby presented to you, acquaints

you with operation and maintenance of your new tractor.

Despite the fact that many of you have rich experience with operation of other tractors, please read thoroughly this

manual.

You fan find here many pieces of new information get perfect knowledge how to utilise the tractor with various

works.

When following the given principles of operation and maintenance of the tractor and safe driving, your tractor will

become reliable partner for years.

We wish you thousands of contented worked off hours.

ZETOR

Brno

3

The data on technical specifications, construction, equipment, materials and appearance are valid in time of printing. The

manufacturer reserves the right of changes.

4

CONTENTS

Page Page

Tractors Z 9641, Z 10641, Z 11441, Z 11741.4C, Z 12441, ..... 6

Acquaintance with the tractor............................................... 7

Reverse switches, switches and levers.................................... 7

Switch of torque multiplier preselection (i) ............................... 8

Tiltable steering wheel.............................................................8

Control panel on the cab right column ..................................... 9

Lighter (Z 11741.4C)................................................................ 9

Lighter and 3-pin socket........................................................... 9

Driver’s seat Grammer Maximo............................................. 10

Driving .................................................................................. 11

Moving off .............................................................................. 11

Transport use....................................................................... 12

Multi-storey quick-adjustable hitch CBM................................ 12

Height adjustment and dismantling of the multi-storey hitch

CBM....................................................................................... 12

Automatic guiding device of the multi-storey hitch CBM

>31/03/2007........................................................................... 13

Automatic guiding device of the multi-storey hitch CBM

01/04/2007< ........................................................................... 13

Modular system of hitches for trailers and semi-trailers......... 14

Module of swinging tow bar bracket....................................... 14

Swinging tow bar.................................................................... 14

Module of swinging tow bar bracket with fixed pin................. 14

Module of the bracket with ball ø 80...................................... 15

Hitch CBM for single-axle trailers........................................... 15

Maximum permitted vertical static load of hitches for trailers

and semi-trailers .................................................................... 16

Drive of agricultural machines............................................ 18

Front output shaft Zuidberg.................................................... 18

Maximum transferred power .................................................. 18

Hitches.................................................................................. 19

∗Front 3-point hitch.................................................................19

Front 3-point hitch control.......................................................19

Adjustment of speed of lifting of the front 3-point hitch........... 19

Hydraulic locking of front 3-point hitch....................................20

Working and transport positions of front 3-point hitch ...........20

Working position of the front 3-point hitch..............................20

Electric installation ..............................................................21

Electric set..............................................................................21

Lead battery...........................................................................21

Battery disconnector...............................................................21

Fuse dose (17 fuses)..............................................................22

Fuse dose (21 fuses)..............................................................23

Planned technical maintenance.......................................... 24

Oils for 4-cylinder turbo-charged engines of Z 8641 to Z 12441. 24

Recommended oils for turbo-charged engines according to

ambient temperature..............................................................25

Oils for gearboxes of Z 8641 to Z 12441................................26

Oils for front output shafts Zuidberg....................................... 27

Maintenance instructions.................................................... 28

Refilling of brake fluid.............................................................28

Oil tank of hydrostatic steering...............................................28

Front output shaft................................................................... 28

Essential technical parameters ..............................................29

Technical specifications of engines of tractors Z 11741.4C,

Z 9641, Z 10641, Z 11441, Z 12441.....................................29

Forces (kN) and powers (kW) – engines TIER II....................31

Forces (kN) and powers (kW) – engines TIER III...................32

Speed of the front output shaft Zuidberg................................33

Values for tractors Z 11741.4C and Z 12441 .........................34

Index...................................................................................... 35

5

TRACTORS Z 9641, Z 10641, Z 11441, Z 11741.4C, Z 12441,

Tractors with 4-cylinder engines:

