Page 1

OPERATOR’S MANUAL

848JJ693A0 (602)

BRUSHCUTTER

YM 415 FW

Page 2

Contents

For safe operation...................................2

Set up......................................................3

Fuel.........................................................4

Use .........................................................4

Maintenance............................................6

Specifications..........................................7

For safe operation

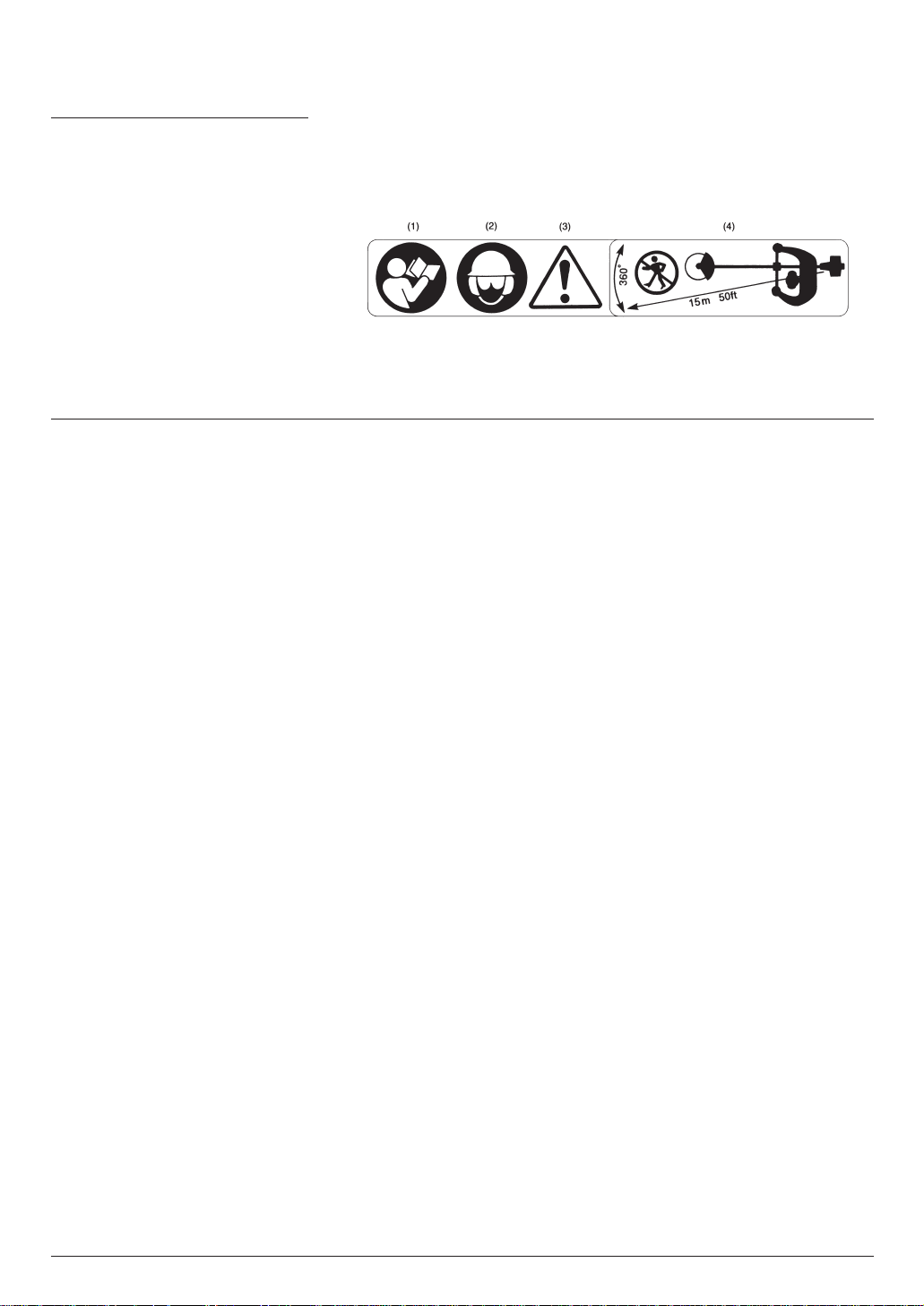

EXPLANATION OF PICTORIALS

(1)Read the owner's manual.

