Zetex TRAC-S2Q16 Datasheet

TRAC® SUPPORT CIRCUIT

ISSUE 1 - JANUARY 2000

DEVICE DESCRIPTION

The TRAC family of Field Programmable

Analog Devices offers an integrated path from

signal processing problems to working silicon

solutions - in minutes! The Totally

Reconfigurable Analog Circuit is a highly

flexible single chip solution to the signal

processing problems found in many markets.

Introducing a Top-Down, Structured design

discipline, TRAC enables rapid

implementation, prototyping and product

release. Rather than working at the component

level, TRAC champions the Computational

Approach, providing designers with benefits

formerly associated only with programmable

digital devices. TRAC brings a truly integrated

Signal Processing problem solving process,

offering a path to Custom Silicon for higher

volume users.

TRAC devices have to be loaded with program

data at power-up and run from a split 5V

supply. By integrating the loading interface

circuitry, voltage regulation, supply

monitoring and thermal protection, the TRAC

support circuit (TRAC-S2) further simplifies

circuit integration and interface with memory

devices.

An adjustable frequency oscillator clocks

program data out of a serial output memory

device and into any number of cascaded TRAC

devices. By monitoring the bit stream pattern,

TRAC-S2 can sense when loading is complete

and stop clocking automatically.

An adjustable ‘rail-splitter’ generates the

ground supply rail, and the supply monitoring

function initiates program load on power-up,

and after power failure or serious fluctuation.

Thermal shutdown further protects the device

against overheating.

