HOUSEHOLD INSTANT GAS WATER HEATER

(Flue Exhaust Type)

INSTRUCTION MANUAL

8l, 12l, 16l, 20l

Certified to ISO9001

LPGSASA Permit No 1008-26/1-RSA-12-A

Indoor & Outdoor Use

Please read the manual carefully and understand the operation prior to installation and use.

The registered LPGSASA gas practitioner must commission the gas water heater before you sign the certificate of

compliance.

Retain this manual for future reference.

Technical Data

Name

8lt

12lt

16lt

20lt

Model No

JSD 16-LN1

JSD 24-LN1

JSD 32-LN1

JSD 40-LN1

Type of Gas

LPG

LPG

LPG

LPG

Consumption at MAX

1.50 kg/h

2.25 kg/h

3.0 kg/h

3.75 kg/h

Operating Pressure

2.8 kPa

2.8 kPa

2.8 kPa

2.8 kPa

Permit No

1008-26/1-RSA-12-A

1008-26/1-RSA-12-A

1008-26/1-RSA-12-A

1008-26/1-RSA-12-A

Product Type

CLASS 'B' FOR INDOOR INSTALLATION. CAN BE INSTALLED OUTDOORS BUT MUST BE FLUED

FLUE AVAILABLE FROM GEYSER INSTALLER

Gas Consumption as per Technical data sheet above

The unit is to be installed by a certified LPGSASA gas practitioner

If the unit is installed outside the gas water heater MUST be flued

This gas water heater will switch off within 4 minutes if no flue is fitted

NB - Only a SANS 1237 Approved 2.8kPa regulator must be fitted

NB - This appliance must be installed in accordance with SANS 10087 part 1

NB - This appliance must ONLY be installed by a LPGSASA installer

For Your Safety

This appliance is set to operate on LPG only

If you smell gas;

• Turn off the gas supply at the cylinder / bottle

• Extinguish ALL naked flames

• Do NOT operate any electrical appliances

• Ventilate the area

NB - Should the odour persist, contact your local dealer or gas suppliers immediately

Burn - Back (Fire in the tube or chamber)

In the event of a burn-back, immediately turn off the gas supply at the cylinder valve. After

ensuring that the naked flame is extinguished, re-open and re-light the appliance in the normal

manner. Should the appliance burn-back again, close the control valve and phone a service

technician.

Do NOT use the appliance again until the service technician has declared that it is safe to do so.

Gas Pressure Regulator

This appliance requires an operating pressure of 2.8 kPa at the appliance. A suitable LPG

regulator that complies with the requirements of SANS 1237 must be installed / used.

Important Information to the User

This appliance may ONLY be installed by a certified LP gas installer. All registered installers are

issued with a card showing their registration number. Ask to be shown the card before allowing

any installation to commence and make note of the installer QCC number.

Upon completion of the installation, the installer is required to explain the operation details of

the appliance together with the safety instructions. You will be asked to sign acceptance of the

installation and be provided with a completion certificate.

You should only sign for acceptance of the installation when the installation is completed to

your satisfaction. Note that your invoice is required in the event that you wish to make a

guarantee claim.

Important Information to the Installer

This appliance may only be installed by an LP gas installer, registered to the Liquefied Petroleum

Gas Association of Southern Africa. The appliance must be installed in accordance with the

requirements of SANS 10087-1 and any fire department regulation and / or local bylaws

applicable to the area.

If in doubt, check with the relevant authority before undertaking the installation. Upon

completion of the installation, you are required to fully explain and demonstrate to the user the

operational details and safety practices applicable to the appliance and installation.

Correct Indoor Installation

If flexible hose is being used, it MUST be BS3212 of SANS1156 approved hose. The hose MUST

NOT be longer than 2 meters. The hose should NOT be fed directly through a wall or

cupboard, neither should it be behind or above the gas water heater.