(2)Wear helmet, eye and ear protection.

(3)Warning / Attention

(4)Keep all children, bystanders and helpers

15 meters away from the brushcutter.

1. Read this manual carefully until you completely understand

and can follow all safety notes, precautions, and operating

instructions before using of the unit.

2. Do not operate this tool when you are tired, ill, or under the

influence of alcohol, drugs, or medication.

3. Always wear eye or face protection and hearing protection.

4. Do not wear loose clothing, jewelry, short trousers, sandals, or

go barefoot. Do not wear anything which might be caught by

branches or moving parts of the unit. Secure hair so it is above

shoulder length.

5. Never start or run the engine inside a closed room or building.

Exhaust gases contain dangerous carbon monoxide.

6. Before starting the engine, inspect the entire unit for loose

fasteners and fuel leakage. Make sure that the cutting

attachment is properly installed and securely fastened.

7. Be sure the cutting attachment guard is firmly attached in

place.

8. Fuel is highly flammable. Always keep open flames and sparks

away from the unit and fuel depot. Do not smoke while

refueling the unit or mixing fuel.

9. When refueling the unit, make sure to stop the engine and

allow it to cool down. Wipe spilled fuel completely from the

unit. Move at least 3 meters away from fueling site before

starting the engine.

10. Check the condition of working area to avoid any accident by

hitting hidden obstacles such as stumps, stones, cans, or

broken grass.

11.Keep bystanders and animals at least 15 meters away from

the operating point. If you are approached, immediately stop

the engine.

12. Keep firm footholds and balance at all times. Do not use the

unit where footing is unsteady or slippery.

13.Keep cutting attachment below waist level.

15.Warn the operator of the danger of blade thrust (Kick back).

Blade thrust may occur when the spinning blade contacts a

solid object in the critical area. A dangerous reaction may

occur causing the entire unit and operator to be thrust

violently. This reaction is called Kick back. As a result, the

operator can lose control of the unit which can cause serious

or fatal injury. Kick back is more likely to occur in areas where

it is difficult to see the material to be cut.

16. When inspecting or servicing the unit, make sure to stop the

engine and disconnect the spark plug as necessary.

17. Cover the blade when transporting or storing the unit. Secure

the unit before storage or transporting to prevent loss of fuel,

damage or injury.

18.When replacing cutting attachment or other components, be

sure to use the parts supplied or recommended by

S.P.

19. When the unit is turned off, make sure the cutting attachment

has stopped before the unit is set down.

20.For units equipped with a clutch, be sure the cutting

attachment stops turning when the engine idles.

21. Use only for tasks explained in the instruction handbook.

22.Discard blades that are bent, warped, cracked, broken or

damaged in any way.

23. Instructions on stopping a coasting blade. A blade can injure

while it continues to spin after the engine is stopped or throttle

control is released.

24.Stop the engine and blade before removing material that is

blocking or entangling the cutting attachment.

25.Use a sharp blade. A dull blade is more likely to snag and

thrust. Replace the fastening nut according to the

manufacturer's instruction.

26. Cut only material recommended by the manufacturer. Do not

let the blade contact material it cannot cut, such as rocks,

metal etc.

YANMAR

14.Keep all parts of your body away from rotating cutting

attachment and hot surfaces.

2

27. Always wear safety boots, additionally a helmet is required if

there is a risk of contact with falling objects.

Page 3

Set up

F1

F2

F3

■ ENGINE

• Using attached 4 socket screws, secure the connection firmly with equal force. (F1)

■ INSTALLING HANDLE

1. Loosen the 4 bolts on the handle bracket. (F2)

2. Insert the right handle (throttle lever is attached) and the left handle assembly into the

bracket and retighten the bolts securely. (F2)

(1) Handle bracket (2) Right handle (3) Bolt (4) Left handle (5) Engine side

3. Remove the screw (F3-1) from the right grip (F3-2) and put the grip onto the right

handle. Align the positioning holes and put the screw through them. Fasten the clamp.