TRAC-S2

FEATURES & BENEFITS

Makes designing TRAC circuits easier,

production prototyping quicker

Reduces component count and

manufacturing costs

Enables simple connection of a serial output

EEPROM or other memory device to TRAC

Compatible with current and future TRAC

devices

Automatic program loading at power-up

Supply monitor function reloads program

after power failure or fluctuation

Frequency of on-chip oscillator user-defined

Senses number of cascaded TRAC devices

automatically

Automatically stops clocking when program

loading complete

Simplifies generation of TRAC supply

voltages

Ground voltage user defined

Thermal shutdown function protects against

overloading due to circuit failures

Full industrial temperature range

ORDERING INFORMATION

PART NUMBER PACKAGE PART

TRAC-S2Q16 QSOP16 TRAC-S2

MARK

1

TRAC-S2

ABSOLUTE MAXIMUM RATINGS

Supply Voltage 0V to +7V

Supply Current 50mA

Operating Temperature Range -40°C to 85°C

Storage Temperature Range -55°C to 125°C

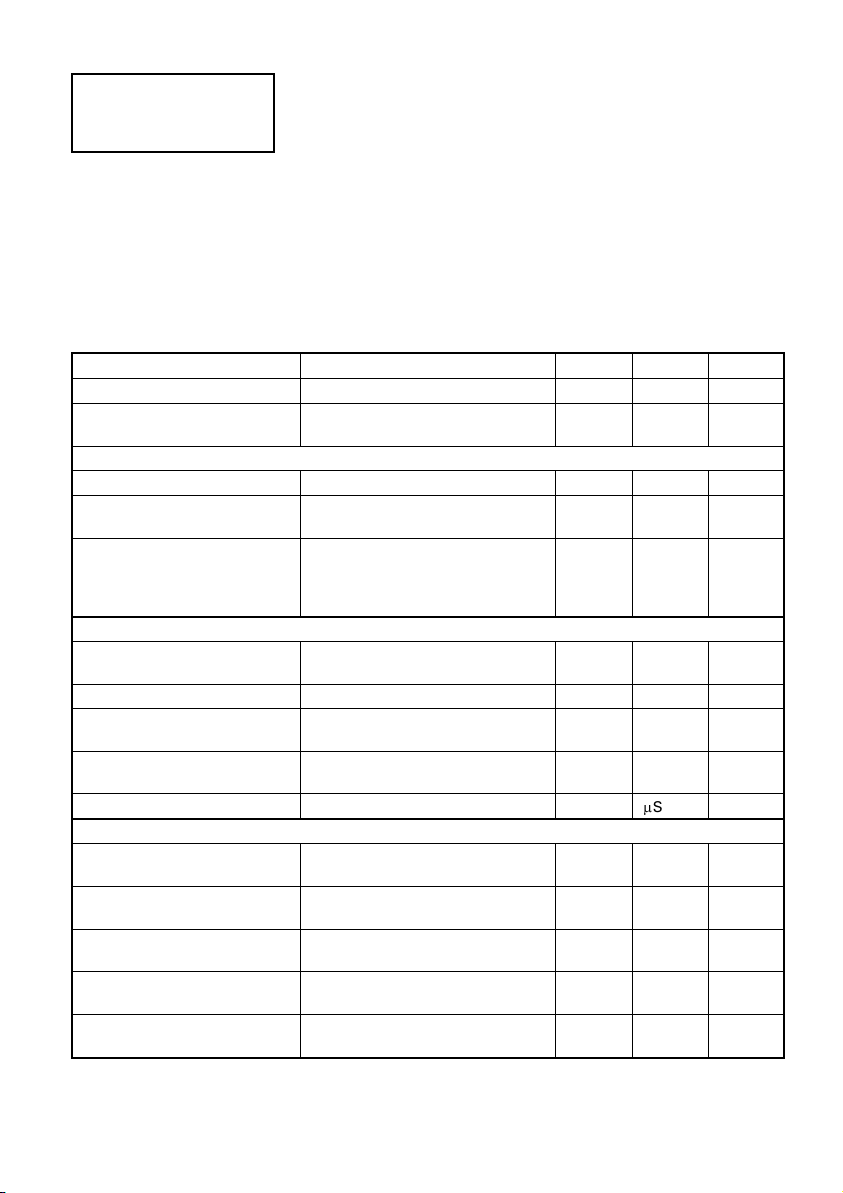

ELECTRICAL CHARACTERISTICS

Test Conditions: Temperature=25°C, V

100nF between AGND_OUT and V

PARAMETER CONDITIONS MIN TYPICAL MAX

Supply Voltage Operating Range 4.8V 5.0V 5.2V

Supply Current Standby (CLCR_IN = 0V)

RAIL SPLITTER

SETV(Input Current) SETV = 2.50V 50nA 200nA

AGND_OUT

(Output Voltage)

AGND_OUT

(Output Voltage)

SUPPLY MONITOR

RESET_OUT

(Threshold Voltage)

RESET_OUT (Hysteresis) 0.01V 0.02V 0.08V

RESET_OUT

(Onstate output sink current)

RESET_OUT

(Offstate output current)

PROPAGATION DELAY VDD step from 5.0V to 4.0V

PROGRAMMING LOGIC

CLK_OUT

(Frequency)

CLK_OUT

(Max Programming Frequency)

CLK_OUT

(High output voltage)

NOT CLK_OUT(Frequency) 2.2nF between CAP and V

NOT CLK_OUT(High output

voltage)

Clocking (CLCR_IN = 5V)

SETV = 2.50V (No Load)

SETV = 2.0V (No Load)

SETV = 2.50V; I

SETV = 2.50V; I

High State Output (VDD increasing)

Low State Output (VDD decreasing)

VDD = RESET_OUT = 4V 0.14mA

VDD = RESET_OUT = 5V 0.18mA

2.2nF between CAP and V

CLCR_IN = 5V

47pF between CAP and V

CLCR_IN = 5V

2.2nF between CAP and V

CLCR_IN = 5V

CLCR_IN = 5V

2.2nF between CAP and V

CLCR_IN = 5V

=5V, VSS=0V, CLCR_IN=0V,

DD

, unless otherwise stated.

SS

1.5mA

2.9mA

2.49V

1.99V

= 20mA

SINK

= 2 0 mA AGND_OUT

SOURCE

SS

SS

SS

SS

SS

- 0.010V

4.35V

4.35V

7kHz 10kHz 15kHz

3.90V 4.10V 4.50V

7kHz 10kHz 15kHz

4.00V 4.20V 4.60V

1.9mA

3.7mA

2.50V

2.00V

4.67V

4.65V

S

1

2.8mA

5.5mA

2.51V

2.01V

AGND_OUT

+ 0.010V

4.75V

4.75V

200kHz

2

TRAC-S2

ELECTRICAL CHARACTERISTICS

Test Conditions: Temperature=25°C, V

100nF between AGND_OUT and V

DATA_OUT(Frequency) 2.2nF between CAP and V

DATA_OUT(High output

voltage)

SELECT

(Output Voltage)

