Page 1

115 34 40-10 (002)

OWNER’S MANUAL

POWER SPRAYER

NS2522

G

G

B

B

NS2522

Original Language

GB-1

Page 2

NS2522

EC DECLARATION OF CONFORMITY

(Applies to Europe only)

The undersigned manufacturer,

Husqvarna Zenoah Co.,Ltd.,

1-9, Minamidai, Kawagoe, Saitama, Japan,

declares under sole responsibility that the following products referred to in this

declaration conform with the requirement of the following COUNCIL’S DIRECTIVE.

The products referred to are :

DESIGNATION : Power sprayer

MANUFACTURER : Husqvarna Zenoah Co., Ltd.

MODELS : NS2522

SERIAL NUMBERS DATING : 2010 and onwards

(The year is cleary stated on the rating plate,

follwed by the serial number)

This declaration conform with :

・DIRECTIVE 2006/42/EC

(The following standards have been applied: ISO 12100-1,-2, FprEN 15503: 2009)

・DIRECTIVE 2004/108/EC

(The following standards have been applied: EN 61000-6-1, EN 55012 (CISPR 12: 2005))

・DIRECTIVE 2000/14/EC

conformity assessment procedure followed ANNEX V

・DIRECTIVE 2002/88/EC

Date :

Signature :

Kiyoshi Honda

General Manager, Development Center

Authorised representative :

Person authorised to compile the technical file :

29 December 2009

Husqvarna AB

SE-561 82 Huskvarna, Sweden

Bo R Jonsson

SE-561 82 Huskvarna, Sweden

EXPLANATION OF SYMBOLS AND SAFETY WARNINGS

WARNING!!!

RISK OF DAMAGING HEARING

Wear head, eye and ear protection.

MODEL SOUND LEVEL

ISO 11201 ISO 8662-1

NS2522 21.7 cm

3

L

pAav

88 dB(A) 106 dB(A) 0.2 m/s

* Specifications are subject to change without notice

1) Noise emissions in the environment measured as sound power (L

Reported soundpower level for the machine has been measured with the original attachment that gives the highest level.

The difference between guaranteed and measured sound power is that the guaranteed sound power also includes dispersion in the measurement result and the variations between different machines of the same model according to Directive

2000/14/EC.

Reported data for equivalent sound pressure level (L

dispersion (standard deviation) of 1 dB (A).

2) Reported data for equivalent vibration level (a

of 1 m/s

2

.

1)

VIBRATION LEVEL

2000/14/EC

ISO 3744

L

wA

guaranteed

hv,eq) at the control handle has a typical statistical dispersion (standard deviation)

idling

2

WA) in conformity with EC directive 2000/14/EC.

pAeq) at the operator’s ear for the machine has a typical statistical

2.6 m/s

2

2)

2002/44/EC

ISO 22867

ahv, eqracing A(8)