(F3-3)

F4

F5

F6

■ PROTECTOR

• Wrap the protector around the outer pipe as shown in the figure (F4), and fasten the

hooks.

■ SAFETY GUARD

• Attach the safety guard to the gear case and fix it with the clamp and 2 bolts (M5 x 25)

securely. (F5)

(1) Bolt (2) Clamp (3) Main pipe (4) Safety guard

■ BLADE

1. Put the angled bar (F6-1) into the side holes of the inner holder (F6-4)and the

gearcase.

2. Remove the blade bolt (F6-2, Lefthanded) and the outer holder (F6-3) from the

gearshaft.

3. Put the blade onto the inner holder.

4. Put the outer holder onto the gearshaft making the recessed side face the blade.

5. Fasten the blade by the blade bolt with the washers (F6-5) and the bolt cover (F6-6).

• Detailed attachments and set up method will be shown in separate Thai language

manual.

3

Page 4

WARNING

Fuel

WARNING

NOTE

F7

Use

F8

• Keep open flames away from the area where fuel is handled or stored.

•Mix and store fuel only in an approved gasoline container.

Mix a regular grade gasoline (leaded or unleaded, alcohol-free) and a quality-proven

motor oil for air cooled 2-cycle gasoline engine use.

Recommended mixing ratio:

Condition Gasoline : Oil

Up to 20 hours use 20 : 1

After 20 hours use 25 : 1

Most engine troubles are caused, directly or indirectly, by the fuel used on the

machine. Take special care not to mix a motor oil for 4-cycle engine use.

■ STARTING THE ENGINE

Take care that the cutting head will start rotating upon the engine starts.

1. Open the fuel tank cock. (F8-1-b)

25 : 1 Mix Chart

Gasoline (liters)

2-cycle oil (ml.)

1 2345

40 80 120 160 200

F10

F11

F12

2. Move the choke lever to the closed position. (F8-2-a)

3. Set the engine switch (F10-a) to the " I " position. Set the throttle lever to the start

position. (F10, 1-2-3)

4. Place the unit on a flat, firm place. Keep the cutting head clear of everything around it.

5. While holding the unit firmly, pull out the starter rope quickly. (F11)

6. After the engine has started, open the choke gradually and allow the engine to warm

up. Pull the throttle lever to unlock it.

■ STOPPING ENGINE

1. Release the throttle lever .

2. Move the engine switch to the “ O ” position.

■ ADJUSTING THROTTLE CABLE

• The normal play is 1 or 2mm when measured at the carburetor side end. Readjust with

the cable adjuster (F12-1) as required.

■ ADJUSTING IDLING SPEED

• It is normal that the engine keeps running without the blade rotation, when the throttle

lever is released. When the engine speed is too high or too slow, readjust the idle set

screw. (F12-2)

4

Page 5

WARNING

Use

F13

F14

F15

Cutting work

• By using the shoulder strap, hang the unit on your right side. Adjust the strap length so

that the cutting head may become parallel to the ground. (F13)

■ SWIVEL LOCK

a) When the unit is not hung down with the harness, as in transportation, use the swivel

lock to prevent the engine from roll down.

b) To lock the swivel, thrn the wing nut (F14-1) clockwise.

c) For normal operation, keep the wing nut loose.

• Choose a suitable recommended cutting attachment according to the object to be cut.

(F15) Never use other cutting attachement not approved by YANMAR S.P.

■ WHEN USING A METAL BLADE

1. Check the bolt to fasten the blade and be sure the bolt has no fault, and no abrasion.

2. Be sure that the blade and the holder have been fastened according to instruction and

the blade turns smoothly without abnormal noise.

• The rotating parts fastened incorrectly may cause serious accident to the

operator.

F15

F22

■ CUTTING METHOD

(a)Use the front left side for cutting.

(b)Guide the blade from your right to left with it tilted slightly to your left. (F16)

(c) When mowing a wide area, start working from your left end to avoid interference of cut

grass.

(d)The blade may be seized by weeds if the engine speed is too low, or the blade cuts too

deep into weeds. Adjust the engine speed and cutting depth according to the condition

of object.

• For your health and to prevent the risk from vibration, refrain from working for a long

time at the cold temperature.

