Page 1

Adjustable Speed Drives

Page 2

How The Zero-Max® Drive Works

A Zero-Max Drive is a mechanical adjustable speed drive.

Five sizes provide constant torque of 12 to 200 inch pounds

throughout the speed range. The speed range is innitely

variable from 0 to 1/4 of the input speed under full rated

load. This is generally stated as 0-400 RPM assuming an input

of 1800 RPM.

For lower speed/higher torque applications, some Zero-Max

Drives are available with right angle gearheads. Some

Zero-Max Drives may be purchased with standard electric

motors or they may be connected to any rotating power

source up to 2000 RPM. Speed adjustments are easily

made by moving a lever control through an arc or turning

the handwheel of a screw type control. In either case,

precise speed control settings are possible.

Over 1 million Zero-Max Drives have been put to work

in a wide variety of applications. They are available from

distributors in all major markets throughout the world.

Features ........................................... Benets

Compact ................................................ Easy to handle/compact

Simple to install ...................................... No special wiring/training

Simple operation .................................... Repeatable & easy to operate with lever or screw control

Use anywhere on machine ....................... Accepts input to 2,000 RPM. Ideal as a secondary drive

Constant torque ...................................... Delivers constant torque throughout the speed range

4:1 speed reduction ................................ Often usable without additional speed reduction

Change speed anytime ............................ Speed set-ups are made quickly and easily

Change speed frequently ......................... Permits slow or fast, small or large speed changes

Change speed continuously ..................... Ideal for dancer applications/constant speed changes

Leave at one setting ................................ No daily speed cycling

Accurate speed holding ........................... No “wear-in” period/constant speed operation

Accepts any input ................................... World’s most versatile, economical secondary drive

Goes to zero output ................................ Ideal for use as a clutch

Shaft/control/motor options ..................... Versatile

Innitely adjustable ................................. 0-400 RPM speed range with 1800 RPM input

1

Page 3

Match the Zero-Max® Drive to These Components

To achieve the exact performance characteristics

you desire, Zero-Max provides the following

matching components:

For Model E and JK Drives, a right angle gearhead and

selection of motors are available.

For models Y, QX and ZX Drives, C-Flange adapters are

available for connecting customer supplied motors to the

drive you have selected.

Unidirectional Drives

E Models

1, 2, 41 or 42

Torque Rating 12in. lbs.

Speed Range 0-400.

Normal Input 1/4-1/3 H.P.

JK Models

1, 2, 41 or 42

Torque Rating 25in. lbs.

Speed Range 0-400.

Normal Input 1/4-1/3 H.P.

Y Models

1, 2, 41, or 42

Torque Rating 60in. lbs.

Speed Range 0-400.

Normal Input 1/2 H.P.

Lever control is standard on all drives. Optional controls

include: screw control, extended screw control, extended

lever control, extended control shaft, microdial control,

plus atted and drilled control levers.

Direction of output rotation must be speci ed and is

independent of input direction. Model numbers ending

in “1” are CCW output, “2” are CW output and “3”

are reversible.

QX Models

1, 2, 41 or 42

Torque Rating 100in. lbs.

Speed Range 0-400.

Normal Input 3/4 H.P.

ZX Models

1, 2, 41 or 42

Torque Rating 200in. lbs.

Speed Range 0-400.

Normal Input 1-1/2H.P.

Reversible Drives Gearhead Motors

E Model 3

Torque Rating 12in. lbs.

Speed Range 400-0-400.

Normal Input 1/4-1/3 H.P.

JK Model 3

Torque Rating 25in.lbs.

Speed Range 400-0-400.

Normal Input 1/4-1/3 H.P.

Y Model 3

Torque Rating 60in.lbs.

Speed Range 0-400.

Normal Input 1/2 H.P.

Right angle gearheads

available for E and JK Models.

Right Angle - 4 Models

W1 4:1 W2 10:1

W3 20:1 W4 40:1

Many popular voltage, Hz,

phase and enclosures are

available for use with drive.

E Models 1, 2, 3/ JK

Models 1, 2 and 3

C-Face Adapters

MODEL CFY*

Includes coupling for

56 frame motor

.

MODEL CFQ

Includes coupling for

56 frame motor.

MODEL CFZ

Includes coupling for

56 frame motor.

All C-Face Adapters will accept 56, 143T and 145T frame motors.