Zetor 9641 Forterra turbo.............. 66 kW

Zetor 106 41 Forterra turbo........... 74 kW

Zetor 114 41 Forterra turbo........... 81 kW

Zetor 117 41.4C Forterra turbo ..... 90 kW

Zetor 124 41 Forterra turbo........... 90 kW

F_02_10

6

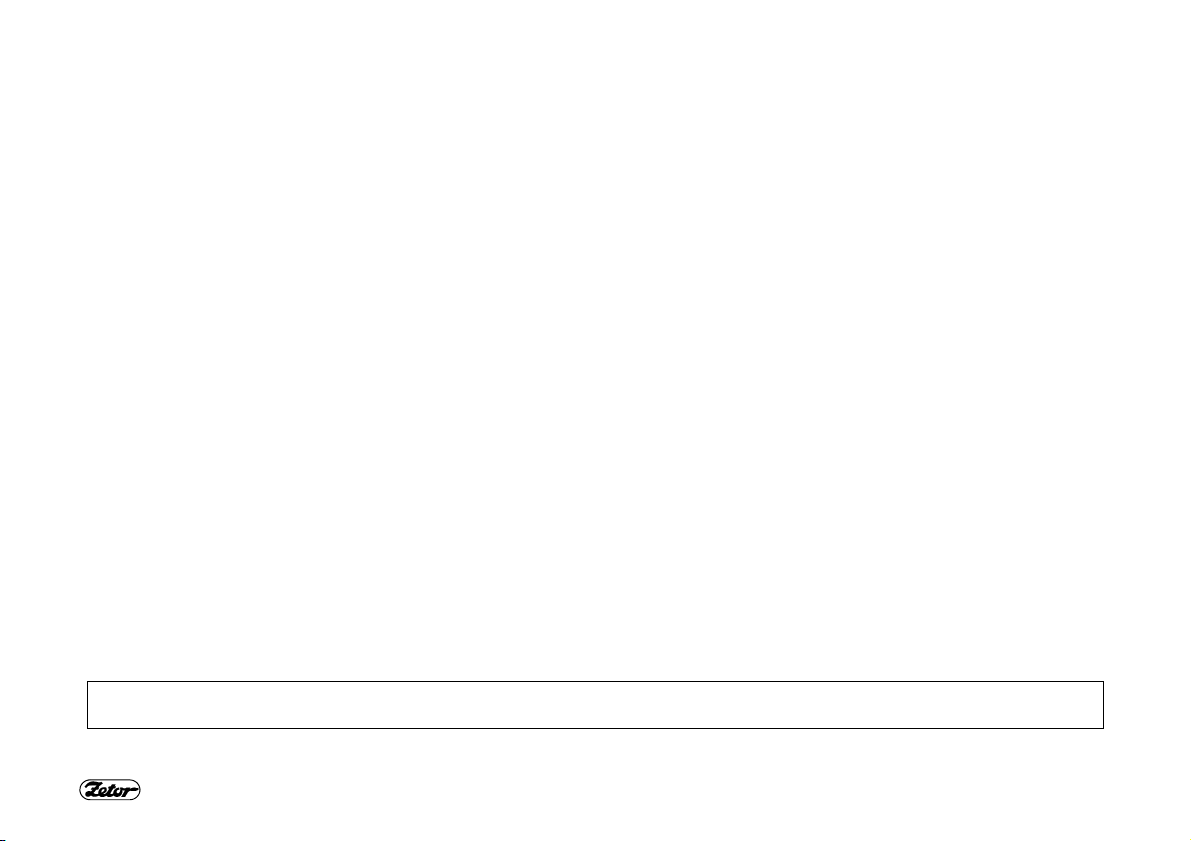

ACQUAINTANCE WITH THE TRACTOR

REVERSE SWITCHES, SWITCHES AND LEVERS

a - Switch of lights (off, parking, main)

b - Reverse switch of low beams in the front mask

and working lights in the cab.

c - Switch of the fog light (off/on). Function of the fog

light is indicated by an illuminated symbol on the

switch.

d - Switch of the rear working headlamp (off/on).

Function of the working headlamp is indicated by

an illuminated symbol on the switch.

e - Switch of warning flashlights.

f - Switch of the front driving axle. Switched on front

driving axle is indicated by an illuminated symbol

on the switch.

g - Switch of the beacon (off/on).

h - Free position.

i - Switch of torque multiplier preselection.

j - Pushbutton of the differential lock.

k - Engine stopping device.

l - Reverse switch of direction indicators, low and

high beams and acoustic horn and flash.