7.3 m/s2 2.6 m/s

2

GB-2

APPROVAL NUMBER OF CE EXHAUST EMISSION REGULATION

DIRECTIVE 97/68/EC AMENDED 2002/88/EC

e13✱97/68SH2G3✱2002/88✱0109✱02

Page 3

NS2522

2

3

5

1

SAFETY PRECAUTIONS

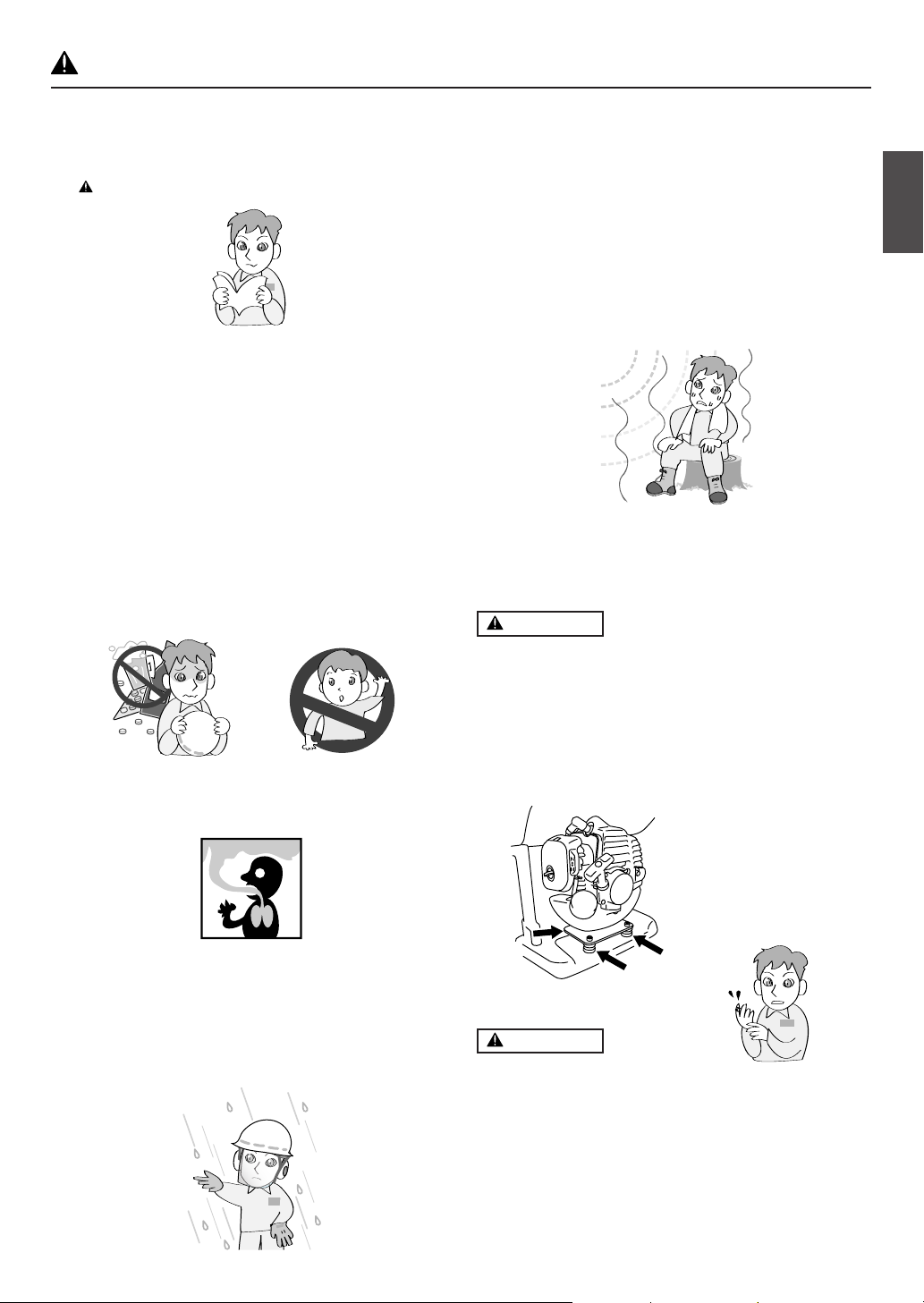

Warning labels bearing the mark on the product and in this

Manual refer to important safety matters. Please familiarize yourself with them and observe them well.

If a warning label on the product becomes soiled or detached,

please order a replacement label from your dealer and attach it

in the requisite place.

PRECAUTIONS

In this Operator's Manual, precautions that are considered to be

particularly important are indicated as follows.

WARNINGS IN THE MANUAL

WARNING

Failure to observe the precaution may result in the risk of death

or serious injury.

IMPORTANT

Failure to observe the precaution may result in damage or malfunction of the product.

NOTE

Other additional explanations that may be of use when operating the product.