We DO NOT recommend using hose for the gas connection. This will restrict the gas flow and

volume and will underperform, as a result. We recommend to use copper, composite stainlesssteel flex pipe.

Air Entry and Vent Area Requirements

Thermal Burner (KW)

Min area of the Air-In Hole and Vent Hole (Cm²)

<12

100

12 - 16

130

16 - 20

160

20 - 26

200

Installation

Gas inlet – Use two wrenches (It will break if held with one wrench at the gas water heater

outlet)

Use a swivel fitting as supplied

NB - Hot water outlet – It is recommended to fit a FULL-BORE water valve. Do NOT use flex type

toilet connectors. The flow will be restricted and will result in gas water heater failure

Cold water inlet – Flush the cold-water pipe before connecting to free the pipe of dirt. When

using water from a storage tank, it is recommended to fit an inline water filter.

Do NOT use flex type toilet connectors.

Preparation

The gas water heater ignition function is powered by two large 1.5V. DC (Type D) torch

batteries. Please insert the correct way as indicated on the battery housing.

Batteries are NOT included.

Ignition

Open the gas at the cylinder valve and the gas valve after the regulator.

Open the warm water tap. The electronic ignitors will light up the main burners after 6 to 10

seconds.

First time ignition after installation, or when changing the cylinder, might take longer as there

will be air inside the gas pipe. Repeat if ignition is not obtained within the 10 seconds.

NB - Remember that the installer must by law commission your newly installed water heater in

your, or your representative’s presence, before you sign off the installation.