m - Ignition switch

F101

7

ACQUAINTANCE WITH THE TRACTOR

D102 F205

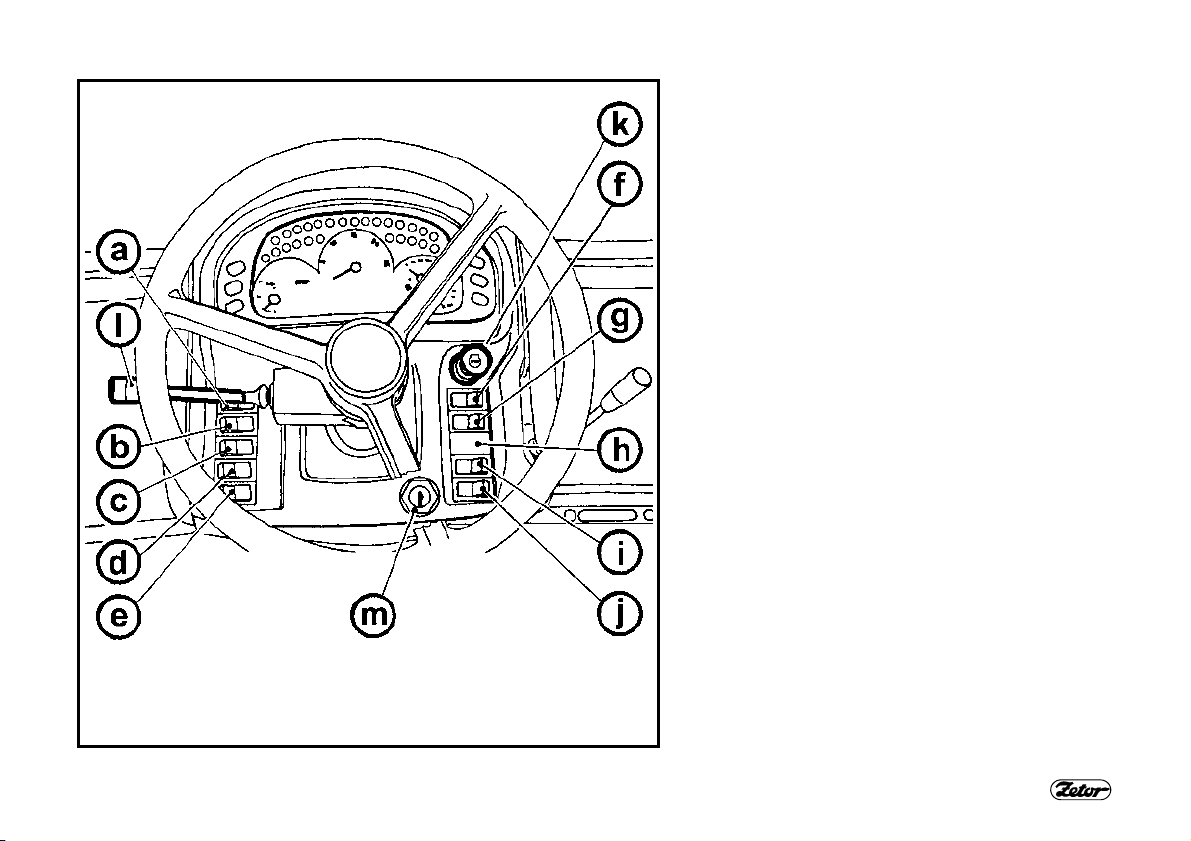

SWITCH OF TORQUE MULTIPLIER PRESELECTION (i)

a - Preselection switch off

b - Preselection switch on

Preselection switch on - position (b) - is

indicated by an illuminated symbol on

the switch.

In case the preselection switch is on (b),

each depression of the clutch pedal engages automatically the medium stage pf

the multiplier M – indicator with a symbol

of a turtle is lit on the dashboard (see the

chapter Driving / indication of function of

the multiplier in the ”Instruction manual“).

After release of the clutch pedal the multiplier can be controlled using the

pushbuttons on the speed change lever.

When starting the engine, the

switch must be in position off (a).

TILTABLE STEERING WHEEL

The steering wheel tilting column enables variable adjustment of the steering

wheel (height and angle adjustment).

Steering wheel height adjustment

Adjustment is carried out by extraction or

retraction of the steering wheel after

unlocking of arrestment by turning of the

lever (1) in direction of the arrow. After

adjustment lock the lever (1) by its tightening against direction of the arrow.

Steering wheel angle adjustment

Adjustment is carried out by tilting of the

steering wheel after unlocking of the arrestment by turning of the lever (2) in direction of the arrow. After adjustment

lock the lever (2) by its tightening against

direction of the arrow.