Contents

1. Parts location ................................................. 3

2. Specification .................................................. 4

3. Symbols in the manual ................................... 4

4. Symbols on the machine................................ 4

5. For safe operation .......................................... 5

6. Set up ............................................................. 8

7. Fuel .............................................................. 10

8. Chemical filling............................................. 11

9. Operation ..................................................... 11

10. Maintenance ................................................ 12

11. Storage......................................................... 15

12. Troubleshooting guide ................................. 15

13. Disposal ....................................................... 16

G

B

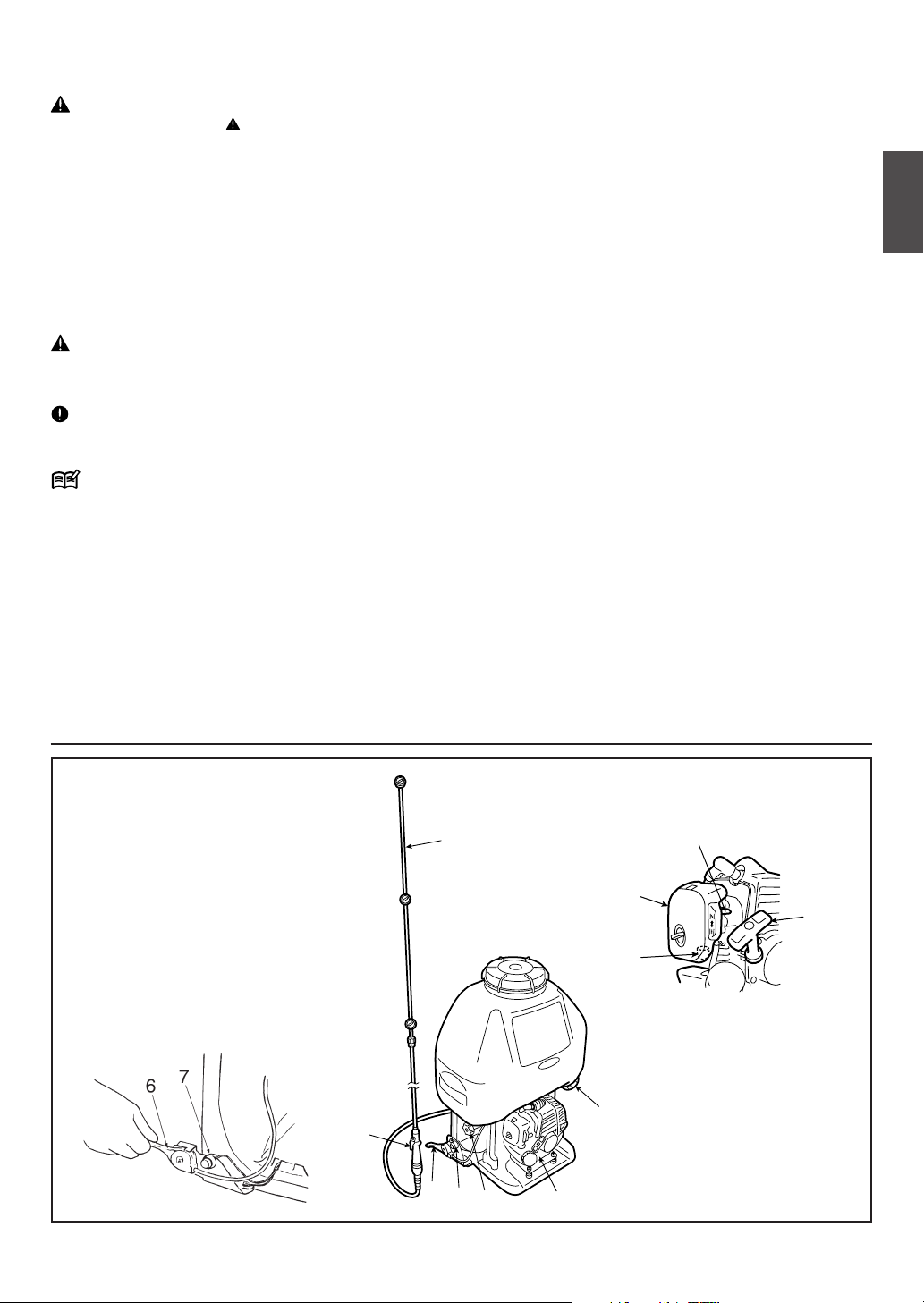

1. Parts location

(1) Primer

(2) Air cleaner cover

(3) Choke lever

(4) Fuel tank

(5) Starter knob

(6) Throttle lever

(7) Stop switch

(8) Spray rod

(9) Grip

(10) Pressure regulating dial

(11) Fluid drain cap

8

11

9

6

7

10

4

GB-3

Page 4

NS2522

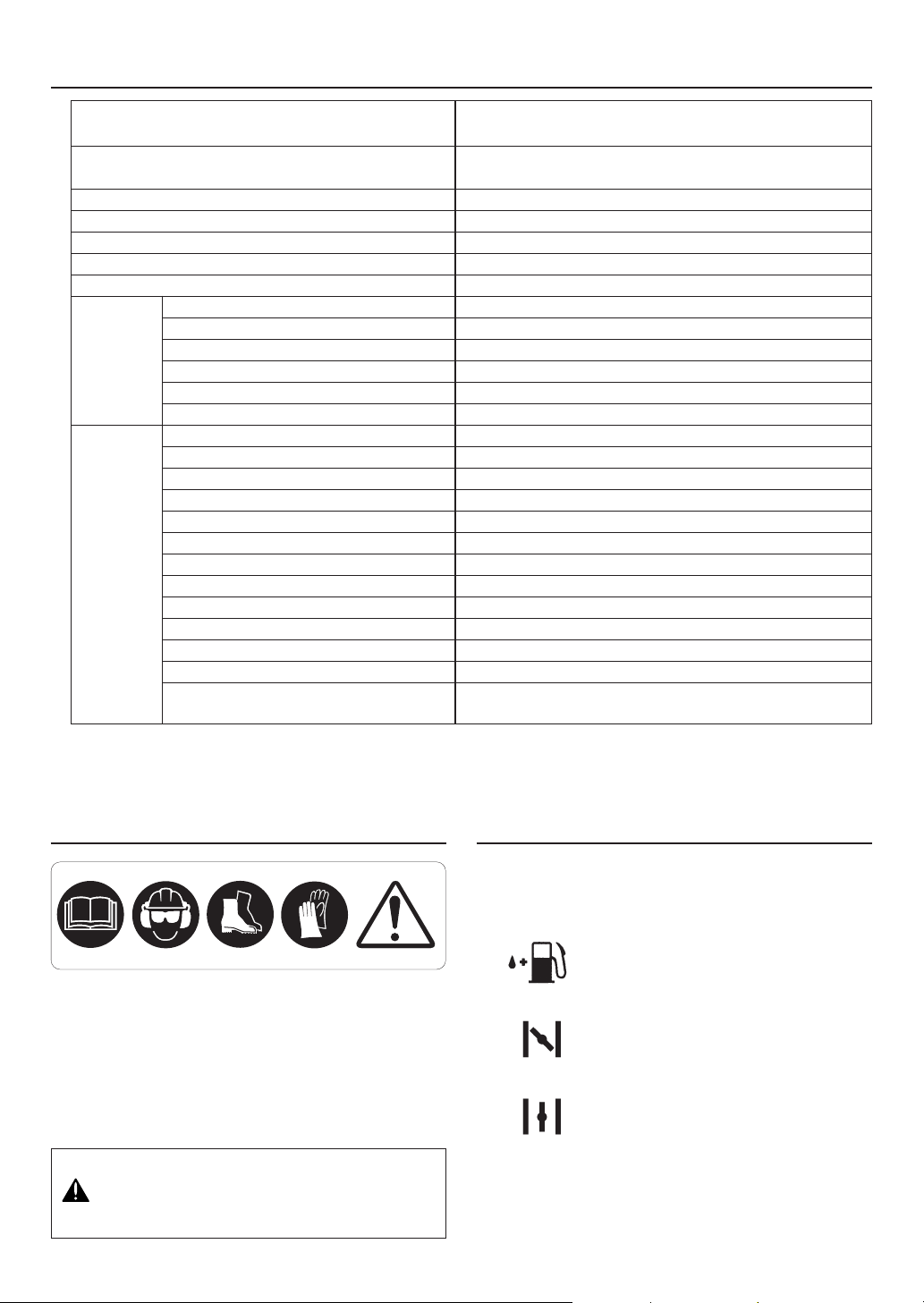

2. Specification

Model name and number Zenoah Back-Packed Motorized Sprayer

NS2522

Purpose Spraying agricultural chemicals and cold water

for pest control, weeding, and growth control

Dry weight ∗ (kg) 8.7

External dimensions of main unit

(length x width x height) ∗∗ (mm) 320x470x630

Capacity of chemical fluid tank (litres) 25

Capacity of fuel tank (litres) 0.47

Pump Type Double parallel piston pump

Speed (rpm) 1800

Spray output Normal (MPa) 2.0

Maximum (MPa) 2.5

Maximum water absorption (litres/min) 9

Motor transmission system Centrifugal clutch

Engine Type Single-cylinder air-cooled 2-cycle gasoline engine

Model number Zenoah G20LS

Exhaust capacity (cc) 21.7

Fuel used Lubricating oil/gasoline mix

Lubricating oil used 2-cycle engine oil

Admixture ratio Gasoline 50 : Oil 1 (when using ZENOAH genuine oil)

Carburetor Diaphragm, rotary valve type

Ignition system Electronic controlled flywheel magnet type

Spark plugs NGK BPMR7A

Starter system Recoil starter type

Stopping system Primary cable short circuit

Air cleaner Dry type

Standard accessories 1 spray rod, 1 rod, 1 cock, 1 grip, 1 joint,

1 hose, 1 mix tank, 1 plug wrench

∗ When nozzle (supplied) is attached.

∗∗ Nozzle and back belt are not included.

Due to product improvements, these specifications are subject to change without notice.

3. Symbols in the manual

(1) (2) (4) (5)

(1) Read owner’s manual before operating this

machine.

(2) Wear head, eye and ear protection.

(3) Wear foot protection.

(4) Wear gloves.

(5) Warning / Attention

Never modify your machine.

We won’t warrant the machine, if you use the

remodeled power sprayer or if you don’t observe

the proper usage written in the manual.

GB-4

(3)

4. Symbols on the machine

For safe operation and maintenance, symbols are carved

in relief on the machine. According to these indications,

please be careful not to make a mistake.