*CFY adapter not compatible with Y3 reversible drive

2

Page 4

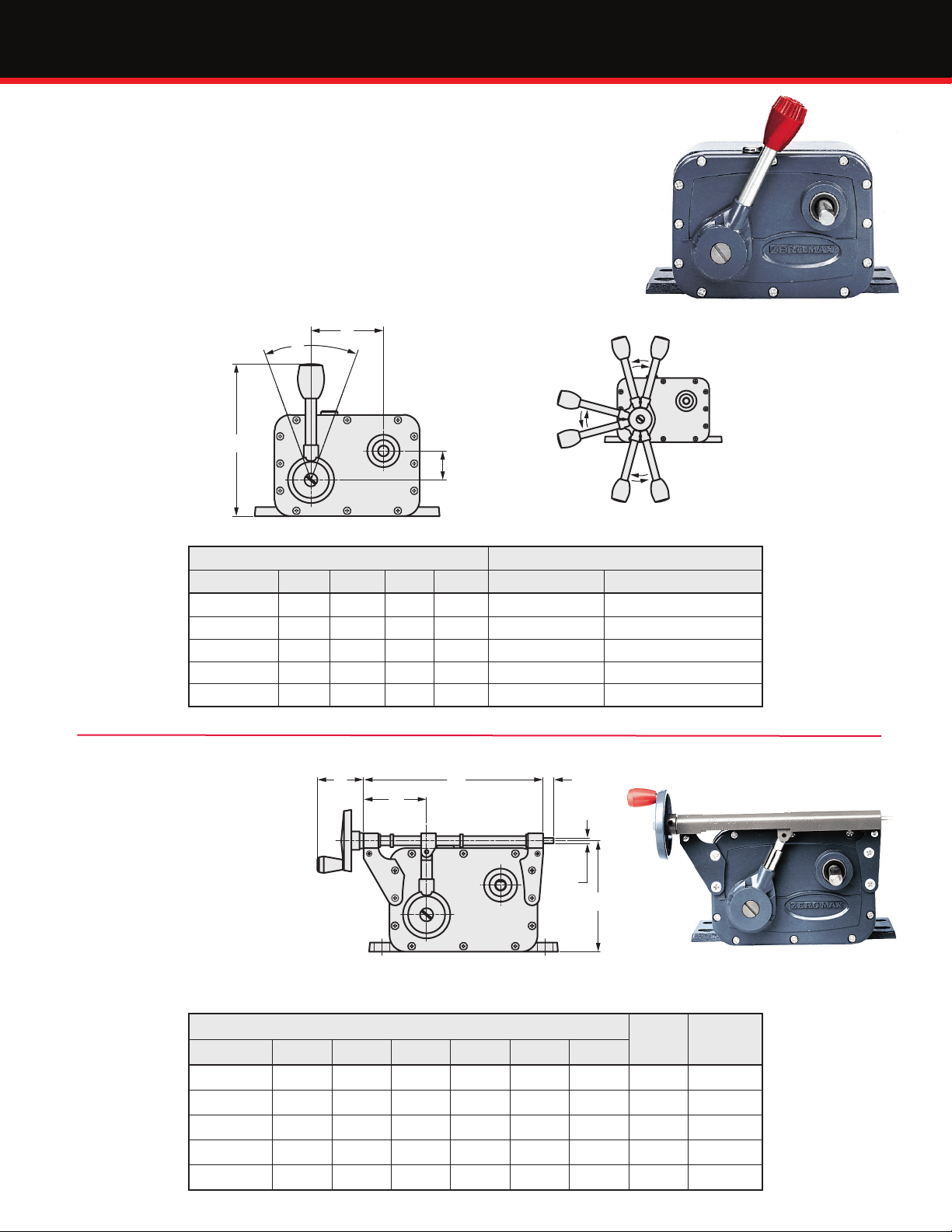

STANDARD

6 O'CLOCK

Controls for Zero-Max® Drives

Standard Lever Type Control

The lever control can be removed from its

customary 12 o’clock position and moved

to a 6 or 9 o’clock position on E and JK

Models and to any position on Y, QX and

ZX Models that will not interfere with

the casebody or shaft. Flatted and drilled,

as well as extended levers, are available

for easy attachment to any kind of remote

control, or for use on tension control

applications.

C

Standard Lever

B

9 O'CLOCK

A

D

Lever Control Dimensions Lever Torque

Drive Model A B C D (Running, no load) (Not running, full load)

E 5.25 52° 2.50 1.00 7 in. lbs. 20 in. lbs.

JK 5.25 52° 2.50 1.00 7 in. lbs. 35 in. lbs.

Y 6.75 52° 3.25 1.68 15 in. lbs. 66 in. lbs.

QX 8.25 54° 3.55 1.90 36 in. lbs. 90 in. lbs.

ZX 10.00 63° 3.06 2.40 50 in. lbs. 160 in. lbs.

Optional Screw Type Control

All Zero-Max Drives are available

A

B

C

with screw control. Screw controls

give very precise control of speed

and many kinds of remote control

attachments are easily made. They

are positive and easy to calibrate.

Kits are available for adding

screw control to drives in the eld.

The hand-wheel can be mounted

on either end of the screw.

Drive Model A B C D E F

E__SC 1.50 2.12 6.06 0.37 3.75 0.18 38 2 in. lbs.

JK__SC 1.50 2.12 6.06 0.37 3.75 0.18 38 2 in. lbs.

Y__SC 1.50 2.25 7.42 0.44 4.58 0.18 50 3 in. lbs.

QX__SC 2.12 2.87 8.81 0.37 5.87 0.25 68 4 in. lbs.

ZX__SC 2.12 6.12 12.31 0.50 7.44 0.31 91 4 in. lbs.

SCREW CONTROL DIMENSIONS

3

D

F

E

Screw Control

Number

of Screw

Turns

Screw

Torque

(inch-Lbs.)

Page 5

Controls for Zero-Max® Drives

Optional Microdial Type Control

Drive models E, JK, and Y are available with Microdial control.

The Microdial is an enhanced Screw control that will provide the

user with a numerical value that will correspond to a given speed

setting. For added exibility, these units can be ordered with the

Microdial counter on either end of the control. The Microdial

is ideal for applications that require the speed setting to be

adjusted often and need a high level of repeatability. Kits are

available for adding the Microdial control to drives in the eld.

Microdial Control*

*LH (left hand) conguration shown

Numerical

G

C

Counter

H

E

I

Drive Model A C E G H I J

E__MD-__ 1.50 6.12 3.75 1.66 1.97 0.25 2.14 0-76

JK__MD-__ 1.50 6.12 3.75 1.66 1.97 0.25 2.14 0-76

Y__MD-__ 1.50 7.42 4.58 1.66 1.97 0.34 2.14 0-100

Type MD-LH

MICRODIAL DIMENSIONS

Drive Operating Characteristics

Input Speed should not exceed 2,000

RPM. There is no minimum, but as input

speeds approach zero, slight variations

in the angular velocity of the output

may become noticeable. It is much

better to use higher input speeds and

take as much reduction as possible

from the output shaft to maximize

precise speed control. Direction of the

input does not affect direction of output

but does affect the speed range and

performance of the Zero-Max Drive. The

recommended input rotation direction

in relation to output is given below.