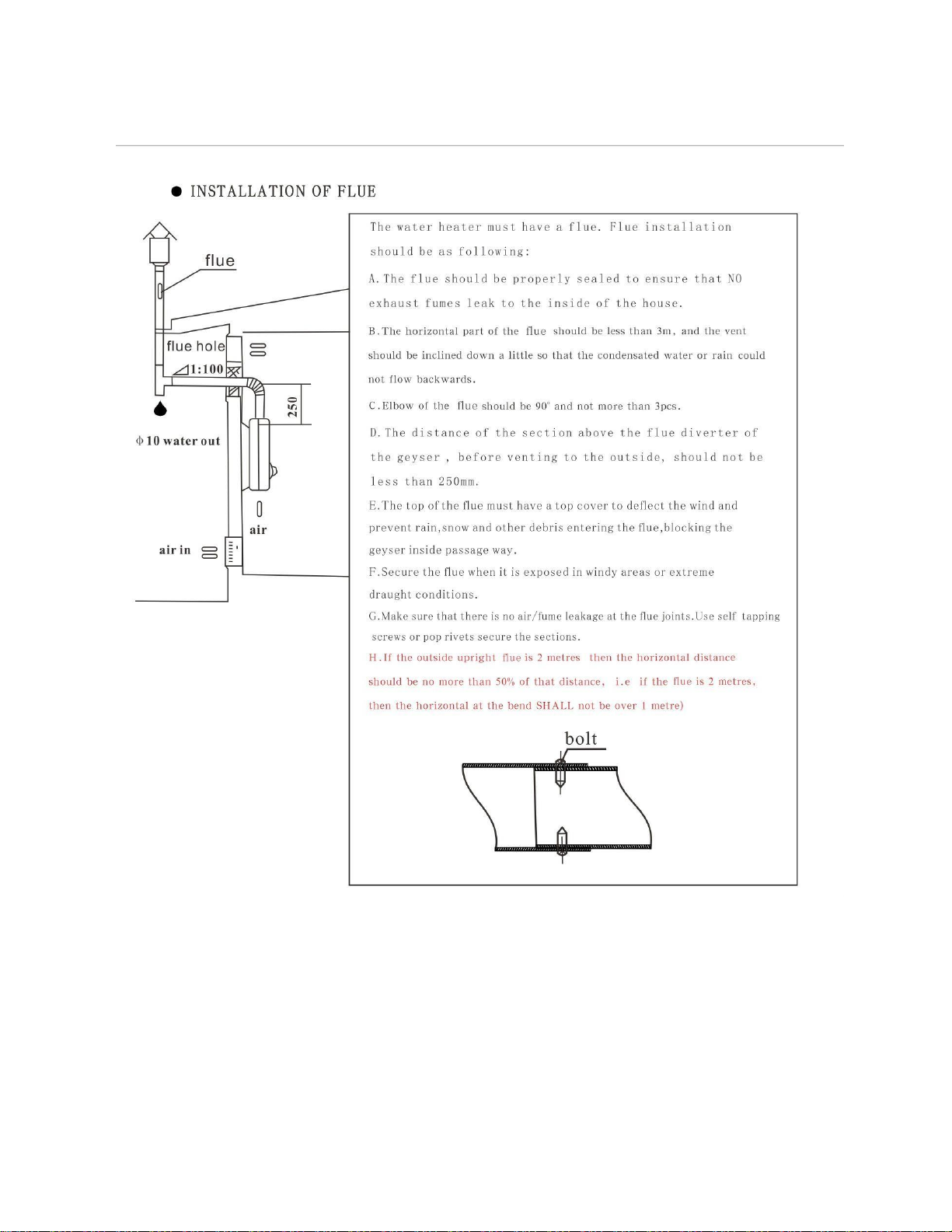

Installation of Flue

Setting up the Air Vent

The air vent should be as near to the floor as possible, but below the halfway distance of the

total distance to the ceiling.

The exhaust flue should be to the outside of the room and properly sealed to prevent exhaust

fumes entering to the inside.

The bend to the outside will not be less than 250mm from the centre of the flue to the gas

water heater connection.

Precautions

As a precaution, if you are away from home and the gas water heater will not be used for some

time, CLOSE THE CYLINDER VALVE. Always close the cylinder valve first before changing the

empty cylinder with a full cylinder.