The port to refuel the “MIX GASOLINE”

Position: FUEL TANK CAP

The direction to close the choke

Position: AIR CLEANER COVER

The direction to open the choke

Position: AIR CLEANER COVER

Page 5

5. For safe operation

NS2522

Before using this product, please read this Operator's

Manual thoroughly to ensure correct operation. The following are precautions that should be observed in order

to use the product smoothly. Elsewhere in the Manual,

the warning mark is used to bring your attention to

these precautions.

BEFORE USING THE PRODUCT

• This product has been designed mainly for the pur-

pose of spraying pest control chemicals and

weedkillers. Please do not use it for any other purpose, as this may cause unforeseen accidents.

• Since this product uses agricultural chemicals that

require careful operation, misuse can be dangerous.

Do not use this product when tired or otherwise in

poor physical condition, or when you may be unable

to judge correctly or operate accurately, such as after

taking cold relief medicines or drinking alcohol. Also,

children or persons who are unable to understand the

contents of this Manual should under no circumstances be permitted to use the product.

• When using for the first time, before commencing

actual spraying please receive guidance in operating the product from a person with adequate experience.

• Fatigue reduces powers of concentration and increases the risk

of accidents. When planning work, please allow ample

time,

setting a limit of 30-40 minutes for single spraying

sessions and breaks of 10-20 minutes in between.

Also, do not spray for more than 2 hours in any one

day.

• Please take good care of this Operator's Manual and

refer to it for additional information from time to time.

• When selling or lending this product, it should be accompanied by this Operator's Manual.

WARNING

G

B

• The engine exhaust gas contains toxic carbon monoxide. Please do not use the product indoors, in vinyl

houses or tunnels, or in other poorly ventilated places.

• Do not use this product in the following cases.

1. When the product could fall over or in other situations

when it is difficult to hold or operate.

2. After sunset or at other times when eyesight is poor

and the safety of the spraying area is difficult to ascertain.

3. In worsening weather (rain, fog, strong wind, lightning,

etc.)

• Check to see if the shock-absorbing rubber mount

has become cracked or otherwise damaged. Note

that failing to replace this rubber mount when it has

become cracked or damaged may cause the engine

to come loose from its frame during use, thus resulting in possible serious bodily injury.

• If cracked, be sure to replace without delay.

WARNING

1. If you don’t observe the working time, or working

manner, Repetitive Stress Injury (RSI) could occur.

If you feel discomfort, redness and swelling of your

fingers or any other part of your body, see a doctor

before getting worse.

2. To avoid noise complaints, in general, operate product between 8 a.m. and 5 p.m. on weekdays and 9

a.m. to 5 p.m. on weekends.

GB-5

Page 6

NS2522

5. For safe operation

IMPORTANT

Check and follow the local regulations as to sound

level and hours of operations for the product.

PRECAUTIONS BEFORE SPRAYING

• Make sure you have the correct protective clothing,

headgear, rubber gloves and boots, a protective

mask, goggles, a towel, protective cream, etc., to prevent chemicals from coming into contact with your

skin or entering your lungs. When spraying, please

wear this protective gear to prevent any risk of injury.

1. Protective headgear

2. Protective goggles

3. Protective mask

4. Rubber boots

5. Ear muffs

6. Neck covering

7. Protective clothing

8. Rubber gloves

9. Protective clothing

• Please store chemicals in a locked storage box, locker,

or other safe place out of the reach of children.

• Carefully read the instructions for using the chemicals, and familiarize yourself with the level of toxicity,

method of use, etc.

• Please pay all due consideration to the area in which

you will be spraying, to ensure that you do not pollute

the water supply, rivers, lakes, ponds, etc., or cause

any damage to residents, passers-by, livestock, etc.

•Prepare yourself physically on the day before spraying, by for example cutting down on alcoholic beverages or late-night work.

• Do not allow children, animals, etc., to enter the

chemical spraying area.

PRECAUTIONS WHEN TRANSPORTING THE

SPRAYER

• Do not transport the sprayer while it has chemicals or

fuel in the tank, as these could leak out as a result of

impact during transportation.

• When transporting in a vehicle, please use a rope or

similar to fix the sprayer firmly to the cargo trailer in

an upright position. Please do not transport by bicycle

or motorbike, as this is dangerous.

PRECAUTIONS CONCERNING FUEL

• The engine of this product is fueled by "mixed gasoline" that includes highly combustible fuel. Do not refuel or store fuel containers where there is any risk of

combustion from incinerators, burners, bonfires,

kitchen stoves, electric sparks, welding sparks, etc.

• Smoking while spraying or refueling is dangerous.

Please avoid this at all costs.

• When refueling during use, always stop the engine

and make sure there are no naked flames in the vicinity before refilling.

• Any fuel spilt during refueling should be wiped off completely with a rag or similar before starting the engine.

• After refueling, seal the fuel container, tightly close the fuel

tank cap, and start the engine at least 3 meters away.

PRECAUTIONS WHEN REFILLING CHEMICALS

• Before filling the tank with chemicals, please make

sure that the spray lever is completely at rest.

• After chemical refilling, firmly tighten the tank cap. If

not fully tightened the cap may become loose during

spraying, with the risk of physical exposure to the

chemicals.

• Before spraying, please prepare fully by inspecting

sprayer nozzles and checking for abnormalities such

as loose screws or spray hose connections, fuel leaks,

defective or broken fluid gaskets, or damage to the

carrying band.

PRECAUTIONS WHEN TRANSPORTING CHEMICALS

• When transporting chemicals, please handle with care

to ensure that there is no spillage of chemicals from

torn bags, broken bottles, or loose stoppers.

• Do not carry chemicals in the same container as food.

GB-6

PRECAUTION WHEN STARTING THE ENGINE

• Please keep children, animals, etc. well away when

starting the engine and spraying.

PRECAUTIONS WHEN SPRAYING

• Since protective clothing generally offers poor ventilation and thus places stress on the body, there is a

risk of contracting heatstroke or other illness when

operating for long periods under high temperatures.

Please avoid spraying on hot days, aiming instead

for early morning and late afternoon times when temperatures are relatively cool and winds are low.