If output speeds are substantially in

excess of rated speeds or if the drive is

noisy or vibrating at top speed, the nonpreferred direction input is probably

being used. Try reversing the motor so

the input is in the other direction.

Output Speed is innitely adjustable

from 0 to 1/4th of the input speed.

Speeds can be maintained or repeated

with accuracy of 1% or less of

maximum speed in the upper 90% of

the range providing output load and

input speed are constant.

Zero-Max Drives

Models vary in their ability to give

absolute zero under light loads. All

models go to zero output speed under

full rated load.Output Torque ratings

listed for various models are constant

throughout the speed range and

assume an input speed of 1800 RPM.

The drives are designed for continuous

duty running at one speed, a variety

of speeds or continuous speed cycling.

Additional output torque may be

gained by lowering input speed. In

general, the torque rating of all models

may be increased 25% if the input

speed is 900 RPM or lower.

Temperature

A rise of 40° C above ambient may be

expected in the drive assuming input

speed of 1800 RPM. This temperature

will generate surface heat too hot for

continued skin contact. This does not

indicate a malfunction nor does it affect

the performance of the drive. The drives

are built to withstand high operating

temperatures but they should never

exceed 90° C.

A

J

A

J

C

G

H

E

Type MD-RH

Numerical

Counter

Range

Thrust

Model

E & JK 20 12 25

*Note: At mid-point of Input and Output Shafts

Overhung Load Pounds

Output Input

Y 40 30 75

QX 50 40 100

ZX 400 100 400

W 400 – 500

*

Pounds

Load

Control Linearity

Movement of the Zero-Max speed

control lever or rotation of the screw

control produces a change in output

speed that is non-linear. A typical

speed-control curve of a Zero-Max

Drive under full rated load is shown

in the chart below.

100

80

60

40

20

At Full Rated Load

r--

r--

And

1800 RPM Input Speed

,,,

V

/

,....

~

~

0510 15 20 25 30 35 40 45 50

-

/

I/

/

4

Page 6

How to Select a Zero-Max® Drive

1. Start By Determining The Torque Required To Start And Run Your Machine. This may be the

most important step in selecting the best drive model for your application. All Zero-Max

Drives are rated for constant torque and variable horsepower throughout the speed range.

Be sure to consider the type of machine and apply the proper service factor.

2. Determine Speed Range Required For Your Machine Processes. The Zero-Max Drive speed

range of 0-400 RPM is given assuming an input speed of 1800 RPM and full load on the

output shaft. The selection of input speed and direction of input will have an effect on the

nal output speed. Lower input speeds reduce the speed range proportionately.

Running the input in the non-preferred direction substantially increases the speed range

but may result in higher operating temperature. For best results, run the Zero-Max in the

preferred direction and match the speed range to your machine requirement. Take as much

reduction as possible, from the output shaft to the load, to provide adequate torque and to

maximize accuracy of speed control.

3. Determine Output Shaft Rotation. This is done by looking directly at the end of the output

shaft. Model numbers ending in “1” are CCW output, “2” are CW output and “3” are

reversible. Use of the Zero-Max right angle gearhead does not change the direction of

rotation of the nal output shaft.

4. Select The Proper Method Of Providing Input Speed To The Zero-Max Drive. If the Zero-Max

Drive is being used as a secondary drive unit, input is best provided by a timing belt drive.

Other common methods include shaft couplings, chain and sprocket drive, V-belt, and

at belt drives which are less desirable because of the potential for excessive overhung

loading on the shaft.

In any case, care should be taken to mount pulleys, sprockets etc. as close to the Zero-Max

Drive case as possible to minimize overhung loads on the shafts. If a Zero-Max motor is to

be used, select the standard motor from the chart on page 12.

5. Determine The Type Of Control Best Suited To Your Application. Lever control is supplied as

standard with all models of Zero-Max Drives. Other controls are available as discussed on

page 3 and 4. The lever control is best suited for applications requiring rapid and frequent

speed changes. The screw control is best suited for precise settings and speed repeating.