8

ACQUAINTANCE WITH THE TRACTOR

F_02_156 D103

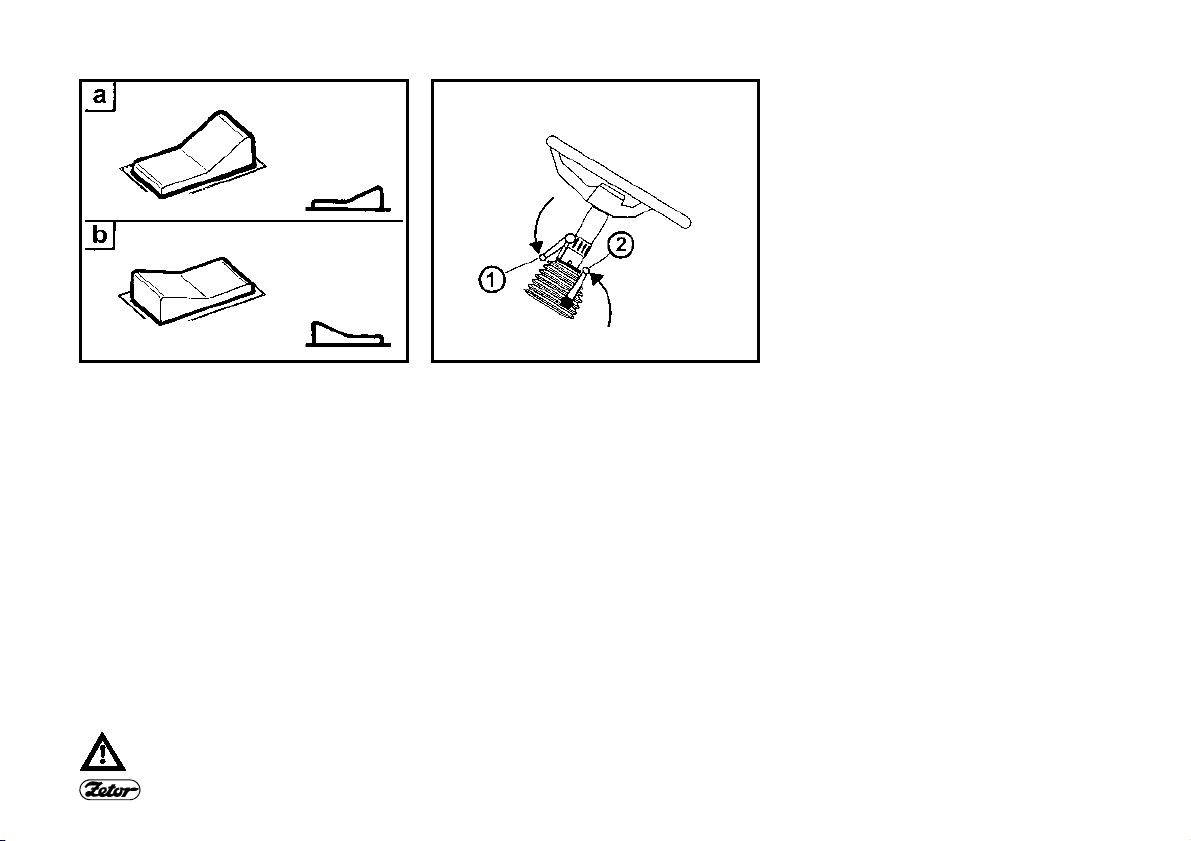

CONTROL PANEL ON THE CAB RIGHT COLUMN

1- ∗Switch of the front output shaft

2- Switch of the rear output shaft

3- Switch of the front working lights on

the cab roof

4- Switch of rear working lights on the

cab roof

5- ∗Switch of heating of the rear-view

mirrors

6- ∗Switch of heating of the rear window

7- Switch of rear wiper

8- 2-position reverse switch of the front

wiper and control of the front wind-

screen washer

9- Cab lighting

LIGHTER (Z 11741.4C)

The lighter is installed on the face of the

driving console, under the dashboard.

After its removal the socket can be used

for power supply of some additional consumers.

9

LIGHTER AND 3-PIN SOCKET

The lighter (1) and 3-pin socket (2) are

installed on the rear right mud guard

panel.