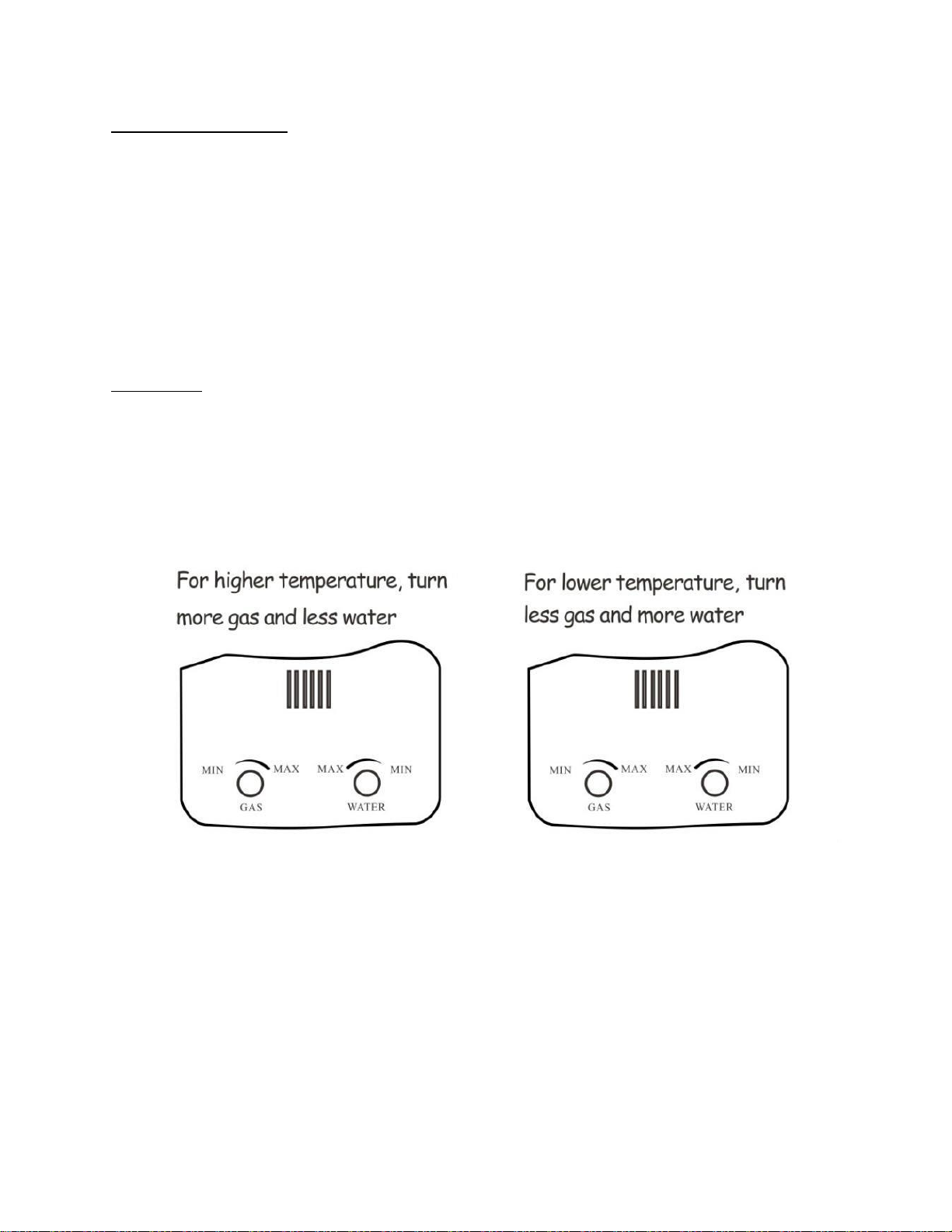

Temperature Control

To adjust;

Use clearly marked controls on the gas water heater control panel. You can adjust the flame

from low to high as well as the required water flow.

Should the water flow be too high, close the valve at the cold-water inlet slightly.

Shut-Off

The gas water heater will shut off automatically when you close the warm water supply. It will

also shut off if you close the cold water supply to the gas water heater, or if you close the

cylinder valve.

This gas water heater MUST NOT be used for anything other than the heating of water.

NB – The gas water heater should not be used continuously for periods longer than 20 minutes

at a time.

Trouble Shooting

Protective Function

Reaction

Solution / Remarks

Water Pressure Too High

If Water Pressure is Over 0.8Mpa, the Water-Out

Valve will Release Water and Lower the Pressure

Increase Valve Pressure Limit

According to Local Water Supply

Pressure

Water Pressure Too Low

If Water Pressure is Below 0.025Mpa the Water

Heater Cannot be Ignited

Water Pressure Pump to be Fitted or

Use Water Heater when Pressure is

Higher

20 Minute Auto Shut Off

Shuts Off Automatically After 20 Minutes of Use

Restart Water Heater

Low Battery

Although a Spark Sound can be heard the Battery

Power is too Low to Open the Solenoid Valve

Change to New Quality Batteries

Over Heat Protection

Water Heater Automatically Shuts Off when Water

Temperature is Above 77˚C

Restart Water Heater When Water

has Cooled

Repair and Maintenance – by Professional Person

Gas water heaters MUST be checked by a professional person annually. The following points

MUST be checked;

Leaks on the gas connections.

Leaks on water in and outlets.

Water inlet sieve – free from dirt and clogging – clean if necessary.

All parts functioning 100%

Flame quality and combustion (Soot)

Carbon accumulation on heat exchanger – clean if necessary.

No combustion leaks to the inside of the room.

Gas regulator – checked.

Clean carbon accumulation and oxidation on ceramic ignitors – if necessary.

Repair and Maintenance – by Owner

Clean the outside cover with warm water and a mild detergent using a soft cloth.

Do NOT use any abrasive cleaners or scourers.

Clean the cover vents with a soft brush.

Check the flue, make sure there are no obstructions. After cleaning, make sure that the flue is

properly fitted so that NO combustion will be released to the inside of the room.