• When starting work, please pay all due consideration

to the spraying time, wind direction, etc., to ensure

that no noise disturbance or chemical hazard is

caused to nearby residents, passers-by, farm crops,

and so on.

• While spraying please hold the grip firmly at all times

and be careful not to point the nozzle in the direction

of people or animals.

Page 7

5. For safe operation

NS2522

• While spraying please be careful of the wind direction and always stand on the upwind side, to avoid

spraying yourself with chemicals.

• Should you begin to feel even

slightly unwell while spraying, consult a doctor immediately. When doing so, inform the doctor of the name

of the chemical you were using, the conditions of use,

etc.

•If the sprayer is tilted the chemical may leak out

through the air holes in the cap. When spraying always make sure you have a firm footing and maintain

your balance.

• Do not touch the spark plugs or plug cords while the

engine is running, as you may get an electric shock.

• Do not touch the muffler, spark plugs, or other metal

parts with your bare hands while the engine is running or immediately after stopping the engine, as there

is the risk of burns due to high temperatures.

work, duration of the work, and other details.

• Please keep the following points in mind when selecting or using protective gear.

a) Protective clothing

Choose clothing that is cool to wear and offers good

ventilation and waterproofing. In addition, wear items

that enable you to carry out spraying work in total

comfort and safety.

b) Spraying hood

Use a hood with a brim that is waterproof and covers

your neck and shoulders.

c) Gloves

Use gloves that are difficult for chemicals to penetrate

and do not slip even if you perspire while doing the

work.

d) Rubber apron

When mixing chemicals, wear a long, thick, and wide

apron that cannot be penetrated by chemical

splashes.

e) Protective goggles, mask, etc.

Select suitable protective goggles, mask, rubber

boots, eye washer, and protective cream, etc., paying attention to standards and the recommendations

of farm work safety promotion organizations.

G

B

PRECAUTIONS AFTER SPRAYING

• Please seal unused chemicals and store them out of

the reach of children.

• Do not simply discard empty chemical containers, but

dispose of them safely by incinerating, burying, or

another similar method. In addition, please take every care that the water used to clean spraying tools

does not create any hazard.

• Fully inspect and maintain protective clothing, masks,

gloves, and other protective gear in preparation for

the next session.

• After completing the work and tidying away chemicals and spraying tools, you should immediately take

a bath or wash your hands, feet, face, etc. thoroughly

with soap, as well as washing your mouth out.

•You should change all clothes worn, including underwear, and wash them thoroughly. Clothes worn during spraying should not be worn again the following

day.

• After spraying, please limit your alcohol intake and

rest thoroughly by going to bed early. If you feel even

slightly unwell, please see a doctor as soon as

possible.

OTHER PRECAUTIONS

• When engaged in spraying work over a protracted

period of time, please have your health checked regularly.

• Please carry out spraying in a planned fashion, keeping a daily record of the date and time of spraying,

the chemicals used, the target pest, contents of the

MAINTENANCE PRECAUTIONS

• In order to maintain the functions of the product, regularly carry out the maintenance inspections listed in

this Manual. When maintenance or parts replacement

not indicated in this Manual are required, please consult your product supplier or nearest ZENOAH product dealer.

• Never keep the engine running while carrying out inspections or maintenance.

• Do not modify the sprayer or dismantle the engine.

This could lead to breakdown and serious accidents

during operation.

• Do not touch the muffler or spark plugs with your bare

hands immediately after stopping the engine. There

is the risk of burns due to high temperature.

• For replacement parts, please use original ZENOAH

parts or brands designated by ZENOAH.

MAINTENANCE OF LABELS

1. Please keep warning labels clean and unmarked.

2. If warning labels become soiled or peel off, please

order from your supplier and replace with new ones.

3. When affixing new labels please wipe off all dirt and

moisture.

GB-7

Page 8

NS2522

6. Set up

A Package contains the items as illustrated.

1

7

3

6

4

5

2

9

8

10

(1) Unit

(2) Spray rod

(3) Cock

(4) Grip

(5) Joint

(6) Spray hose

(7) Rod

(8) Plug wrench (S13/S19) with phillips screw driver

(9) Mix tank

(10) Owner’s manual

GB-8

Page 9

6. Set up

a

b

c

NS2522

■ Connecting the spray hose and nozzle

h

f

g

e

a. spray rod

b. cock

c. grip

d. joint

e. spray hose

f. connecting nut

g. spray outlet

h. rod

a

b

c

d

1. Connect the spray hose to the pump spray outlet and

firmly tighten the connecting nut.

2. Tightly screw the joint onto the hose.

3. Tightly screw the grip onto the joint.

4. Tightly screw the cock onto the grip.

5. Tightly screw the rod onto the cock.

6. Tightly screw the spray rod onto the rod.

■ Adjusting spray pressure

• NS2522 has a pressure regulating dial to change

spray pressure. Set the pressure at a level appropriate to the spray conditions.

Set the pressure regulating dial as follows:

•Turn in a clockwise direction to increase the pressure.

•Turn in a counterclockwise direction to decrease the

pressure.

a. Pressure regulating dial

b. Decreasing the pressure

c. Increasing the pressure

G

B

GB-9

Page 10

NS2522

7. Fuel

■ FUEL

WARNING

• Gasoline is very flammable. Avoid smoking or

bringing any flame or sparks near fuel. Make sure

to stop the engine and allow it cool before refueling the unit. Select outdoor bare ground for fueling and move at least 3 m (10 ft) away from the

fueling point before starting the engine.

• The Zenoah engines are lubricated by oil specially

formulated for air-cooled 2-cycle gasoline engine use.

If Zenoah oil is not available, use an anti-oxidant added

quality oil expressly labeled for air-cooled 2-cycle

engine use (JASO FC GRADE OIL or ISO EGC

GRADE).

• Do not use BIA or TCW (2-stroke water-cooling type)

mixed oil.

■ RECOMMENDED MIXING RATIO

GASOLINE 50 : OIL 1

(when using ZENOAH genuine oil)

• Exhaust emission are controlled by the fundamental engine parameters and components (eq.,

carburation, ignition timing and port timing) without addition of any major hardware or the introduction of an inert material during combustion.