■ WHEN USING A NYLON LINE HEAD

1. Guide the head from your left to right to let the cut grass be thrown away from you.

(F22)

2. Always do cutting with the engine running at full throttle.

3. Use only the tip of the oine for cutting, and allow it to trim at its own pace.

5

Page 6

0.6— 0.7mm

Maintenance

IMPORTANT

IMPORTANT

IMPORTANT

WARNING

F18

Before cleaning, inspecting, or repairing the unit, make sure that the

engine has stopped and is cool.

■ BLADE

• Check the blade and the fasteners for looseness, cracking, or bending.

• Check the cutting edges and reform with a flat file.

Point (F18):

1. Keep the end corner sharp.

2. Round the root of the edge.

3. Do not use water when using a grinder.

F19

F20

F21a

■ AIR CLEANER

• Check and clean the filter element in warm, soapy water as required. Dry completely

before installing. If the element is broken or shrunk, replace with a new one. (F19)

(1) Cover (2) Element (3) Screen (4) Body

A clogged air filter may increase fuel consumption while cutting down the engine power.

And operate the brushcutter without the air filter or with a deformed filter element will

quickly ruin the engine.

■ FUEL FILTER

• Take the filter out of the fueling port using a small wire hook. Disconnect the filter

assembly from the fuel pipe and unhook the retainer to disassemble it. Clean the

components with gasoline. (F20)

(1) Strainer (2) Fuel tank

A clogged fuel filter may cause poor acceleration of the engine.

■ SPARK PLUG

• Starting failure and mis-firing are often caused by a fouled spark plug. Periodically

clean the spark plug and replace with a new one as required. (F21a)

• REPLACEMENT PLUG IS A Champion CJ-6Y.

F21

6

■ GEAR CASE

• Supply multi-purpose grease at every 25 hours of use.

• Remove the cutter holders to arrange for old grease to exit. (F21)

(1) Inner holder (2) Plug

■ MAINTENANCE BEFORE STORAGE

• Old fuel left in the carburetor may cause starting failure. When a series of operation

finished, make sure to empty the fuel tank and drain the carburetor.

• Check all parts and the functions. If the failured or damaged parts have been found,

replace them with new ones.

Page 7

Specifications

Limited warranty

Model name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . YM415FW

Engine model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G45L

Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.5cm

Carburetor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Float

Ignition system. . . . . . . . . . . . . . . . . . . . . . . IC controlled flywheel magneto

Spark plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion CJ-6Y

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . Mixture (Gasoline 25 : 2-Cycle Oil 1)

Fuel tank capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.8 litres

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Recoil starter

Clutch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Cetrifugal type

Reduction ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.333

Cutter rotation . . . . . . . . . . . . . Counter-clockwise as viewed from operator

Overall dimension L . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1800mm

W . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 630mm

H . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 480mm

Dry weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.3kg

• Specifications are subject to change without notice

Should any failure occur on the product

under normal operating conditions within

the applicable warranty period, the failed

3

part will be replaced or repaired at free of

charge by YANMAR S.P. authorized

dealer.

WARRANTY PERIOD: 6 months from the

date of initial purchase.

IMPORTANT: The following cases are not

covered by this warranty:

(a) Any failure resulted from neglect of

instructions for proper operation and

maintenance of the product described

in the operator's manual.

(b) Any damage due to accidents, abuse,

negligence, alteration, or use of any

parts or accessories other than those

specified by YANMAR S.P.

(c) Any failure due to use of improper fuel.

(d) Replacement of normally consumed

parts: cutter blades, spark plugs,

starter ropes, etc.

(e) Regular maintenance and adjustments

explained in the operator's manual.

(f) Incidental or consequential damages.

(g) Transportation charge for

failed/repaired unit.

Nothing contained in this warranty affects

the consumer's statutory rights.

7

Page 8

Distributed by

YANMAR S.P. CO., LTD.

LAD KRABANG INDUSTRIAL ESTATE

109 Moo 9 Chalong Krung Rd., Lamplatiew

Lad Krang Bangkok 10520 Thailand.

PRINTED ON RECYCLED PAPER PRINTED IN JAPAN

Loading...

Loading...