Series Shaft Options Available Output Torque Recommended Input HP

E 1, 2, 3, 41, 42 12 In-Lbs 1.4 Nm 1/4 HP

JK 1, 2, 3, 41, 42 25 In-Lbs 2.8 Nm 1/3 HP

Y 1, 2, 3, 41, 42 60 In-Lbs 6.8 Nm 1/2 HP

QX 1, 2, 41, 42 100 In-Lbs 11.3 Nm 3/4 HP

ZX 1, 2, 41, 42 200 In-Lbs 22.6 Nm 1 1/2 HP

5

Page 7

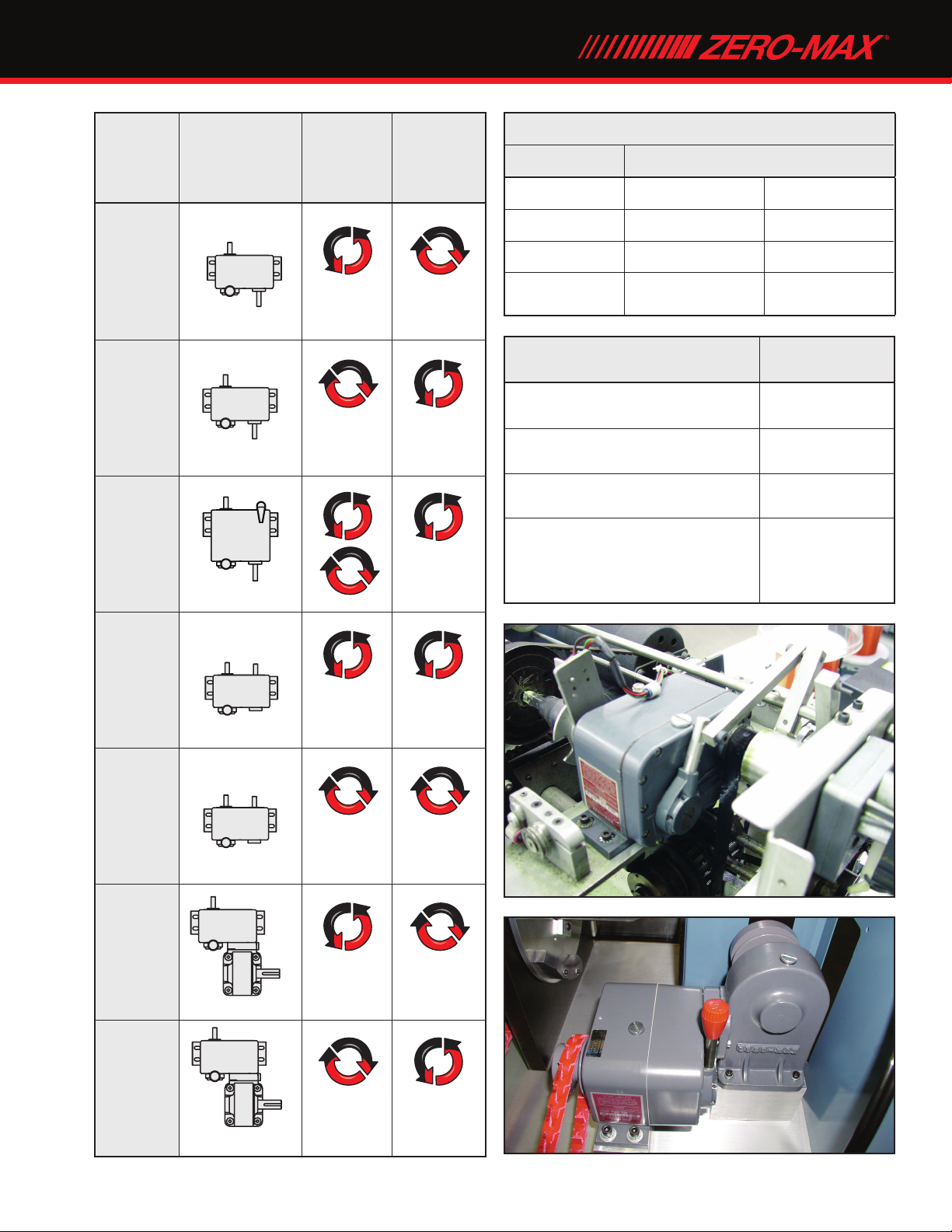

Zero-Max® Drives

Type

E1, JK1,

Y1, QX1,

ZX1

E2, JK2,

Y2, QX2,

ZX2

E3, JK3,

Y3

Note: Shaft

rotations are

always referenced

by viewing the end

of that shaft

Input

Output

Rotation

CCW CW

q ''

Output

Input

Output

Input

Output

Preferred

Input

Rotation

CW CCW

Both CCW

Service Factors

Type of Load Type of Duty

Uniform 8 to 10 hrs./day 1.0 24 hrs./day 1.5

Moderate Shock 1.5 2.0

Heavy Shock 2.0 3.0

Reversing Service 2.0 3.0

Types of Applications

General machines with ball

or roller bearings

General machines

with sleeve bearings

Conveyors and machines

with excessive sliding friction

Machines that have “high” load

spots in their cycle like printing,

punch presses and machines

with cams /crank-operation.

Running Torque

Multiplier

1.2–1.3

1.3–1.6

1.6–2.5

2.5–6.0

E41,

JK41,

Y41,

QX41,

ZX41

E42,

JK42,

Y42,

QX42,

ZX42

E1-W_ ,

JK1-W_

Input Output

c:)

Input

Output

c:)

Input

Output

Input

CCW CCW

'' ''

CW CW

CCW CW

''