• These engines are certified to operate on unleaded

gasoline.

• Make sure to use gasoline with a minimum octane

number of 89RON (USA/Canada: 87AL).

• If you use a gasoline of a lower octane value than

prescribed, there is a danger that the engine temperature may rise and an engine problem such as

piston seizing may consequently occur.

• Unleaded gasoline is recommended to reduce the

contamination of the air for the sake of your health

and the environment.

•Poor quality gasolines or oils may damage sealing

rings, fuel lines or fuel tank of the engine.

■ HOW TO MIX FUEL

WARNING

4. Pour in the rest of gasoline and agitate again for at

least one minute. As some oils may be difficult to agitate depending on oil ingredients, sufficient agitation

is necessary for the engine to last long. Be careful

that, if the agitation is insufficient, there is an increased

danger of early piston seizing due to abnormally lean

mixture.

5. Put a clear indication on the outside of the container

to avoid mixing up with gasoline or other containers.

6. Indicate the contents on outside of container for easy

identification.

■ FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a

dustless place.

2. Put fuel into the fuel tank to 80% of the full capacity.

3. Fasten the fuel cap securely and wipe up any fuel

spillage around the unit.

WARNING

1. Select bare ground for fueling.

2. Move at least 3 meters (10 feet ) away from the fueling point before starting the engine.

3. Stop the engine before refueling the unit. At that time,

be sure to sufficiently agitate the mixed gasoline in

the container.

■ FOR YOUR ENGINE LIFE, AVOID:

1. FUEL WITH NO OIL (RAW GASOLINE) – It will cause

severe damage to the internal engine parts very

quickly.

2. GASOHOL – It can cause deterioration of rubber and/

or plastic parts and disruption of engine lubrication.

3. OIL FOR 4-CYCLE ENGINE USE – It can cause spark

plug fouling, exhaust port blocking, or piston ring sticking.

4. Mixed fuels which have been left unused for a period

of one month or more may clog the carburetor and

result in the engine failing to operate properly.

5. In the case of storing the product for a long period of

time, clean the fuel tank after rendering it empty. Next,

activate the engine and empty the carburetor of the

composite fuel.

6. In the case of scrapping the used mixed oil container,

scrap it only at an authorized repository site.

NOTE

• As for details of quality assurance, read the description in the section Limited Warranty carefully. Moreover, normal wear and change in product with no functional influence are not covered by the warranty. Also,

be careful that, if the usage in the instruction manual

is not observed as to the mixed gasoline, etc. described therein, it may not be covered by the warranty.

• Pay attention to agitation.

1. Measure out the quantities of gasoline and oil to be

mixed.

2. Put some of the gasoline into a clean, approved fuel

container.

3. Pour in all of the oil and agitate well.

GB-10

Page 11

8. Chemical filling

WARNING

• Chemical substances should be handled correctly,

observing the precautions marked on the container.

Some chemicals are extremely hazardous to humans

and animals, and handling errors can cause serious

poisoning or even fatal accidents.

• When not in use, chemical substance containers

should be stored separately from other containers out

of the reach of children.

IMPORTANT

• Do not fill the chemical tank with undiluted fluid. This

could cause the gasket and valves to lose their durability.

9. Operation

NS2522

■ Procedure for filling

1. Use a bucket or other suitable container and dilute

the chemical to the requisite strength.

2. Place the sprayer on an even and stable surface and

remove the chemical tank cap.

3. Fill the tank by passing chemical through the strainer.

4. When filling is complete, firmly tighten the cap.

a. strainer

Chemical tank capacity: 25 litres

G

B

WARNING

• Highly combustible. When refueling, switch the engine off and keep well away from naked flames.

• After filling the tank with fuel, firmly tighten the

cap.

a. cap

b. fuel tank

a

■ Starting engine

WARNING

• Before starting the engine, make sure that the spray

lever (spray valve) is completely returned. Starting with

the spray lever still pulled out is dangerous, as chemical fluid may spray out of the nozzle as soon as the

engine is started.

b

1. Press the primer at the bottom of the carburetor a few

times with your finger until the fuel starts to flow through

the transparent pipe.

a. air cleaner

b. choke lever

c. close

d. open

e. transparent pipe

f. primer

NOTE

• There is no need to operate the primer when restarting immediately after stopping the engine, provided

there is fuel left in the fuel tank.

2. Lift the choke lever on the right of the air cleaner until

it is in the "closed" position, then open the throttle lever on the main unit side about 1/3-1/2 from the "slow"

position.

g. throttle lever

h. fast

i. slow

•To start the engine, place the sprayer on an even and

stable surface or platform. If the sprayer is unstable,

the reaction on starting etc. may cause it to fall.

IMPORTANT

• Do not allow the chemical fluid or water in the tank to

run out while the engine is running. If the engine runs

empty it may cause breakage of the spray pump.

NOTE

• When restarting immediately after stopping the engine, set the choke lever to "open" and the throttle

lever to "slow".

GB-11

Page 12

NS2522

9. Operation

3. Place the sprayer in a stable location, and pull the

starter knob with the right hand while holding the

chemical tank down with the left hand. The starter knob

should first be pulled out lightly, then, when resistance

is felt, pulled more swiftly and vigorously.

IMPORTANT

• Do not pull the rope out completely or release the knob

so that the rope returns, as this can cause starter malfunction.

4. Once the engine has started, gradually open the

choke, warm up at low speed for 1-2 minutes, then

return the throttle lever to the "slow" position.

IMPORTANT

• If the rope is pulled continuously with the choke

closed, the spark plugs may become flooded and the

engine may fail to start. If so, you should first remove

the spark plugs and dry the electrodes, then repeat

the starting procedure.

■ Stopping engine

WARNING

• Stop the engine immediately in the event of an emergency.

1. Lower the throttle lever fully and cool the engine down

for 1-2 minutes at low speed.

2. Hold down stop switch on the left side of the sprayer

frame until the engine has come to a complete stop .

a. Stop switch

■ Spraying

WARNING

• Please use correctly, observing the precautions in this

Manual ("For Safe Operation", p5 to 7).

• Before lifting the sprayer onto your back, check that

the chemical tank and fuel tank caps are tightly closed.