ACQUAINTANCE WITH THE TRACTOR

D104

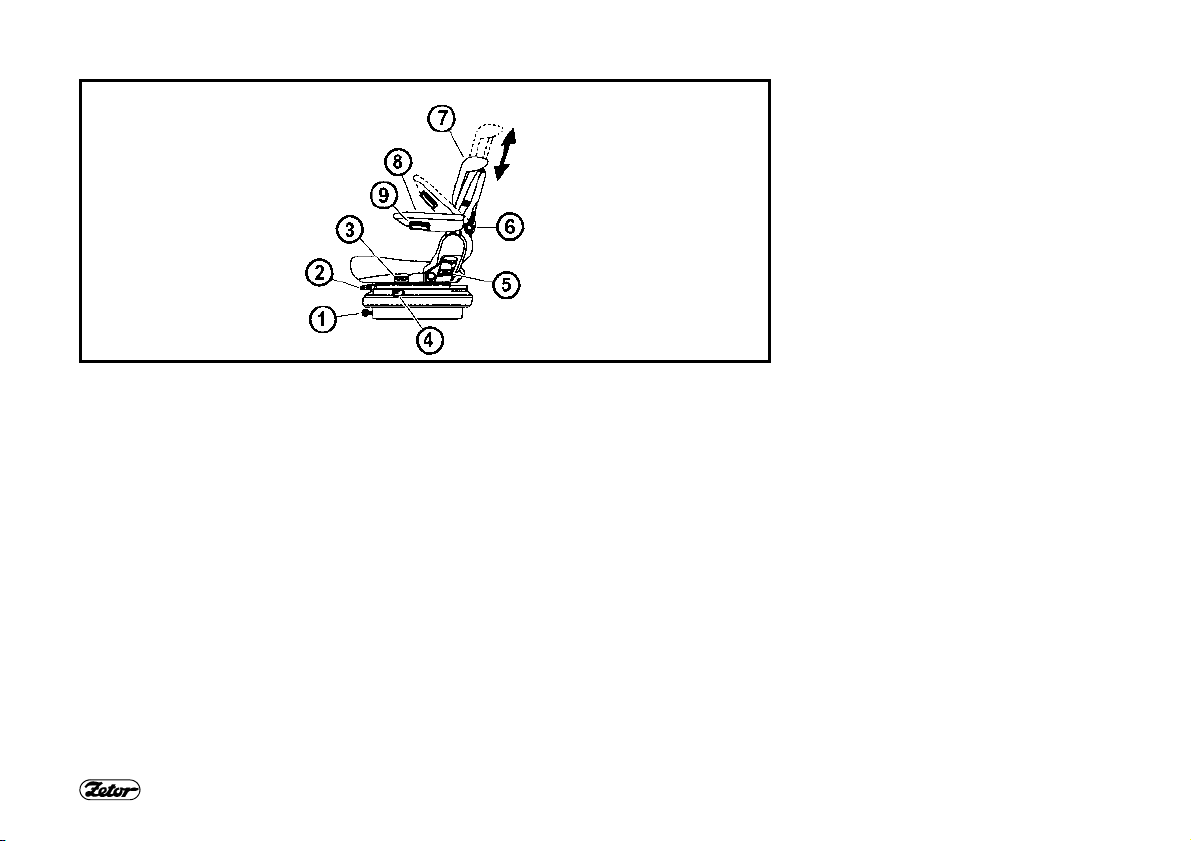

DRIVER’S SEAT GRAMMER MAXIMO

1- Controller of adjustment of seat air hitch according to the driver’s weight

2- Lever of seat longitudinal adjustment (located on the seat right side)

3- Controller of the seat turning device (the seat can be turned by 20° to both sides)

4- Controller of absorption of seat vibrations (tilting of the controller forwards engages

floating position of the seat)

5- Controller of adjustment of the seat backrest

6- Controller of adjustment of the backrest shape

7- Height adjustable backrest (pulling or pus hing in direction of arrow adjusts the back-

rest within 170mm range)

8- Tiltable armrest

9- Controller of adjustment of the armrest (turning of the controller adjusts height of the

armrest)

10

MOVING OFF

1. Select road or reduced gears.

2. Depress the clutch pedal.

3. Move the main shifting lever and reversing lever to neutral position,

switch off the PTO switches on the

right column of the cab.