CW CCW

====~~

~~~~

E2-W_ ,

JK2-W_

''

Output

6

Page 8

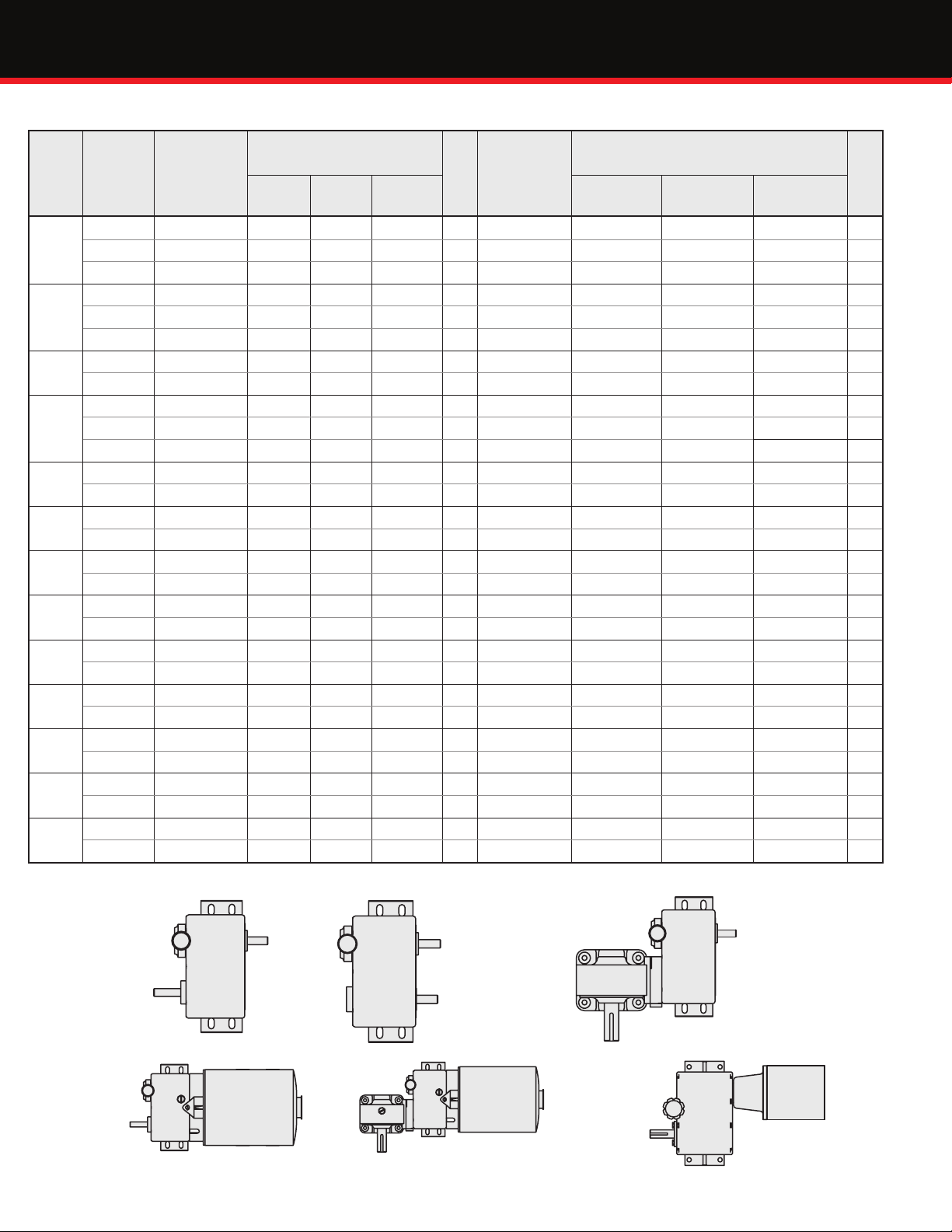

Torque and Speed Range Selection Chart

Standard Zero-Max Drives -- Order By Complete Model Number.

Torque

Rating

(In.

Lbs.)

12

25

35

60

75

90

100

155

190

200

240

300

300

Speed

Range

w/ 1800

RPM

input

0-400 A E1 E2 - 4 D E1-M3 E2-M3 - 18

400-0-400 A - - E3 5 D - - E3-M3 19

0-400 B E41 E42 - 4 - - - - -

0-400 A JK1 JK2 - 6 D JK1-M3 JK2-M3 - 20

400-0-400 A - - JK3 6 D - - JK3-M3 20

0-400 B JK41 JK42 - 6 - - - - -

0-100 C E1-W1 E2-W1 - 9 E E1-W1-M3 E2-W1-M3 - 23

100-0-100 C - - E3-W1 10 E - - E3-W1-M3 24

0-400 A Y1 Y2 - 10 F Y1-CFY Y2-CFY - 16

400-0-400 A - - Y3 15 - - - - -

0-400 B Y41 Y42 - 10 - - - - -

0-100 C JK1-W1 JK2-W1 - 11 E JK1-W1-M3 JK2-W1-M3 - 25

10-0-100 C - - JK3-W1 11 E - - JK3-W1-M3 25

0-40 C E1-W2 E2-W2 - 9 E E1-W2-M3 E2-W2-M3 - 23

40-0-40 C - - E3-W2 10 E - - E3-W2-M3 24

0-400 A QX1 QX2 - 21 F QX1-CFQ QX2-CFQ - 26

0-400 B QX41 QX42 - 21 - - - - -

0-20 C E1-W3 E2-W3 - 9 E E1-W1-M3 E2-W3-M3 - 23

20-0-20 C - - E3-W3 10 E - - E3-W3-M3 24

0-40 C JK1-W2 JK2-W2 - 11 E JK1-W2-M3 JK2-W2-M3 - 25

40-0-40 C - - JK3-W2 11 E - - JK3-W2-M3 25

0-400 A ZX1 ZX2 - 32 F ZX1-CFZ ZX2-CFZ - 37

0-400 B ZX41 ZX42 - 32 - - - - -

0-10 C E1-W4 E2-W4 - 9 E E1-W4-M3 E2-W4-M3 - 23

10-0-10 C - - E3-W4 10 E - - E3-W4-M3 24

0-20 C JK1-W3 JK2-W3 - 11 E JK1-W3-M3 JK2-W3-M3 - 25

20-0-20 C - - JK3-W3 11 E - - JK-W3-M3 25

0-10 C JK1-W4 JK2-W4 - 11 E JK1-W4-M3 JK2-W4-M3 - 25

10-0-10 C - - JK3-W4 11 E - - JK3-W4-M3 25

Shaft

Arrangement

Model Number - without

Motor Output Shaft Rotation

CCW CW Reverse CCW CW Reverse

Net

Wt.

Lbs.

Shaft

Arrangement

Model Number - with Motor or

C-Flange Adapter Output Shaft Rotation

Net

Wt.

Lbs.

Standard Shaft Arrangements

Output

Output

Input

A

D

Output

Input

B

Output

E

7

Input

C

Output

F

Output

Page 9

U

XC

A

P

XH

Zero-Max® Drives

Standard Drives Models E, JK, Y, QX and ZX Dimensions

XB

I

H

A 6.37 6.37 6.37 6.37 8.50 8.50 10.25 10.25 12.62 12.62

AG 2.84 2.84 3.98 3.98 4.70 4.70 6.81 6.81 6.75 6.75

AT 0.31 0.31 0.31 0.31 0.31 0.31 0.37 0.37 0.50 0.50

B 2.00 2.00 2.00 2.00 2.87 2.87 3.00 3.00 4.75 4.75

BA 1.22 1.22 2.34 2.34 2.28 2.28 2.41 2.41 1.50 1.50

D 2.25 2.25 2.25 2.25 3.00 3.00 3.50 3.50 4.50 4.50

FG 1.12 1.12 1.12 1.12 1.50 1.50 2.00 2.00 2.00 2.00

FU 0.375 0.375 0.375 0.375 0.500 0.500 0.625 0.625 0.875 0.875

H (slots) 0.28 dia. 0.28 dia. 0.28 dia. 0.28 dia. 0.40 dia. 0.40 dia. 0.40 dia. 0.40 dia. 0.53 dia. 0.53 dia.

I 0.25 0.25 0.25 0.25 0.22 0.22 0.10 0.10 0.0 0.0

N 1.56 --- 1.56 --- 2.00 --- 3.00 --- 3.25 ---

N* --- 1.12 --- 1.12 --- 2.00 --- 2.87 --- 3.25

O 3.50 3.50 3.50 3.50 4.50 4.50 5.50 5.50 7.00 7.00

O* 5.25 5.25 5.25 5.25 6.75 6.75 8.25 8.25 10.00 10.00

P 5.00 5.00 5.00 5.00 6.50 6.50 8.00 8.00 10.00 10.00

U 0.375 --- 0.375 --- 0.625 --- 0.750 --- 1.00 ---

U* --- 0.375 --- 0.375 --- 0.625 --- 0.750 --- 1.00

XA 1.25 1.25 1.25 1.25 1.53 1.53 2.00 2.00 2.50 2.50

XB 2.50 2.50 2.50 2.50 3.50 3.50 4.00 4.00 5.00 5.00

XC 0.00 0.00 0.00 0.00 0.25 0.25 0.45 0.45 1.94 1.94

XD 1.25 1.25 1.25 1.25 1.31 1.31 1.60 1.60 2.09 2.09

XE 0.56 0.56 0.56 0.56 0.75 0.75 0.91 0.91 1.00 1.00

XF 0.72 0.72 1.84 1.84 1.78 1.78 1.89 1.89 1.00 1.00

XG 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50 0.50

XH 0.69 0.69 0.69 0.69 1.00 1.00 1.13 1.13 1.31 1.31

ZE 5.50 5.50 5.50 5.50 7.50 7.50 9.25 9.25 11.25 11.25

ZF 1.00 1.00 1.00 1.00 1.87 1.87 2.00 2.00 3.75 3.75

FG

E1&2 E 41&42 JK1&2 JK 41&42 Y1&2 Y 41&42 QX1&2 QX 41&42 ZX1&2 ZX 41&42

U*FU

N*

XG

ZF

BA

AG

N