Make sure that NO dirt is dropped to the inside of the gas water heater.

Check fittings and connections regularly with a 50/50% soap and water solution for gas leaks.

If there is a leak, stop using the gas water heater and close the valve on the cylinder.

Remove the batteries from the gas water heater.

Contact your installer or your local qualified gas dealer.

Do NOT use the gas water heater for any other purpose except for producing hot water i.e.

drying clothes – this will block the air vents

Always drain the water at the water exhaust if the gas water heater is not to be used for some

time, or if the temperatures drop below 0˚C ambient temperature.

Tampering

Under NO circumstance may an unauthorized person tamper with the unit. ONLY authorized

LPGSASA certified persons may carry out repairs to the unit. For anyone else to do so is not only

extremely dangerous, but AGAINST THE LAW – SANS 347

Department of Labour, Pressure Equipment Regulations, South African National Standard

(DOL / PER)

Maintenance and Repair Guide to Common Malfunctions

Cause / Malfunction

Solutions

Improper Operation

Gas Valve not Open

Open Gas Valve

Water Supply not Open

Open Water Valve

Improper Regulation Method of

Water temp

Increase Gas Volume, Reduce Water Volume

Reduce Gas Volume, Increase Water Volume

Improper Position of Water Switch

Turn Water Switch to Hot Water Position

Air in Gas Feed Line

Open and Close Hot Water Supply Several Times

Inadequate Fresh Water Supply

Improve Ventilation and Ensure Air Supply

Gas Pressure

Gas Pressure too High

Regulate Pressure Relief Valve - Reduce Overall Gas

Supply

Gas Pressure too Low

Check for any Twists in Gas Supply Hose

Water Pressure

Water Pressure too High

Reduce Water Supply

Water Pressure too Low

Utilize when Water Pressure is back to Normal

Surroundings &

Gas Valve is Half Opened

Open Gas Valve Completely

Inadequate Supply of

Gas

Gas Feed Hose is too Long

Check for Correct Hose Size and Length

Diameter of Joints too Small

Check for Restrictions in Gas hose. Use Full Bore Valves

&

Fittings

Improper Pressure Relief Valve

Water Heater of a Content Over 8lt - Pressure Relief

Valve (LPG) 1.2m 3kg/h

Simultaneous Consumption of Gas

by Several Users

Stop Other Users from Using the Gas

Blockage of Water Route

Clean Filtration Net on Water Admitting Orifice

Blockage of Shower

Clean Shower Device

Blockage of Vent Pipe

Clean Flue Pipe

Inadequate Battery Voltage

Replace Batteries with Quality Batteries

Low Water Temperature

Reduce Water Volume

Safety Protection

Exorbitant Air Pressure Protective

Device

Utilize when Air Pressure Recovers to Normal

Electrical Leakage Protective Device

Professional Repair Only

Heat Protective Switch

Professional Repair Only

20 Minute Protective Device

Re-open Hot Water Valve

Other Causes

Professional Repair Only

The installer MUST use two wrenches

One to hold the gas inlet on the gas water heater and one to tighten the ½” swivel to 15mm

copper solder – supplied.

This is the correct way to install the gas inlet, without breaking the pipes.

If using a ½” female to hose tail connection with an 8mm hose, the gas flow volume will be

inhibited and this will decrease the gas pressure.

This gas water heater operates on gas pressure 2.8 kPa ONLY. Do not increase pressure.

If Installed Inside, ensure that;

The installer abides by SANS 10087-1 specifications of cross ventilation.

NB - If installed outside, a flue must be fitted as this unit is fitted with a flue sensor.

NB – If installed inside, a flue must be flued to the outside of the building.

NB - By Law, it must cut out within 4 minutes if no flue is fitted.

NB - Bridging out of the flue sensor is not permitted.

NB – A valid COC Certificate must accompany any warranty claim.

Rev 0 – 11/2017

Loading...

Loading...