•When spraying, do not point the nozzle at your face,

or at other people, animals, etc.

• If the sprayer is tilted too much, chemical fluid or fuel

may leak out through the air holes in the cap. When

using, always try to maintain an upright posture.

IMPORTANT

• If the chemical tank becomes empty while spraying,

reduce the engine to low speed immediately. Empty

running of the engine may cause the spray pump to

break.

• Please avoid using multiple nozzles, jet nozzles, or

other nozzles that give a large spray volume, as spraying efficiency is sometimes impaired owing to insufficient pressure.

■ Spraying procedure

1. Start the engine, and lift the sprayer onto your back.

2. Adjust the carrying band to a suitable length for carrying.

3. Increase the engine speed, and open the spray cock.

Chemical fluid starts to spray out from the nozzle in

the form of mist.

4. When stopping work, close the spray cock fully and

reduce the engine speed.

b

c

a

b

■ Cleaning after completion of spraying

1. Loosen the fluid drain cap , transfer the chemical fluid

left inside the tank into a suitable container, and process appropriately with all due consideration to safety.

2. Pour about 5 litres of clean water into the chemical

tank, spray through the nozzle for 2-3 minutes, and

drain the water left inside the tank.

a. Spray cock

b. Close

c. Open

IMPORTANT

• Except for an emergency, avoid stopping the engine

while pulling the throttle trigger.

GB-12

a. Fluid drain cap

Page 13

10. Maintenance

Every Every Every

System/components Procedure

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

idle speed adjuster ✔

spark plug ✔

ENGINE

intake air cooling vent clean ✔

throttle lever, stop switch check operation ✔

screws/nuts/bolts tighten/replace ✔✔except adjusting screws

WARNING

• Make sure that the engine has stopped and is cool

before performing any service to the machine. Contact with hot muffler may result in a personal injury.

• Do not modify the sprayer or dismantle the engine.

• When replacing parts please use Zenoah original

parts or designated parts.

see adjusting replace carburetor

idling speed if necessary

clean and readjust GAP: 0.6 to 0.7 mm (.025 in)

plug gap replace, if necessary

Before

use

25 50 100

hours hours hours

after after after

■ Fuel filter

After every 25 hours of operation, empty the fuel tank,

detach the fuel filter from the tank, and remove all dirt. If

the filter is too clogged, please replace it with a new

one.

Note

NS2522

G

B

■ Air cleaner

• After every 25 hours of operation, please remove the

air cleaner cover and inspect the element. If it is too

dirty, wash it carefully in warm water containing a neutral detergent, and return it to its original position after drying it thoroughly.

• If the element is distorted or damaged, please replace

it with a new one.

a. Element

b. Air cleaner cover

IMPORTANT

• If the air cleaner element is blocked, the efficiency of

the engine will be reduced. In addition, the engine

interior will suffer abnormal wear if operated without

the element or if continually operated with a distorted

or damaged element fitted.

a. Fuel filter

IMPORTANT

• If the fuel filter is clogged, the engine speed may be

limited or speed fluctuations may occur.

• If the engine is operated without a fuel filter, dirt will

accumulate in the carburetor and cause it to malfunction.

■ Spark plug

WARNING

• Do not touch the spark plug with your bare hands

immediately after operation, as there is the risk of

burns due to high temperature.

• After every 50 hours of operation, detach the spark

plug and remove dirt from the electrodes with a wire

brush or similar.

• The correct electrode gap is 0.6 to 0.7mm.

GB-13

Page 14

NS2522

10. Maintenance

• When replacing plugs, please use designated items.

NGK (BPMR7A)

IMPORTANT

• If too much fuel is absorbed or poor quality oil is used,

the spark plug electrodes become dirty, making the

engine harder to start.

• Note that using any spark plug other than those designated may result in the engine failing to operate

properly or in the engine becoming overheated and

damaged.

•To install the spark plug, first turn the plug until it is

finger tight, then tighten it a quarter turn more with a

socket wrench.

TIGHTENING TORQUE:

14.7 to 21.6 N.m.

(150 to 220 kgf-cm)

■ Adjusting the engine

Although the engine is adjusted on leaving the factory,

after repeated use it may sometimes require readjustment or maintenance. Please consult your original supplier regarding inspections and maintenance other than

those shown below.

NOTE

•Warm up the engine before adjusting the idling speed.

• Throttle wire play

Throttle wire play should be 1 to 2 mm. After completely returning the throttle lever, take the throttle wire

at the carburetor end in your fingers and give a light

tug. If the play is too great or too small, readjust the

position of the wire retaining nut. Loosen the lock nut

and turn the wire retaining nut clockwise (screw in) to

increase the play and counter-clockwise (unscrew)

to reduce it. After adjusting, please fasten the wire

retaining nut by tightening the lock nut.

a. lock nut

b. wire retaining nut

c. wire sleeve

MUFFLER

WARNING

• Idling speed

If the engine stalls or the pump continues to move

when in idling position with the throttle lever completely

lowered, readjust the engine speed using the idle

speed adjuster on the left of the carburetor.

a. idle speed adjuster

b. increase speed

c. reduce speed

•Turn the idling adjustment screw:

— counter-clockwise to reduce engine speed

— clockwise to increase engine speed

• Inspect periodically, the muffler for loose fasteners, any damage or corrosion. If any sign of exhaust leakage is found, stop using the machine

and have it repaired immediately in the repair specialty store.

• Note that failing to do so may result in the engine

catching on fire.

INTAKE AIR COOLING VENT

WARNING

• Check the intake air cooling vent after every 25

hours of use for blockage.

■ PERIODICAL SERVICE POINTS

1. CYLINDER FINS

Periodically check and clean the cylinder fins in the repair specialty store.

IMPORTANT

• If waste gets stuck and causes blockage around the

intake air cooling vent, it may cause the engine to overheat, and that in turn may cause mechanical failure

GB-14

Page 15

10. Maintenance

on the part of the brushcutter.

(1) Intake air cooling vent

11. Storage

WARNING

• When draining fuel, please be careful not to spill it. If

fuel is spilt, wipe off thoroughly. In addition, please be

sure to close the storage container cap tightly.