~~~=~

ZE

XA

J_

-.

1r

AT

O

!

O*

D

XD

8

Page 10

XB

P

AG

P

C

Drives Dimensions

Reverse Drives Models E3, JK3 and Y3 Dimensions

REVERSE

LEVER

D

XD

A

A B D

E3 6.37 2.00 2.25

JK3 6.37 2.00 2.25

Y3 8.50 2.87 3.00

O*

O

AT

H

slots

N O O* P U AG AT BA FG FU XA XB NC XD XE XF XG ZE ZF

0.28

1.56 3.50 4.50 5.00 0.375 3.23 0.31 1.59 1.12 0.375 1.25 2.50 1.00 1.25 0.56 0.50 1.00 5.50 1.00

dia.

0.28

1.68 3.50 4.50 5.00 0.375 4.37 0.31 2.71 1.12 0.375 1.25 2.50 2.12 1.25 0.56 0.50 1.00 5.50 1.00

dia.

0.40

2.00 4.53 5.53 6.60 0.625 5.83 0.31 3.39 1.50 0.500 1.53 3.50 2.89 1.31 0.75 0.50 1.50 7.50 1.87

dia.

Motorized Drives Models E and JK Dimensions

XB

XA

XFXE

BA

E3 and JK3

ONLY

ZF

FG

FU

ZE

U

XA

XG

H

N NC B

U

O'

XD

XC

D

AO

AB

ZE

AG

A

A D H (slots) H" (slots)* P U AE AO AT BA XA XB XC XD XE XF XH ZE ZF

E1 & E2 6.37 2.25 0.28 dia. 0.34 dia. 5.62 0.375 3.18 2.75 0.31 1.22 1.25 5.00 3.50 4.50 0.56 1.00 2.75 5.50 1.00

E3 6.37 2.25 0.28 dia. 0.34 dia. 5.62 0.375 3.18 2.75 0.31 1.59 1.25 5.00 3.50 4.50 0.56 1.00 2.75 5.50 1.00

JK1 & JK2 6.37 2.25 0.28 dia. 0.34 dia. 5.62 0.375 3.18 2.75 0.31 2.34 1.25 5.00 3.50 4.50 0.56 1.00 2.75 5.50 1.00

JK3 6.37 2.25 0.28 dia. 0.34 dia. 5.62 0.375 3.18 2.75 0.31 2.71 1.25 5.00 3.50 4.50 0.56 1.00 2.75 5.50 1.00

*Motor slots are centered 4.25 apart.

Z.M.

Motor

M3

M9 DP 1/3 230 60 1 12.95 13.35 14.09 14.47 4.37 5.81

M42L** DP 1/3 230/460 60 3 15.07 15.48 16.20 16.57 4.42 5.81

M5 TEFC 1/4 115 60 1 14.06 14.38 15.18 15.53 4.37 6.39

M45 TEFC 1/4 230/460 60 3 14.06 14.38 15.18 15.53 4.37 6.39

**M42L (long) has replaced M42 motor. Contact factory with questions.

Other motors are available, please contact the factory with your requirements.