CLCR_IN = 5V

2.2nF between CAP and V

CLCR_IN = 5V

2.2nF between CAP and V

CLCR_IN = 5V

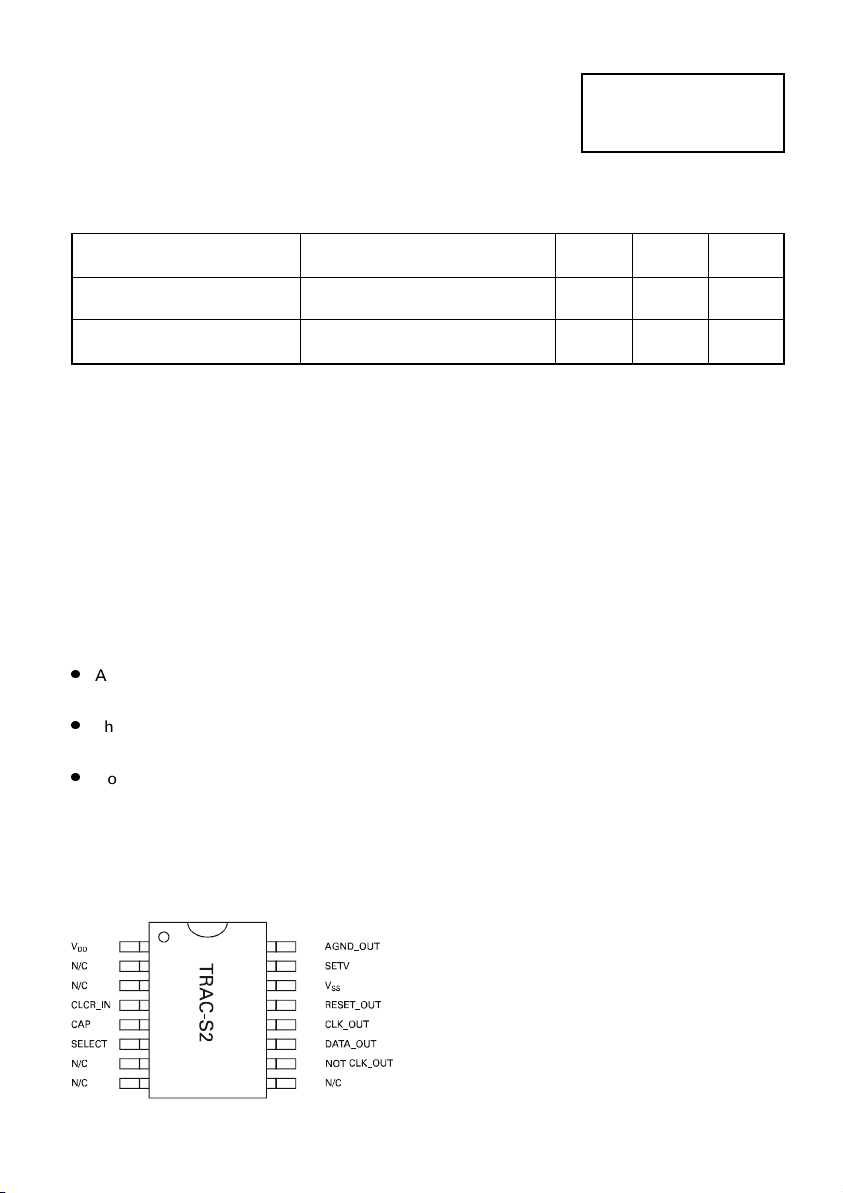

DESCRIPTION OF PIN FUNCTIONS

Inputs

SETV Defines the AGND_OUT voltage. Normally set by potential divider

CLCR_IN Active high to enable clock

CAP Capacitor to V

Outputs

AGND_OUT Analog Ground. Able to source and sink current

SELECT Active high when CLCR_IN is logic high. Enables memory device

CLK_OUT Fed to EEPROM clock input

NOT CLK_OUT Fed to TRAC clock input

DATA_OUT CLK_OUT divided by four. Fed to serial output memory device

RESET_OUT Reset for TRAC Support Circuit and TRAC devices

sets clock frequency

SS

General notes for the TRAC Support Circuit

An on-chip oscillator produces the output CLK_OUT and NOT CLK_OUT. CLCR_IN must be logic high

(V

) to activate CLK_OUT and NOT CLK_OUT

DD

The CLK_OUT output frequency is divided by four to give the DATA_OUT output. Therefore CLCR_IN

must be logic high (V

For AGND_OUT stability under load, a 100nF capacitor is required between AGND_OUT and V

) to activate DATA_OUT

DD

=5V, VSS=0V, CLCR_IN=0V,

DD

, unless otherwise stated.

SS

SS

SS

SS

1.7kHz 2.5kHz 4.0kHz

3.90V 4.10V 4.50V

4.8V 4.99V 5.00V

SS

3

Loading...

Loading...