4. Start up the engine.

5. Adjust speed to 750-800/min-1.

6. Move the reversing lever to the desired driving direction (forward or

backward).

7. Select the desired moving off driving

gear.

8. Increase slightly the engine speed.

9. Grasp the hand brake lever.

DRIVING

F_02_36

10.Release the clutch pedal just up to

the point of drive engagement and

when increasing the engine speed,

continue in releasing of the clutch

pedal.

11.Release completely the hand brake.

12.Move off smoothly and slowly.

Very fast moving off may cause overloading of the driving mechanism, increased fuel consumption, excessive

wearing of tyres and damage to the load.

Moving off using the first gear should

only be used when driving with a heavy

trailer into slope and rough terrain.

When shifting individual gears (1-

4) or reverse (F-R), follow instructions given in this manual for

moving off and shifting. In case of

running engine and tractor in

standstill wait approximately 2

seconds after depressing the

clutch pedal and then engage the

desired gear or reverse.

When shifting in standstill, use

also the foot brake to increase

safety and prevent any unforeseen situations.

11

D201 D202

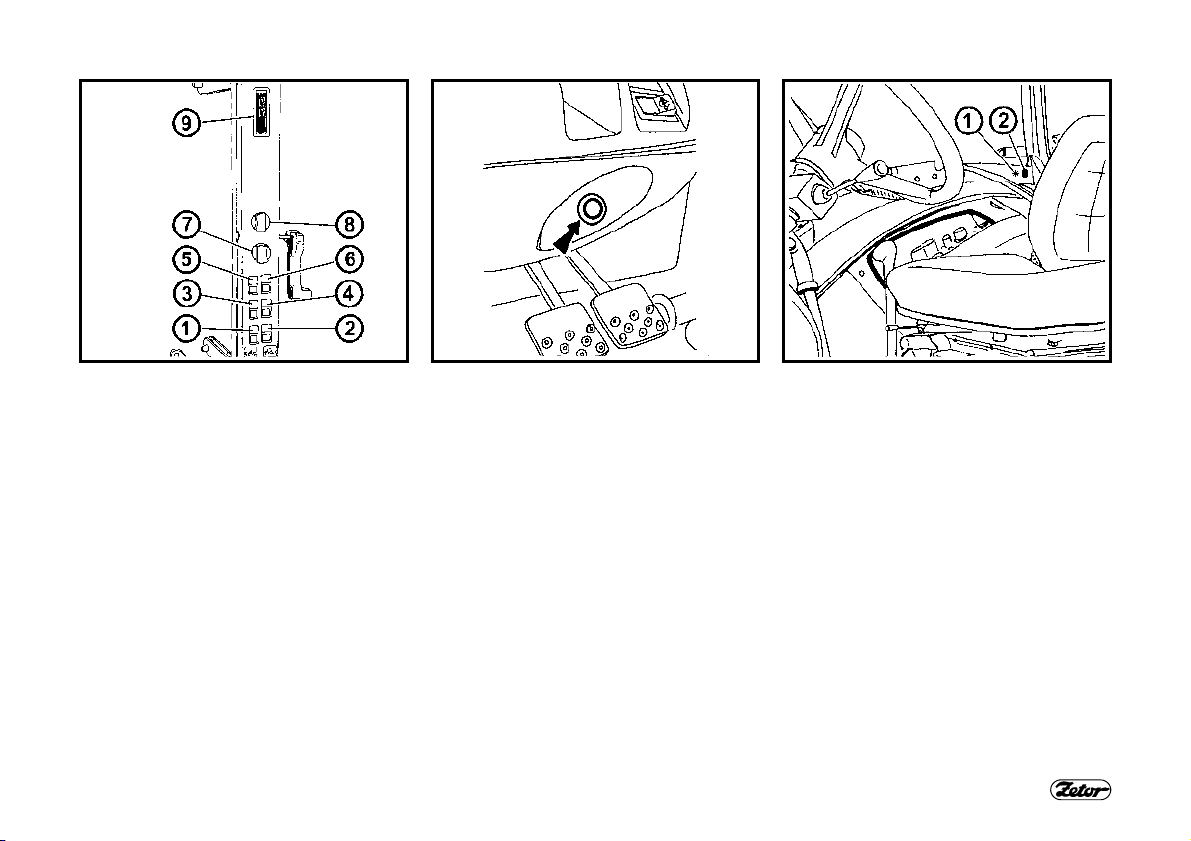

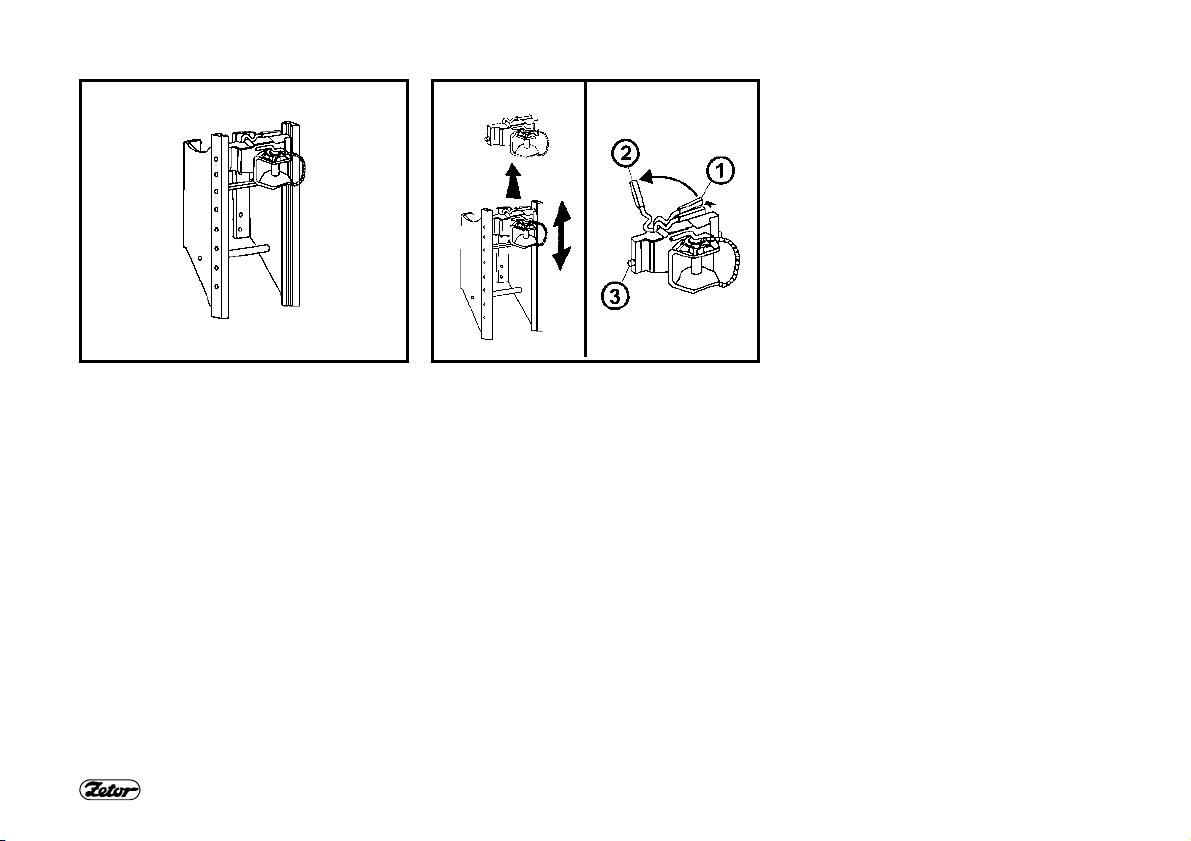

MULTI-STOREY QUICK-ADJUSTABLE HITCH CBM

It is used for connection of double-axle

and light single-axle trailers. The guiding

device is height adjustable. When working with various agricultural machines it

may be necessary to adjust height of the

hitch as desired or dismantle it.

TRANSPORT USE

HEIGHT ADJUSTMENT AND

DISMANTLING OF THE MULTISTOREY HITCH CBM

Unlock the lever by its moving in direction of the arrow to position (1); then

move it to position (2) to engage the arrestment pins (3). This releases completely the multi-storey hitch that can be

adjusted or dismantled.

Release of the lever from position (2)

disengages the arrestment pins (3) and

the lever returns automatically to its initial position.

12

Loading...

Loading...