Used

With ENCL

DP 1/3 115 60 1 12.95 13.35 14.09 14.47 4.37 5.81

E

or

JK

Horse

Power Voltage Hz Phase

XF

XE

AT'

BA

ZF

H

XG

C DIMENSION

w/ E1

& E2 w/ E3

XH

w/ JK1

& JK2 w/ JK3

H"

XG O’

9

Page 11

XD

XE

XF

*

C

N

XA

XB

XC

AG

XG

XF

*

AG

XH

XB

XA

N

C

XG

A A

D

D

XG

XF

*

AG

XH

XB

XA

N

C

A

D

Drives Dimensions

Drives with C-Flange Adapters Models Y, QX and ZX Dimensions

D

N

XA

,_

XB

XC

AG

1=

Model Y

A

XDXG

XF

XE

I

--~~

------~~~~~-0

*

C

1

Model QX Model ZX

D

J_

q::t:::::::::t:~

XG

-

XD

N

---.----

XA

XB

XC

AG

.._____________o

A

XE

-

XF

I

~l

-- -

~,

J

A

D

*

*

XG

XF

N

l

XA

XB

AG

..____J

XH

j -

C

i=::::::==i

C

A C D N AG XA XB XC XD XE XF XG

Y 9.31 10.37 3.50 2.00 8.37 2.28 4.15 6.22 3.25 6.50 7.00 0.50

QX 10.37 13.97 3.50 3.00 11.10 2.39 4.41 8.37 1.63 7.12 8.63 0.63

ZX 12.12 14.12 4.50 3.25 10.88 1.50 5.25 - - - 10.62 0.62

*Accepts 56, 143T and 145T frame, C-face motor.

Note: CFY adapter not compatible with Y3 reversible drive

CFY CFQ CFZ

10

Page 12

Drives Dimensions

Standard Drives with Right Angle

Gearhead Dimensions

E1& E2 E3 JK1 & JK2 JK3

Right Angle Gearheads (W)

A 7.68 7.68 7.68 7.68

C' 8.53 8.90 9.65 10.02

D 3.81 3.81 3.81 3.81

H (slots) 0.28 dia. 0.28 dia. 0.28 dia. 0.28 dia.

==

H" (slots)* 0.34 dia. 0.34 dia. 0.34 dia. 0.34 dia.

1--------------f---------------------'

*Motor slots are centered 4.25 apart

========

H' 0.26 dia. 0.26 dia. 0.26 dia. 0.26 dia.

N 2.00 2.00 2.00 2.00

O 5.84 5.84 5.84 5.84

P 5.62 5.62 5.62 5.62

U 0.750 0.750 0.750 0.750

AB 3.18 3.18 3.18 3.18

AG 6.37 6.37 6.37 6.37

AO 2.75 2.75 2.75 2.75

AT 0.35 0.35 0.35 0.35

AT' 0.31 0.31 0.31 0.31

XA 0.06 0.06 0.06 0.06

XB 5.00 5.00 5.00 5.00

XC 2.38 2.38 2.38 2.38

XD 0.43 0.43 0.43 0.43

XE 1.43 1.43 1.43 1.43

XF 2.87 2.87 2.87 2.87

XH 2.43 2.84 3.59 3.93

XI 1.00 1.00 1.00 1.00

XK 2.75 2.75 2.75 2.75

XL 2.43 2.43 2.43 2.43

XN - 4.50 - 4.50

ZE 5.50 5.50 5.50 5.50

==

E and JK Drives with Right Angle Gearheads

(W) Dimensions with Motor

C

C'