IMPORTANT

• If fuel is left in the engine for protracted periods, the

inside of the carburetor may become clogged and

cause engine malfunction (faulty starting and insufficient output).

• During storage, slightly loosen the cap of the chemical fluid tank. If screwed too tightly, the gasket may

become distorted.

On completion of all work procedures, when not planning to use again for a protracted period please carry

out the following pre-storage care, to prevent trouble

caused by time-lapse changes.

NS2522

G

B

1. Clean the chemical fluid tank and nozzle (see page

11).

2. Remove dirt from the sprayer, inspect it for any damage or looseness, and, if any abnormality is found,

correct it thoroughly in preparation for the next time

you use the unit.

3. Drain the fuel tank.

4. Start the engine, and leave it in idling condition until

all the fuel inside the carburetor is spent and the engine comes to a natural stop.

5. Remove the spark plug and put a few drops (1 to 2

cc) of 2-cycle oil inside the engine. After pulling the

starter rope 2 or 3 times, return the spark plugs to

their original position and stop in compressed position.

6. After oiling the throttle lever and other metal parts with

anti-corrosive oil, cover the sprayer and store indoors

in a low-humidity location.

12. Troubleshooting guide

Case 1. Starting failure

CHECK PROBABLE CAUSES ACTION

fuel tank → incorrect fuel → drain it and use correct fuel

fuel filter → fuel filter is clogged → clean

carburetor adjustment screw → out of normal range → adjust to normal range

sparking (no spark) → spark plug is fouled/wet → clean/dry

→ plug gap is incorrect → correct (GAP: 0.6 to 0.7 mm)

spark plug → disconnected → retighten

Case 2. Engine starts but does not keep running/hard re-starting

CHECK PROBABLE CAUSES ACTION

fuel tank → incorrect fuel or staled fuel → drain it and use correct fuel

carburetor adjustment screw → out of normal range → adjust to normal range

muffler, cylinder (exhaust port) → carbon is built-up → consult with the repair specialty store

air cleaner → clogged with dust → wash

cylinder fin, fan cover → clogged with dust → consult with the repair specialty store

When your unit seems to need further service, please consult with our ZENOAH® service shop in your area.

GB-15

Page 16

NS2522

13. Disposal

• When you dispose of the machine, do not disassemble the machine.

• When you dispose of the machine, fuel, oil, be sure

to follow your local regulations.

Limited warranty

Should any failure occur on the product under normal operating conditions within the applicable warranty period, the

failed part will be replaced or repaired free of charge by a

ZENOAH® authorized dealer.

WARRANTY PERIOD: 1 year (6 months if used professionally, and 30 days if used for rental purpose) from the date of

initial purchase.

THE PURCHASER SHALL BEAR COSTS OF TRANSPORTING THE UNIT TO AND FROM THE ZENOAH DEALER.

THE PURCHASER SHALL NOT BE CHARGED FOR DIAGNOSTIC LABOR WHICH LEADS TO THE DETERMINATION

THAT A WARRANTED PART IS DEFECTIVE, IF THE DIAGNOSTIC WORK IS PERFORMED AT THE ZENOAH DEALER.

THE PURCHASER OR OWNER IS RESPONSIBLE FOR THE

PERFORMANCE OF THE REQUIRED MAINTENANCE AS

DEFINED BY THE MANUFACTURER IN THE OWNER/OPERATOR MANUAL.

ANY WARRANTED PART WHICH IS NOT SCHEDULED FOR

REPLACEMENT AS REQUIRED MAINTENANCE, OR

WHICH IS SCHEDULED ONLY FOR REGULAR INSPECTION

TO THE EFFECT OF REPAIR OR “REPLACE AS NECESSARY” SHALL BE WARRANTED FOR THE WARRANTY PERIOD. ANY WARRANTED PART WHICH IS SCHEDULED

FOR REPLACEMENT AS REQUIRED MAINTENANCE

SHALL BE WARRANTED FOR THE PERIOD OF TIME UP

TO THE FIRST SCHEDULED REPLACEMENT POINT FOR

THE PART.

ANY REPLACEMENT PART THAT IS EQUIVALENT IN PERFORMANCE AND DURABILITY MAY BE USED IN NONWARRANTY MAINTENANCE OR REPAIRS, AND SHALL

NOT REDUCE THE WARRANTY OBLIGATION OF THE

COMPANY.

THE COMPANY IS LIABLE FOR DAMAGES TO OTHER

ENGINE COMPONENTS CAUSED BY THE FAIRURE OF A

WARRANTED PARTS STILL UNDER WARRANTY.

THE WARRANTY DOES NOT APPLY TO THOSE UNITS

WHICH HAVE BEEN DAMAGED BY NEGLIGENCE OF INSTRUCTION LISTED IN THE OWNER/OPERATOR MANUAL

FOR PROPER USE AND MAINTENANCE OF THE UNITS

ACCIDENT MISHANDLING, ALTERATION, ABUSE, IMPROPER LUBRICATION, USE OF ANY PARTS OR ACCESSORIES OTHER THAN THOSE SPECIFIED BY THE COMPANY, OR OTHER CAUSES BEYOND THE COMPANY’S

CONTROL.

THIS WARRANTY DOES NOT COVER THOSE PARTS REPLACED BY NORMAL WEAR OR HARMLESS CHANGES

IN THEIR APPEARANCE.

THERE ARE NO OTHER EXPRESS WARRANTIES.

IMPLIED WARRANTIES INCLUDING THOSE OF MER-

CHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO TWO (2) YEARS OF HOME USE

[ONE (1) YEAR FOR ANY OTHER USE] FROM THE ORIGINAL DELIVERY DATE.

LIABILITIES FOR INCIDENTAL OR CONSEQUENTIAL

DAMAGE UNDER ANY AND ALL WARRANTIES ARE

EXCLUDED.

IF YOU NEED TO OBTAIN MORE INFORMATION, PLEASE

CALL YOUR NEAREST SERVICE CENTER,

OR CHECK PLEASE ZENOAH WEB SITE

http://www.zenoah.net

GB-16

Loading...

Loading...