XL

1-

.-------+--

~~

l

O

j

~

AT

FX XD

-1

XE

E3 AND

JK3 ONLY

XN

~~~

XI

P

XB

ZE

AG

A

H

XC

XG

XK

U

N

H'

XH

AO

AB

AT'

XA

O'

H"

D

SHAFT AND KEYWAY DETAILS

Model Output Input

E & JK Flat 1/16" deep x 1-1/8" Flat 1/16" deep x 3/4"

Y Keyway 3/16" x 1-5/8" Flat 1/16" deep x 1"

QX Keyway 3/16" x 2-1/2" Keyway 3/16" x 1-1/2"

ZX Keyway 1/4" x 2-1/8" Keyway 3/16" x 1-1/4"

W Keyway 3/16" x 1-1/4" Hollow Shaft

Specications are subject to change. When dimensions are

critical, detailed drawings should be obtained from the factory.

Motor* w/E1

&

M9 15.95 16.33 17.06 17.45 4.37 5.81

M3

M42L** 18.05 18.43 19.18 19.56 4.42 5.81

M5 16.75 17.25 18.00 18.38 4.37 6.39

M45 16.75 17.25 18.00 18.38 4.37 6.39

*See page 12 for motor data.

**M42L (long) has replaced M42 motor. Contact factory with questions.

11

MOTORS*

Right Angle Gearheads (W)

C XG O’

&

E2 w/E3 w/JK1 & JK2 w/JK3

Page 13

Ordering Model Code

□

Model

E

Y

Output

Torque

12 in-lbs

25 in-lbs

60 in-lbs

100 in-lbs

200 in-lbs

Code

JK

QX

ZX

□ □ □

Code

* Reversing drives are available in sizes

E, JK, and Y only.

1

2

3*

41

42

Example:

Con guration

Output

Rotation

Counter

Clockwise

Clockwise

Both CCW

and CW

Counter

Clockwise

Clockwise

Shaft

Con guration

Input

Output

Input

Output

Control Options

Code Output Torque

Omit

SC

MD-LH

MD-RH

Note: Microdial controls not

available on QX and ZX

models as standard.

·------------------------------------

1

I

Standard

Control Lever

Screw Control

Microdial

(Left Hand

Installation)

Microdial

(Right Hand

Installation)

Integrated Electric Motor

(Available for E and JK drives only)

Right Angle Gear Reducer

(Available for E and JK drives only)

Code

Omit

W1

W2

W3

W4

Gear Ratio

□

I

·--

None

4 : 1

10 : 1

20 : 1

40 : 1

• Required output torque is 20 in-lbs.

• Output shaft rotation is clockwise.

• Input and output shaft arrangement

to be on same side of housing.

• Screw control option is desired.

• Gear reduction is not required.

• Integrated motor is not required

Model Code is JK42SC

C-Face Adapters

Part Number Description

CFY*

CFQ Designed to mount a 56C frame motors to a QX drive

CFZ Designed to mount a 56C frame motors to a ZX drive

Note: All kits include the shaft coupling.

*CFY adapter not compatible with Y3 reversible drive

Designed to mount a 56C frame motors to a Y drive

Code HP Voltage Phase Enclosure

Omit

M3

M9

M42L

M5

M45

1/3 115 1 Drip Proof

1/3 230 1 Drip Proof

1/3 230/460 3 Drip Proof

1/4 115 1

1/4 230/460 3

MODEL CFQ MODEL CFZMODEL CFY

None

Totally Enclosed

Fan Cooled (TEFC)

Totally Enclosed

Fan Cooled (TEFC)

12

Page 14

PRECISE. RELIABLE. ROBUST. AVAILABLE.

CD® Couplings

High-performance couplings that

outperform and outlast bellows

and steel disc designs. The unique

design of the composite disc

enables the CD Couplings to

withstand punishing applications

and deliver high precision

performance. Fully Customizable.

ServoClass® Couplings

Designed for demanding

servomotor applications. Zero

backlash, high torsional stiffness,

high speed design. Features

exible metal discs for high

misalignment capacity and keyless

clamp-type mounting hubs.

Schmidt Offset Couplings

Designed to handle high amounts

(up to 17") of parallel shaft offset

with constant angular velocity.

Standard models with torque

capacities up to 459,000 in-lbs

and extensive custom capabilities.

Keyless Shaft Locking Devices

ETP® keyless connections and

Posi-Lok® keyless bushings provide

quick, easy and accurate assembly

of mounted shaft components. Both

inch and metric bore sizes are

available from stock.

Crown Gear Drives

Available in 5-sizes, 3 congurations,

and with 1:1 and 2:1 ratios. High

quality AGMA class 10 spiral bevel

gears. Stainless steel shafts and either

black anodized or IP65-Rated nickelplated aluminum housing.

Adjustable Speed Drives

Easy to install and maintenance free.

Zero-Max

variable speeds from 0 rpm to 1/4

of input rpm. 5 models with torque

ranges from 12 in-lbs to 200 in-lbs.

®

Drives offer innitely

Overload Safety Couplings

Torque Tender® Couplings provide

reliable overload protection in any

mechanical power transmission

system. Full selection of styles and

sizes with set-point torque ranges

from 3 to 3,000 in-lbs.

Control-Flex® Couplings

Zero backlash couplings designed

for encoder and instrumentation

type applications. Features high

misalignment capacity, constant

velocity, and an electrically

Roh’Lix® Linear Actuators

Simple conversion of rotary motion into

precise linear motion. Available in ve

models and multiple congurations.

Roh’Lix actuators have thrust ratings

from 5 to 200 lbs. All models feature

built-in overload protection.

OHLA® Overhung Load Adaptors

Designed to protect hydraulic motors

and pumps from radial/axial loads and

to provide additional seal protection.

11 models available for mounts from

SAE A to SAE F. Fully customizable.

isolated hub design.

Warranty. Zero-Max, Inc. the manufacturer, warrants that for a period of 12 months from date of shipment it will repair, or at its option, replace any new apparatus which proves defective in material or workmanship, or

which does not conform to applicable drawings and specications approved by the manufacturer. All repairs and replacements shall be F.O.B. factory. All claims must be made in writing to the manufacturer.

and under no circumstances shall manufacturer be liable for (a) damages in shipment; (b) failures or damages due to misuse, abuse, improper installation or abnormal conditions of temperature, dirt, water or corrosives; (c)

failures due to operation, intentional or otherwise, above rated capacities, and (d) non-authorized expenses for removal, inspection, transportation, repair or rework. Nor shall manufacturer ever be liable for consequential

and incidental damages, or in any amount greater than the purchase price of the apparatus.

or change shall create any liability on the part of Zero-Max, Inc. in respect to its products in the hands of customers or products on order not incorporating such changes even though delivered after any such change.

warranty is in LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING (BUT NOT LIMITED TO) ANY IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE TERMS OF THIS

WARRANTY CONSTITUTE ALL BUYER’S OR USER’S SOLE AND EXCLUSIVE REMEDY, AND ARE IN LIEU OF ANY RIGHT TO RECOVER FOR NEGLIGENCE, BREACH OF WARRANTY, STRICT TORT LIABILITY OR UPON ANY OTHER THEORY.

Any legal proceedings arising out of the sale or use of this apparatus must be commenced within 18 months of the date of purchase.

recommendations.

Zero-Max®, CD®, ETP®, ServoClass®, Torq-Tender®, Control-Flex®, Posi-Lok®, Roh’Lix® , Crown® , Schmidt® and OHLA® are registered trademarks of Zero-Max, Inc. In U.S.A.

•

Zero Max, Inc. reserves the right to discontinue models or to change specications at any time without notice. No discontinuance

•

CAUTION: Rotating equipment must be guarded. Also refer to OSHA specications and

•

©Zero-Max, Inc., All Rights Reserved

In no event

•

This

•

Printed in U.S.A., Rev2.01W

Loading...

Loading...